Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208 results about "Vinylcyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic resin composition having improved external appearance and excellent weatherability

The present invention relates to an acrylonitrile (ASA) type thermoplastic resin composition with excellent weatherability and appearance properties, and more particularly, to an acrylate-styrene-acrylonitrile type thermoplastic resin composition comprising a) an acrylate-styrene-acrylonitrile graft copolymer; b) a butadienc-acrylonitrile mcthylmethacrylate graft copolymer; c) a copolymer of aromatic vinyl compound and vinylcyanide compound; and d) an alkyl acrylate copolymer, which has remarkably improved appearance properties such as scratch resistance, color (color stability) and gloss as well as excellent basic properties and weatherability.

Owner:LG CHEM LTD

Polycarbonate Resin Composition and Molded Article Using the Same

A polycarbonate resin composition and a molded article manufactured using the same. The polycarbonate resin composition includes: (A) a polycarbonate resin; (B) a vinyl cyanide compound-aromatic vinyl compound copolymer; (C) an acrylonitrile-butadiene-styrene graft copolymer including (C-1) a first acrylonitrile-butadiene-styrene graft copolymer, a rubbery polymer of which has an average particle diameter of about 200 nm to about 350 nm and (C-2) a second acrylonitrile-butadiene-styrene graft copolymer, a rubbery polymer of which has an average particle diameter of about 400 nm to about 600 nm; and (D) a compatibilizer.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermoplastic Acrylonitrile-Butadiene-Styrene Resin Composition With Excellent Releasability And Colorability

ActiveUS20100048798A1Excellent colorability and releasabilityImprove colorabilityThermoplasticPolymer chemistry

A thermoplastic acrylonitrile-butadiene-styrene (ABS) resin composition of the present invention comprises (a) a bimodal graft copolymer of a conjugated diene rubbery polymer whose average particle diameter of 800 to 1,500 Å and a conjugated diene rubbery polymer whose average particle diameter of 2,500 to 3,500 Å, the conjugated diene rubbery polymers being grafted with an aromatic vinyl compound and a vinyl cyanide compound, (b) an acrylic resin of a methacrylic or acrylic acid alkyl ester compound, an aromatic vinyl compound and a vinyl cyanide compound, (c) a copolymer of an aromatic vinyl compound and a vinyl cyanide compound, and (d) polysiloxane masterbatches. The ABS resin composition has excellent colorability and releasability while maintaining the inherent physical properties (e.g., impact strength and tensile strength) of the base resin.

Owner:LG CHEM LTD

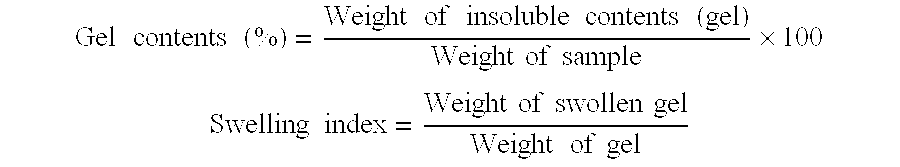

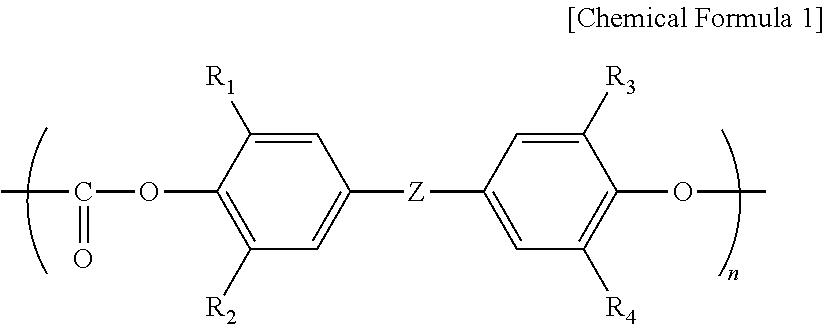

Aromatic polycarbonate resin composition and molded product produced from the same

InactiveUS20090214861A1Improve flame retardant performanceExcellent surface impact propertySynthetic resin layered productsGlass/slag layered productsPolymer sciencePolyolefin

