Patents

Literature

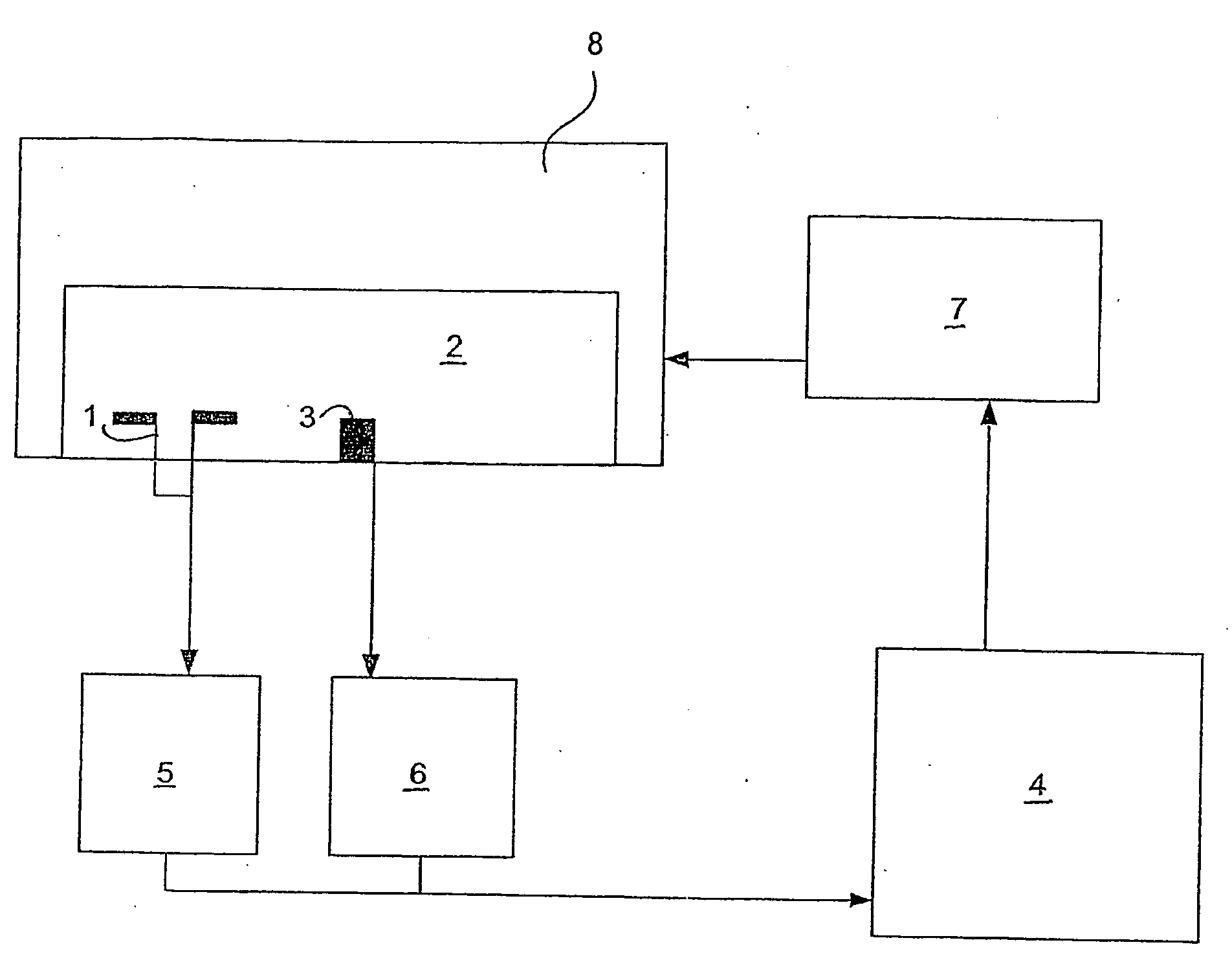

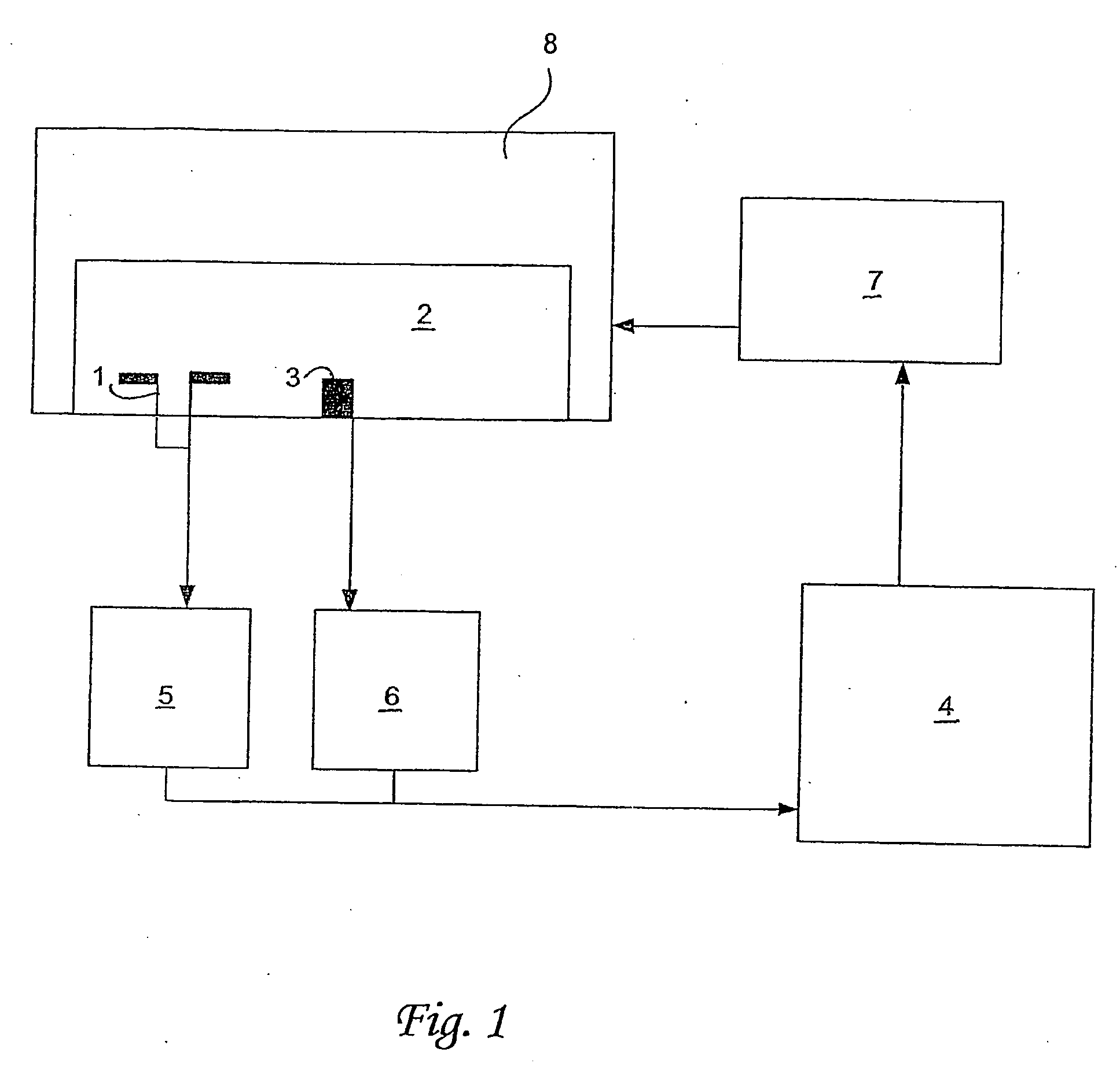

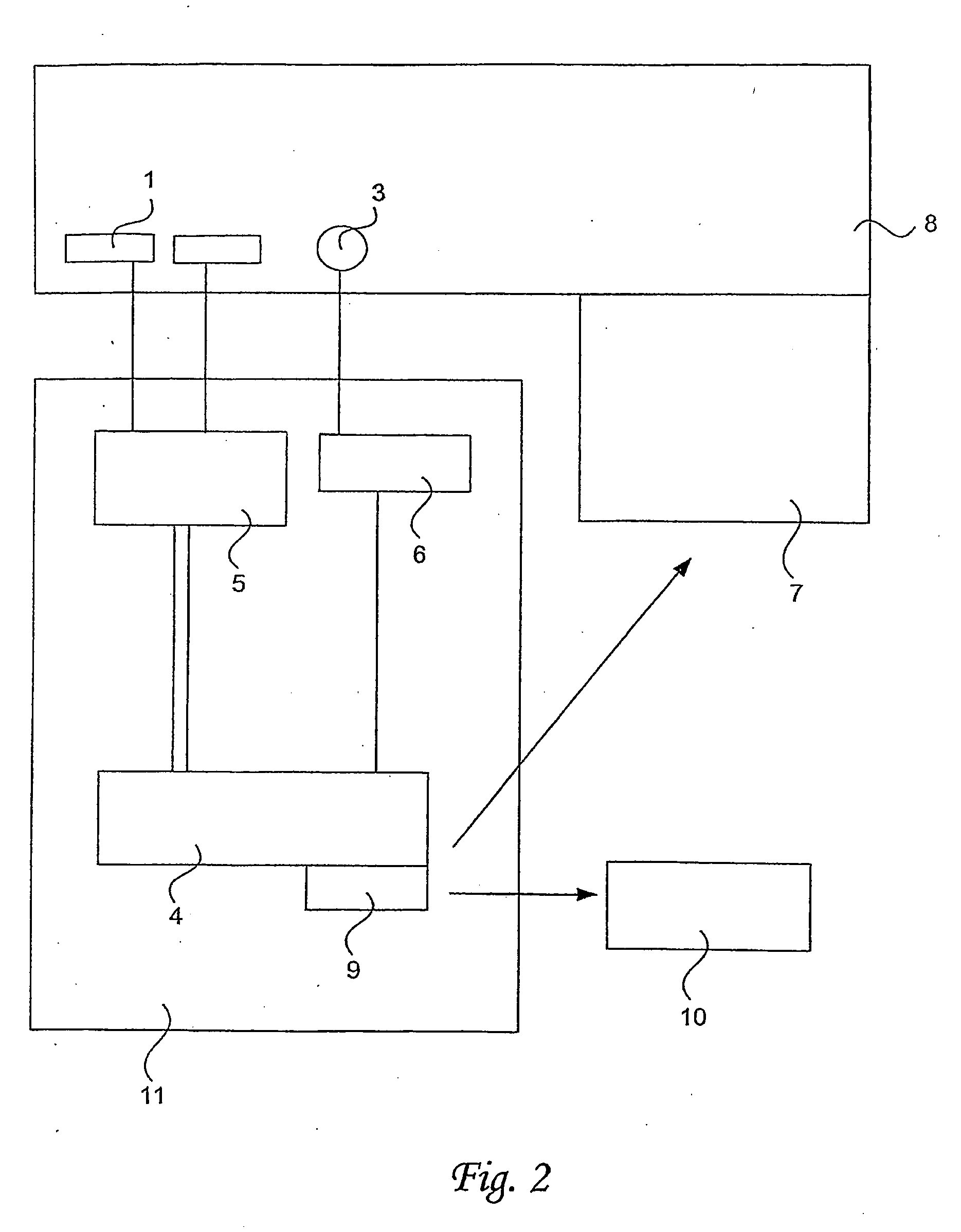

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Free from cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

