Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Dendrite refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

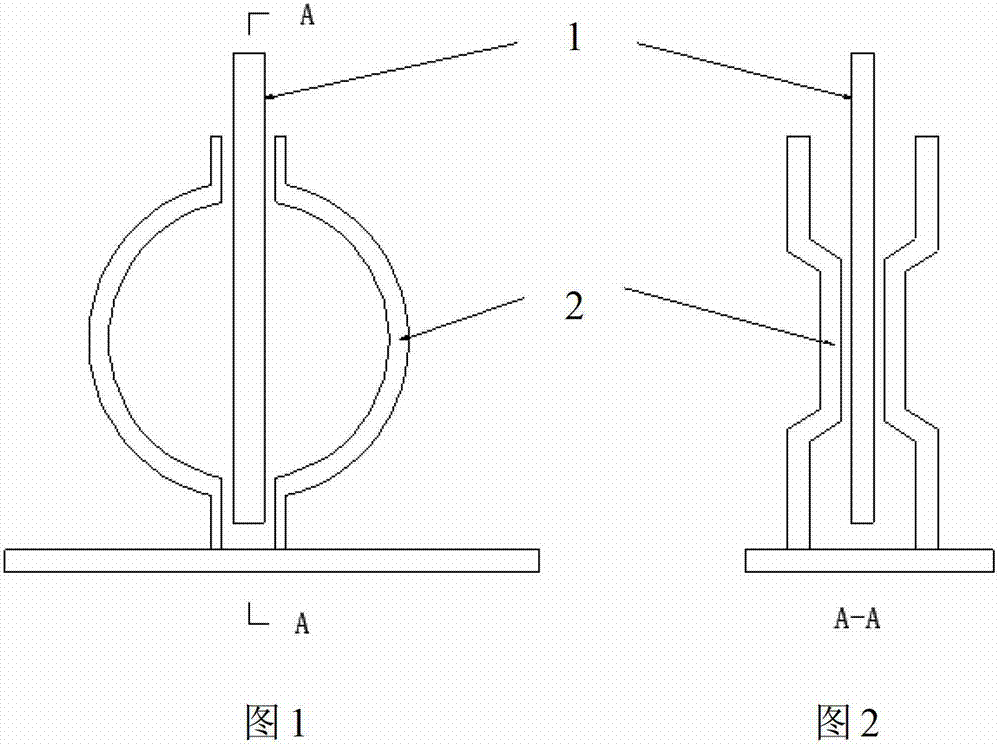

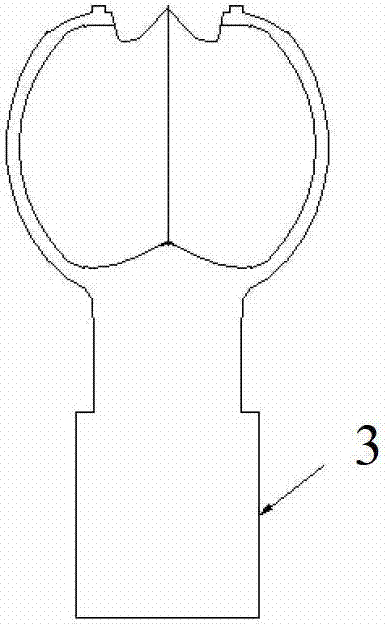

Electroslag smelting casting method of fixed blades of water turbine

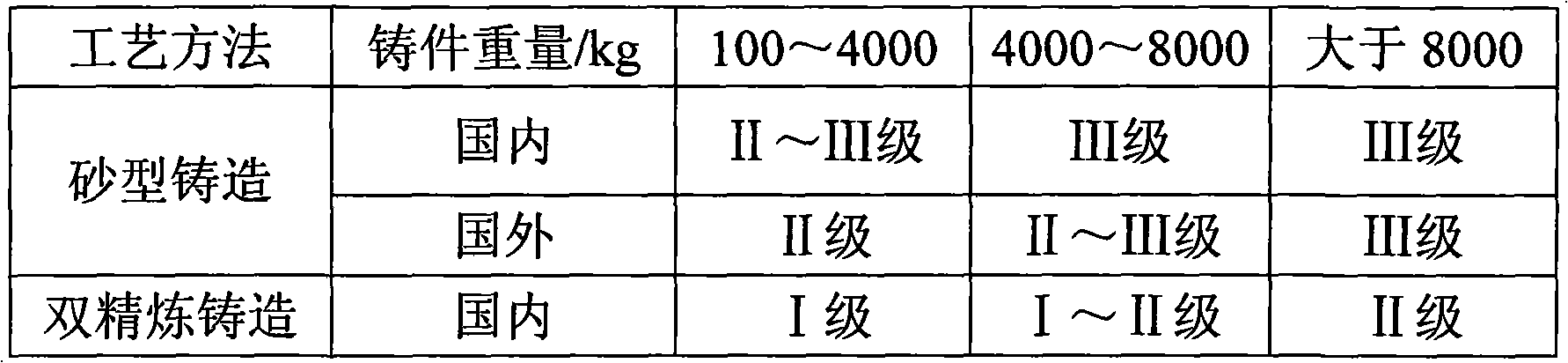

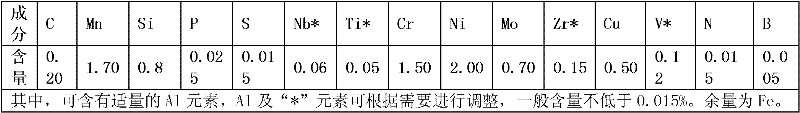

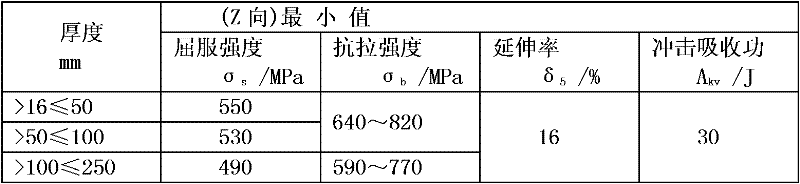

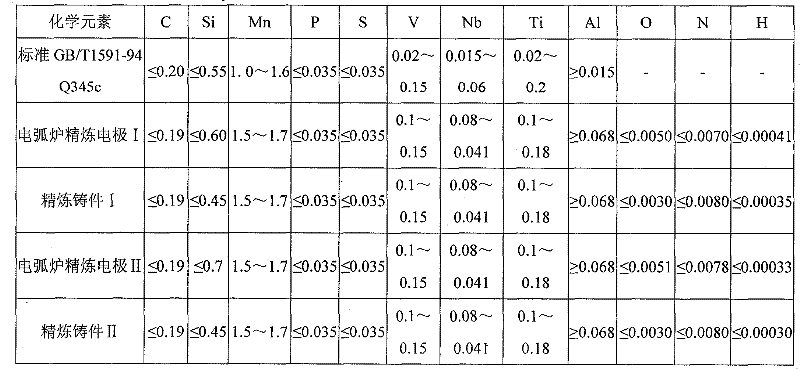

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

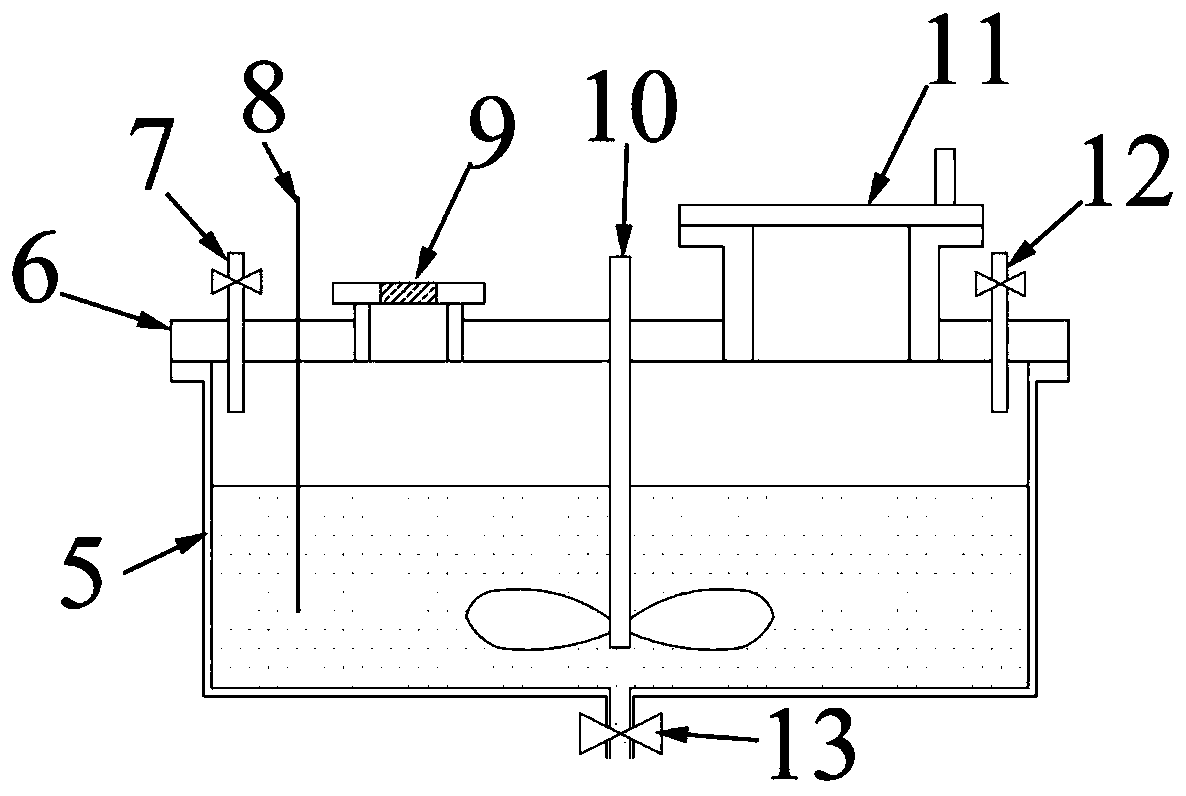

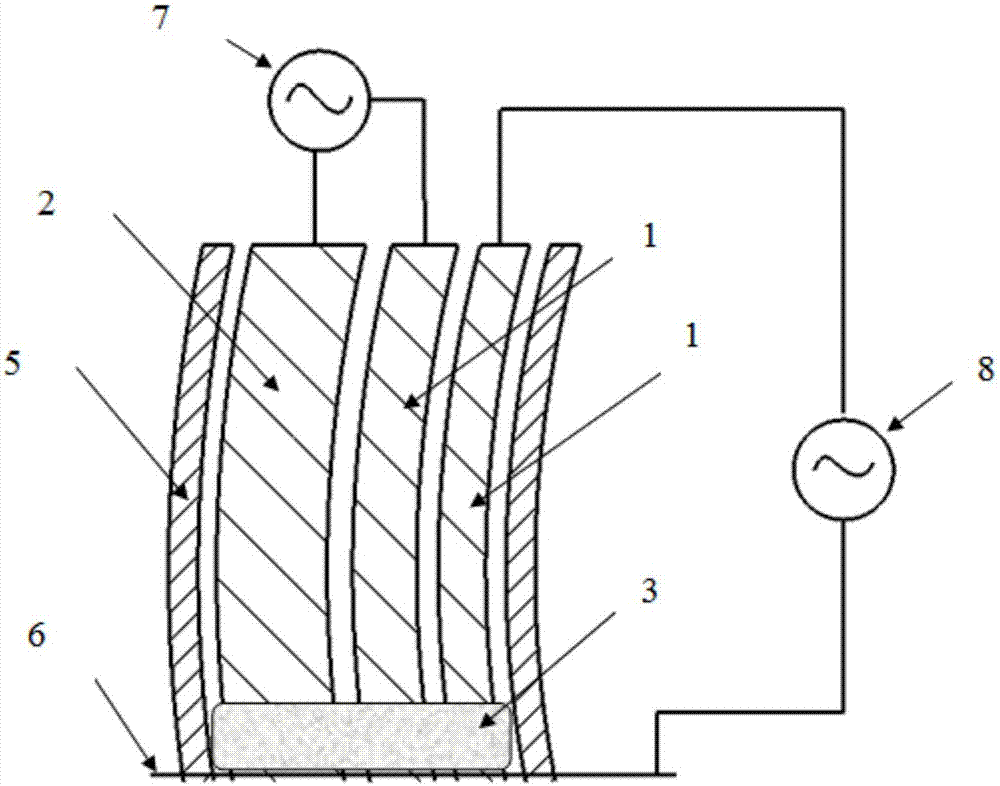

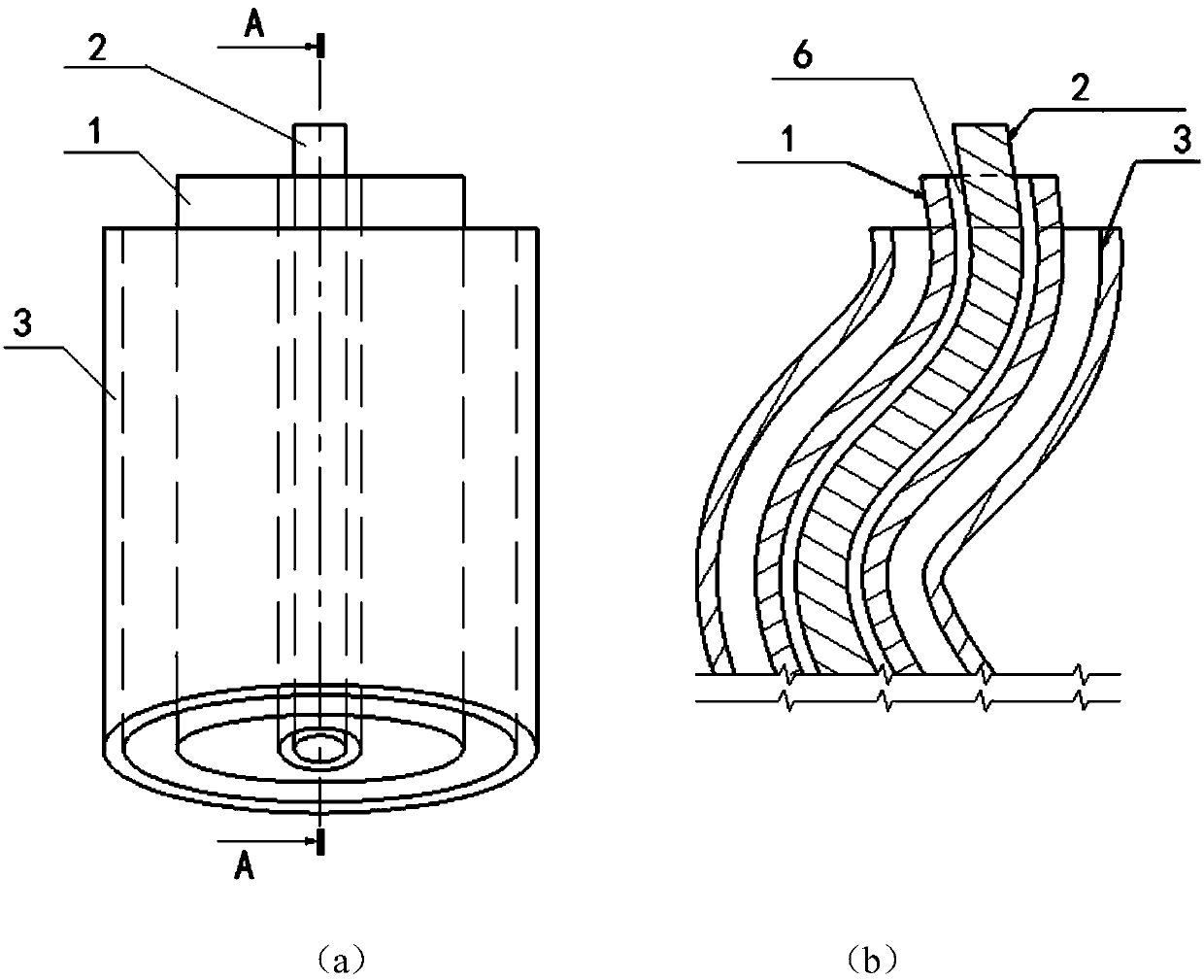

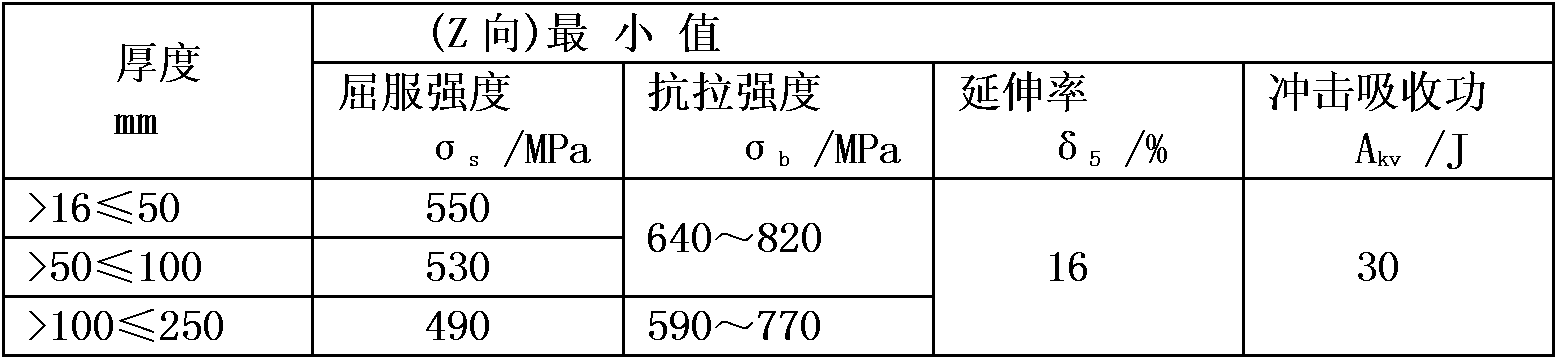

Electroslag fusion casting manufacturing method for annular plate of hydraulic generator

ActiveCN102416463AAchieve the purpose of near-net shape in melting and castingHigh dimensional accuracyManufacturing technologySlag

The invention discloses an electroslag fusion casting manufacturing method for an annular plate of a hydraulic generator. The method is characterized by comprising the following steps of: 1) controlling slag systems and slag amount; 2) igniting; 3) selecting a crystallizer; 4) rotating the crystallizer by using a control system; 5) selecting power supply parameters; 6) controlling casting alloy components after fusion casting; and 7) selecting a casting thermal processing process. A near-net-shape forming annular plate manufacturing technology is provided for producing annular anti-tear steel plates for hydraulic generator seat rings, top covers and bottom rings at present; a rotatable crystallizer is used for electroslag fusion casting formation, so that technical requirements on production of the annular plate are met; and the produced annular plate has high laminated tearing resistance, higher fatigue resistance and higher crack generation and expansion resistance, and the quality and the performance of the annular plate are not lower than those of a specially-forged product which is made of the same material as that of the annular plate.

Owner:沈阳市盛华特种铸造有限公司

Hoop surface hot dip coating tin alloy process

