Ti microalloyed medium manganese steel plate for offshore platform and preparation method thereof

A micro-alloying and offshore platform technology, applied in the field of steel production in the metallurgical industry, can solve the problems of single strengthening mechanism, complex preparation process, uneven structure and properties, and achieve simple control and operation, inhibit abnormal growth, and enhance the uniformity of structure and properties. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A Ti microalloyed medium-manganese steel plate for offshore platforms, the chemical composition of which is: C: 0.10%, Mn: 4.0%, Ti: 0.02%, Si: 0.12%, S: 0.001%, P : 0.004%, Al: 0.02%, Cr: 0.40%, Ni: 0.11%, Mo: 0.10%, Cu: 0.12%, and the rest are Fe and other unavoidable impurities.

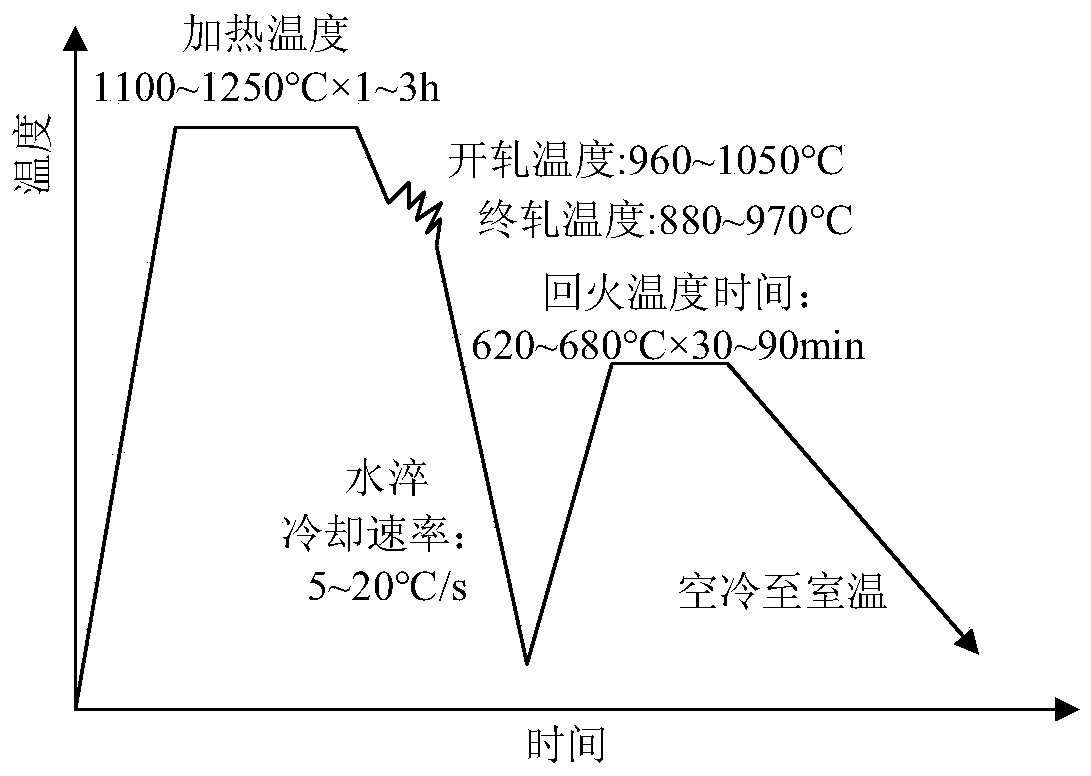

[0035] A preparation method for Ti microalloyed medium-manganese steel plate for offshore platform, comprising the following process steps:

[0036] Step 1, billet heating:

[0037] The ocean platform is forged with a Ti microalloyed medium-manganese steel plate alloy ingot to form a 140mm thick blank, heated to 1250 ° C with the furnace, and kept for 1 hour to obtain a heated blank. The chemical composition of the heated blank is: C: 0.10%, Mn: 4.0%, Ti: 0.02%, Si: 0.12%, S: 0.001%, P: 0.004%, Al: 0.02%, Cr: 0.40%, Ni: 0.11%, Mo: 0.10%, Cu: 0.12%, the rest is Fe and other unavoidable impurities.

[0038] Step 2: Hot Rolling Treatment:

[0039] (1) Hot-rolling the heated billet for 13 t...

Embodiment 2

[0045] A Ti microalloyed medium-manganese steel plate for offshore platforms, the chemical composition of which is: C: 0.06%, Mn: 6.0%, Ti: 0.05%, Si: 0.25%, S: 0.001%, P : 0.003%, Al: 0.024%, Cr: 0.10%, Ni: 0.20%, Mo: 0.25%, Cu: 0.20%, and the rest are Fe and other unavoidable impurities.

[0046] A preparation method for Ti microalloyed medium-manganese steel plate for offshore platform, comprising the following process steps:

[0047] Step 1, billet heating:

[0048] The offshore platform is forged with Ti microalloyed medium-manganese steel medium-thick plate alloy ingot to form a 140mm thick billet, heated to 1200°C with the furnace, and kept for 2 hours to obtain the heated bad material. The chemical composition according to the weight percentage is: C: 0.06%, Mn: 6.0%, Ti: 0.05%, Si: 0.25%, S: 0.001%, P: 0.003%, Al: 0.024%, Cr: 0.10%, Ni: 0.20%, Mo: 0.25%, Cu: 0.20%, the rest is Fe and other unavoidable impurities.

[0049] Step 2: Hot Rolling Treatment:

[0050] (1) ...

Embodiment 3

[0056] A Ti microalloyed medium-manganese steel plate for offshore platforms, the chemical composition of which is: C: 0.03%, Mn: 8.0%, Ti: 0.10%, Si: 0.39%, S: 0.002%, P : 0.003%, Al: 0.05%, Cr: 0.40%, Ni: 0.30%, Mo: 0.35%, Cu: 0.30%, and the rest are Fe and other unavoidable impurities.

[0057] A preparation method for Ti microalloyed medium-manganese steel plate for offshore platform, comprising the following process steps:

[0058] Step 1, billet heating:

[0059] The ocean platform is forged with a Ti microalloyed medium-manganese steel medium-thick plate alloy ingot to form a 140mm thick billet, heated to 1100°C with the furnace, and kept for 3 hours to obtain the heated billet. The chemical composition of the heated billet is: C: 0.03 %, Mn: 8.0%, Ti: 0.10%, Si: 0.39%, S: 0.002%, P: 0.003%, Al: 0.05%, Cr: 0.40%, Ni: 0.30%, Mo: 0.35%, Cu: 0.30 %, the rest is Fe and other unavoidable impurities.

[0060] Step 2: Hot Rolling Treatment:

[0061] (1) Hot rolling the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com