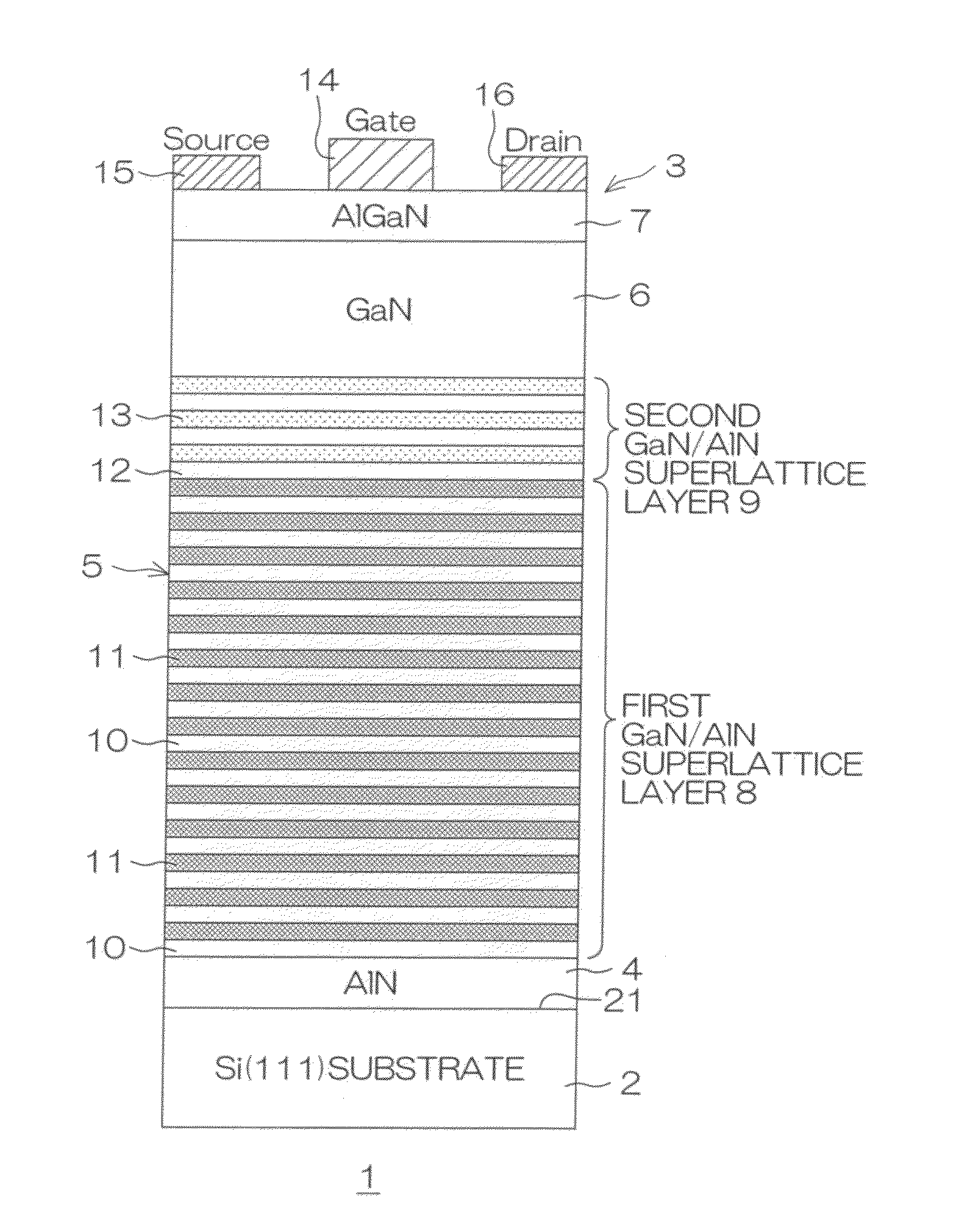

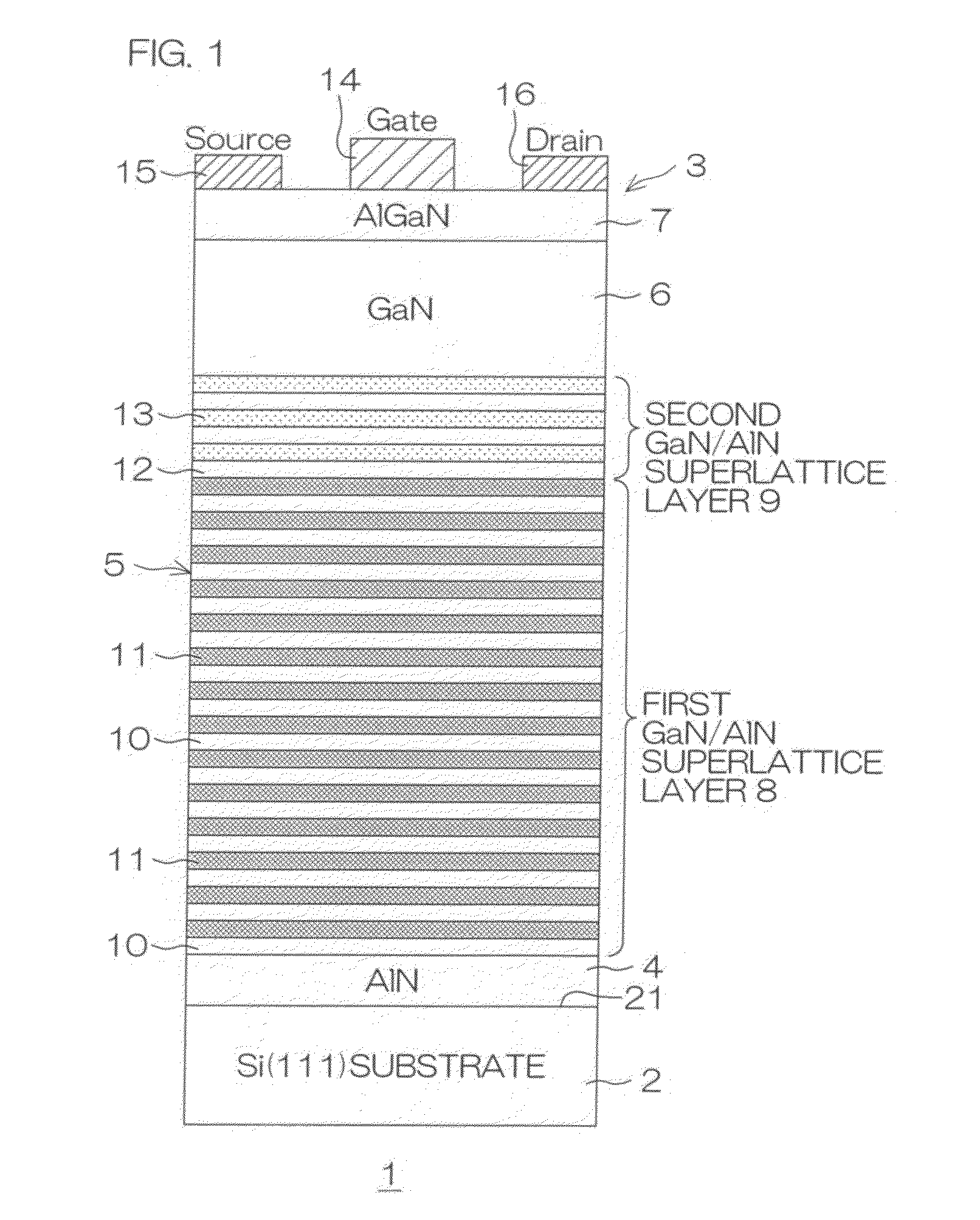

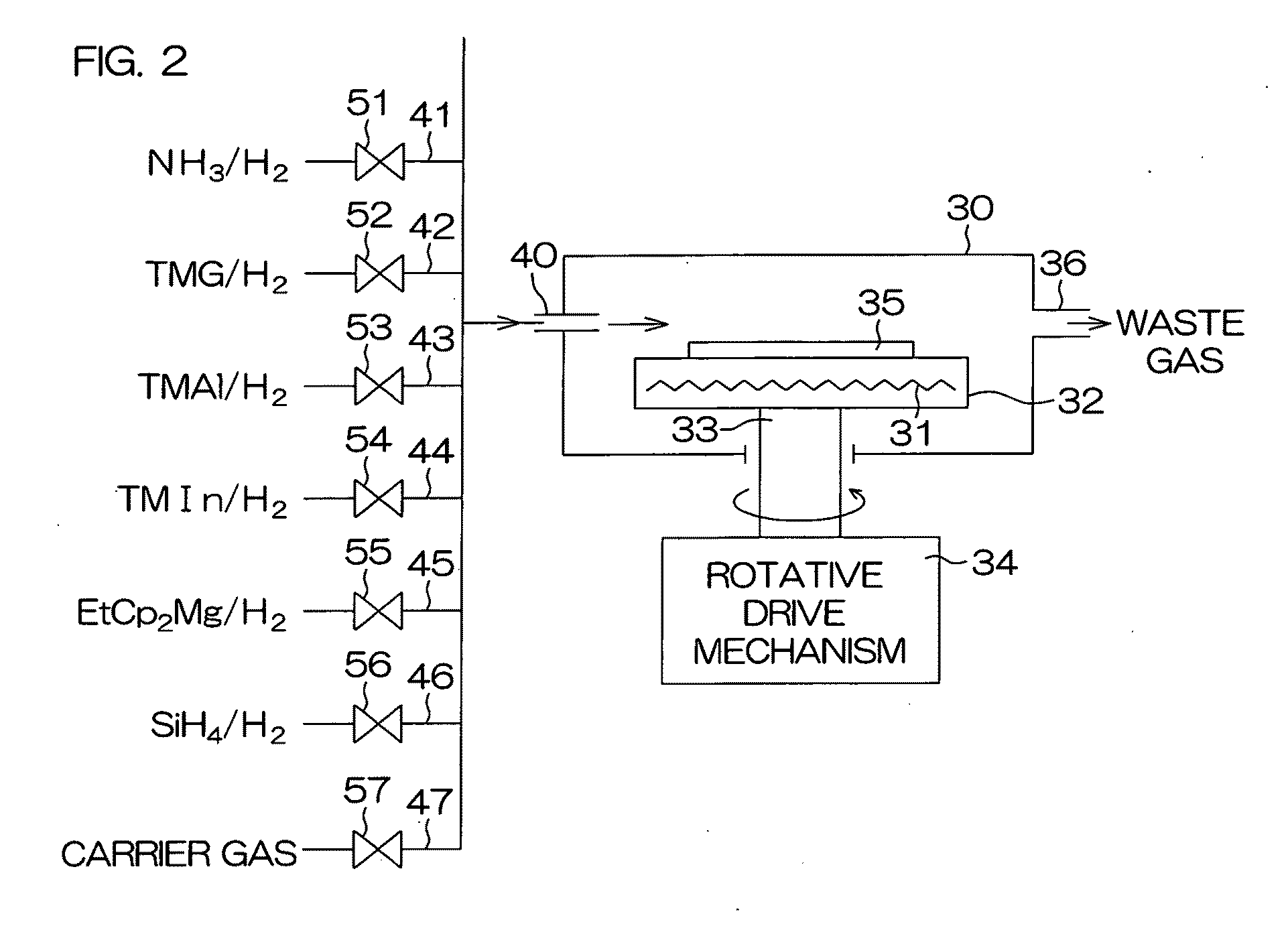

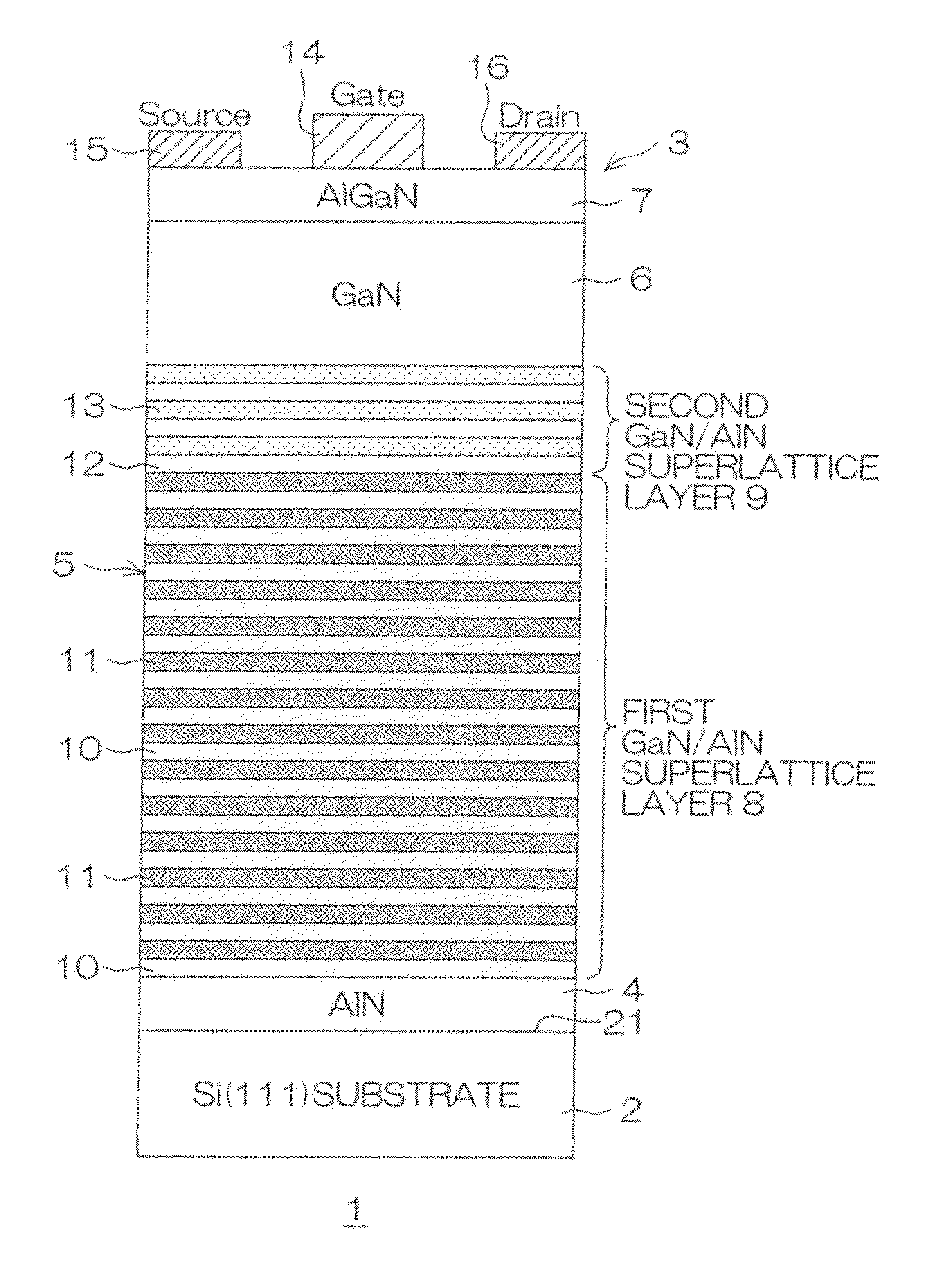

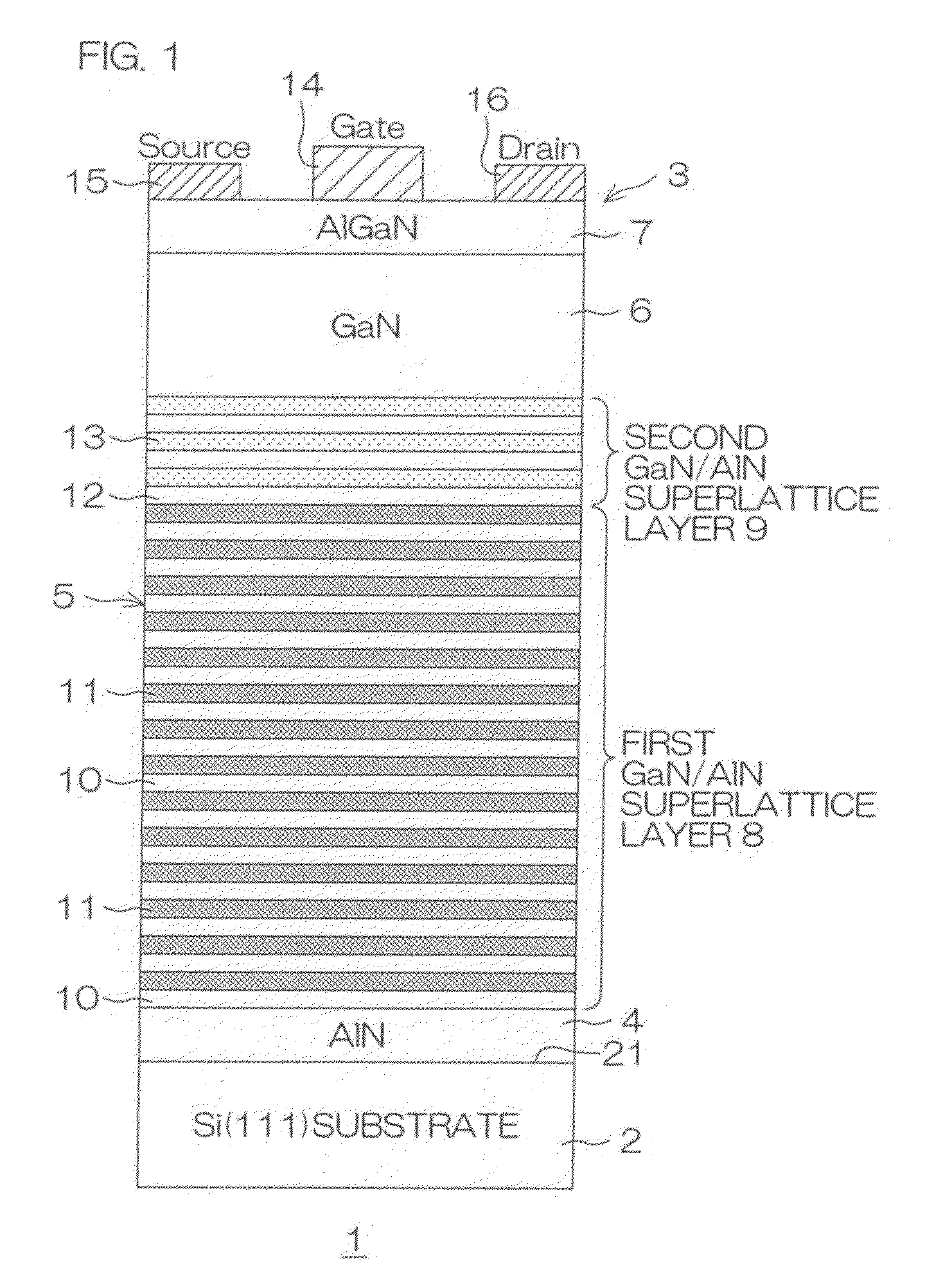

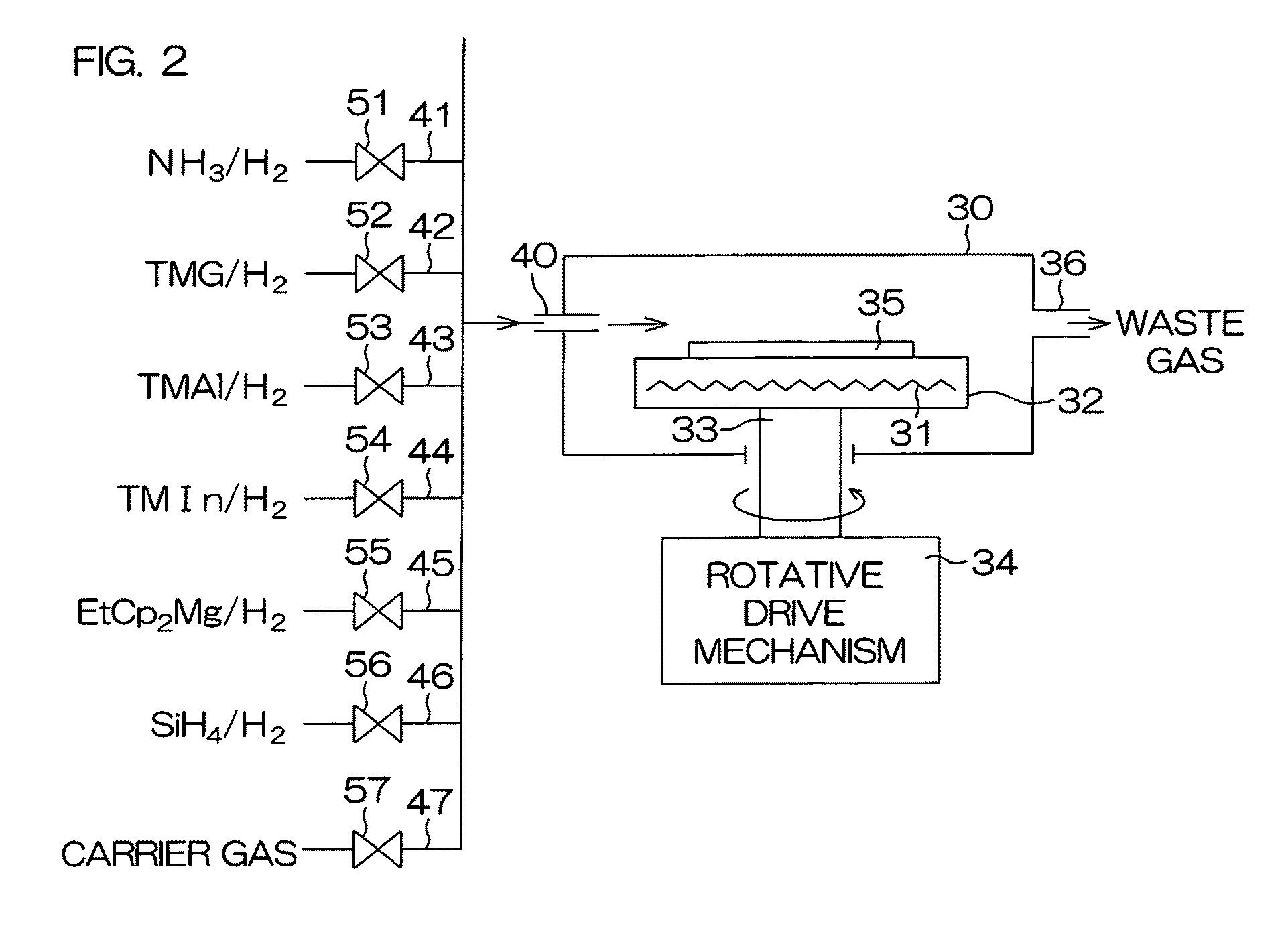

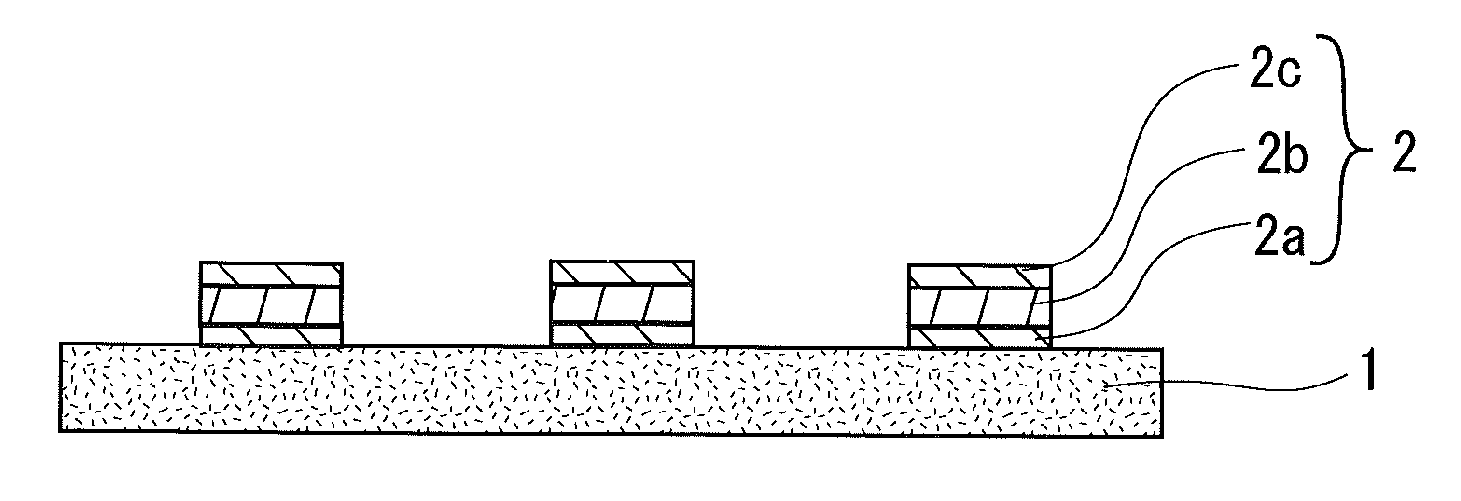

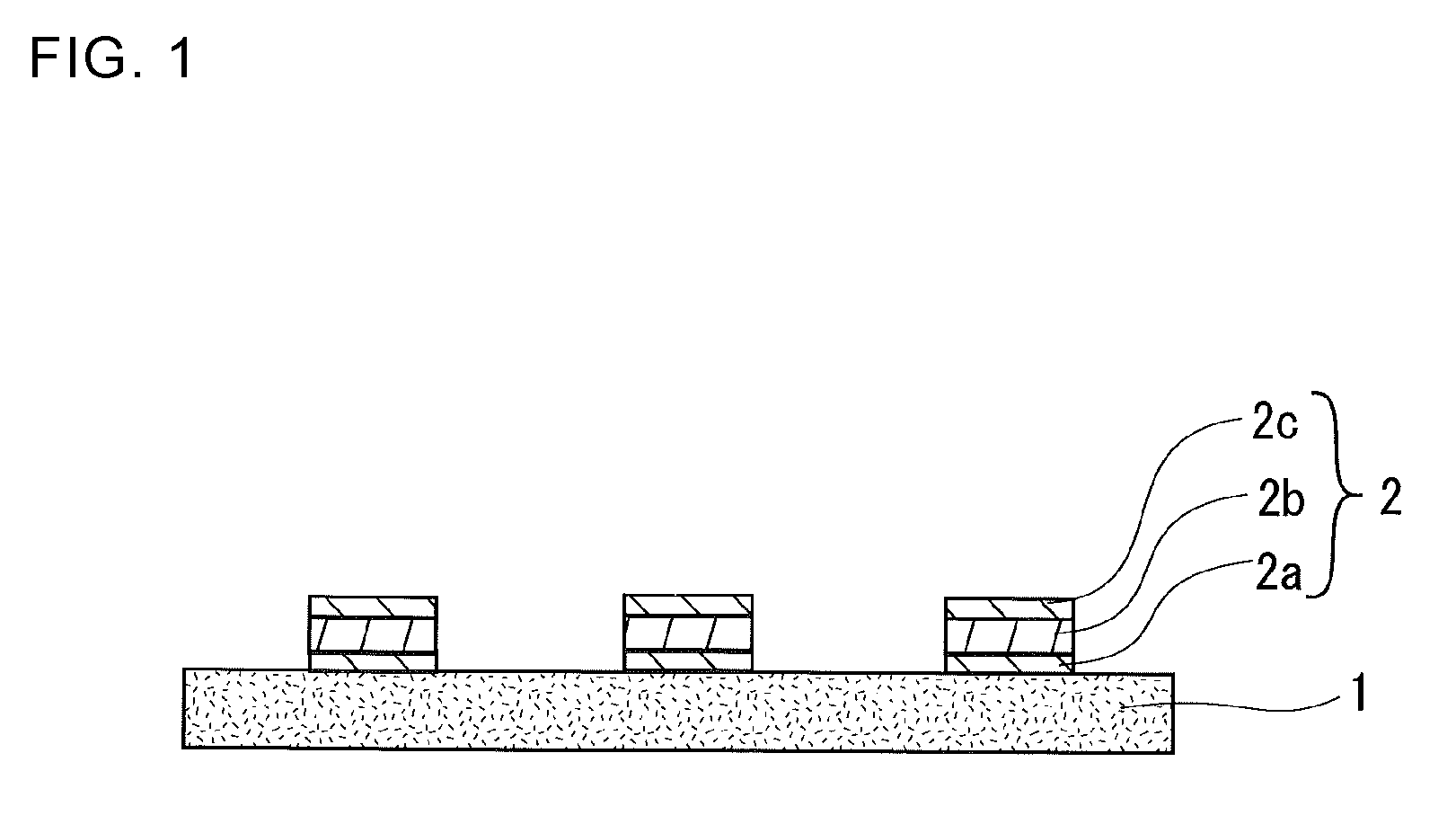

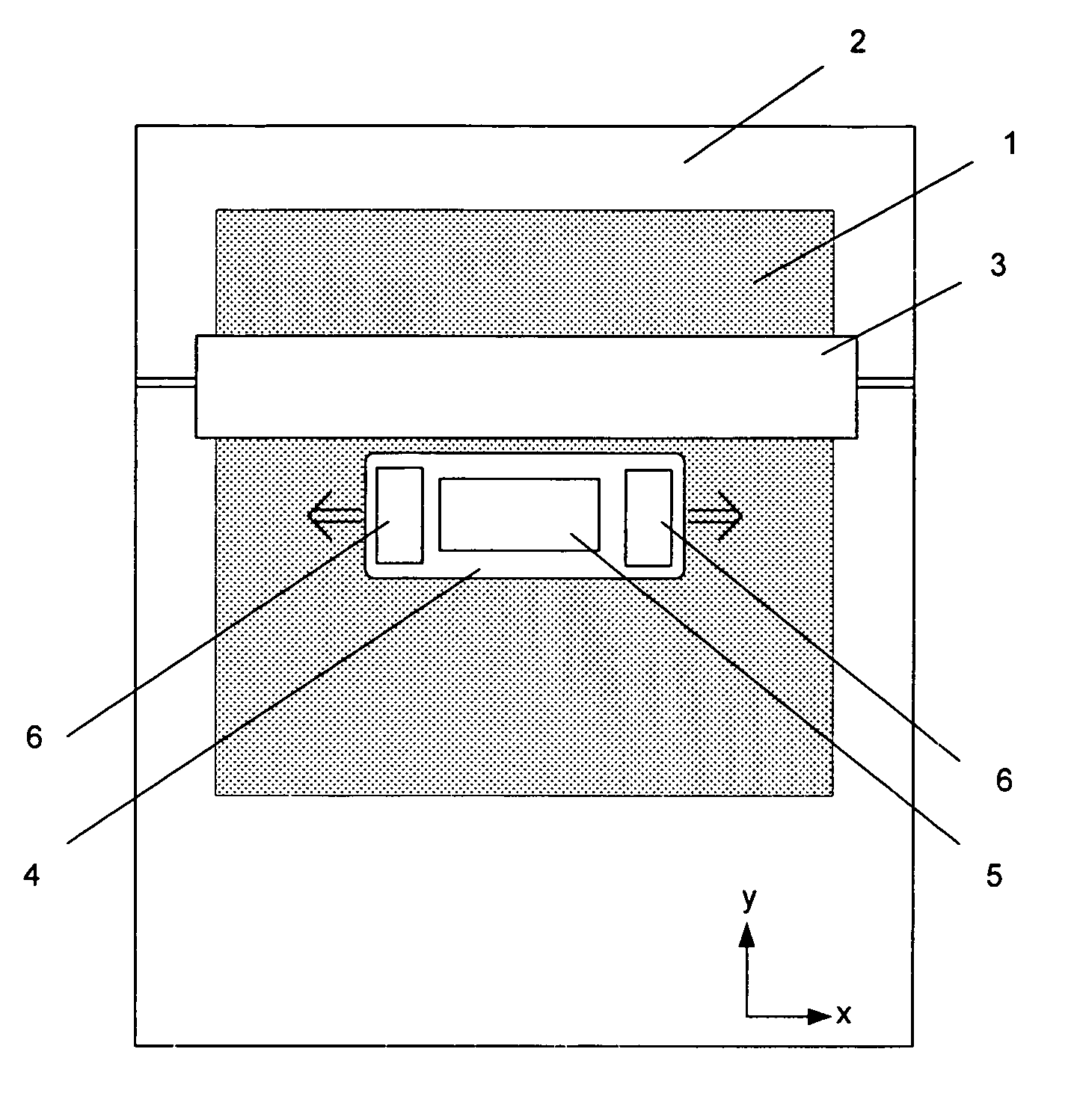

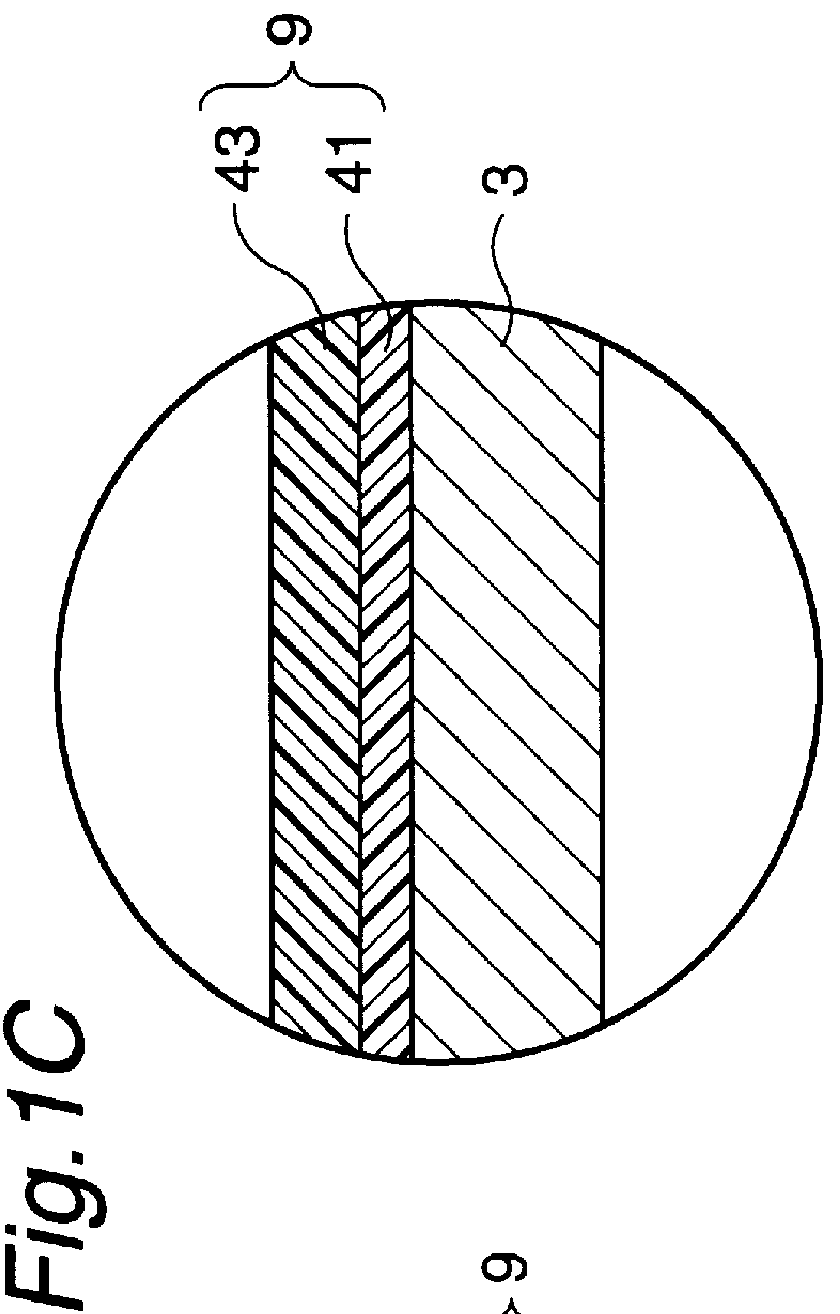

Nitride semiconductor device

ActiveUS20110272665A1Increase currentFree from increase in leak currentSemiconductor/solid-state device manufacturingSemiconductor devicesLattice constantNitride semiconductors

An inventive nitride semiconductor device includes: a substrate; a first buffer layer provided on the substrate, and having a superlattice structure which includes two types of Group III nitride semiconductor sublayers having different compositions and alternately stacked in pairs; a second buffer layer provided on the first buffer layer in contact with the first buffer layer, and having a superlattice structure which includes two types of Group III nitride semiconductor sublayers having different compositions and alternately stacked in pairs; and a device operation layer of a Group III nitride semiconductor provided on the second buffer layer; wherein an average lattice constant LC1 of the first buffer layer, an average lattice constant LC2 of the second buffer layer and an average lattice constant LC3 of the device operation layer satisfy the following expression (1):LC1<LC2<LC3 (1)

