Method for improving super plasticity of copper-based superplastic alloy

A technology of plastic alloy and plastic properties, applied in the field of improving the superplastic properties of copper-based superplastic alloys, can solve the problems of unsatisfactory plasticity, difficult to reach 100%, etc. organizational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking Cu-9.5Al-4Fe alloy as an example, the operation steps of this method are as follows:

[0021] Copper Alloy Composition:

[0022] components

Al

Fe

Cu

Weight percentage (%)

9.5

4

Residual weight

[0023] Preparation method of superplastic alloy:

[0024] 1. Conventional smelting with induction furnace and protection with inert gas. Put the above ingredients into the furnace and raise the temperature to 1200°C for melting and keep it warm for 30 minutes to ensure that the alloy is melted and mixed evenly;

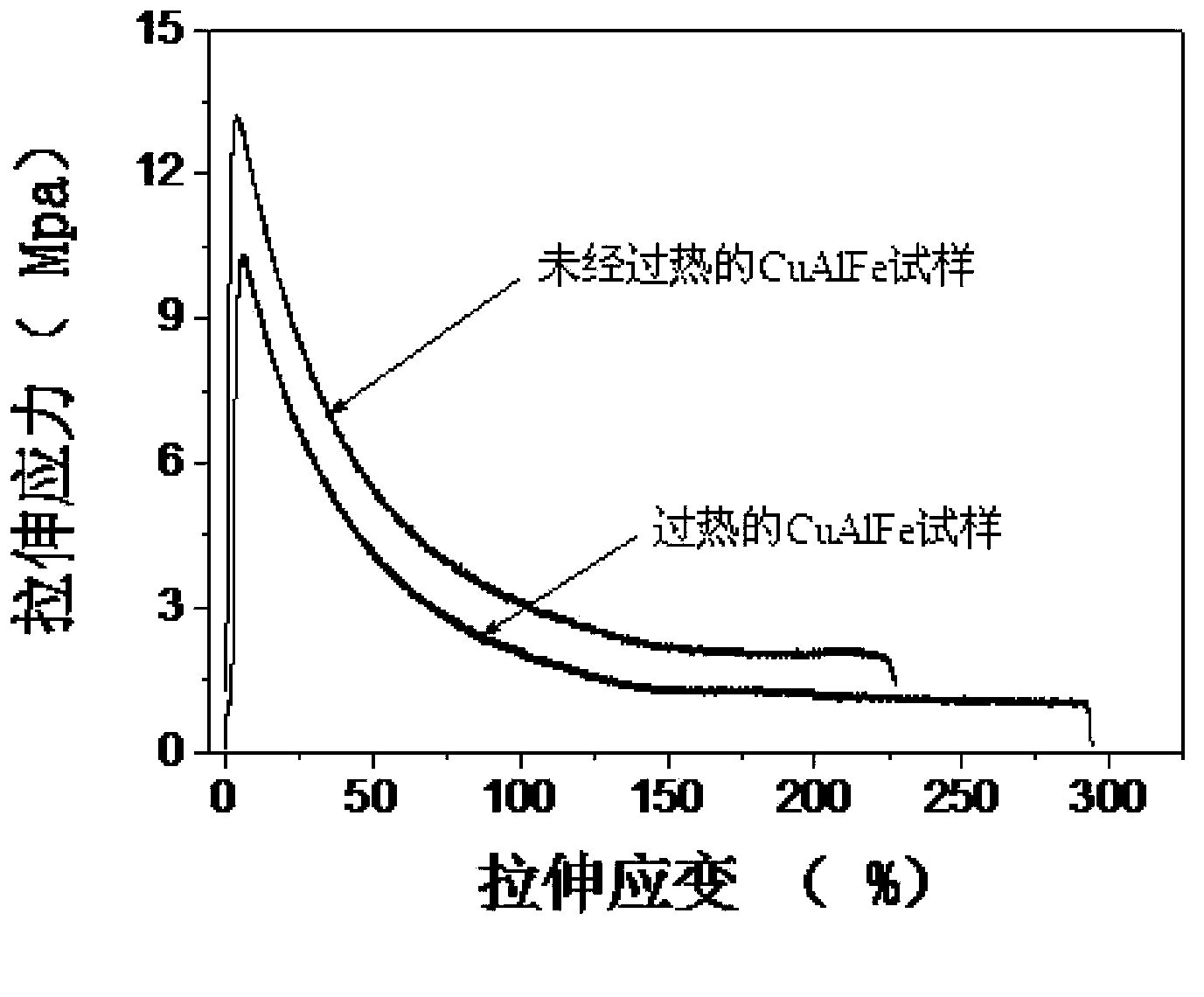

[0025] 2. Then continue to raise the temperature of the alloy melt to overheat to 1360°C and keep it warm for 35 minutes. After the heat preservation is over, the rapid furnace is cooled to the pouring temperature range of 1150°C, and the heat preservation is continued for 10 minutes. Finally, continuous casting (water-cooled crystallizer) rapid solidification method is adopted to cast and stretch into 8mm thick ...

Embodiment 2

[0030] Taking Cu-2.8Al-1.8Si-0.4Co alloy as an example, the operation steps of this method are as follows:

[0031] Copper Alloy Composition:

[0032] components

Al

Si

co

Cu

Weight percentage (%)

2.8

1.8

0.4

Residual weight

[0033] Preparation method of superplastic alloy:

[0034] 1. Use induction furnace, resistance furnace, etc. for conventional melting, and protect with inert gas. Put the above ingredients into the furnace and raise the temperature to 1200°C for melting and keep it warm for 30 minutes to ensure that the alloy is melted and mixed evenly;

[0035] 2. Then continue to raise the temperature of the alloy melt to overheat to 1440°C and keep it warm for 25 minutes. After the heat preservation is over, the furnace is rapidly cooled to the pouring temperature range of 1180°C, and the heat preservation is continued for 5 minutes. Finally, continuous casting (water-cooled crystallizer) rapid solidification m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com