Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Excellent performance balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

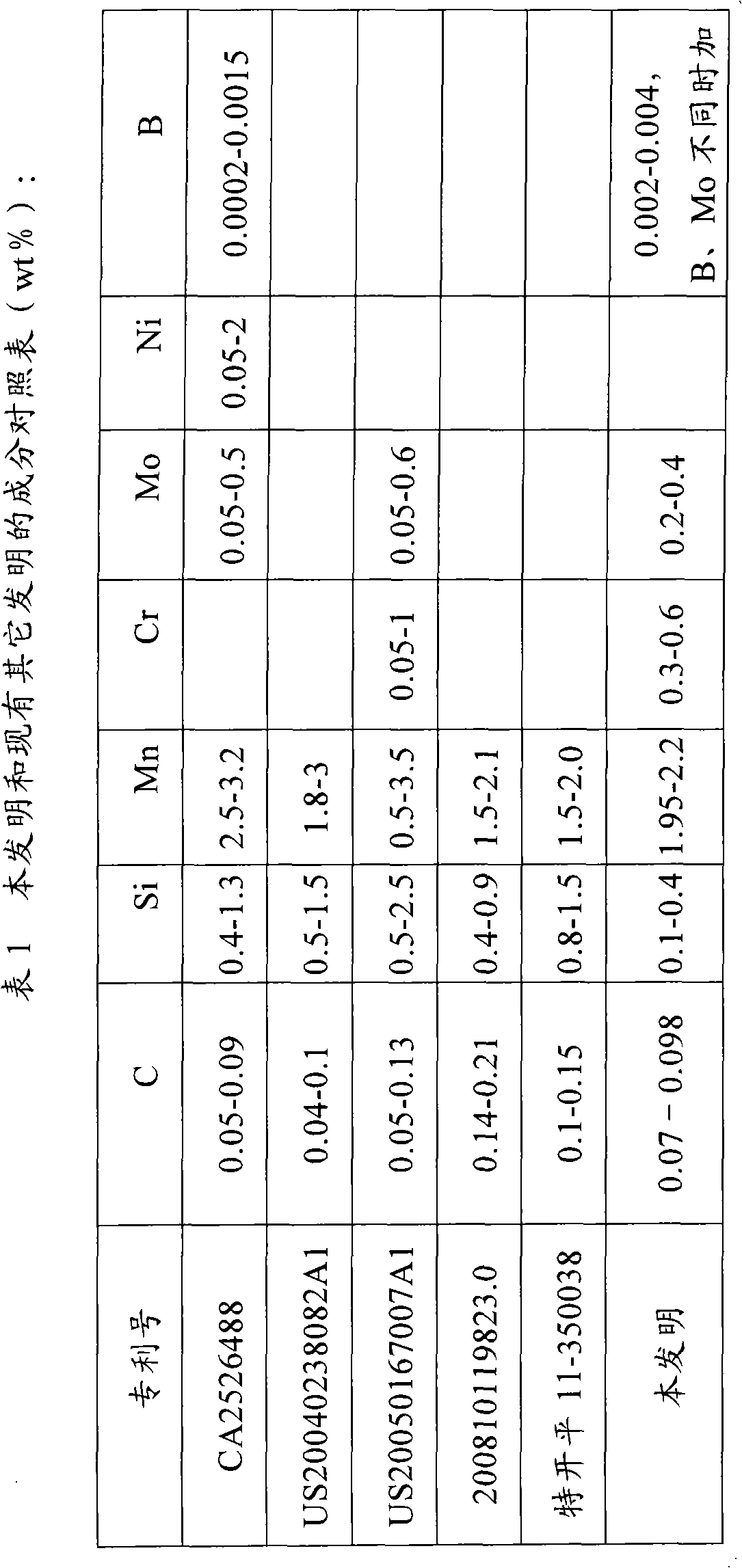

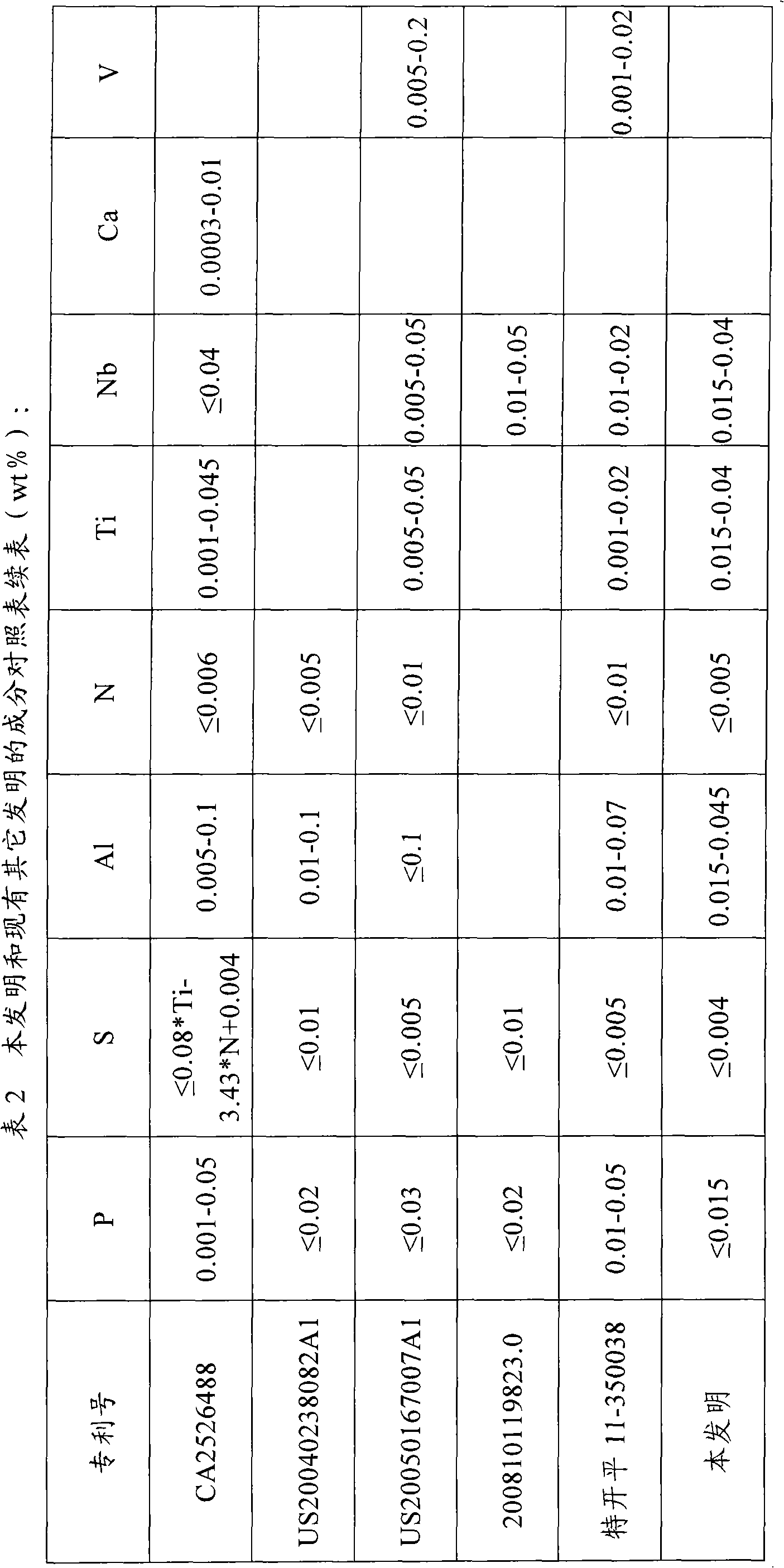

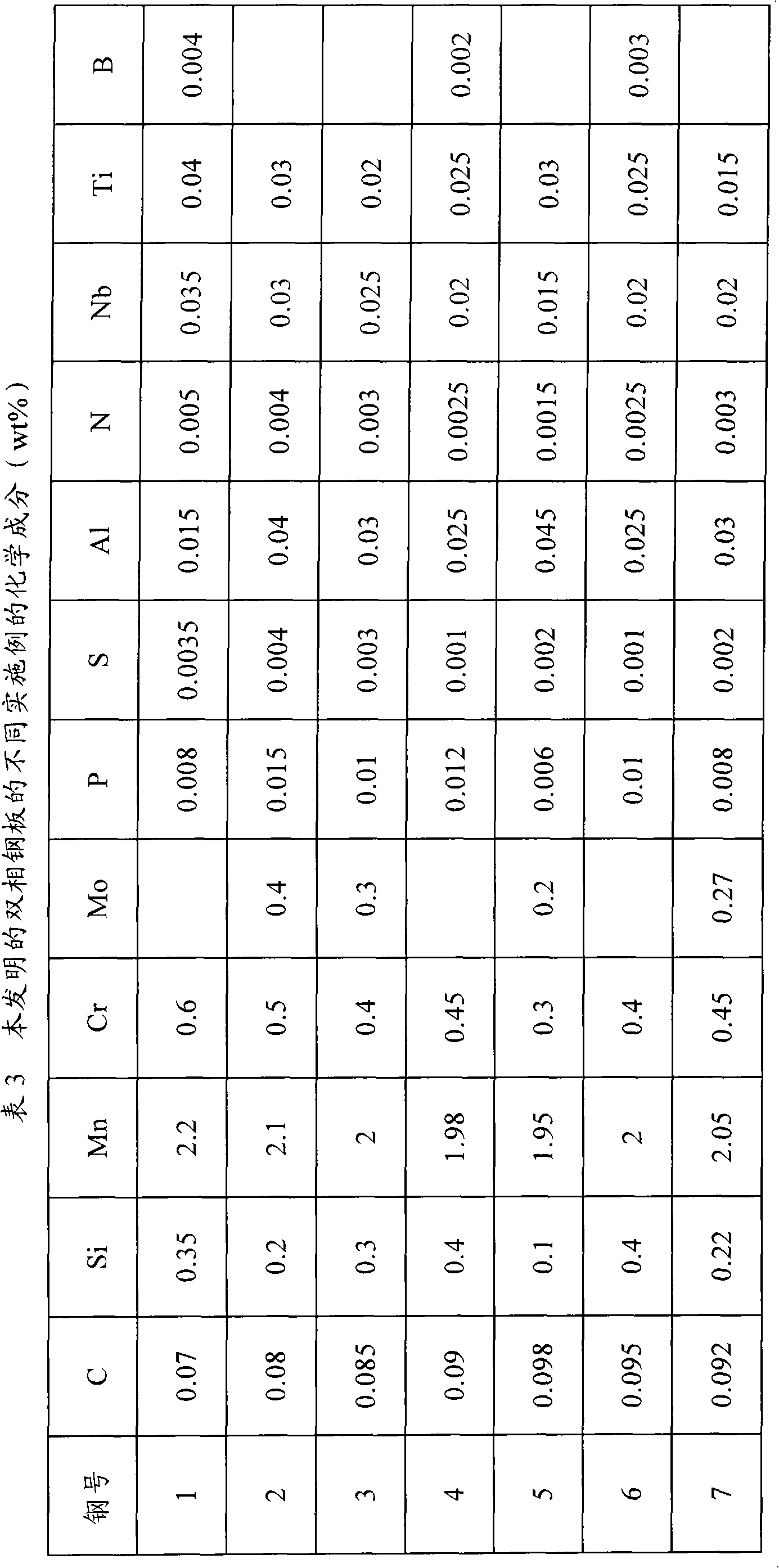

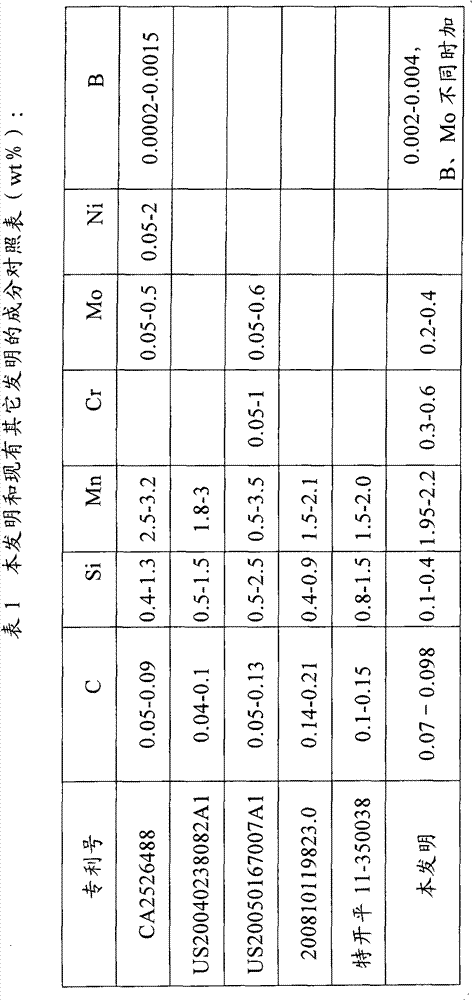

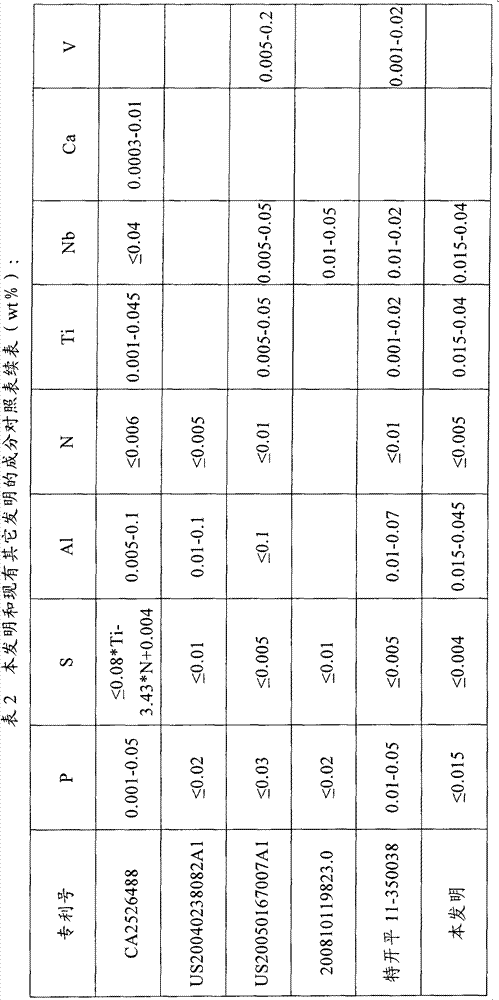

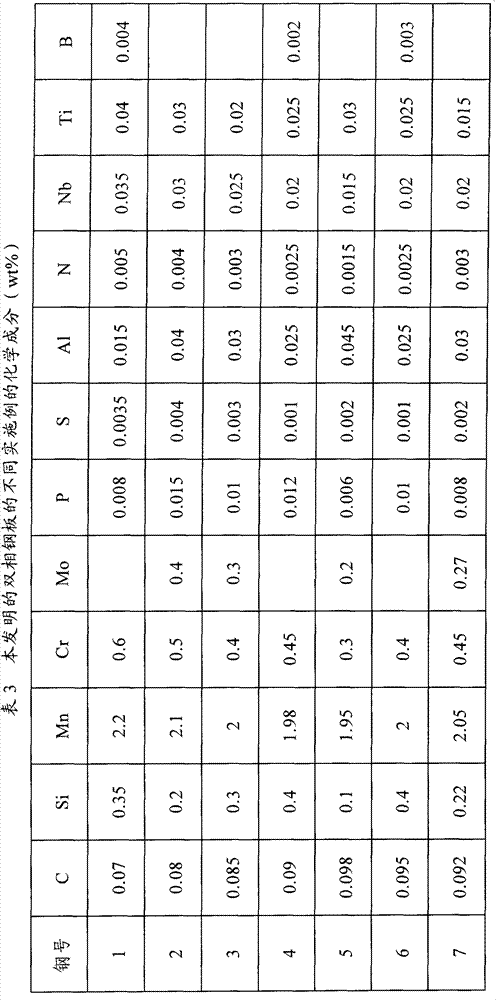

Double-phase steel plate and manufacturing method thereof

ActiveCN102586688AReduce the degree of enrichmentReduce defects such as red rustManufacturing technologyDouble phase

The invention provides a double-phase steel plate which comprises 0.07-0.098 of C, 0.1-0.4 of Si, 1.95-2.2 of Mn, 0.3-0.6 of Cr, less than or equal to 0.015 of P, less than or equal to 0.004 of S, less than or equal to 0.005 of N, 0.015-0.04 of Nb, 0.015-0.04 of Ti, 0.015-0.045 of Al, and 0.002-0.004 of B or 0.2-0.4 or Mo, wherein Pcm equals to C+Si / 30+Mn / 20+2P+4S which is less than or equals to 0.24; and the double-phase steel plate also comprises the balance of Fe and unavoidable impurities. The invention also provides a manufacturing method of the double-phase steel plate. The high-strength uniform-performance double-phase steel plate can be obtained by the proper composition design and manufacturing technology, and the manufacturing requirements on parts of a high-strength automobile body can be better met.