InactiveCN105586557ALow melting pointImprove corrosion resistanceHot-dipping/immersion processesTinningMetal coating

The invention discloses a hoop surface hot dip coating tin alloy process. The hoop surface hot dip coating tin alloy process comprises the steps of sanding, alkali wash oil removal, acid pickling, plating assisting, preheating, hot dip coating and analysis and detection. According to the hoop surface hot dip coating tin alloy process, no harmful heavy metal ion or phosphorus or sediment exists, heating is not needed, the treatment time is short, the number of treatment steps is small, a surface adjusting procedure can be omitted, hot drip coating can be reused, and the adhesive force of a metal coating to a substrate is effectively improved.

Owner:大连新锋钢管厂

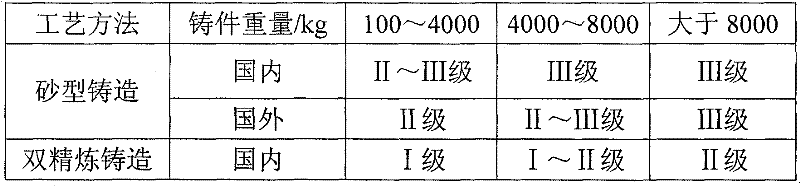

Electroslag casting production method for waterwheel blade green compact

An electroslag casting production method for a waterwheel blade green compact is characterized by comprising the following steps: confirming the outline of the blade green compact according to the intelligent three-dimensional expanded size of a water turbine blade; producing a crystallizer and a consumable electrode of the blade green compact; preparing the qualified blade green compact of the electroslag casting water turbine by optimizing electroslag casting process parameters and the anti-cracking heat treatment process. The method has the advantages that the detects of the conventional blade green compact of the water turbine can be overcome; a near-net forming green compact producing process is provided for the water turbine blade formed through heated-die pressing process; the produced blade green compact material is high in degree of purity, uniform in chemical constituents, compact in structure, free of defects such as looseness, slag inclusion and hole shrinkage, favorable in mechanical property, and higher in fatigue resistance performance, anti-cracking performance and expansibility, and can reach the mechanical property of forge pieces made of the same material and meet the requirements of flaw detection indexes.

