Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Enhanced precipitation strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and manufacturing method thereof

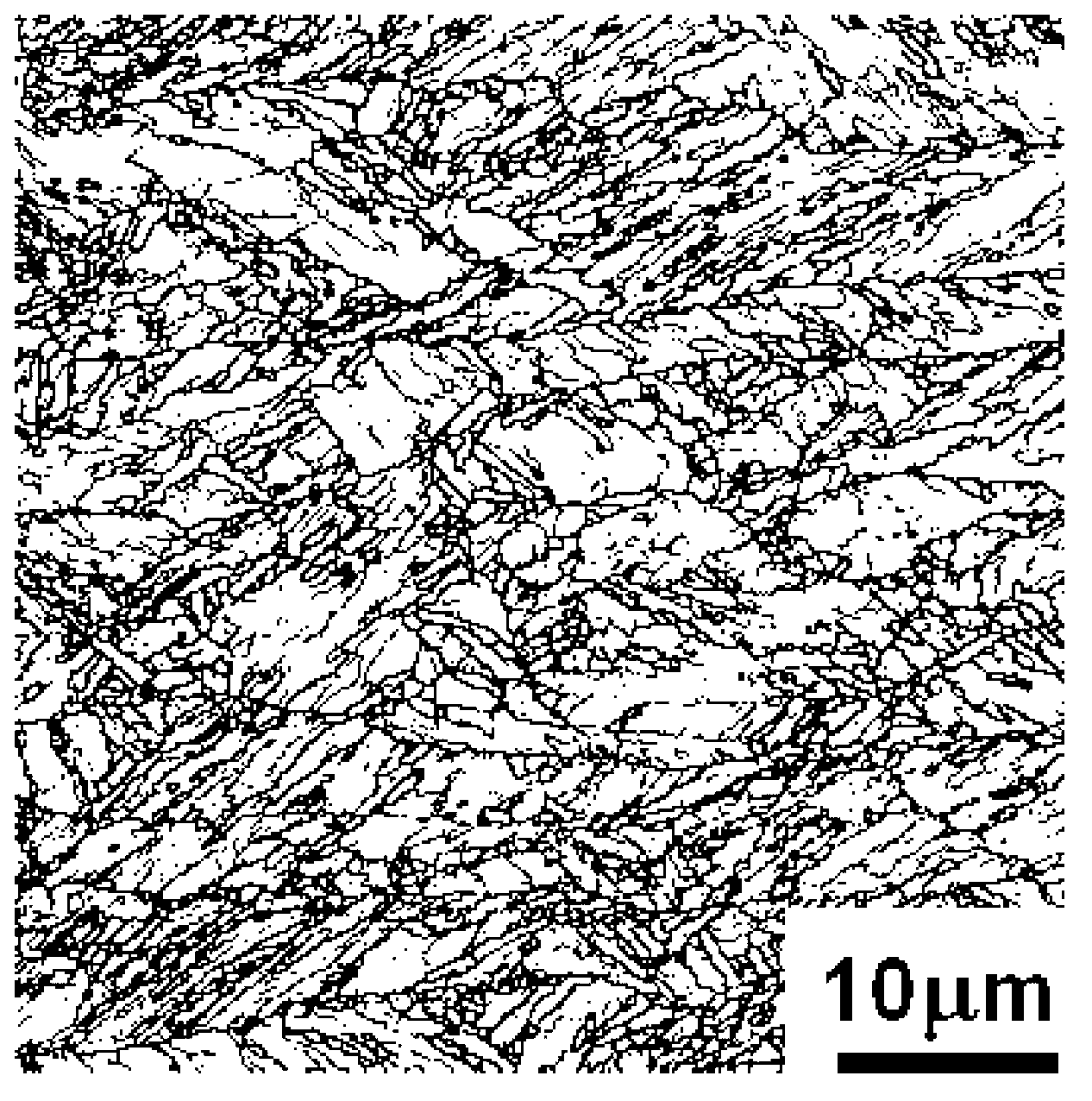

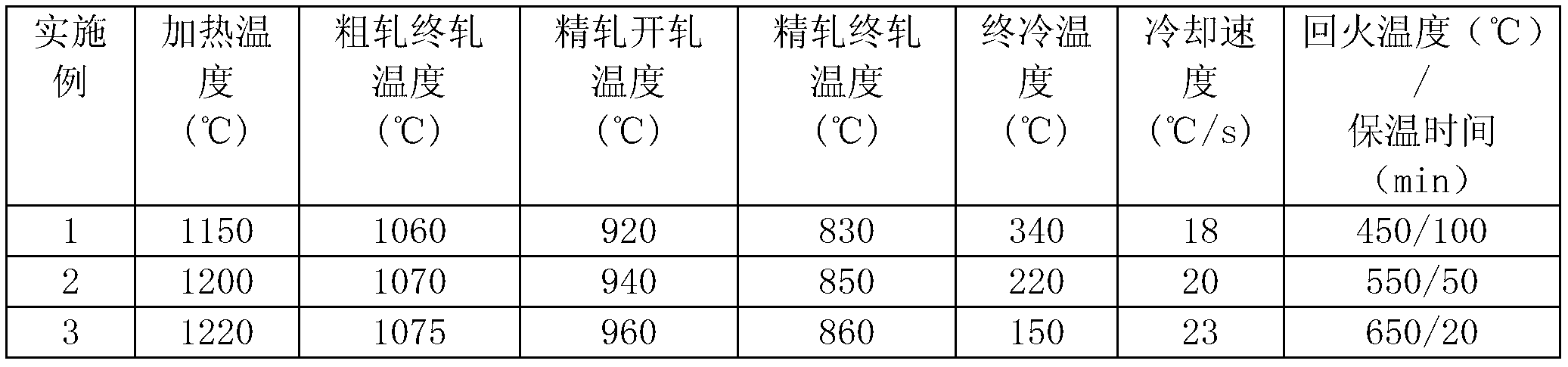

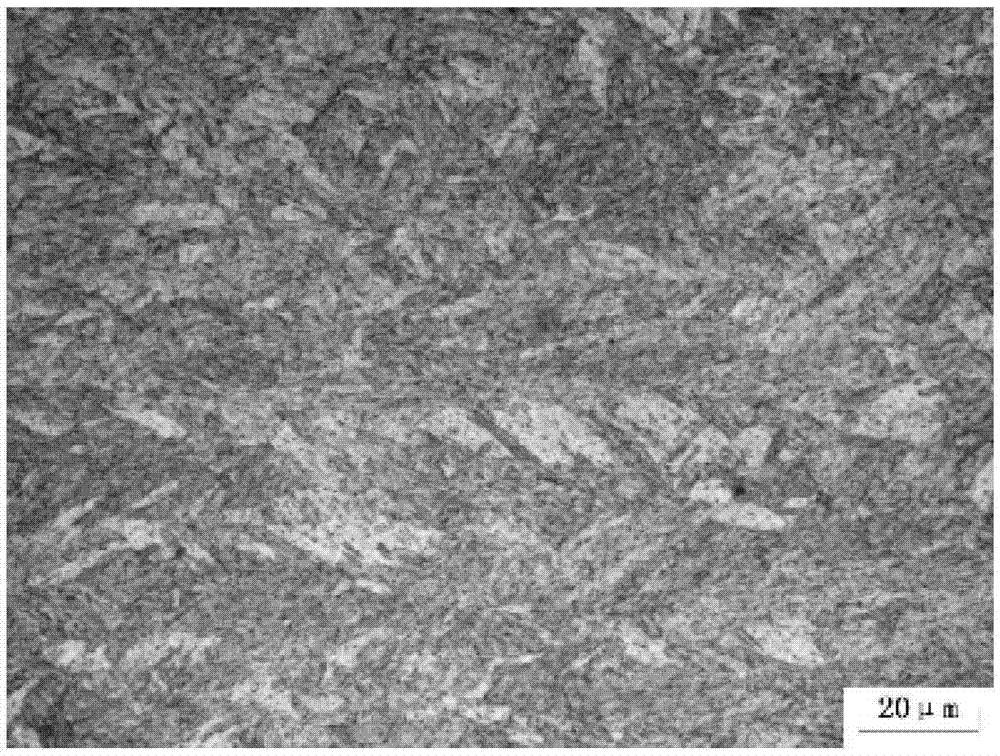

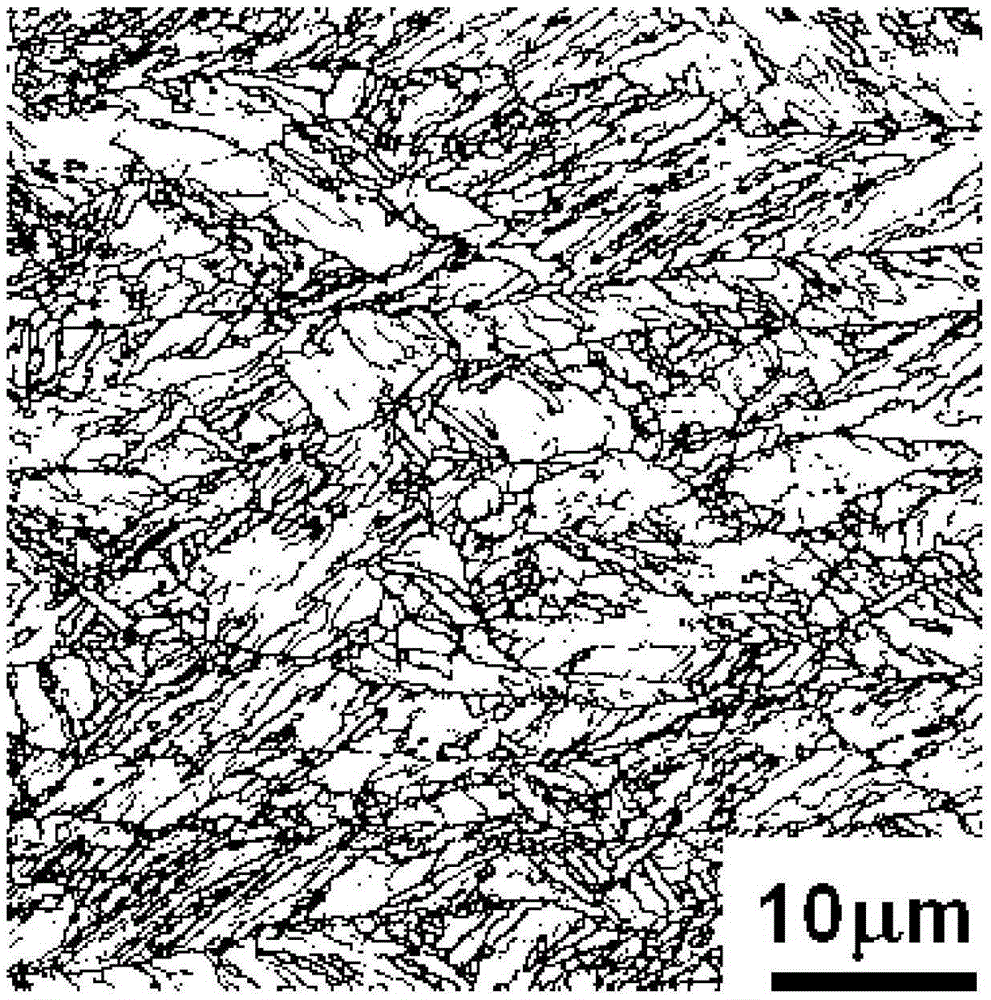

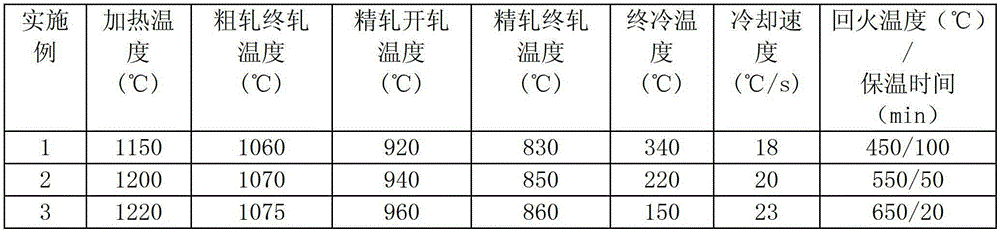

The invention relates to an ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and a manufacturing method thereof. The steel plate comprises the chemical components of: 0.06-0.11% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, 0.20-0.50% of Cr, 0.10-0.30% of Ni, 0.10-0.30% of Mo, 0.02-0.05% of Nb, 0.02-0 .06% of V, 0.008-0.03% of Ti, 0.0005-0.003% of B, 0.02-0.05% of Al, and balance of Fe. According to the invention, through two-stage controlled rolling, and direct quenching and tempering, a refined tempered martensite or lower bainite structure is obtained. Defects such as long process, high energy consumption, large alloy addition amount, and the like of traditional quenching and tempering process are overcome. The obtained steel plate has good toughness and cold bending performance.

Owner:NANJING IRON & STEEL CO LTD +1

Rare-earth-modified Al-Si-Mg-Mn cast alloy and preparation method thereof

The invention relates to a rare-earth-modified Al-Si-Mg-Mn cast alloy and a preparation method thereof, and belongs to the technical field of metal materials and metallurgy. The rare-earth-modified Al-Si-Mg-Mn cast alloy comprises the following components, by weight percentage: 6.0-8.5% of Si, 0.65-1.5% of Mg, 0.25-0.75% of Mn, 0.08-0.25% of Ti, less than or equal to 0.2% of Be, less than or equalto 0.5% of Zn, less than or equal to 0.5% of Cr, less than or equal to 0.5% of Zr, and the balance Al. The preparation method comprises the following steps that (1) raw materials are prepared; (2) analuminum ingot is heated into an aluminum melt, the other raw materials are added into the aluminum melt, and uniform stirring is carried out after the other raw materials are molten; (3) a refiningagent is added for refining treatment, and then an Al-10RE modifier is added for modification treatment; (4) slagging-off is carried out after degassing is carried out, standing is carried out at thetemperature of 700-800 DEG C, and then casting is carried out to form a casting; and (5) solid solution treatment and aging treatment are carried out on the casting. According to the method, after modification is carried out by utilizing rare earth, the problem that the modifying effect degenerates and declines due to the fact that the Mn content is increased can be solved, the precipitation strengthening effect of the high-Mg alloy is brought into full play, and the mechanical property of the alloy can be improved.

Owner:DARE WHEEL MFG +1

Multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and manufacturing method thereof

ActiveCN107083508AImprove room temperature and high temperature mechanical propertiesImproves strength and hardnessRare-earth elementCorrosion resistant

