Nickel-cobalt-based high-temperature alloy welding wire

A high-temperature alloy, nickel-cobalt-based technology, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems that cannot meet the service requirements of power plant boilers

Pending Publication Date: 2021-03-19

CHINA HUANENG GRP CO LTD +1

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a nickel-cobalt-based superalloy welding wire with reasonable composition design and high performance, aiming at the fact that the existing high-temperature alloy welding wire cannot meet the service requirements of power plant boilers above 750°C

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

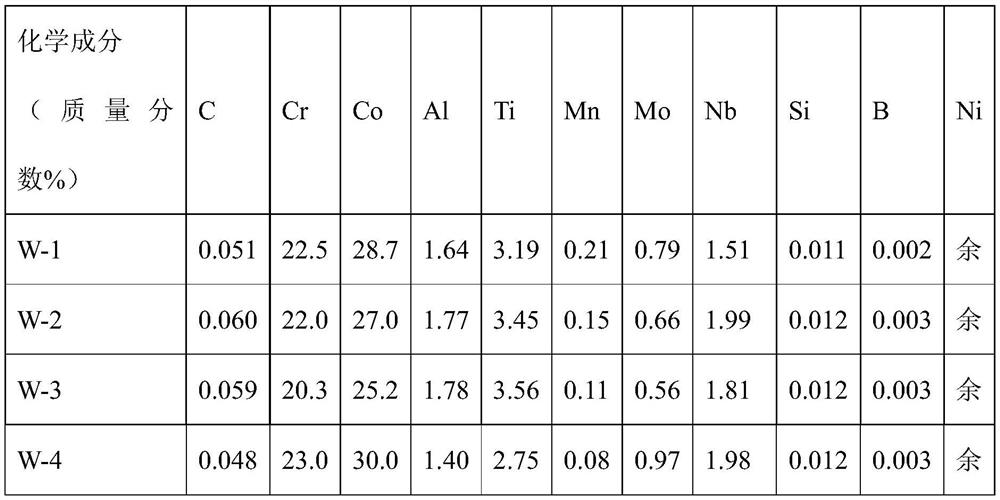

[0026] Referring to Table 1, the yield strength of the welding wire with W-1 composition in Table 1 is 650MPa at 800°C.

Embodiment 2

[0028] See Table 1, the yield strength of the welding wire with W-2 composition in Table 1 is 730MPa at 800°C.

Embodiment 3

[0030] Referring to Table 1, the yield strength of the welding wire with W-3 composition in Table 1 is 730MPa at 800°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of welding materials, and particularly relates to a precipitation strengthening type nickel-cobalt-based high-temperature alloy welding wire for welding a high-temperature part of an 800-DEG C ultra-supercritical power station. The welding wire is mainly characterized in that Ti / Al is more than or equal to 1.5 and less than or equal to 2, and C / Nb is more than orequal to 0.03. The yield strength of the welding wire at 800 DEG C is not less than 600 MPa. An alloy comprises, by mass percent, 25-30% of Co, 20-23% of Cr, 1.4-1.8% of Al, 2.1-3.6% of Ti, 1.5-2.0%of Nb, 0.5-1.0% of Mo, less than or equal to 0.1% of Si, less than or equal to 0.3% of Mn, less than or equal to 0.01% of Cu, less than or equal to 0.04% of C, less than or equal to 0.003% of B, and the balance of Ni, and no rare earth element is contained. A deposited metal matrix of the welding wire is an austenite (gamma) phase of a disordered face-centered structure, precipitation strengthening phases are a Ni3 (Al, Ti) gamma'phase and a primary carbide NbC, and carbide phases are distributed between crystals. The welding wire fills up the blank in the prior art, has excellent high-temperature performance, can be widely applied to homogeneous and heterogeneous welding of high-temperature alloy parts under the condition of ultra-supercritical water vapor at the temperature of 750-800 DEG C, and can also replace an existing nickel-based / nickel-cobalt-based high-temperature alloy welding wire.

Description

technical field [0001] The invention belongs to the field of welding materials, and in particular relates to a Ni-Cr-Co precipitation-strengthened nickel-cobalt-based superalloy welding wire. Background technique [0002] With the advancement of ultra-supercritical power generation technology above 750 °C, a large number of applications of high-temperature alloy materials in this field have been promoted. Filler. Since the welding joint (weld seam) is the weak link of the key high-temperature components of the power station, the welding filler material of one grade higher than the base metal is usually selected during welding to ensure welding performance and quality. High-temperature alloy welding wire is widely used in welding (including dissimilar welding) of heat-resistant steel in power stations due to its excellent high-temperature comprehensive performance. At present, the welding of candidate materials (such as HAYNES282, INCONEL 740H, etc.) Performance will be re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/30

CPCB23K35/3033

Inventor 尹宏飞袁勇鲁金涛党莹樱杨珍谷月峰严靖博

Owner CHINA HUANENG GRP CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com