Owner:BAOSHAN IRON & STEEL CO LTD

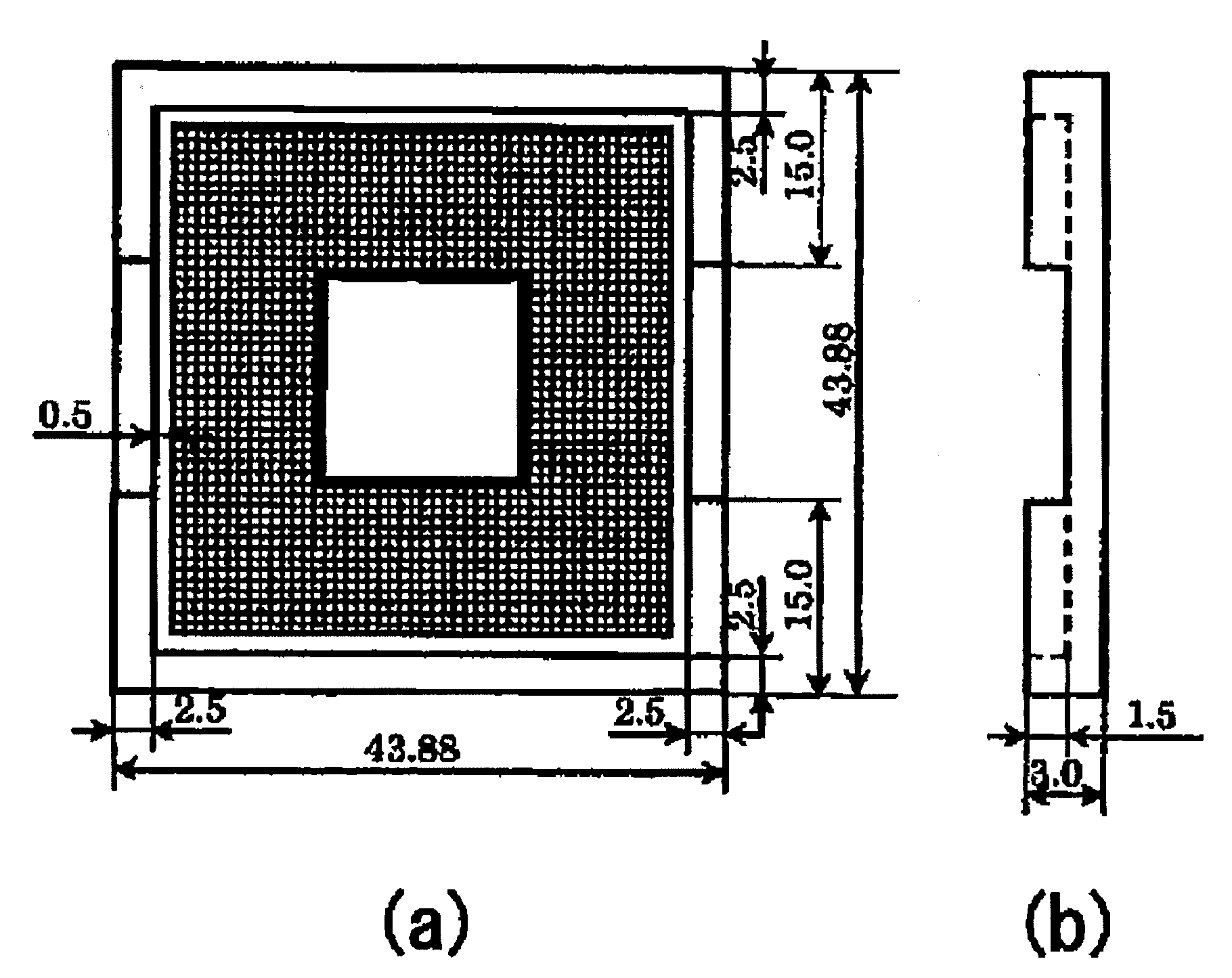

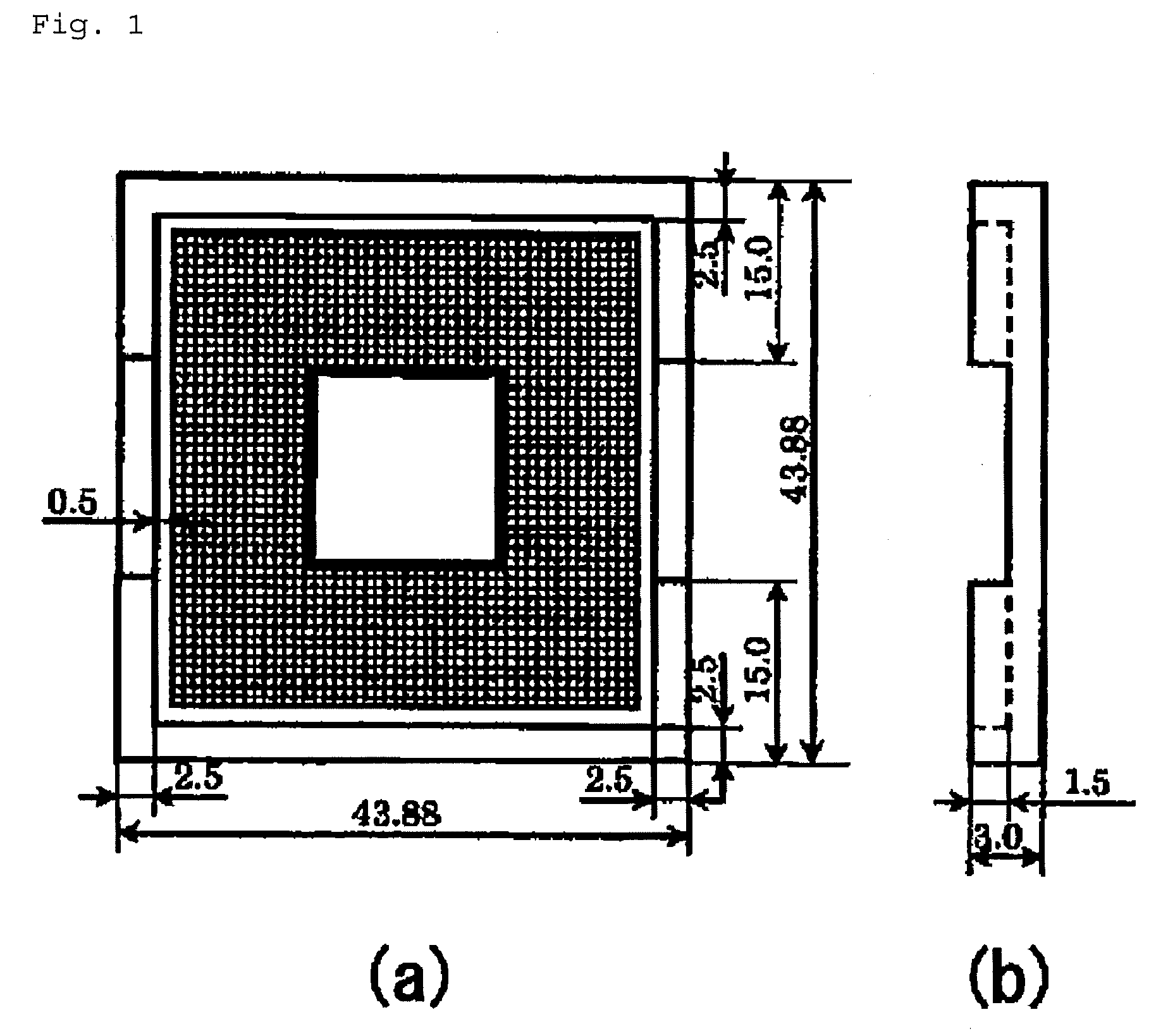

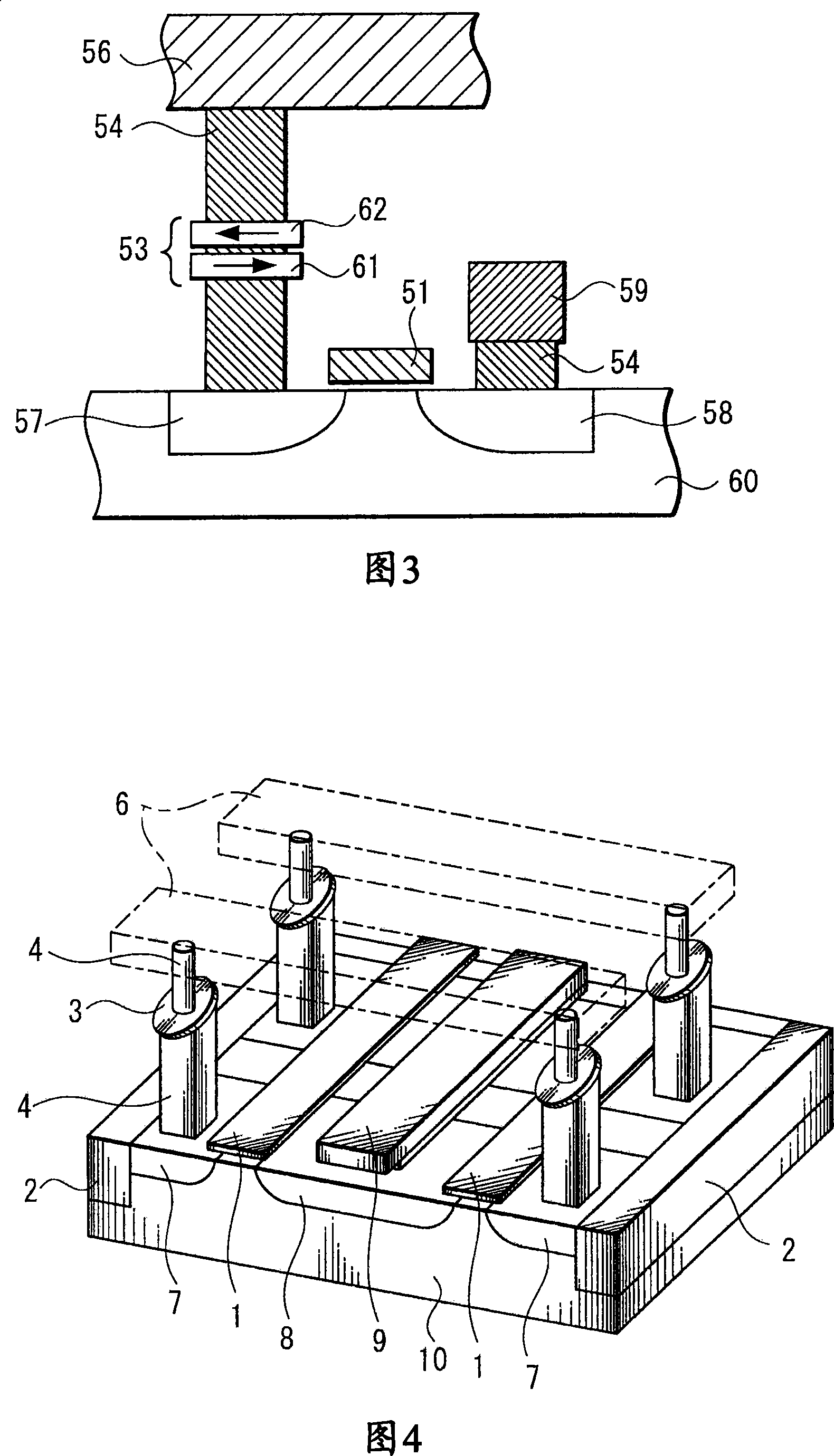

Asymmetric electronic parts

InactiveUS7980897B2Improve mechanical propertiesReduce warpageLiquid crystal compositionsSecuring/insulating coupling contact membersLiquid crystallineHeat resistance

Provided is a material capable of forming a molded product which has good mechanical properties with low warpage while being excellent in any of the performance including heat resistance and flowability, even if the molded product is an asymmetric electronic parts. Specifically, the asymmetric electronic parts is prepared by molding a liquid crystalline polymer composition comprising (A) a fibrous filler having an average fiber diameter within the range of 5 to 30 μm, having a weight average fiber length within the range of 250 to 350 μm, excluding 10 μm or shorter fiber length, and having a content of a fibrous filler being 700 μm or longer within the range of 5% by weight or less; and (B) a plate-like filler having an average particle size within the range of 0.5 to 200 μm, the total filling amount of (A) and (B) components in the composition being within the range of 40 to 60% by weight, the weight ratio of (A) component being within the range of 10 to 20% by weight, the weight ratio of (B) component being within the range of 30 to 40% by weight, the molded product having no symmetry in any of the axial plane XY, the axial plane YZ, and the axial plane XZ of the molded product.