The invention discloses a multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and a manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy. The ingredients of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy comprise pure magnesium ingots, pure zinc ingots, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg-Ca alloy, Mg-Zr alloy and nanometer-scale NdN particles. The elements in the raw materials comprise, by mass, 3.5-5.0% of Gd, 1.0%-3.0% of Y, 0.5%-0.8% of Nd, 0.8%-1.5% of Zn, 0.3%-0.8% of Ca, 0.3%-0.6% of Zr, 0.5%-1.5% of nanometer-scale NdN particles and the balance Mg. The sequence of the mass percentage contents of the three rare earth elements of the Gd, the Y and the Nd from large to small is Gd>Y>Nd, and the mass percentage of the total addition amount of the three rare earth elements of the Gd, the Y and the Nd does not exceed 10%. The particle size of the nanometer-scale NdN particles is 80-150 nm. The steps of pretreatment and cladding of the NdN particles, preheating of the ingredients, smelting, refining, doping, pouring, sectioned solution treatment and artificial aging treatment are sequentially conducted, and then the fine, dispersive nanometer-precipitated-phase microscopic-structure heat-resistant corrosion-resistant magnesium alloy product is obtained. By the adoption of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and the manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy, the manufacturing cost is low, and the heat resistance and corrosion resistance of the magnesium alloy are excellent.

Owner:YANGZHOU FENG MING METAL PROD +1

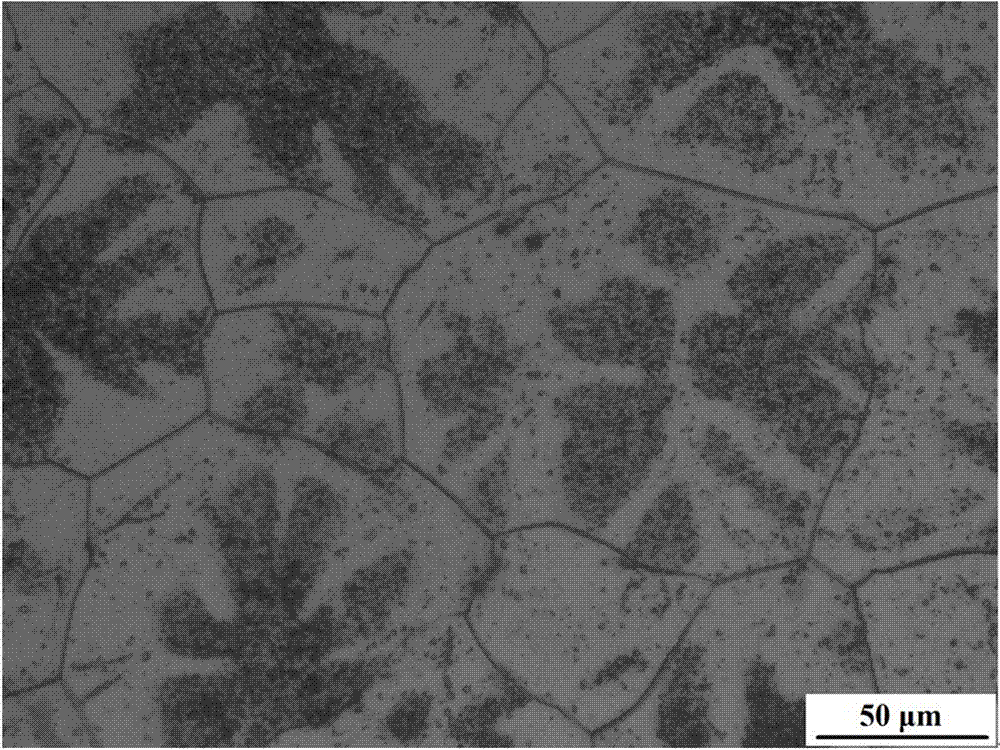

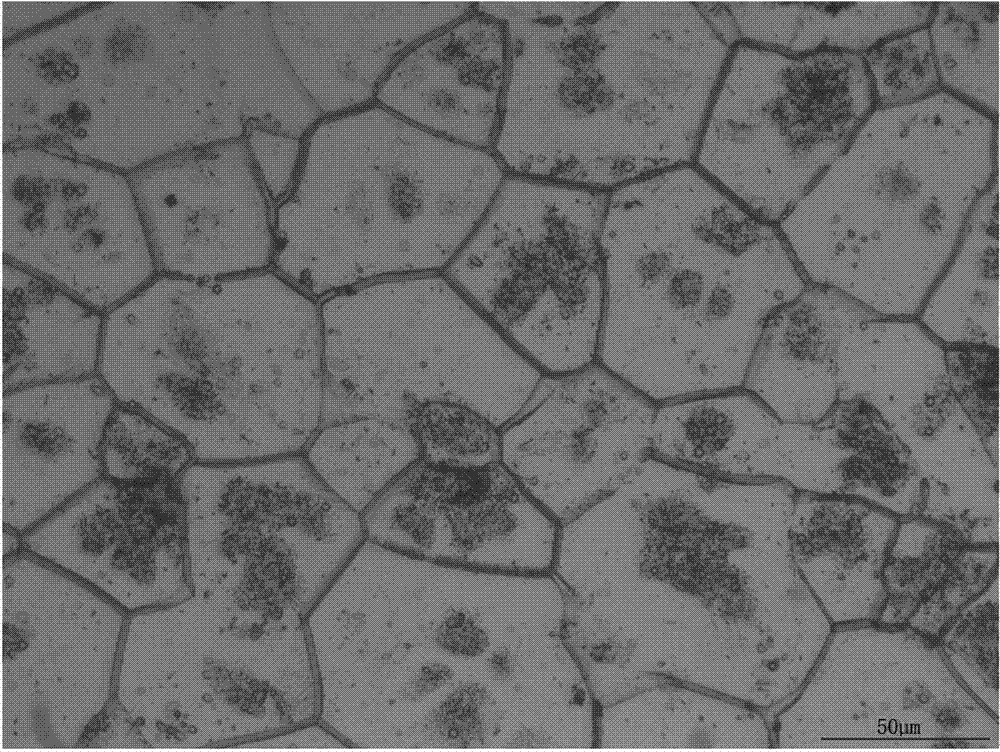

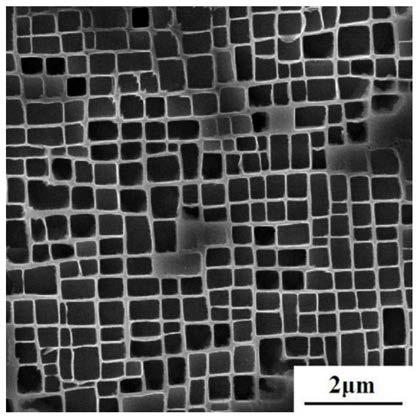

Third-generation nickle base monocrystal high temperature alloy with stable texture and preparation method

ActiveCN111455220AImproved creep propertiesEnsure organizational stabilityPolycrystalline material growthAfter-treatment detailsSingle crystal superalloyDirectional solidification

The invention discloses third-generation nickle base monocrystal high temperature alloy with a stable texture and a preparation method thereof. The third-generation nickle base monocrystal high temperature alloy is composed of Al, Ta, W, Re, Mo, Cr, Co, Hf and Ni; and W and Ni are added in the form of Ni-W intermediate alloy. Directional solidification is adopted to prepare monocrystal alloy; through multistep high temperature long-time solid solution homogenization treatment, high temperature aging treatment and low temperature aging treatment, the third-generation nickle base monocrystal high temperature alloy is free of incipient melting and precipitation of TCP phase to lower the TCP precipitation tendency, so that alloy reducing Re content reaches the performance level of the third-generation nickle base monocrystal high temperature alloy, and the obtained nickle base monocrystal high temperature alloy has higher intermediate and high temperature strength, excellent instant tensile property and creep property and high texture stability.