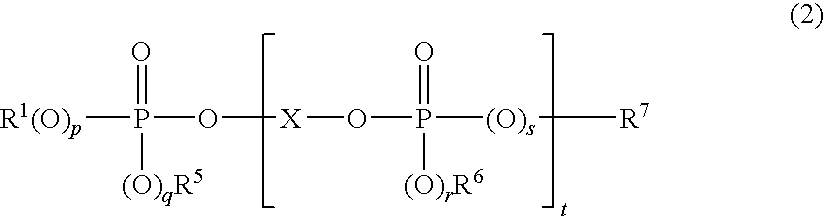

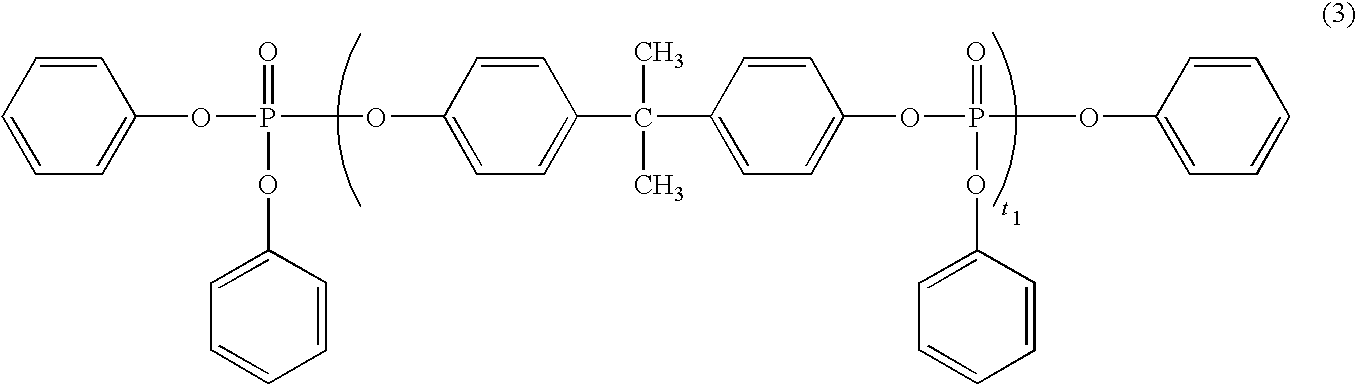

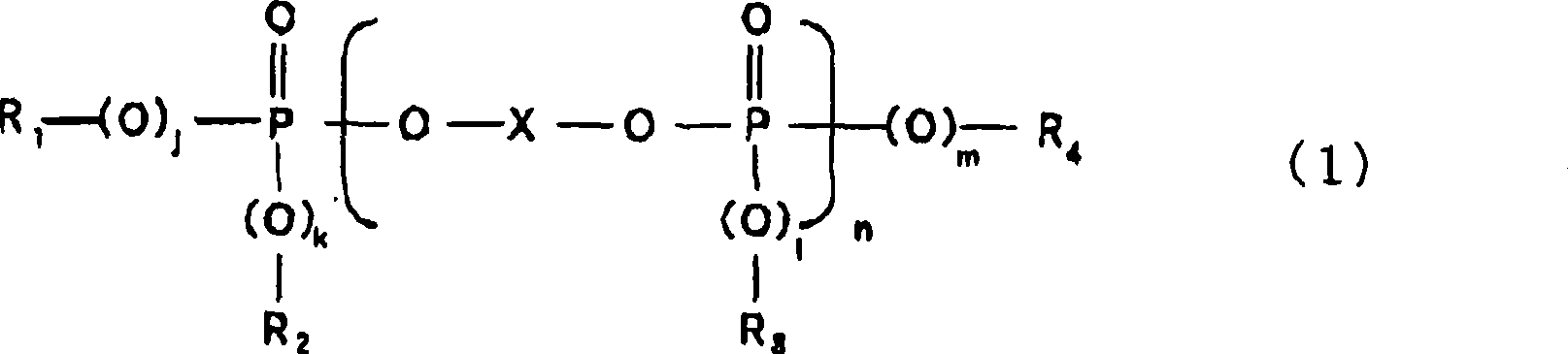

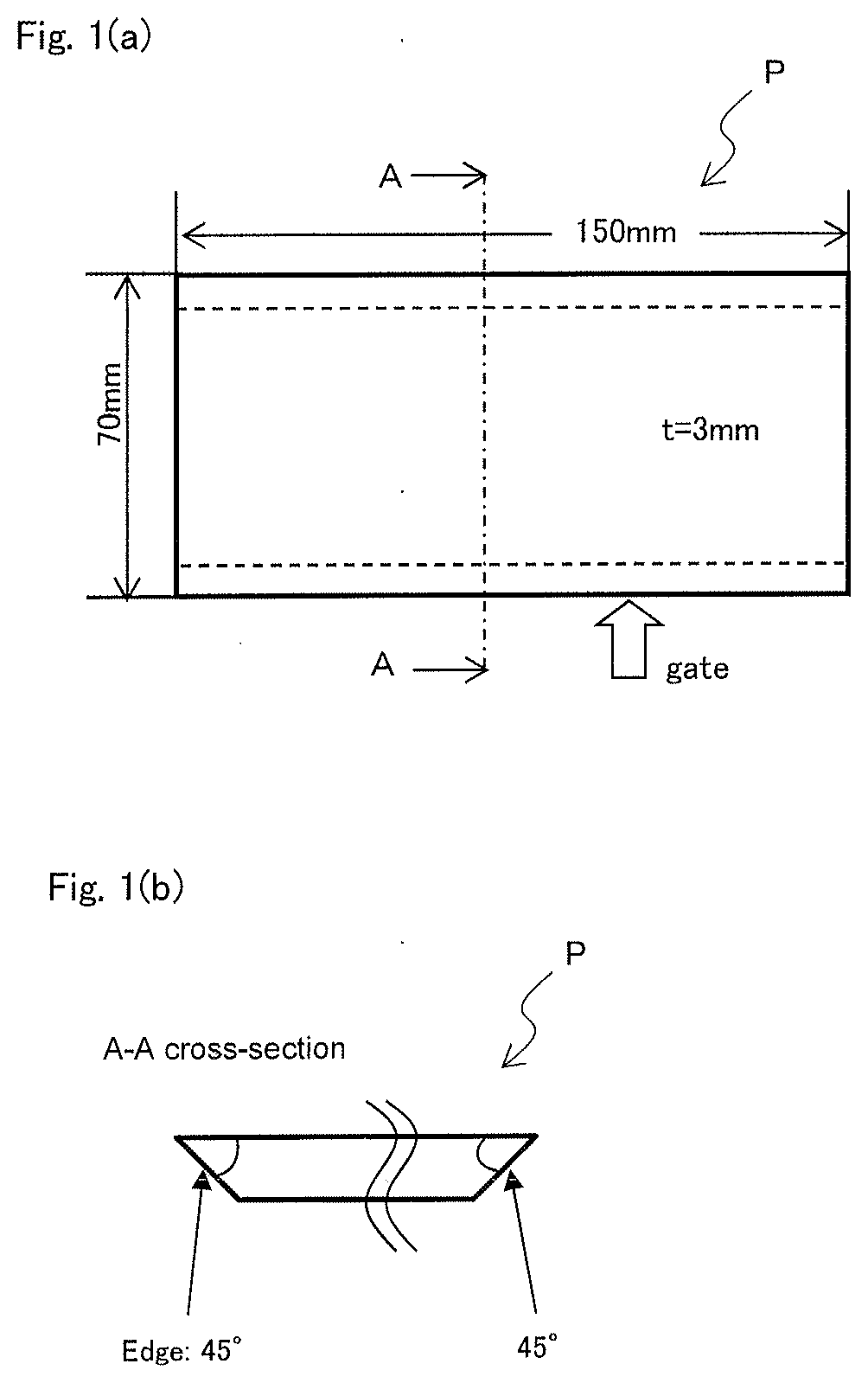

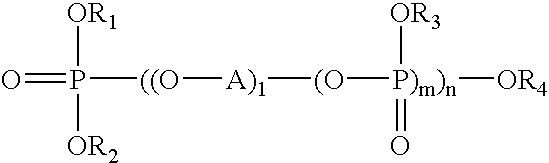

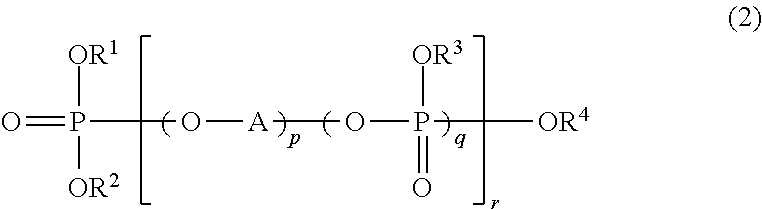

The present invention provides an aromatic polycarbonate resin composition having excellent surface impact strength and flame retardancy which is suitable for production of thin-wall molded products, as well as a molded product produced from the composition.The aromatic polycarbonate resin composition comprises.100 parts by weight of a mixture comprising 60 to 90% by weight of an aromatic polycarbonate resin (a), 10 to 40% by weight of a rubber polymer / aromatic vinyl / cyanided vinyl-based copolymer (b-1) and 0 to 35% by weight of an aromatic vinyl / cyanided vinyl-based copolymer (b-2);10 to 40 parts by weight of (c) a phosphorus-based flame retardant;0 to 5 parts by weight of (d) a fluorinated polyolefin; and0 to 50 parts by weight of an inorganic filler (e),a content of the rubber polymer component being 31 to 50% by weight on the basis of a total amount of the components (b-1) and (b-2), and which aromatic polycarbonate resin composition has such a property that an injection-molded product obtained from the aromatic polycarbonate resin composition satisfies the following relational formula (1):Cpf / Cpc<2 (1)wherein Cpf is a notched Charpy impact strength in a direction parallel with a flow direction of the resin composition; and Cpc is a notched Charpy impact strength in a direction perpendicular to a flow direction of the resin composition as measured according to JIS K7111.

Owner:MITSUBISHI ENG PLASTICS CORP

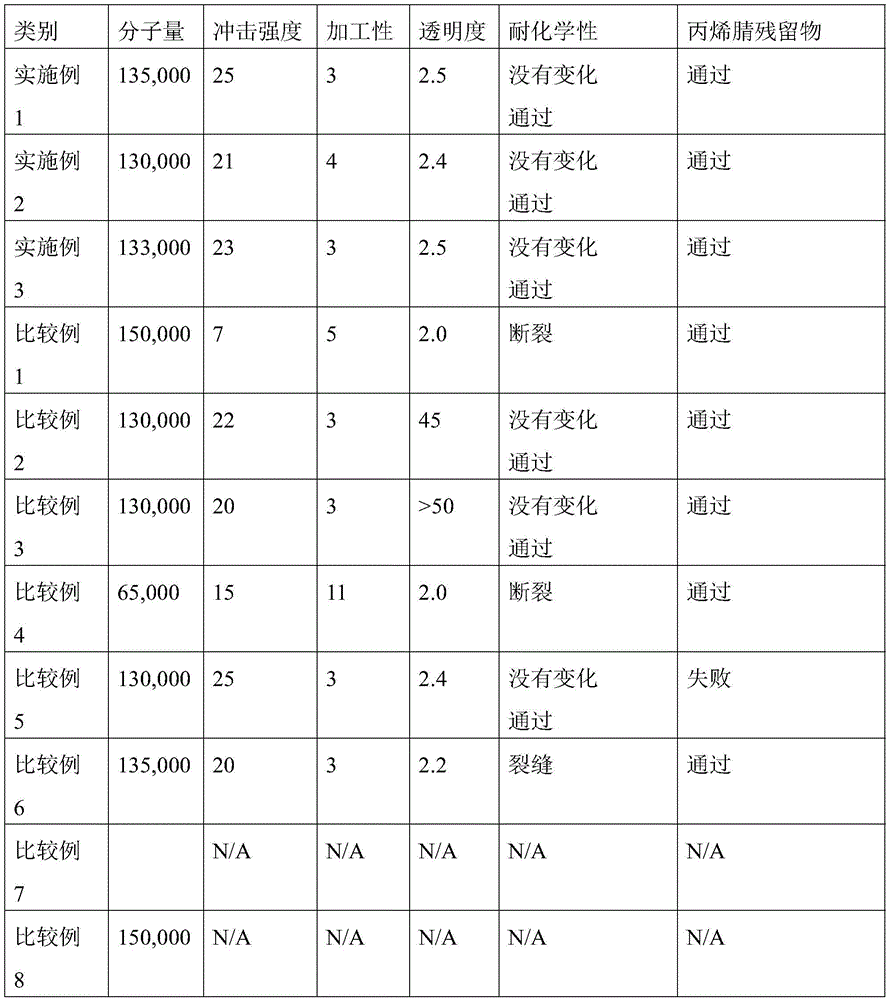

Acrylonitrile-butadiene-styrene (ABS) thermoplastic transparent resin

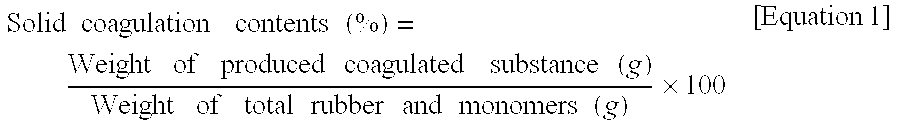

The present invention relates to a process for preparing thermoplastic resin for extrusion sheets, and particularly to a process for preparing acrylonitrile-butadiene-styrene (ABS) thermoplastic transparent resin for extrusion sheets having superior impact resistance, chemical resistance, processability, whitening resistance, high temperature elongation, etc. and very superior transparency, by controlling a mixing ratio of a methacrylate alkylester compound or acrylate alkylester compound, an aromatic vinyl compound, and a vinylcyanide compound grafted on conjugated diene rubber latex of which an average particle diameter and gel contents (degree of crosslinking) are optimized to control a refractive index of the monomer mixture to be similar to that of the rubber latex, and optimizing the molecular weight.

Owner:YOO KEUN HOON +4

Reinforced thermoplastic resin composition and molded article

ActiveUS20120178860A1Good molding effectIncrease resistancePhosphorus organic compoundsCyanide compoundPolymer science

The reinforced thermoplastic resin composition of the present invention includes: 50 to 90% by weight of a polycarbonate resin (A); 10 to 50% by weight of a graft copolymer mixture (B) (provided that a total amount of the component (A) and the component (B) accounts for 100% by weight) which is obtained by graft-polymerizing an aromatic alkenyl compound monomer unit (a) and a vinyl cyanide compound monomer unit (b) onto a rubber polymer (B1); and 6 to 22 parts by weight of an inorganic filler (D) which has been surface-treated with a water-soluble polyamide, relative to the total of 100 parts by weight of the polycarbonate resin (A) and the graft copolymer mixture (B). There is provided a reinforced thermoplastic resin composition exhibiting excellent moldability, generates a minimal amount of gas during molding, and also being capable of improving the rigidity of the resulting molded article and the impact resistance when dropping the product.