Owner:ROHM CO LTD

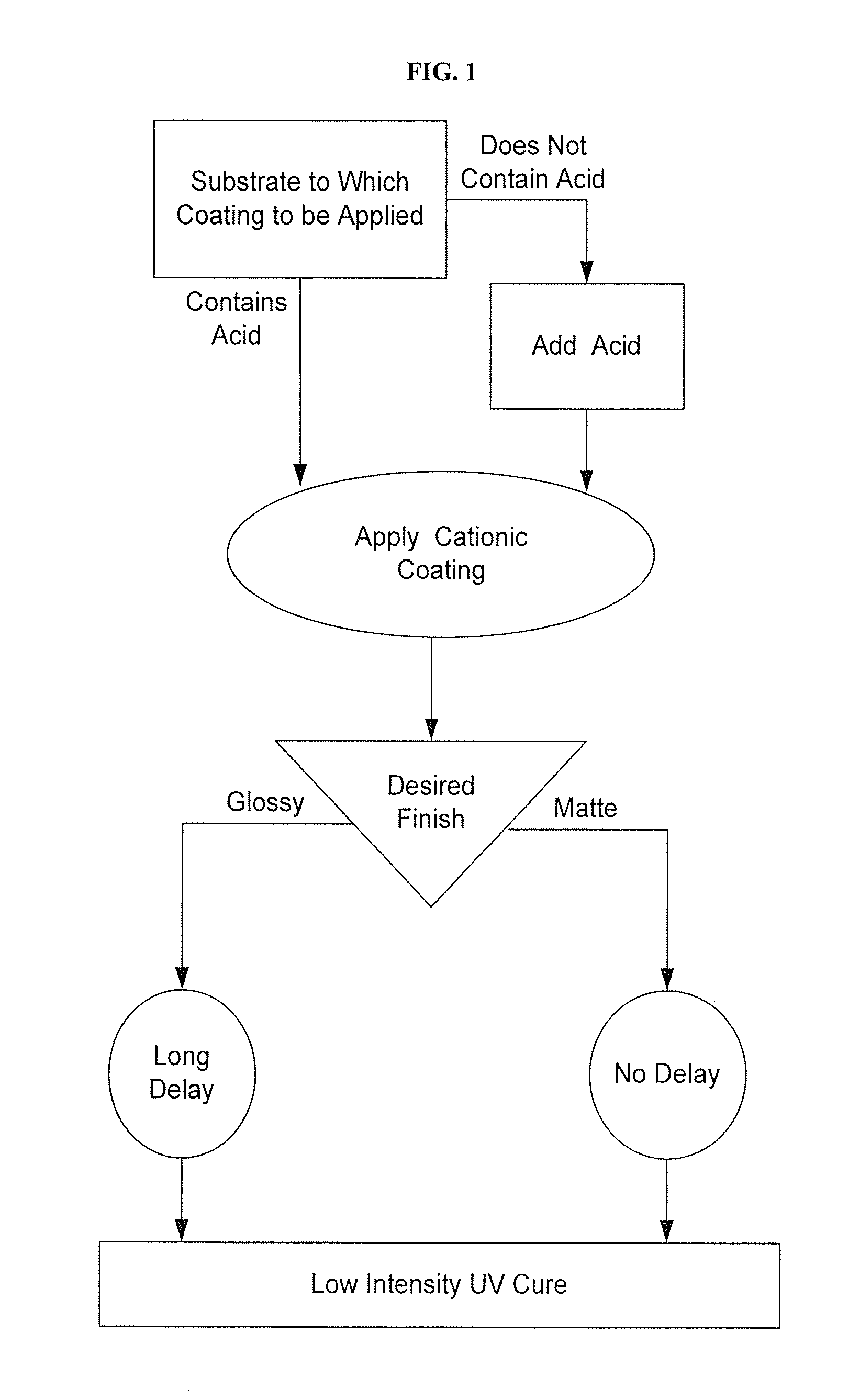

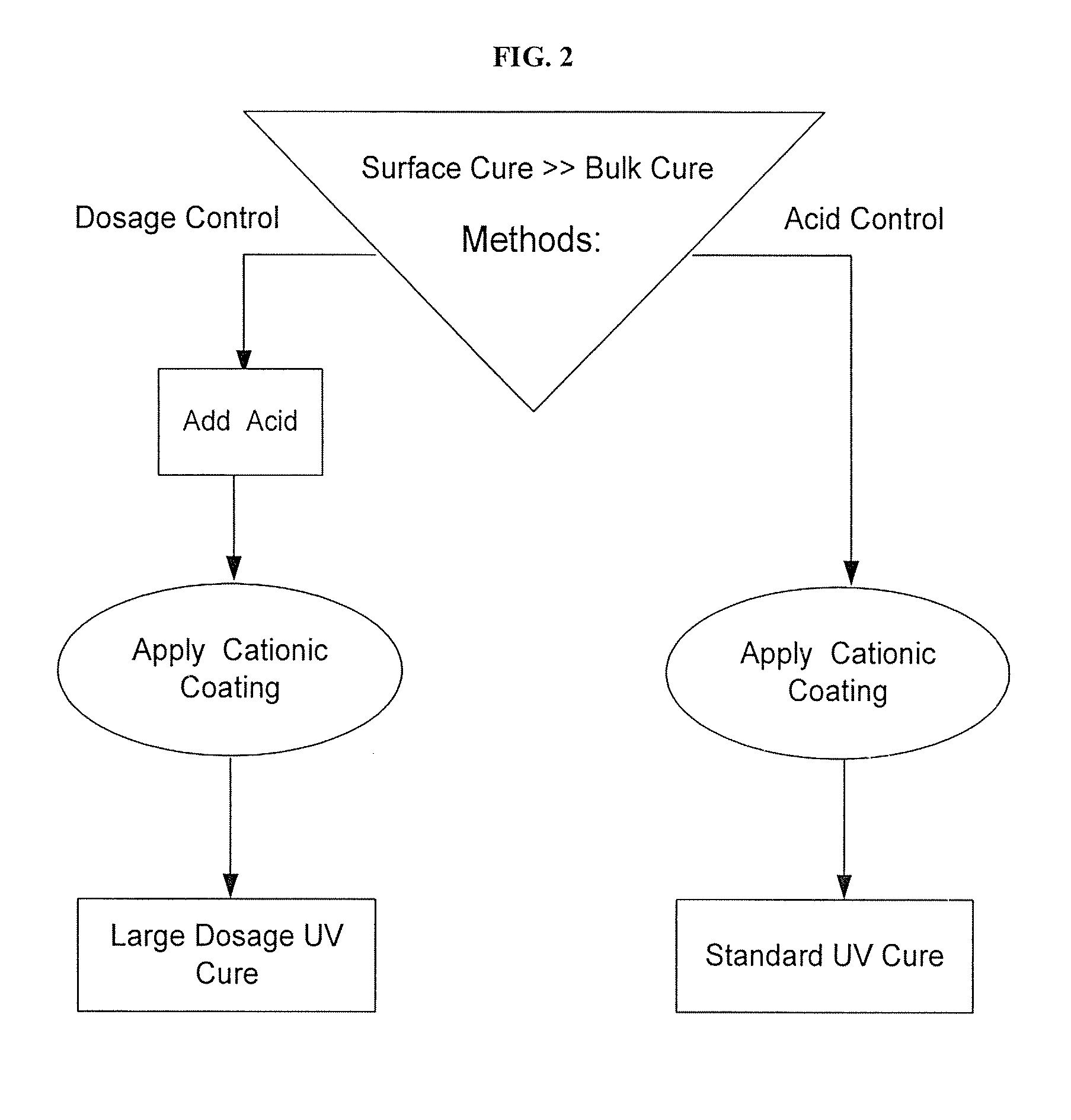

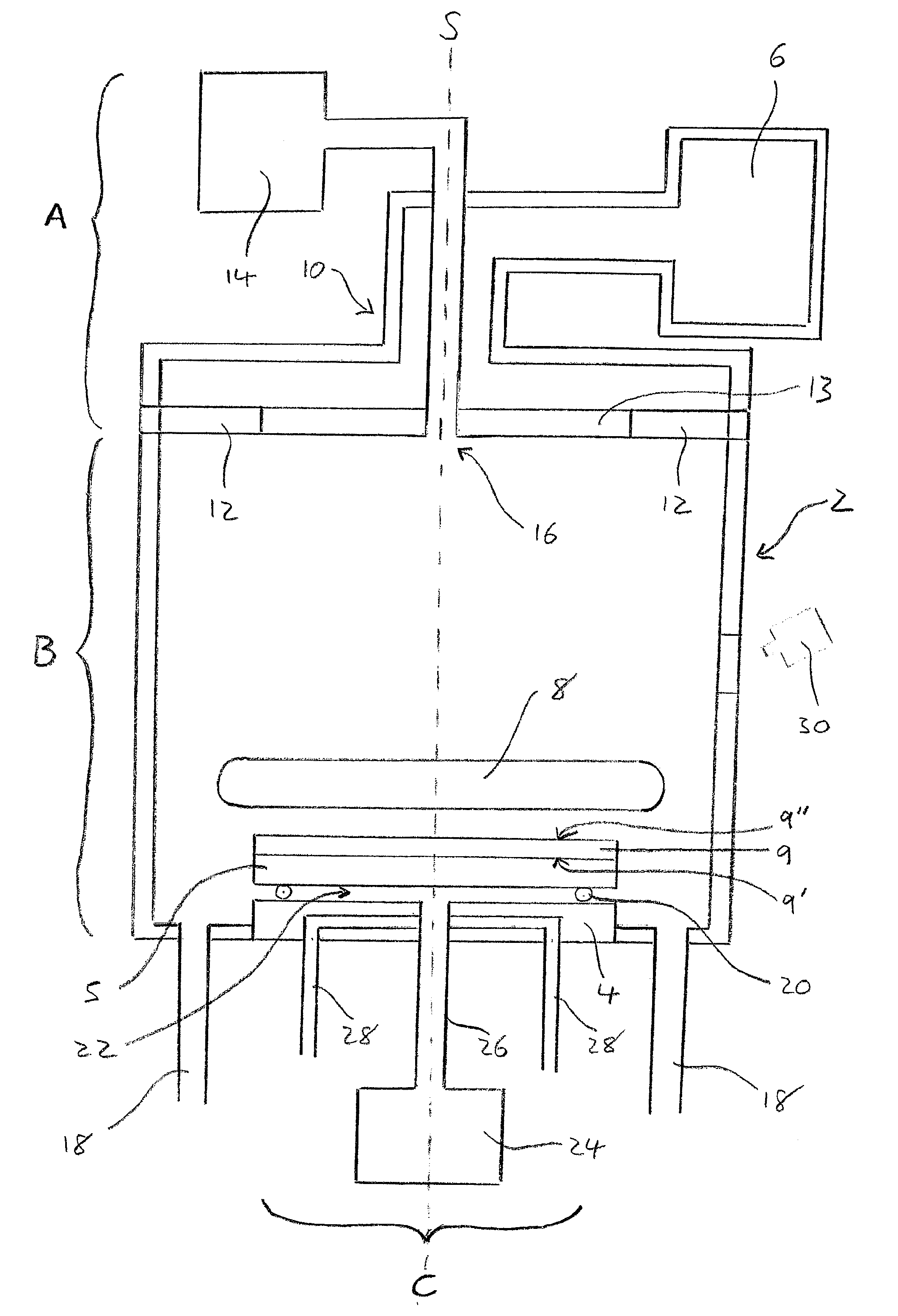

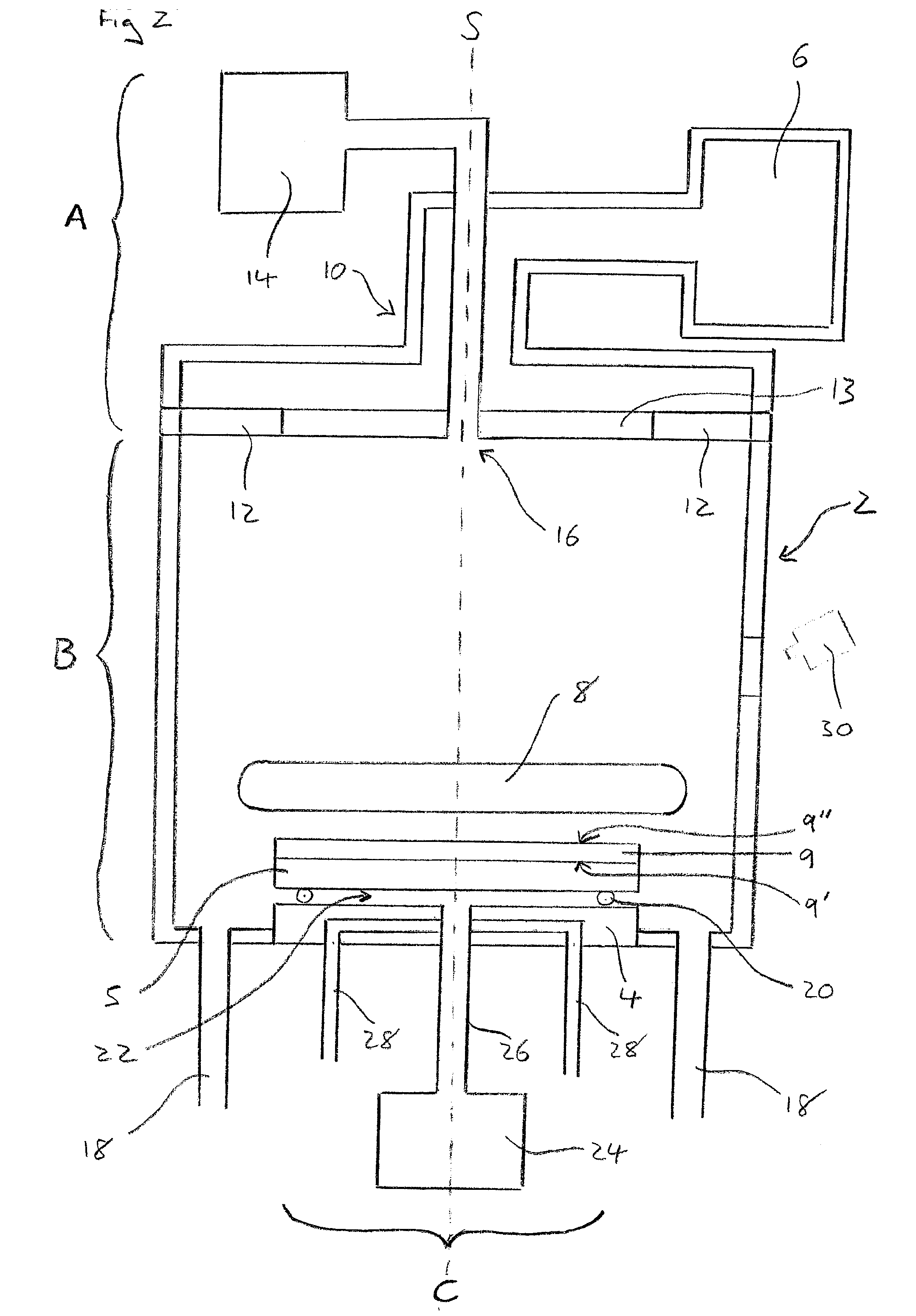

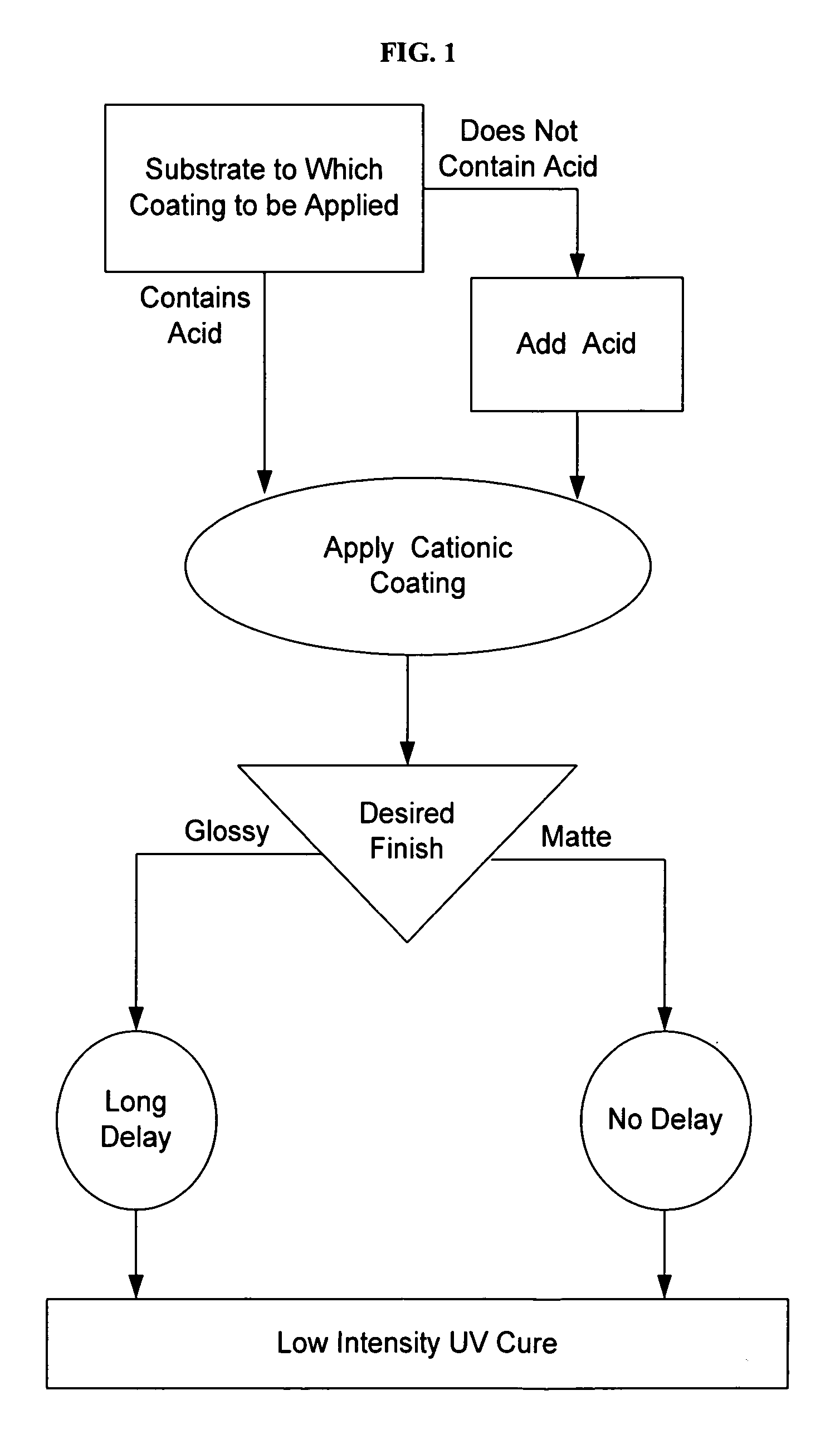

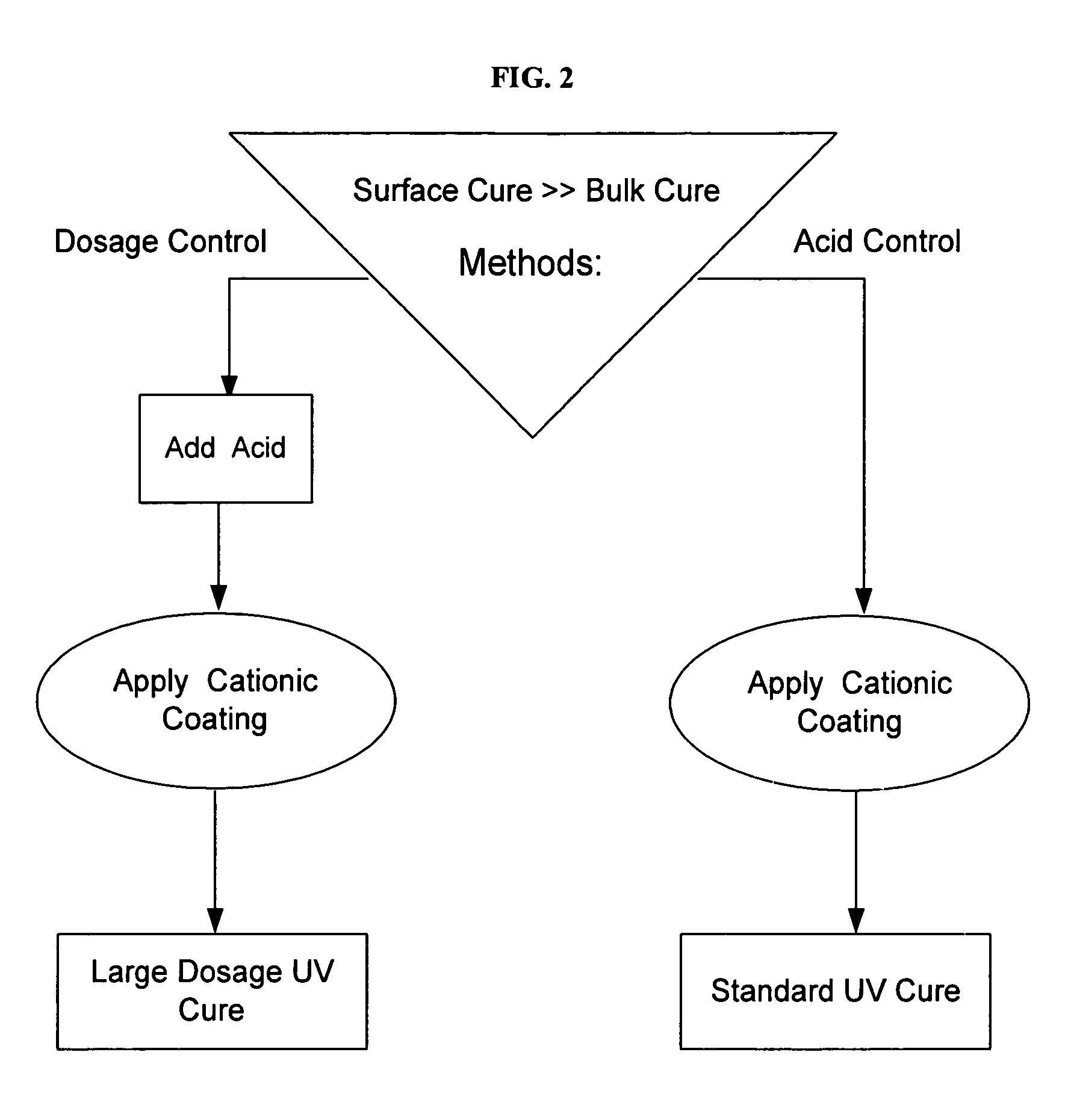

Light Cure of Cationic Ink on Acidic

InactiveUS20070109382A1Enough workable timeLow heatOther printing apparatusThin material handlingNanometreLight cure

This invention is an advance in coating chemistry, curing technology, related apparatus and the products made thereby. The invention encompasses a substrate bonded to a coating cured, at least in part, cationically by a light having a wavelength in a range of 100 nm to 1200 nm and intensity in a range of 0.0003 W / cm2 / nm to 0.05 W / cm2 / nm. Methods and systems for coating substrates and curing the coated products are encompassed. The invention encompasses apparatus and ink jet printers utilizing this curing technology. The invention also includes providing a “moving shadow” from ultraviolet light that is uniformly distributed over a print zone defined by a path of carriage motion illuminated by the light.

Owner:GERBER SCI INT

Organic, open cell foam materials, their carbonized derivatives, and methods for producing same

InactiveUS20060079587A1Improve structural strengthFree from crackingThermal insulationPipe protection by thermal insulationPolymer sciencePerylene derivatives

Organic, small pore area materials (“SPMs”) are provided comprising open cell foams in unlimited sizes and shapes. These SPMs exhibit minimal shrinkage and cracking. Processes for preparing SPMs are also provided that do not require supercritical extraction. These processes comprise sol-gel polymerization of a hydroxylated aromatic in the presence of at least one suitable electrophilic linking agent and at least one suitable solvent capable of strengthening the sol-gel. Also disclosed are the carbonized derivatives of the organic SPMs.