Owner:苏州高晶新材料科技有限公司

High-strength corrosion-resistant aluminum alloy and preparation method thereof

ActiveCN111500906AIncreases alloy ductility and corrosion resistanceImprove alloy strengthAlloy elementCorrosion resistant

The invention belongs to the field of aluminum alloy materials and discloses a high-strength corrosion-resistant aluminum alloy. The high-strength corrosion-resistant aluminum alloy comprises the following components: 1.3-1.8% of Mg, 1.5-2.0% of Si, 0.7-0.9% of Mn, 0.1-0.4% of Cu, 0.3-0.8% of Zn, 0.1-0.3% of Fe, 0.08-0.2% of Cr, 0.1-0.3% of other alloying elements and the balance Al; the other alloying elements comprise Ni, V, Ti, Zr, and a combination of rare earth elements, with a ratio being (0.2-0.4): (1.6-1.8): (0.4-0.6): (1.4-1.6): 0.2; the ratio of Zn to Fe is 3:1; and the rare earth elements comprises Gd, La, Eu, with Gd accounting for 60% or more of the total amount of the rare earth elements. The aluminum alloy of the invention improves the strength and mechanical properties by improving the material formula, and is mainly used for manufacturing some aluminum alloy parts which require corrosion resistance and certain high strength.

Owner:福建祥鑫股份有限公司

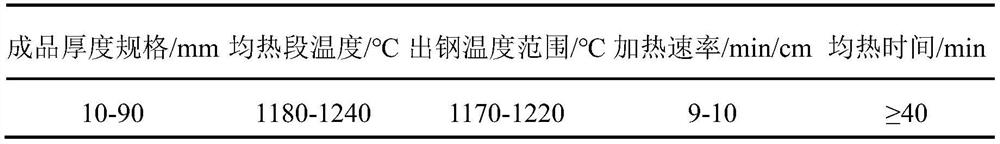

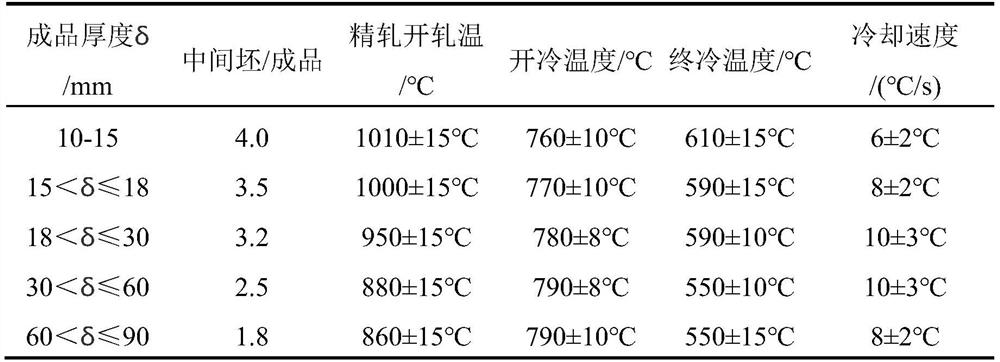

800MPa grade automobile box steel and production method thereof

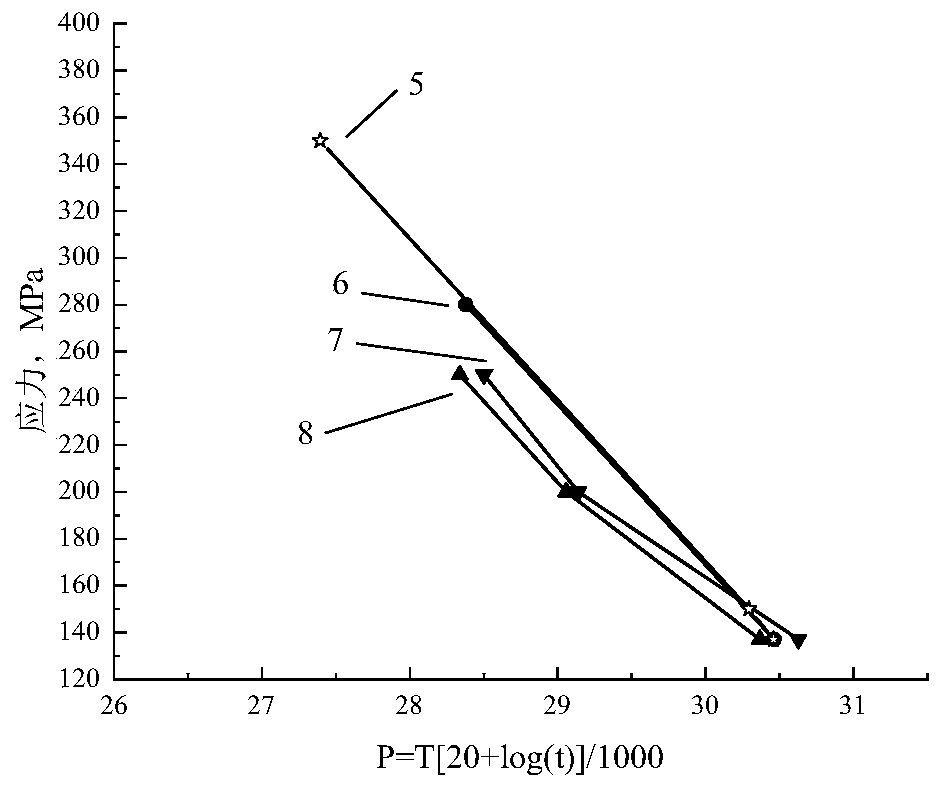

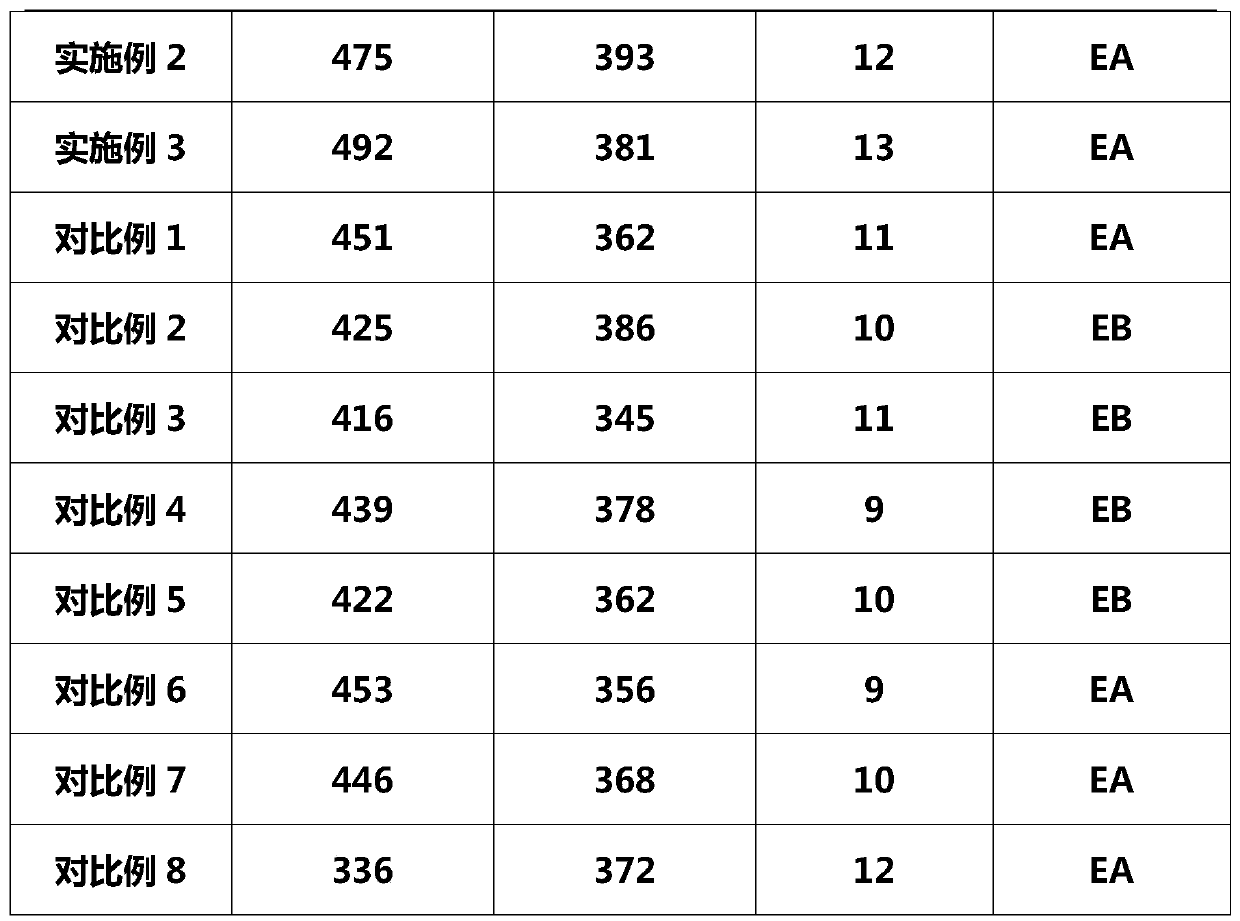

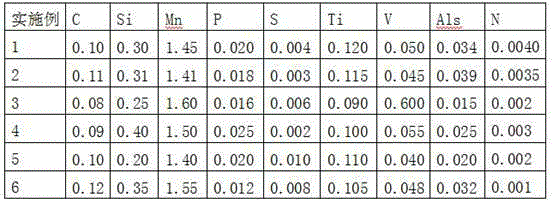

The invention discloses an 800MPa grade automobile box steel and a production method thereof. The production method comprises the steps of heating, rough rolling, finish rolling, cooling and coiling; the slab adopted contains the following components in percentage by mass: 0.08-0.12% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, less than or equal to 0.025% of P, less than or equal to 0.010% of S, 0.040-0.060% of V, 0.090-0.120% of Ti, greater than or equal to 0.015% of Als, less than or equal to 0.004% of N and the balance of Fe and inevitable impurities. The steel is strengthened by both vanadium and titanium and a precipitation strengthening effect can be developed more thoroughly, and the overall properties of the steel plate can be improved; besides, the load of rolling can be reduced thoroughly and the production difficulty can be reduced; the steel has the characteristics of low cost, high quality and easiness in machining. According to the method, the precipitation of carbon and carbonitrides, the recrystallization of the austenite and the deformation state of the austenite are controlled by controlling the tapping temperature of the rolled steel, the temperature of the intermediate slab, the finish rolling temperature and the coiling temperature; the strength index and the overall properties of the obtained product are guaranteed, and the product is low in production cost and easy to machine.