Owner:TECHNO UMG CO LTD

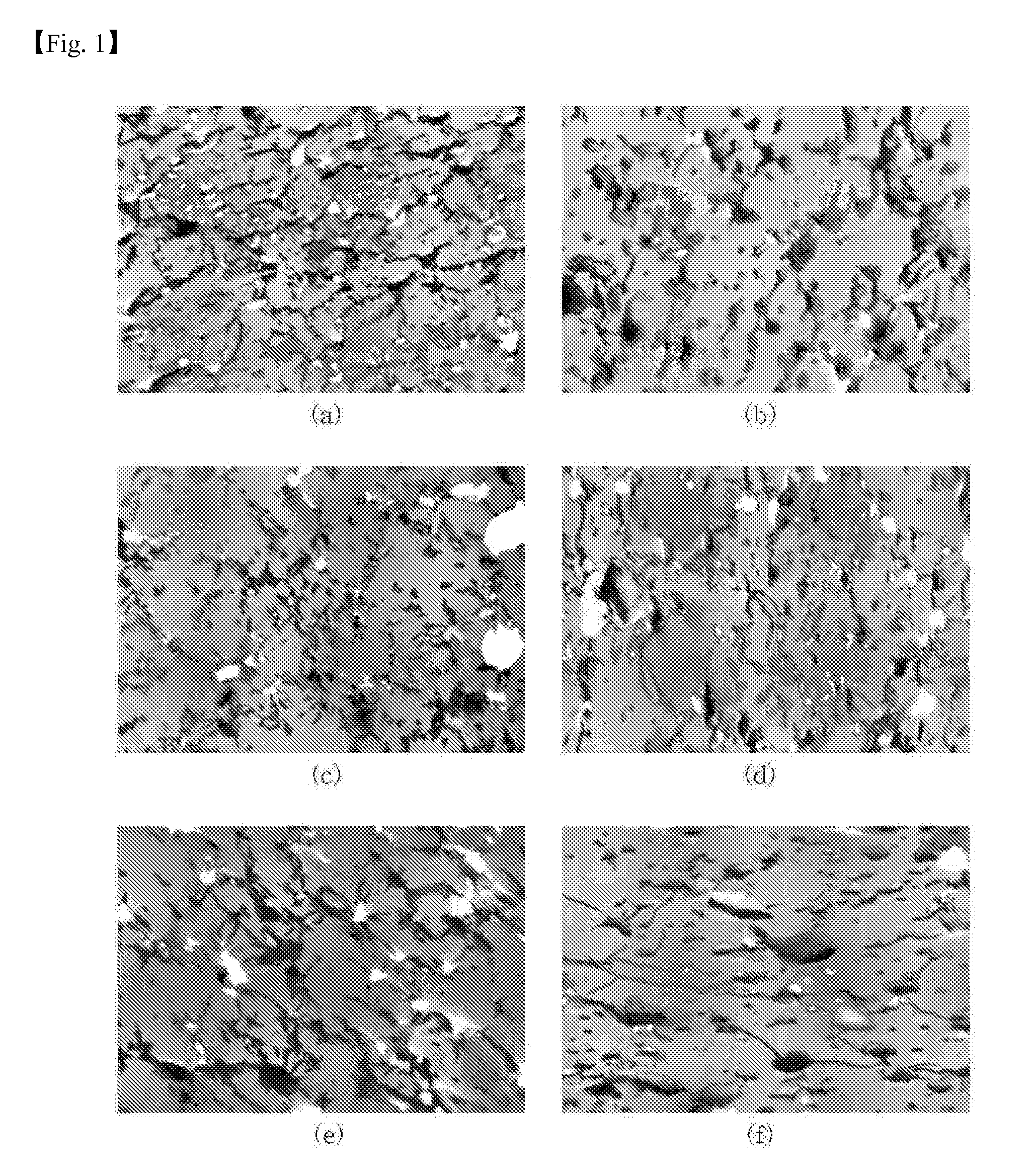

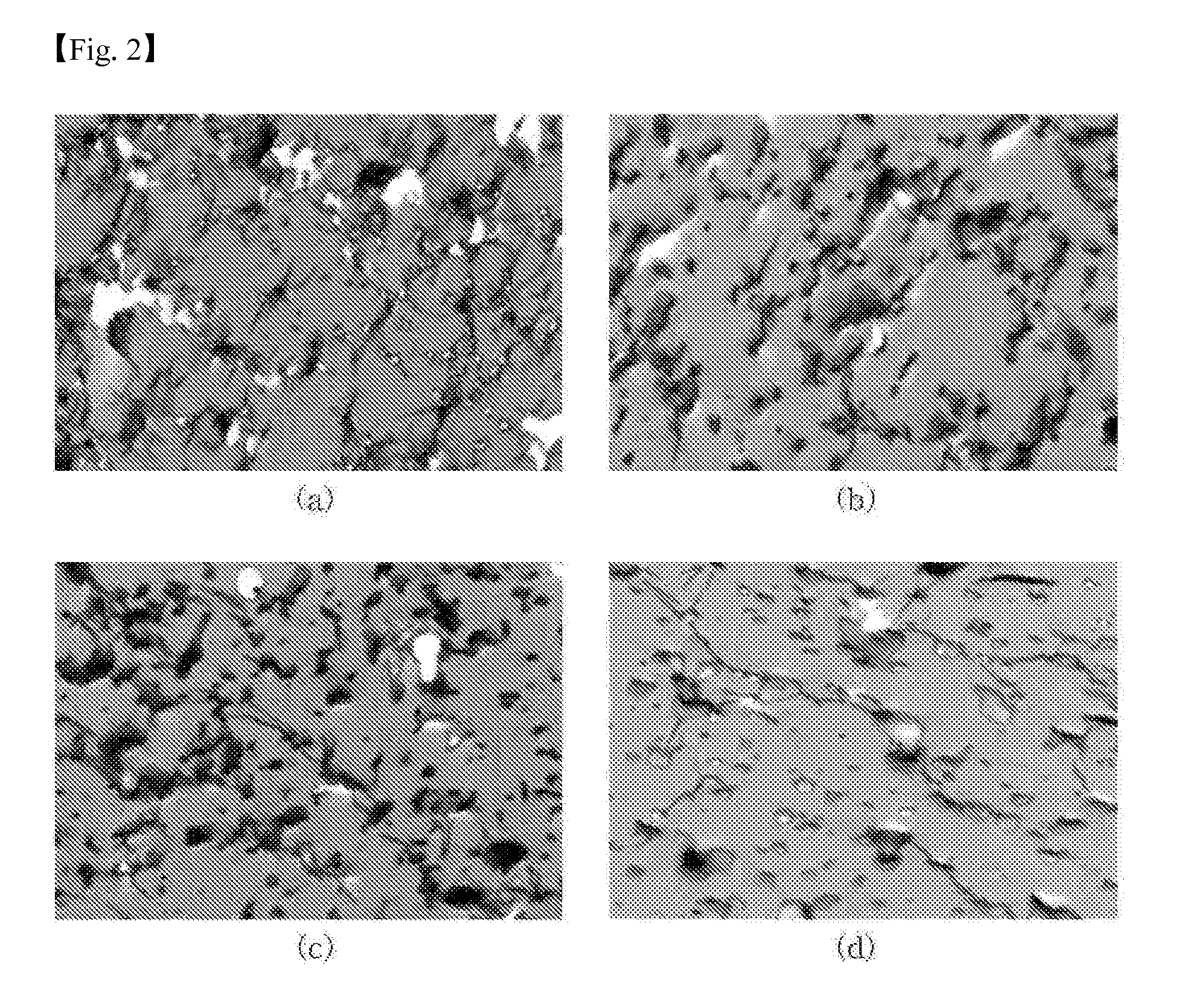

Weather Resistant Thermoplastic Resin Having Excellent Low Gloss Characteristics and Method of Preparing the Same

A weather resistant thermoplastic resin having excellent low gloss characteristics according to the present invention comprises a (meth)acrylic acid alkyl ester-based polymer (A) and an aromatic vinyl-cyanide vinyl based copolymer (B), wherein the (meth)acrylic acid alkyl ester-based polymer (A) forms a network-shaped disperse phase, and the aromatic vinyl-cyanide vinyl based copolymer (B) forms a continuous phase. The thermoplastic resin has excellent low gloss characteristics as well as superior weatherability, impact resistance, thermal resistance, delamination characteristics, and the like.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermoplastic resin composition and method for preparing the same

The present invention relates to a thermoplastic resin composition and a preparation method of the same, and more precisely a thermoplastic resin having excellent impact strength, surface gloss, and beautiful color, as well as a high level of hardness and scratch resistance, which comprises a) a primary graft copolymer prepared by polymerization of conjugated diene rubber latex with (metha)acrylic acid alkyl ester compound, aromatic vinyl compound and vinyl cyan compound; and b) a secondary copolymer prepared by polymerization of (metha)acrylic acid alkyl ester compound with aromatic vinyl compound and vinyl cyan compound.

Owner:LG CHEM LTD

Method for preparing rubber-reinforced thermoplastic resin, and rubber-reinforced themoplastic resin composition using the same

The present invention relates to a method for preparing a rubber-reinforced thermoplastic resin, a rubber-reinforced thermoplastic resin prepared by the same method, and a rubber-reinforced thermoplastic resin composition using the same, wherein the rubber-reinforced thermoplastic resin has excellent heat-sealability and thermal stability maintaining good mechanical properties. More specifically, the present invention relates to a method for preparing a rubber-reinforced thermoplastic resin, a rubber-reinforced thermoplastic resin prepared by the same method, and a rubber-reinforced thermoplastic resin composition using the same characterized by, on the basis of 100 weight parts of total monomer used to prepare graft copolymer, using the mixture comprising 10 to 30 weight parts of a rubber latex having average particle diameter of 0.08 to 0.16 mum and gel content of 65 to 95 weight % and 15 to 45 weight parts of a rubber latex having average particle diameter of 0.26 to 0.34 mum and gel content of 55 to 85 weight %, keeping the weight ratio of vinyl cyanide compound including acrylonitrile to aromatic vinyl compound including styrene from 16 / 84 to 24 / 76 as a monomer composition grafted on rubber latex, and adjusting the graft ratio of graft copolymer, i.e. rubber-reinforced thermoplastic resin, from 25 to 65.

