Welding wire with welding seam aging embrittlement resistance for high-grade martensitic heat-resistant steel and application of welding wire

A high-grade, anti-aging technology, used in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as aging embrittlement of welds, achieve good weld formation, good process adaptability, and improve precipitation. The effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The fluidity of molten iron in Example 1 is better than that of Comparative Example 1, so its process operability is good, and welding defects such as incomplete fusion and incomplete penetration are not easy to occur.

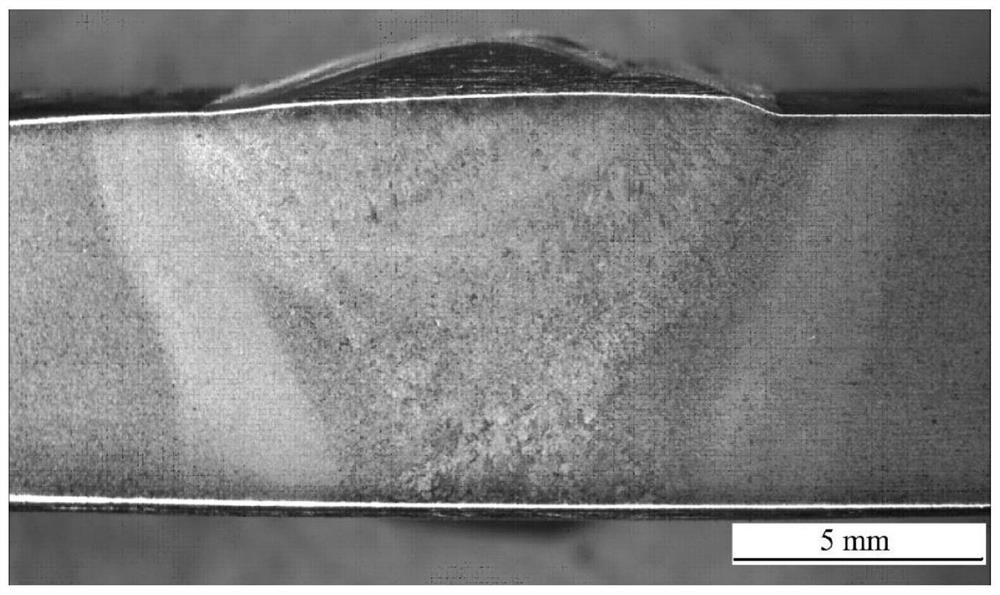

[0080] figure 1 It is a macroscopic photo of the GTAW joint welded by the welding wire of Example 1. The figure shows that the welding wire of Example 1 can meet the requirements of the GTAW welding process, and the weld is well formed without defects such as cracks, pores and inclusions.

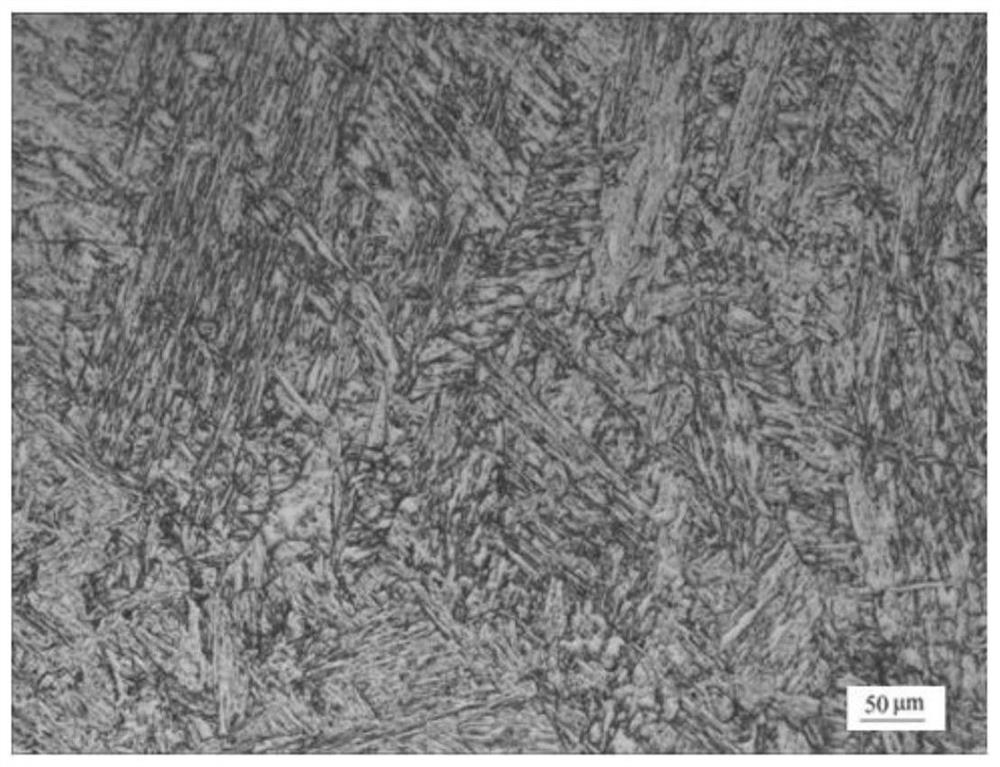

[0081] figure 2 It is the weld microstructure of the GTAW joint welded by the welding wire of Example 1. The figure shows that the welding seam of the welding wire of Example 1 under the GTAW process is a tempered lath martensitic structure, and no δ-ferrite appears.

[0082] The room temperature mechanical properties of the joints of Example 1 and Comparative Example 1 were evaluated according to DL / T868 Welding Procedure Qualification Regulations, and the results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com