Owner:HEBEI IRON AND STEEL

Nickel iron based welding wire for boiler of 700 DEG C ultra-supercritical power station

ActiveCN108723637AReduce wire costsMature technologyArc welding apparatusWelding/cutting media/materialsPower stationCarbide

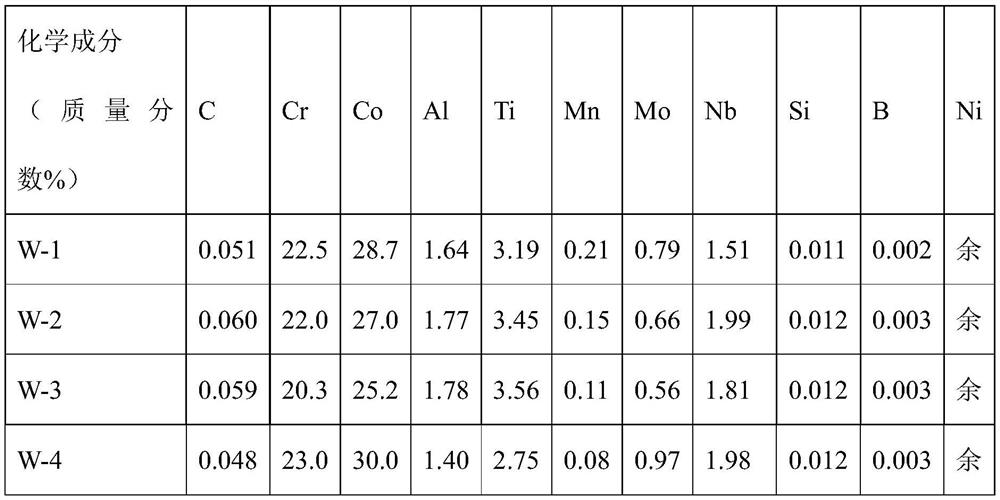

The invention discloses a nickel iron based welding wire for a boiler of a 700 DEG C ultra-supercritical power station, and belongs to the field of welding materials of ultra-supercritical power stations. The nickel iron based welding wire is prepared through the following components in percentage by mass: 23-30% of Fe, 19-24% of Cr, 1.8-2.4% of Al, 2.0-2.5% of Ti, 3.0-5.2% of Mo, less than 0.4% of W, not greater than 0.15% of Si, 0.4-0.8% of Mn, 0.04-0.07% of C, 0.001-0.003% of B, not greater than 0.02% of Zr, and the balance Ni, wherein Ti / Al is not less than 1; the sum of other impure elements is less than 0.1%. According to the nickel iron based welding wire, a weld joint can be microalloyed after welding through TIG (argon tungsten-arc welding), and thus the obtained weld joint meetsthe standard requirement; a weld joint area substrate formed by the nickel iron based welding wire is an austenite (gamma) phase of an irregular surface-core structure; the precipitate reinforcing phase is gamma' (Ni3(Al, Ti)) phase; and carbide phases are distributed among crystals.

Owner:HUANENG POWER INTERNATIONAL +1

High-strength and high-toughness steel for rock drilling tools and production method thereof

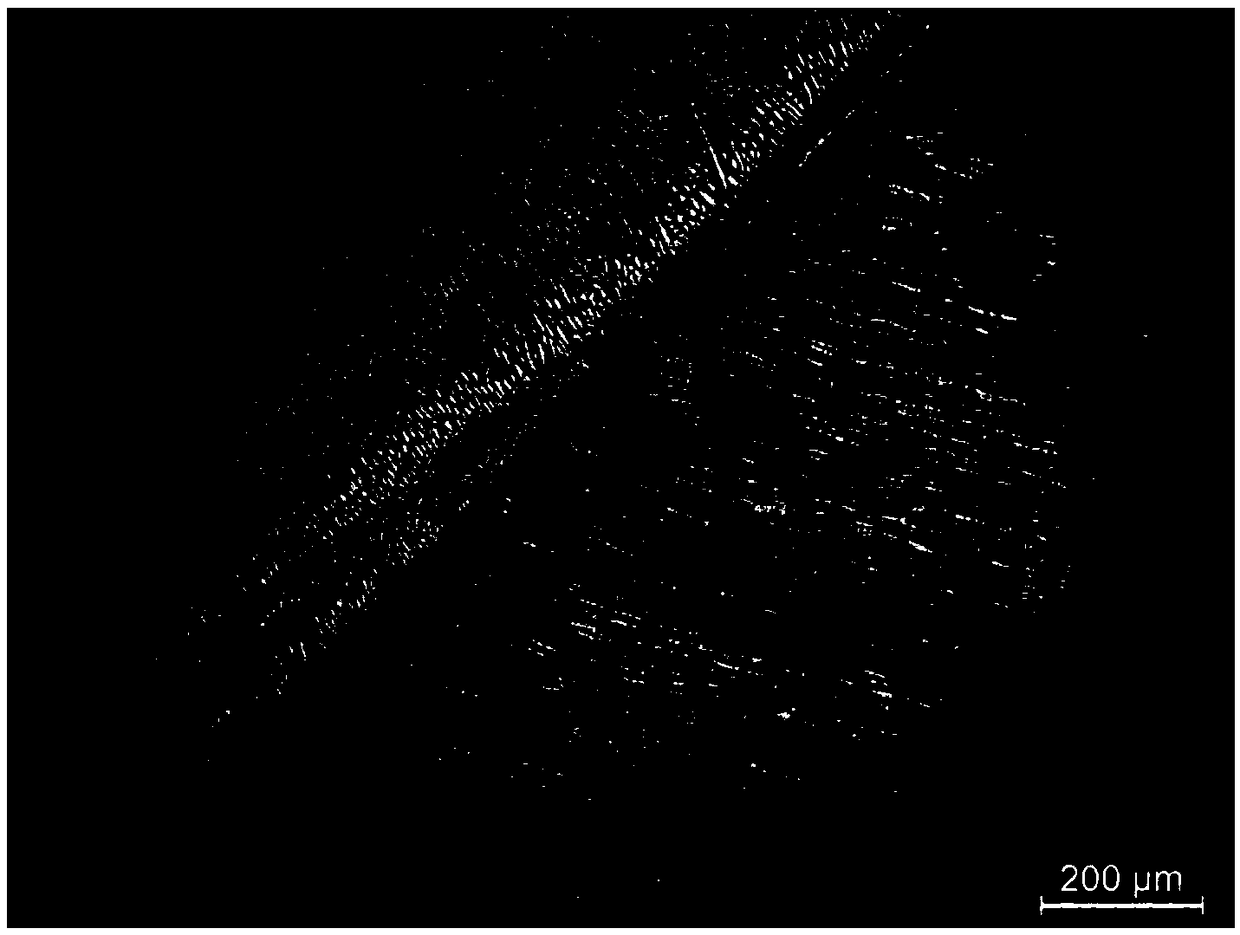

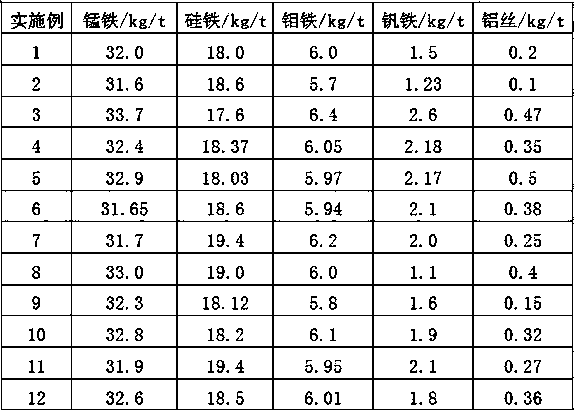

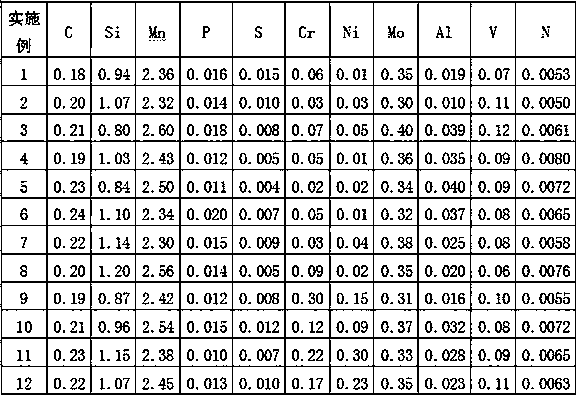

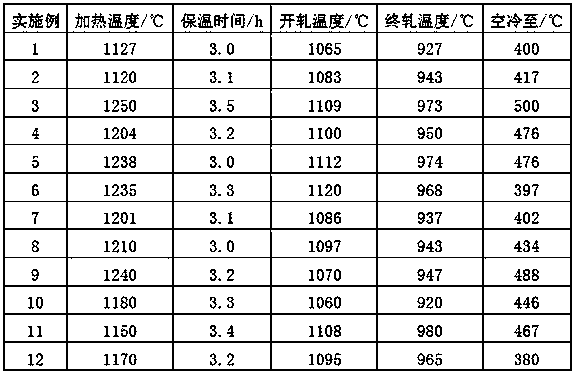

The invention discloses high-strength and high-toughness steel for rock drilling tools and a production method thereof. The high-strength and high-toughness steel for the rock drilling tools is prepared from the chemical compositions in percentage by mass: 0.18%-0.24% of C, 0.80%-1.20% of Si, 2.30%-2.60% of Mn, less than or equal to 0.30% of Cr, 0.30%-0.40% of Mo, less than or equal to 0.30% of Ni, 0.06%-0.12% of V, 0.010%-0.040% of Al, less than or equal to 0.020% of P, less than or equal to 0.015% of S, 0.0050%-0.0080% of N and the balance of Fe and inevitable impurities. Without the addition of a precious alloy Ni and a low hardenability element Cr, the strength, impact toughness and hardenability of the steel for the rock drilling tools are significantly increased by increasing the content of Si, Mn, Mo, V and other alloying elements, and the requirements of the rock drilling tools in low cost, good forging performance, high hardenability, high strength and high toughness are met.The process of "smelting + continuous casting + continuous rolling"is adopted, the production process is simple, the tensile strength of the product is more than or equal to 1450 Mpa and the impact Aku2 is more than or equal to 60 J, and the characteristics of low cost, simple process and stable product performance are achieved.