Owner:LG CHEM LTD

Thermoplastic resin composition having superior chemical resistance and transparency, method of preparing the same and molded article including the same

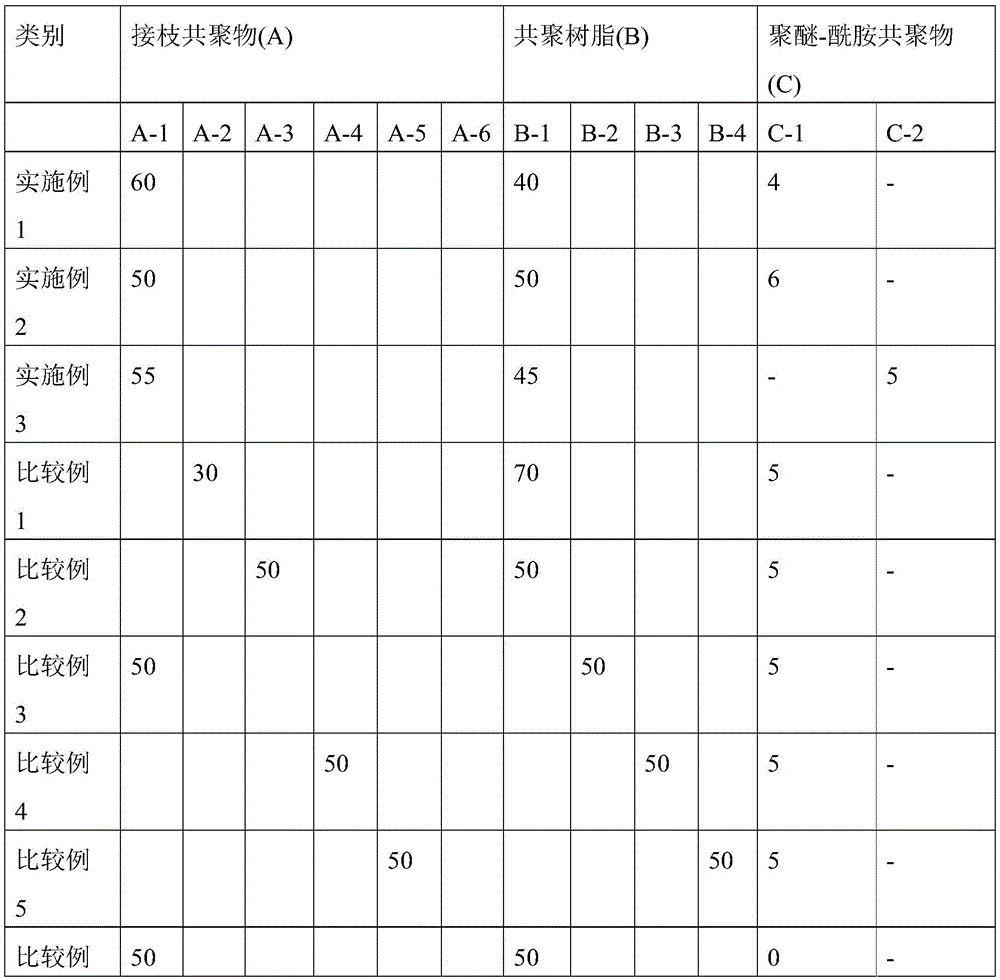

Disclosed are a transparent resin composition, which may be used in medical products and food storage containers, having superior chemical resistance and transparency, a method of preparing the same and a molded article manufactured therefrom. More particularly, disclosed are a thermoplastic transparent resin composition having superior chemical resistance and transparency, which comprises (A) a graft copolymer in which a) a conjugated diene rubber latex is graft copolymerized with b) a methacrylate alkyl ester compound or an acrylate alkyl ester compound, c) an aromatic vinyl compound, and d) a vinyl cyano compound; (B) a copolymerized resin in which i) a methacrylate alkyl ester compound or an acrylate alkyl ester compound, ii) an aromatic vinyl compound and iii) a vinyl cyano compound are copolymerized; and (C) a polyether-amide block copolymer, a method of preparing the same, and a molded article manufactured therefrom.

Owner:LG CHEM LTD

Thermoplastic resin composition having excellent chemical resistance and transparency, method for preparing same, and molded product comprising same

The present invention relates to a transparent resin composition which has excellent chemical resistance and transparency and is usable for medical purposes and food containers, a method for preparing the same, and a molded product manufactured therefrom and, specifically, to a transparent thermoplastic resin composition having excellent chemical resistance and transparency, a method for preparing the same, and a molded product manufactured therefrom, wherein the resin composition contains: (A) a graft copolymer obtained by graft-copolymerizing, onto a) conjugated diene rubber latex, b) a methacrylic acid alkyl ester compound or an acrylic acid alkyl ester compound, c) an aromatic vinyl compound, and d) a vinyl cyan compound; (B) a copolymer resin obtained by copolymerizing i) a methacrylic acid alkyl ester compound or an acrylic acid alkyl ester compound, ii) an aromatic vinyl compound, and iii) a vinyl cyan compound; and (C) a polyether-amide bloc copolymer.

Owner:LG CHEM LTD

Thermoplastic abs resin composition with improved impact resistance, dimensional stability and blow molding property

The thermoplastic ABS resin composition according to the present invention comprises (a) 2 to 25 parts by weight of a graft copolymer particle containing rubbers having a volume average particle diameter range from 0.05 D to less than 0.18 D; (b) 2 to 25 parts by weight of a graft copolymer particle containing rubbers having a volume average particle diameter range from 0.18 D to less than 0.4 D; (c) 2 to 18 parts by weight of a graft copolymer particle containing rubbers having a volume average particle diameter range from 0.4 D to less than 4 D; (d) 10 to 70 parts by weight of a branched vinyl cyanide- vinyl aromatic copolymer; and (e) 1 to 60 parts by weight of a long-chain linear vinyl cyanide- vinyl aromatic copolymer.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermoplastic resin compsn. having excellent chemical resistance and easy vacuum formability

InactiveCN1481420AWell balanced physical propertiesBalanced Physical PropertiesDomestic articlesCyanide compoundPolymer science

The resin composition according to the present invention comprises(A)a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of diene rubber,(B)a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30%by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of acrylic rubber,(C)a linear copolymer prepared by polymerizing 40-50% by weight of vinyl cyanide compound and 50-60% by weight of vinyl aromatic compound, and (D) a branched copolymer prepared by 30-35% by weight of vinyl cyanide compound and 65-70% by weight of vinyl aromatic compound.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Acrylonitrile-butadiene-styrene (abs) thermoplastic transparent resin

The present invention relates to a process for preparing thermoplastic resin for extrusion sheets, and particularly to a process for preparing acrylonitrile-butadiene-styrene (ABS) thermoplastic transparent resin for extrusion sheets having superior impact resistance, chemical resistance, processability, whitening resistance, high temperature elongation, etc. and very superior transparency, by controlling a mixing ratio of a methacrylate alkylester compound or acrylate alkylester compound, an aromatic vinyl compound, and a vinylcyanide compound grafted on conjugated diene rubber latex of which an average particle diameter and gel contents (degree of crosslinking) are optimized to control a refractive index of the monomer mixture to be similar to that of the rubber latex, and optimizing the molecular weight.

Owner:LG CHEM LTD

Thermoplastic resin composition having improved external appearance and excellent weatherability

The present invention relates to an acrylonitrile (ASA) type thermoplastic resin composition with excellent weatherability and appearance properties, and more particularly, to an acrylate-styrene-acrylonitrile type thermoplastic resin composition comprising a) an acrylate-styrene-acrylonitrile graft copolymer; b) a butadienc-acrylonitrile methylmethacrylate graft copolymer; c) a copolymer of aromatic vinyl compound and vinylcyanide compound; and d) an alkyl acrylate copolymer, which has remarkably improved appearance properties such as scratch resistance, color (color stability) and gloss as well as excellent basic properties and weatherability.

Owner:LG CHEM LTD

Method of preparing thermoplastic resin composition having superior surface clearness and gloss

ActiveUS20160096957A1Superior surface clearnessHigh glossSpecial tyresEmulsion polymerizationMoisture

Disclosed are a method of preparing a thermoplastic resin composition having superior surface clearness and gloss. More particularly, the present invention relates to a method of preparing a superior thermoplastic resin composition which has superior surface clearness and superior gloss and may prevent mold deposition during a high speed injection process, by using a reactive emulsifier during emulsion polymerization of rubber latex composed of polybutadiene, preparing resin latex using a hydrophobic initiator during graft copolymerization of rubber latex, an aromatic vinyl monomer, and a vinyl cyan monomer, compression dehydrating a moisture content to less than 10% using a compression type dehydrator after agglomerating the resin latex, and performing a wet powder extrusion process.

Owner:LG CHEM LTD

Alkyl acrylate-aromatic vinyl compound-vinyl cyanide compound copolymer with improved low-temperature impact strength and polycarbonate composition comprising the same

ActiveUS20160304651A1High impact strengthLow-temperature impact strengthCyanide compoundCompound (substance)

Disclosed are an alkyl acrylate-aromatic vinyl compound-vinyl cyanide compound copolymer which is prepared using a polyalkylene cross-linking agent such as polyethylene glycol diacrylate or polyethylene glycol dimethacrylate for a core of the alkyl acrylate-aromatic vinyl compound-vinyl cyanide compound copolymer and thus advantageously improves low-temperature impact strength of resins when the copolymer is applied to a polycarbonate resin composition, and the polycarbonate resin composition comprising the copolymer.

Owner:LG CHEM LTD

Flame retardant aromatic polycarbonate resin composition

The invention provides a flame retardant aromatic series panlite polycarbonate resin composite, wherein, as per parts by weight, the composite contains 50-90 parts by weight of aromatic series panlite polycarbonate resin (component A) and 1-50 parts by weight of thermoplastic graft copolymer (component B), which is formed by grafting vinylcyanide compounds and aromatic series vinyl-compounds on dienes rubber constituent, and does not present an absorption peak derived from fatty amide between 3200cm<-1> and 3400cm<-1> in the measurement of infrared absorption spectrum, and the rubber constituent content of which is 5-80 percent by weight, and contains 1-30 parts by weight of organophosphorous flame retardant (component C) and 0.05-2 parts by weight of fluorine-containing drip-proof agent (component D) as well, and all the contents of the composite amount to 100 parts by weight. The invention also relates to a flame retardance aromatic series panlite polycarbonate resin composite which contains aromatic series panlite polycarbonate resin, ABS resin, organophosphorous flame retardant and fluorine-containing drip-proof agent and the flame retardance of which is further improved without reducing flowability and mechanical features.

Owner:TEIJIN KASEK KK

Acrylonitrile-butadiene-styrene copolymer transparent resin having superior chemical resistance and transparency and preparation thereof

The present invention relates to acrylonitrile-butadiene-styrene copolymer transparent resin having superior chemical resistance and transparency and preparation thereof, and particularly to acrylonitrile-butadiene-styrene copolymer transparent resin having superior chemical resistance and transparency by graft-copolymerzing on a) conjugated diene rubber latex, b) methacrylate alkylester or acrylate alkylester compound, c) aromatic vinyl compound and d) vinyl cyanide compound, and preparation thereof. In addition, according to the present invention, chemical resistance and ESCR can be further improved by further adding e) polyester-amide copolymer to the acrylonitrile-butadiene-styrene copolymer transparent resin.