Owner:POLYPLASTICS CO LTD

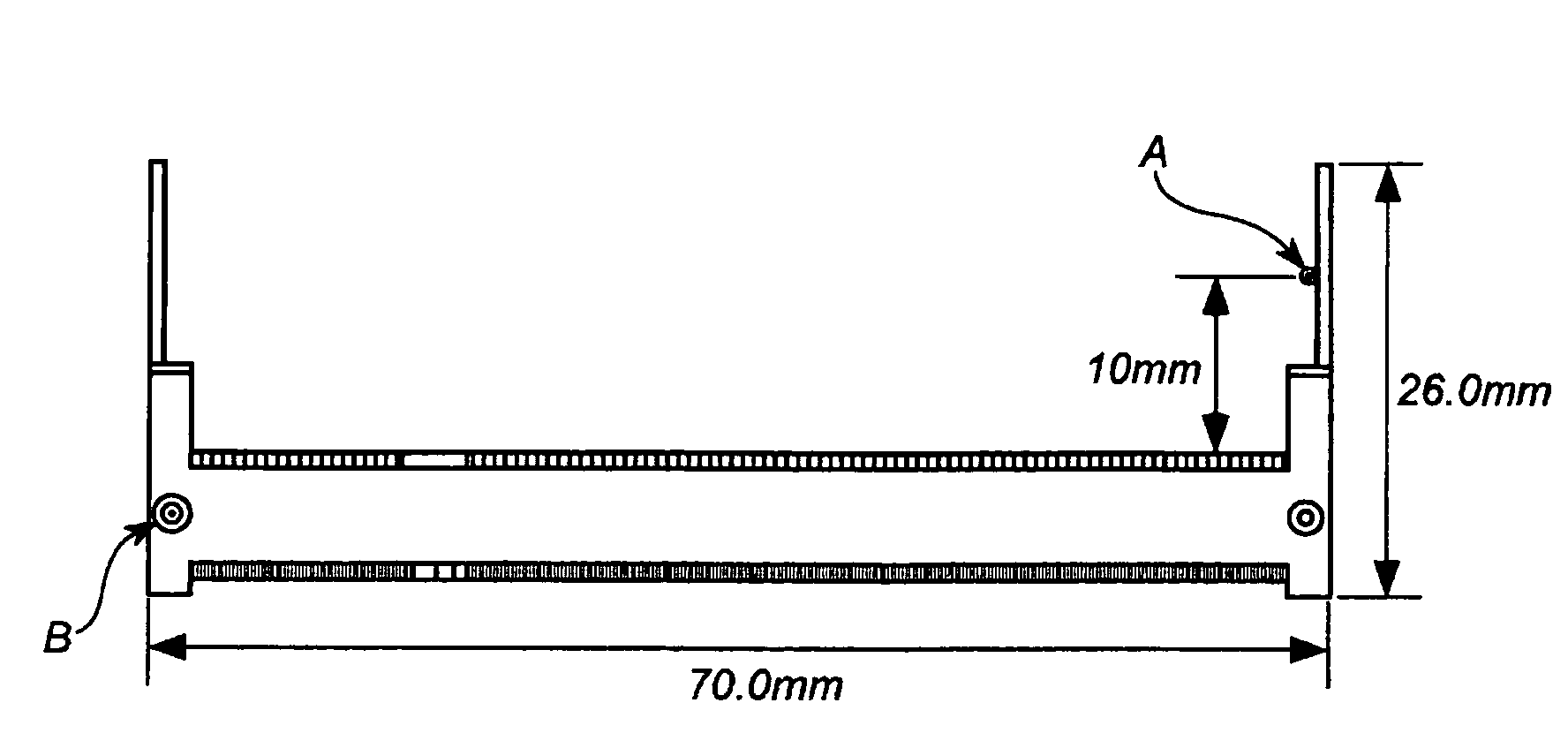

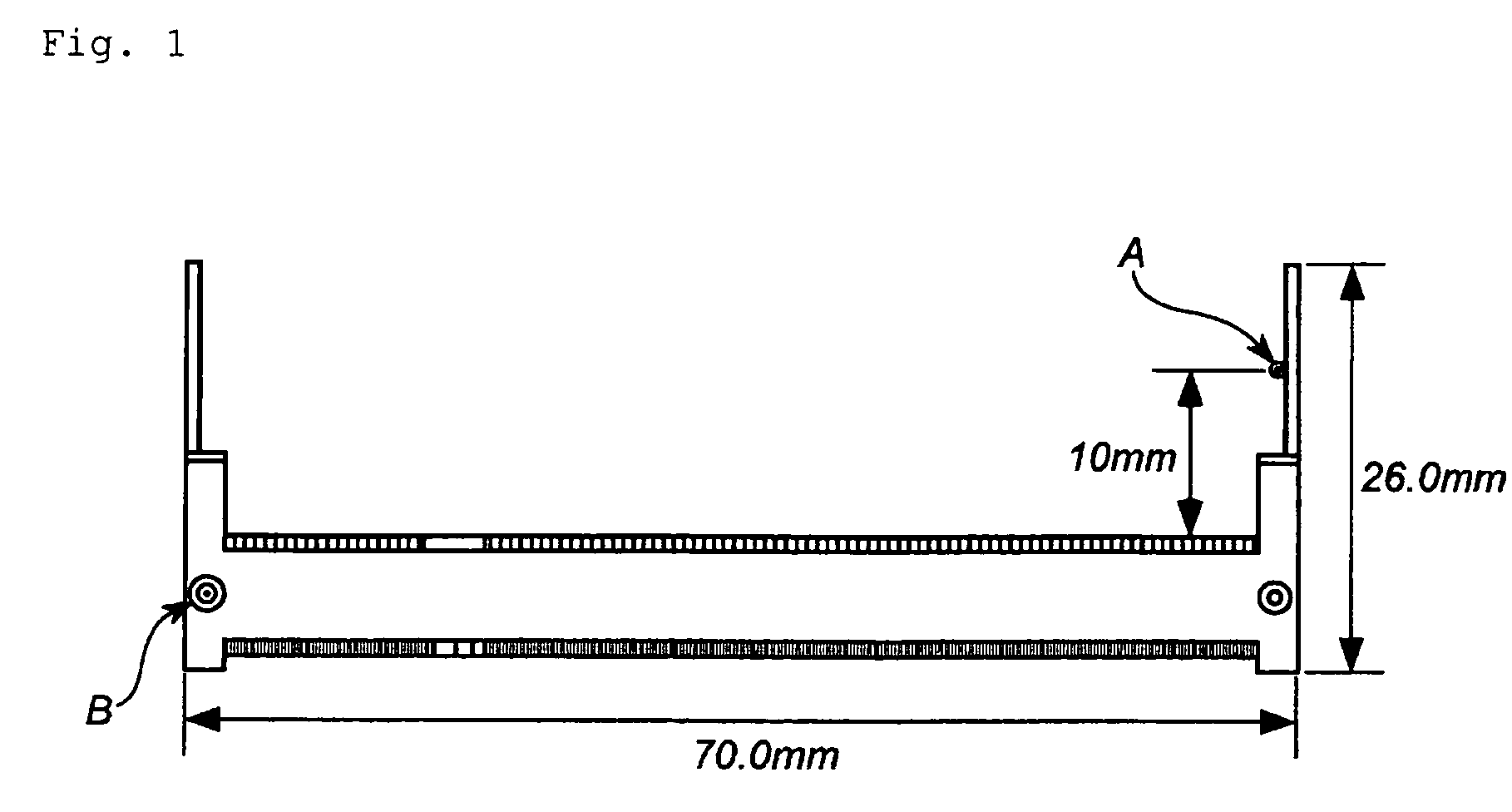

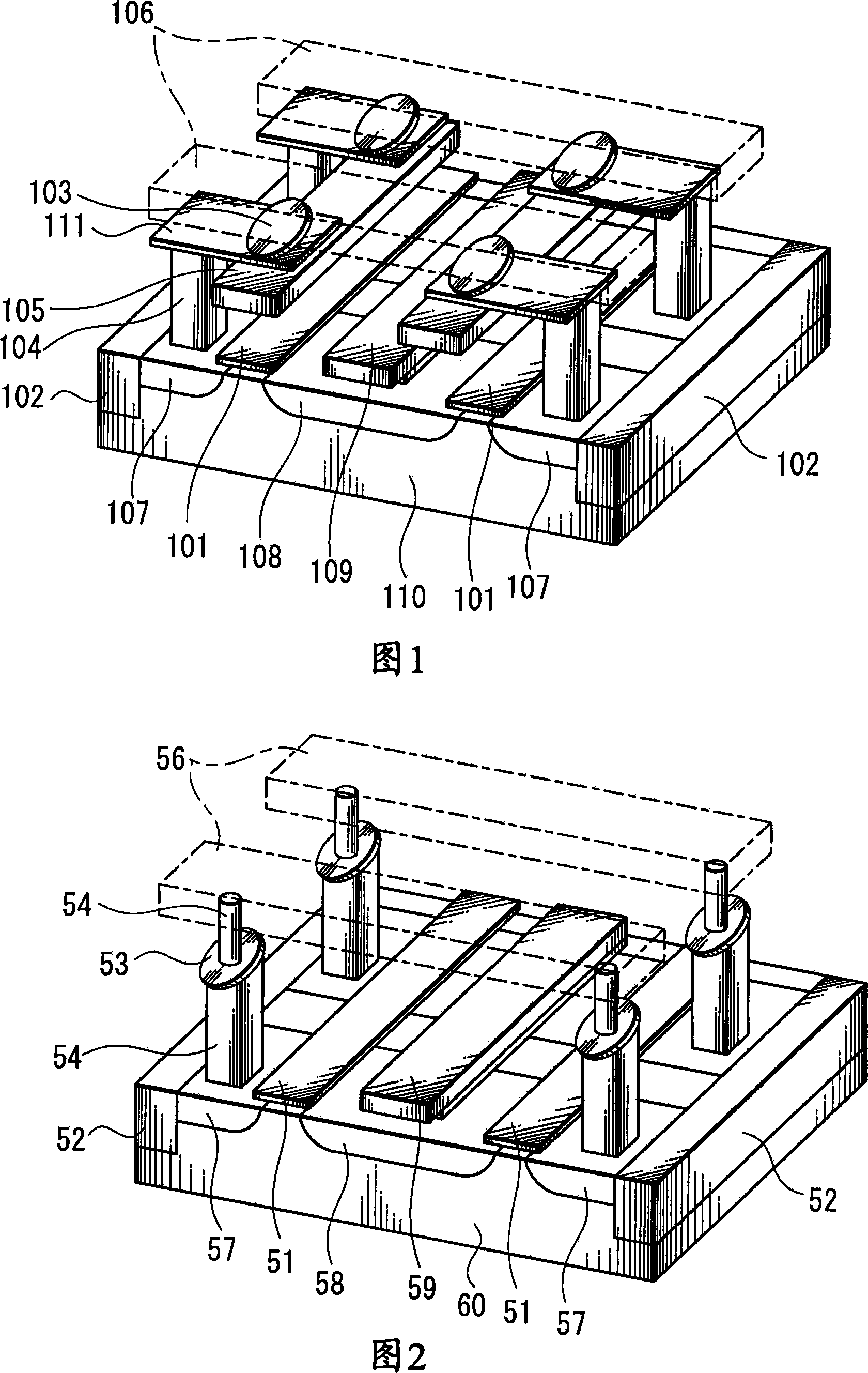

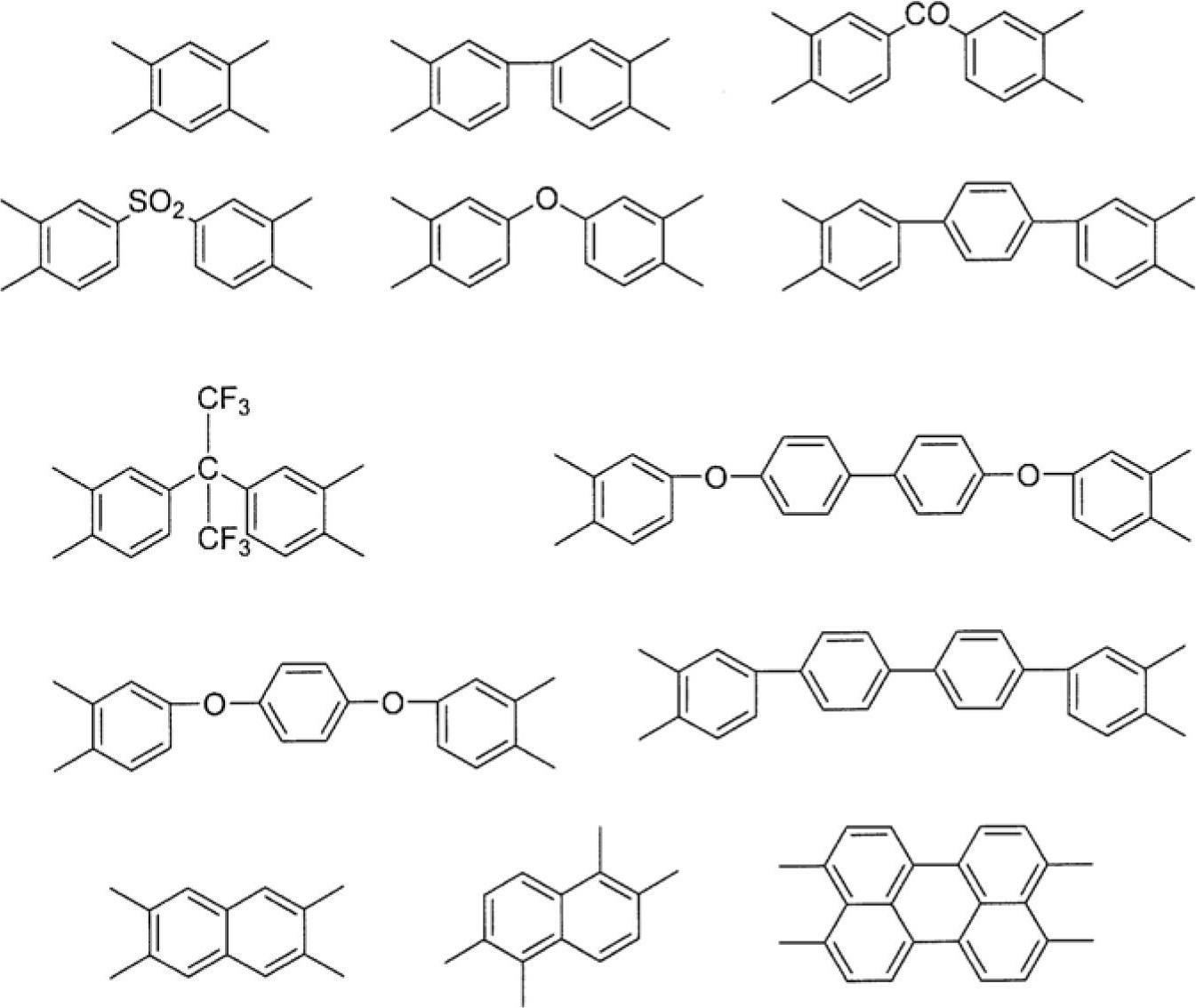

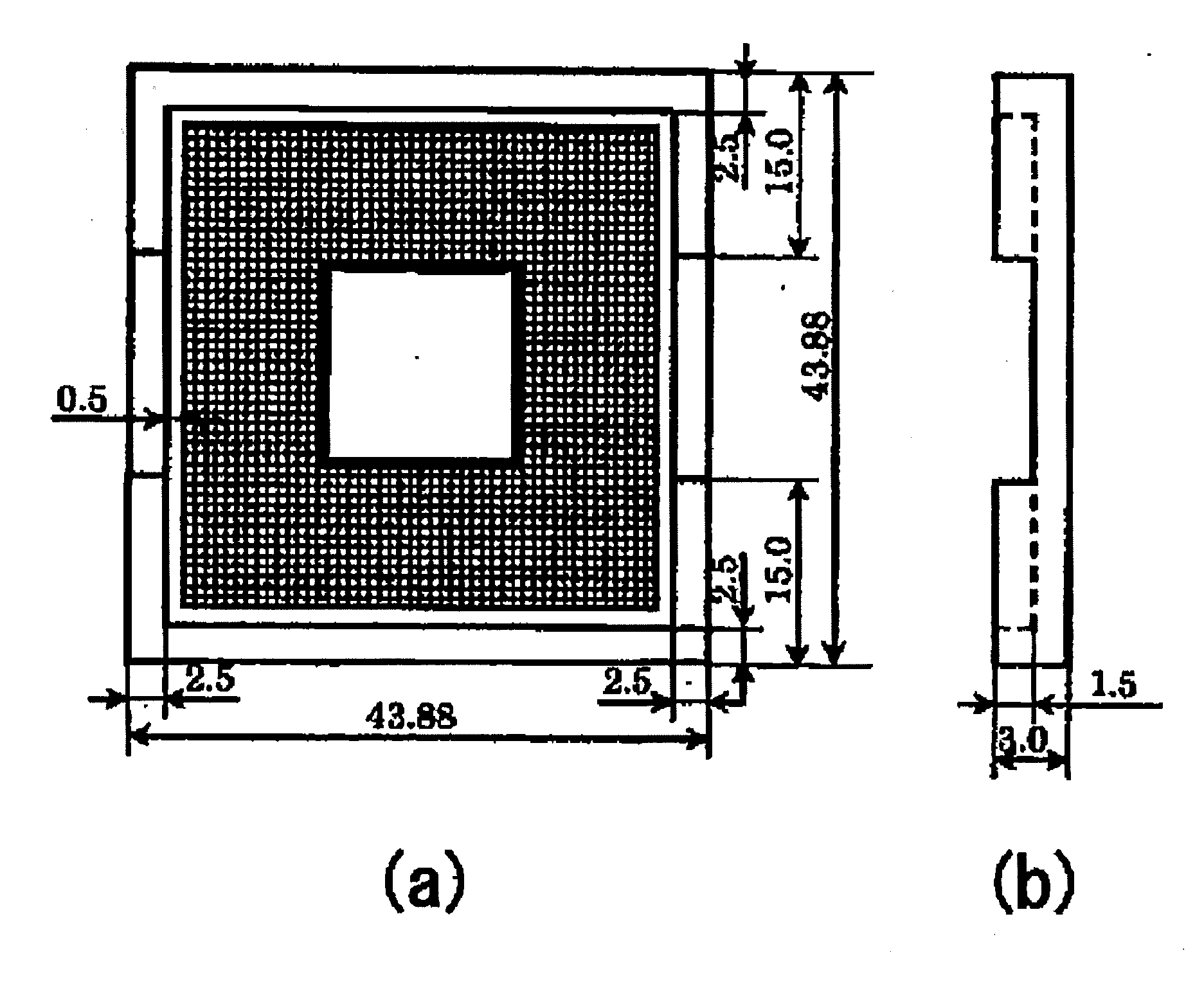

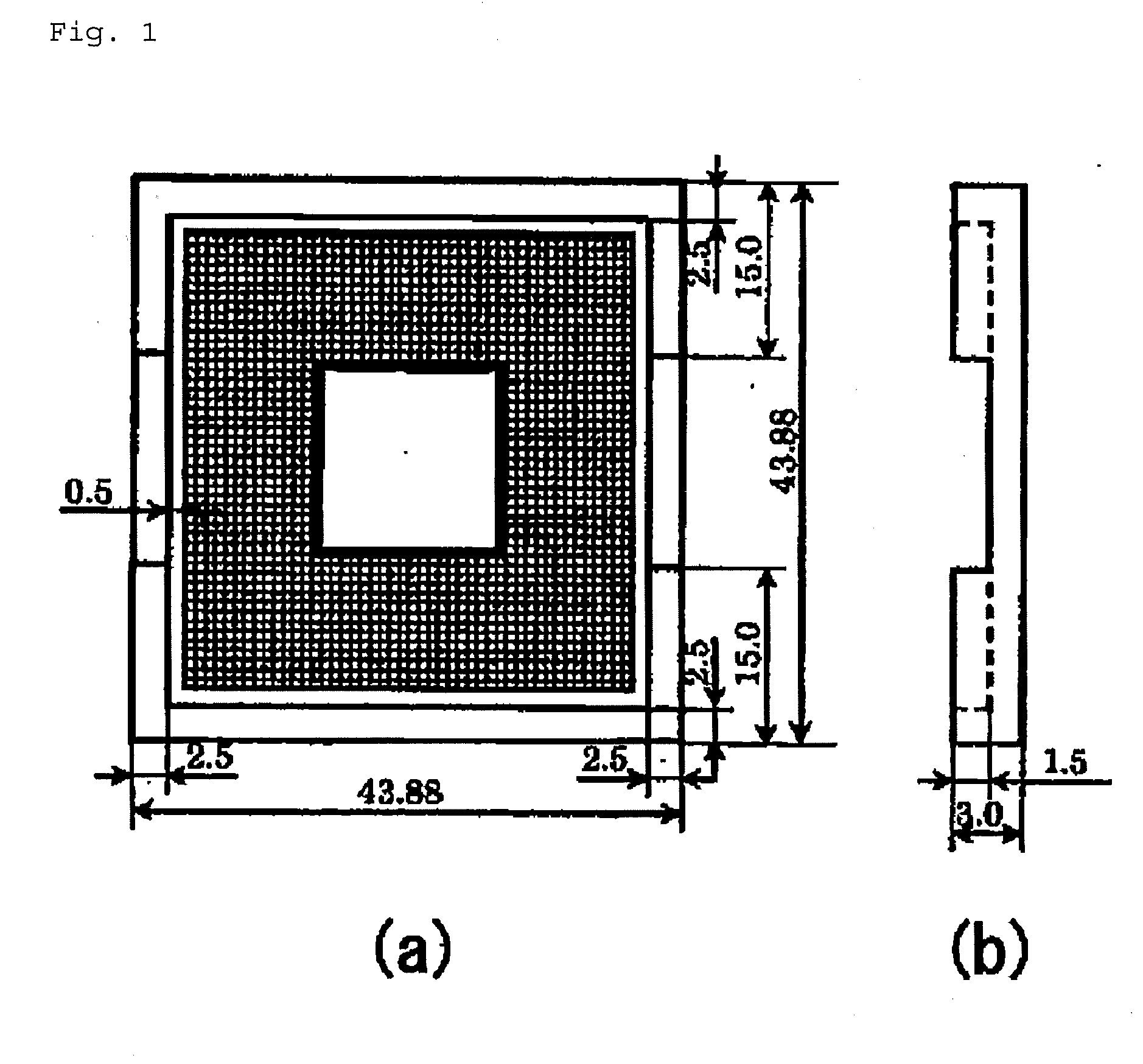

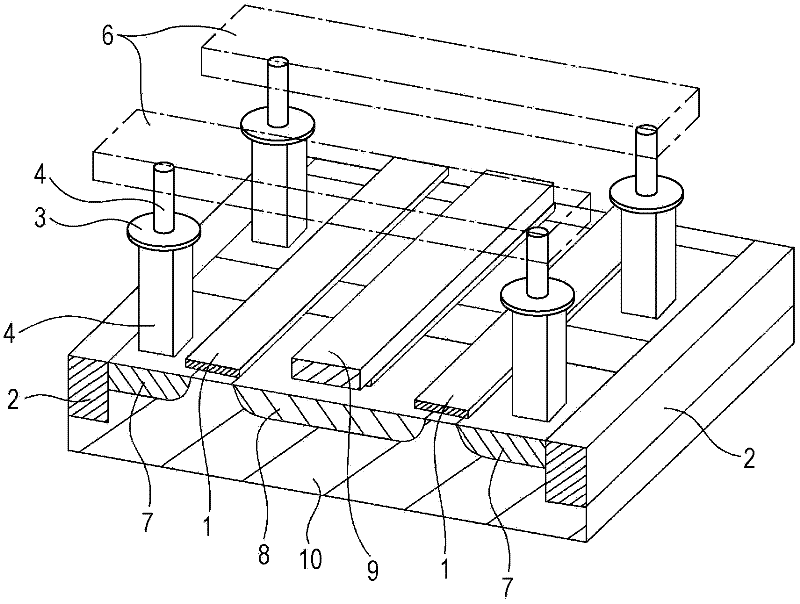

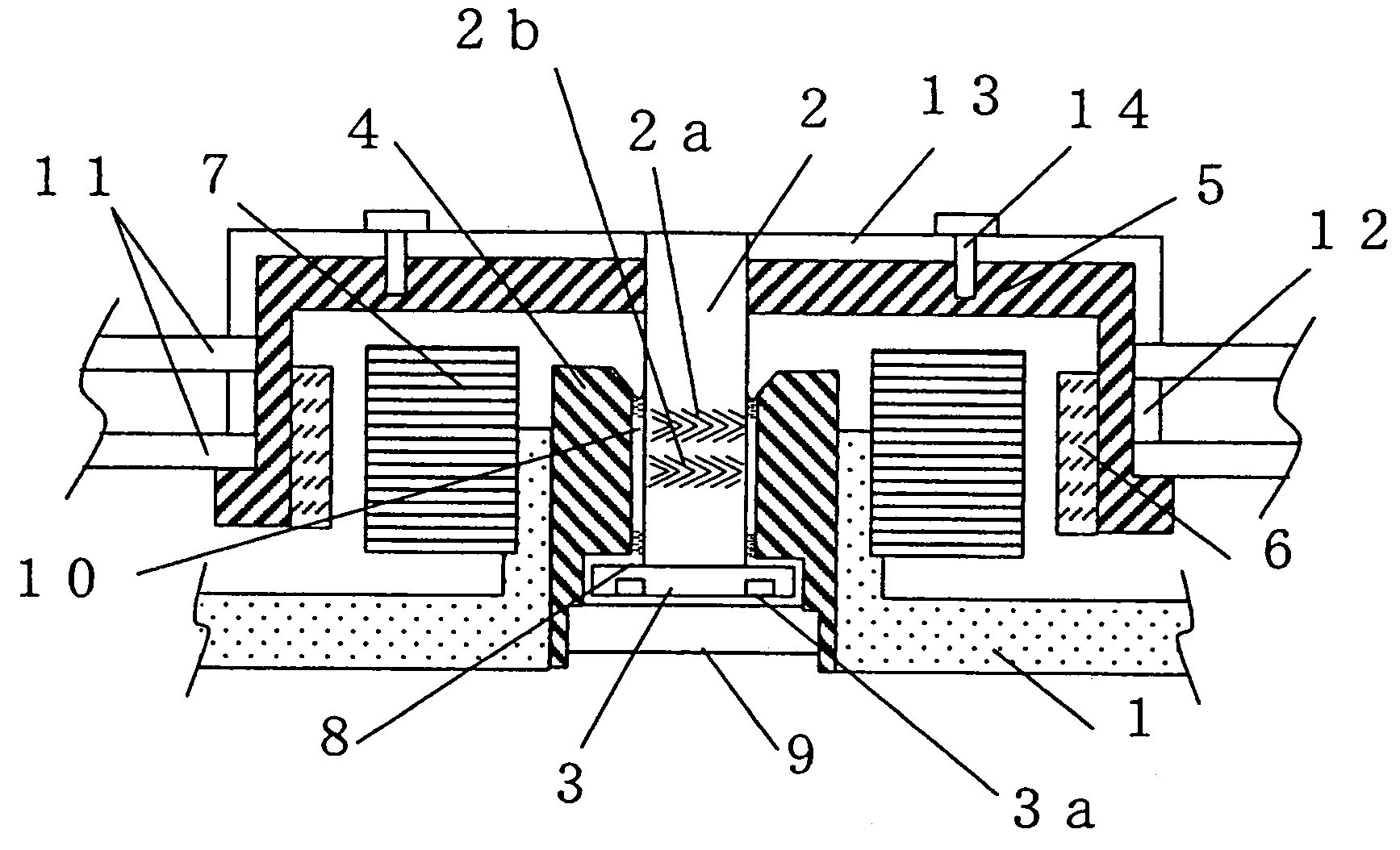

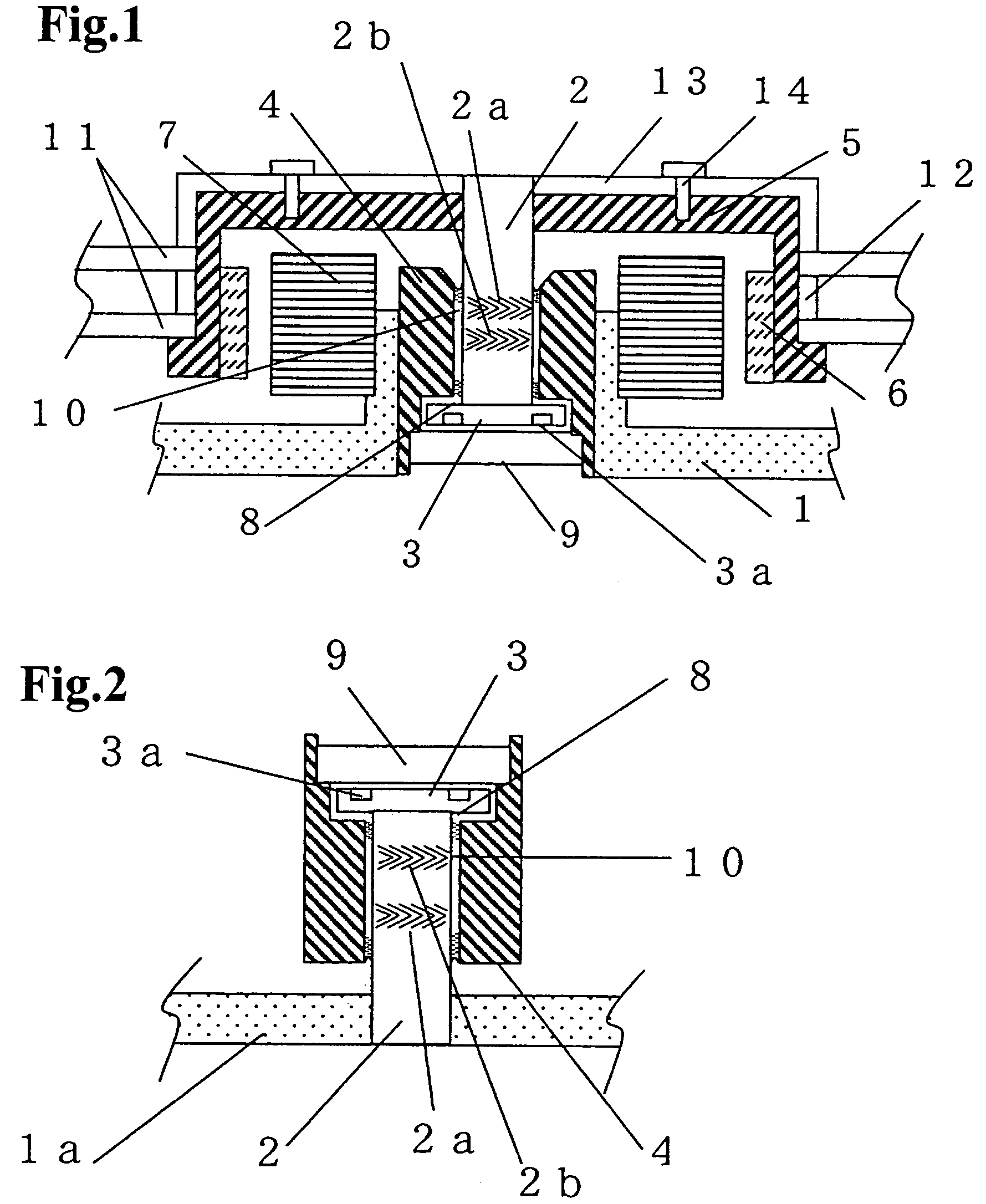

Planar connector

InactiveUS8272879B2Excellent performance balanceImprove performanceLiquid crystal compositionsPlastic/resin/waxes insulatorsLiquid crystallineBenzoic acid