Owner:MOUNT ROYAL VENTURES I +1

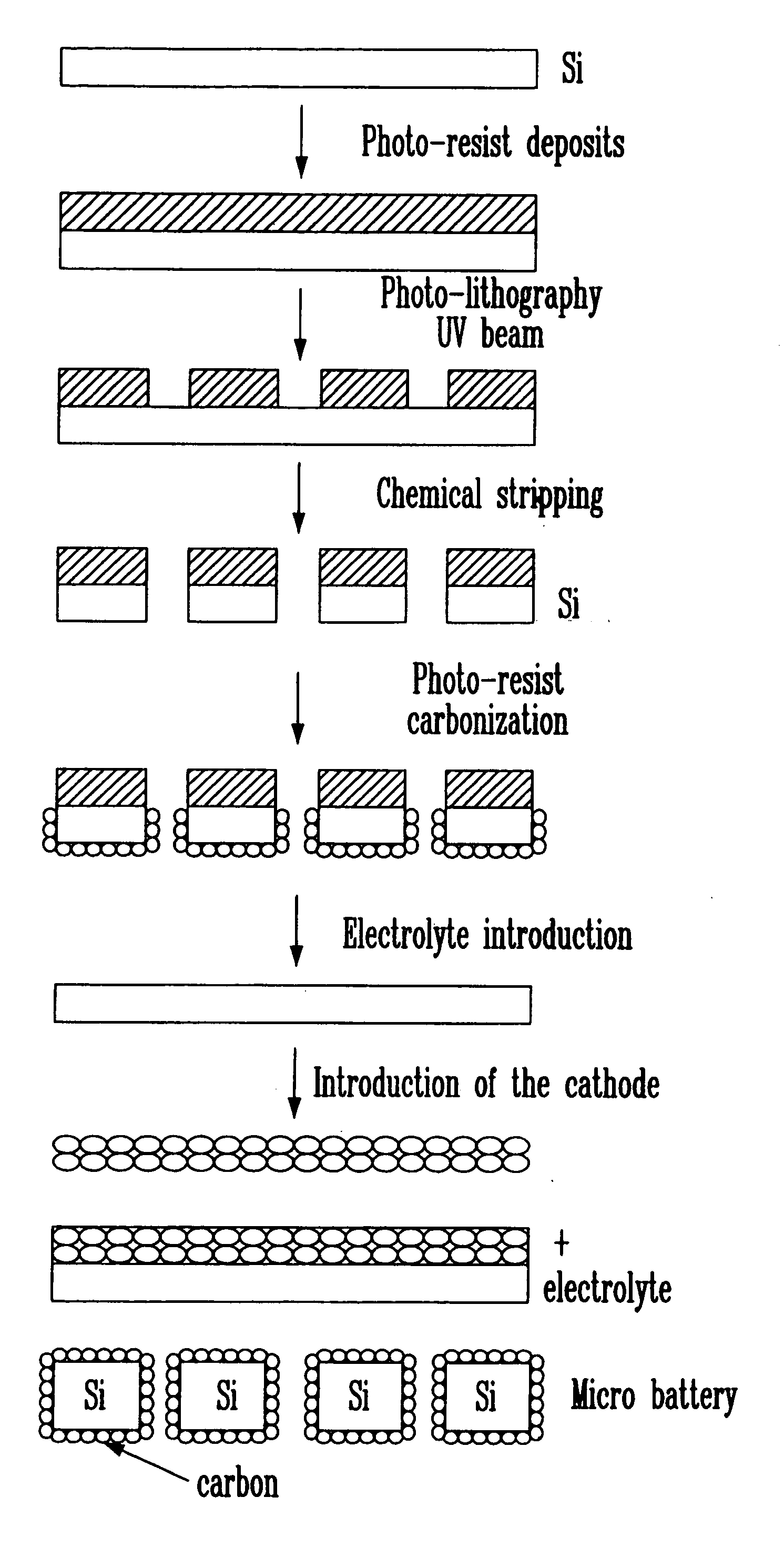

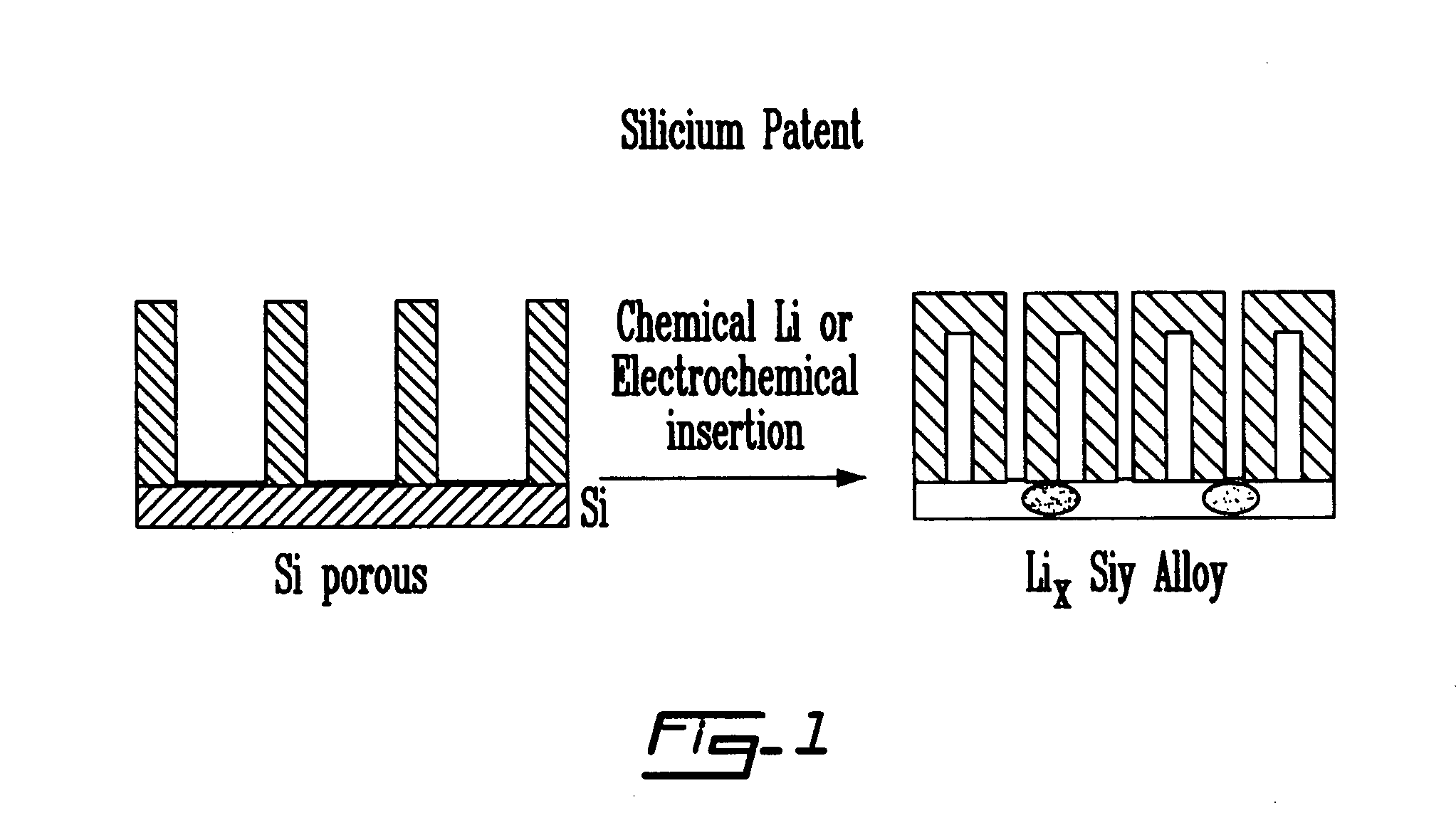

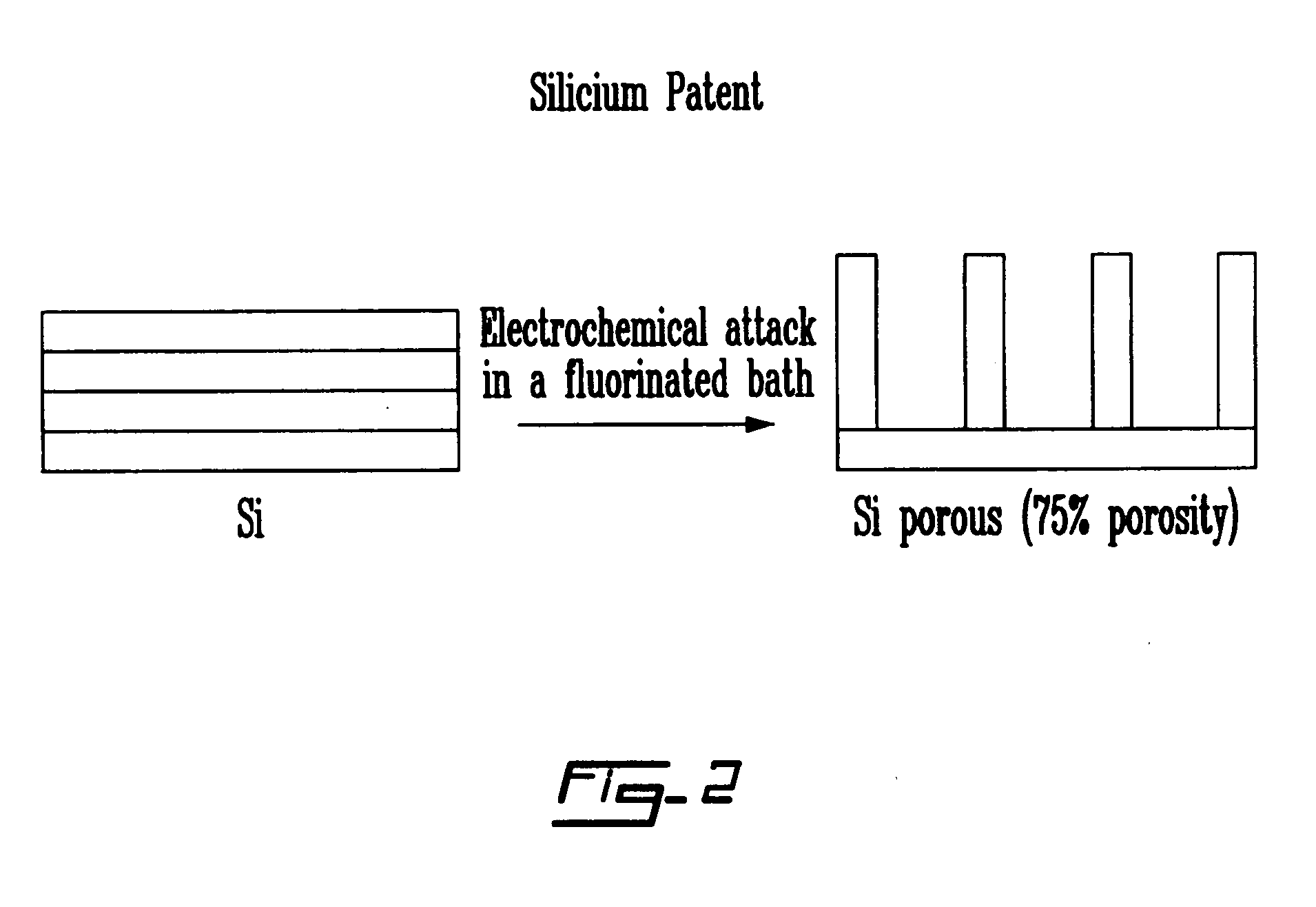

Process for the preparation of an electrode from a porous material, electrode thus obtained and corresponding electrochemical system

ActiveUS20070154805A1Free from crackingElectrochemical processing of electrodesSiliconGramElectrochemistry

Process for the preparation of electrodes from a porous material making it possible to obtain electrodes that are useful in electrochemical systems and that have at least one of the following properties: a high capacity in mnAh / gram, a high capaciaty in mAh / liter, a good capacity for cycling, a low rate of self discharge, and a good environmental tolerance.

Owner:HYDRO QUEBEC CORP

Nitride semiconductor device

ActiveUS8405064B2Free from increase in leak currentFree from crackingSemiconductor/solid-state device manufacturingSemiconductor devicesLattice constantNitride semiconductors

An inventive nitride semiconductor device includes: a substrate; a first buffer layer provided on the substrate, and having a superlattice structure which includes two types of Group III nitride semiconductor sublayers having different compositions and alternately stacked in pairs; a second buffer layer provided on the first buffer layer in contact with the first buffer layer, and having a superlattice structure which includes two types of Group III nitride semiconductor sublayers having different compositions and alternately stacked in pairs; and a device operation layer of a Group III nitride semiconductor provided on the second buffer layer; wherein an average lattice constant LC1 of the first buffer layer, an average lattice constant LC2 of the second buffer layer and an average lattice constant LC3 of the device operation layer satisfy the following expression (1):LC1<LC2<LC3 (1).

Owner:ROHM CO LTD

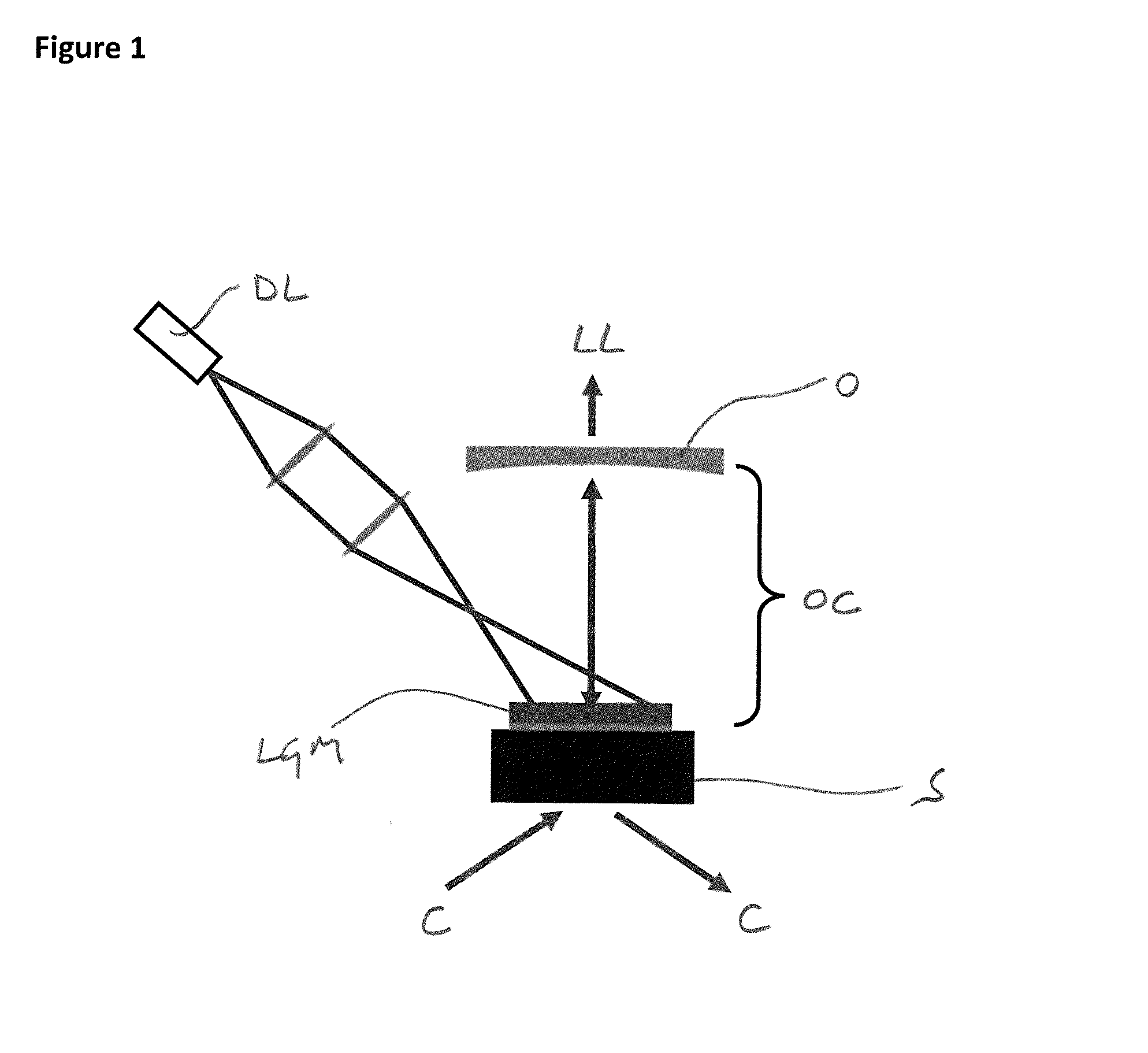

Thick polycrystalline synthetic diamond wafers for heat spreading applications and microwave plasma chemical vapour depositon synthesis techniques

ActiveUS20150222087A1Low costNegating economic benefitPolycrystalline material growthLaser detailsMolecular nitrogenGas concentration

A method of fabricating a polycrystalline CVD synthetic diamond material having an average thermal conductivity at room temperature through a thickness of the polycrystalline CVD synthetic diamond material of at least 2000 Wm−1K−1, the method comprising: loading a refractory metal substrate into a CVD reactor; locating a refractory metal guard ring around a peripheral region of the refractory metal substrate, the refractory metal guard ring defining a gap between an edge of the refractory metal substrate and the refractory metal guard ring having a width 1.5 mm to 5.0 mm; introducing microwaves into the CVD reactor at a power such that the power density in terms of power per unit area of the refractory metal substrate is in a range 2.5 to 4.5 W mm−2; introducing process gas into the CVD reactor wherein the process gas within the CVD reactor comprises a nitrogen concentration in a range 600 ppb to 1500 ppb calculated as molecular nitrogen N2, a carbon containing gas concentration in a range 0.5% to 3.0% by volume, and a hydrogen concentration in a range 92% to 98.5% by volume; controlling an average temperature of the refractory metal substrate to lie in a range 750° C. to 950° C. and to maintain a temperature difference between an edge and a centre point on the refractory metal substrate of no more than 80° C. growing polycrystalline CVD synthetic diamond material to a thickness of at least 1.3 mm on the refractory metal substrate; and cooling the polycrystalline CVD synthetic diamond material to yield a polycrystalline CVD synthetic diamond material having a thickness of at least 1.3 mm, an average thermal conductivity at room temperature through the thickness of the polycrystalline CVD synthetic diamond material of at least 2000 Wm−1K−1 over at least a central area of the polycrystalline CVD synthetic diamond material, wherein the central area is at least 70% of a total area of the polycrystalline CVD synthetic diamond material, a single substitutional nitrogen concentration no more than 0.80 ppm over at least the central area of the polycrystalline CVD synthetic diamond material, and wherein the polycrystalline CVD synthetic diamond material is substantially crack free over at least the central area thereof such that the central area has no cracks which intersect both external major faces of the polycrystalline CVD synthetic diamond material and extend greater than 2 mm in length.

Owner:ELEMENT SIX TECH LTD

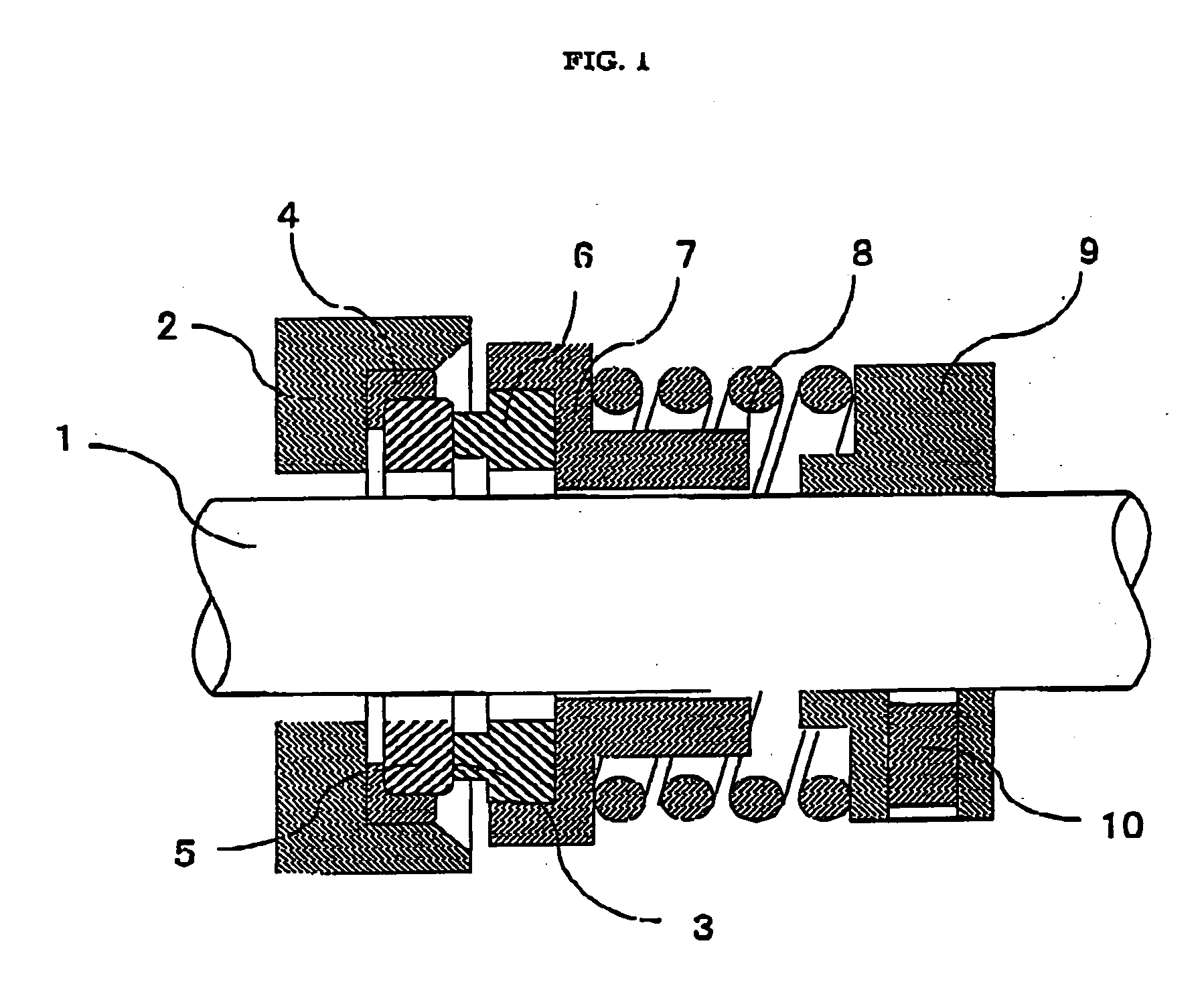

Porous ceramic sintered body for slidable member, manufacturing method thereof, and seal ring

InactiveUS20050181197A1Increase production capacityHigh-quality porousEngine sealsLayered productsCross-linkPolystyrene

A porous ceramic sintered body for slidable member, which has a mean pore diameter of 20 to 39 μm, and a porosity over 13.0 volume % and not more than 18.0 volume %, can be obtained by: forming bubbles by removing organic matter from a ceramic green body containing ceramic powder, forming aid, and pore forming material which is resin beads selected from suspension-polymerized non-cross-linked polystyrene and suspension-polymerized non-cross-linked styrene-acryl copolymer; followed by heating and sintering. The porous ceramic sintered body is used as a slidable member such as a seal ring.

Owner:KYOCERA CORP

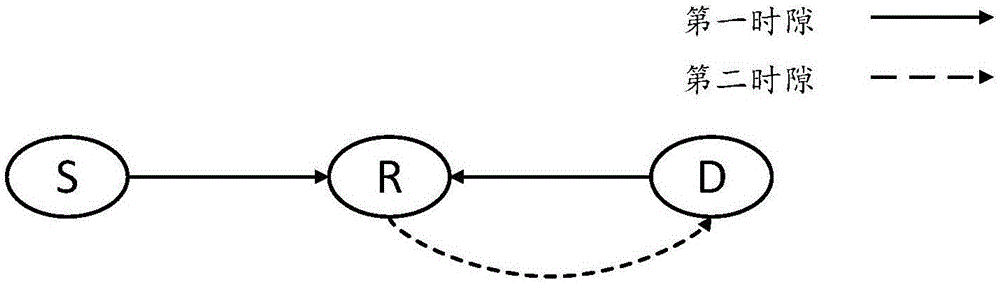

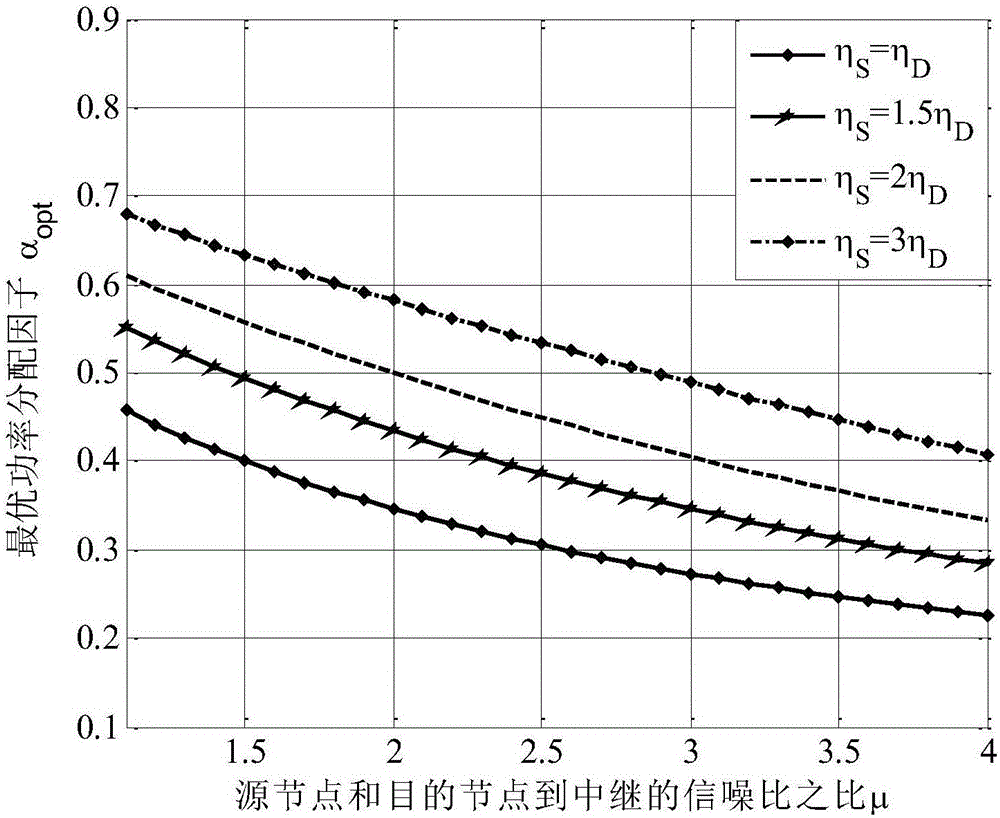

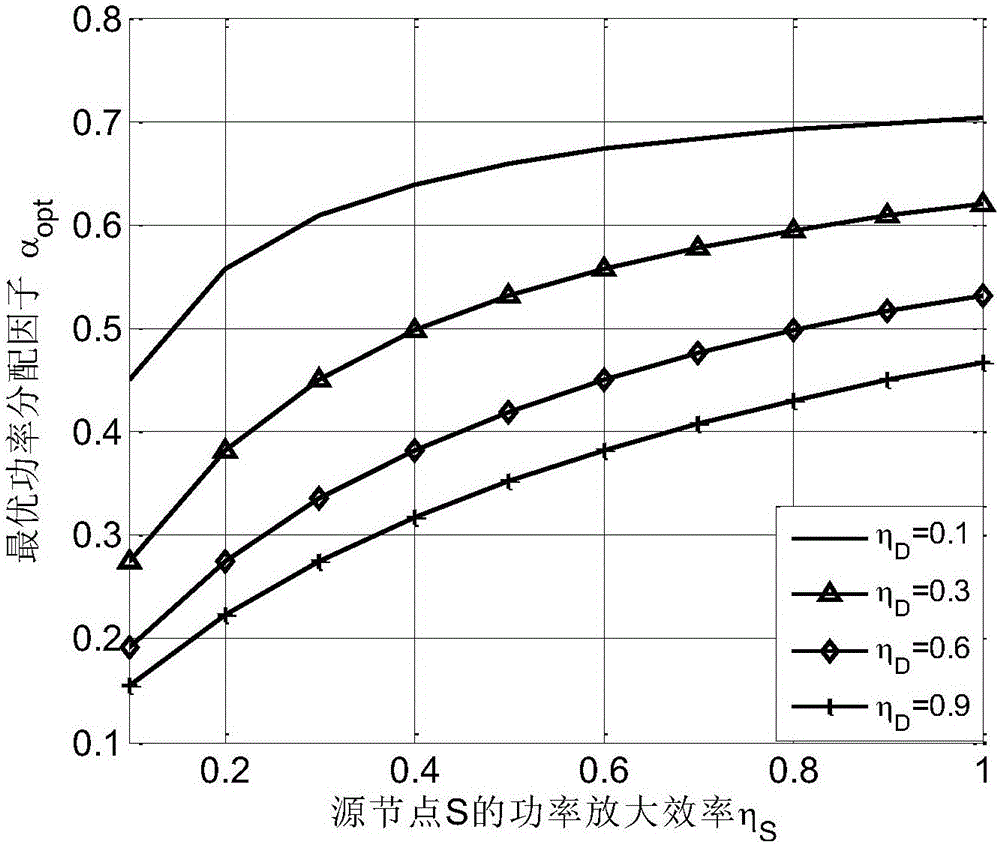

Optimal power distribution method in untrusted relay network

ActiveCN106376073AFree from crackingMaximize safe energy efficiencyPower managementHalf duplex relayDistribution method

The invention provides an optimal power distribution method in an untrusted relay network. A communication process of a two-hop half-duplex relay network is modelled at first; then, the system security capacity and the energy efficiency are comprehensively considered; on the premise that the total power is ensured to be constant, an optical power distribution factor is solved; therefore, the security energy efficiency of a system is maximum; and the security energy efficiency of the power limited two-hop half-duplex network is increased. According to the optical power distribution method disclosed by the invention, the energy efficiency is considered; the security energy efficiency can be maximized under a total power limiting condition; furthermore, user information is prevented from being cracked by an untrusted relay node as much as possible; a calculation process is simplified through a taylor expansion; and furthermore, the estimation error due to use of the first item in the expansion is not beyond 1%, and can be ignored.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Organic, open cell foam materials, their carbonized derivatives, and methods for producing same

InactiveUS7005181B2Improve structural strengthFree from crackingThermal insulationLayered productsSolventElectron

Organic, small pore area materials (“SPMs”) are provided comprising open cell foams in unlimited sizes and shapes. These SPMs exhibit minimal shrinkage and cracking. Processes for preparing SPMs are also provided that do not require supercritical extraction. These processes comprise sol-gel polymerization of a hydroxylated aromatic in the presence of at least one suitable electrophilic linking agent and at least one suitable solvent capable of strengthening the sol-gel. Also disclosed are the carbonized derivatives of the organic SPMs.