Owner:SHENYANG RES INST OF FOUNDRY

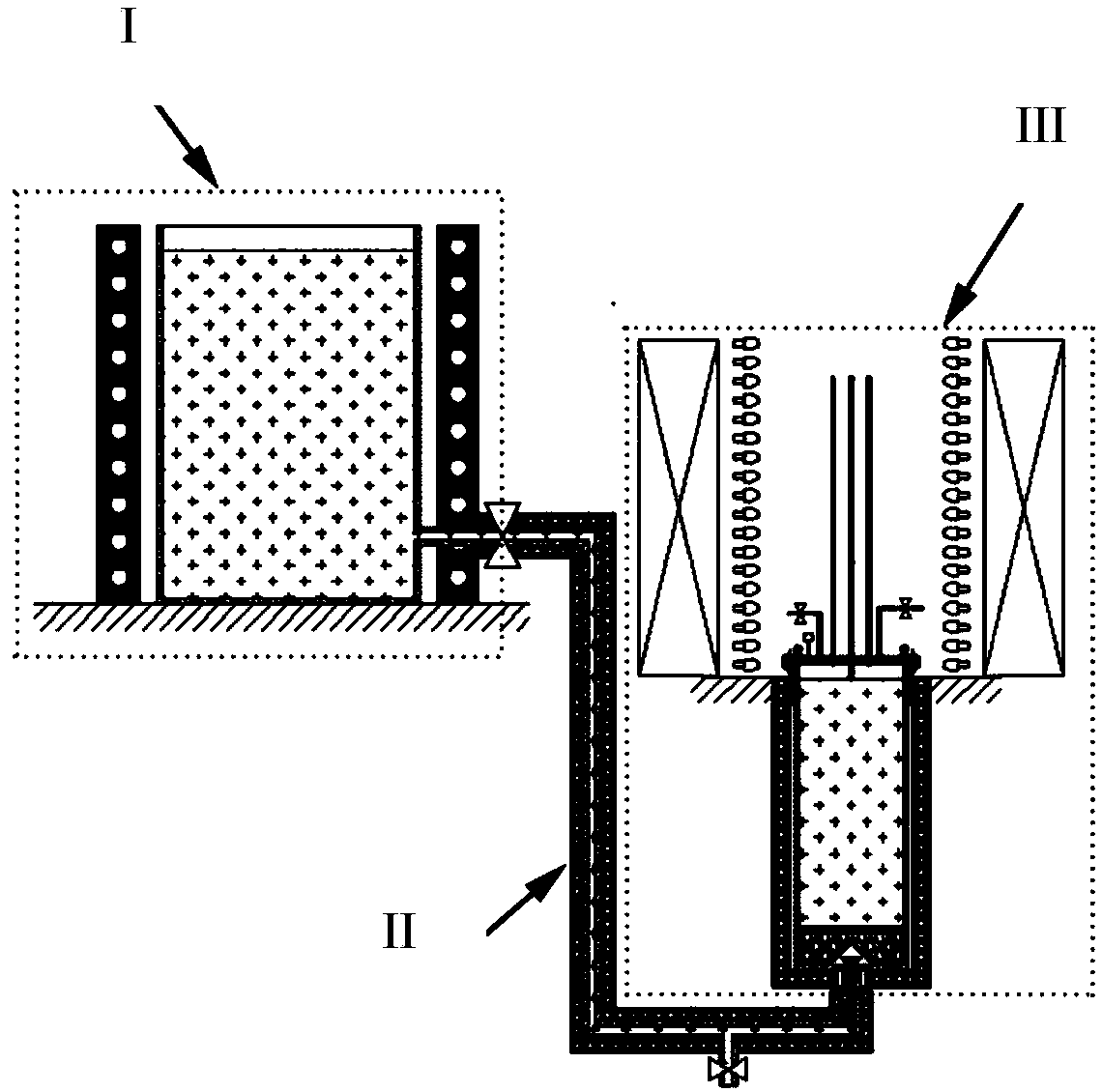

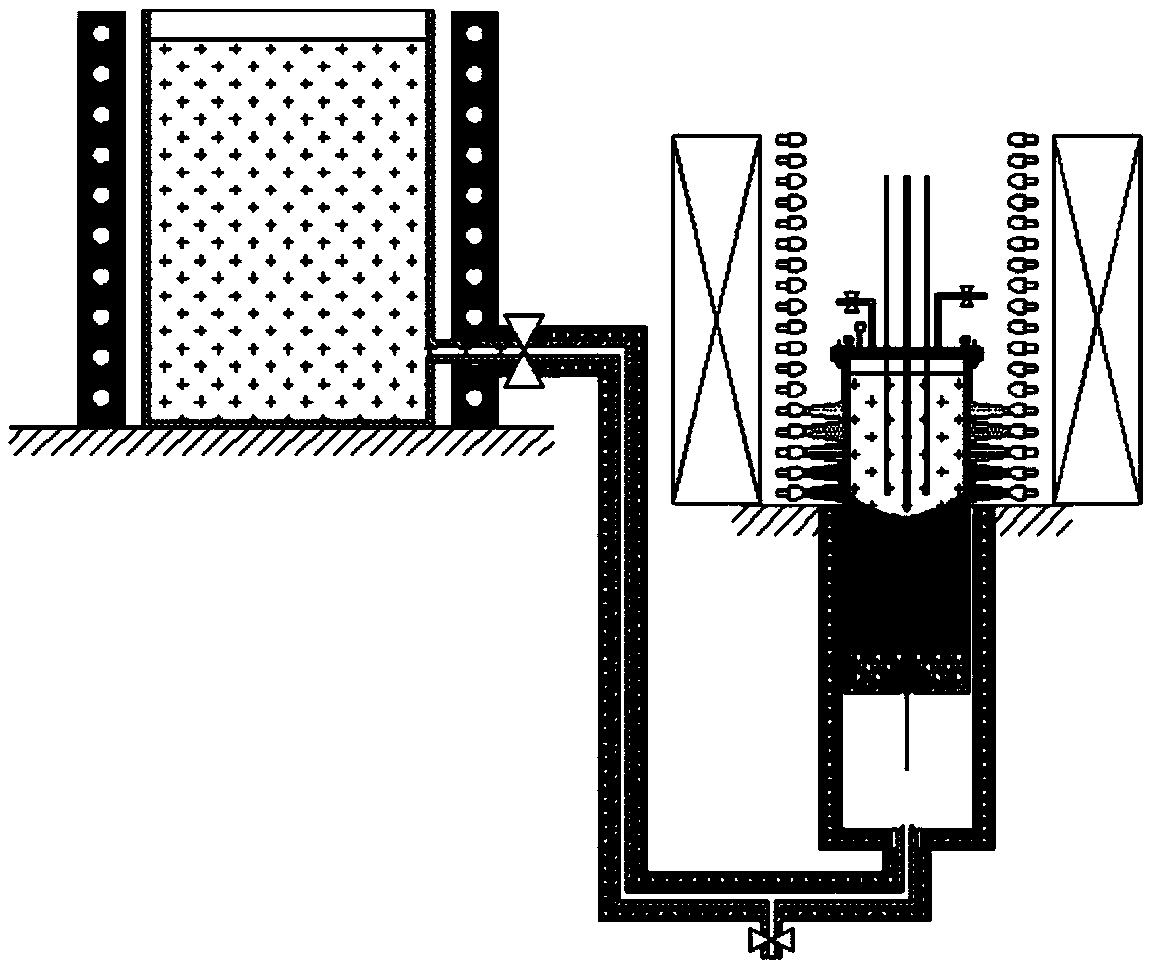

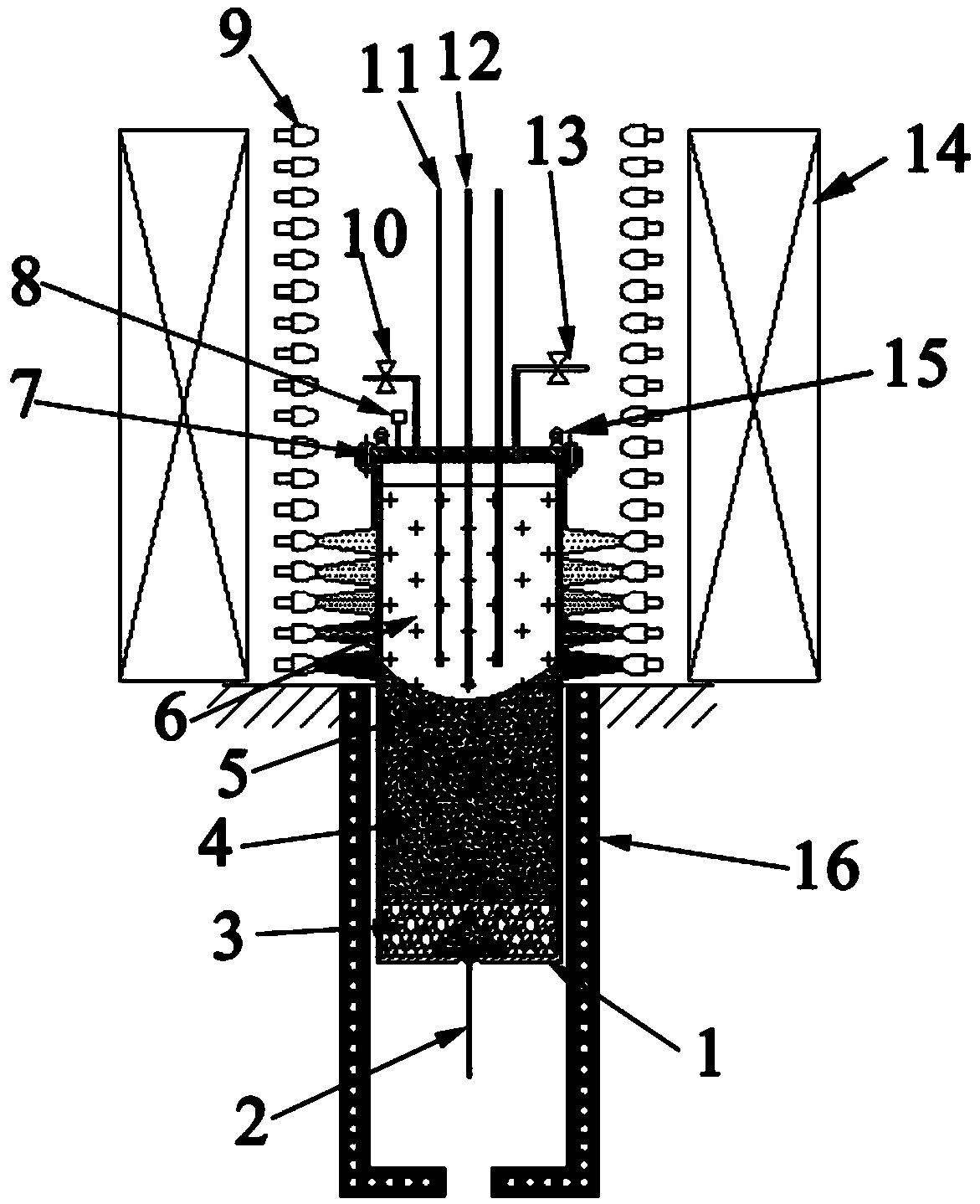

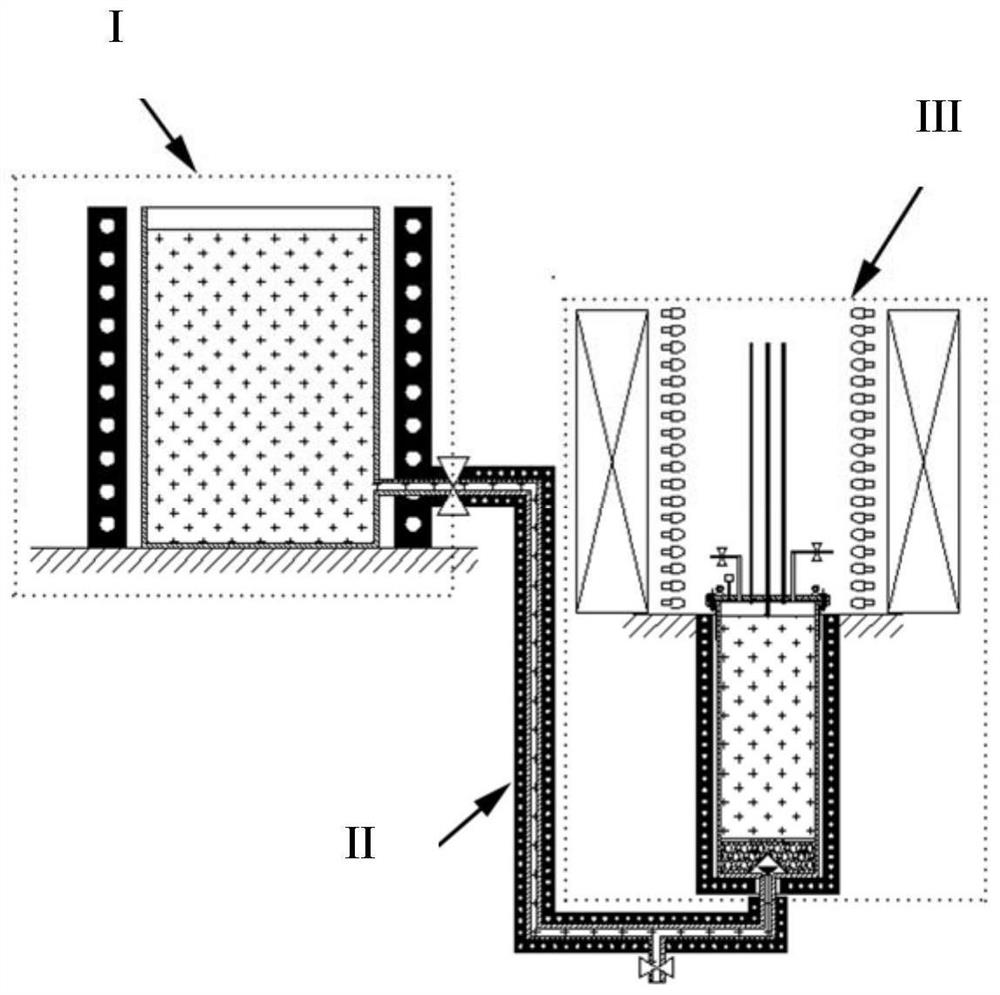

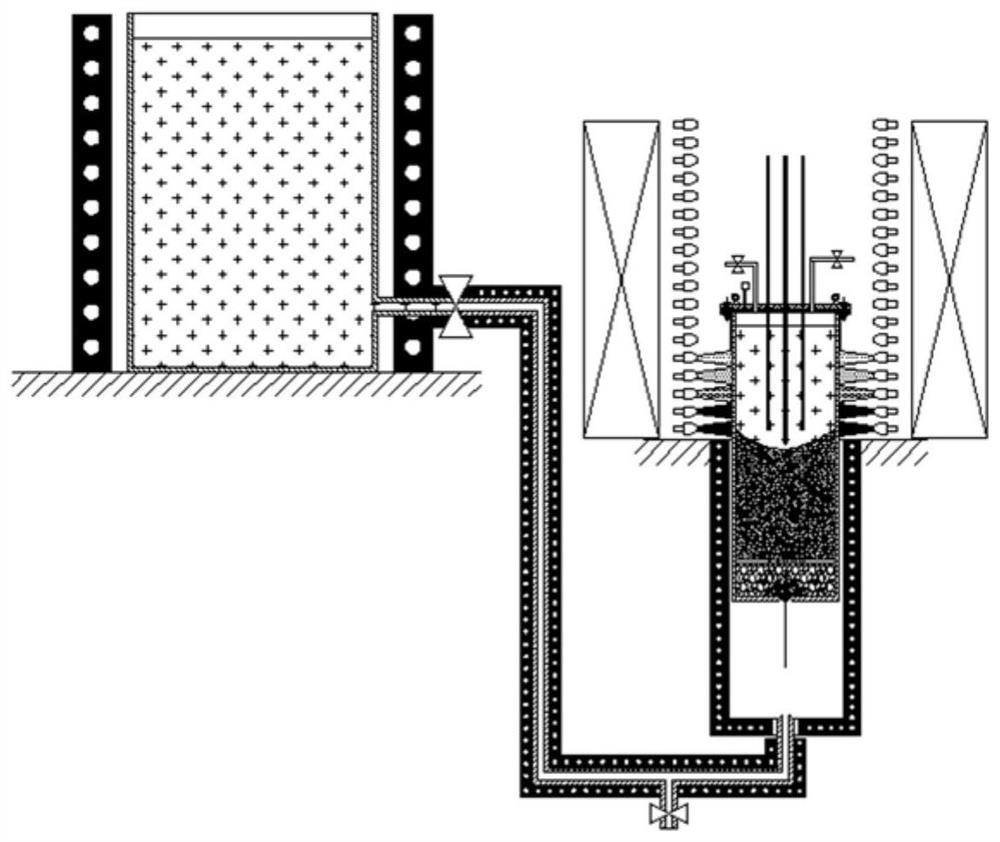

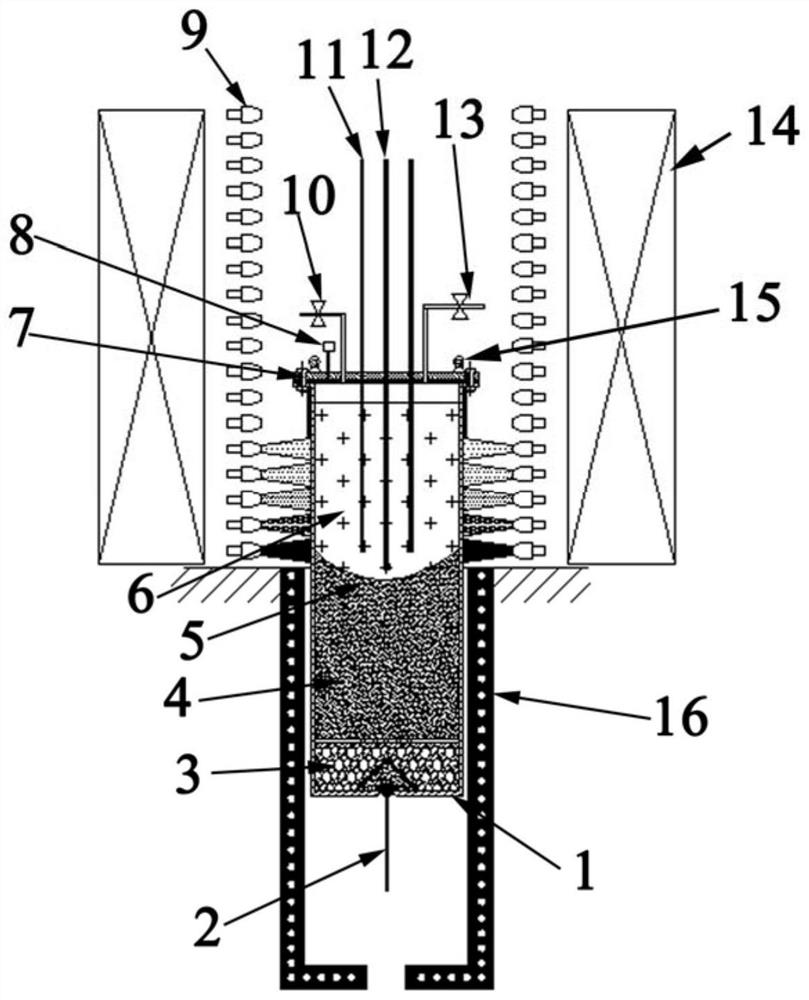

High-purity high-homogenization casting method of magnesium alloy and magnesium-lithium alloy

The invention discloses a high-purity high-homogenization casting method of magnesium alloy and magnesium-lithium alloy. The method comprises the following steps: (1) putting fully preheated magnesiumingots into a smelting crucible, and protecting the melt by adopting vacuum and inert gas; (2) performing electrifying to melt the magnesium ingots, adding alloying raw materials, keeping argon gas introduction in the feeding process, and adjusting the argon gas pressure to 1*10<5>Pa; (3) pushing the melt to carry out underflow type transfer injection by utilizing potential energy difference andgas pressure difference; and (4) carrying out homogenization solidification and waste heat homogenization on the melt. The invention realizes high-efficiency and continuous casting production of magnesium-lithium alloy ingot blanks and the casting. The reinjection process becomes simple and efficient by undercurrent reinjection. Through capturing of the valley bottom of a U-shaped solid-liquid interface in real time, the solid phase region at the lower part of the valley bottom of the solid-liquid interface starts to be homogenized at a constant temperature when the temperature of a core partis close to the solidus temperature, so that solidification shrinkage is reduced, and the cracking risk of a large ingot is greatly reduced.