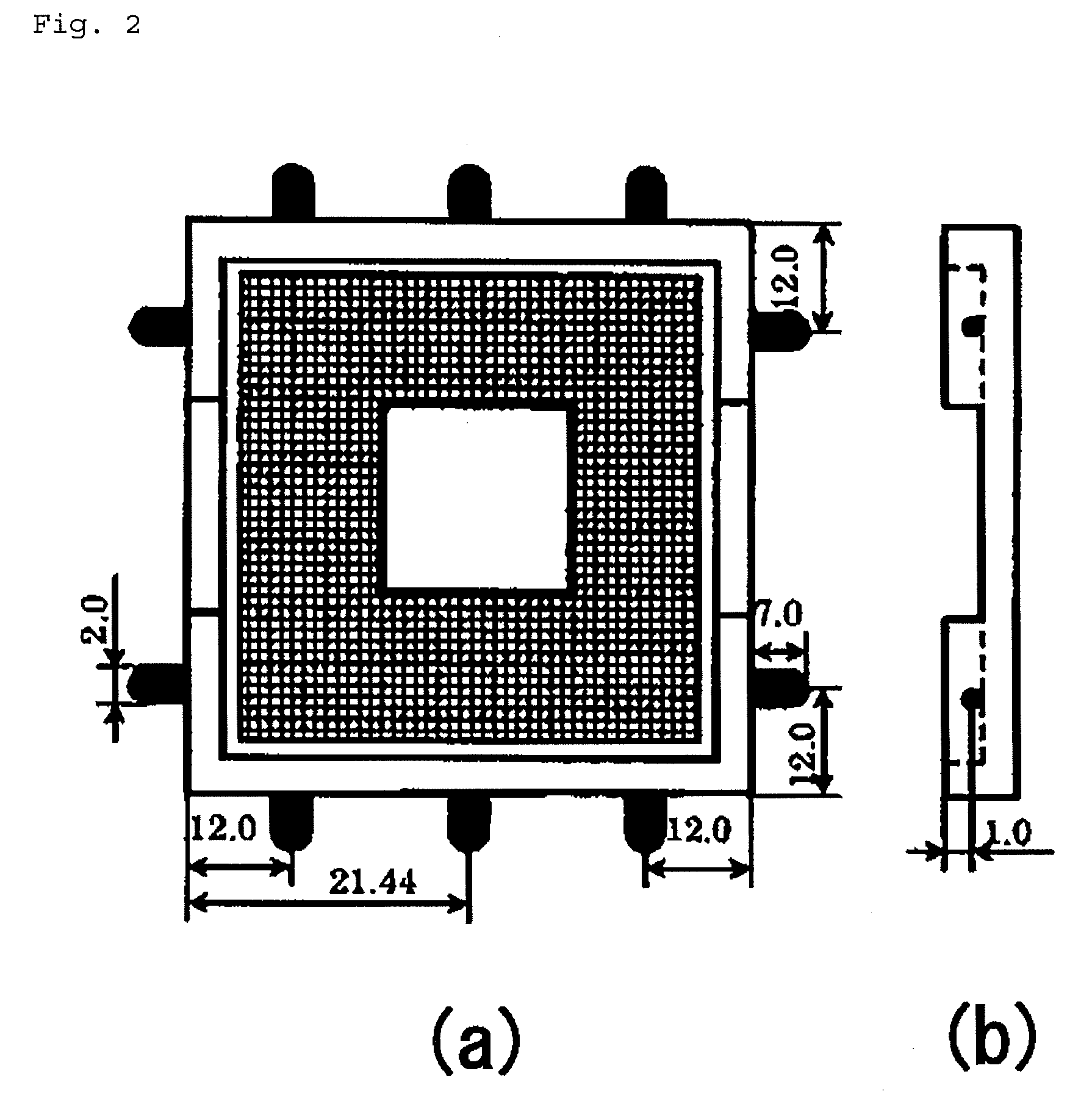

The present invention provides a planar connector having excellent performances including flatness, warp-deformation resistance, and heat resistance, being capable of responding to shape changes in recent planar connectors. Specifically, the planar connector is composed of a composite resin composition comprises (A) a liquid crystalline polymer containing 55% by mole or less of p-hydroxy benzoic acid residue and having a melting point of 330° C. or higher, (B) a plate-like inorganic filler, and (C) a fibrous filler having a weight average fiber length within a range of 250 to 600 μm, the amount of (B) component being 25 to 35% by weight to the total composition, the amount of (C) component being 10 to 25% by weight to the total composition, the sum in total of (B) component and (C) component being 40 to 50% by weight to the total composition, wherein the connector has a lattice structure inside an outer frame, and has an opening inside the lattice area, and wherein the pitch interval of the lattice area is 1.5 mm or less, and the ratio of the thickness of the thickness of the lattice area to the outer frame area is 0.8 or less.

Owner:POLYPLASTICS CO LTD

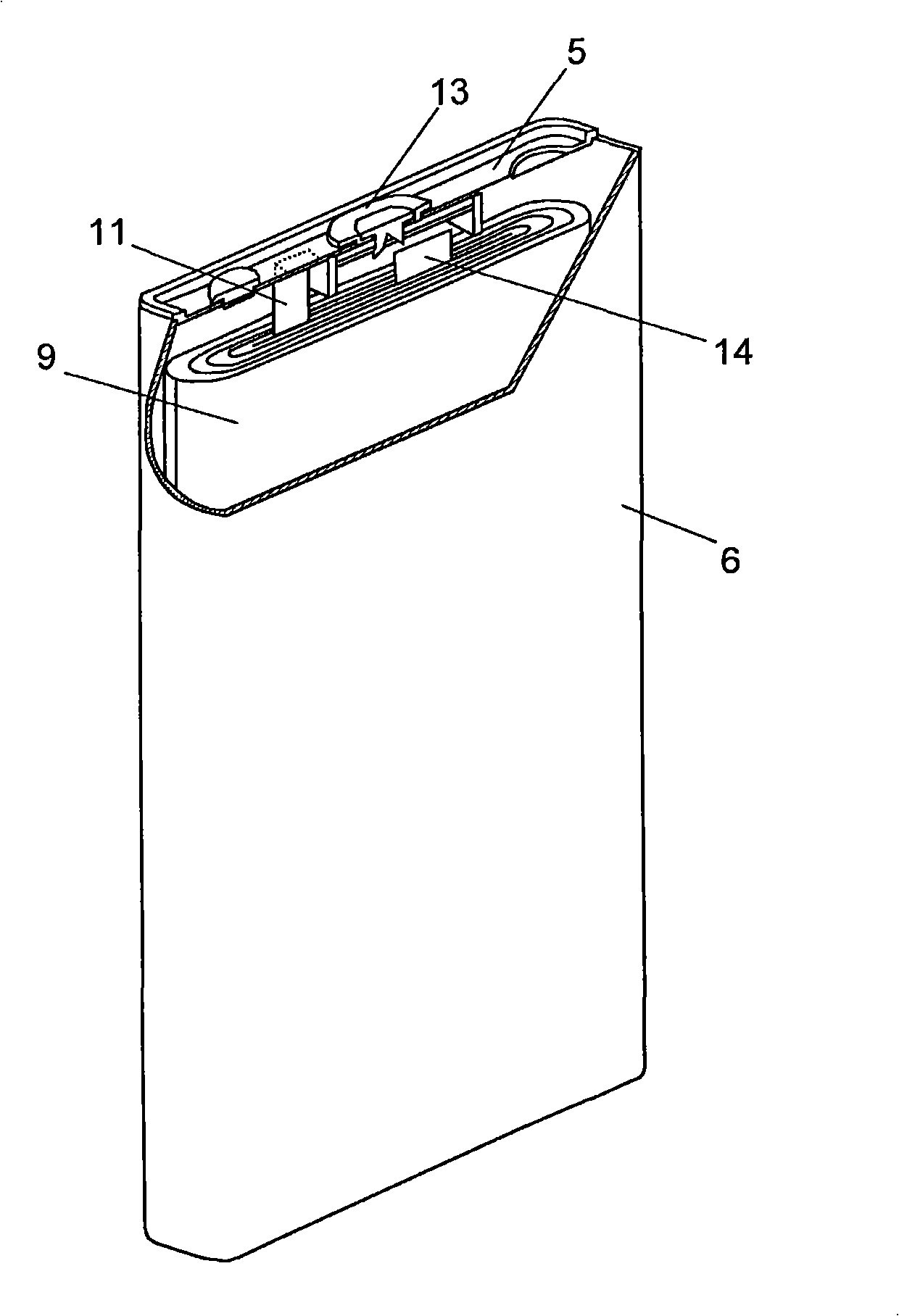

Non-aqueous electrolytic solution and non-aqueous electrolyte secondary battery using the same

ActiveUS20170162906A1Improve performanceExcellent performance balanceCell electrodesSecondary cellsAlloyMetal particle

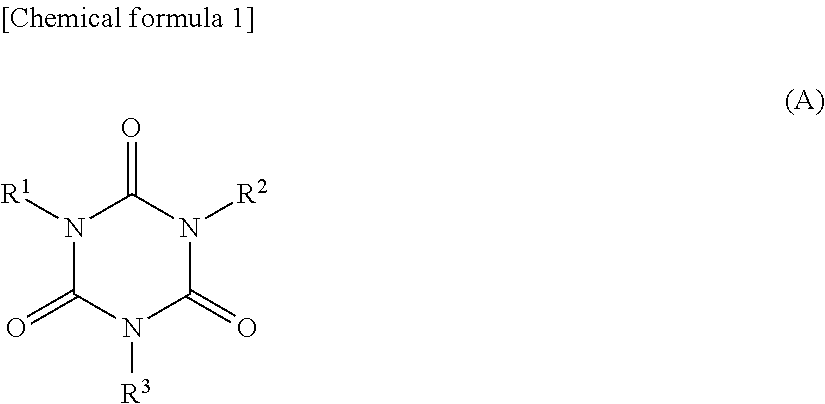

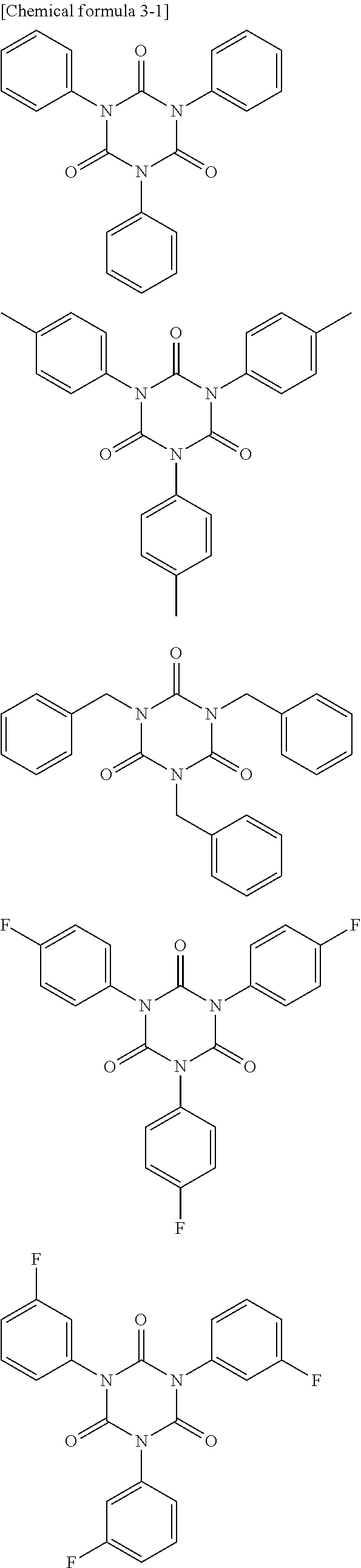

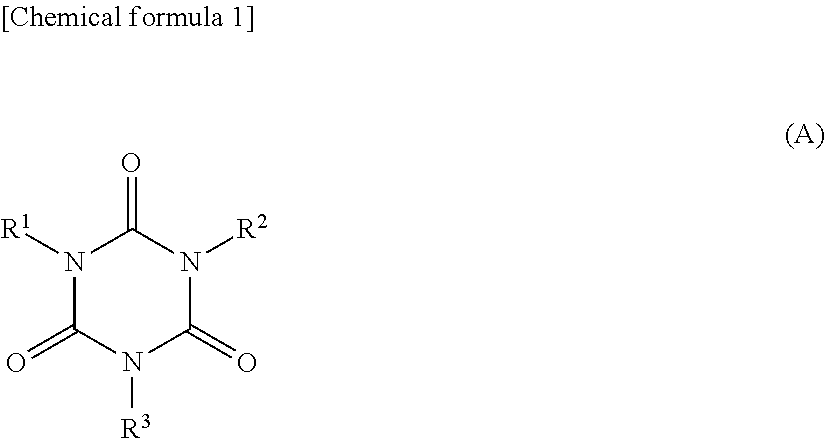

An object of the present invention 1 is to provide a non-aqueous electrolyte secondary battery having excellent general performance balance between durability performance and properties, such as a capacity, a resistance, and output characteristics. The present invention 1 is directed to a non-aqueous electrolytic solution for use in a non-aqueous electrolyte secondary battery which comprises: a positive electrode being capable of having occluded therein and releasing metal ions; a negative electrode being capable of having occluded therein and releasing metal ions, and comprising a negative electrode active material containing metal particles capable of forming an alloy together with Li and graphite particles; and a non-aqueous electrolytic solution comprising a non-aqueous solvent and an electrolyte dissolved in the non-aqueous solvent, wherein the non-aqueous electrolytic solution contains a compound represented by the general formula (A), and a non-aqueous electrolyte secondary battery using the non-aqueous electrolytic solution.

Owner:MU IONIC SOLUTIONS CORP +1

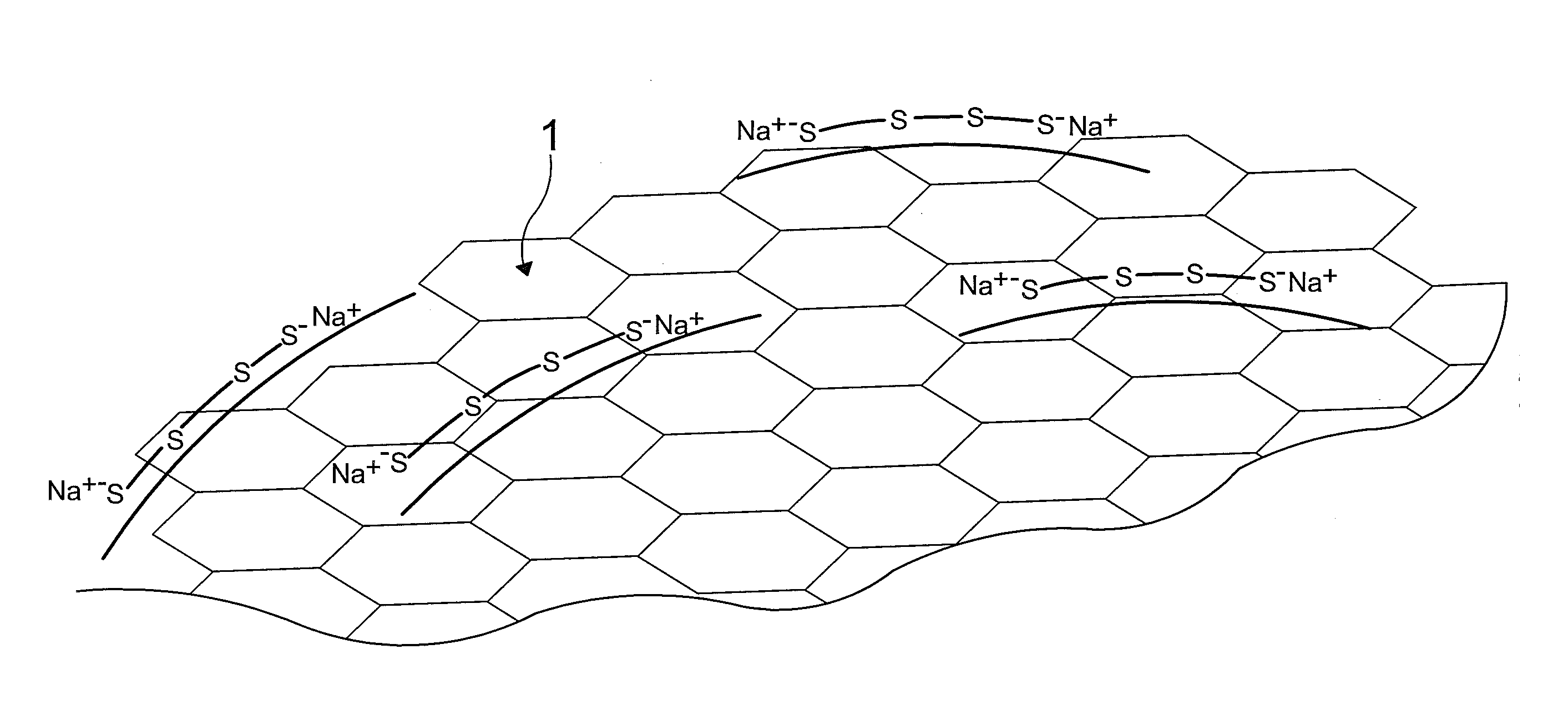

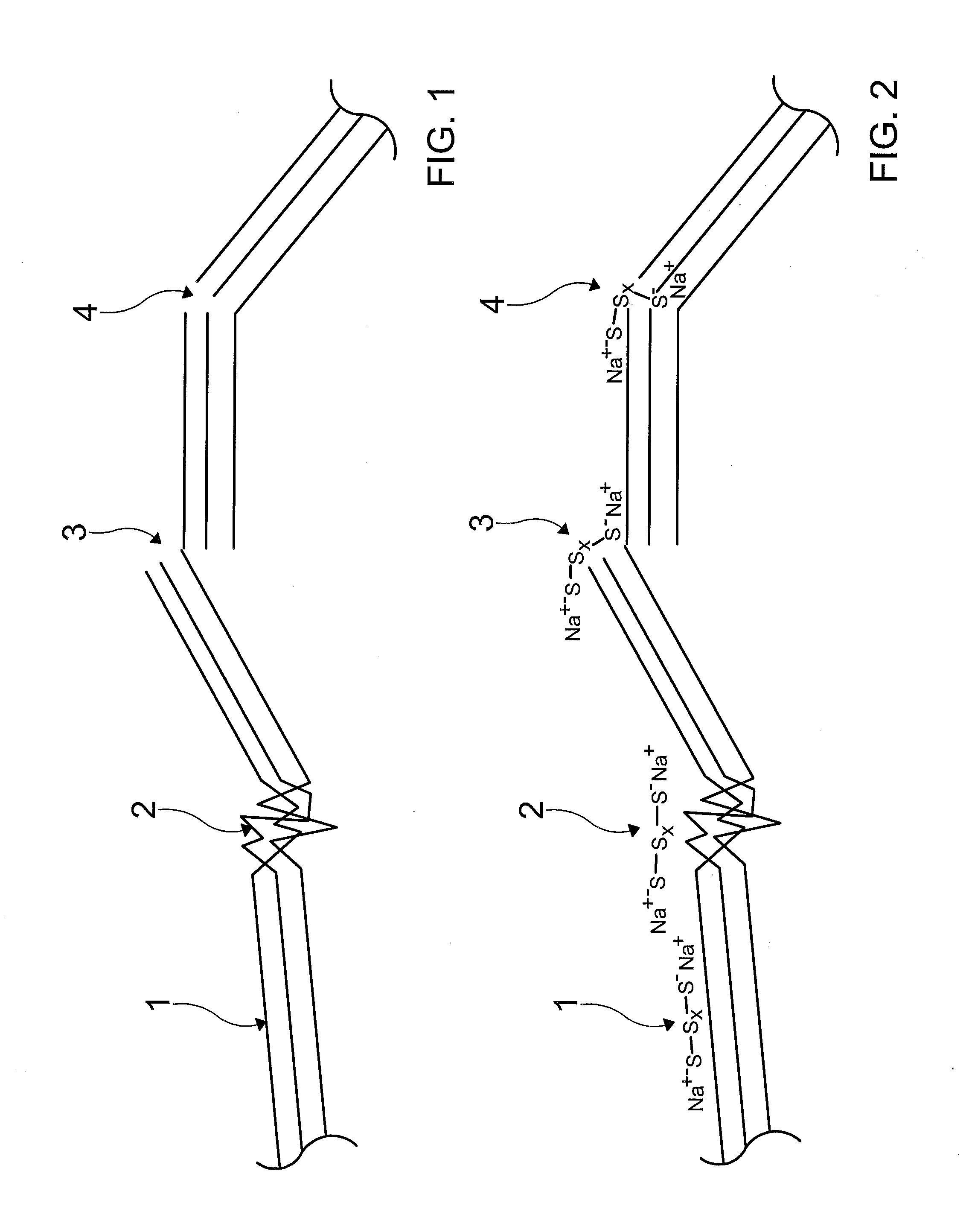

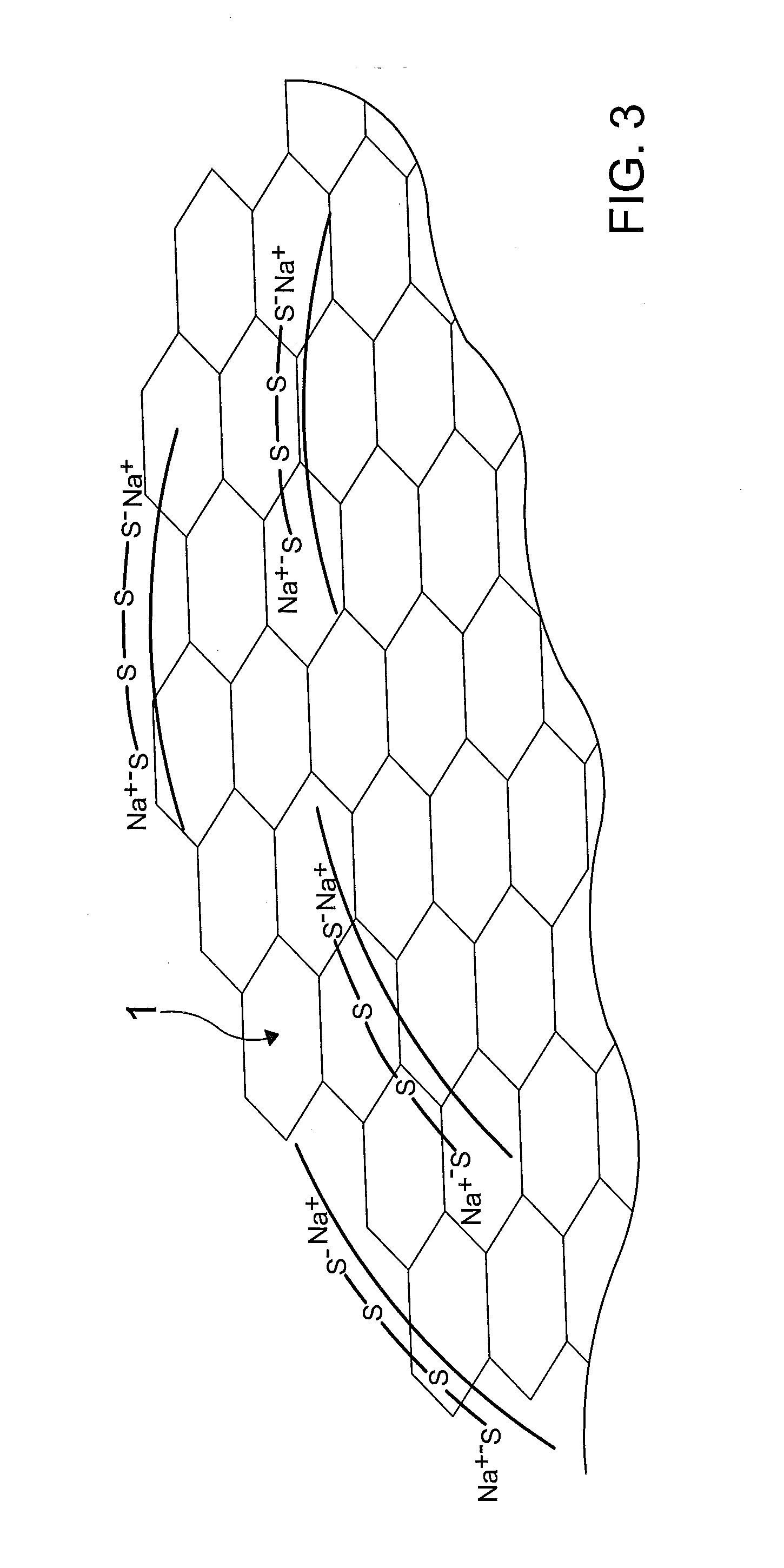

Polysulfide treatment of carbon black filler and elastomeric compositions with polysulfide treated carbon black