Owner:MOUNT ROYAL VENTURES I +1

Curable Composition Containing as Constituent Material Silica Obtained by Decomposing Chrysotile and Cured Object

InactiveUS20080264302A1Mitigate the heat island effectEasy constructionSilicaCovering/liningsBiological bodyFiber

Chrysotile or chrysotile-containing serpentinite containing chrysotile is treated to convert the chrysotile contained therein into a non-asbestos material, so that the non-asbestos material is used as a material that can be recycled safely and is effective from the view point of environmental protection.[Means for Solving Problems] A curable composition characterized by containing at least a porous fibrous amorphous silica obtained by decomposing chrysotile or chrysotile-containing serpentinite with acid to substantially eliminate an influence of asbestos on living body, and a reinforcing fiber. The curable composition preferably contains a surfactant and a thickener and / or a filler and / or a colorant or an air-hardening material and / or water-hardening material and a thickener. The composition preferably contains 15 to 100% of the porous fibrous amorphous silica obtained by decomposing the chrysotile or the chrysotile-serpentinite with acid, 0 to 75% of a slaked line, 0 to 3% of a thickener, and 0 to 10% of a pulp.

Owner:NOZAWA CORP

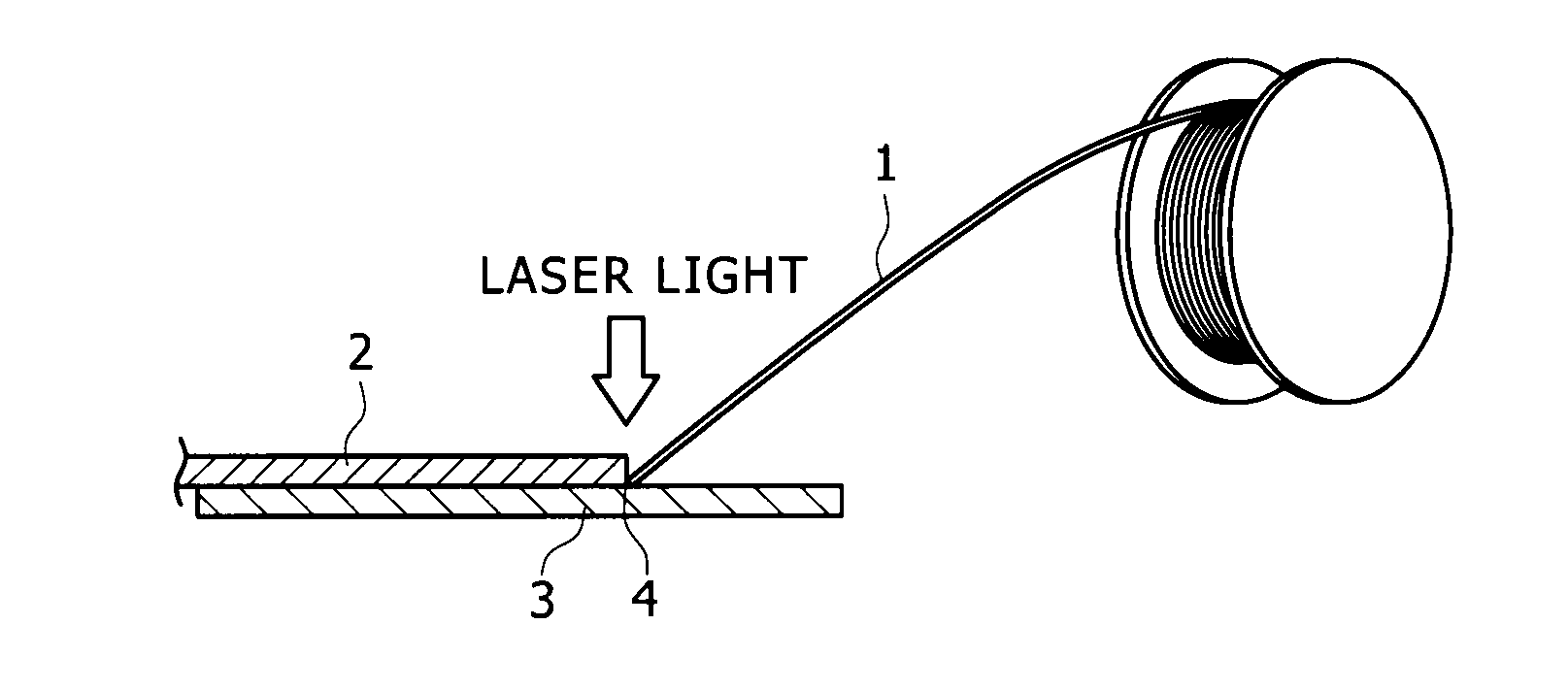

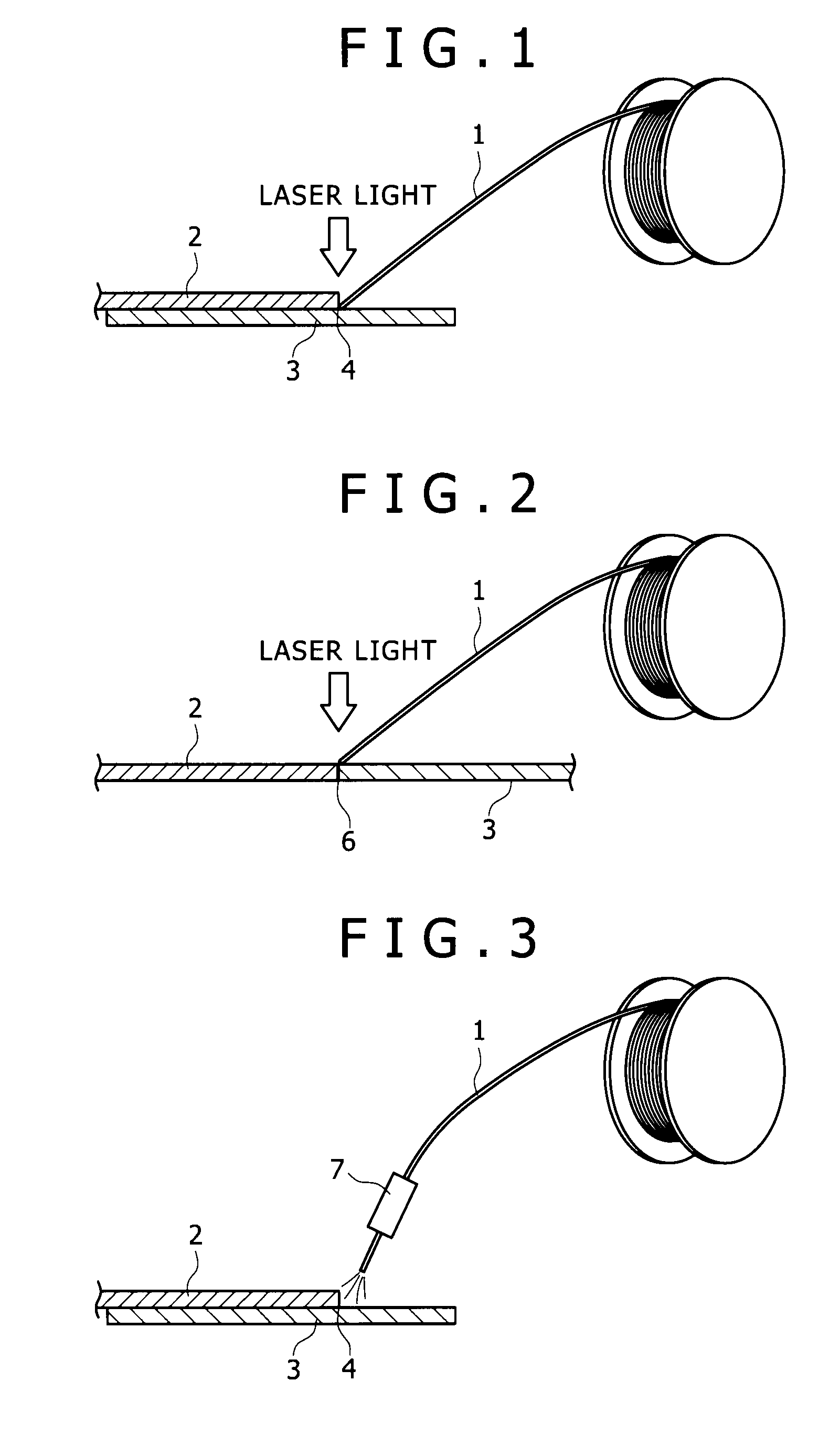

Flux-cored wire for welding different materials, method for laser welding of different materials and method for mig welding of different materials

ActiveUS20120074111A1Appropriate amountImprove joint strengthArc welding apparatusVehicle componentsFluorideUltimate tensile strength

There are provided a flux-cored wire for welding different materials, a method for laser welding of different materials and a method for MIG welding of different materials which can improve tensile shear strength of a welded joint portion and peeling strength of a welded portion interface in welding aluminum or an aluminum alloy material and a steel material. The flux-cored wire has a cylindrical sheath comprising an aluminum alloy which contains Si in an amount of 1.5 to 2.5% by mass and Zr in an amount of 0.05 to 0.25% by mass, with the remainder being aluminum and inevitable impurities, and a flux filling inside this sheath and containing cesium fluoride in an amount of 20 to 60% by mass, and the packing fraction of the flux being 5 to 20% by mass of the total mass of the wire.

Owner:KOBE STEEL LTD

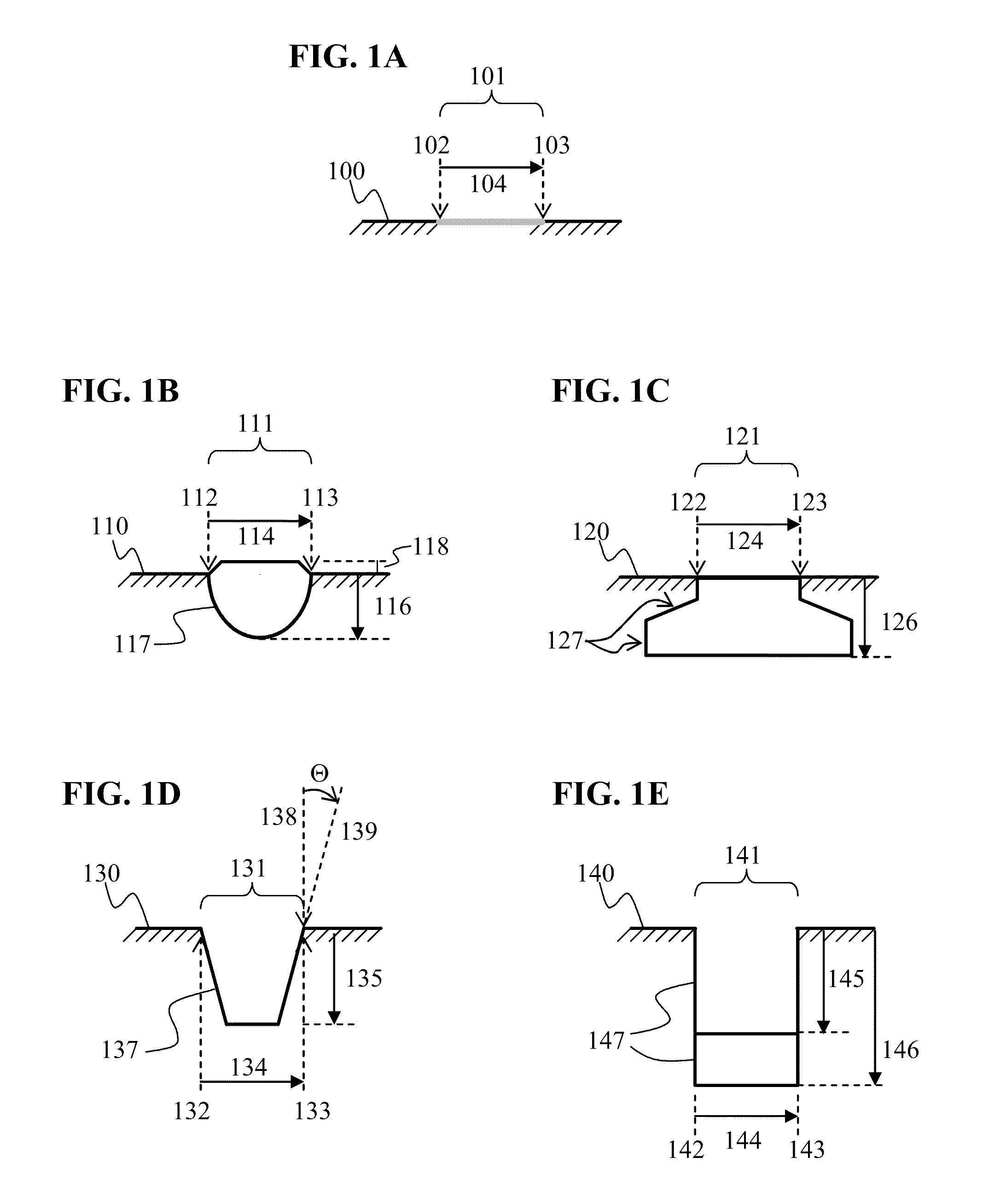

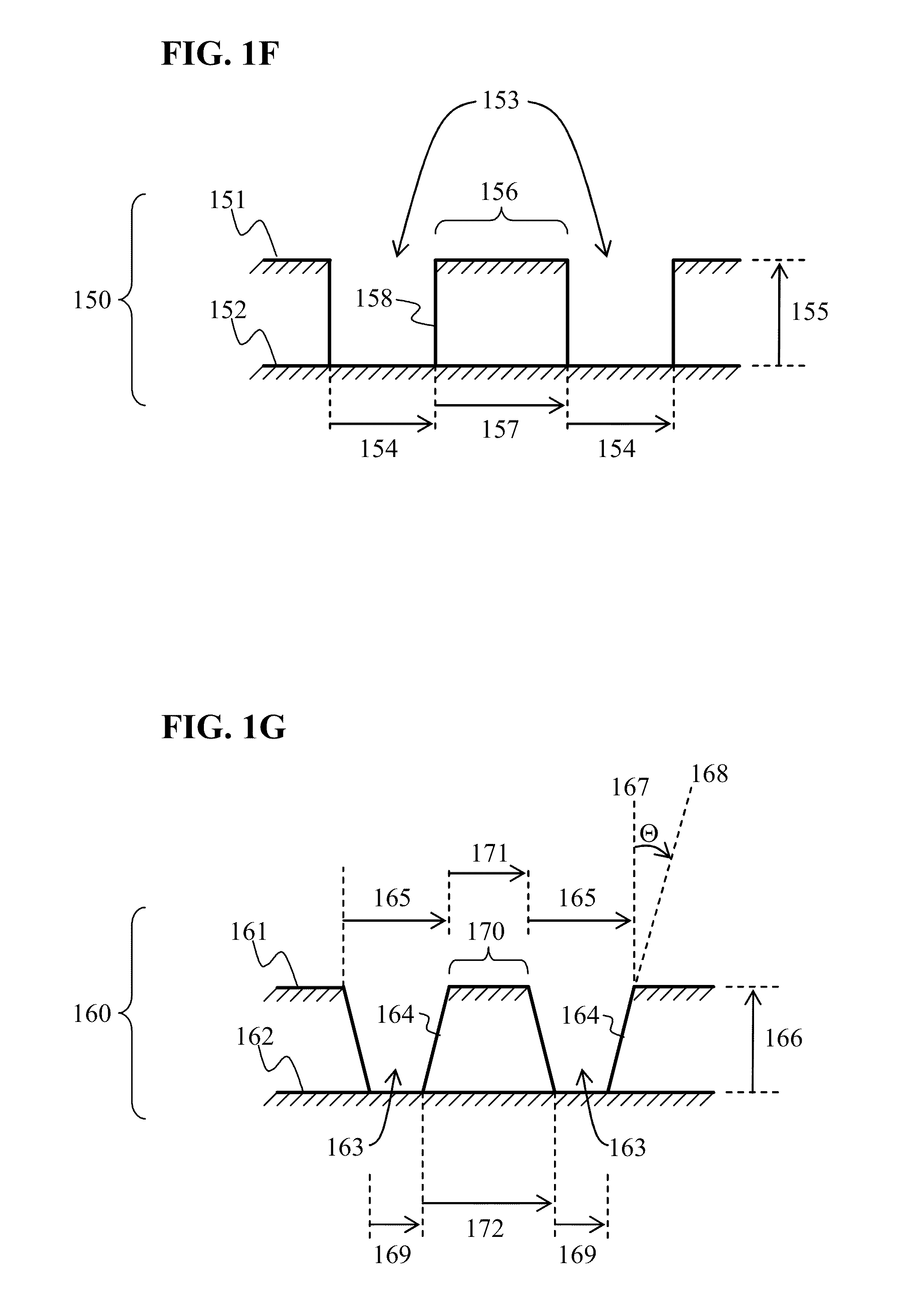

Methods of Patterning Substrates Using Microcontact Printed Polymer Resists and Articles Prepared Therefrom

InactiveUS20100252955A1Efficient and cost-effectiveFree from crackingConfectioneryNanoinformaticsMicrocontact printingResist

The present invention is directed to methods for patterning substrates using contact printing to form patterns comprising a polymer, using the patterns formed therefrom as resists, and process products formed by the process.

Owner:NANO TERRA INC +1

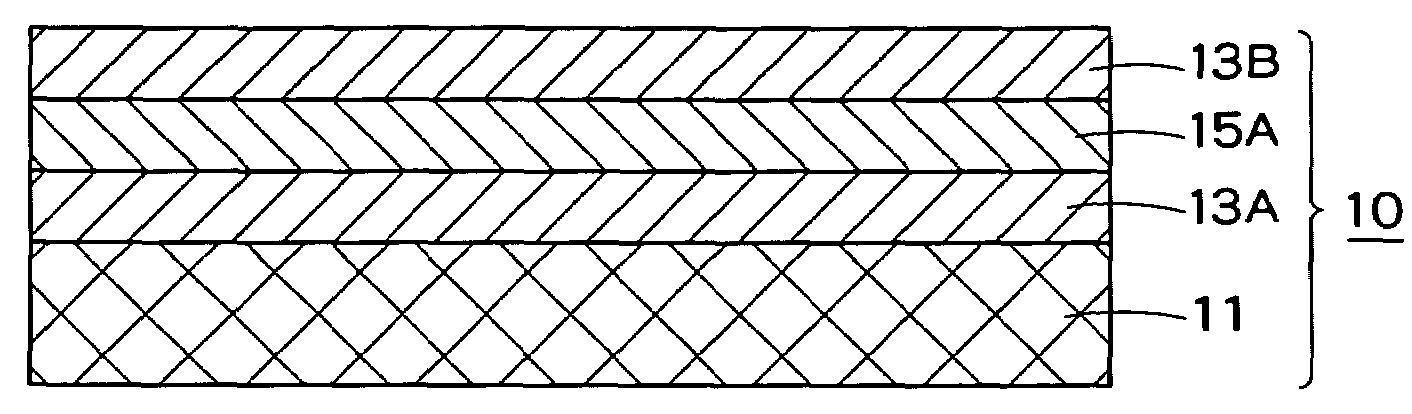

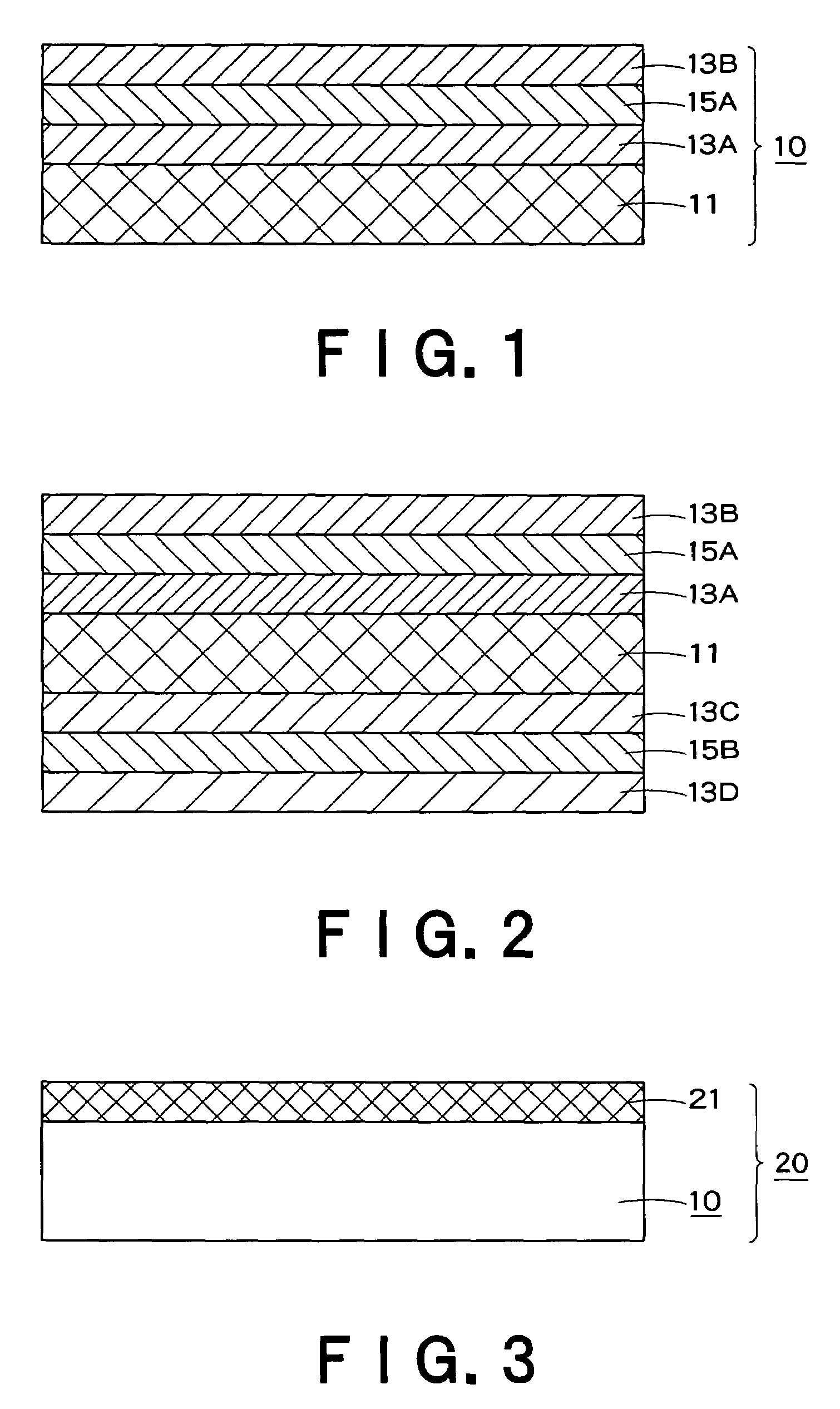

Gas barrier clear film, and display substrate and display using the same

InactiveUS7341766B2Practical and reliableReduce crackingLiquid crystal compositionsCoatingsPolymer substrateHeat resistance

There is provided a gas barrier clear film 10 as a polymer substrate that is flexible, is light, is free from cracking, can be bent, has a high level of heat resistance, is excellent particularly in gas shielding properties, and can be used as an alternative to glass substrates.The gas barrier clear film comprises: a clear resin base material film 11 having a coefficient of linear expansion of 15 to 100 ppm / K and a glass transition temperature Tg of 150 to 300° C.; and a first clear inorganic compound layer 13A, a sol-gel coat layer 15A, and a second clear inorganic compound layer 13B provided in that order on the clear resin base material film 11. The second clear inorganic compound layer 13B has an Ra (average roughness) value of not more than 5 nm and an Rmax (maximum roughness) value of not more than 80 nm.

Owner:DAI NIPPON PRINTING CO LTD

Organic, open cell foam materials, their carbonized derivatives, and methods for producing same

InactiveUS7521485B2Improve structural strengthFree from crackingPhysical/chemical process catalystsThermal insulationPolymer sciencePerylene derivatives

Organic, small pore area materials (“SPMs”) are provided comprising open cell foams in unlimited sizes and shapes. These SPMs exhibit minimal shrinkage and cracking. Processes for preparing SPMs are also provided that do not require supercritical extraction. These processes comprise sol-gel polymerization of a hydroxylated aromatic in the presence of at least one suitable electrophilic linking agent and at least one suitable solvent capable of strengthening the sol-gel. Also disclosed are the carbonized derivatives of the organic SPMs.

Owner:MOUNT ROYAL VENTURES I +1

Ion exchange polymer dispersion, process for its production and its use

ActiveUS20050143540A1High strengthConstant swellingIon-exchanger regenerationCell electrodesPolymer scienceShear rate

A thickened ion exchange polymer dispersion is obtained by applying ultrasonic vibration or a shearing force to an ion exchange polymer dispersion having a fluorinated polymer having sulfonic acid groups as an ion exchange polymer uniformly dispersed in a dispersion medium so that the viscosity of the dispersion at 25° C. at a shear rate of 10 (1 / s) increases 2-2000 times in a thickening step. When formed into a membrane, the dispersion can forms an ion exchange membrane having a uniform and small thickness, high strength, which is free from cracking and shows constant swelling in water and steam. Further, a layer formed by applying a coating solution containing this dispersion and a catalyst powder comprising catalyst metal particles and a carbon support loaded with the catalyst metal particles to a substrate can be used to prepare a membrane-electrode assembly as a catalyst layer for at least one of the cathode and the anode by providing the catalyst layer adjacently to an ion exchange membrane. Because the catalyst layer is highly strong, has few defects and is excellently smooth, a high-performance membrane-electrode assembly for solid polymer electrolyte fuel cells can be obtained.