Owner:LG CHEM LTD

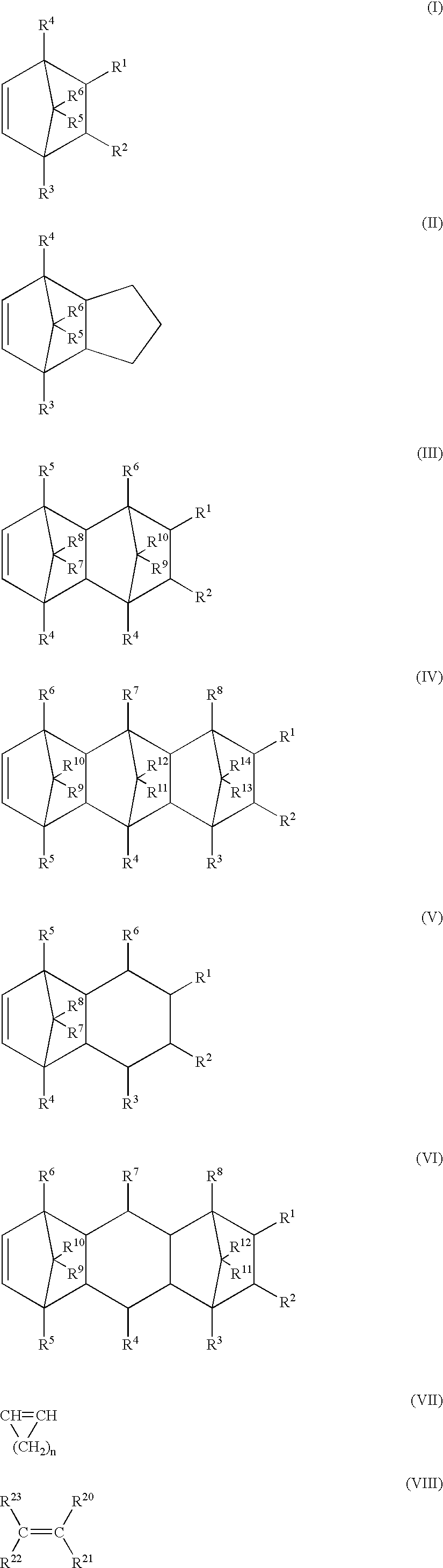

Noncrystalline polyolefin resin composition

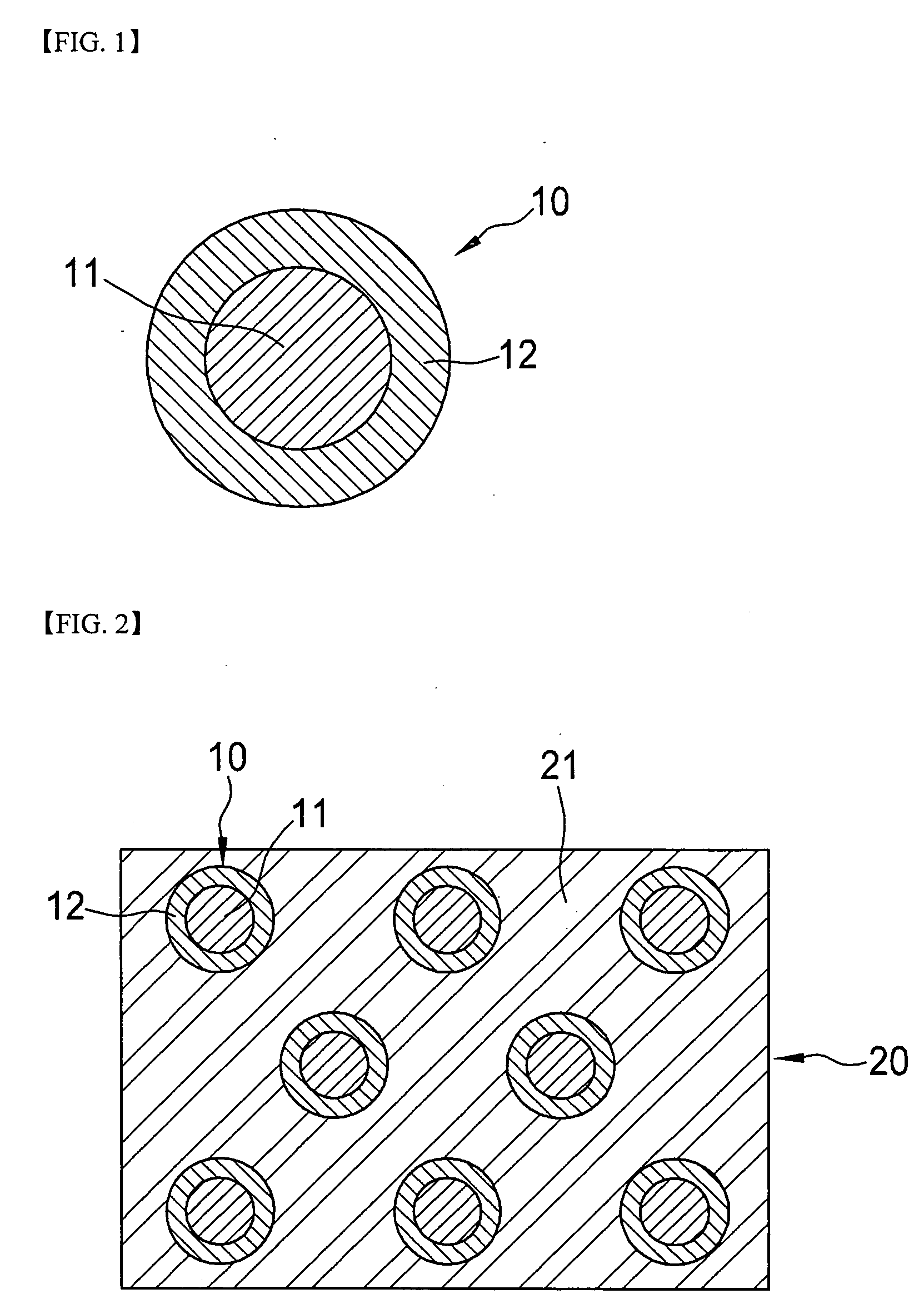

InactiveUS6683134B2Good balance of transparency and impact resistanceImprove balanceElastomerCyanide compound

Amorphous polyolefin resin compositions having an impact resistance remarkably improved without impairing the transparency by an impact modifier which can be prepared from easily available raw materials by a general polymerization method, the compositions containing as the impact modifier a core-shell elastomer obtained by graft polymerization of a monomer mixture of an alkyl (meth)acrylate with an alkyl group having 3 to 8 carbon atoms, an alkyl (meth)acrylate with an alkyl group having 2 or less carbon atom or a vinyl cyanide compound, and an aromatic vinyl monomer in a specific ratio in the presence of a conjugated diene copolymer rubber.

Owner:KANEKA CORP

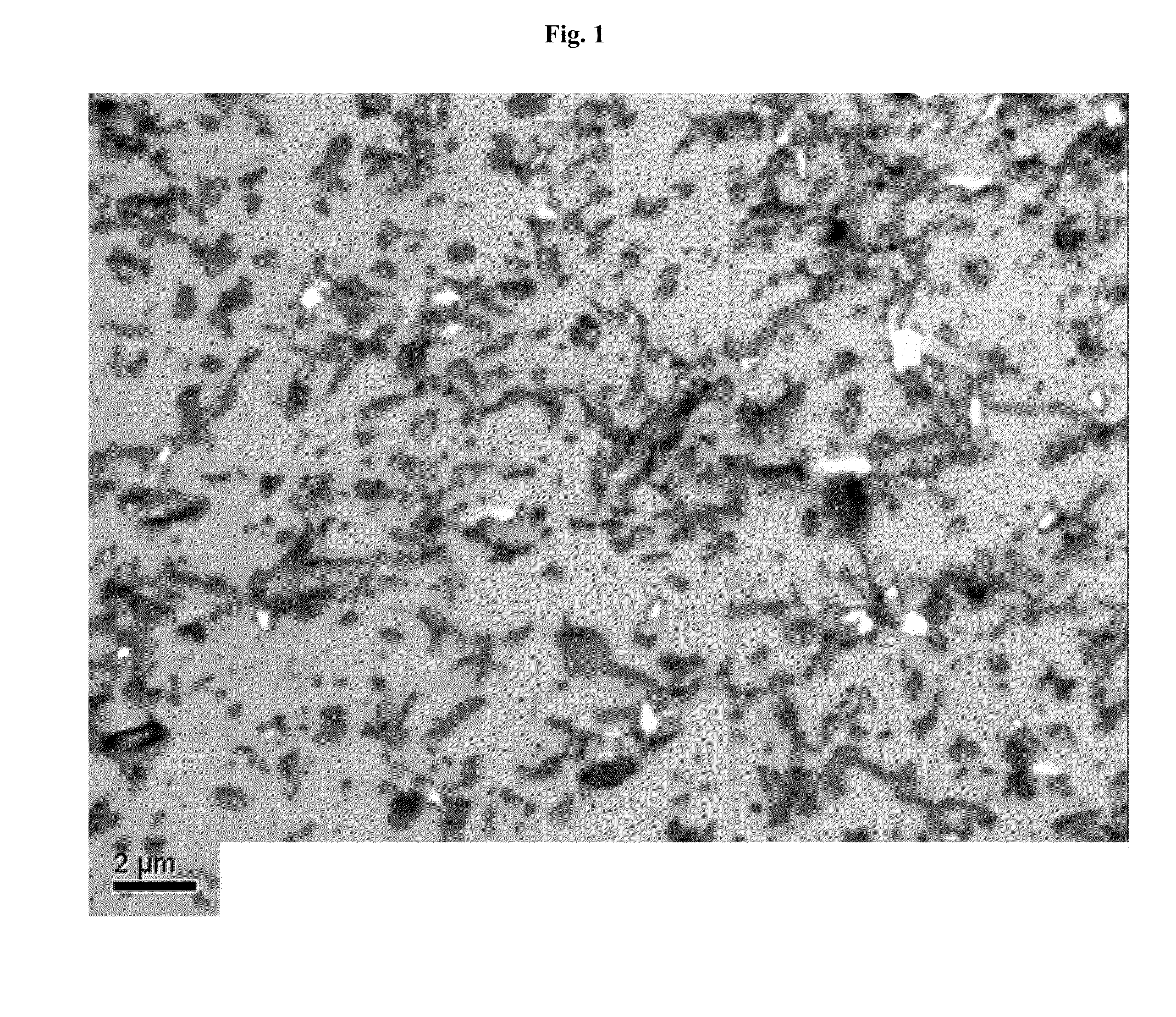

Weatherable Thermoplastic Resin Composition Having Excellent Low Gloss Characteristic and Method of Preparing the Same