Owner:GRIMAT ENG INST CO LTD

High-strength and abrasion resisting copper alloy contact wire and preparation technology thereof

InactiveCN109504872AHigh chemical activityHigh affinityTrolley linesRare-earth elementSolution treatment

The invention relates to the field of copper alloy technical processing, in particular to a high-strength and abrasion resisting copper alloy contact wire and a preparation technology thereof. The high-strength and abrasion resisting copper alloy contact wire is prepared from the raw materials in percentage by weight: 0.01-0.30% of a rare earth element, 0.01-0.10% of a metallic oxide, and the balance of the copper alloy. The preparation method comprises alloy product preparation, semi-solid state treatment, horizontal continuous casting, continuous extrusion, first cold working, solution treatment, second cold working, two-stage aging, and drawing forming. The high-strength and abrasion resisting copper alloy contact wire has good electrical conductivity, high strength, high high-temperature resistance, and abrasion resistance, and can be used as a contact wire material for high speed railways, especially for a high-speed railway with speed of more than 400 kilometers per hour.

Owner:SHANDONG YANGGU CABLE GROUP

Electroslag fusion casting manufacture method of rotating wheel blanks of impact type hydraulic generator

ActiveCN102756111AImprove qualityEasy for CNC machiningFurnace typesHeat treatment furnacesElectricityManufacturing technology

The invention relates to the manufacture field of impact type rotating wheels, and in particular relates to an electroslag fusion casting manufacture method of rotating wheel blanks of an impact type hydraulic generator. The electroslag fusion casting manufacture method is an electroslag fusion casting technology for impact type rotating wheel integral casting blanks and individual rotating wheel water tank blanks. According to the method, self-consumable electrodes and the electroslag fusion casting technology are adopted; the rotating wheel integral casting blanks are produced by rotating wheel integral casting circular type blank crystallizers under an integral structure or an individual combined structure; and the individual rotating wheel water tank blanks are produced by rotating wheels water tank crystallizers under the integral structure or the individual combined structure. With the adoption of the method, the shortcomings of the current production technology of high water head impact type rotating wheel blanks can be solved; the near net forming impact type rotating wheel integral casting blank manufacture technology and the individual rotating wheel water tank blank manufacture technology are adopted; the produced rotating wheel blanks and the water tank blanks are high in fatigue resistance, high in crack generation and expansion resistance, long in service lives and high in use safety; and the quality and performance of the produced rotating wheel blanks and the water tank blanks are in line with those of forged blanks obtained by using the same materials; and the method has the advantages of low production cost, short production period and the like.

Owner:沈阳市盛华特种铸造有限公司

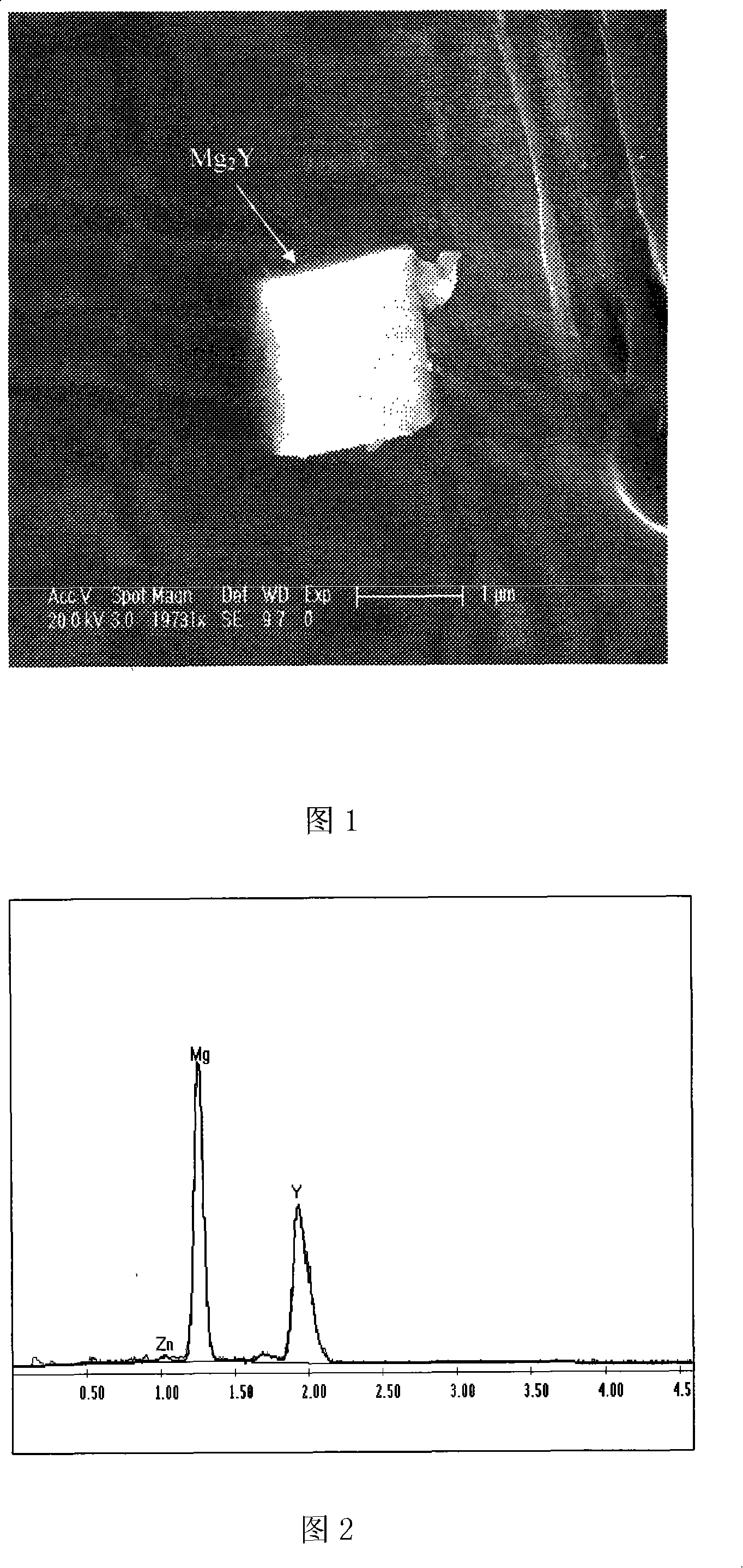

Aluminum-free heat-resistant die-casting rare earth magnesium alloy

The heat resistant no-aluminum die cast Mg-RE alloy consists of Y 2-4 wt%, Gd 0.2-0.6 wt%, Zn 0.3-0.6 wt%, Mn 0.1-0.3 wt%, and Mg for the rest. Y as the excellent additive for raising the performance of Mg alloy can refine the dendrite crystal in the alloy, increase the rate of fiber structures in alloy fracture and raise the plasticity of the alloy; and Gd and Zn serve as the alloy reinforcing elements too. The heat resistant no-aluminum die cast Mg-RE alloy has excellent room temperature mechanical performance, high temperature mechanical performance superior to that of AE44 alloy, and excellent creep resistance in the conditions up to 250 deg.c and 30 MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

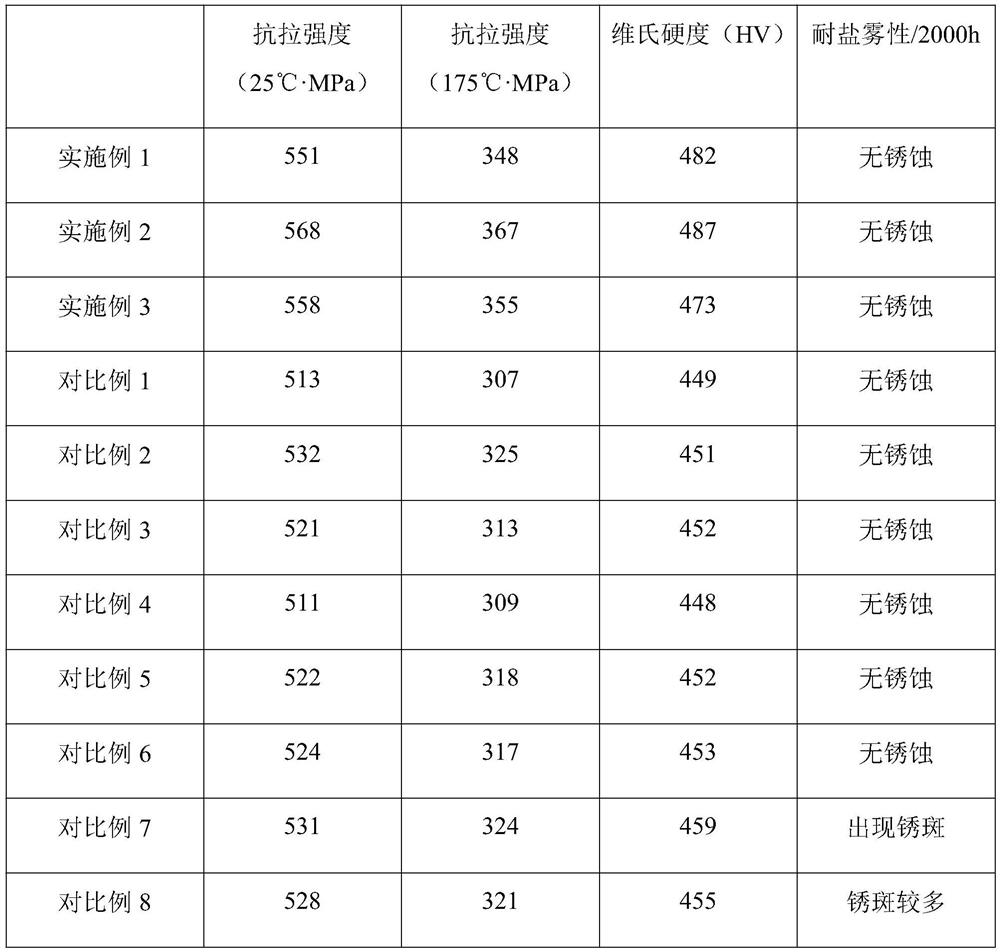

High-strength aluminum alloy profile for brake chamber and processing technology of high-strength aluminum alloy profile

ActiveCN114672684AImprove corrosion resistanceImprove wear resistanceAnodisationElectrolytic agentSilumin

According to the high-strength aluminum alloy profile for the brake chamber and the machining technology of the high-strength aluminum alloy profile, ZL205A is selected to be made into an aluminum alloy body, the microstructure of the aluminum alloy is improved by limiting the type and content of the added alterant and matching with a proper solid solution aging heat treatment method, and then the normal-temperature and high-temperature mechanical properties of the alloy are improved; rare earth Sc and rare earth La are added into the alloy for modification treatment, and an aluminum alloy body is treated by using an ion nitriding technology, so that the hardness, wear resistance and fatigue resistance of the aluminum alloy body are remarkably improved, and the aluminum alloy body is uniform and compact in structure and gentle in hardness gradient; the impurity removal and purification capacity is enhanced by limiting a refining agent and a rotary blowing degassing and purification treatment process, and the precision of the aluminum alloy is effectively improved; the components and content of the electrolyte are limited, anodic oxidation is carried out on the surface of the aluminum alloy body, and the composite nano cerium oxide is introduced, so that the corrosion resistance of the surface of the aluminum alloy body is improved, and meanwhile, the service life of the aluminum alloy profile is greatly prolonged.

