800MPa grade automobile box steel and production method thereof

A production method and 800MPa technology, applied in the 800MPa grade automobile box steel and its production field, can solve the problems of difficult rolling process control and high production cost, and achieve the guaranteed strength index and overall performance, low production cost, and reduced The effect of the brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: The process steps of the production method of the 800MPa grade automobile box body steel are as follows.

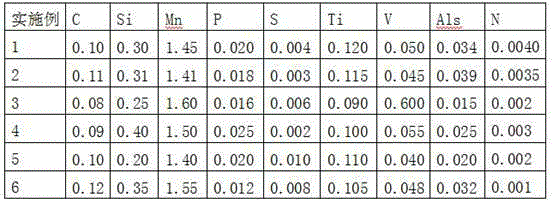

[0020] The slab with the chemical composition shown in Example 1 in Table 1 is used for production, and the processes of heating, high-pressure water descaling, rough rolling, hot coil box crimping, finish rolling, cooling and coiling are adopted. Heating process: put the slab into the heating furnace for heating, the slab is required to be cold-rolled into the furnace, and the slab is required to be fully heated before ≤ 1000 °C; when the slab is > 1000 °C, it is required to be heated rapidly to reach the stipulated output of the slab The temperature prevents the austenite grain size from growing. The heating rate is 10°C / min, and the billet reaches 1220°C. 73 minutes in the oven. High-pressure water descaling process: After heating, the slab is descaled by high-pressure water and then rolled. Rough rolling process: In order to ensure the reduction...

Embodiment 2

[0022] Embodiment 2: The process steps of the production method of the 800MPa grade automobile box steel are as follows.

[0023] Put the slab shown in Example 2 in Table 1 into a hot furnace for heating. The slab requires cold rolling into the furnace, and the slab requires sufficient heating before ≤1000°C; when the slab is >1000°C, the heating rate is 12°C / min, the billet reaches 1220°C and comes out of the furnace; the total heating time is 151 minutes, the preheating section and the first heating section are in the furnace for 76 minutes, and the second heating section and soaking section are in the furnace for 75 minutes. After heating, the slab is descaled by high-pressure water and then roughed and finished rolled; the rough rolling Rt5 temperature is 1083°C, the thickness of the intermediate billet is 39.1mm; the finishing rolling temperature is 830°C, the coiling temperature is 580°C, and it is put into storage for slow cooling.

[0024] The product obtained in this...

Embodiment 3

[0025] Embodiment 3: The process steps of the production method of the 800MPa grade automobile box body steel are as follows.

[0026] Put the slab shown in Example 3 in Table 1 into a hot furnace for heating. The slab is required to be cold-rolled into the furnace, and the slab needs to be fully heated before ≤ 1000 ° C; when the slab is > 1000 ° C, the heating rate is 8 ° C / min, the billet reaches 1220°C and comes out of the furnace; the total heating time is 148 minutes, the preheating section and the first heating section are in the furnace for 72 minutes, and the second heating section and soaking section are in the furnace for 76 minutes. After heating, the slab is descaled by high-pressure water and then roughed and finished rolled; the rough rolling Rt5 temperature is 1067°C, the thickness of the intermediate billet is 39.1mm; the finishing rolling temperature is 854°C, the coiling temperature is 620°C, and it is put into storage for slow cooling.

[0027] The produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com