Owner:SHIJIAZHUANG IRON & STEEL

Composite cored wire composed of solid calcium metal, silicon iron and titanium-silicon nitride alloy containing rare earth, barium and molybdenum

The invention relates to an alloy cored wire, in particular to a composite cored wire composed of solid calcium metal, silicon iron and titanium-silicon nitride alloy containing rare earth, barium and molybdenum. The cored wire comprises a core layer and a steel sheet layer wrapping the core layer. A meshed supporting layer made of steel or iron is arranged between the core layer and the steel sheet layer. The core layer comprises a silicon iron and titanium-silicon nitride alloy powder layer, a middle protecting layer and a solid calcium metal wire, wherein the solid calcium metal wire is wrapped with the middle protecting layer; the silicon iron and titanium-silicon nitride alloy powder layer wraps the middle protecting layer and is composed of silicon iron powder and titanium-silicon nitride alloy powder containing rare earth, barium and molybdenum; the particle size of the silicon iron powder and the particle size of the titanium-silicon nitride alloy powder are both below 3 mm; and the mass ratio of the solid calcium metal wire to the silicon iron powder to the titanium-silicon nitride alloy powder containing rare earth, barium and molybdenum is 1:(1-2):(2-5). Compared with a conventional calcium metal wire, the composite cored wire has the advantages of being higher in yield, longer in preservation time and more stable in yield, and also has significant economic benefits.

Owner:浙江宝信炉料股份有限公司

Nickel-cobalt-based high-temperature alloy welding wire

PendingCN112518172AImprove performanceIncrease contentWelding/cutting media/materialsSoldering mediaRare-earth elementSuperalloy

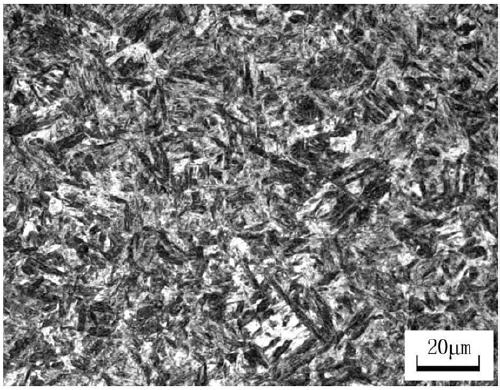

The invention belongs to the field of welding materials, and particularly relates to a precipitation strengthening type nickel-cobalt-based high-temperature alloy welding wire for welding a high-temperature part of an 800-DEG C ultra-supercritical power station. The welding wire is mainly characterized in that Ti / Al is more than or equal to 1.5 and less than or equal to 2, and C / Nb is more than orequal to 0.03. The yield strength of the welding wire at 800 DEG C is not less than 600 MPa. An alloy comprises, by mass percent, 25-30% of Co, 20-23% of Cr, 1.4-1.8% of Al, 2.1-3.6% of Ti, 1.5-2.0%of Nb, 0.5-1.0% of Mo, less than or equal to 0.1% of Si, less than or equal to 0.3% of Mn, less than or equal to 0.01% of Cu, less than or equal to 0.04% of C, less than or equal to 0.003% of B, and the balance of Ni, and no rare earth element is contained. A deposited metal matrix of the welding wire is an austenite (gamma) phase of a disordered face-centered structure, precipitation strengthening phases are a Ni3 (Al, Ti) gamma'phase and a primary carbide NbC, and carbide phases are distributed between crystals. The welding wire fills up the blank in the prior art, has excellent high-temperature performance, can be widely applied to homogeneous and heterogeneous welding of high-temperature alloy parts under the condition of ultra-supercritical water vapor at the temperature of 750-800 DEG C, and can also replace an existing nickel-based / nickel-cobalt-based high-temperature alloy welding wire.

Owner:CHINA HUANENG GRP CO LTD +1

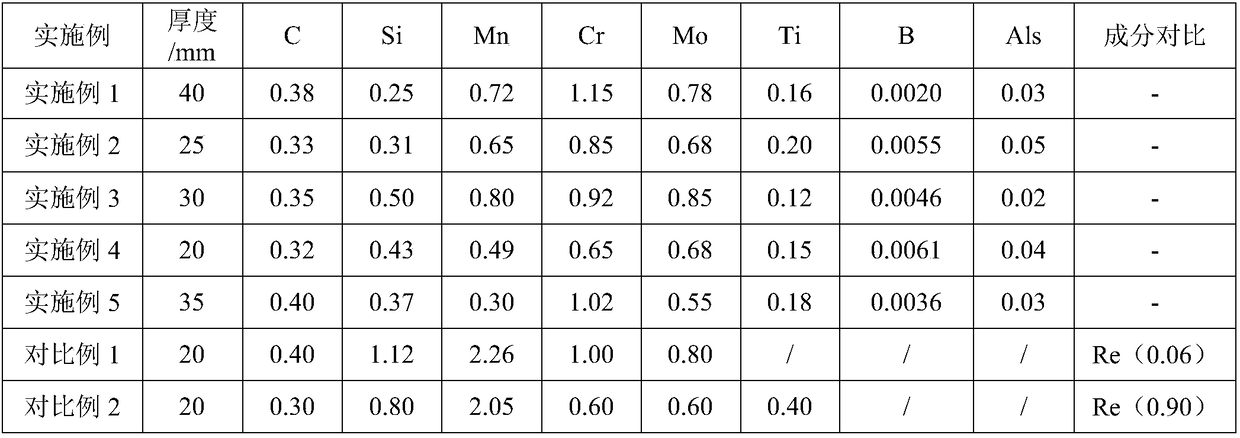

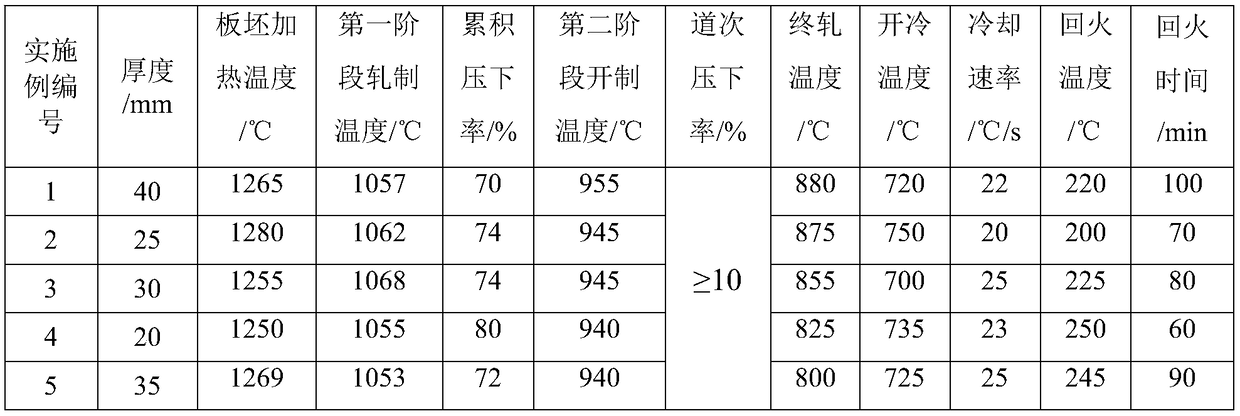

HB500-level martensitic abrasion-resistant steel for shovel edge and machining method thereof

The invention discloses HB500-level martensitic abrasion-resistant steel. The HB500-level martensitic abrasion-resistant steel comprises, by mass, 0.30%-0.40% of C, 0.25%-0.50% of Si, 0.30%-0.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, and 0.65%-1.15% of Cr, 0.55%-0.85% of Mo, 0.12%-0.20% of Ti, 0.002%-0.006% of B, 0.02%-0.05% of Als and the balance Fe and trace impurity elements. A C-Si-Mn-Mo-Cr alloy system and Ti-B microalloying composition design are adopted to achieve the effect of sliding abrasion resistance, so that the obtained steel shows excellentmechanical properties; and the related alloy addition amount is less, and the alloy cost is low; and meanwhile, a short process manufacturing process is adopted, so that the manufacturing process isgreatly simplified, and remarkable economic and social benefits are achieved.

Owner:武汉钢铁有限公司

High-strength weldable aluminum alloy and preparation method thereof

The invention belongs to the field of an aluminum alloy material and discloses high-strength weldable aluminum alloy. The high-strength weldable aluminum alloy comprises the following components: 0.4to 1.2 percent of Mg, 0.7 to 1.4 percent of Si, 0.2 to 0.7 percent of Mn, 0.05 to 0.2 percent of Cu, 0.1 to 0.5 percent of Zn, 0.4 to 0.6 percent of Fe, 0.05 to 0.15 percent of Cr, 0.1 to 0.3 percentof other alloy element and the balance of Al, wherein other alloy element comprises combination of Ni, V, Ti, Zr and rare earth element with the ratio of (1.2-1.4):(0.6-0.8):(2.4-2.6):(0.4-0.6):0.2; and the rare earth element comprises Ce, La and Er, and Ce account for more than 60 percent of the total amount of the rare earth element. Through improvement of the original formula, the aluminum alloy improves strength and mechanical property and can serve as aluminum alloy parts, such as an end plate and a tray, in a power battery of a new energy automobile.

Owner:福建祥鑫股份有限公司

Solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn

The invention relates to alloy core spun yarn, in particular to solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn. The solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn comprises a core layer and a sheet steel layer wrapping the outside of the core layer; a netlike supporting layer made of steel or iron is arranged between the core layer and the sheet steel layer; the core layer comprises a ferrosilicon and titanium-silicon nitride alloy powder layer, a middle protection layer and a solid calcium metal line; the solid calcium metal line is wrapped with the middle protection layer; the ferrosilicon and titanium-silicon nitride alloy powder layer wraps the middle protection layer and is composed of ferrosilicon powder and titanium-silicon nitride alloy powder of which the particle sizes are 3 mm or smaller; and the mass ratio of the solid calcium metal line to the ferrosilicon power to the titanium-silicon nitride alloy powder is 1:(1-2):(2-5). Compared with common solid calcium metal lines, the solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn has the advantages that the yield is higher, the preservation time is longer, the yield is more stable, and remarkable economic benefits are achieved.