Owner:江苏恒鑫正宏科技有限公司

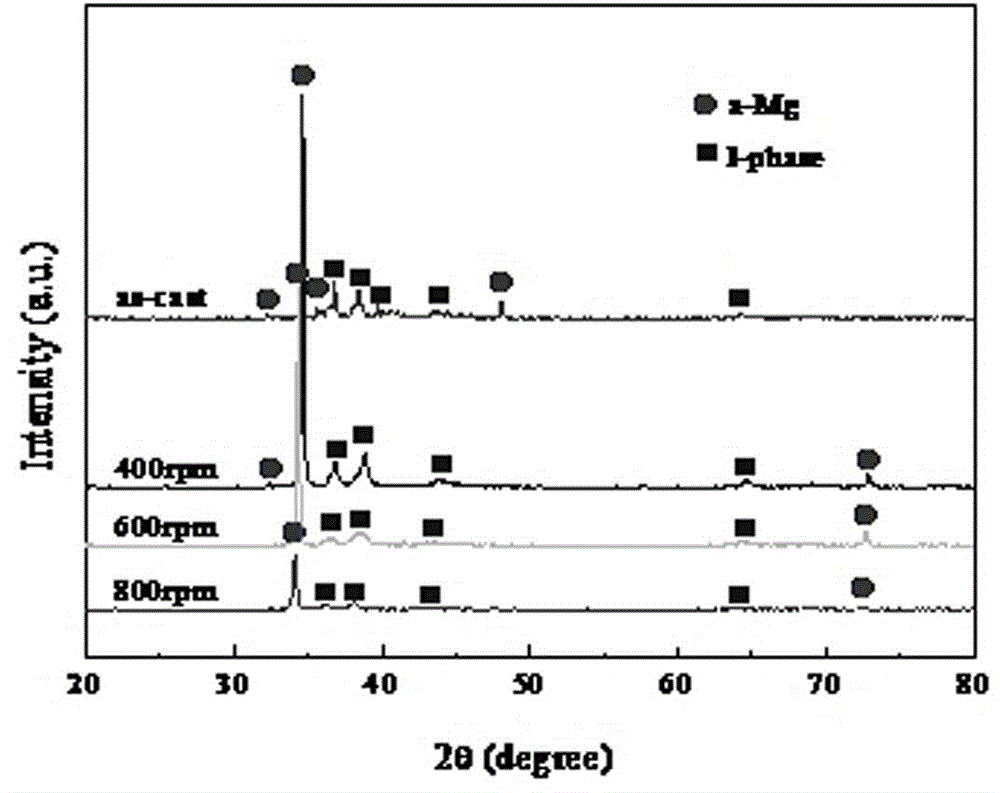

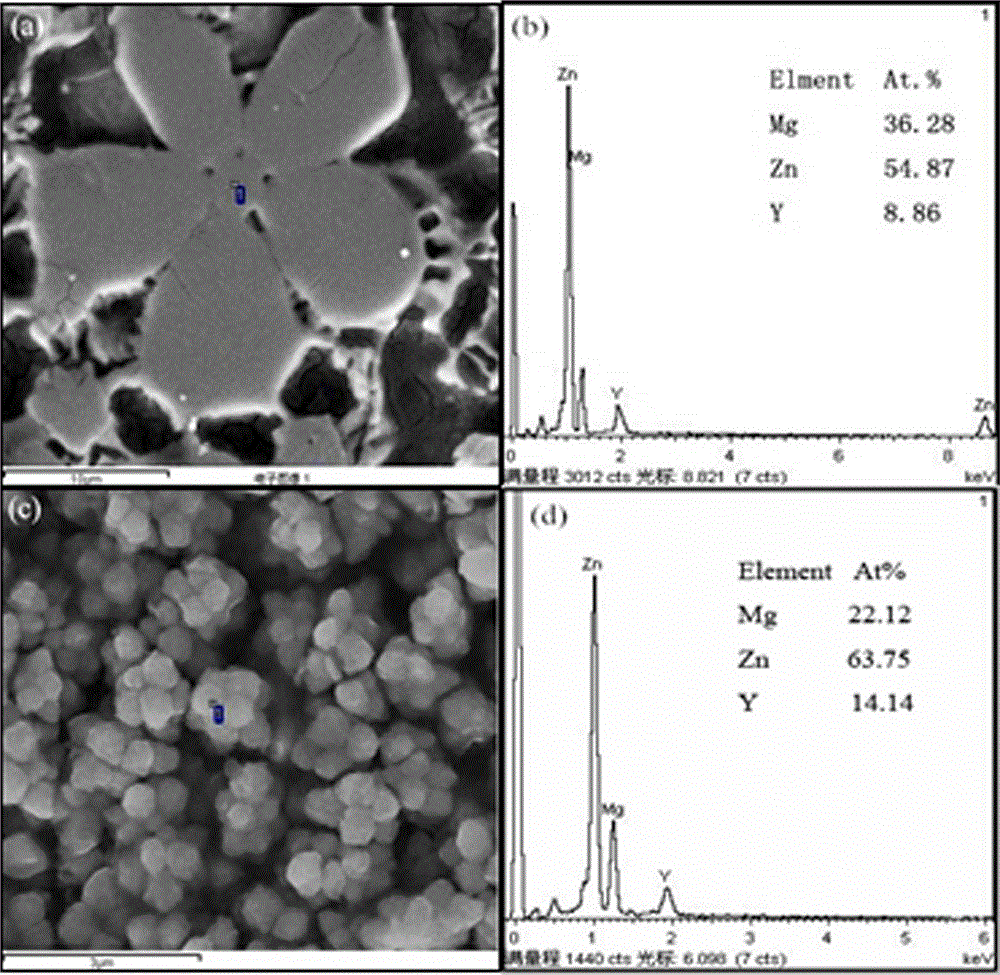

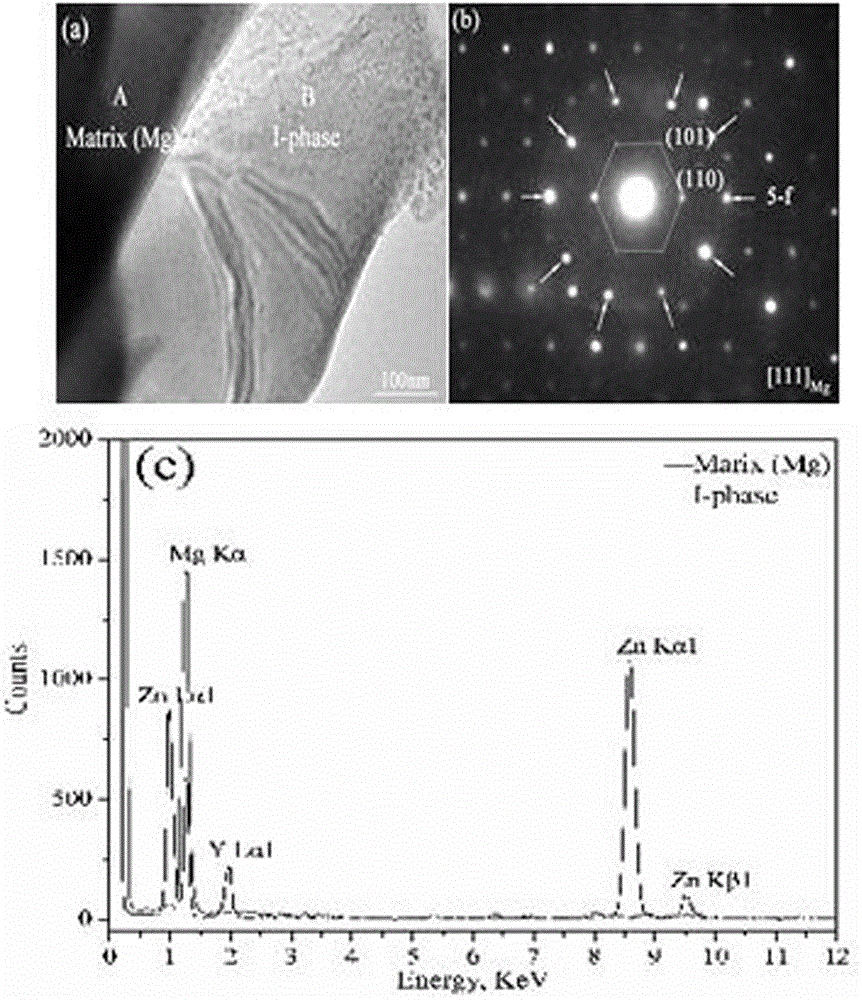

Mg-Zn-Y magnesium alloy and preparation method thereof

ActiveCN104152747AIncrease the volume fraction of quasicrystalline phaseOvercoming the problem of low quasi-crystal integral fractionCorrosion resistantMagnesium alloy

The invention provides an Mg-Zn-Y magnesium alloy. The Mg-Zn-Y magnesium alloy comprises the following components in percentage by mass: 55.50-56.00% of Zn, 11.50-13.00% of Y, and the balance of magnesium and trace impurity elements; and the quasicrystal volume fraction of the Mg-Zn-Y magnesium alloy is 26.8-51.3%. The invention further provides a preparation method of the Mg-Zn-Y magnesium alloy; a fast solidification spraying method is adopted; the operation is simple and convenient; and the promotion and application are convenient. The Mg-Zn-Y magnesium alloy prepared by the fast solidification spraying method increases the quasicrystal phase volume fraction, solves such problems as lower magnesium alloy quasicrystal content and uneven tissue distribution in an existing preparation method, and improves the corrosion resistance and Vickers hardness.

