Acrylate-styrene-acrylonitrile graft polymer with high impact resistance, and preparation method and application thereof

A technique of graft polymer and acrylate, which is applied in the field of high-impact acrylate-styrene-acrylonitrile graft polymer and its preparation, can solve the problems of ASA resin coloring performance reduction and affecting stability, etc., to achieve Effects of increased dispersibility, improved impact strength, and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

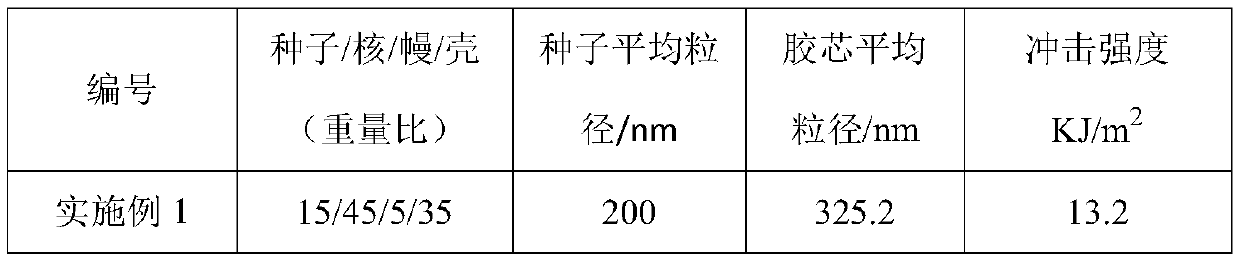

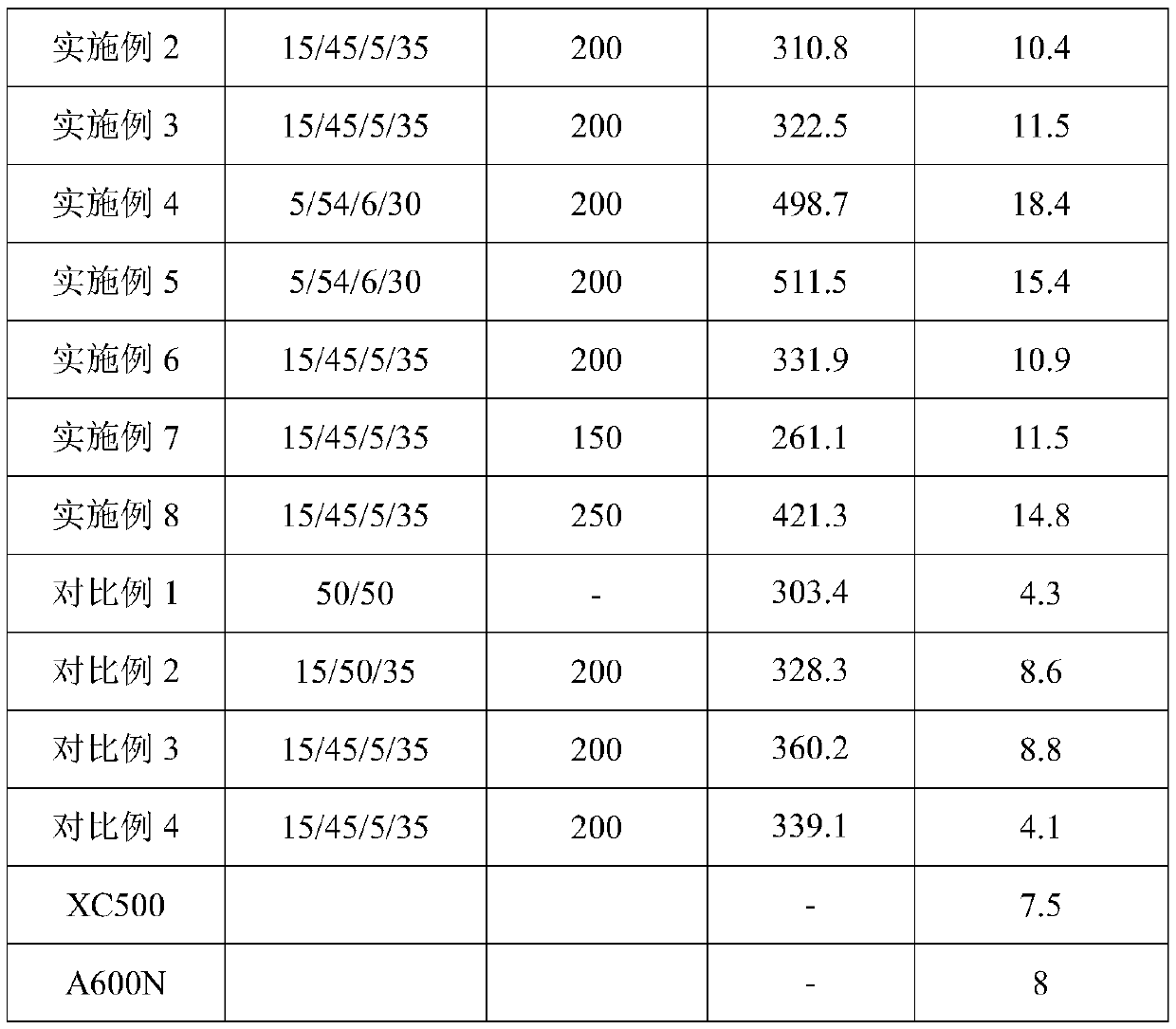

Examples

Embodiment 1

[0048] Preparation of S1.AS seed emulsion

[0049] Prepare mixed monomer A (styrene 162g, acrylonitrile 54g, allyl methacrylate 0.54g);

[0050] In a 2000ml flask equipped with a thermometer, a nitrogen pipe, a reflux device and a stirring device, add 0.2g of diphenoxysulfonate, 0.13g of potassium persulfate, and 504g of deionized water, stir and dissolve with nitrogen and heat up to 70°C , add 26g of mixed monomer A, keep warm for 1~1.5h.

[0051]Take the remaining 190.54g of mixed monomer A, 0.2g of potassium persulfate, 0.5g of diphenoxysulfonate, 1.4g of sodium dodecylbenzenesulfonate, and 118g of deionized water to form a pre-emulsion homogeneously dispersed at high speed. Add the pre-emulsion to the above-mentioned flask dropwise, and control the dropping to complete within 30-60 minutes, keep it warm for 1.5-2 hours, cool down and discharge to prepare the AS seed emulsion.

[0052] S2. Preparation of nuclear emulsion (S2. Crosslinking agent 0.5%)

[0053] In a 2000ml...

Embodiment 2

[0059] Same as Example 1, the only difference is that in S2. Preparation of nuclear emulsion and S3. Preparation of mantle layer, allyl methacrylate is replaced by trimethylolpropane triacrylate, and the dosage remains unchanged.

Embodiment 3

[0060] Embodiment 3 (S2. cross-linking agent 1.5%, S3. cross-linking agent 4%)

[0061] Same as Example 1, the only difference is that allyl methacrylate is replaced by mono[2(1-oxygen-2-propenyl)oxyethyl] maleate in the preparation of S2. nuclear emulsion, and the amount is adjusted is 4.9g, and the amount of butyl acrylate is adjusted to 319.1g. In S3. Mantle layer preparation, allyl methacrylate was replaced with mono[2(1-oxy-2-propenyl)oxyethyl] maleate, and the dosage remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com