Owner:ASAHI GLASS CO LTD

Method for the determination of the stresses occurring in wood when drying

InactiveUS20080148593A1Improve accuracyQuality improvementDrying using combination processesAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic emissionSpectroscopy methods

The present invention relates to a method for the determination of the stresses occurring in wood when drying or being dried. With the method in accordance with the invention, electrodes are used to generate an electric field in drying wood in order to measure the electric complex spectrum using the impedance spectroscopy method while at the same time employing sensors k to measure acoustic emissions from drying wood and using the results for calculating the parameters required for determining the stress state existing in the wood and for monitoring and / or controlling the drying process.

Owner:KORWENSUUN KONETEHDAS

Method for producing thick crack-free coatings from hydrogen silsesquioxane resin

InactiveUS6022625AIncrease coating thicknessShorter and low temperaturePretreated surfacesSemiconductor/solid-state device manufacturingCrack freePhysical chemistry

This invention pertains to a method for producing crack-free, insoluble, greater than 1.25 mu m thick coatings from hydrogen silsesquioxane resin compositions. The method for producing the coating comprises applying a fillerless hydrogen silsesquioxane resin composition onto a substrate and thereafter heating the hydrogen silsesquioxane resin at a temperature of less than 500 DEG C. for a controlled period of time to produce the crack-free coating having a thickness of greater than 1.25 mu m. The resins may be cured in an inert or oxygen containing environment.

Owner:DOW CORNING CORP

Wiring circuit board

InactiveUS20120031648A1Improve tensile propertiesGrowth inhibitionPrinted circuit aspectsPrinted circuit manufactureEngineeringCopper

A wiring circuit board is provided, in which a circuit wiring is substantially free from a softening phenomenon which may otherwise occur due to heat over time, and is highly durable, less brittle and substantially free from cracking. The wiring circuit board includes a substrate comprising an insulative layer, and a circuit wiring provided on the insulative layer of the substrate. The circuit wiring has a layered structure including at least three copper-based metal layers. A lowermost one and an uppermost one of the copper-based metal layers each have a tensile resistance of 100 to 400 MPa at an ordinary temperature, and an intermediate copper-based metal layer present between the lowermost layer and the uppermost layer has a tensile resistance of 700 to 1500 MPa at the ordinary temperature.

Owner:NITTO DENKO CORP

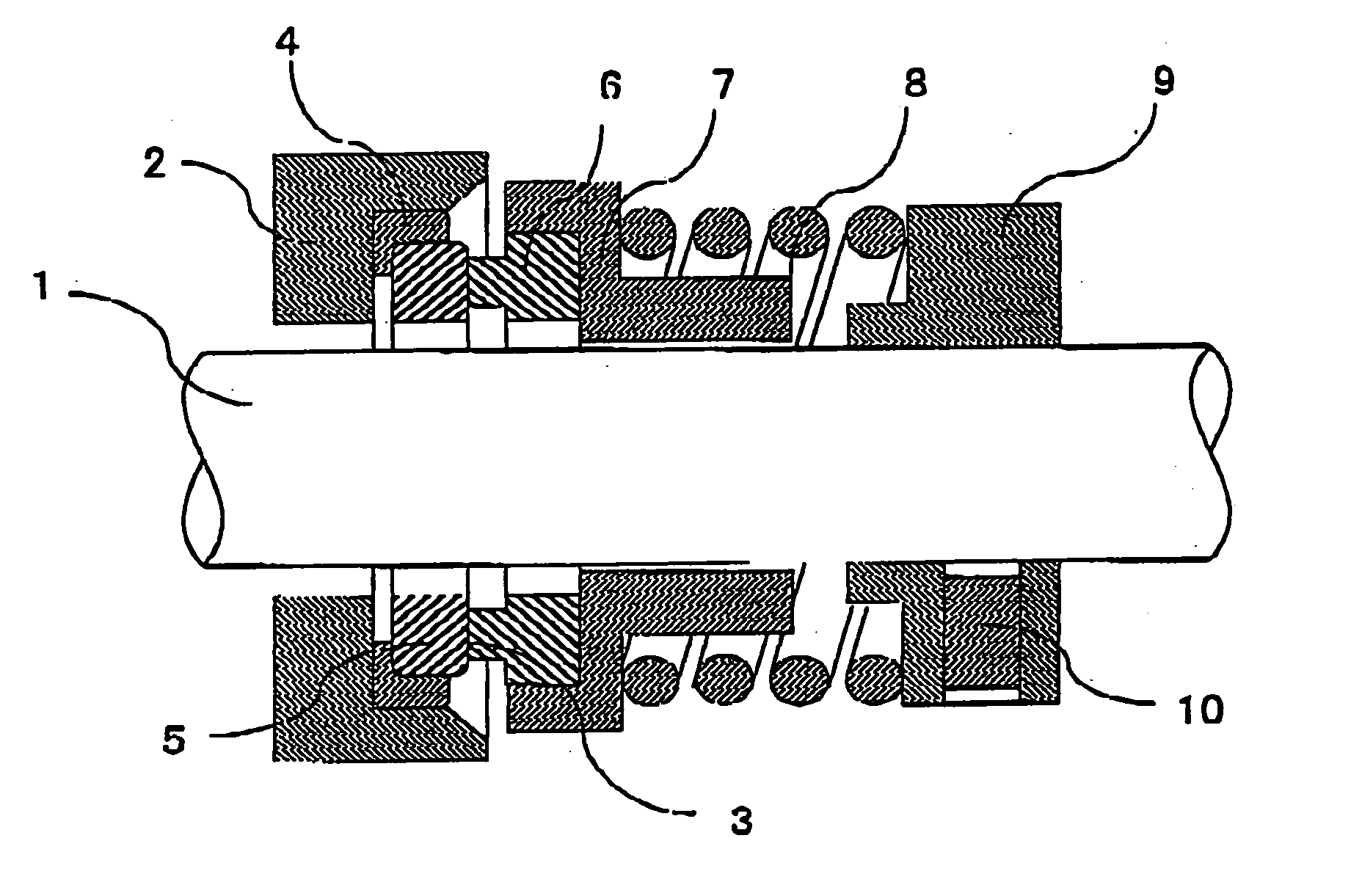

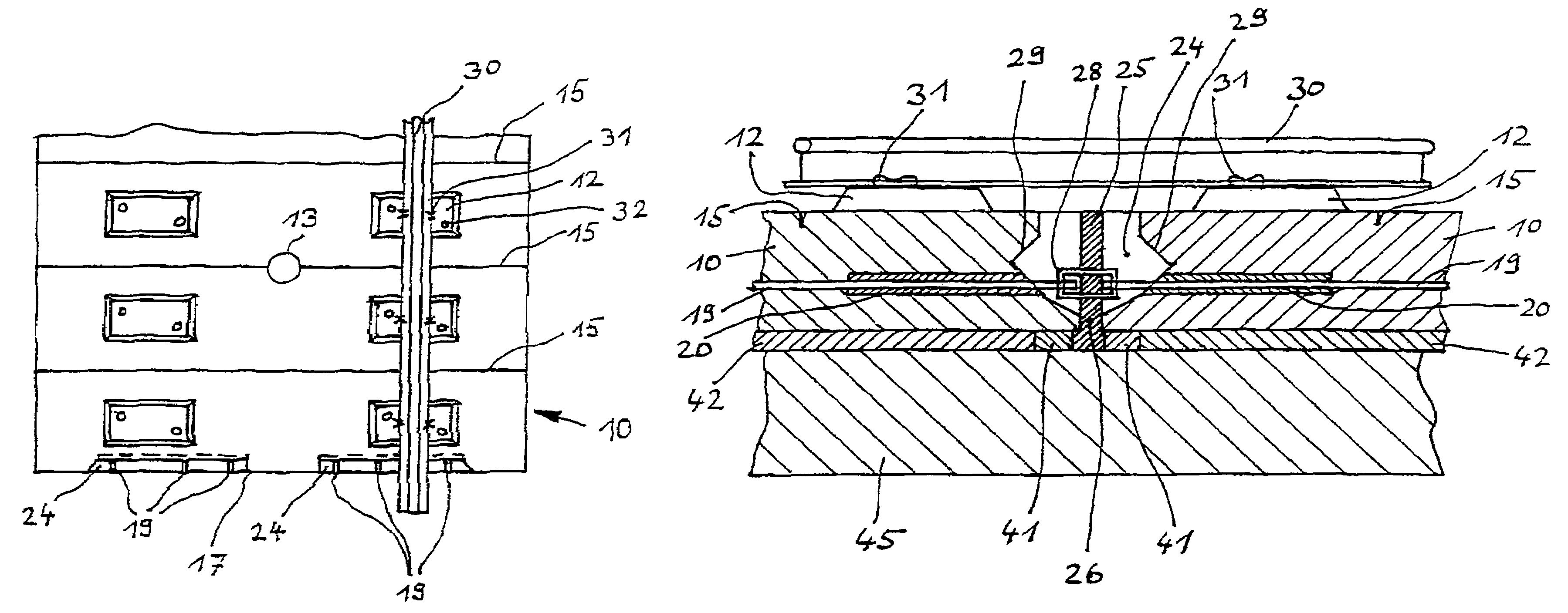

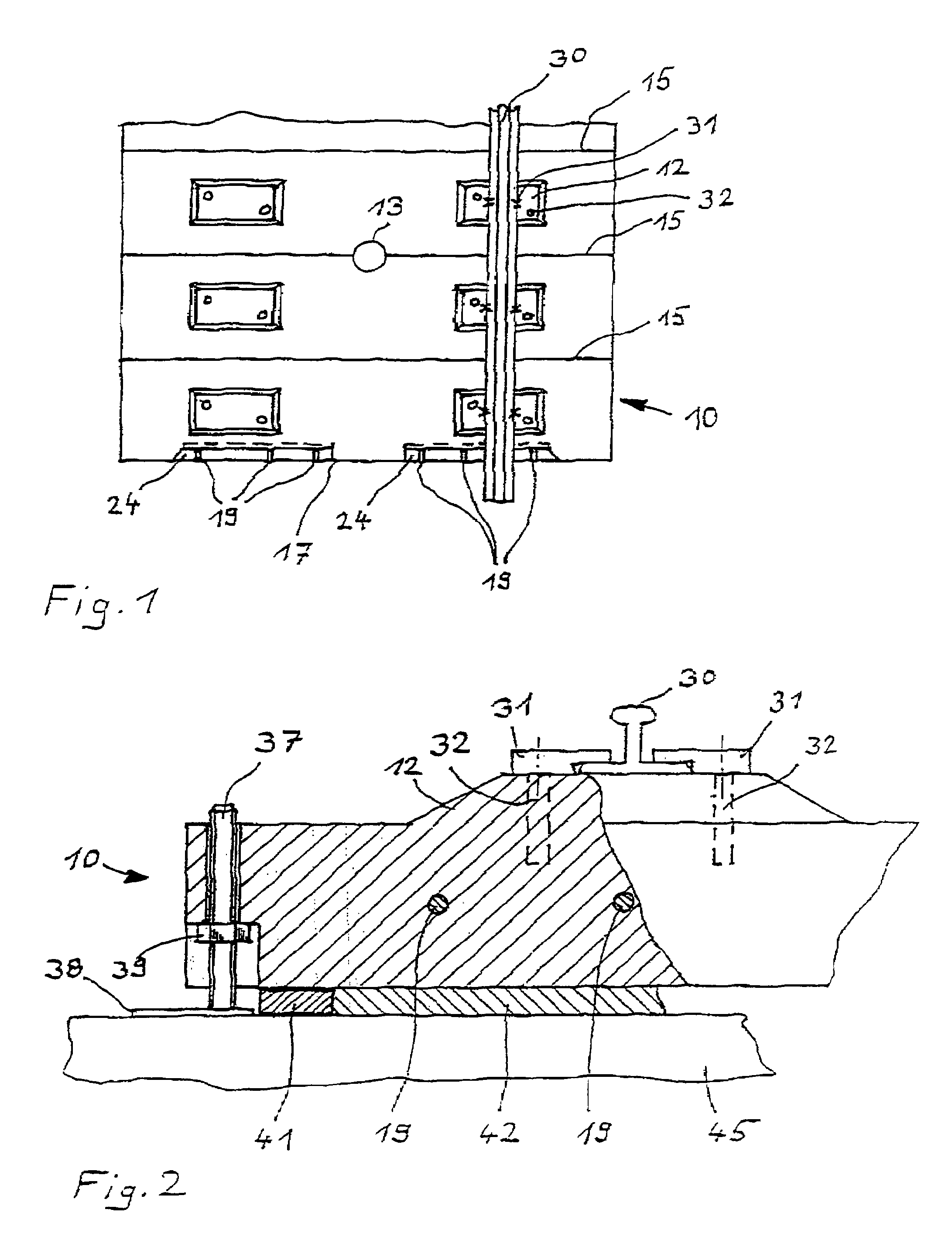

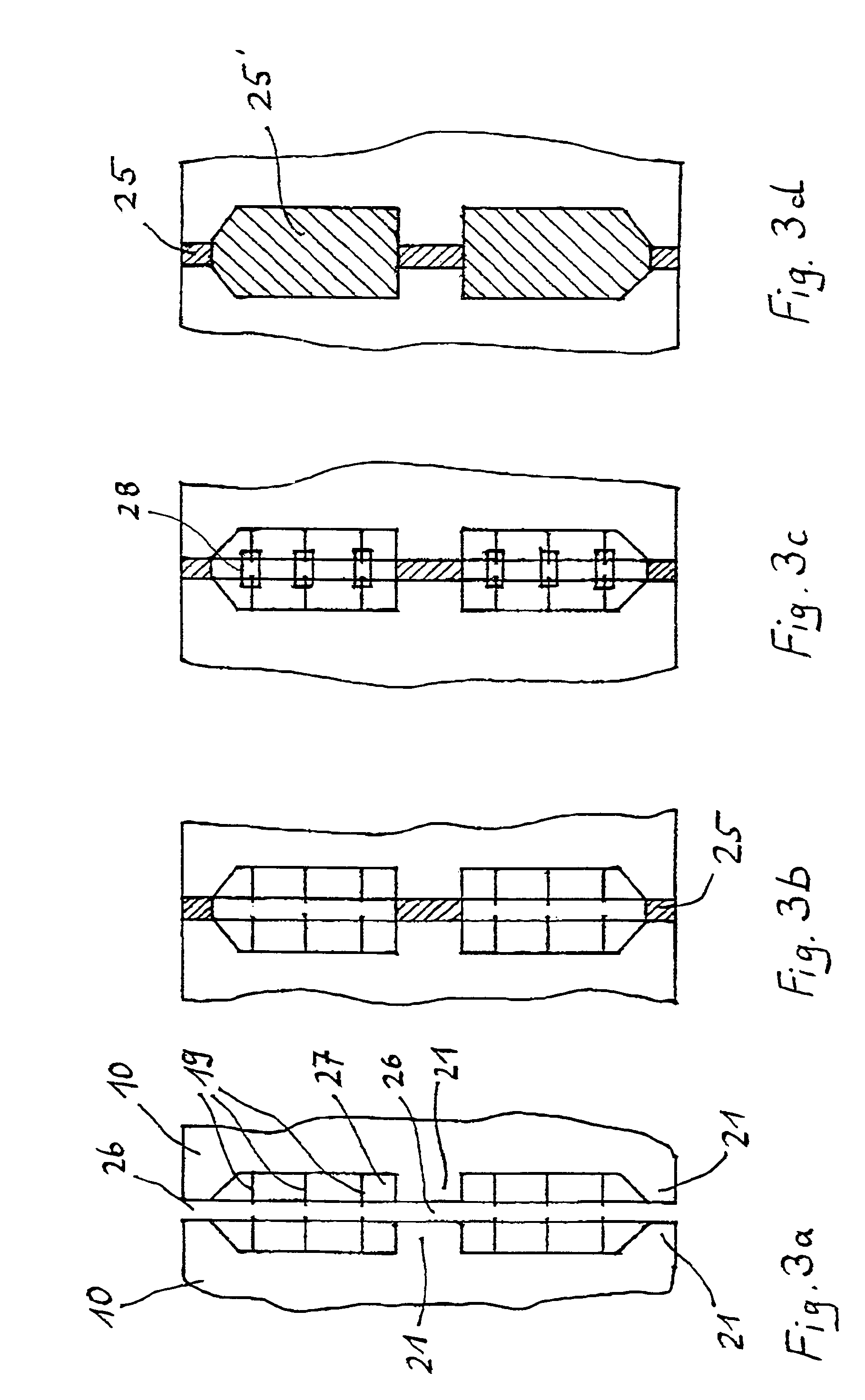

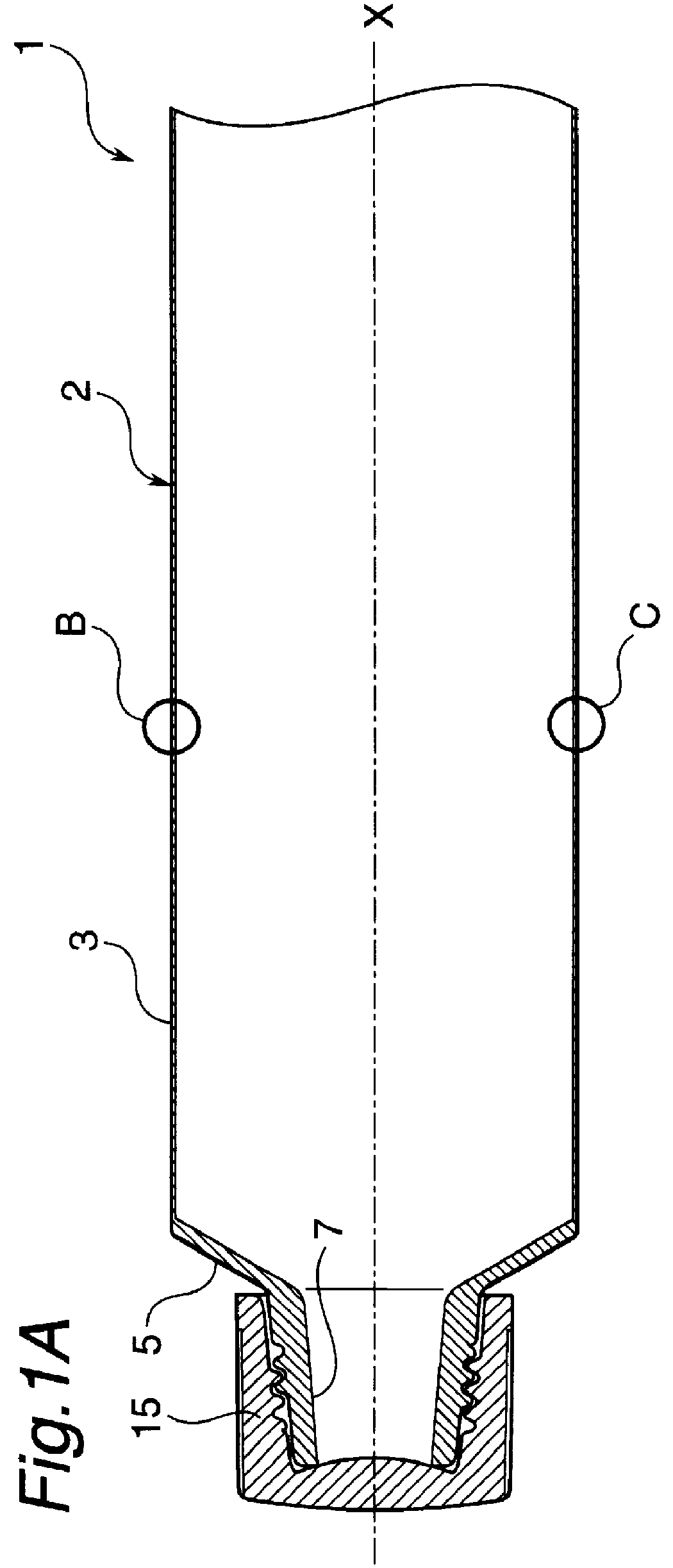

Pre-assembled plate consisting of armoured concrete

InactiveUS7556208B1Free from crackingEasy to monitorSingle unit pavingsBallastwayChemical compoundRebar

The invention relates to a pre-assembled plate consisting of armored concrete, especially for the use as a component of a solid roadway for high-speed means of transport. At least two steel rods extending in the longitudinal direction of the pre-assembled plate of armored concrete (10) and protruding over the concrete surface thereof on the front face (17) are provided. The pre-assembled plate (10) is provided with at least one, preferably several, predetermined breaking points (15) which extends crosswise in relation to the steel rods (19). The steel rod (19) is anchored in the area between the front face (17) of the pre-assembled plate (10) and the first predetermined breaking point (1) respectively and is mounted in the direction towards the respective front face (17) in the longitudinal direction thereof in an essentially freely moveable manner. According to a method for producing a plate composite structure of pre-assembled plates of armored concrete (10), the pre-assembled plate (10) is placed and exactly positioned. A casting compound (42) is underpoured under the exactly positioned pre-assembled plate. The pre-assembled plate (10) is connected to the adjacent pre-assembled plate (10) by casting the joint and connecting the steel rods (19) after the casting compound (42) has hardened.

Owner:MAX BOGL BAUUNTERNEHMUNG

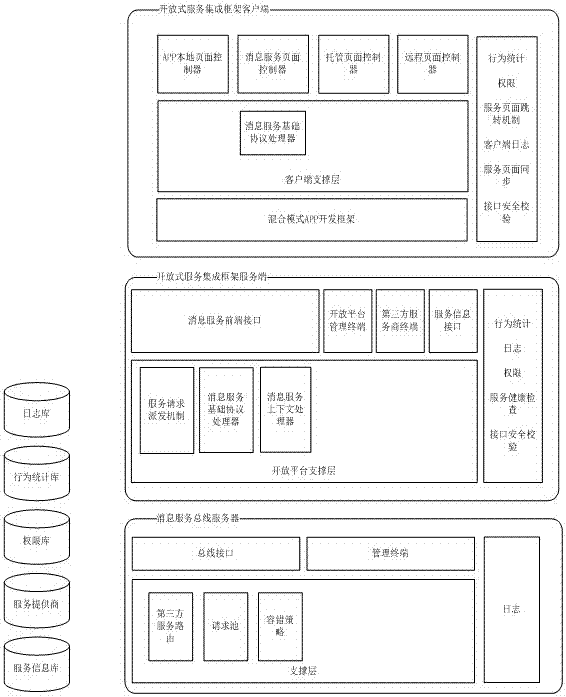

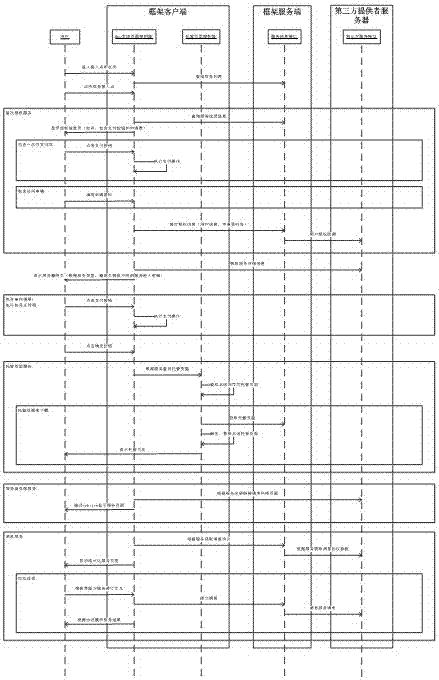

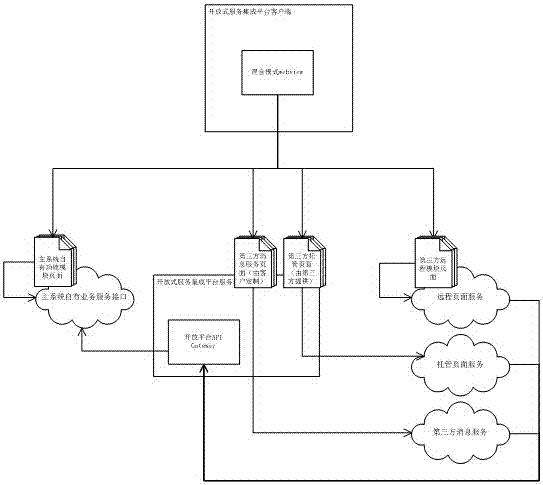

Open application service integration framework

ActiveCN107222524ASupport scalabilitySupport hot swapUser identity/authority verificationThird partyOperating system

The invention provides an open application service integration framework comprising an open service integration framework client, an open service integration framework server and a message service bus server, which are in communication connection with each other in sequence. The open application service integration framework of the invention can help a large number of medium and small application developers to develop and deploy platform type intelligent mobile applications at lower costs. The framework can be deployed and run independently, docking and integrating with the main client system are realized through interfaces, and service interface exposure and third party service integration and other ability are provided for the main system. The framework can be deployed and run on an independent server. The open application service integration framework interacts with the main client system through an http interface. The open application service integration framework is used for supporting third party system services and dynamic operating page access, supporting dynamic expansion and hot plug and other properties of background service and establishing a platform application system via a cordwood system.

Owner:广东智淘信息科技股份有限公司

Ion exchange polymer dispersion, process for its production and its use

ActiveUS7582713B2Uniform and small thicknessHigh strengthIon-exchanger regenerationCell electrodesPolymer scienceShear rate

A thickened ion exchange polymer dispersion is obtained by applying ultrasonic vibration or a shearing force to an ion exchange polymer dispersion having a fluorinated polymer having sulfonic acid groups as an ion exchange polymer uniformly dispersed in a dispersion medium so that the viscosity of the dispersion at 25° C. at a shear rate of 10 (1 / s) increases 2-2000 times in a thickening step. When formed into a membrane, the dispersion can forms an ion exchange membrane having a uniform and small thickness, high strength, which is free from cracking and shows constant swelling in water and steam. Further, a layer formed by applying a coating solution containing this dispersion and a catalyst powder comprising catalyst metal particles and a carbon support loaded with the catalyst metal particles to a substrate can be used to prepare a membrane-electrode assembly as a catalyst layer for at least one of the cathode and the anode by providing the catalyst layer adjacently to an ion exchange membrane. Because the catalyst layer is highly strong, has few defects and is excellently smooth, a high-performance membrane-electrode assembly for solid polymer electrolyte fuel cells can be obtained.