Owner:UNIV OF JINAN

Preparation method of Mg-Zn-Ca series biomedical magnesium alloy

The invention relates to a preparation method of Mg-Zn-Ca series biomedical magnesium alloy, and belongs to the technical field of batch preparation of biomedical degradable magnesium alloy. The method comprises the steps of burdening, smelting and solidification system preparation, alloy smelting and purification, undercurrent transfer injection and forced filtration, precise solidification control and waste heat homogenization, near solidus homogenization treatment and plastic deformation treatment. The low-cost preparation technology has the greatest advantages that the preparation of a Mg-Zn-Ca series biomedical magnesium alloy ingot blank with the high thermal cracking tendency and the cross section area larger than 70000 mm <2> is met, homogeneous clean casting of industrial scale isachieved, and therefore the production efficiency can be greatly improved, the deformation degree is increased, and the performance is improved; and meanwhile, the cracking risk of a large cast ingotis greatly reduced, homogenization of a pasty area and a liquid phase area is achieved, the nucleation rate is increased, dendritic crystals are refined, and meanwhile specific gravity segregation and reverse segregation of Zn are effectively avoided.

Owner:GRIMAT ENG INST CO LTD

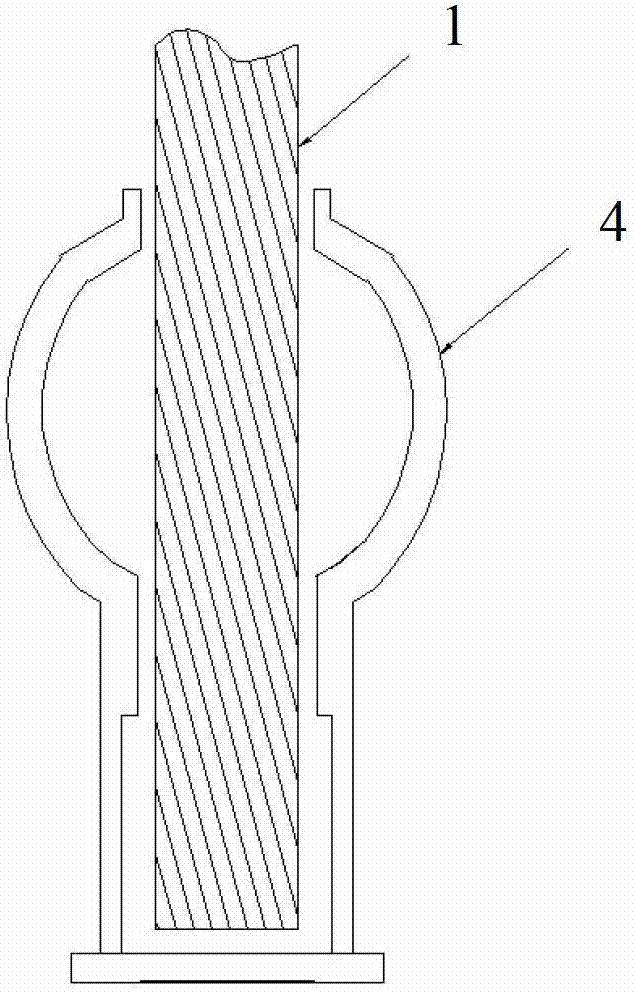

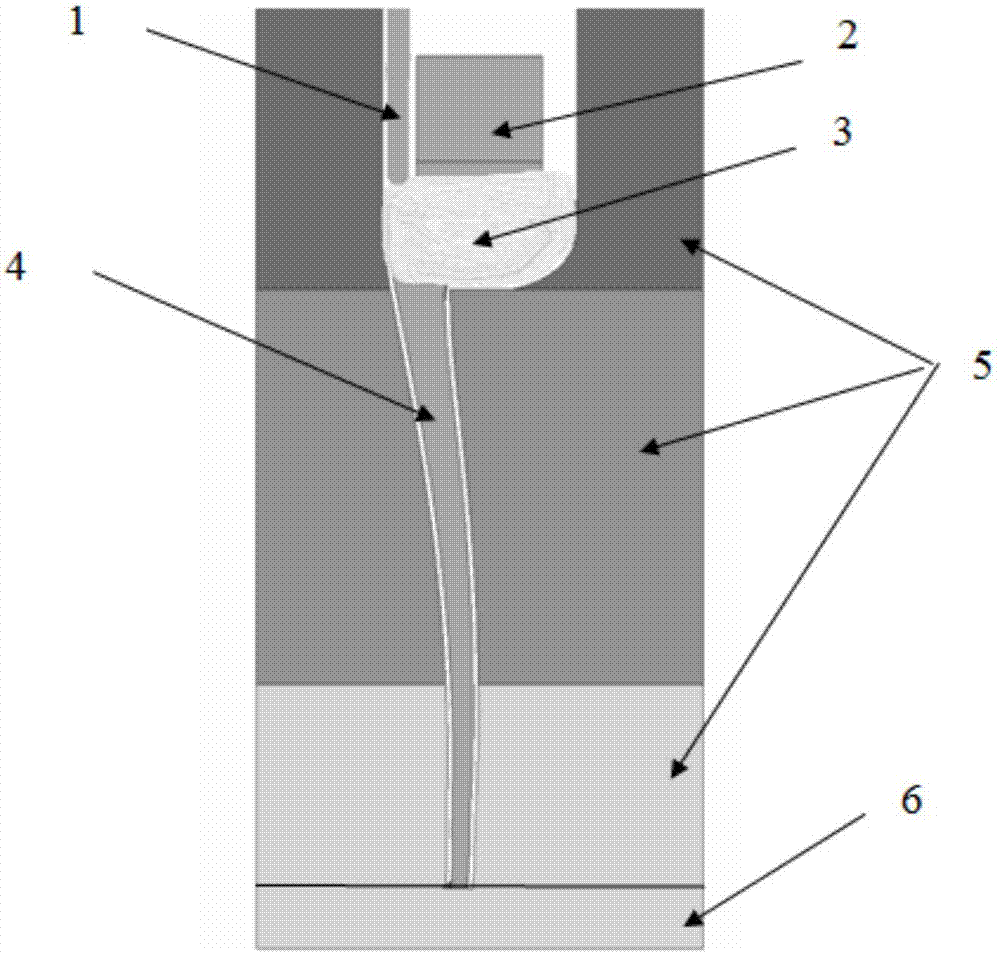

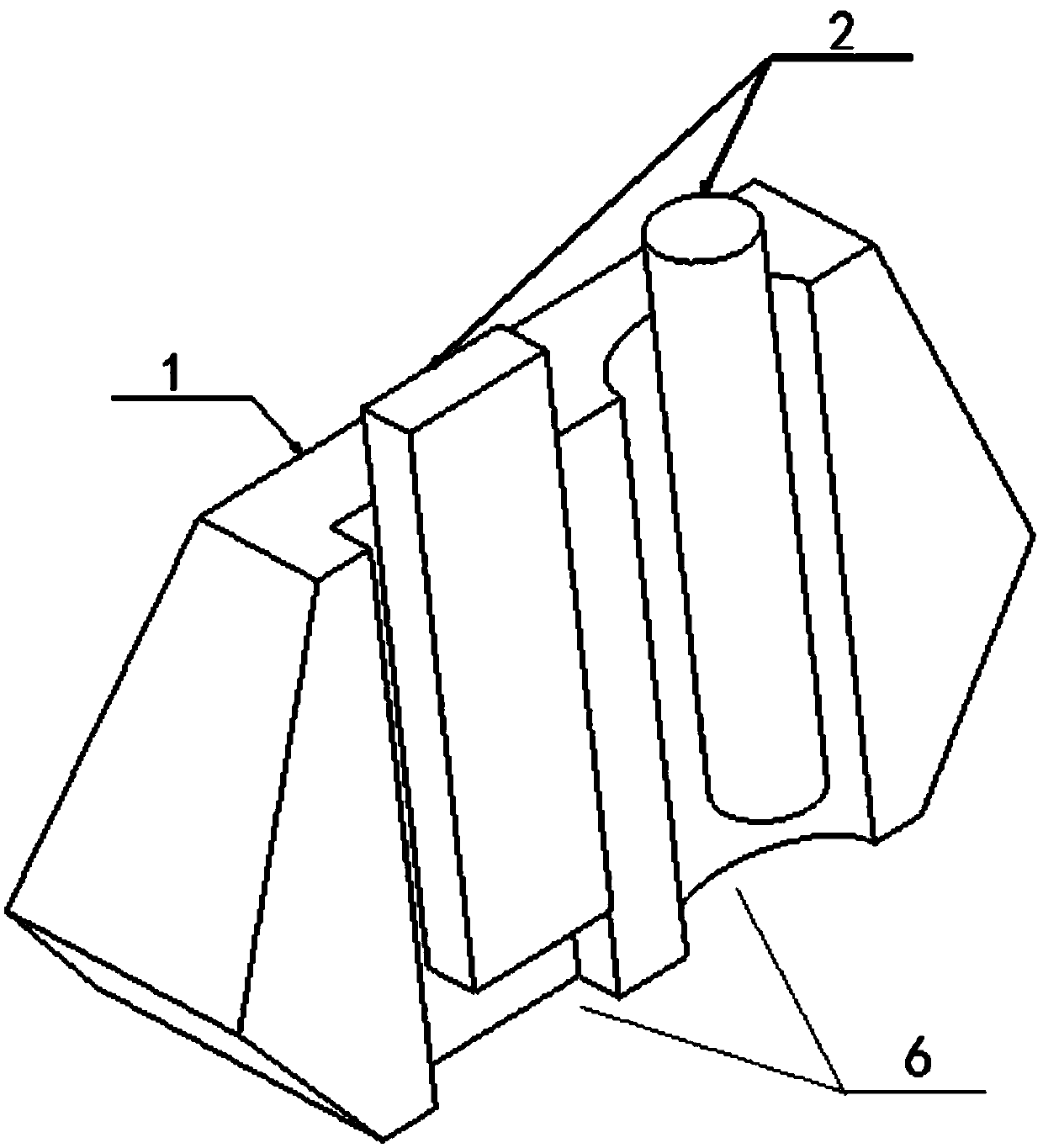

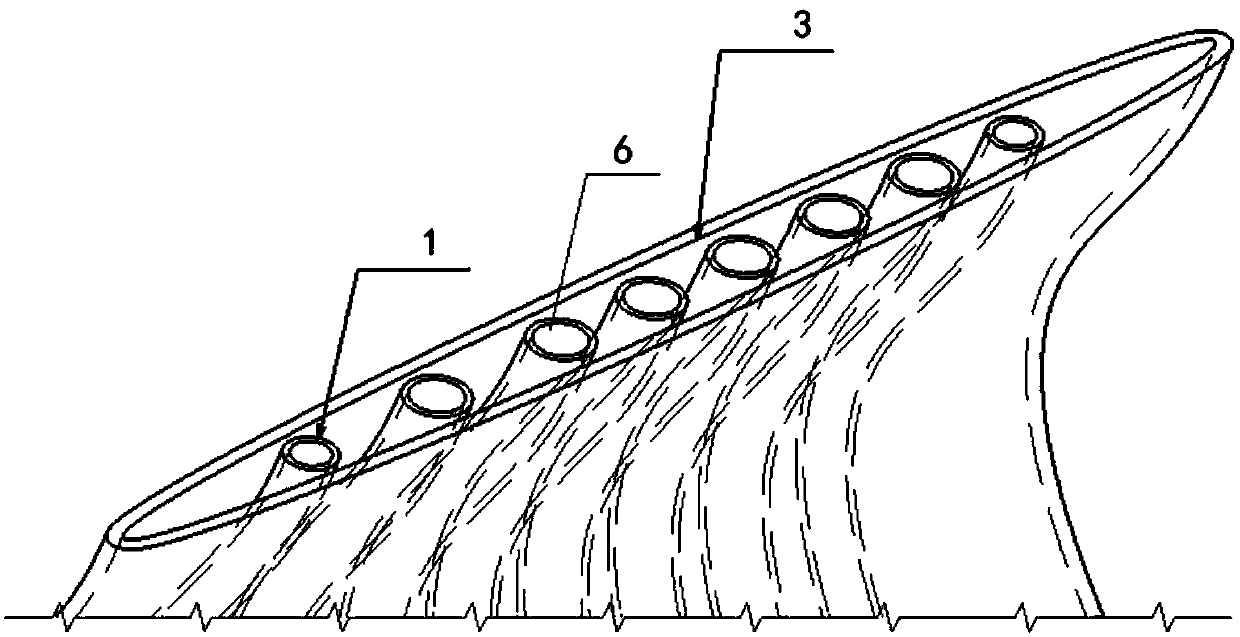

Turbine runner three-dimensional curved surface blade electroslag smelting casting direct forming method

The invention relates to the field of electroslag smelting casting production of turbine runner blade castings, in particular to a turbine runner three-dimensional curved surface blade electroslag smelting casting direct forming method. Electroslag smelting casting is used for completing secondary refining purification and casting near net forming of consumable electrode materials. The specific process comprises the following steps that 1) the structure form of a casting blank crystallizer is of an assembled type or a split type; 2) consumable electrodes in the smelting casting process consistof two parts, namely the fixed electrodes and the movable electrodes; and 3) a power supply mode adopts an alternating current single-electrode series loop and double-electrode series loop mixed power supply mode, by means of a power loop formed between double-electrode series