The present invention provides a weather resistant thermoplastic resin with low gloss and a method of preparing the same. The thermoplastic resin of the present invention comprises a (meth)acrylic acid alkyl ester-based polymer (A) and a (meth)acrylic acid alkyl ester-based oligomeric prepolymer (B), and an aromatic vinyl-cyanide vinyl based copolymer (C), wherein the (meth)acrylic acid alkyl ester-based polymer (A) and the (meth)acrylic acid alkyl ester-based oligomeric prepolymer (B) form a network-shaped disperse phase and the aromatic vinyl-cyanide vinyl based copolymer (C) forms a continuous phase.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Method for producing abs-based graft copolymer and method for producing thermoplastic resin composition

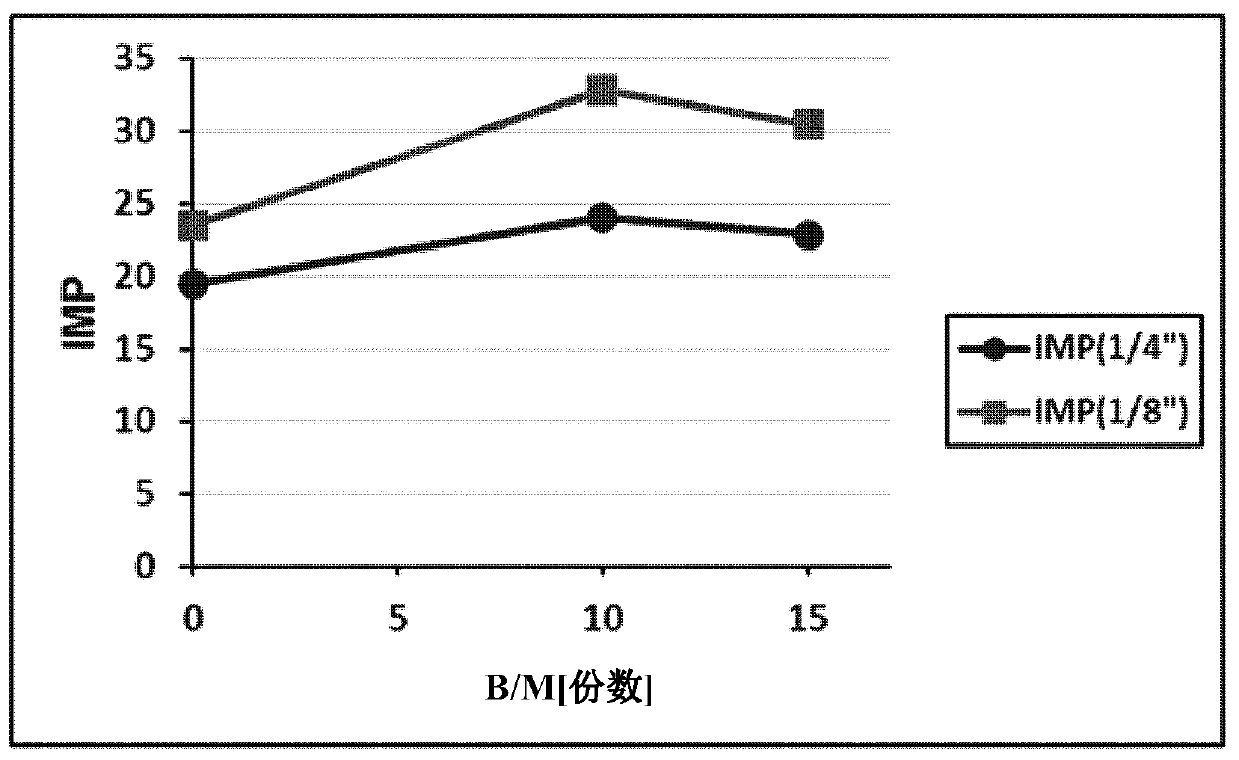

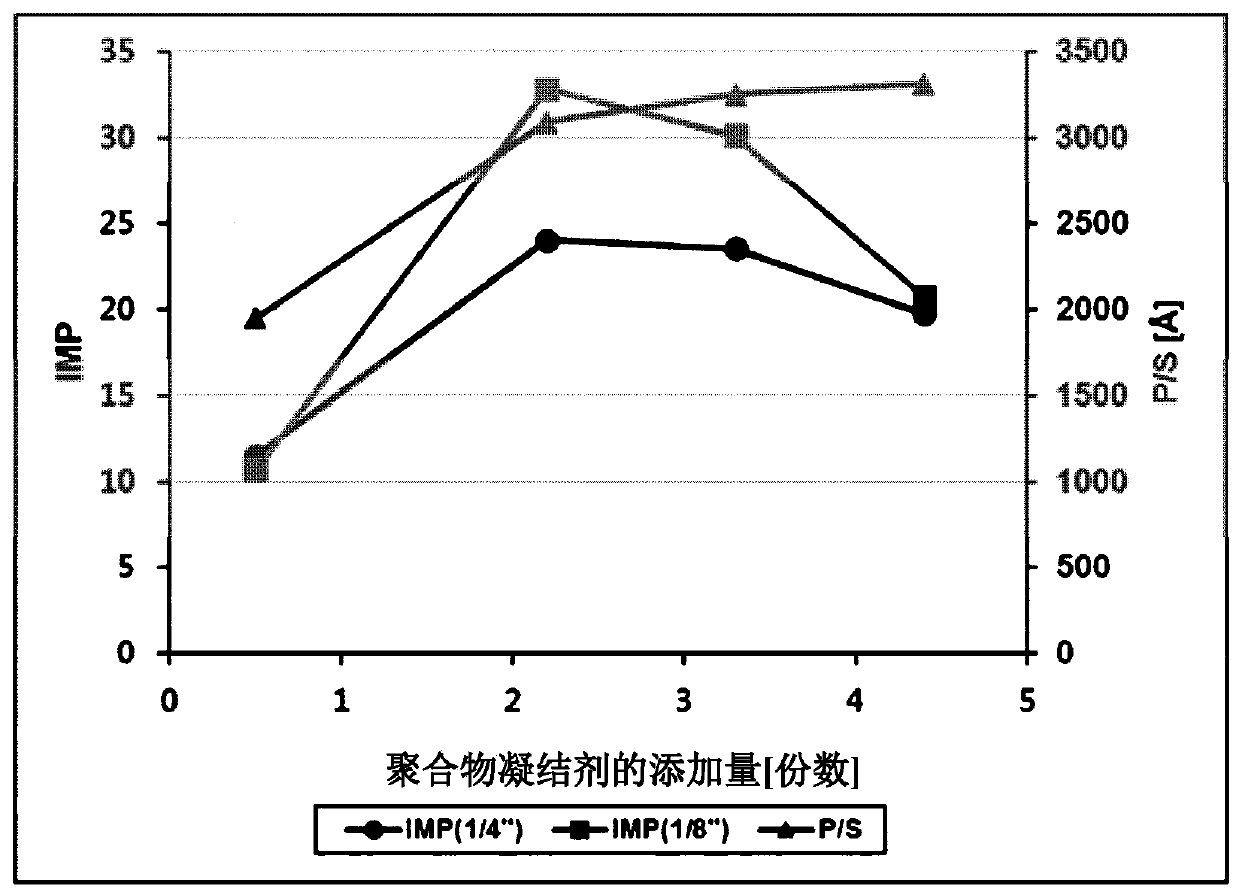

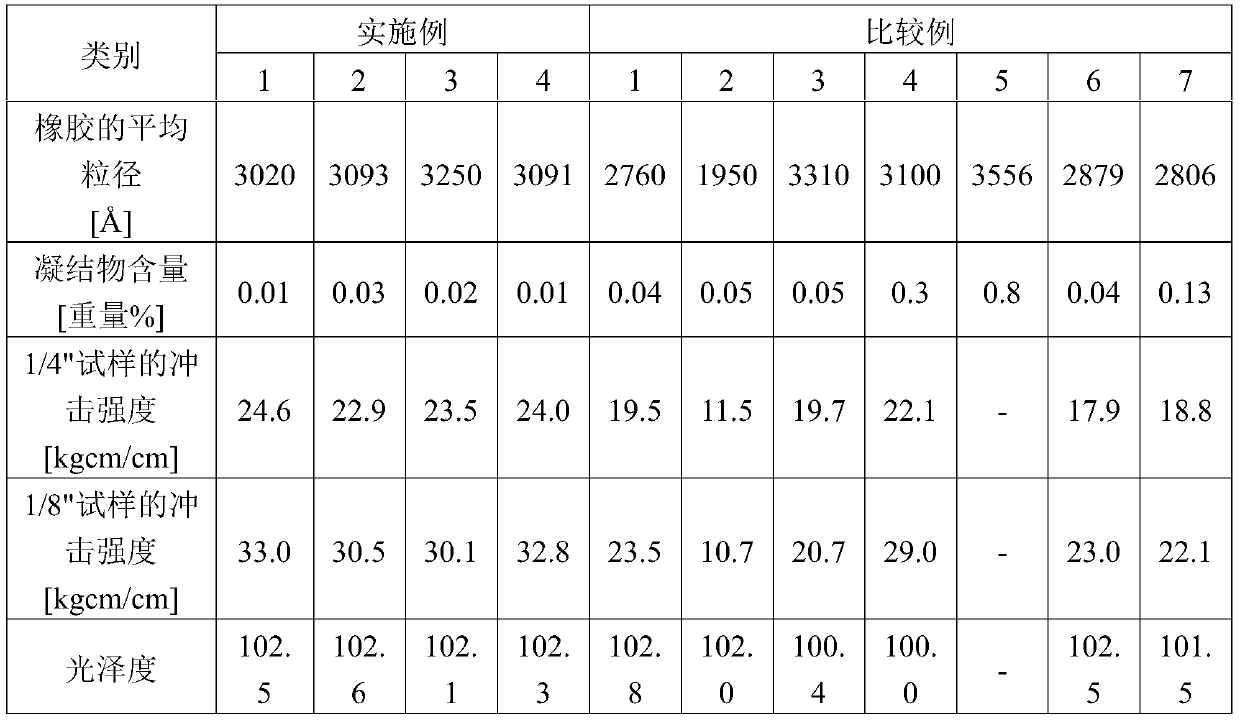

The present invention relates to a method for producing an ABS-based graft copolymer and a method for producing a thermoplastic resin composition comprising same. More specifically, the present invention relates to a method for producing an ABS-based graft copolymer and a method for producing a thermoplastic resin composition comprising same, characterized in that a predetermined amount of a vinylaromatic compound and a vinyl cyan compound are added and partially grafted before enlarging a small-diameter rubber latex, and then a polymer coagulant is added in a specific content range to enlarge the rubber latex. According to the present invention, the stability of the latex can provide an ABS-based graft copolymer and has an advantage of improving impact resistance.

