HB500-level martensitic abrasion-resistant steel for shovel edge and machining method thereof

A technology of martensitic and wear-resistant steel, which is applied in the field of HB500 martensitic wear-resistant steel for blades and its processing field, can solve problems such as insufficient sliding wear resistance, achieve significant economic and social benefits, and increase precipitation Strengthening effect and the effect of less alloy addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

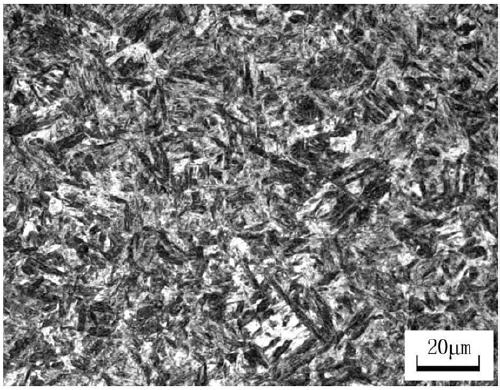

Image

Examples

Embodiment 1~5

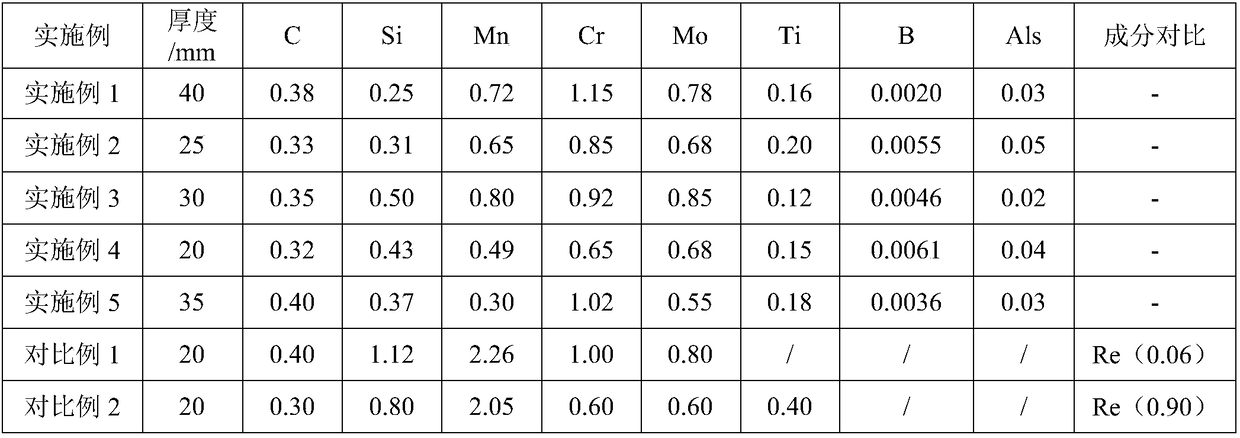

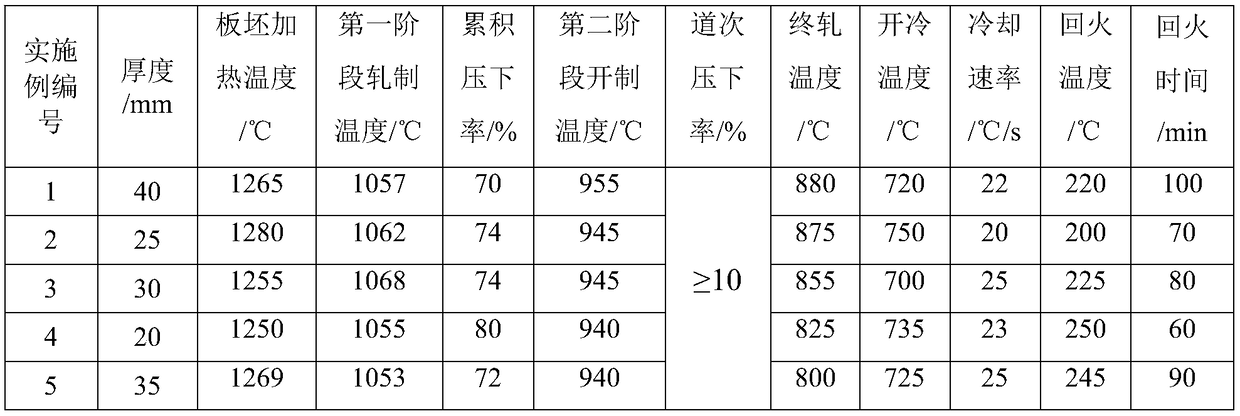

[0030] The chemical composition of the HB500 grade martensitic wear-resistant steel described in Examples 1 to 5 is shown in Table 1, and the process parameters are shown in Table 2; the specific preparation method includes the following steps:

[0031] 1) Carry out molten iron desulfurization;

[0032] 2) Carry out converter smelting and continuous casting to obtain a continuous casting slab with a thickness of 250 mm;

[0033] 3) Conventional continuous casting and heating of the slab, the heating temperature is controlled at 1250-1280°C;

[0034] 4) Carry out controlled rolling and controlled cooling. The rolling temperature in the first stage is ≥1050°C, and the cumulative reduction rate is 70-80%. ≥800°C; opening and cooling temperature 700-750°C, cooling rate 20-25°C / s;

[0035] 5) Perform tempering heat treatment, tempering temperature: 200-250°C, tempering time: plate thickness mm×2min / mm+20min; air cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com