Owner:浙江宝信炉料股份有限公司

Titanium-silicon nitride alloy cored wire

The invention relates to an alloy cored wire and particularly relates to a titanium-silicon nitride alloy cored wire comprises a core layer and a steel sheet layer wrapped outside the core layer, wherein the core layer is made of titanium-silicon nitride alloy powder with particle size being smaller than 3mm; a net-shaped support layer made of steel or iron is arranged between the core layer and the steel sheet layer; the titanium-silicon nitride alloy powder is prepared from elements in percentage by mass. According to the titanium-silicon nitride alloy cored wire, the alloy powder is added into micro-alloyed steel by a method using the cored wire, so that the problem of low recovery rate can be solved; consumption of ferrosilicon and ferromanganese can also be reduced; the application of titanium-silicon nitride and cored wire alloys thereof can be developed; the titanium-silicon nitride alloy cored wire has remarkable economic benefit.

Owner:浙江宝信炉料股份有限公司

High-performance Al-Mg-Si alloy and preparation method thereof

ActiveCN112522553AImprove thermal stabilityHigh yield strengthHeat stabilitySupersaturated solid solution

The invention discloses a high-performance Al-Mg-Si alloy and a preparation method thereof. The alloy is composed of the following components in percentage by mass of 0.50 to 0.85% of Mg, 0.80 to 1.30% of Si, 0.10 to 0.35% of Fe, 0.03-0.25% of Ti, 0.03-0.30% of Zr, smaller than or equal to 0.15% of the sum of inevitable impurities and the balance Al. The alloy preparation method is a short-processsub-rapid solidification cast-rolling preparation method and comprises the five steps of alloy smelting, water-cooling copper roller cast-rolling, multi-pass cold rolling, solid solution heat treatment and artificial aging. The preparation method has the advantages that a formed Al-Ti-Zr ternary phase effectively inhibits abnormal growth of crystal grains in the Al-Mg-Si alloy, the thermal stability of the alloy is remarkably improved, the distribution and the size of a precipitated phase are improved, and precipitation strengthening is improved; a supersaturated solid solution Zr element isintroduced to participate in the nano Mg2Si phase precipitation process through sub-rapid solidification cast rolling, the aging dynamics is promoted, and the age hardening response is improved; and after artificial aging, alloy grains are uniform and fine, the yield strength is high and reaches 312 MPa, and meanwhile high plasticity is kept. According to the preparation method, the technologicalprocess steps and time are shortened, the quality of a plate strip is high, and the yield is high.

Owner:JILIN UNIV

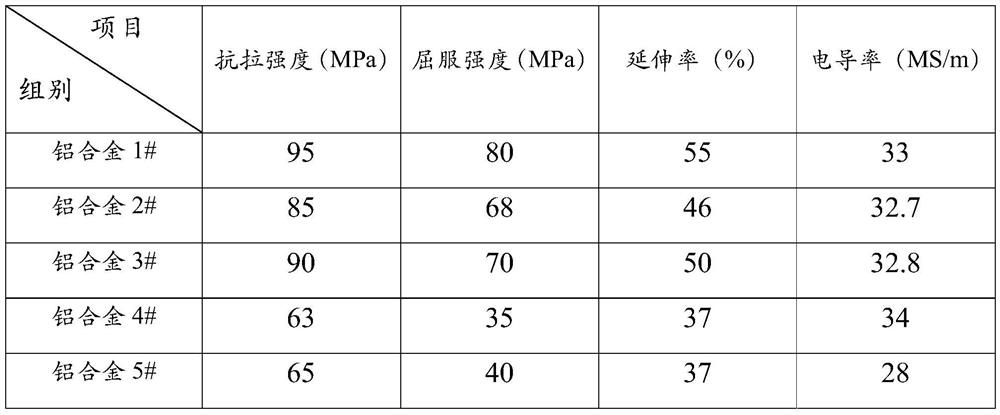

New energy automobile motor rotor casting aluminum alloy and preparation method thereof

The invention discloses a new energy automobile motor rotor casting aluminum alloy and a preparation method thereof, and belongs to the technical field of new energy automobile motors, the new energy automobile motor rotor casting aluminum alloy comprises 0.05 wt%-0.06 wt% of titanium, 0.04 wt%-0.06 wt% of boron, 0.15 wt%-0.5 wt% of silicon, 0.01 wt%-0.08 wt% of iron, 0.5 wt%-0.7 wt% of copper, 0.3 wt%-0.5 wt% of magnesium, 0.01 wt%-0.2 wt% of zinc, 0.02 wt%-0.12 wt% of manganese, and the balance aluminum. By adding new elements and adjusting the proportion of all the elements, the strength of the cast aluminum alloy is improved, and meanwhile excellent conductivity can be kept.

Owner:SHANDONG BOYUAN PRECISION MASCH CO LTD

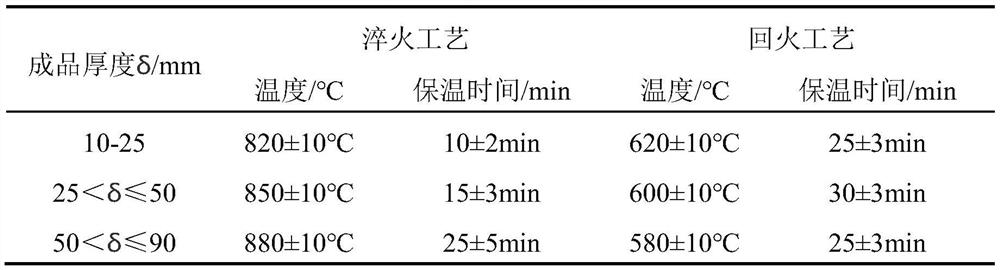

A kind of ultra-high-strength steel plate with a yield strength of 960mpa and its manufacturing method

The invention relates to an ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and a manufacturing method thereof. The steel plate comprises the chemical components of: 0.06-0.11% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, 0.20-0.50% of Cr, 0.10-0.30% of Ni, 0.10-0.30% of Mo, 0.02-0.05% of Nb, 0.02-0 .06% of V, 0.008-0.03% of Ti, 0.0005-0.003% of B, 0.02-0.05% of Al, and balance of Fe. According to the invention, through two-stage controlled rolling, and direct quenching and tempering, a refined tempered martensite or lower bainite structure is obtained. Defects such as long process, high energy consumption, large alloy addition amount, and the like of traditional quenching and tempering process are overcome. The obtained steel plate has good toughness and cold bending performance.

Owner:NANJING IRON & STEEL CO LTD +1

Welding wire with welding seam aging embrittlement resistance for high-grade martensitic heat-resistant steel and application of welding wire

ActiveCN111843285AReduce formationIncrease contentWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

The invention discloses a welding wire with welding seam aging embrittlement resistance for high-grade martensitic heat-resistant steel and application of the welding wire. The welding wire compriseschemical components as follows: 0.05%-0.12% of C, 0.15%-0.40% of Si, 0.40%-1.0% of Mn, 0.01% or smaller than 0.01% of P, 0.008% or smaller than 0.008% of S, 0.20% or smaller than 0.20% of Ni, 8.50%-9.50% of Cr, 0.90%-1.90% of W, 0.30%-1.10% of Mo, 2.50%-3.50% of Co, 0.03%-0.07% of Nb, 0.15%-0.25% of V, 0.03%-0.07% of N, 0.001%-0.004% of B, 0.10% or smaller than 0.10% of Cu, 0.01% or smaller than 0.01% of Ti, 0.03% or smaller than 0.03% of Al and the balance Fe and inevitable impurities. According to the welding wire, the welding seam formation is good, the initial toughness is high, the agingembrittlement tendency is small, and a joint has excellent high-temperature creep lasting strength.

Owner:WUHAN UNIV

Production method of 650 MPa-grade ultrahigh-strength steel bars

InactiveCN112176242AAvoid wastingThe solution consumes a lot,Manufacturing convertersRebarIndustrial engineering

The invention discloses a production method of 650 MPa-grade ultrahigh-strength steel bars. The production method comprises the steps of smelting and rolling. According to the method, a production process combining vanadium-nitrogen microalloying and controlled rolling and controlled cooling technologies is adopted, a novel molten steel nitrogen increasing process is adopted for smelting, and it is guaranteed that sufficient nitrogen and vanadium microalloying elements are combined to generate sufficient dispersedly-distributed two-phase particles, so that a stronger precipitation strengthening effect is achieved; and a whole-process high-precision temperature controlled rolling and temperature controlled cooling new technology is adopted for rolling, adding of a large number of precious microalloy elements is effectively reduced, meanwhile, the low-temperature toughness and welding performance of the product are improved, energy-saving, environment-friendly and green production of the650 MPa-grade ultrahigh-strength steel bars is achieved, new breakthrough of industrial production is achieved on the basis of existing 600 MPa-grade high-strength steel bars, and great significancein promoting material-saving and energy-saving sustainable development of the construction industry is achieved.

Owner:宁夏建龙龙祥钢铁有限公司

Titanium-silicon nitride alloy cored wire containing rare earth, calcium, barium and molybdenum

InactiveCN106636544AImprove qualityReduce dosageProcess efficiency improvementRare-earth elementFerrosilicon

The invention relates to an alloy cored wire, in particular to a titanium-silicon nitride alloy cored wire containing rare earth, calcium, barium and molybdenum. The titanium-silicon nitride alloy cored wire containing rare earth, calcium, barium and molybdenum comprises a core layer and a steel skin layer wrapping the core layer. The core layer is titanium-silicon nitride alloy powder which contains rare earth, calcium, barium and molybdenum and has the particle sizes below 3 mm. A netty supporting layer made of steel or iron is arranged between the core layer and the steel skin layer. The titanium-silicon nitride alloy powder containing rare earth, calcium, barium and molybdenum is prepared from, by mass, 1.0%-2.5% of Al, 10%-25% of N, 2.5%-5.0% of Mn, 1.0%-2.5% of Mg, 25%-40% of Ti, 25%-35% of Si, 5%-10% of Ca, 0.5%-1.0% of Mo, 0.5%-1.0% of Ba, 1.0%-2.0% of rare earth elements, no more than 0.1% of P, no more than 0.1% of S, and the balance Fe. The alloy powder is added into microalloyed steel through a cored wire method so that the problem of low recovery rate can be solved, consumption of ferrosilicon and ferromanganese can be reduced, application of titanium-silicon nitride and the titanium-silicon nitride cored wire is developed, and remarkable economic benefits are achieved.