InactiveUS20130340651A1Hysteresis levelExcellent performance balanceNon-macromolecular adhesive additivesInksCarbon blackSulfide

A chemically treated carbon black product is provided, which includes a pellet having an agglomerated mass of carbon black aggregates densified in a generally spheroidal form. The carbon black aggregates have polysulfide adsorbed on surfaces thereof. The polysulfide is thereby distributed throughout the pellet. Elastomeric compositions containing the chemically treated carbon black are also provided, and exhibit a reduction in hysteresis and equivalent or better abrasion resistance. A method for manufacturing the treated carbon black product is also disclosed.

Owner:SID RICHARDSON CARBON CO

Single-component epoxy modified silicone sealant and preparation method thereof

ActiveCN106590501AGood compatibilityHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAviationCross-link

The invention discloses a single-component epoxy modified silicone sealant and a preparation method thereof. the sealant is composed of, by mass, 100 parts of silane modified polyether resin, 10-50 parts of epoxy resin, 80-150 parts of plasticizers, 150-300 parts of nano calcium carbonate, 1-6 parts of first cross-linking agents, 3-10 parts of second cross-linking agents and 2-7 parts of catalysts. The advantages of the epoxy resin and the silane modified polyether resin are combined, the bonding powder, the tensile strength, the elasticity and the weather resistance of the sealant can be improved, and the sealant can be used for the different fields such as constructional engineering, electronics, the automobile industry and space flight and aviation. The sealant has the characteristics that the performance advantages of silicone and the epoxy resin are combined, the silicone and the epoxy resin are subjected to a cross-linking reaction with water molecules and the cross-linking agents under the action of the catalysts, and a three-dimensional spatial netty structure is formed. A cured system is high in binding performance and excellent in mechanical performance and weather resistance.

Owner:广东长鹿新材料科技有限公司

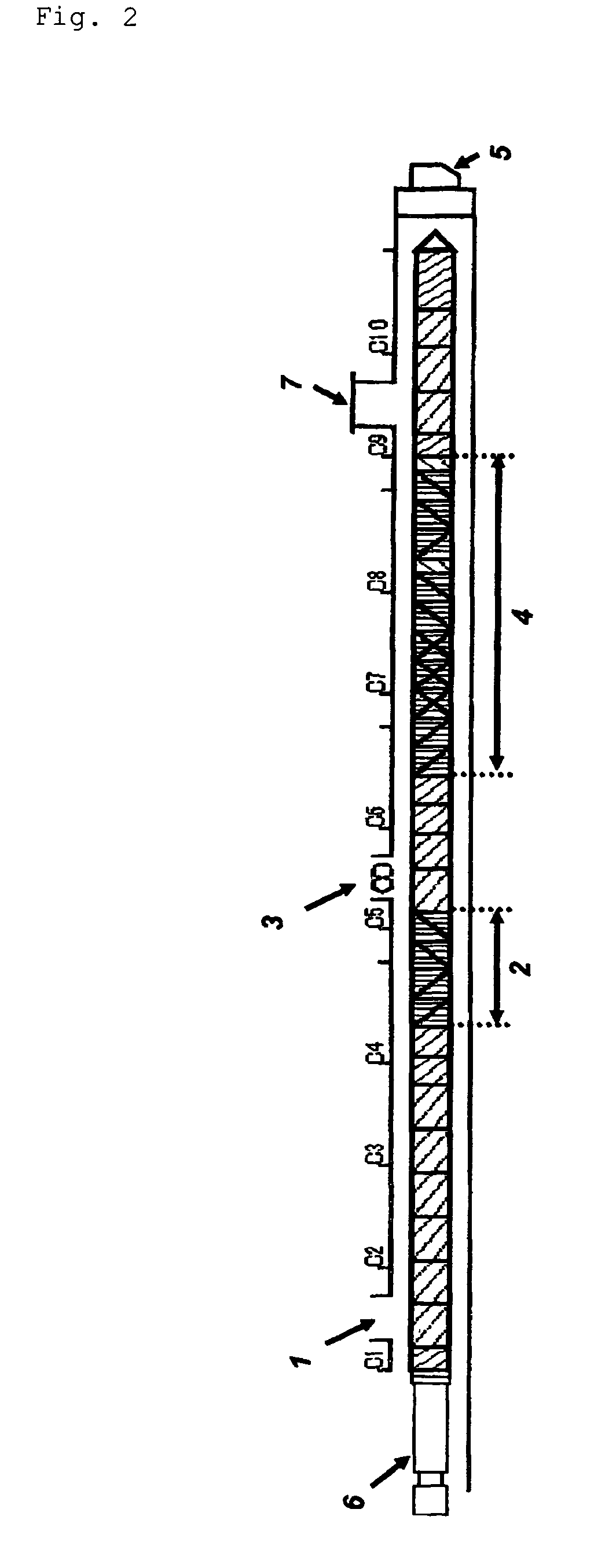

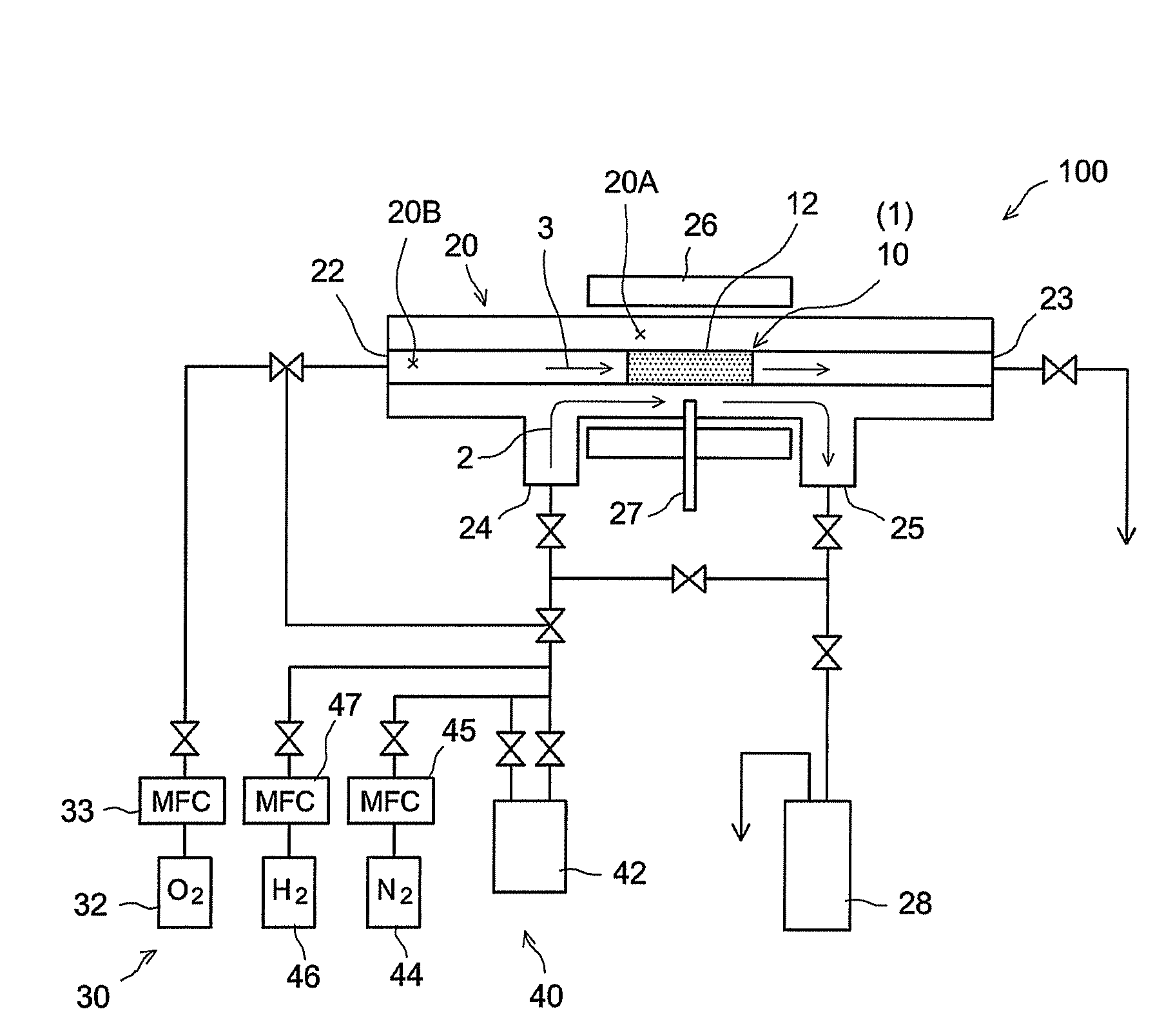

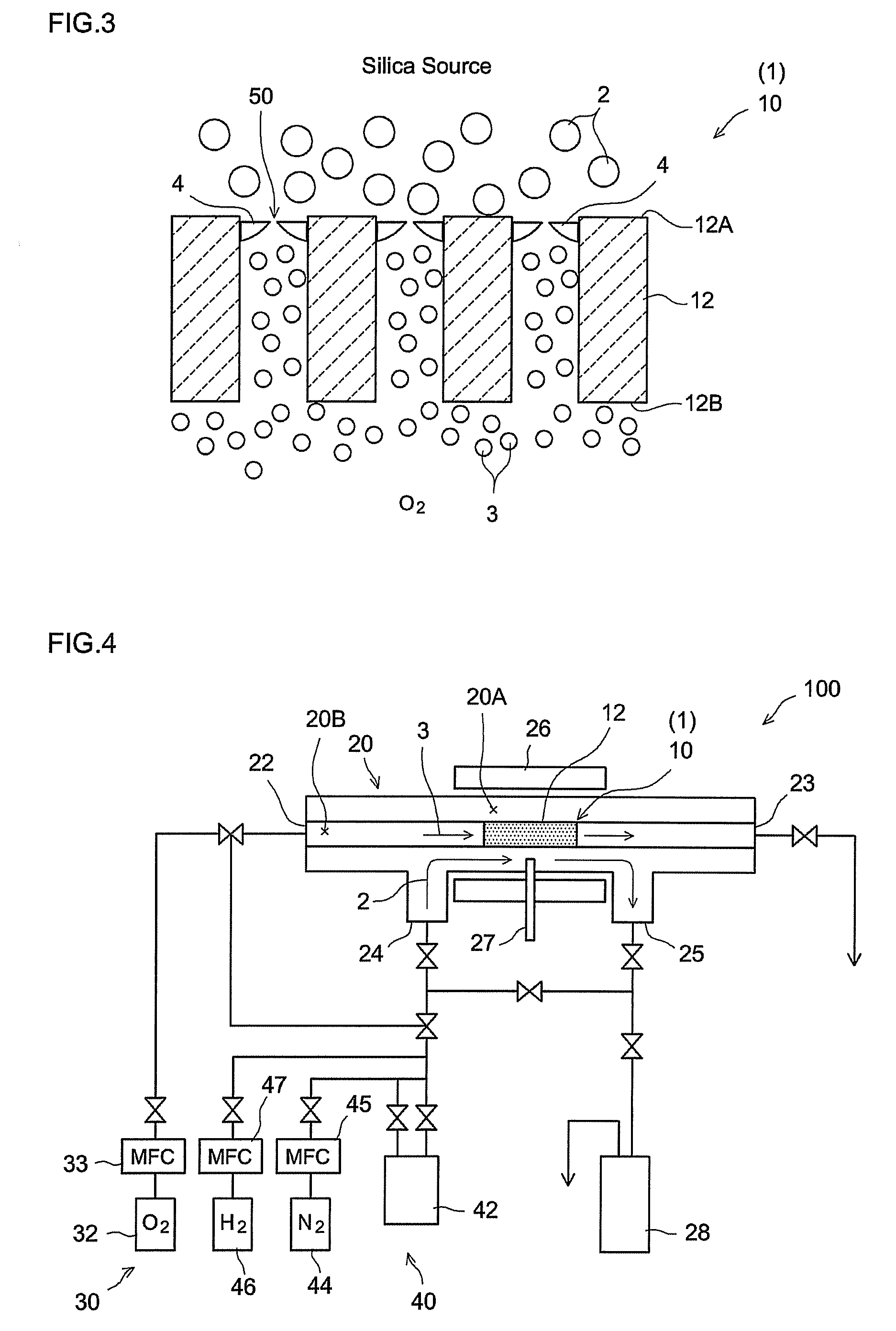

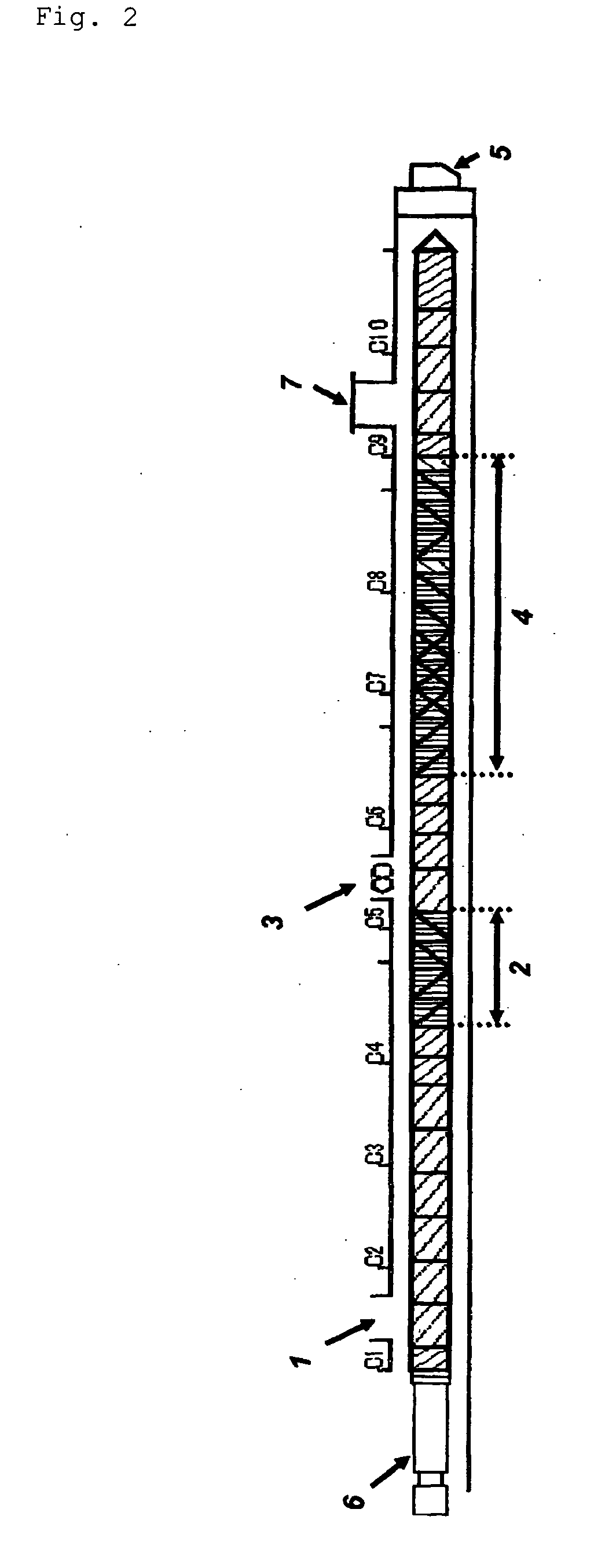

Method for producing hydrogen gas separation material

InactiveUS20080241383A1Suitable molecular sizeExcessive depositionSemi-permeable membranesMembranesGas separationPorous substrate

The invention provides a method for consistently producing a hydrogen gas separator with a good performance balance. The method includes the process for preparing a porous substrate and the process for forming a silica coat on the substrate by chemical vapor deposition in which a reaction is brought about between a silica source provided to one side of the substrate and an oxygen-containing gas supplied to the other side of the substrate. The vapor deposition process is carried out using as the silica source a silicon compound (a) with Si-Z-Si bonds (Z is O or N) in the molecule.