Owner:ASAHI GLASS CO LTD

Light cure of cationic ink on acidic substrates

InactiveUS7878644B2Increase flexibilityFree from crackingPretreated surfacesRecord information storageLength waveLight cure

This invention is an advance in coating chemistry, curing technology, related apparatus and the products made thereby. The invention encompasses a substrate bonded to a coating cured, at least in part, cationically by a light having a wavelength in a range of 100 nm to 1200 nm and an intensity in a range of 0.0003 W / cm2 / nm to 0.05 W / cm2 / nm. Methods and systems for coating substrates and curing the coated products are encompassed. The invention encompasses apparatus and ink jet printers utilizing this curing technology.

Owner:GERBER SCI INT

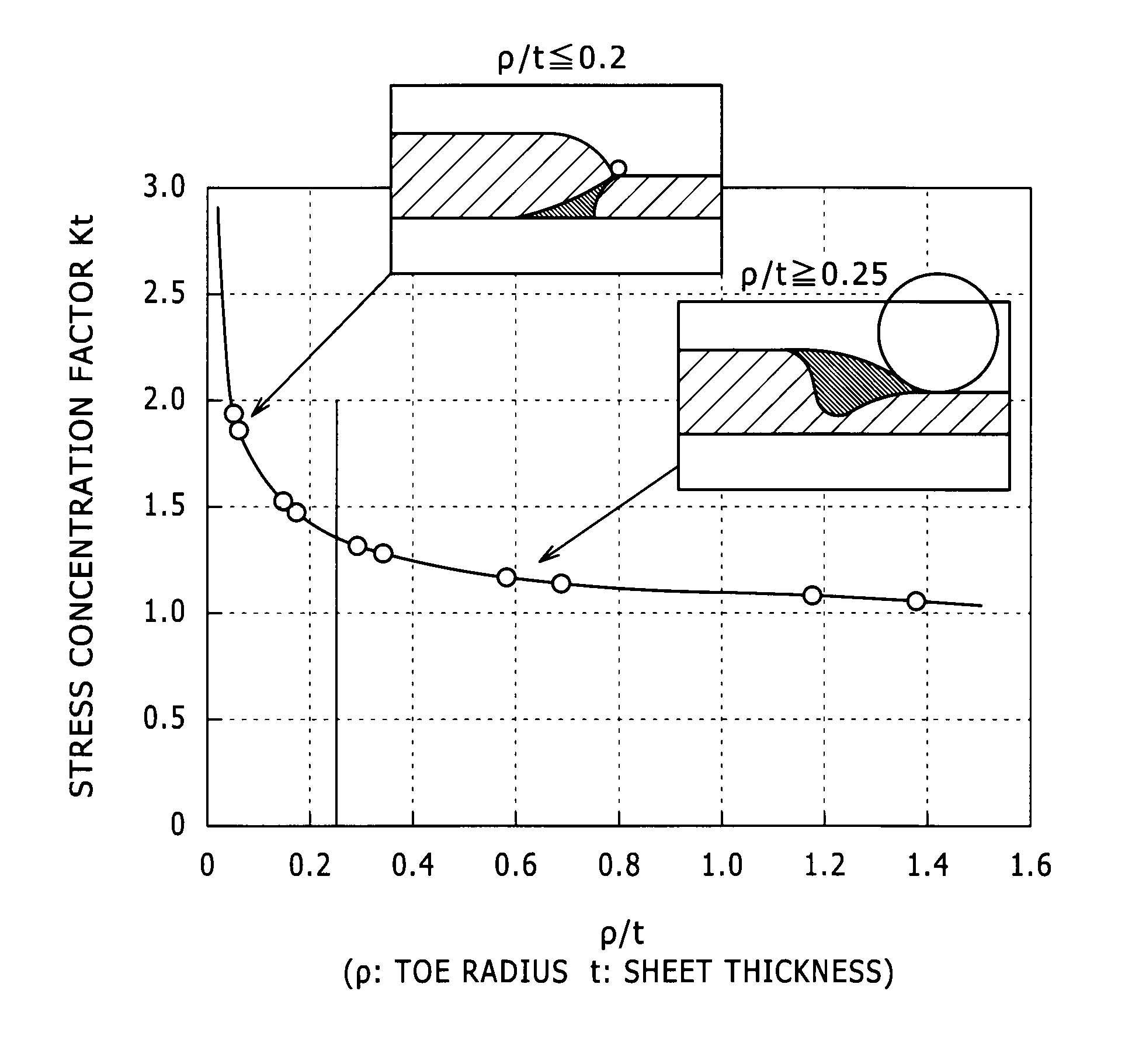

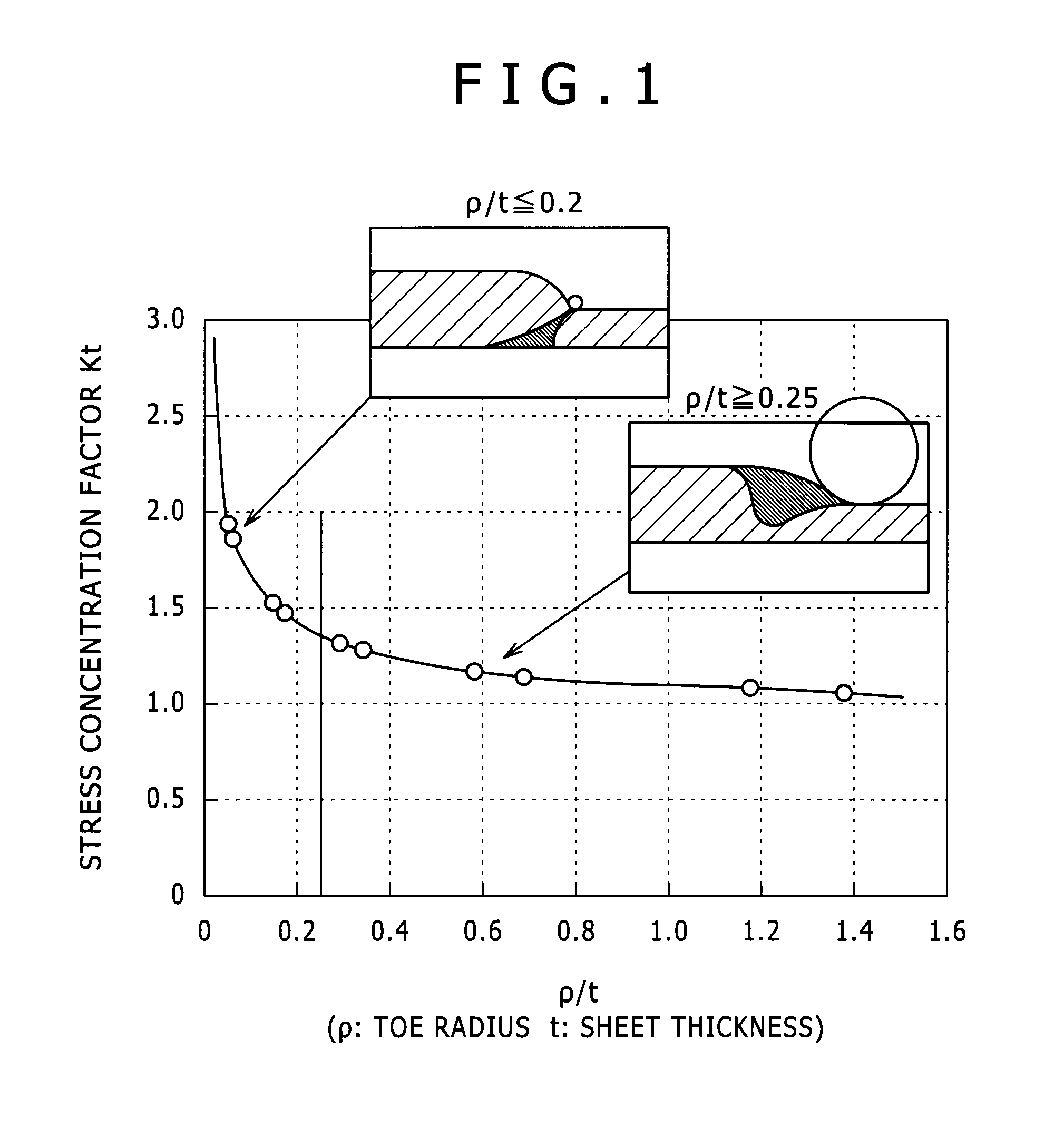

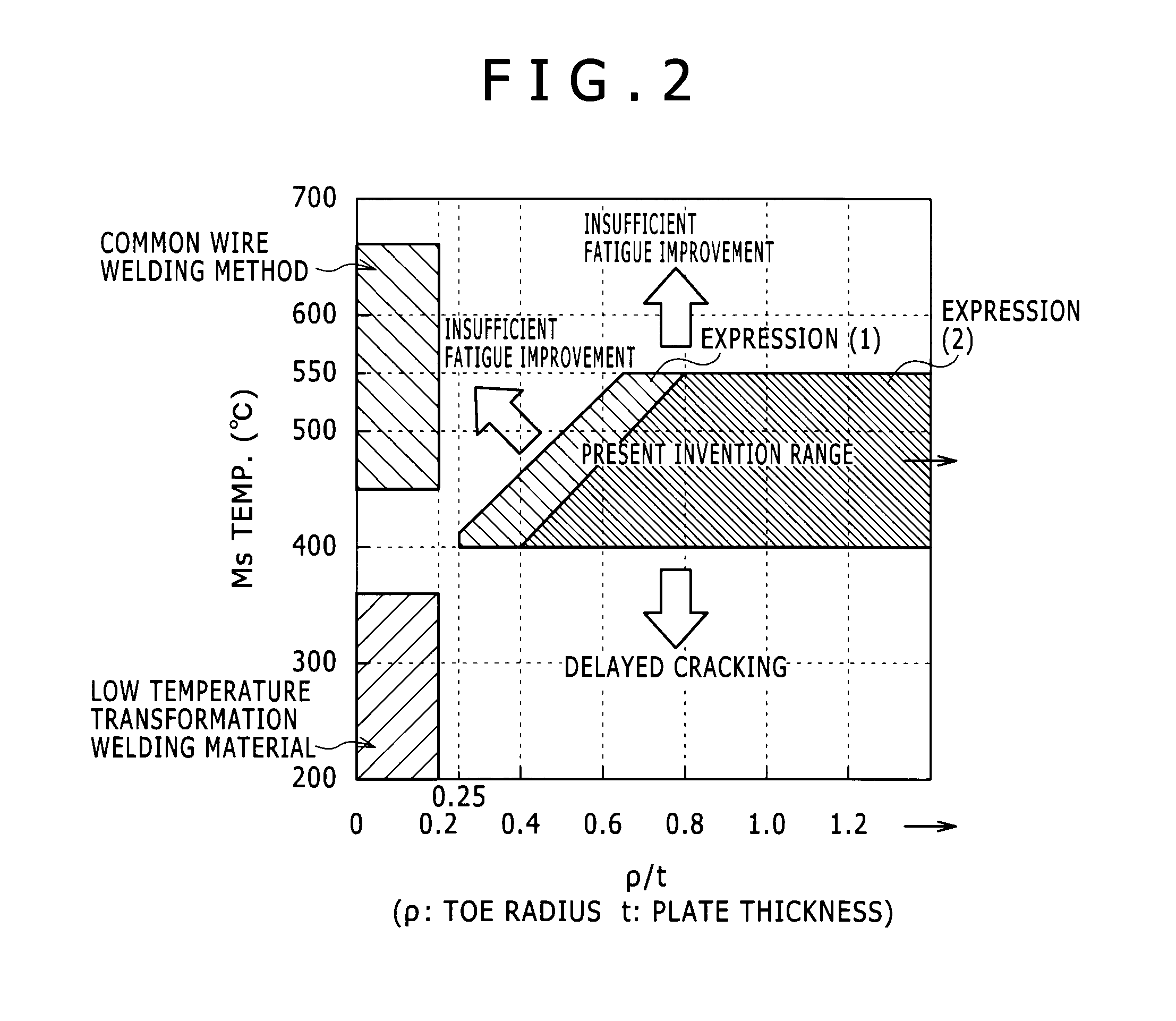

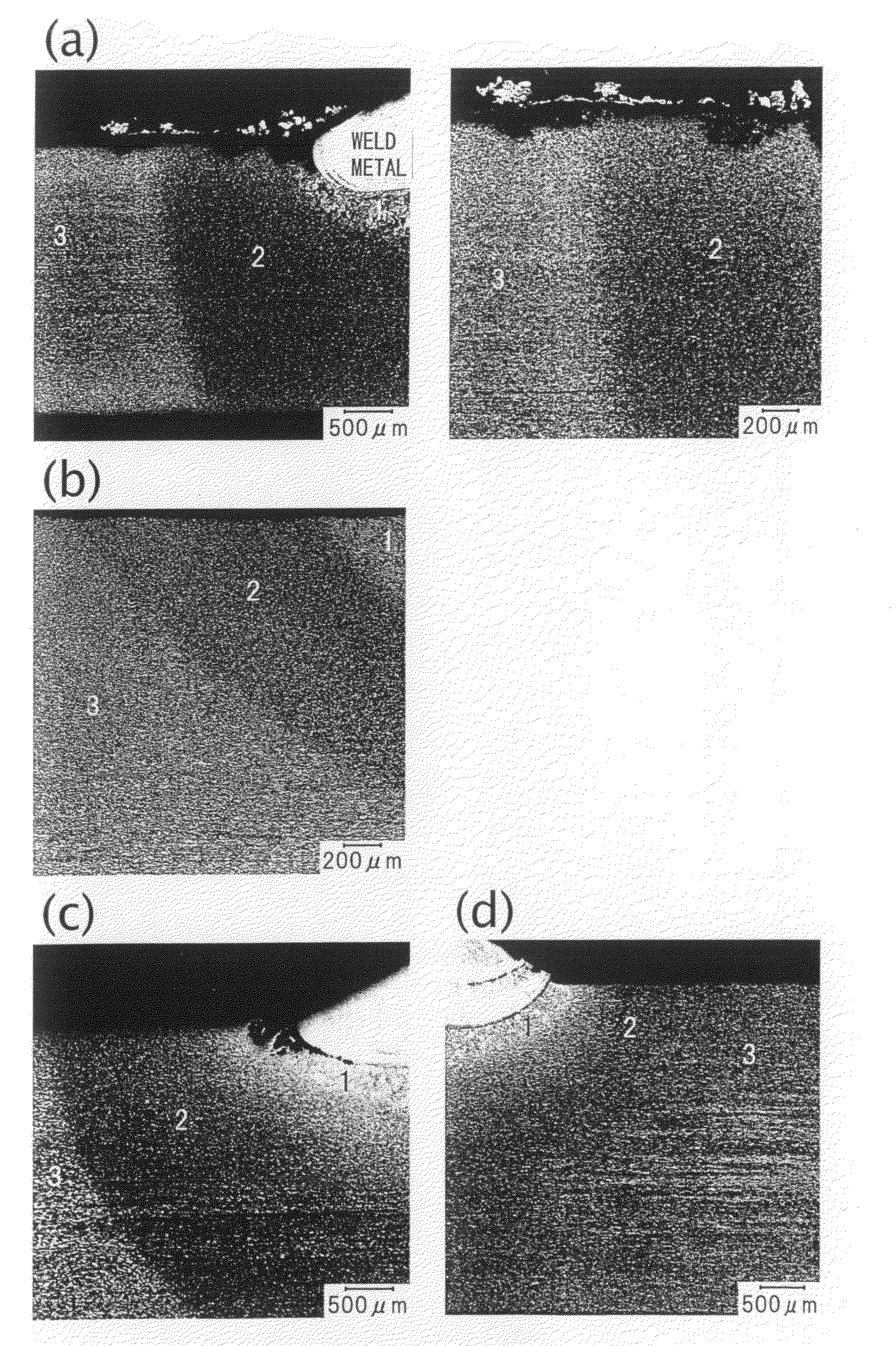

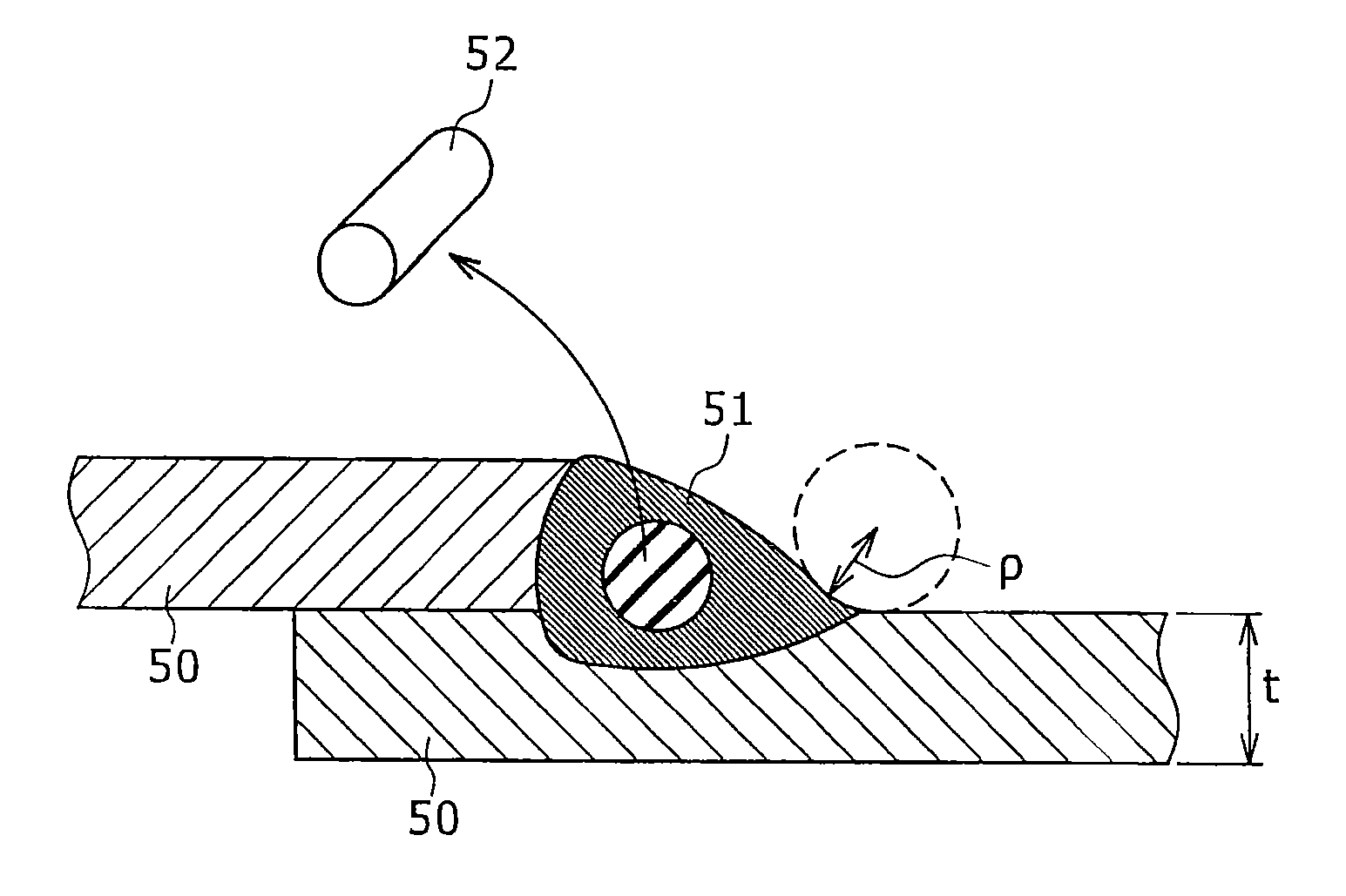

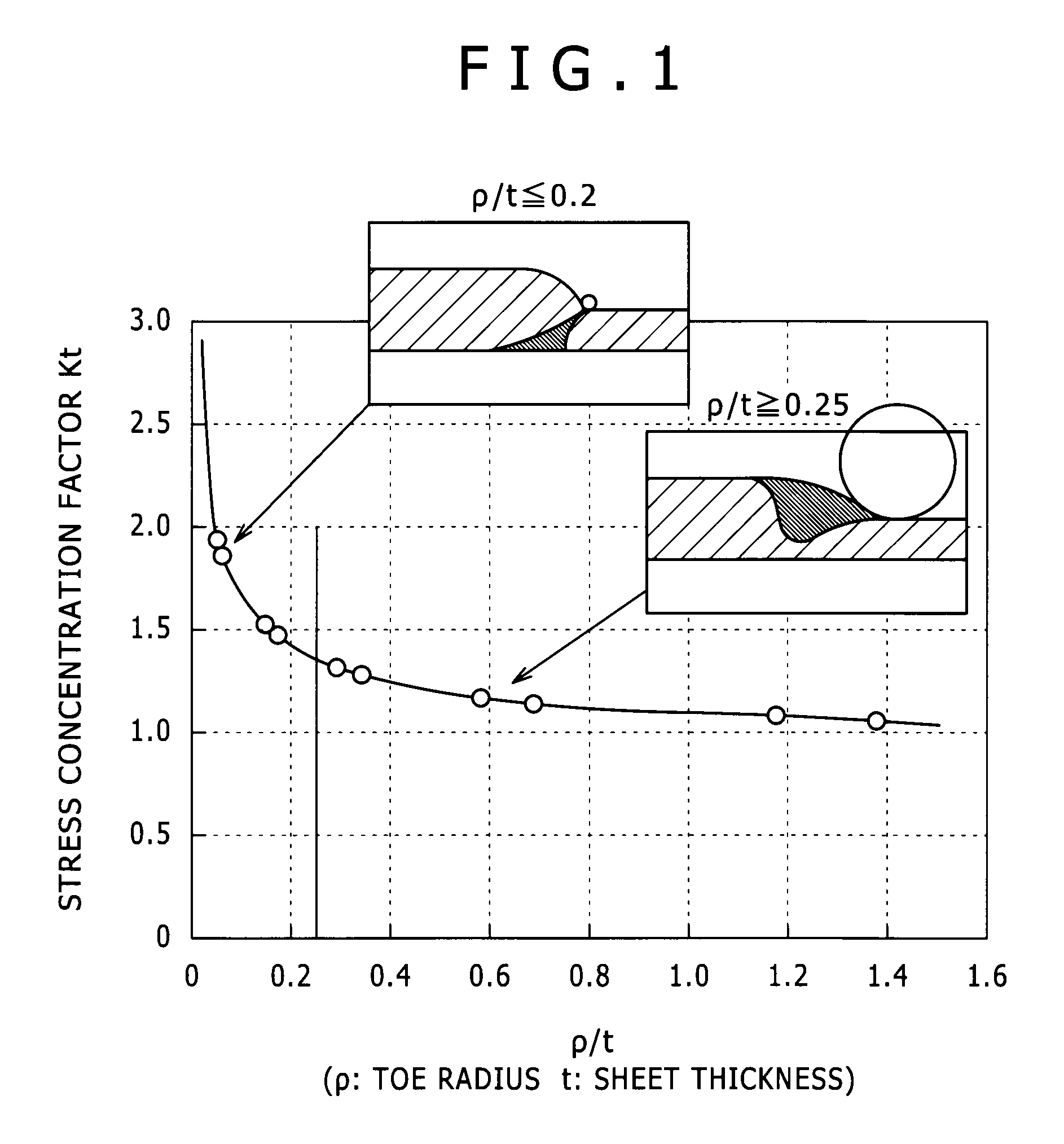

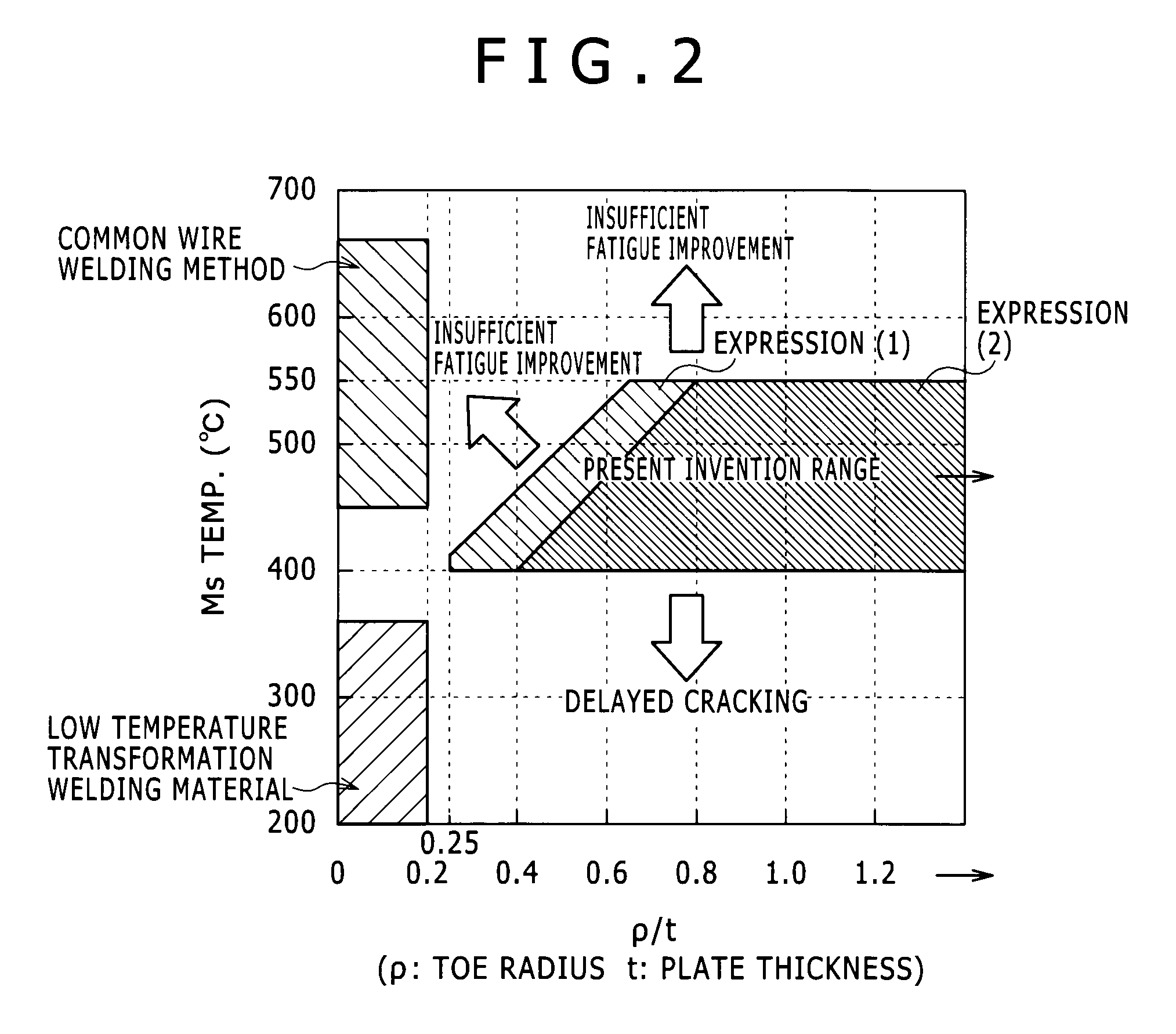

Fillet weld joint and method for gas shielded arc welding

ActiveUS20120003035A1Occurrence is suppressedArc stability is not impededArc welding apparatusFurnace typesStress concentrationMartensite transformation

A fillet weld joint of steel having high fatigue strength by improving stress concentration without excessively relying on imparting a compressive residual stress to a toe part by welding materials, free of cracking, and excellent in the toughness, and a method for gas shielded arc welding for obtaining the fillet weld joint are provided. In the fillet weld joint, a martensitic transformation starting temperature (Ms point) of a weld metal is 400° C. or above and 550° C. or below, a value obtained by dividing a toe radius ρ of a toe part of welding by a sheet thickness t of a base metal (ρ / t) is 0.25 or above, an expression belowMs(° C.)≦375×[ρ / t]+320 (1)is satisfied, and a crack defect does not exist.