Owner:浙江宝信炉料股份有限公司

Nanometer reinforced high-strength low-carbon Nb-contained steel for hot galvanization and preparation method thereof

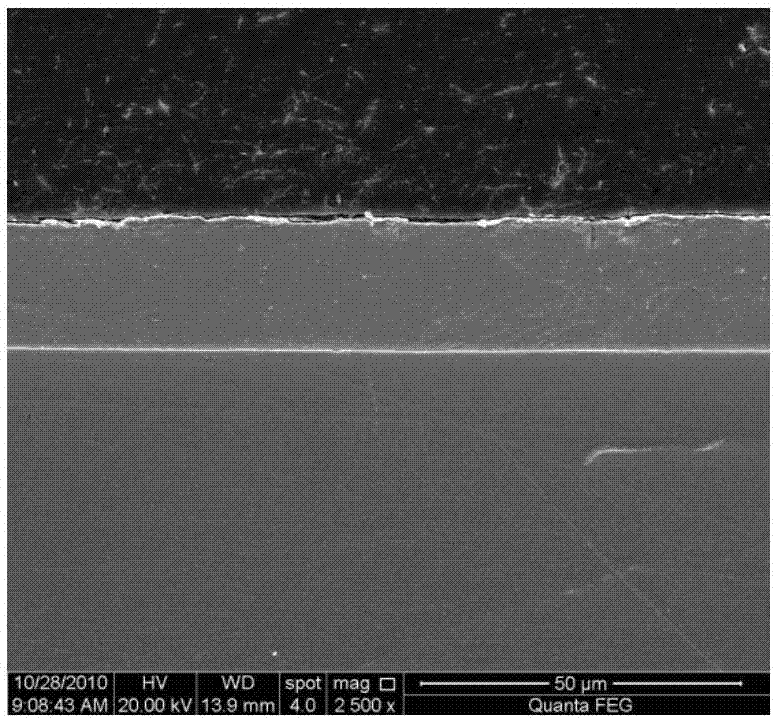

ActiveCN107475630AHigh strengthImprove solid solubilityHot-dipping/immersion processesSheet steelNanoparticle

The invention relates to nanometer reinforced high-strength low-carbon Nb-contained steel for hot galvanization. The steel comprises the following components in percentage by mass: 0.10-0.30 wt% of Nb, 0.10-0.35 wt% of Mo, 0.01-0.05 wt% of C, 0.05-1.2 wt% of Mn, 0.015-0.26 wt% of Si, 0.005-0.025 wt% of P, 0.003-0.020 wt% of S, 0.001-0.015% wt% of Al, 0.001-0.015 wt% of N, and the balance of Fe and inevitable impurities. Meanwhile, the invention further comprises a preparation method of the nanometer reinforced high-strength low-carbon Nb-contained steel for hot galvanization. As the contents of Nb and Mo in the steel are controlled, under the precondition of reducing microalloy elements in the steel, the strength of a steel plate is improved through a precipitation strengthening effect of nanoparticles, the production cost is reduced, the wettability of the surface of the steel plate and zinc liquid is improved, the uniformity of a plated layer is improved, the plating missing rate is reduced, and the platability of the steel plate and the surface quality of the plated layer are improved; and the preparation method has the advantages of low production cost, uniform thickness of a hot-galvanized layer, high surface quality and high adhesion of the plated layer.

Owner:NEW METALLURGY HI TECH GRP

Alloy cored wire containing rare earth, calcium, barium, molybdenum and high-titanium titanium-silicon nitride

The invention relates to an alloy cored wire, in particular to an alloy cored wire containing rare earth, calcium, barium, molybdenum and high-titanium titanium-silicon nitride. The cored wire comprises a core layer, and a steel sheath layer wrapping the exterior of the core layer; the core layer is composed of alloy powder, wherein the particle size of the alloy powder is smaller than 3 mm, and the alloy power contains rare earth, calcium, barium, molybdenum and high-titanium titanium-silicon nitride; a net-shaped supporting layer made from steel or iron is arranged between the core layer and the steel sheath layer; the alloy power containing rare earth, calcium, barium, molybdenum and high-titanium titanium-silicon nitride is composed of, by mass percentage, 1.0-2.5% of Al, 5-15% of N, 2.5-5.0% of Mn, 1.0-2.5% of Mg, 40-50% of Ti, 25-35% of Si, 5-10% of Ca, 0.5-1.0% of Mo, 0.5-1.0% of Ba, 1.0-2.0% of a rare earth element, smaller than or equal to 0.1% of P, smaller than or equal to 0.1% of S and the balance Fe. The alloy powder is added into microalloyed steel in a cored wire method, the problem that the recycling rate is low can be solved, the using amount of ferrosilicon and ferromanganese can also be reduced, application of titanium-silicon nitride and a cored wire alloy thereof is developed, and remarkable economic benefits are achieved.

