Moisture-curable hot-melt adhesive agent

A hot-melt adhesive and moisture-curing technology, which is applied in the direction of adhesive types, rosin adhesives, polyurea/polyurethane adhesives, etc., can solve the difficult problem of preparing moisture-curing hot-melt adhesives, etc. problems, achieve excellent initial bond strength, bond strength improvement, and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

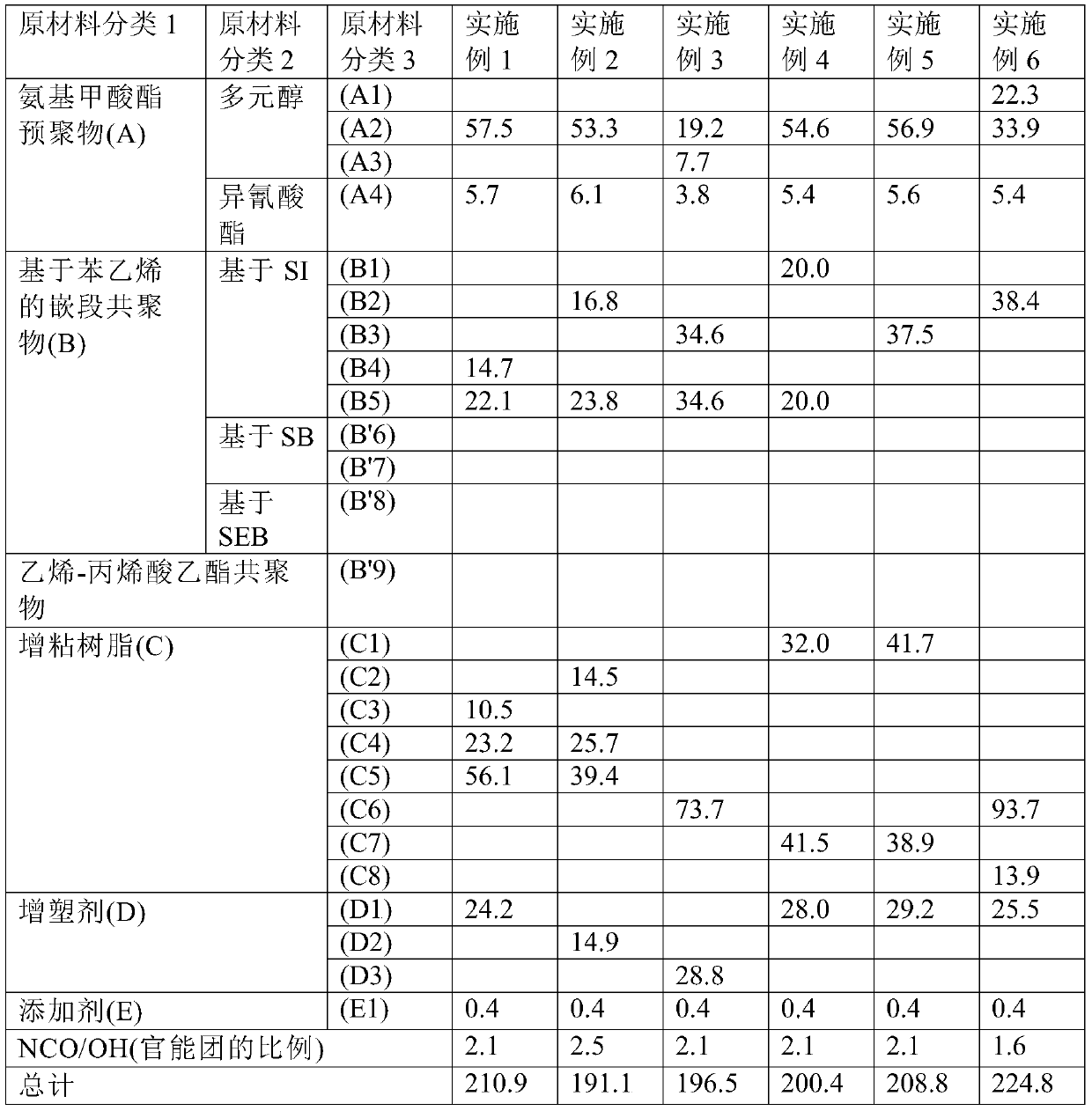

[0173] Components (A) to (E) were mixed to prepare a moisture-curable hot melt adhesive.

[0174] Specifically, components (B4), (B5), (C3), (C4), (C5), (D1) and (E1 ) are melt mixed to prepare a molten composition.

[0175] Then, the polyester polyol (A2) and the above melting composition were mixed in the compositions shown in Table 2 (parts by weight). Place the mixture in a reaction vessel. After heating the mixture at a temperature of 130°C, the mixture was stirred at the same temperature for one hour under reduced pressure. After confirming that moisture is removed and kneading the mixture sufficiently, 4,4'-diphenylmethane diisocyanate (A4) is added thereto, and the mixture is stirred at the same temperature under reduced pressure for one hour to obtain a moisture-curable thermal Melt adhesive.

Embodiment 2-6

[0176]

[0177] Of the compositions shown in Table 2 and Table 4, components (A) to (E) were prepared in the same manner as in Example 1 to prepare a moisture-curable hot melt adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com