Owner:KOBE STEEL LTD

Refractory casting method

ActiveUS20060070715A1Free from crackingGood physical propertiesFoundry mouldsFoundry coresFiberColloidal silica

A method of casting a refractory article. The method includes providing a mold formed from a slurry composition comprising plaster and fibers and adding a refractory composition to the mold. The method also includes allowing the refractory composition to set. The refractory composition comprises colloidal silica.

Owner:MAGNECOMETREL

Metallic extruded tube, aerosol can and method of manufacturing metallic extruded tube

InactiveUS6096376AHigh elongationFree from crackingContainers for flexible articlesLiquid spraying apparatusSpray coatingBody region

PCT No. PCT / JP97 / 00377 Sec. 371 Date Jun. 1, 1998 Sec. 102(e) Date Jun. 1, 1998 PCT Filed Feb. 13, 1997 PCT Pub. No. WO98 / 14384 PCT Pub. Date Apr. 9, 1998A collapsible metal tube, comprising: a metal body portion susceptible of plastic deformation, the body portion being sealed at one end; a shoulder portion and a mouth / neck portion connected to the other end of the body portion; and a resin film provided on the inside wall surface of the body portion, the resin film comprising a metal-adhesive thermoplastic resin layer formed by spray-coating the inside wall surface of the body portion with a dispersion of fine spherical particles consisting of a metal-adhesive thermoplastic resin and then heating to integrate the particles. The resin film formed on the inside of the collapsible metal tube is reliable because it is a dense resin film virtually devoid of pinholes, excellent in elongation at break, and free from cracking when folded or deformed, and is excellent in ability of protecting the metal body portion and the contents.

Owner:TAISEI KAKO CO LTD

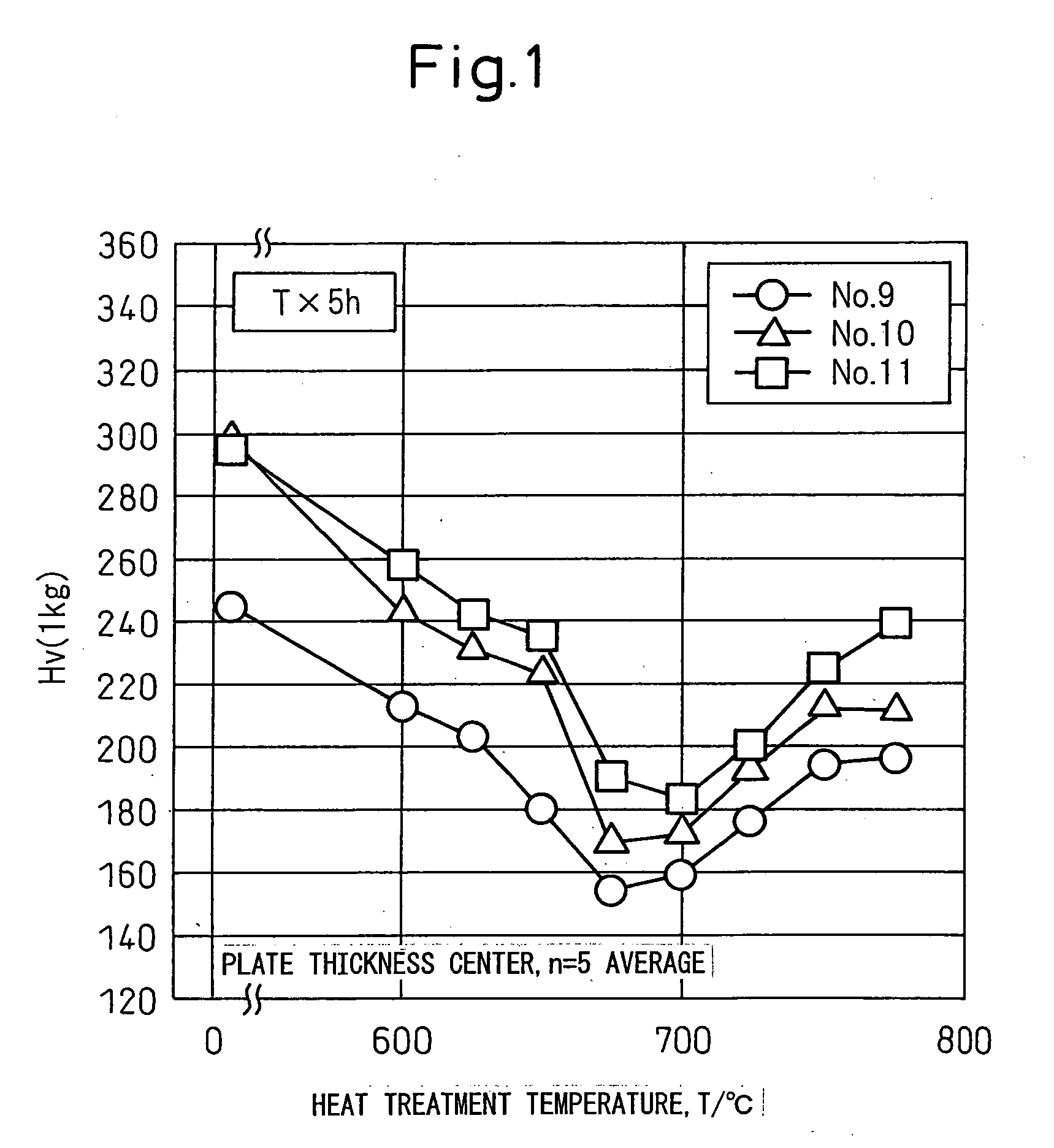

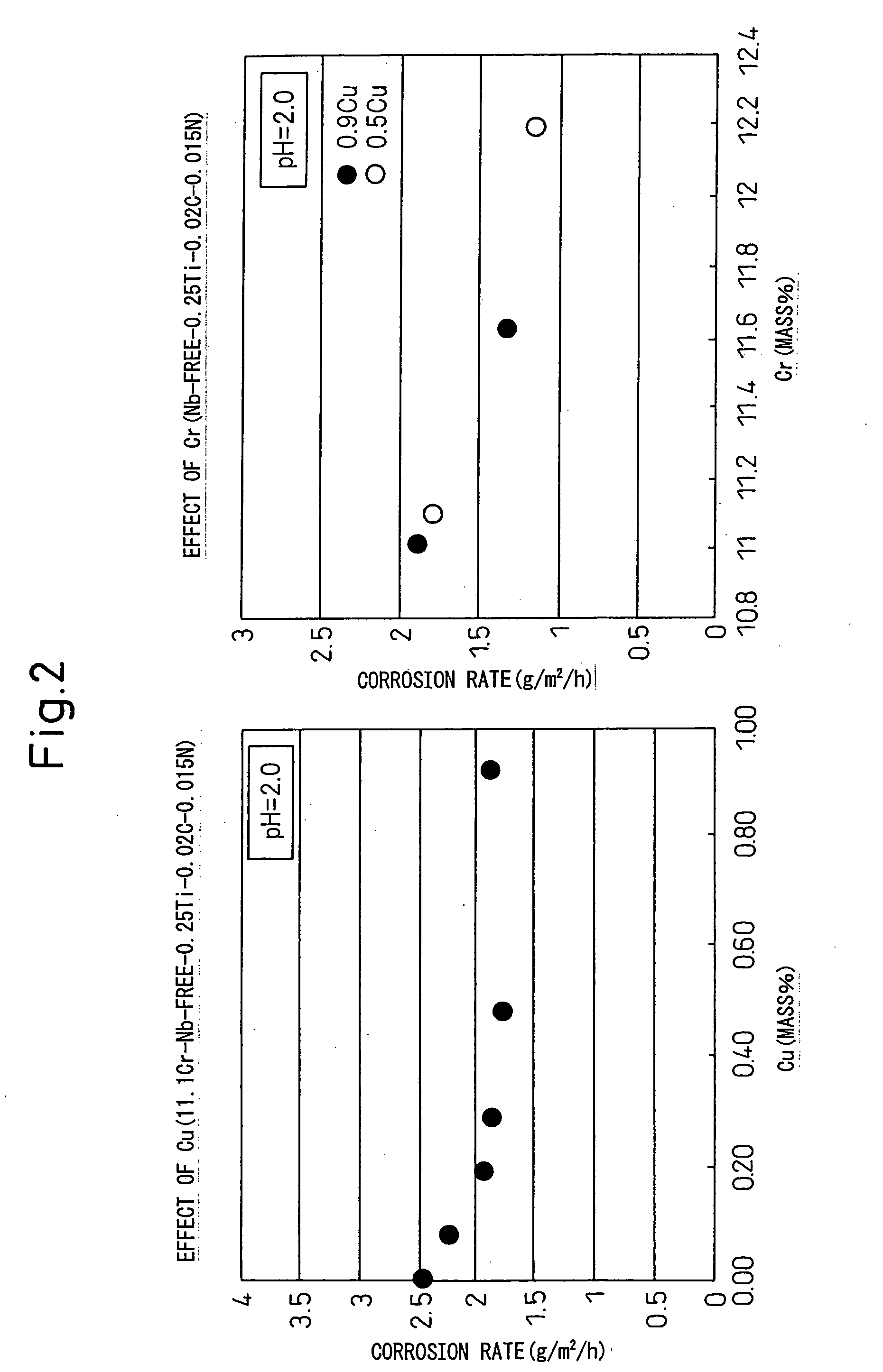

Low Chromium Stainless Steel Superior in Corrosion Resistance of Multipass Welded Heat Affected Zones and Its Method of Production

ActiveUS20090098009A1Superior manufacturabilityHigh strengthFurnace typesHeat treatment furnacesCorrosion resistantChromium

The present invention provides optimal low chromium stainless steel preventing the deterioration in corrosion resistance at the weld zone in the case of multipass welding, superior in grain boundary corrosion resistance of the weld zone even in a harsh corrosive environment, simultaneously free from preferential corrosion at the heat affected zones near weld fusion lines, and further superior in manufacturability, that is, low chromium stainless steel containing, by mass %, C: 0.03% or less, N: 0.004 to 0.02%, Si: 0.2 to 1%, Mn: over 1.5 to 2.5%, P: 0.04% or less, S: 0.03% or less, Cr: 10 to 15%, Ni: 0.2 to 3.0%, and Al: 0.005 to 0.1%, further containing Ti: 4×(C %+N %) to 0.35%, and having a balance of Fe and unavoidable impurities, having a γp(%) expressed by a predetermined formula satisfying 80 or more, and satisfying Ti %×N %<0.004 as well.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

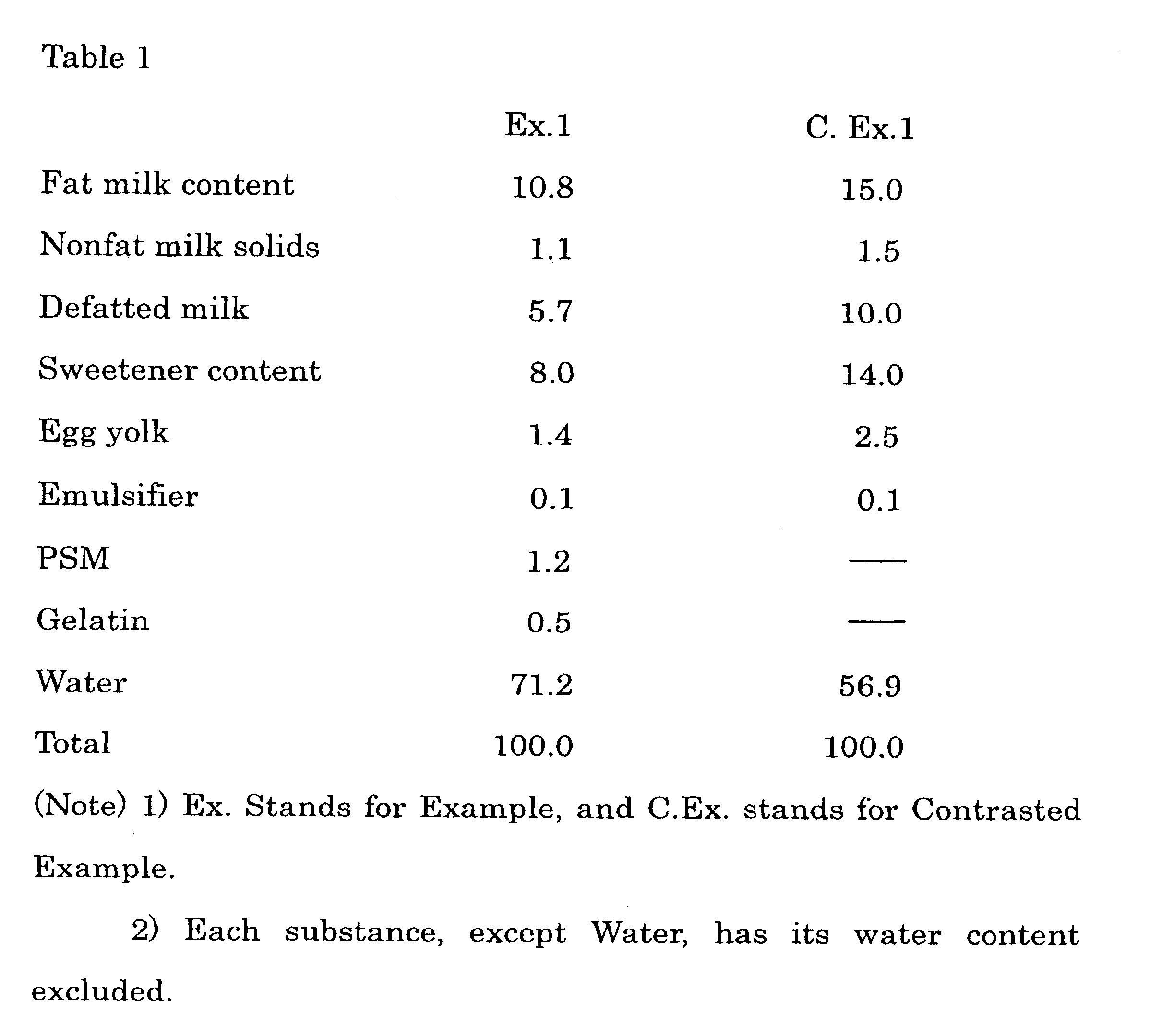

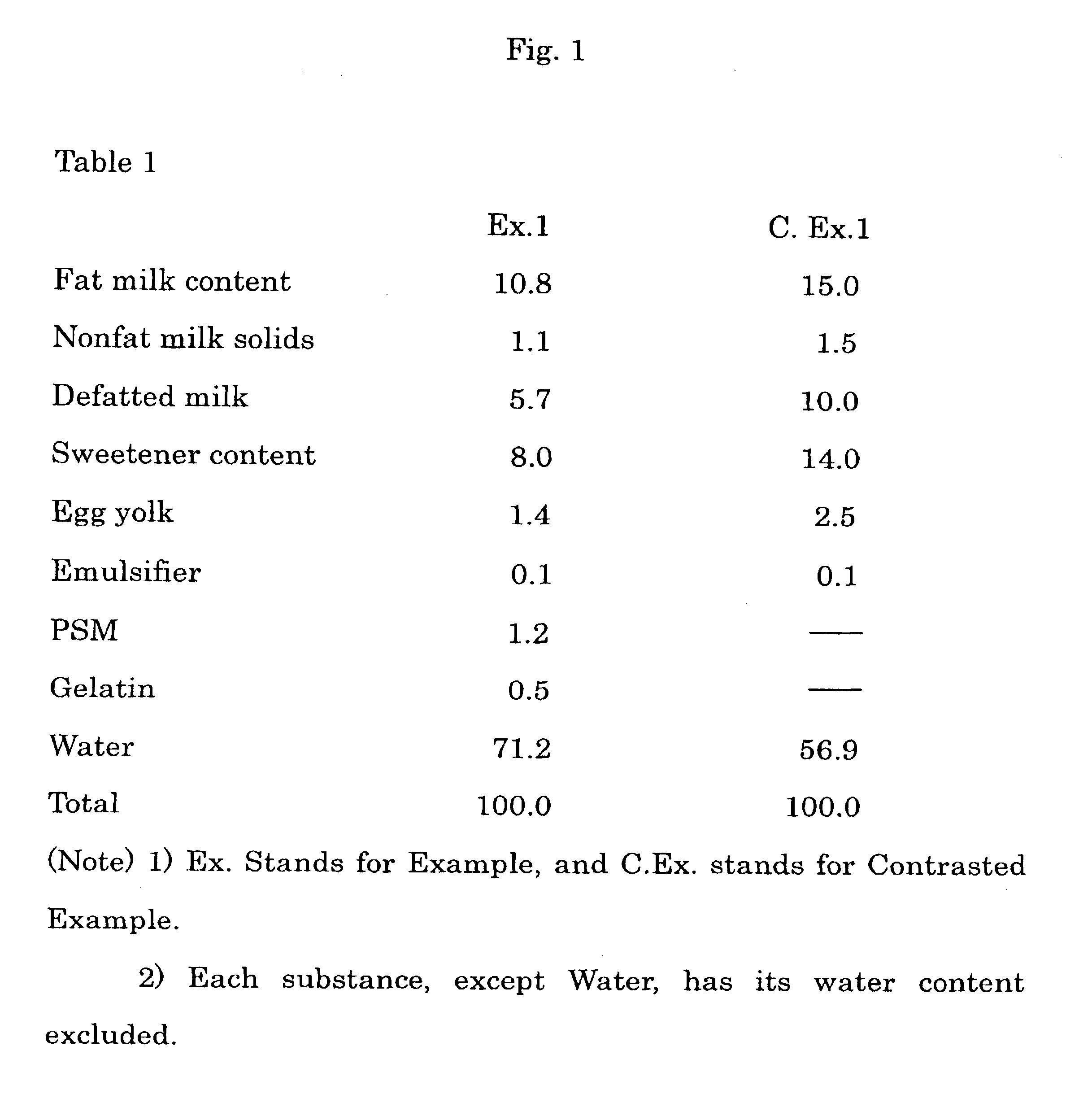

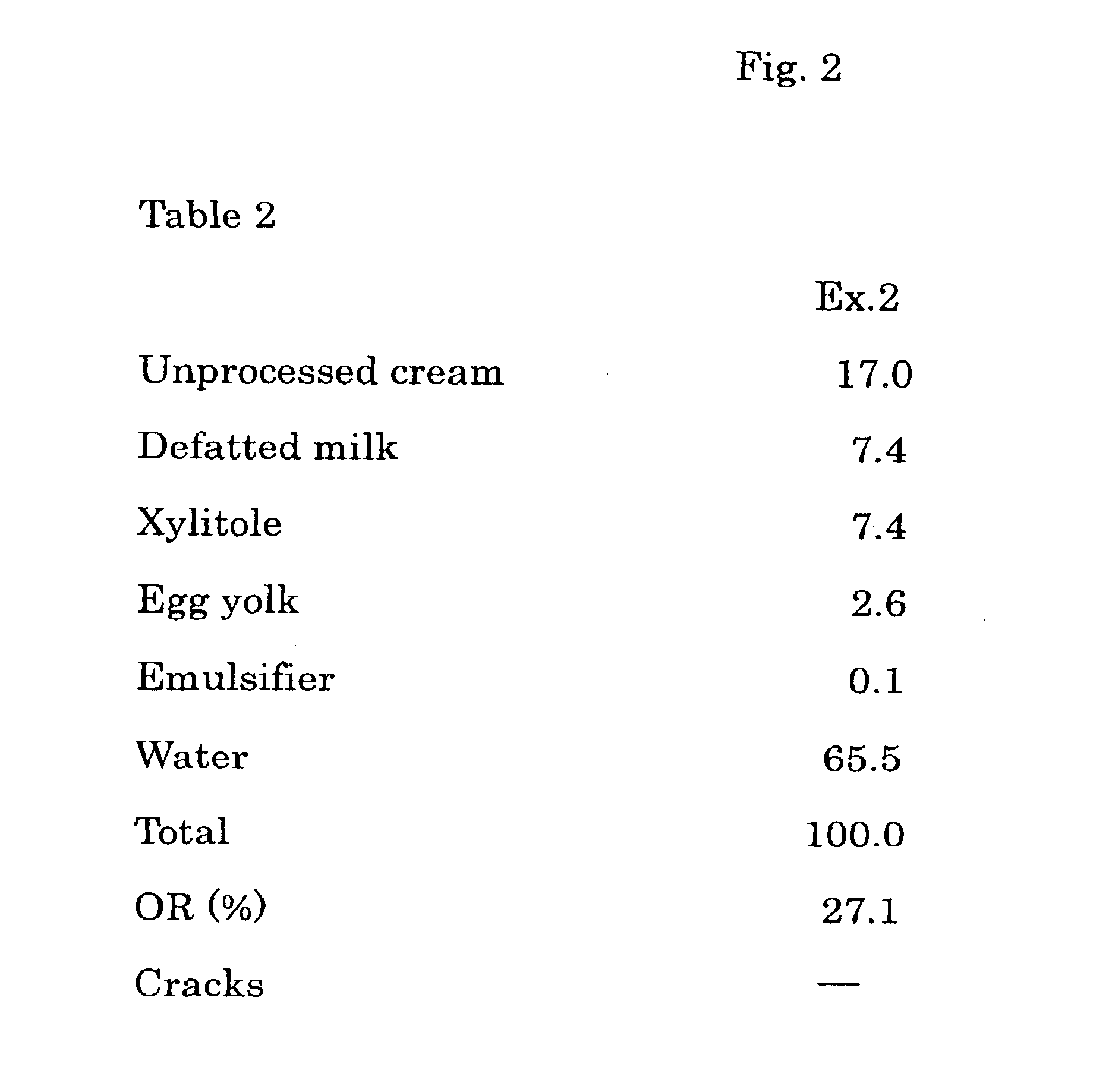

Dehydrated frozen confections

InactiveUS6916498B2Shape stableOvercome difficultiesFrozen sweetsConfectioneryMANNITOL/SORBITOLInulin

A dehydrated frozen confection obtained by freezing and then freeze-drying a starting material containing a milk content and a sweetener content, wherein at least 20% wt of the sweetener content is sugar-alcohol; preferably, the sugar-alcohol is one or more selected from the group consisting of erythritol, xylitol, sorbitol, and mannitol. The frozen confection may also include inulin.

Owner:ASAHI GRP FOODS LTD

Method for the determination of the stresses occurring in wood when drying

InactiveUS7814799B2Improve accuracyQuality improvementDrying using combination processesAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic emissionSpectroscopy methods

The present invention relates to a method for the determination of the stresses occurring in wood when drying or being dried. With the method in accordance with the invention, electrodes are used to generate an electric field in drying wood in order to measure the electric complex spectrum using the impedance spectroscopy method while at the same time employing sensors to measure acoustic emissions from drying wood and using the results for calculating the parameters required for determining the stress state existing in the wood and for monitoring and / or controlling the drying process.

Owner:KORWENSUUN KONETEHDAS

Fillet weld joint and method for gas shielded arc welding

ActiveUS9457416B2Improve fatigue strengthFree from crackingArc welding apparatusFurnace typesFillet weldMetallurgy

Owner:KOBE STEEL LTD

Inkjet receiver media

InactiveUS7152973B2Reduce probabilityEnhanced light scatteringDuplicating/marking methodsCoatingsPorous substrateWater insoluble

A receiver medium for inkjet printing includes a porous substrate, having on at least one surface thereof a porous ink-absorbent coating having a colloidal particulate material, a water-insoluble liner binder polymer, and optionally a film forming polymer dispersion. On printing, the medium rapidly absorbs ink to give a touch-dry surface. The receiver medium can also have a satin finish surface. Also disclosed is a method of making the receiver medium.

Owner:AKZO NOBEL NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com