Owner:浙江宝信炉料股份有限公司

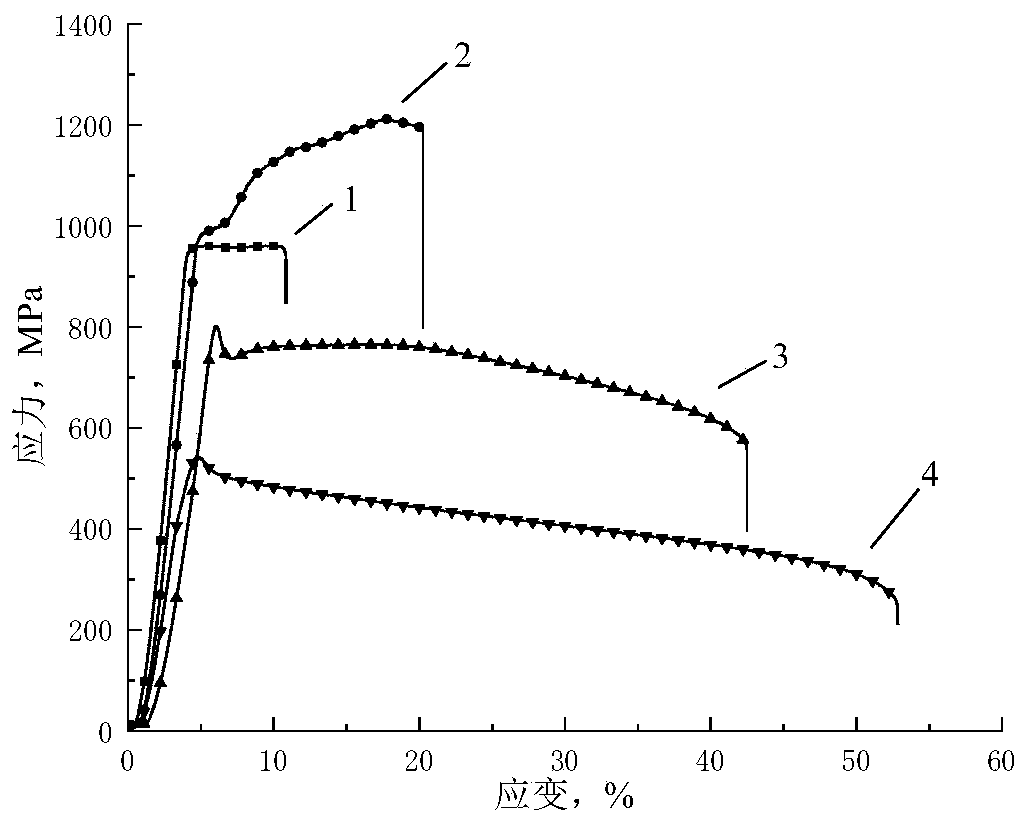

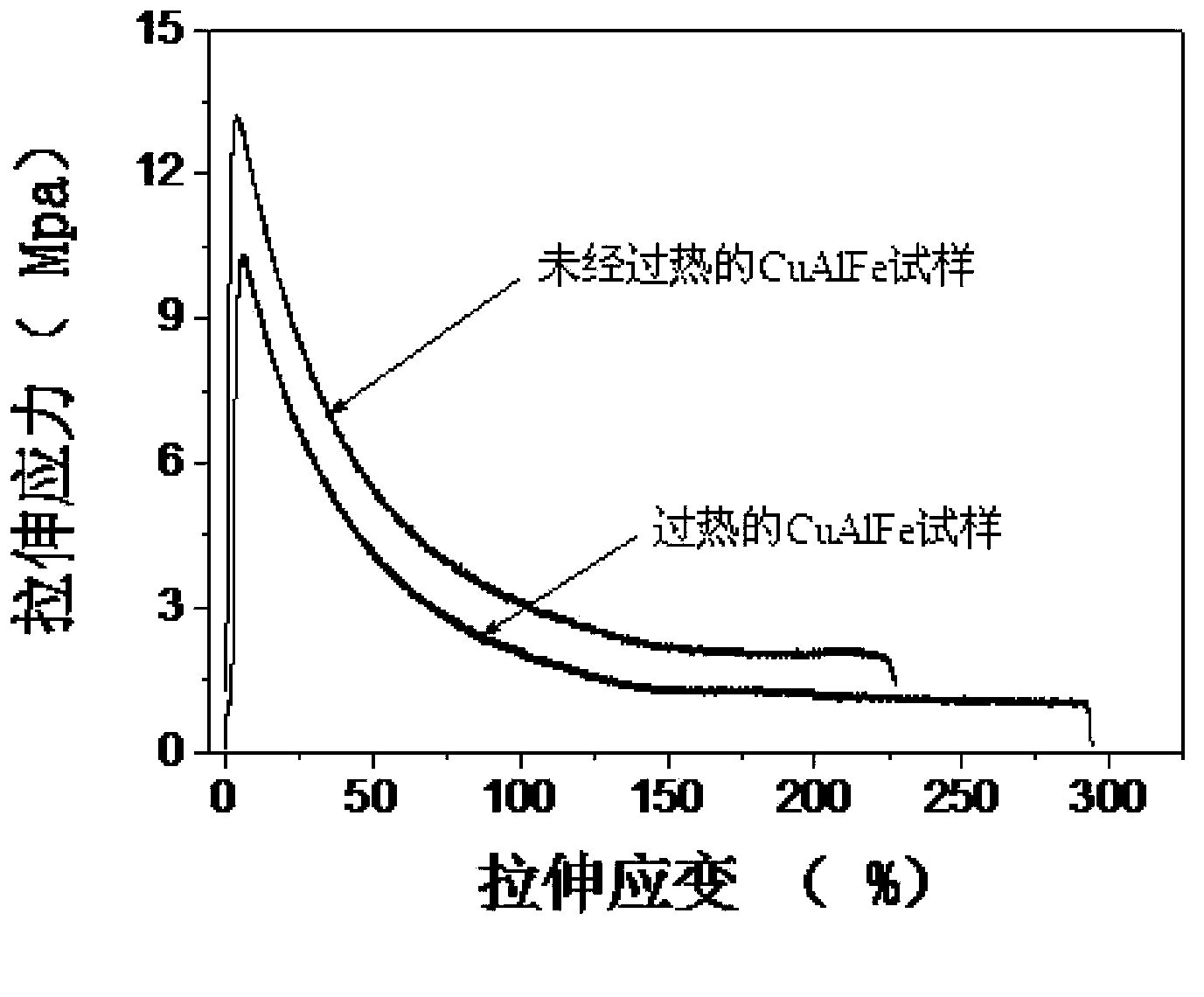

Method for improving super plasticity of copper-based superplastic alloy

The invention discloses a method for improving super plasticity of copper-based superplastic alloy. The super plasticity is improved by carrying out melt overheating treatment process on the copper-based superplastic alloy during a smelting period. The method comprises the steps of alloy melting, overheating treatment, cooling and pouring. According to the invention, at the smelting period of the copper-based alloy with high-temperature super plasticity, the structure of the alloy melts is influenced by the melt overheating treatment process, and heredity of a solid liquid structure is utilized to improve and perfect alloy tissue after solidification to enable the grain to be refined and equiaxial, thereby further improving the super plasticity of the alloy.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Production process for high-grade heat insulation pipe

InactiveCN110016605AEnhanced Precipitation StrengtheningEnhance the effect of fine grain strengtheningManufacturing convertersProcess efficiency improvementSteelmakingManganese

The invention belongs to the technical field of steel production equipment, and particularly relates to a production process for a high-grade heat insulation pipe. A steelmaking production process comprises the following steps of 1, preparation of steel ladles; 2, converter process, which comprises converter tapping, wherein lime top slag addition is 400 kg / furnace, refining slag 300 kg / furnace, aluminum ingots 1.15 kg / t, vanadium-nitrogen alloy 1.3 kg / t, silicon manganese alloy 24 kg / t, ferrosilicon 1.5 kg / t; 3, refining; and 4, continuous casting. A steel rolling production process comprisesthe following steps of 1, blank sizing; 2, heating temperature arrangement of an annular heating furnace; 3, perforation; 4, continuous rolling; 5, stretch reducing; 6, cooling a cooling bed; 7, pipesawing; 8, straightening; 9, carrying out flaw detection; 10, carrying out hydrostatic testing; and 11, diameter checking. According to the production process for the high-grade heat insulation pipe,a proper amount of the vanadium-nitrogen alloy is added into steel, the characteristics of the vanadium-nitrogen alloy are utilized, the precipitation strengthening effect and the fine grain strengthening effect of vanadium are enhanced, and finally the comprehensive performance of the steel pipe is effectively improved.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

700MPa-grade hot-rolled coiled steel and production method thereof

ActiveCN112458357AHigh strengthImprove mechanical propertiesUltimate tensile strengthSteelmaking continuous casting

The invention relates to the technical field of metallurgy, and particularly discloses 700MPa-grade hot-rolled coiled steel and a production method thereof. The 700MPa-grade hot-rolled coiled steel comprises the following components of, in percentage by weight, 0.23%-0.28% of C, 0.20%-0.40% of Si, 0.90%-1.15% of Mn, 0.22%-0.24% of V, 0.025%-0.040% of N, 0.25%-0.45% of Cr, 0.02%-0.04% of Nb, less than or equal to 0.035% of P, less than or equal to 0.035% of S, and the balance Fe and inevitable impurities, and the 700MPa-grade hot-rolled coiled steel is prepared through the procedures of steelmaking, continuous casting, heating, rolling and cooling. Through component adjustment and process optimization, the prepared hot-rolled coiled steel can meet the performance requirements of 700MPa-grade hot-rolled coiled steel, and has the advantages of higher strength, higher toughness, higher plasticity, low production cost, high production efficiency and wide application prospects.

Owner:HEBEI IRON AND STEEL

Solid metal calcium and composite core-spun yarn containing rare earth, niobium, vanadium and boron high-titanium titanium-silicon nitride alloy powder

The invention relates to an alloy core-spun yarn, and particularly relates to solid metal calcium and a composite core-spun yarn containing rare earth, niobium, vanadium and boron high-titanium titanium-silicon nitride alloy powder. The core-spun yarn comprises a sandwich layer and a sheet iron layer, wherein the sheet iron layer wraps the sandwich layer, a steel or iron net support layer is arranged between the sandwich layer and the sheet iron layer, the sandwich layer comprises a titanium-silicon nitride alloy powder layer, a middle protective layer and a solid calcium metal wire, the middle protective layer wraps the solid calcium metal wire, the titanium-silicon nitride alloy powder layer wraps the middle protective layer, the mass ratio of the solid calcium metal wire to the titanium-silicon nitride alloy powder layer is 1:(2 to 5), and the titanium-silicon nitride alloy powder layer is made of rare earth, niobium, vanadium and boron containing high-titanium titanium-silicon nitride alloy powder of which the particle size is below 3 mm. A method of the core-spun yarn is adopted, so that alloy and calcium are added to microalloyed steel, the problem of low recovery rate can be solved, and additionally, compared with a conventional solid calcium metal wire, the composite core-spun yarn has the advantages of high yield, long storage time and stable yield and has obvious economic benefits.

Owner:浙江宝信炉料股份有限公司

Core-spun yarn containing rare earth, niobium, vanadium, boron titanium-silicon nitride alloy powder

InactiveCN106399628AImprove compactnessImprove hot rolling performanceProcess efficiency improvementNiobiumFerrosilicon

The invention relates to alloy powder of a core-spun yarn, and particularly relates to rare earth, niobium, vanadium, boron titanium-silicon nitride alloy powder of a core-spun yarn. The alloy powder is prepared from the following elements in mass percent: 1.0 to 2.5% of Al, 10 to 25% of N, 2.5 to 5.0% of Mn, 1.0 to 2.5% of Mg, 25 to 40% of Ti, 25 to 35% of Si, 0.5 to 1.0% of Nb, 0.5 to 1.0% of V, 0.5 to 1.0% of B, 1.0 to 2.0% of rare earth, less than or equal to 0.1% of P, less than or equal to 0.1% of S and the balance of Fe. The alloy powder is added to microalloyed steel by adopting a method of the core-spun yarn, so that the problem of low recovery rate can be solved, the consumption of ferrosilicon and ferromanganese can be reduced, and the development of titanium-silicon nitride and an alloy application of the core-spun yarn has obvious economic benefits.

Owner:浙江宝信炉料股份有限公司

High-impact 7-series aluminum alloy and preparation method thereof

The invention discloses a high-impact 7-series aluminum alloy. The high-impact 7-series aluminum alloy comprises the following components of 0.1%-0.2% of Si, less than or equal to 0.2% of Fe, 0.35%-0.6% of Cu, less than or equal to 0.5% of Mn, 1.5%-2.5% of Mg, less than or equal to 0.15% of Cr, 6.0%-7.5% of Zn, 0.25%-0.35% of Zr, less than or equal to 0.1% of Ti and the balance Al, wherein other alloy elements are less than or equal to 0.05% individually and less than 0.15% totally, a ratio of the Si to the Fe is 1:0.6-0.8, and a ratio of the Zn to the Mg is 3.4-3.6:1.

Owner:福建祥鑫股份有限公司

56kg-grade ultrahigh-strength maritime work steel plate with low yield ratio and preparation method of 56kg-grade ultrahigh-strength maritime work steel plate

PendingCN114250416AEnhance fine grain strengtheningLow yield ratioTemperature control deviceMetal rolling arrangementsSteel platesTempering

The invention belongs to the field of steel and iron material preparation, and relates to a 56kg-grade low-yield-ratio ultrahigh-strength maritime work steel plate and a preparation method thereof. According to the component design, the steel comprises the following components of 0.05%-0.012% of C, 0.20%-0.50% of Si, 1.00%-1.50% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, 0.010%-0.030% of Nb, 0.010%-0.030% of Ti, 0.20%-0.45% of Cr, 0.010%-0.035% of V, 0.20%-0.50% of Cu, 0.10%-0.25% of Mo, 0.50%-0.95% of Ni, 0.015%-0.045% of Als, smaller than or equal to 0.004% of N and the balance Fe and inevitable impurities, the carbon equivalent CeV is smaller than or equal to 0.55, and the carbon equivalent Pcm is smaller than or equal to 0.25. According to the method, Nb, V and Ti multi-element microalloying elements are utilized, Mo, Ni and other refined and precipitated second-phase particles are added, the refined grain strengthening and precipitation strengthening effects are improved, and the subcritical quenching and high-temperature tempering processes are combined, so that ReH of the steel plate is larger than or equal to 600 Mpa, Rm ranges from 730 Mpa to 800 Mpa, the yield ratio is smaller than or equal to 0.82, and transverse and longitudinal impact energy at the temperature of-60 DEG C is larger than or equal to 200 J; and meanwhile, formed second-phase particles are dispersed and distributed in a welding heat affected zone, the strength of a welding joint is improved, 150-220 kJ / cm input can be achieved, and the impact energy at the temperature of minus 60 DEG C after welding is larger than or equal to 100 J.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD +1

High-titanium titanium-silicon nitride alloy core spun yarn

The invention relates to an alloy core spun yarn, in particular to a high-titanium titanium-silicon nitride alloy core spun yarn. The core spun yarn comprises a core layer and a steel skin layer wrapped at the outer portion of the core layer. The core layer is made of titanium-silicon nitride alloy powder with the particle size being smaller than 3 mm. A net-shaped supporting layer made of steel or iron is arranged between the core layer and the steel skin layer. The titanium-silicon nitride alloy powder comprises the following element components including, by mass percent, 1.0%-2.5% of Al, 5%-15% of N, 2.5%-5.0% of Mn, 1.0%-2.5% of Mg, 40%-60% of Ti, smaller than or equal to 0.1% of P, smaller than or equal to 0.1% of S, 35%-50% of Si and the balance Fe. The alloy powder is added in microalloyed steel in a core spun yarn method, the problem of the low recovery rate can be solved, in addition, the use amount of silicon iron and ferromanganese iron can be saved, application of titanium-silicon nitride and a core spun yarn alloy of the titanium-silicon nitride is developed, and obvious economic benefits are achieved.

Owner:浙江宝信炉料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com