Nickel iron based welding wire for boiler of 700 DEG C ultra-supercritical power station

A power plant boiler and ultra-supercritical technology, which is applied in arc welding equipment, welding equipment, welding media, etc., can solve the problems of insufficient precipitation strengthening effect and inconspicuous cost advantage, and achieve significant economic benefits, low cost, and mature technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] See Table 1 and figure 1 , use the welding wire (W1 composition in Table 1) to weld the INCONEL740H nickel-cobalt-based alloy by manual TIG welding, and heat treatment at 800°C / 5h after welding, without defects such as welding cracks.

Embodiment 2

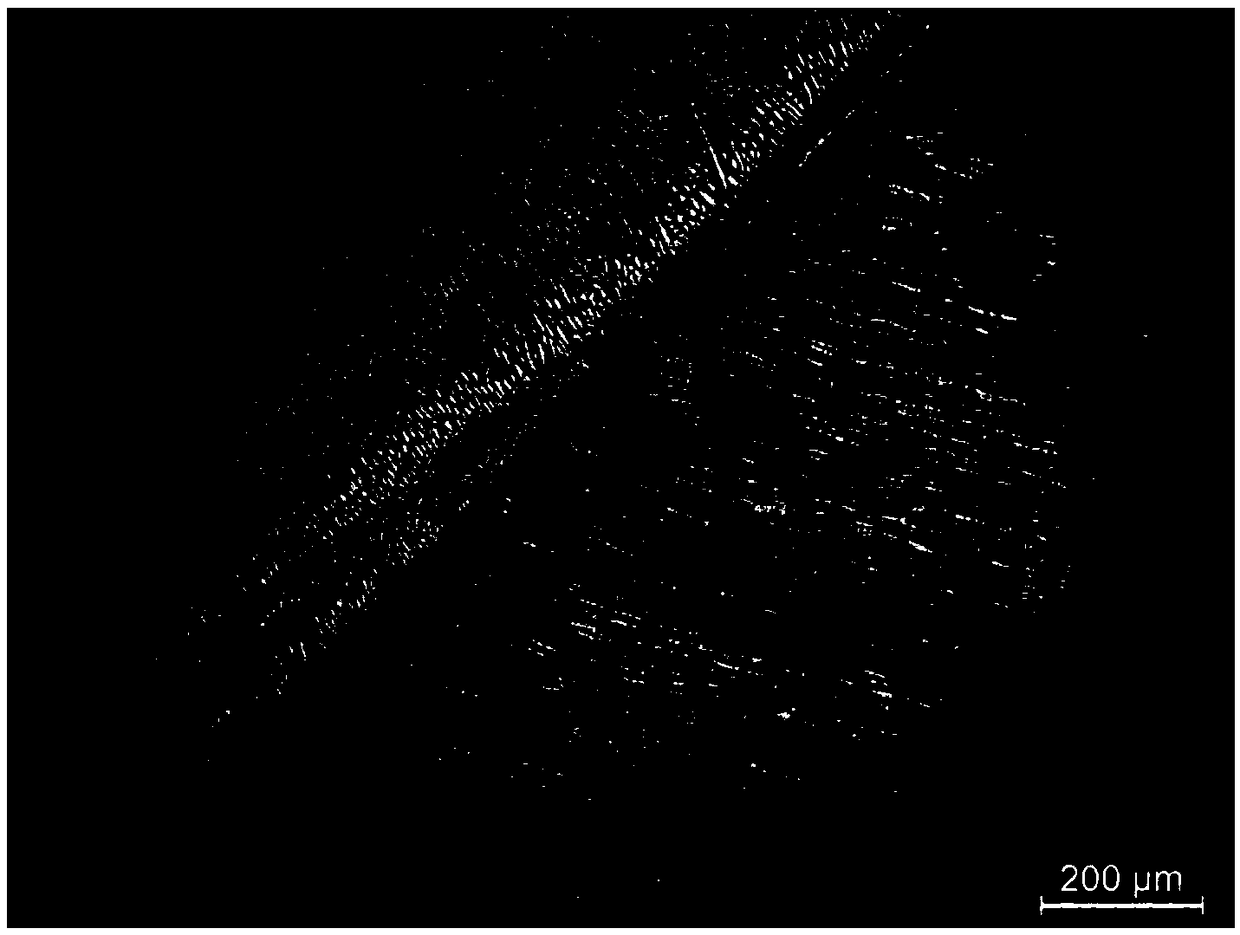

[0028] See Table 1 and figure 2 , use the welding wire (W2 composition in Table 1) to weld the Haynes282 nickel-based alloy by manual TIG welding, and perform heat treatment at 788 °C / 8h after welding, without defects such as welding cracks.

Embodiment 3

[0030] See Table 1 and image 3 , using the welding wire (W3 composition in Table 1) to weld the GH2984 nickel-iron-based alloy by manual TIG welding, and heat treatment at 750°C / 4h after welding, without welding cracks and other defects.

[0031] The actual chemical composition of the welding wire of table 1 embodiment

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com