Owner:NORITAKE CO LTD

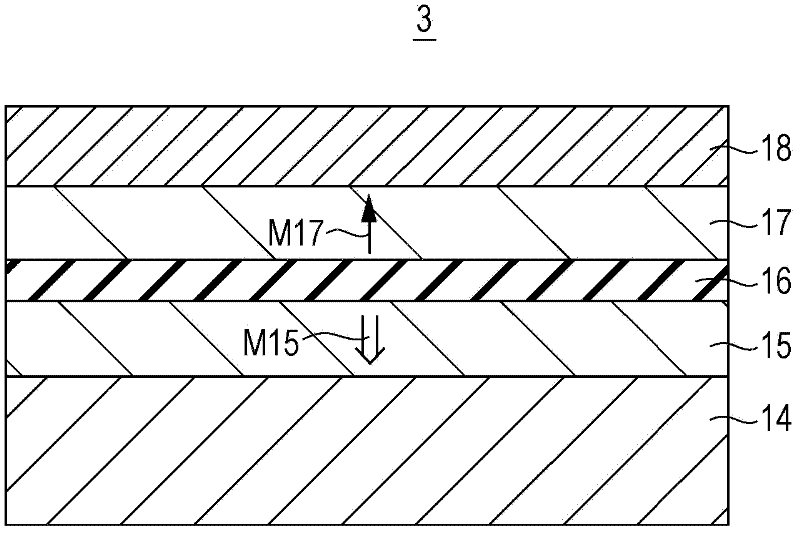

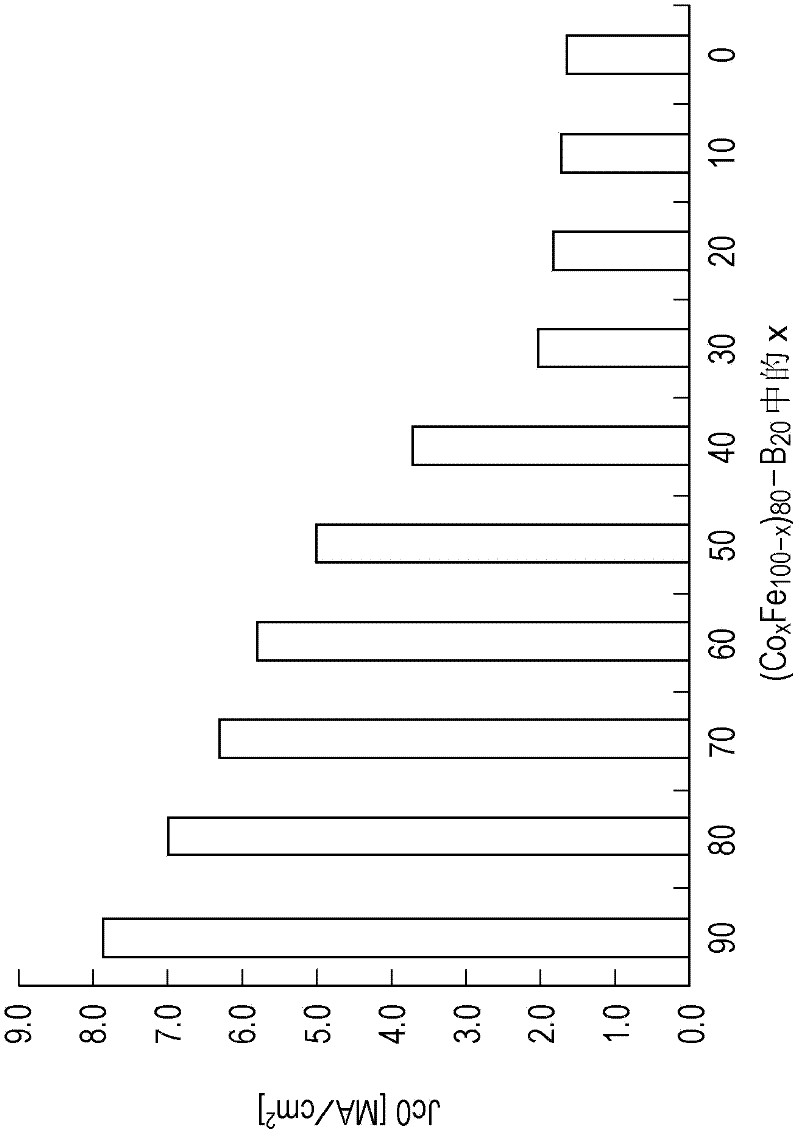

Memory element and memory

A memory element including a memory layer that retains information based on a magnetization state of a magnetic material is provided. In the memory element, a magnetization pinned layer is provided for the memory layer through an intermediate layer, the intermediate layer is formed of an insulator, spin-polarized electrons are injected in a stacking direction to change a magnetization direction of the memory layer, so that information is recorded in the memory layer. Also, a ferromagnetic layer forming the memory layer has a magnetostriction constant of 1x10<-5 >or more.

Owner:SONY CORP

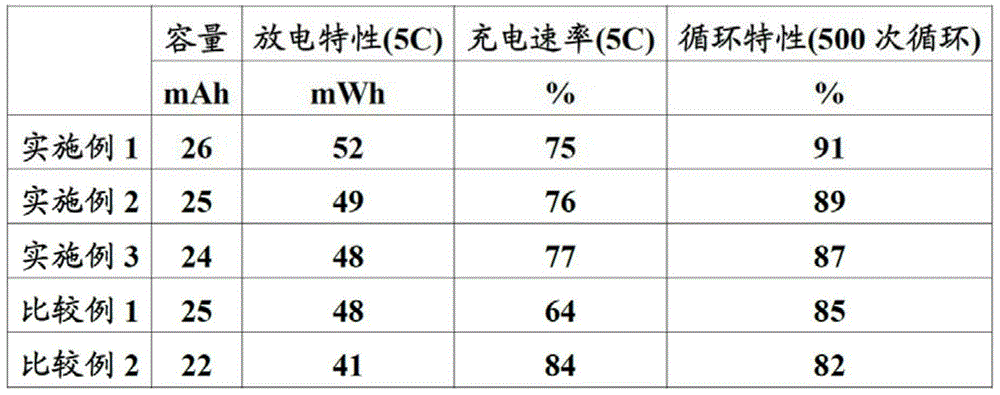

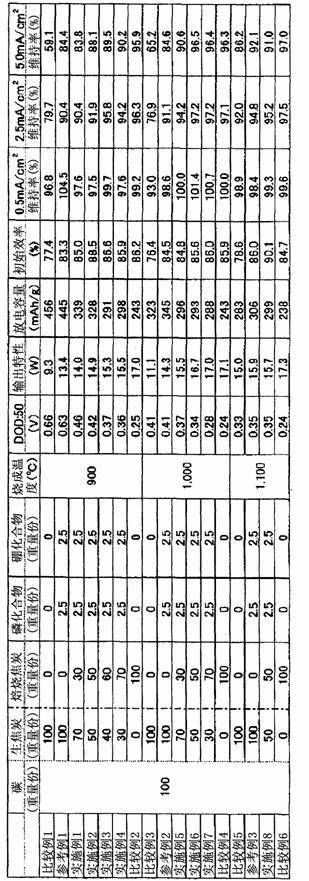

Negative electrode material for lithium ion secondary battery, negative electrode sheet for lithium ion secondary battery, and lithium secondary battery

InactiveCN104838526AExcellent performance balanceExcellent cycle characteristicsCell electrodesSecondary cellsX-rayGraphite

This negative electrode material for a lithium ion secondary battery is characterised by comprising a mixture of: artificial graphite (A) for which the spacing (d(002)) of the (002) surface of the graphite structure, as measured using powder X-ray diffractometry, is in the range 0.335-0.339nm, and the particle diameter (D50) for which the volume total frequency of the particle size distribution measured using laser diffractometry is 50% is 4-10μm; and a carbon material (B) for which d(002) is at least 0.340nm, and D50 is 7-17μm and is greater than the D50 of the artificial graphite (A).

Owner:SHOWA DENKO KK

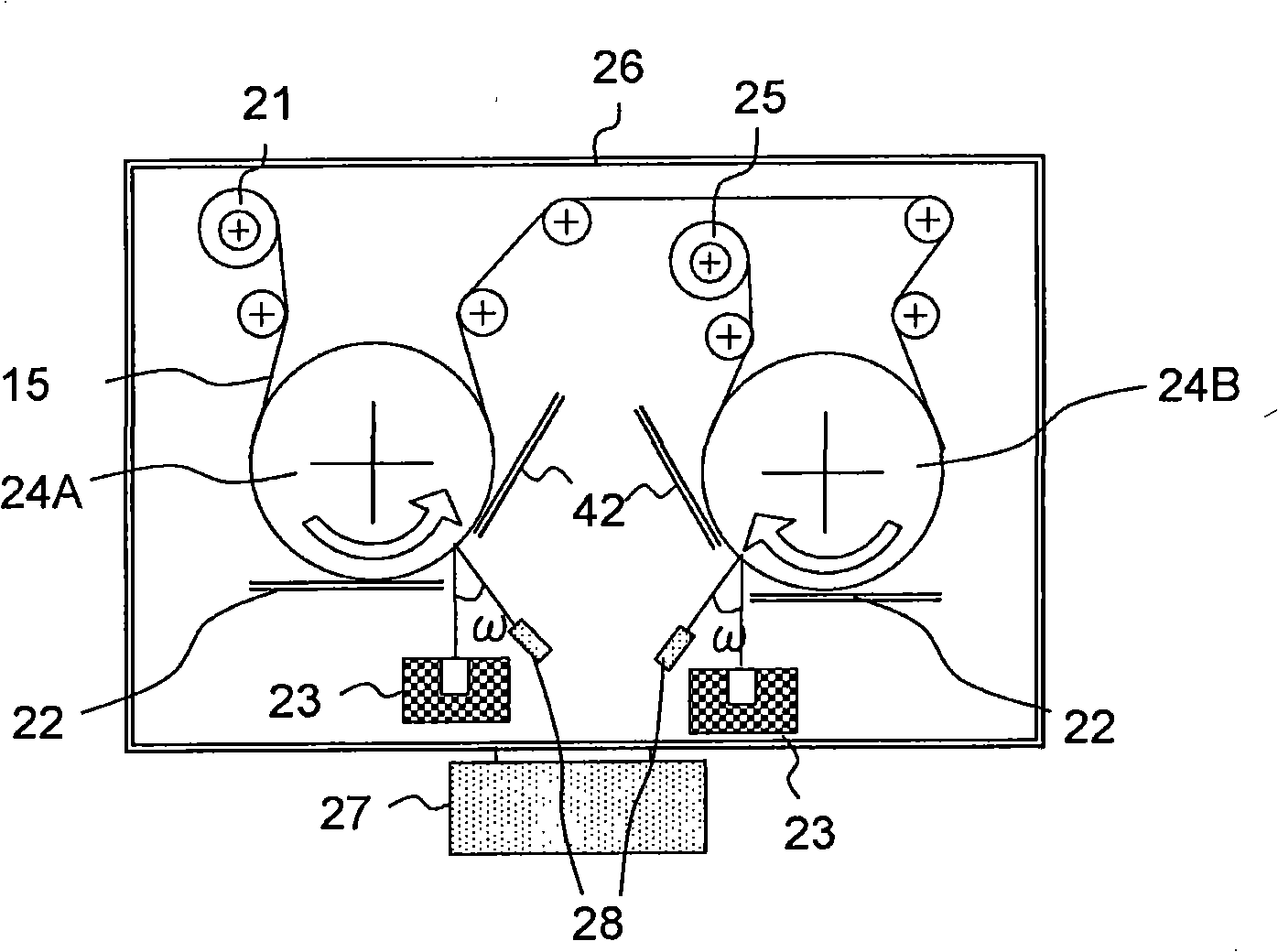

Negative electrode for secondary battery, and secondary battery using same

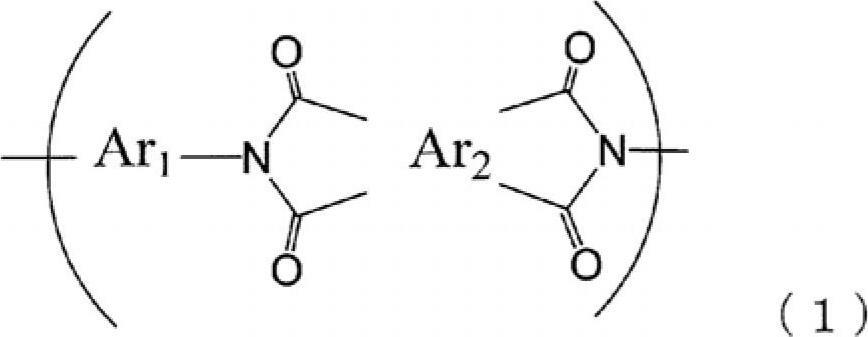

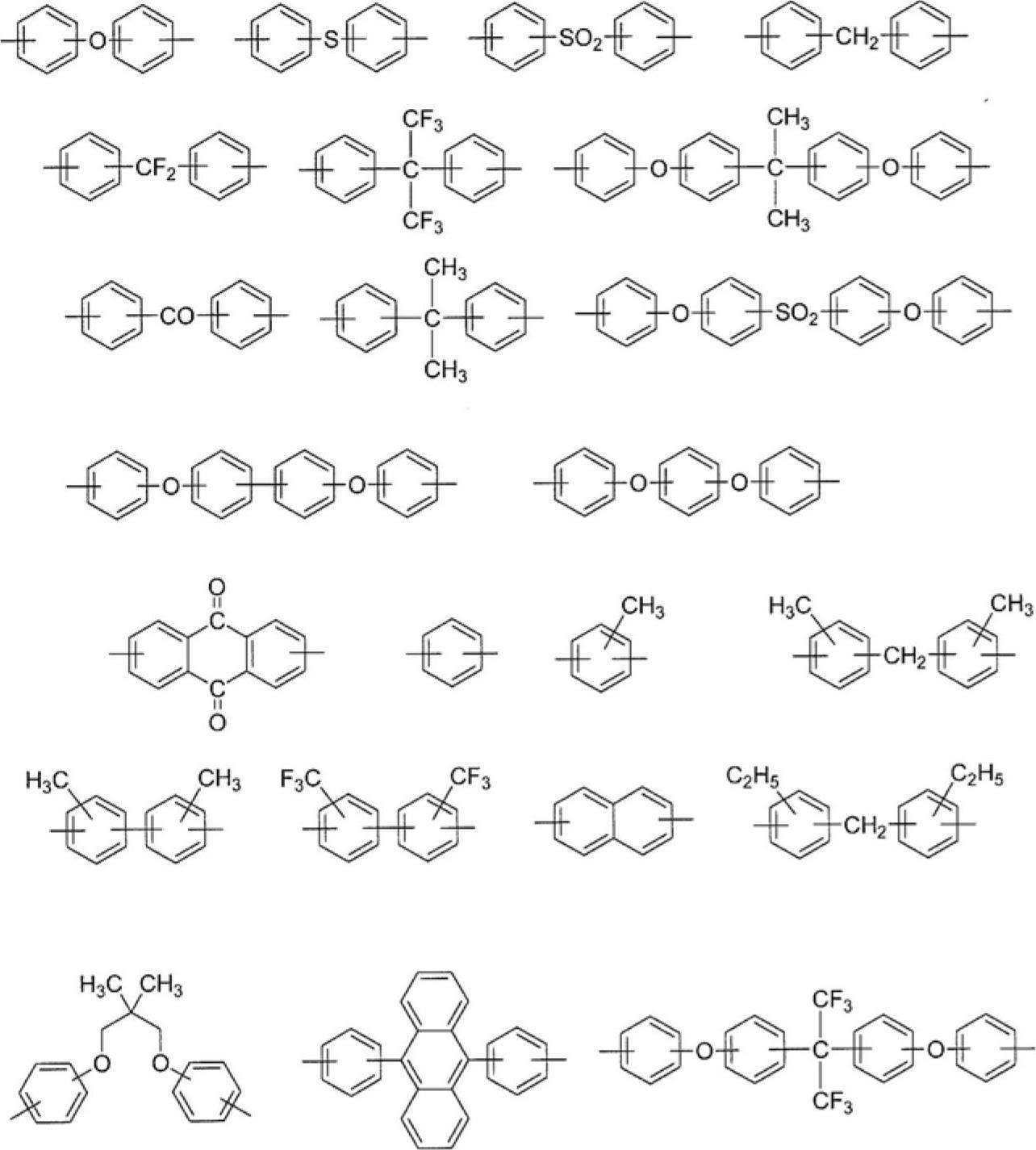

InactiveCN102640330AExcellent performance balanceHigh input and output characteristicsCell electrodesSecondary cellsPolyimideEngineering

Disclosed is a negative electrode for a secondary battery, which is capable of sufficiently improving input / output characteristics of a secondary battery such as cycle life, while having practical characteristics such as discharge capacity, initial efficiency, capacity retention rate and reliability (safety) that are required for use on vehicles such as an HEV. Specifically disclosed is a negative electrode for a secondary battery, which comprises an active material layer in which a negative electrode active material is integrated by a binder. The negative electrode material is obtained by firing a coke material which is obtained by blending one or more kinds of green coal or petroleum coke and one or more kinds of calcined coal or petroleum coke at a mass ratio of from 90:10 to 10:90, and to which a phosphorus compound or a phosphorus compound and a boron compound are added, while essentially containing the phosphorus compound, per 100 parts by mass of the green coke and calcined coke in total. The binder is composed of a polyimide resin.

Owner:NIPPON STEEL CHEMICAL CO LTD

Asymmetric electronic parts

InactiveUS20090197471A1Improve mechanical propertiesReduce warpageLiquid crystal compositionsSecuring/insulating coupling contact membersLiquid crystallinePolymer composition

Provided is a material capable of forming a molded product which has good mechanical properties with low warpage while being excellent in any of the performance including heat resistance and flowability, even if the molded product is an asymmetric electronic parts. Specifically, the asymmetric electronic parts is prepared by molding a liquid crystalline polymer composition comprising (A) a fibrous filler having an average fiber diameter within the range of 5 to 30 μm, having a weight average fiber length within the range of 250 to 350 μm, excluding 10 μm or shorter fiber length, and having a content of a fibrous filler being 700 μm or longer within the range of 5% by weight or less; and (B) a plate-like filler having an average particle size within the range of 0.5 to 200 μm, the total filling amount of (A) and (B) components in the composition being within the range of 40 to 60% by weight, the weight ratio of (A) component being within the range of 10 to 20% by weight, the weight ratio of (B) component being within the range of 30 to 40% by weight, the molded product having no symmetry in any of the axial plane XY, the axial plane YZ, and the axial plane XZ of the molded product.

Owner:POLYPLASTICS CO LTD

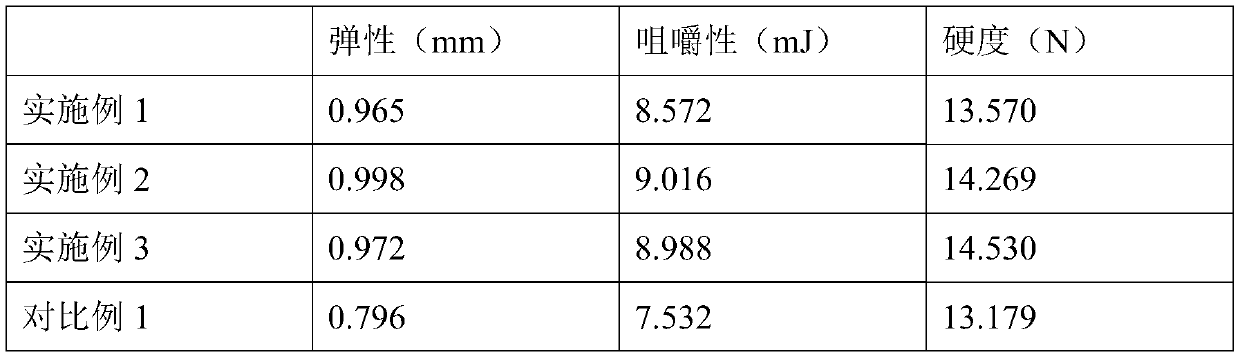

Convenient instant fresh wet noodle and preparation method thereof

The invention discloses a convenient instant fresh noodle and a preparation method thereof, and relates to the field of food processing. The convenient instant fresh wet noodle is mainly composed of high-gluten wheat flour, modified starch, vital gluten and salt. The addition of additives reduces indicator degradation of color, texture and microorganisms during storage. The noodle adopts an extrusion molding curing process to ensure long shelf life by pickling, modified atmosphere packaging and irradiation sterilization.

Owner:湖北戴氏食品科技股份有限公司

Nonwoven fabrics for protective clothing matenial and its mfg. method

The composite nonwoven fabric for protective clothing of the present invention comprises (A) a water vapor-permeable, water-resistant nonwoven fabric made of polyolefin-based ultra-fine fibers having an average fiber diameter of 5 mu m or less, (B) a heat-bonding nonwoven fabric made of thermoplastic elastomer ultra-fine fibers, and (C) a porous fabric. The nonwoven fabric B is interposed between the nonwoven fabric A and the porous fabric C, and the fabrics A, B and C are integrally bonded to each other. The composite nonwoven fabric is suitable for protective clothing because it is water vapor-permeable and water-resistant on its outer side to be exposed to outside air, and is of high strength, sweat-absorption and antistatic on its inner side, and also well-balanced in these properties.