Owner:LG CHEM LTD

Thermoplastic resin composition and moldings thereof

A polyamide resin / rubber-reinforced styrene-based resin composition, particularly, a polyamide resin / ABS resin composition, excellent in the balance between impact strength and fluidity as well as in the heat resistance, chemical resistance and paintability, as well as a shaped article thereof, are provided. The resin composition comprises 100 parts by weight of a thermoplastic resin comprising (A) from 79.5 to 20 parts by weight of a polyamide resin, (B) from 20 to 79.5 parts by weight of a polymer obtained by grafting an aromatic vinyl-based monomer and a vinyl cyanide-based monomer to a specific rubber-like polymer, (C) from 0.5 to 60 parts by weight of an unsaturated carboxylic acid-modified copolymer obtained by copolymerizing an unsaturated carboxylic acid, an aromatic vinyl-based monomer and a vinyl cyanide-based monomer, and (D) from 0 to 50 parts by weight of a copolymer obtained by copolymerizing an aromatic vinyl-based monomer and a vinyl cyanide-based monomer (with the proviso that the total of (A), (B), (C) and (D) is 100 parts by weight), and if desired, further comprises (E) from 0.05 to 150 parts by weight of an inorganic filler.

Owner:UMG ABS +2

Thermoplastic Abs Resin Composition with Improved Impact Resistance, Dimensional Stability and Blow Molding Property

The thermoplastic ABS resin composition according to the present invention comprises (a) 2 to 25 parts by weight of a graft copolymer particle containing rubbers having a volume average particle diameter range from 0.05 μm to less than 0.18 μm; (b) 2 to 25 parts by weight of a graft copolymer particle containing rubbers having a volume average particle diameter range from 0.18 μm to less than 0.4 μm; (c) 2 to 18 parts by weight of a graft copolymer particle containing rubbers having a volume average particle diameter range from 0.4 μm to less than 4 μm; (d) 10 to 70 parts by weight of a branched vinyl cyanide-vinyl aromatic copolymer; and (e) 1 to 60 parts by weight of a long-chain linear vinyl cyanide-vinyl aromatic copolymer.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermoplastic resin and preparation thereof

The present invention relates to ABS thermoplastic resin and preparation thereof, and particularly to a process for preparing an ABS graft copolymer comprising the step of introducing to a) 40 to 80 weight parts of rubber latex comprising i) 10 to 50 weight parts of large diameter polybutadiene rubber latex having a particle diameter of 2500 to 3500 Å, gel contents of 60 to 80%, and a swelling index to 12 to 30, and ii) 50 to 90 weight parts of large diameter rubber latex having a particle diameter of 2500 to 3500 Å, gel contents of 81 to 97%, and a swelling index of 18 to 40, b) 20 to 60 weight parts of a monomer mixture of two or more kinds selected from a group consisting of aromatic vinyl compounds and vinyl cyanide compounds to prepare a graft copolymer, wherein 5 to 30 wt % of the monomer mixture is introduced as a batch and simultaneously 70 to 95 wt % of the monomer mixture is started to be continuously introduced in an emulsified state, and a thermoplastic resin composition using the same. According to the process of the present invention, control of polymerization heat is easy even at high solid contents, and polymerization cohesion contents can be minimized and thus ABS thermoplastic resin having superior impact resistance, gloss, and coloring property can be provided.

Owner:LG CHEM LTD

Thermoplastic resin composition, molded article and coated molded article

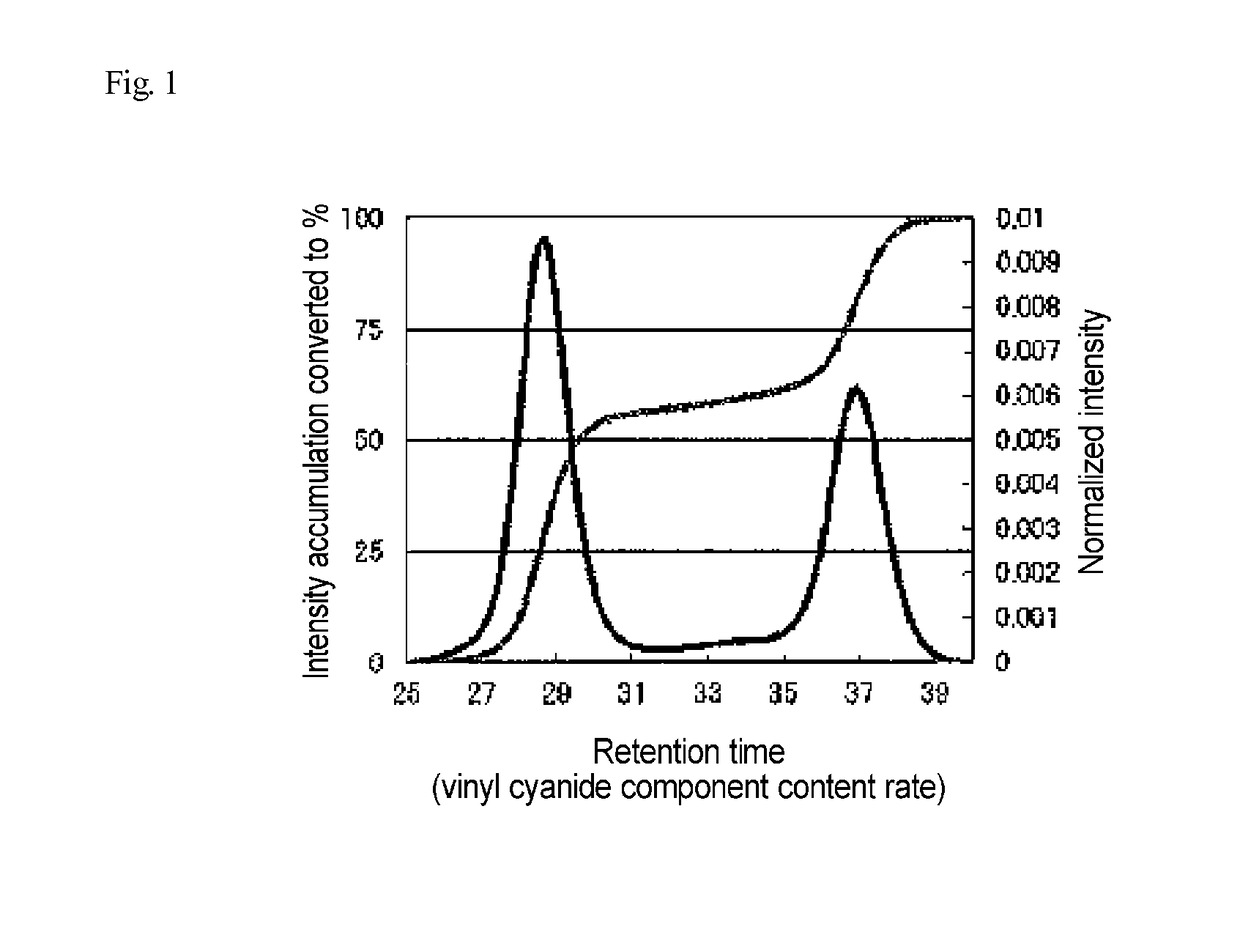

A thermoplastic resin composition, comprising:an aromatic polycarbonate (A);a copolymer mixture (B) comprising a copolymer (b1) of a vinyl cyanide-based monomer and one or more kinds of monomers copolymerizable with said vinyl cyanide-based monomer, and a graft copolymer (b2) of a vinyl cyanide-based monomer, one or more kinds of monomers copolymerizable with said vinyl cyanide-based monomer and a rubbery polymer; andat least one kind of metal atom selected from the group consisting of Mg, Al and Ca,wherein the copolymer mixture (B) comprises an acetone-soluble component,wherein said acetone-soluble component has at least two peak tops, being peak top 1 and peak top 2, within the range of 15 to 50% of vinyl cyanide component content rate, when measuring the vinyl cyanide component content rate by high performance liquid chromatography,wherein the peak top 1 is present in the range of 15% or more to 30% or less of vinyl cyanide component content rate,wherein the peak top 2 is present in the range of from more than 30% to 50% or less of vinyl cyanide component content rate, andwherein the total content of the metal atoms is 10 to 1000 ppm, based on 100 parts by mass of total amount of the aromatic polycarbonate (A) and the copolymer mixture (B).

