High-strength and high-toughness steel for rock drilling tools and production method thereof

A high-strength, high-toughness, production method technology, applied in the field of metallurgy, can solve the problems of low impact toughness, poor forging performance, and short service life of rock drilling tools, so as to improve hydrogen corrosion resistance, strength and toughness, and improve service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0023] Embodiment 1-12: High-strength and high-toughness steel for rock drilling tools and its production method adopt the following process.

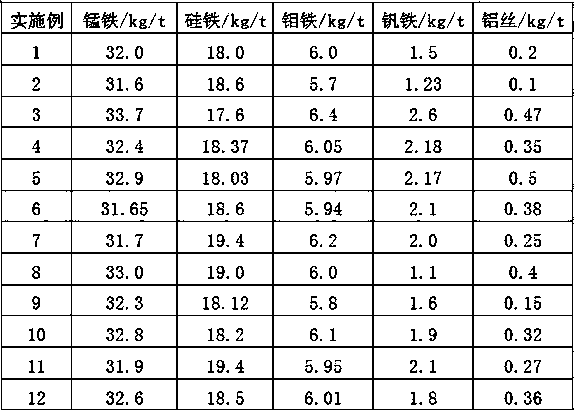

[0024] (1) Smelting process: including converter smelting, LF refining and VD vacuum treatment process; 31.6~33.7kg / t ferromanganese, 17.6~19.4kg / t ferrosilicon, 5.7~ 6.4kg / t; during the LF refining process, 1.1-2.6kg / t steel is added to the ladle; during the VD vacuum treatment process, 0.1-0.5kg / t steel is fed with aluminum wire after degassing treatment. The technological parameters of each embodiment smelting process are shown in Table 1.

[0025] Table 1: Process parameters of the smelting process

[0026]

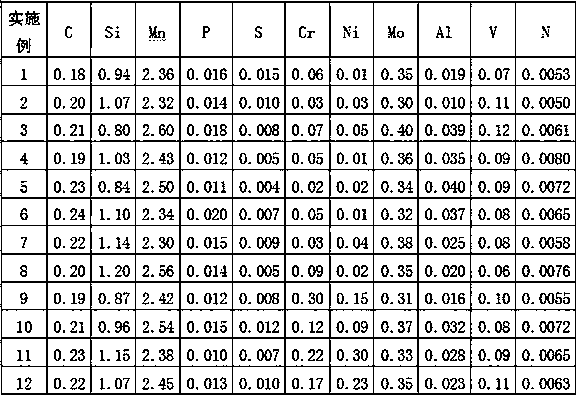

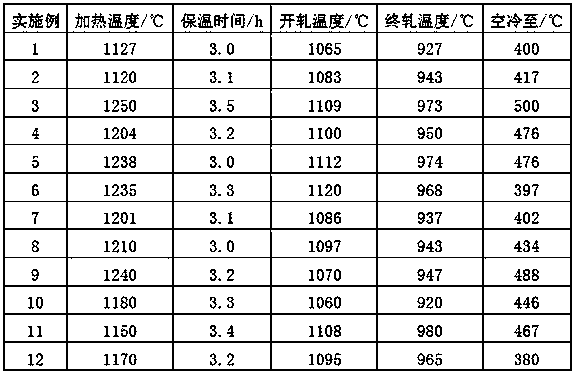

[0027] (2) Continuous casting, heating, rolling and cooling process: In the continuous casting process, molten steel is continuously cast to obtain a billet, and the chemical composition and mass percentage of the billet are shown in Table 2. In the heating process, the billet is heated to a holding temperature of 1120-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com