Owner:KURARAY CO LTD +1

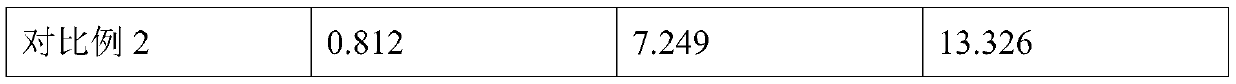

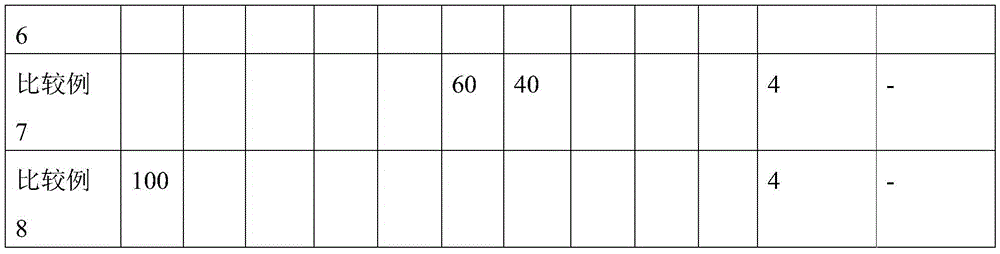

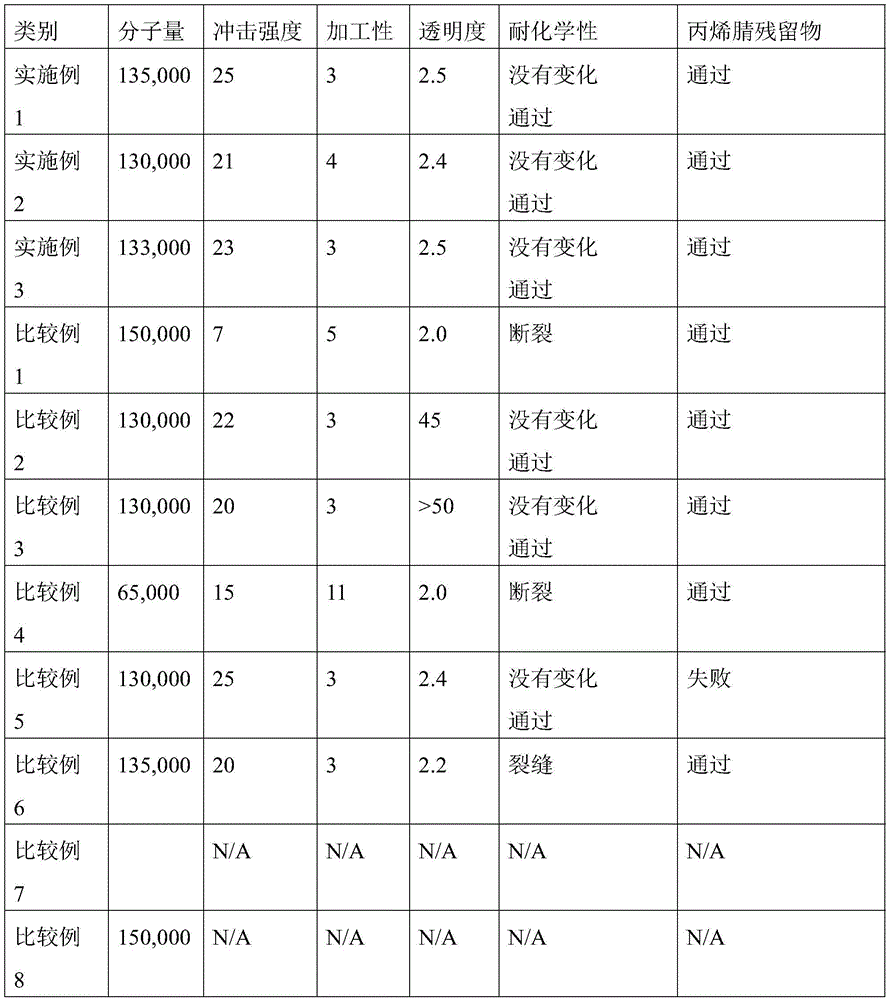

Thermoplastic resin composition having excellent chemical resistance and transparency, method for preparing same, and molded product comprising same

The present invention relates to a transparent resin composition which has excellent chemical resistance and transparency and is usable for medical purposes and food containers, a method for preparing the same, and a molded product manufactured therefrom and, specifically, to a transparent thermoplastic resin composition having excellent chemical resistance and transparency, a method for preparing the same, and a molded product manufactured therefrom, wherein the resin composition contains: (A) a graft copolymer obtained by graft-copolymerizing, onto a) conjugated diene rubber latex, b) a methacrylic acid alkyl ester compound or an acrylic acid alkyl ester compound, c) an aromatic vinyl compound, and d) a vinyl cyan compound; (B) a copolymer resin obtained by copolymerizing i) a methacrylic acid alkyl ester compound or an acrylic acid alkyl ester compound, ii) an aromatic vinyl compound, and iii) a vinyl cyan compound; and (C) a polyether-amide bloc copolymer.

Owner:LG CHEM LTD

Planar connector

InactiveUS20110086968A1Good molding effectSmall widthLiquid crystal compositionsPlastic/resin/waxes insulatorsLiquid crystallineBenzoic acid

The present invention provides a planar connector having excellent performances including flatness, warp-deformation resistance, and heat resistance, being capable of responding to shape changes in recent planar connectors. Specifically, the planar connector is composed of a composite resin composition comprises (A) a liquid crystalline polymer containing 55% by mole or less of p-hydroxy benzoic acid residue and having a melting point of 330° C. or higher, (B) a plate-like inorganic filler, and (C) a fibrous filler having a weight average fiber length within a range of 250 to 600 μm, the amount of (B) component being 25 to 35% by weight to the total composition, the amount of (C) component being 10 to 25% by weight to the total composition, the sum in total of (B) component and (C) component being 40 to 50% by weight to the total composition, wherein the connector has a lattice structure inside an outer frame, and has an opening inside the lattice area, and wherein the pitch interval of the lattice area is 1.5 mm or less, and the ratio of the thickness of the thickness of the lattice area to the outer frame area is 0.8 or less.

Owner:POLYPLASTICS CO LTD

Anode active material for lithium secondary batteries, anode electrode for lithium secondary batteries, in-vehicle lithium secondary battery using said anode active material and anode electrode, and method for manufacturing an anode active material for lithium secondary batteries

InactiveCN102428594AImprove output characteristicsExcellent performance balanceFinal product manufactureCell electrodesLithiumIn vehicle

Green coke from coal and / or petroleum and calcined coke from coal and / or petroleum are blended using a weight ratio between 90:10 and 10:90, and for each 100 parts by weight of the resulting coke blend, 0.1 to 6.0 parts by weight of a phosphor compound and 0.1 to 6.0 parts by weight of a boron compound are added, with weights calculated in terms of elemental phosphor / boron equivalent. The resulting coke material is fired to produce a novel anode active material for lithium secondary batteries, said anode active material having stable charging / discharging characteristics and excellent output characteristics, initial efficiency, and capacity retention rate.

Owner:NIPPON STEEL CHEMICAL CO LTD

Nonaqueous electrolyte secondary battery and process for producing negative electrode thereof

InactiveCN101346837AExcellent performance balanceImprove performanceElectrode manufacturing processesActive material electrodesLithiumAgglomerate

A process for producing a negative electrode, comprising the first step of forming multiple columnar active substance agglomerates capable of electrochemical occlusion / release of lithium ions on a surface of current collector and the second step of incorporating granular lithium in interstices of the active substance agglomerates.

Owner:PANASONIC CORP

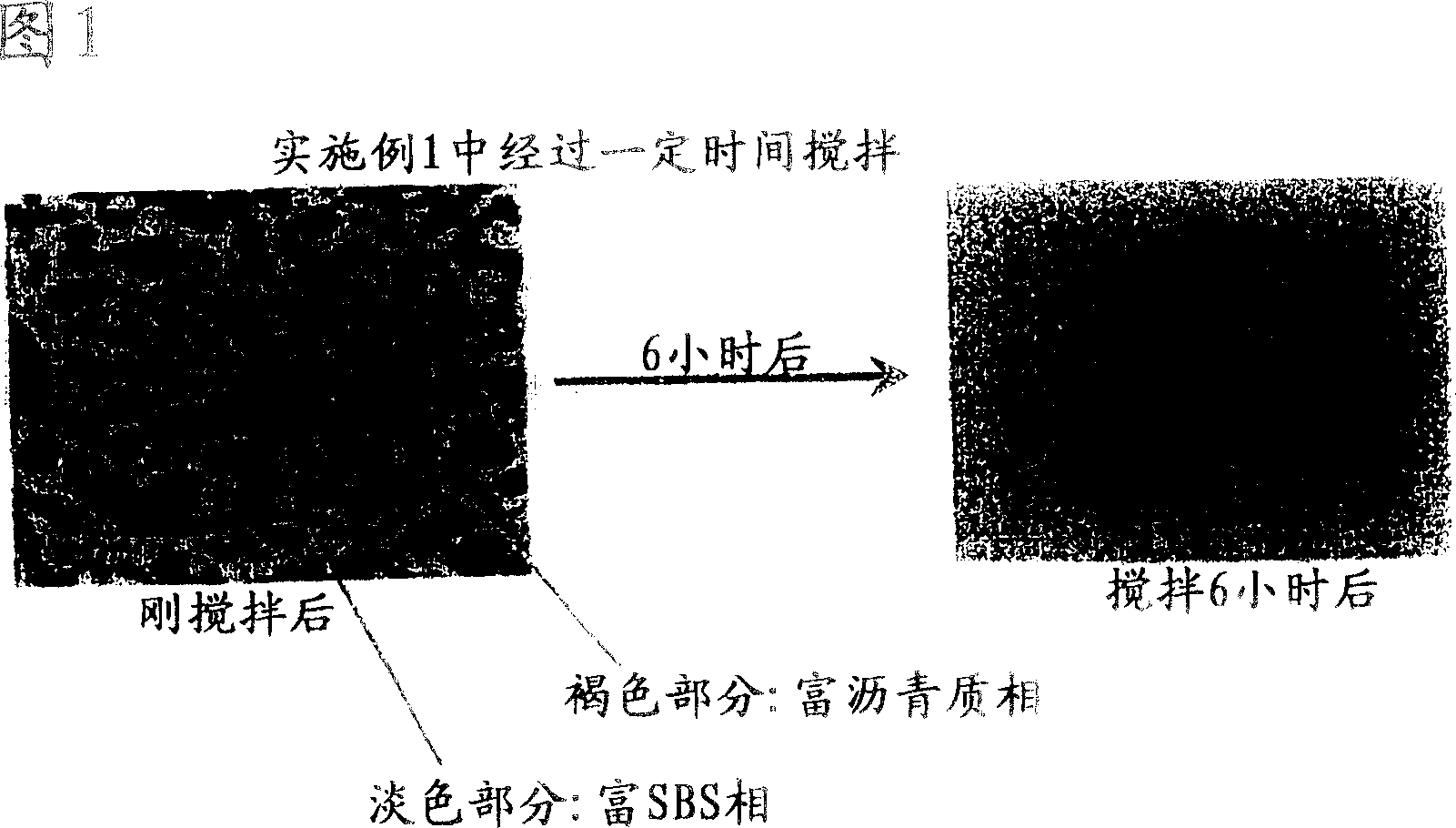

Block copolymer composition for asphalt modification, process for producing the same, and asphalt composition

InactiveCN1969011AImprove solubilityExcellent toughness and elasticityBuilding insulationsHigh temperature storageSolubility

A block copolymer composition for asphalt modification which is excellent in solubility in asphalt and high-temperature storage stability, has a low melt viscosity, and attains excellent asphalt properties, especially torsion resistance; and an asphalt composition. The block copolymer composition for asphalt modification comprises (i) a block copolymer comprising at least two polymer blocks formed mainly from an aromatic vinyl compound and at least one polymer block formed mainly from a conjugated diene and (ii) a block (co)polymer which comprises one or more aromatic vinyl polymer blocks as an essential component and optionally further contains one or more polymer blocks formed mainly from a conjugated diene and in which the peak molecular weight thereof in terms of standard polystyrene, as measured by gel permeation chromatography (GPC), is less than 1 / 3 the peak molecular weight of the block copolymer (i), the (i) / (ii) proportion being (95-70) / (5-30) (by weight). The asphalt composition is obtained by adding the modifying composition to asphalt.

Owner:KRATON JSR ELASTOMERS KK

Storing element and storing device

InactiveCN102403030AReduce the amount of write currentReduce power consumptionMagnetic-field-controlled resistorsSolid-state devicesMagnetizationSpin polarization

The invention discloses a storing element and a storing device. The storing element comprises a storing layer having a magnetization piece varying the magnetization direction with corresponding information and perpendicular to the surface of a film; a magnetization fixing layer having a magnetization piece perpendicular to the surface of the film; an insulating layer equipped between the storing layer and magnetization fixing layer. Self-spinning polarized electrons are injected along the overlapping direction of the layer structure. The magnetization direction of the storing layer is then changed. Information about the storing layer is recorded. The effective counter magnetic field received by the storing layer has a size smaller than the saturated magnetization volume of the storing layer. Meanwhile, a Ta film is formed in a way to a magnetization fixing layer face opposed to the insulating layer.

Owner:SONY CORP

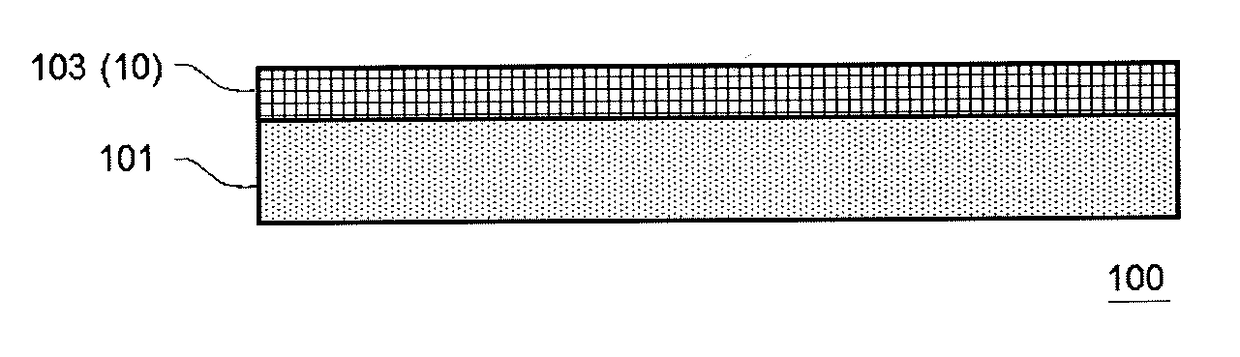

Gas barrier polymer, gas barrier film, and gas barrier laminate

InactiveUS20170341352A1Improve balanceGood lookingLayered product treatmentSynthetic resin layered productsPolyamine CompoundCarboxylic acid

A gas barrier polymer of the present invention is formed by heating a mixture including a polycarboxylic acid and a polyamine compound, in which, in an infrared absorption spectrum of the gas barrier polymer, when a total peak area in a range of an absorption band of equal to or more than 1493 cm−3 and equal to or less than 1780 cm−1 is A, and a total peak area in a range of an absorption band of equal to or more than 1598 cm−1 and equal to or less than 1690 cm−1 is B, an area ratio of an amide bond indicated by B / A is 0.370 or more.

Owner:MITSUI CHEM TOHCELLO INC

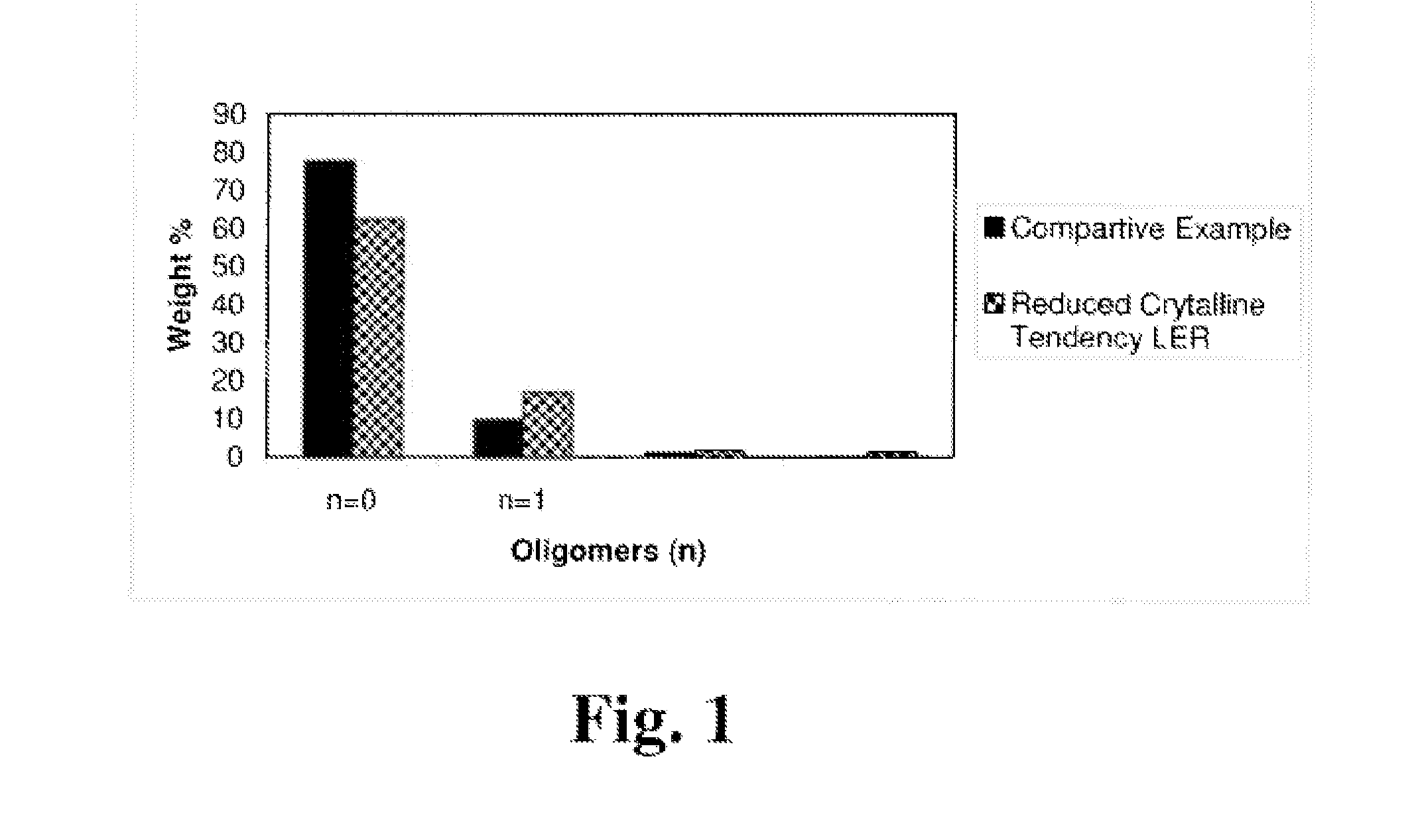

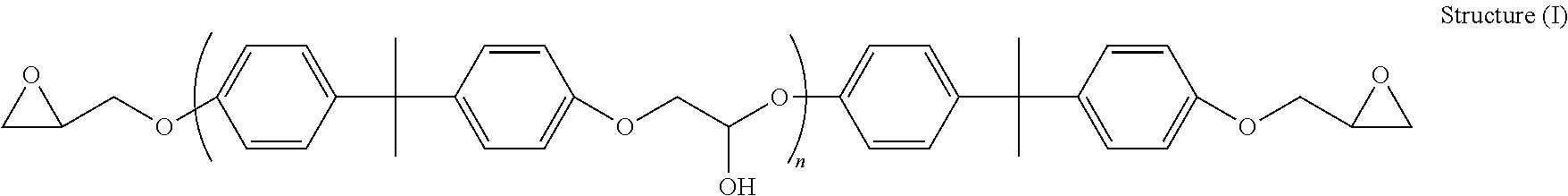

Liquid epoxy resin formulations

ActiveUS20140256856A1Reduce crystallization tendencyImprove the immunityOrganic chemistryEpoxyPolymer science

A liquid epoxy resin composition having a reduced tendency to crystallize including at least one liquid epoxy resin having the following generic chemical Structure (I): where n is 0 or an integer of 1 or more; and wherein n=0 is in the range of between about 1 wt % and about 90 wt %; wherein; n=1 is in the range of between about 7 wt % and about 20 wt %; n=2 is in the range of between about 0.8 wt % and about 3 wt %; and n=3 and above is in the range of about 0 wt % and about 2 wt %.