Owner:ASAHI KASEI CHEM CORP

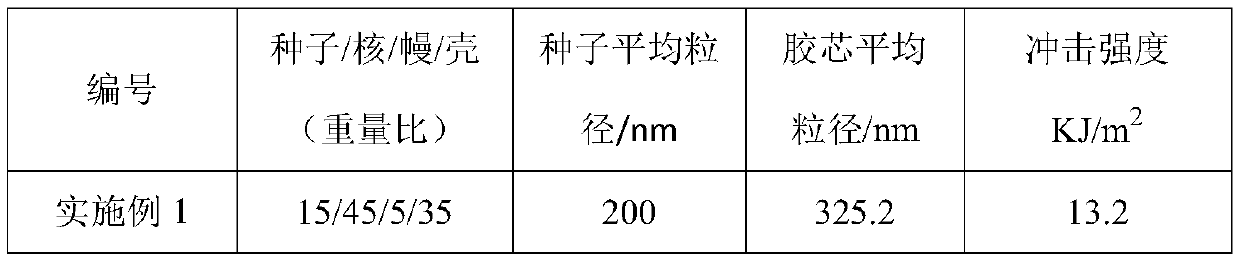

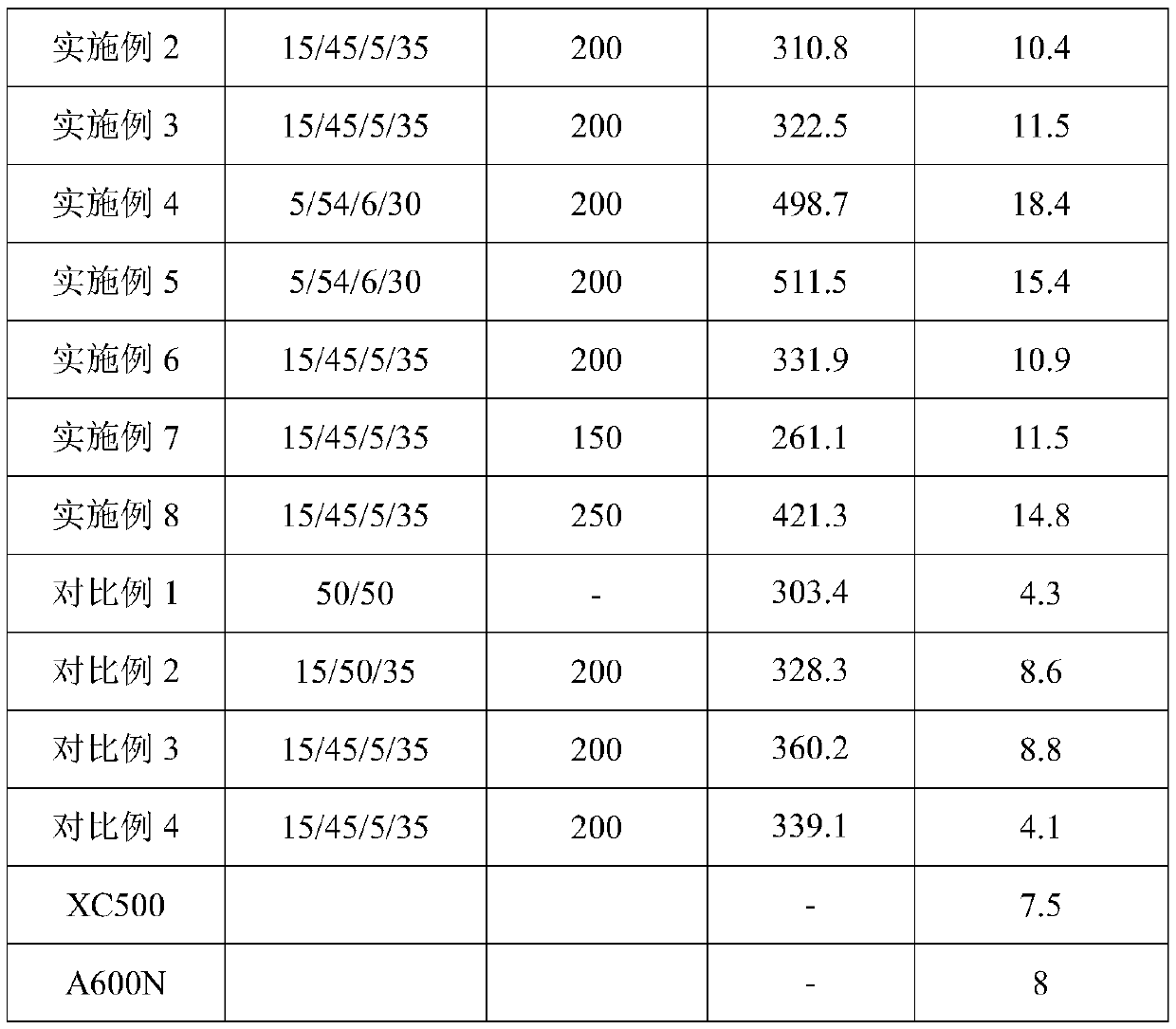

Acrylate-styrene-acrylonitrile graft polymer with high impact resistance, and preparation method and application thereof

The invention provides an acrylate-styrene-acrylonitrile graft polymer with high impact resistance, and a preparation method and an application thereof. The particle of the acrylate-styrene-acrylonitrile graft polymer has a four-layer structure; under the combined action of a hard AS seed, a medium-crosslinking-density core and a high-crosslinking mantle layer in the particle, the particle is endowed with high elasticity; due to the high elasticity of the particle, resin can absorb more capacity under the action of an external force, and can restore to an original state after the external force disappears; thus, the resin can be endowed with high impact resistance. The aromatic vinyl compound-vinyl cyanide shell layer grafted outside the mantle layer can increase the dispersing performanceof the particle in base resin, and facilitates improving impact strength.

Owner:SHINE POLYMER (ZHUHAI) CO LTD

Thermoplastic resin composition and molded article thereof

A thermoplastic resin composition exhibiting good balance of mechanical properties, heat resistance, flowability, and size stability as well as excellent stability in retention in the molding, appearance of the molded article, and coating properties, and also, a molded article thereof are provided. The thermoplastic resin composition is a blend of a polycarbonate resin (I), a graft copolymer (II) which comprises a graft copolymer (II-1) prepared by graft polymerization of a monomer mixture containing an aromatic vinyl monomer and a vinyl cyanide monomer in the presence of a diene rubbery polymer or a graft copolymer (II-2) prepared by graft polymerization of a monomer mixture containing an aromatic vinyl monomer and a vinyl cyanide monomer in the presence of an acryl rubbery polymer, a vinyl copolymer (III) prepared by copolymerizing an aromatic vinyl monomer and a vinyl cyanide monomer, a crystalline resin (IV), and a plate-shaped inorganic filler (V), and when total amount of (I)+(II)+(III)+(IV)+(V) is 100% by weight, (I) is 50 to 70% by weight, (II) is 3 to 15% by weight, (III) is 10 to 25% by weight, (IV) is 1 to 9% by weight, and (V) is 10 to 20% by weight, and content ratio of (IV) to 100% by weight of (V) is at least 10% by weight and less than 50% by weight.

Owner:TORAY IND INC

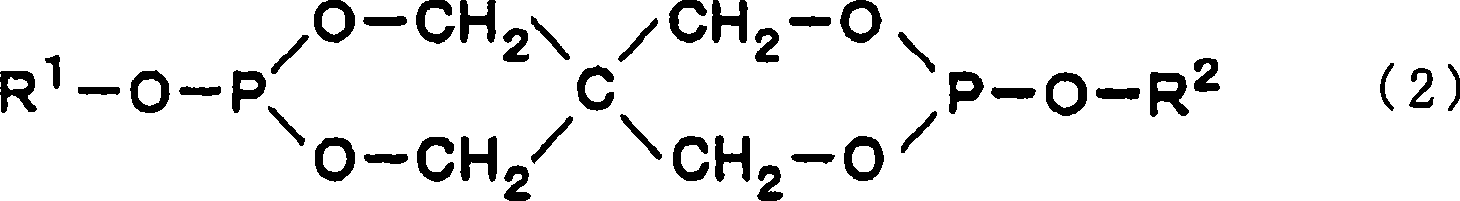

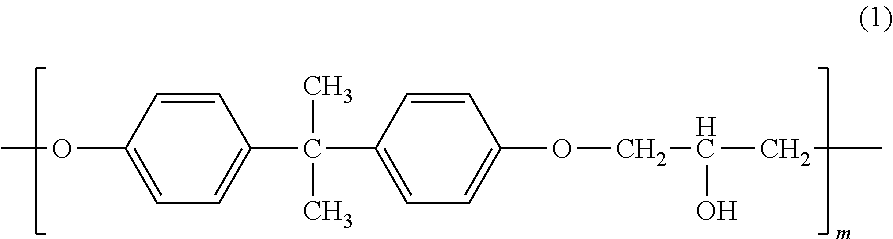

Resin composition for plating substrate and resin molding using the same, and metal plated parts

InactiveUS7122251B2High bonding strengthMaintain good propertiesPlastic/resin/waxes insulatorsSynthetic resin layered productsPhosphateCopolymer

The resin composition for a platable substrate of the present invention comprises 100 parts by weight of a resin composition (C) comprising 10 to 60% by weight of a graft copolymer (A) prepared by graft polymerization of a rubbery polymer (A1) and a monomer component (A2) containing an aromatic alkenyl compound monomer unit (a) and a vinyl cyanide compound monomer unit (b) and 40 to 90% by weight of the other polymer (B) (provided that the total amount of the components (A) and (B) is 100% by weight), and 5 to 40 parts by weight of a phosphate ester flame retardant (D) having a molecular weight of more than 326 or 2 to 40 parts by weight of a red phosphorus flame retardant (D′). The resin composition for a platable substrate of the present invention is excellent in production stability such as moldability, dimensional stability, mechanical strength and plating properties, and is also environmentally friendly. Excellent plated parts having good thermal conductivity can be provided by forming a metal plating layer on a resin molded article obtained by molding the resin composition for a platable substrate using a plating treatment. The resulting plated parts are suitable for use as housings for laptop PC and portable devices.

Owner:TECHNO UMG CO LTD

Reinforced Thermoplastic Resin Composition And Molded Article

A reinforced thermoplastic resin composition comprising specific amounts of: a main resin component (C) comprising 50 to 100% by weight of a polycarbonate resin (A) and 0 to 50% by weight of a graft copolymer (B) obtained by polymerizing an aromatic alkenyl compound monomer (a) and a vinyl cyanide compound monomer (b) in the presence of a rubber polymer (B1); a grass fiber (D); a glycidyl ether unit-containing polymer (E) containing glycidyl ether units and having a weight average molecular weight of 3,800 to 60,000; a phosphoric acid ester-based flame retardant (F); and an organomodified siloxane (G).

Owner:TECHNO UMG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com