56kg-grade ultrahigh-strength maritime work steel plate with low yield ratio and preparation method of 56kg-grade ultrahigh-strength maritime work steel plate

A low yield ratio, steel plate technology, applied in the direction of metal rolling, temperature control, etc., can solve the problems of low yield ratio, achieve the effect of low yield ratio, refine grain, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

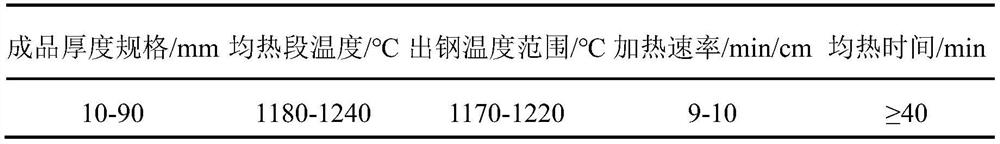

[0061] The present invention provides a 56 kg of low-flexion ratio ultra high high sea industrial steel plate and its preparation method, which is as follows:

[0062] The production process of the present invention is: steel water converter smelting - RH + LF refining - continuous casting - coil heating, rolling - heat treatment. Example 1 Smelting ingredients are shown in Table 4, each component is in line with the scope of the invention.

[0063] Table 4 Example 1 Sollow component

[0064]

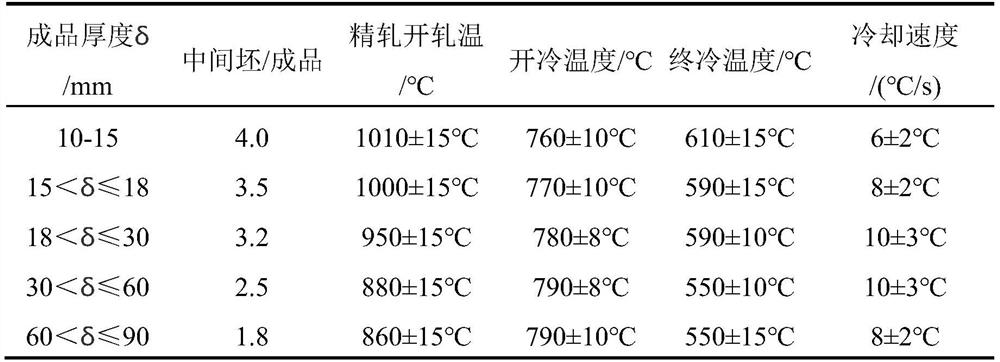

[0065] Example 1 Steel roller rolling, controlled cold processes showed that each of the specific steel sheet rolled, cold-controlled temperatures, and heat treatment processes were in accordance with the design range of the present invention.

[0066] Table 5 Example 1 Steel rolling, cold control process

[0067]

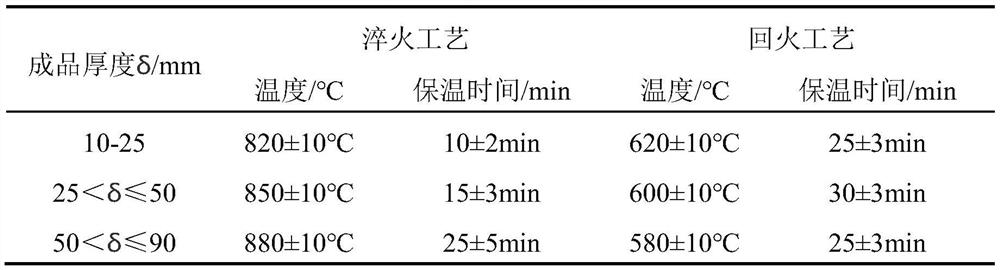

[0068] Table 6 Example 1 Heat treatment process

[0069]

[0070] Example 1 Steel rolling mechanical properties As shown in Table 7, REH ≥ 602 MPa, Rm ≥ 730 MPa of each sp...

Embodiment 2

[0077] The production process of the present invention is: steel water converter smelting - RH + LF refining - continuous casting - slab heating, rolling - heat treatment. Example 2 The smelting component is shown in Table 9, each of which is in line with the design range of the present invention.

[0078] Table 9 Example 2 Sollow component

[0079]

[0080] Example 2 Steel rolling, controlled cold process, heat treatment as shown in Table 10, each specified steel sheet process is in line with the design range of the present invention.

[0081] Table 10 Example 2 Steel rolling, cold control process

[0082]

[0083] Table 11 Example 2 Heat treatment process

[0084]

[0085] Example 2 Steel rolling mechanism performance As shown in Table 12, REH ≥ 600 MPa, Rm ≥ 730 MPa of each specified steel sheet, and the flexion ratio of ≤0.82, -60 ° C, and longitudinal shock power ≥ 200j.

[0086] Table 12 Example 2 Steel plate mechanical properties

[0087]

[0088] Example 2 Steel We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal impact work | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com