Owner:BLUE CUBE IP

Moisture-Curable Hot-Melt Adhesive Agent

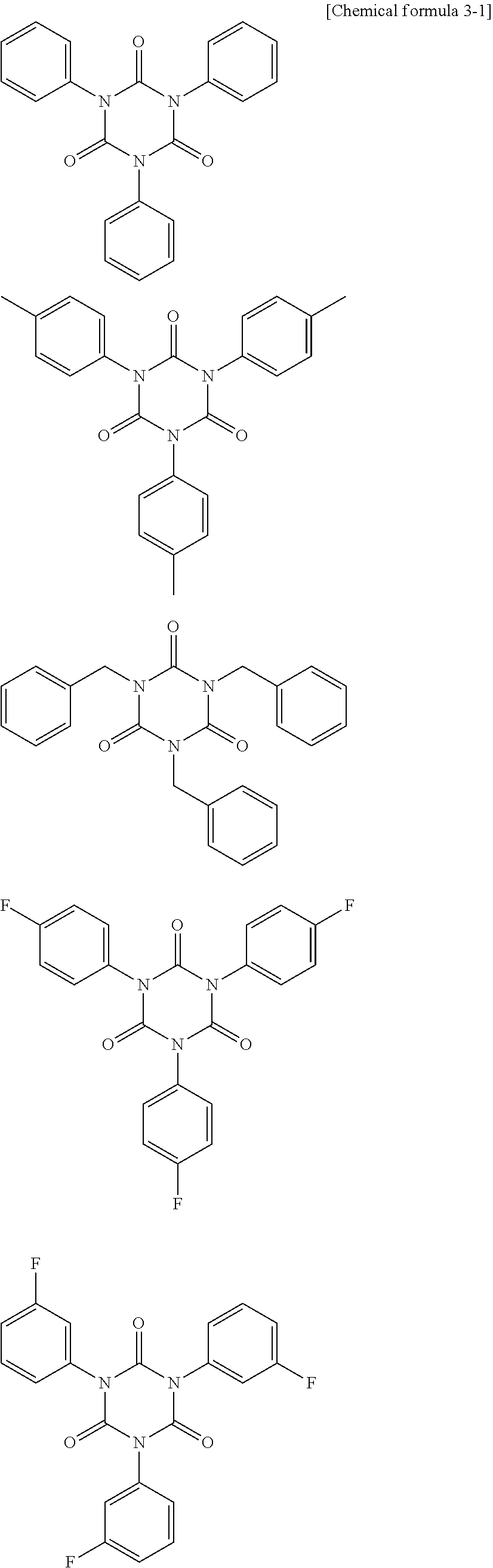

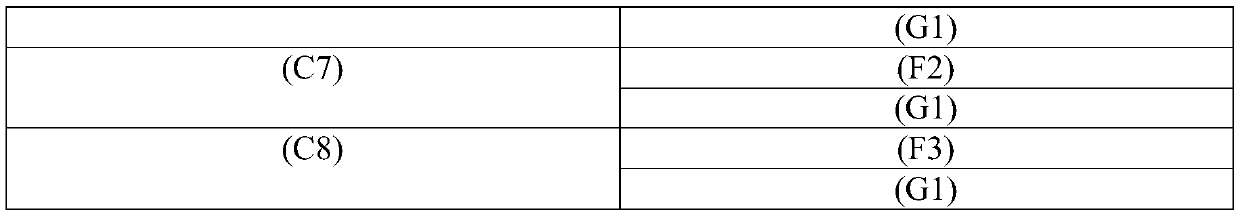

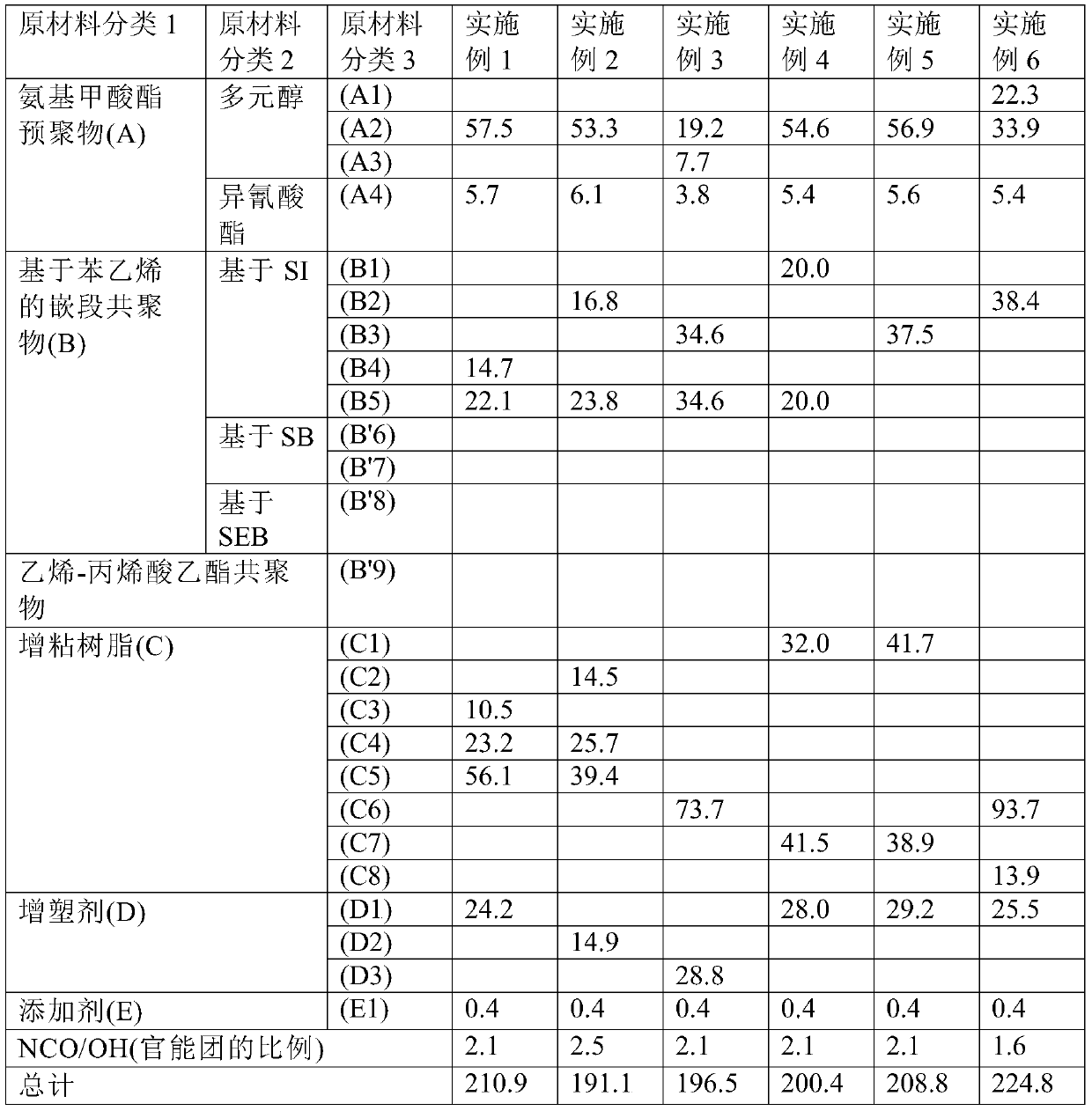

InactiveUS20200087542A1Improve adhesion strengthExcellent performance balanceFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

To provide a moisture-curable hot-melt adhesive agent having excellent balance of initial adhesive strength, adhesive strength after curing and heat resistance and the like, and a layered product bonded with the moisture-curable hot-melt adhesive agent.Means for solving the problem: A moisture-curable hot-melt adhesive agent comprisingan urethane prepolymer having an isocyanate group at the end (A),a styrene-isoprene based block copolymer (B), anda tackifying resin (C), whereinthe moisture-curable hot-melt adhesive agent comprises 25 to 64% by weight of (A), based on 100 parts by weight in total of (A) and (B).

Owner:HENKEL KGAA

A kind of dual-phase steel plate and its manufacturing method

ActiveCN102586688BReduce the degree of enrichmentReduce defects such as red rustManufacturing technologyMetallurgy

The invention provides a double-phase steel plate which comprises 0.07-0.098 of C, 0.1-0.4 of Si, 1.95-2.2 of Mn, 0.3-0.6 of Cr, less than or equal to 0.015 of P, less than or equal to 0.004 of S, less than or equal to 0.005 of N, 0.015-0.04 of Nb, 0.015-0.04 of Ti, 0.015-0.045 of Al, and 0.002-0.004 of B or 0.2-0.4 or Mo, wherein Pcm equals to C+Si / 30+Mn / 20+2P+4S which is less than or equals to 0.24; and the double-phase steel plate also comprises the balance of Fe and unavoidable impurities. The invention also provides a manufacturing method of the double-phase steel plate. The high-strength uniform-performance double-phase steel plate can be obtained by the proper composition design and manufacturing technology, and the manufacturing requirements on parts of a high-strength automobile body can be better met.

Owner:BAOSHAN IRON & STEEL CO LTD

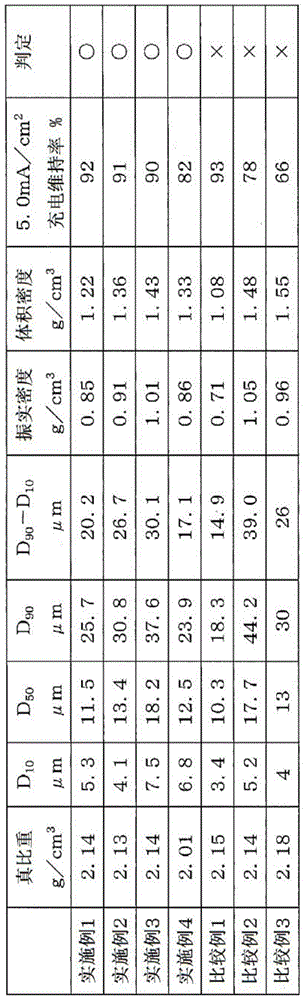

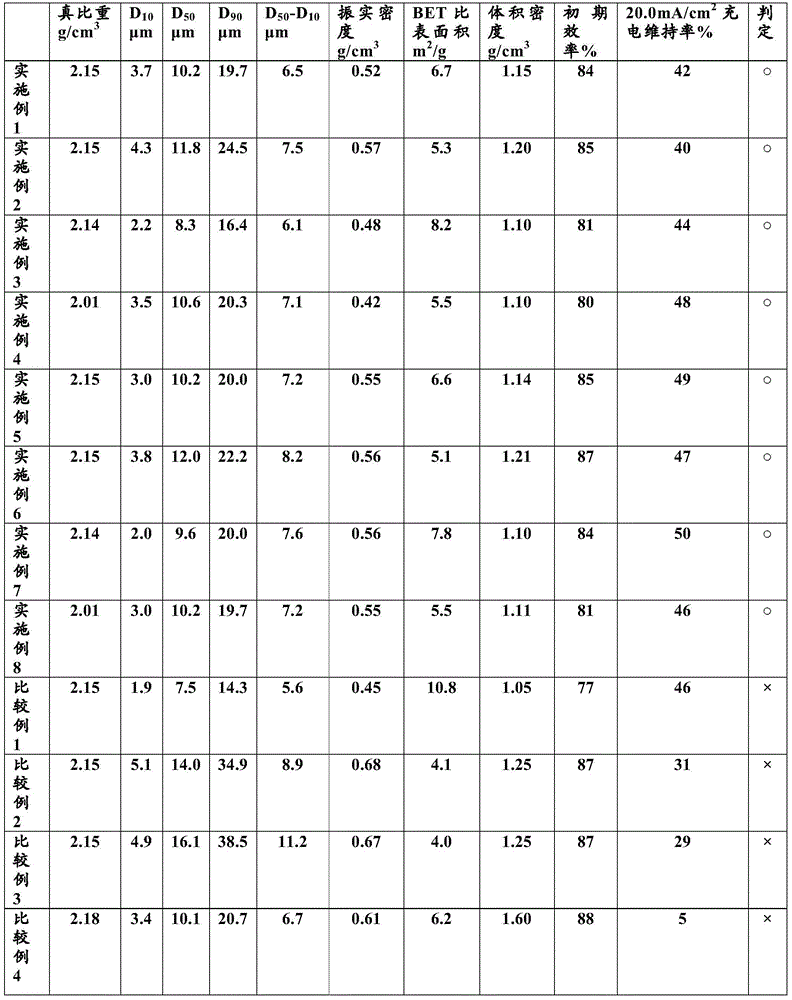

Active substance for use in negative electrode of lithium ion secondary battery, and negative electrode of lithium ion secondary battery and lithium ion secondary battery using same

InactiveCN104604000AIncrease bulk densityExcellent performance balanceCell electrodesElectrolyte accumulators manufactureSpecific gravityIn vehicle

Provided are: an active substance for use in the negative electrode of a lithium ion secondary battery that has a high capacity per unit volume (weight) and that possesses practical characteristics related to the discharge capacity, initial efficiency, input characteristics, capacity retention rate, and the like of a lithium ion secondary battery that make it possible for said active substance to be used in vehicles such as HEVs and PHEVs; and a negative electrode of a lithium ion secondary battery and a lithium ion secondary battery using said active substance. The active substance for use in the negative electrode of a lithium ion secondary battery: is formed from a carbon material having a true specific gravity of 2.00-2.16 g / cm3; has a volume-based particle size distribution that is within a range in which D10 is 3-9 µm, D50 is 10-20 µm, D90 is 21-40 µm, and D90-D10 is 15-35 µm; and has a tap density of 0.8 g / cc or higher. The lithium ion secondary battery comprises: a negative electrode comprising a composite layer formed by mixing the active substance for use in the negative electrode of a lithium ion secondary battery with a binder on a current collector; and a separator via which the negative electrode and a positive electrode are arranged to face each other.

Owner:NIPPON STEEL CHEMICAL CO LTD

Hydrodynamic bearing device, and spindle motor and information device using the same

InactiveUS7846883B2Improve conductivityLow resistivityBearing componentsSliding contact bearingsCarbon numberAlcohol

A hydrodynamic bearing device, comprising a shaft structure, a sleeve, a dynamic pressure-generating groove which is formed on surface of at least one of a shaft structure and a sleeve, and a lubricant present in a gap between the shaft structure and the sleeve; wherein the lubricant contains a diester with a total carbon number of 20 to 28 obtainable by a divalent alcohol that has three ether bond, and one or more types of a saturated monovalent fatty acid with carbon number of 6 to 10.

Owner:PHC HLDG CORP

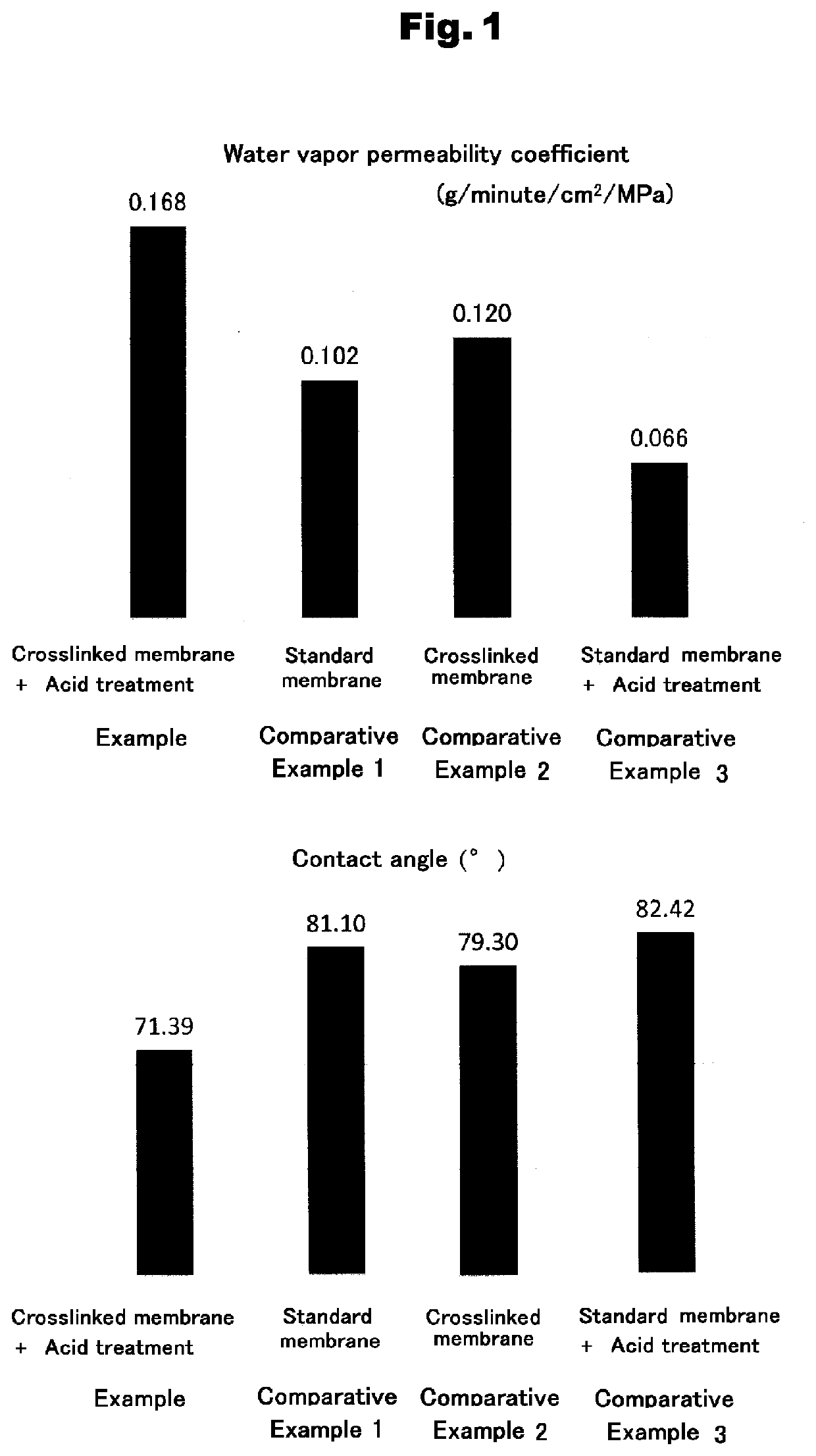

Method for producing porous hollow fiber membrane for humidification

PendingUS20210268449A1Good effectPrevent elutionMembranesSemi-permeable membranesPolymer scienceSpinning

A method for producing a porous hollow fiber membrane for humidification, the method comprising dry-wet spinning a spinning dope comprising a water-soluble organic solvent solution composed of polyphenylsulfone resin and hydrophilic polyvinylpyrrolidone using water as a core liquid; then performing a crosslinking treatment at 120 to 220° C. for 1 to 20 hours; and then dipping the resultant in an acidic solution with a concentration of 5 to 500 ppm. The obtained porous hollow fiber membrane has improved hydrophilicity without impairing the wettability of the porous hollow fiber membrane. Since, humidification performance of the porous hollow fiber membrane alone can be improved, it is effective as a humidifying membrane for fuel cells.

Owner:NOK CORP

Nonaqueous electrolyte secondary battery and process for producing negative electrode thereof

InactiveCN101346837BExcellent performance balanceImprove performanceElectrode manufacturing processesActive material electrodesLithiumPhysical chemistry

A process for producing a negative electrode, comprising the first step of forming multiple columnar active substance agglomerates capable of electrochemical occlusion / release of lithium ions on a surface of current collector and the second step of incorporating granular lithium in interstices of the active substance agglomerates.

Owner:PANASONIC CORP

Negative electrode active material for lithium ion secondary battery, negative electrode for lithium ion secondary battery using the same, and lithium ion secondary battery

InactiveCN104916842AIncrease bulk densityExcellent performance balanceCarbon compoundsCell electrodesSpecific gravityElectrical battery

The invention provides a negative electrode active material for a lithium ion secondary battery, a negative electrode for a lithium ion secondary battery using the same, and a lithium ion secondary battery. The negative electrode active material possesses the practical features of realizing HEV and PHE vehicle purposes as the discharge capacity, initial efficiency, input characteristics and capacity retention of a lithium ion secondary battery, and the capacity of each unit volume (weight) s high. The negative electrode active material for a lithium ion secondary battery is prepared by carbon materials with the true specific gravity of 2.00-2.16 g / cm3; in the grain fineness distribution of grains based on a volume basis, D10 is in a range of 2-5 mum, D50 is in a range of 8-12 mum, D90 is in a range of 16-26 mum, and D50 is in a range of 5-10 mum, and a tap density is above 0.4g / cc; a BET specific area employing the nitrogen adsorption flowing method is 5.1-9.0 m2 / g.

Owner:NIPPON MICROMETAL

Non-aqueous electrolytic solution and non-aqueous electrolyte secondary battery using the same

ActiveUS20200036041A1Improve performanceExcellent performance balanceCell electrodesSecondary cellsElectrolytic agentAqueous electrolyte

An object of the present invention 1 is to provide a non-aqueous electrolyte secondary battery having excellent general performance balance between durability performance and properties, such as a capacity, a resistance, and output characteristics. The present invention 1 is directed to a non-aqueous electrolytic solution for use in a non-aqueous electrolyte secondary battery which comprises: a positive electrode being capable of having occluded therein and releasing metal ions; a negative electrode being capable of having occluded therein and releasing metal ions, and comprising a negative electrode active material containing metal particles capable of forming an alloy together with Li and graphite particles; and a non-aqueous electrolytic solution comprising a non-aqueous solvent and an electrolyte dissolved in the non-aqueous solvent, wherein the non-aqueous electrolytic solution contains a compound represented by the general formula (A), and a non-aqueous electrolyte secondary battery using the non-aqueous electrolytic solution.

Owner:MITSUBISHI CHEM CORP +1

Moisture-curable hot-melt adhesive agent

InactiveCN110678494AImproved initial bond strengthHigh initial bond strengthFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

To provide a moisture-curable hot-melt adhesive agent having excellent balance of initial adhesive strength, adhesive strength after curing and heat resistance and the like, and a layered product bonded with the moisture-curable hot-melt adhesive agent. Means for solving the problem: A moisture-curable hot-melt adhesive agent comprising an urethane prepolymer having an isocyanate group at the end(A), a styrene-isoprene based block copolymer (B), and a tackifying resin (C), wherein the moisture-curable hot-melt adhesive agent comprises 25 to 64% by weight of (A), based on 100 parts by weight in total of (A) and (B).

Owner:HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com