Thermoplastic resin composition having excellent chemical resistance and transparency, method for preparing same, and molded product comprising same

一种热塑性树脂、组合物的技术,应用在热塑性树脂组合物领域,能够解决使用ABS类树脂限制、耐化学性不足、医疗产品应用限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

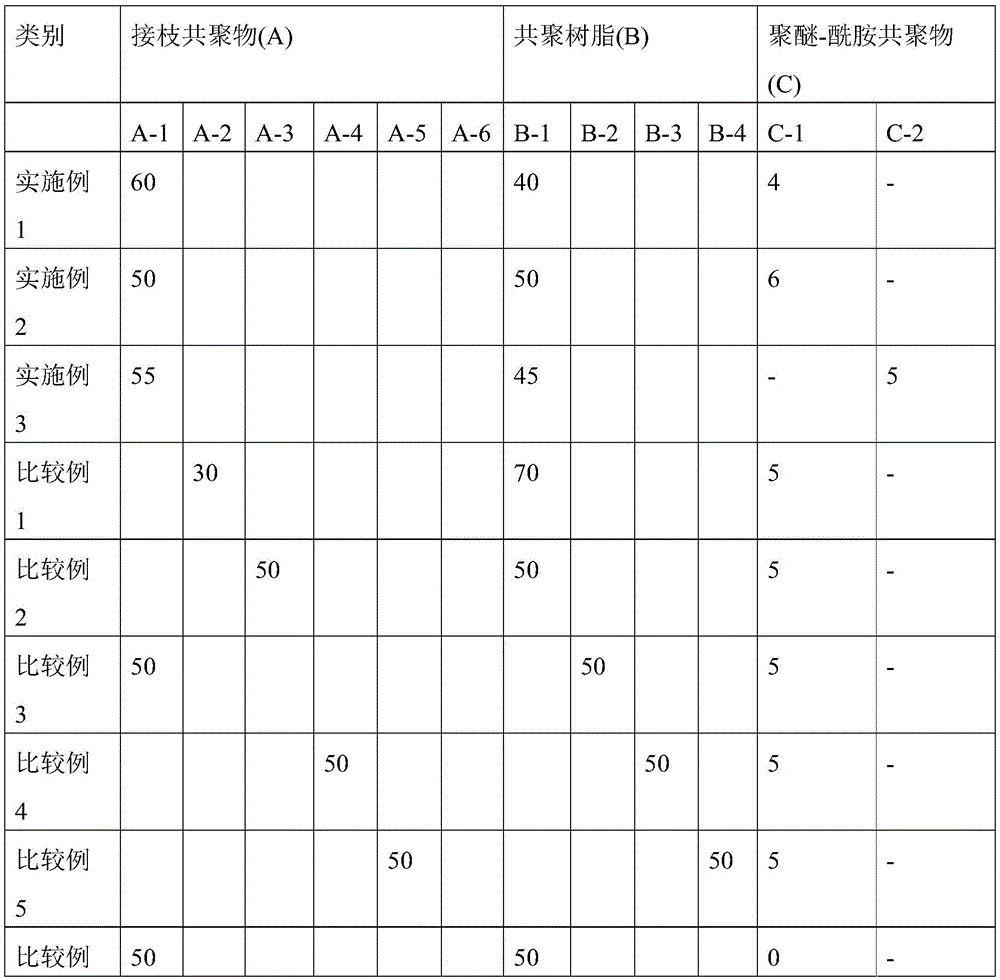

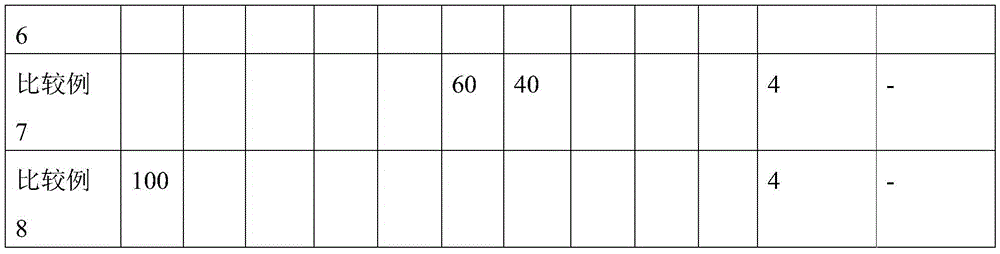

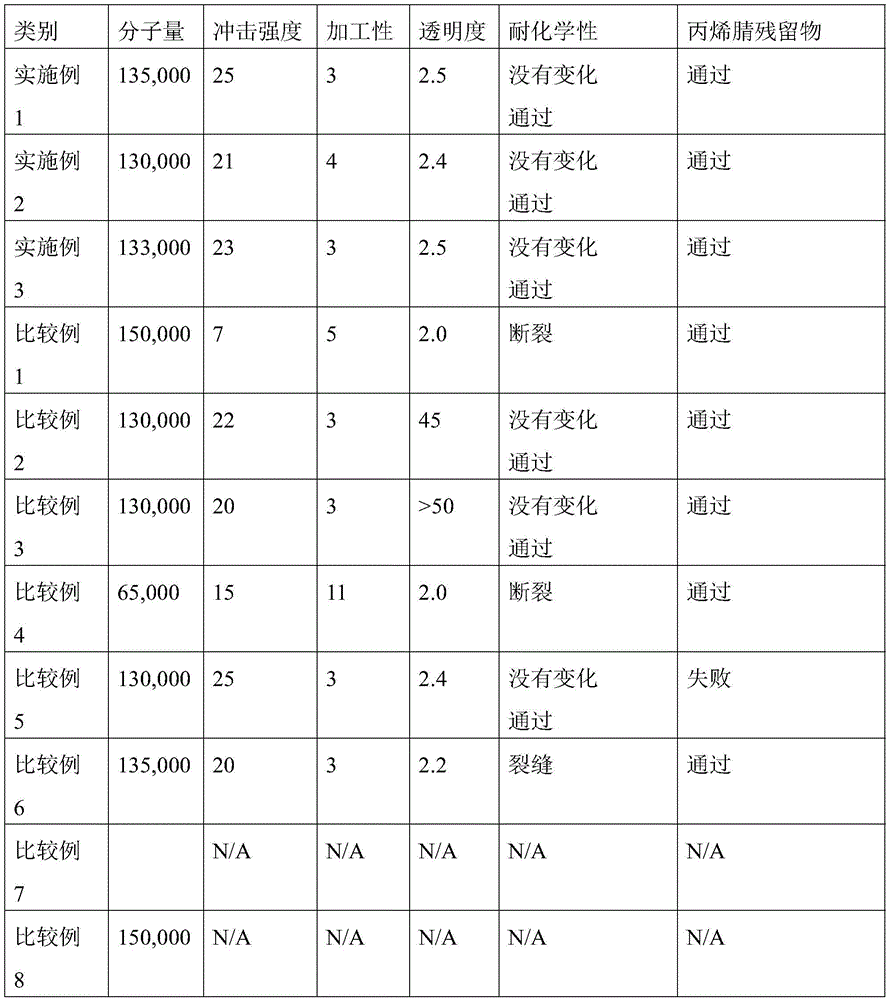

Examples

preparation Embodiment A-1

[0088] Preparation Example A-1: Graft Copolymer Preparation-1

[0089] In order to prepare the graft copolymer, 100 parts by weight of ion-exchanged water, 1.0 parts by weight of sodium oleate as an emulsifier, 35 parts by weight of methyl methacrylate, 12 parts by weight of styrene, and 3 parts by weight of propylene Nitrile, the tert-dodecyl mercaptan of 0.3 parts by weight, the ethylenediaminetetraacetic acid of 0.05 parts by weight, the sodium formaldehyde sulfoxylate of 0.1 parts by weight, the ferrous sulfate of 0.001 parts by weight and the tertiary hydroperoxide of 0.2 parts by weight Butyl was continuously added to 50 parts by weight (based on solid content) of polybutadiene rubber latex containing 70% by weight of gel and having an average particle diameter of 0.3 μm prepared by emulsion polymerization, and the reaction was allowed to proceed at 75° C. 5 hours. Next, the temperature was raised to 80° C. and aged for 1 hour, and then the reaction was terminated. ...

preparation Embodiment A-2

[0090] Preparation Example A-2: Graft Copolymer Preparation-2

[0091] Graft copolymer was prepared in the same manner as in Preparation Example A-1, except that 18 parts by weight of rubber latex was used instead of 50 parts by weight of rubber latex, and 58.5 parts by weight of methyl methacrylate replaced 35 parts by weight of methyl methacrylate, and 20.5 parts by weight of styrene instead of 12 parts by weight of styrene. The refractive index of the obtained graft copolymer was 1.516, and the weight average molecular weight was 170,000 g / mol.

preparation Embodiment A-3

[0092] Preparation Example A-3: Graft Copolymer Preparation-3

[0093] The graft copolymer was prepared in the same manner as in Preparation Example A-1, except that 29.8 parts by weight of methyl methacrylate was used instead of 35 parts by weight of methyl methacrylate, and 19.2 parts by weight of styrene was used instead of 12 parts by weight of styrene. The refractive index of the obtained graft copolymer was 1.53, and the weight average molecular weight was 150,000 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com