electrodes, the slag layer temperature of an electroslag smelting casting area is increased, the metal fluidity of the area is improved, the solidification speed of the area is controlled, and blade smelting casting forming is achieved. The technology provided by the invention is applicable to manufacturing of the castings of tubular turbine generator runner blades or mixed-flow turbine generator runner blades or axial flow turbine generator runner blades.

Owner:沈阳市盛华特种铸造有限公司

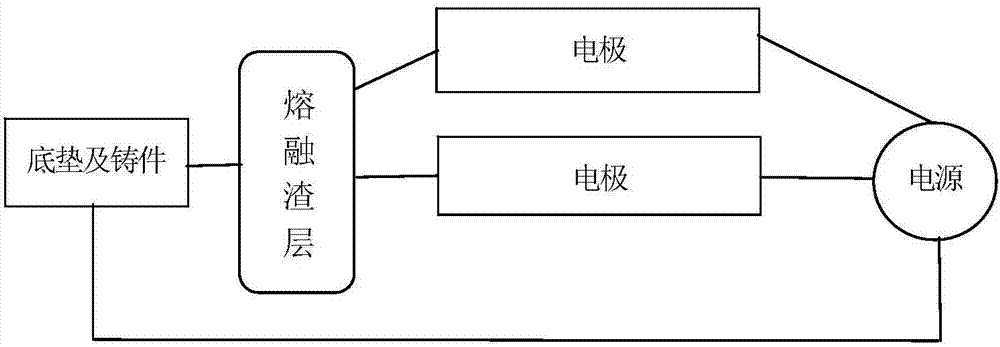

Technology of slag fused casting train shaft

An electroslag casting technology for manufacturing the wheel axle of high-speed train includes using the water bottom tray of crystallizer as electrode, using the axle billet as consummable electrode, choosing slag system and filling ratio, and electroslag casting. Its advantages are high mechanical performance and long endurance life.

Owner:潘明忠 +2

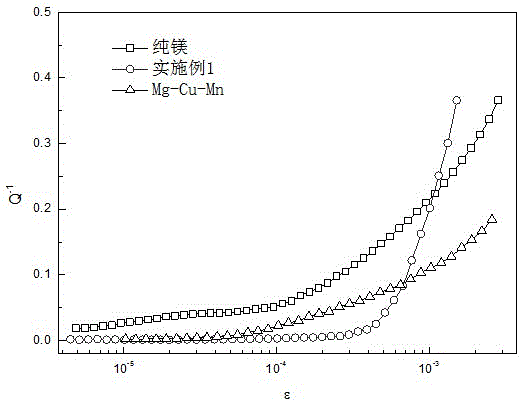

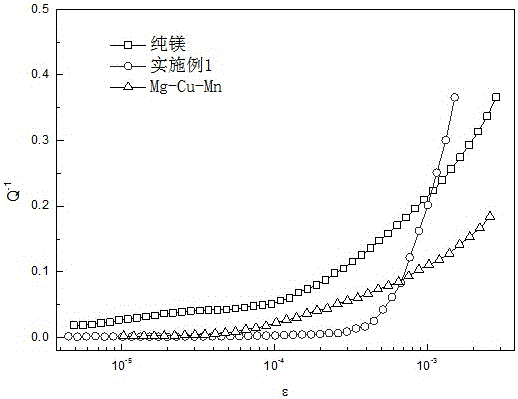

High-damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy and preparation method thereof

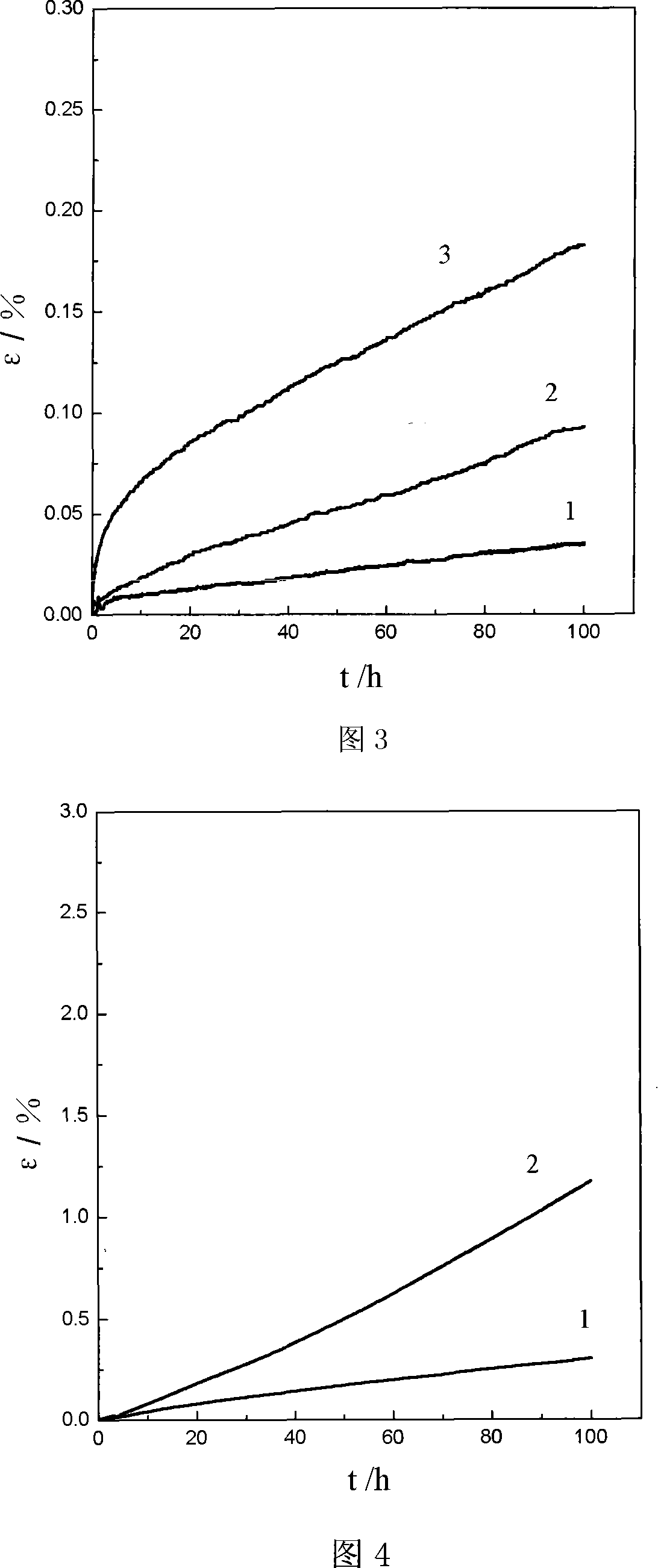

The invention relates to a high-damping Mg-Mn-Ce-Al-Zn-Y alloy which comprises the following alloying element components, distributed in an alloy, in percentage by weight: 1.3-2.2% of Mn, 0.15-0.35% of Ce, 0.1-0.3% of Al, 0.25-0.55% of Zn, 0.5-1.5% of Y and the balance magnesium and inevitable impurities. The high-damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy is prepared by the following process: adding the alloy elements in proportion, smelting and ingoting the alloy elements in vacuum, and carrying out water quenching on the smelted alloy to the room temperature, thereby obtaining the high-damping magnesium alloy. According to the process, by virtue of the synergistic effect in many ways, the alloy has relatively high damping capacity and very good plasticity. The damping capacity (Q<-1>) of the material prepared by the alloy can reach 0.2 at a room temperature when strain is 10<-3>. The preparation method is simple in process, is strong in transportability, is easy to operate, and is low in cost, so that the room-temperature damping capacity of the alloy is remarkably improved, and the applied range of the magnesium alloy is expanded.

Owner:CHONGQING UNIV

Forming process for outdoor high and low parallel bars

InactiveCN108060367AReduce porosityReduce tensionFoundry mouldsParallel barsEngineeringForming processes

Owner:苏州胤宗智能科技有限公司

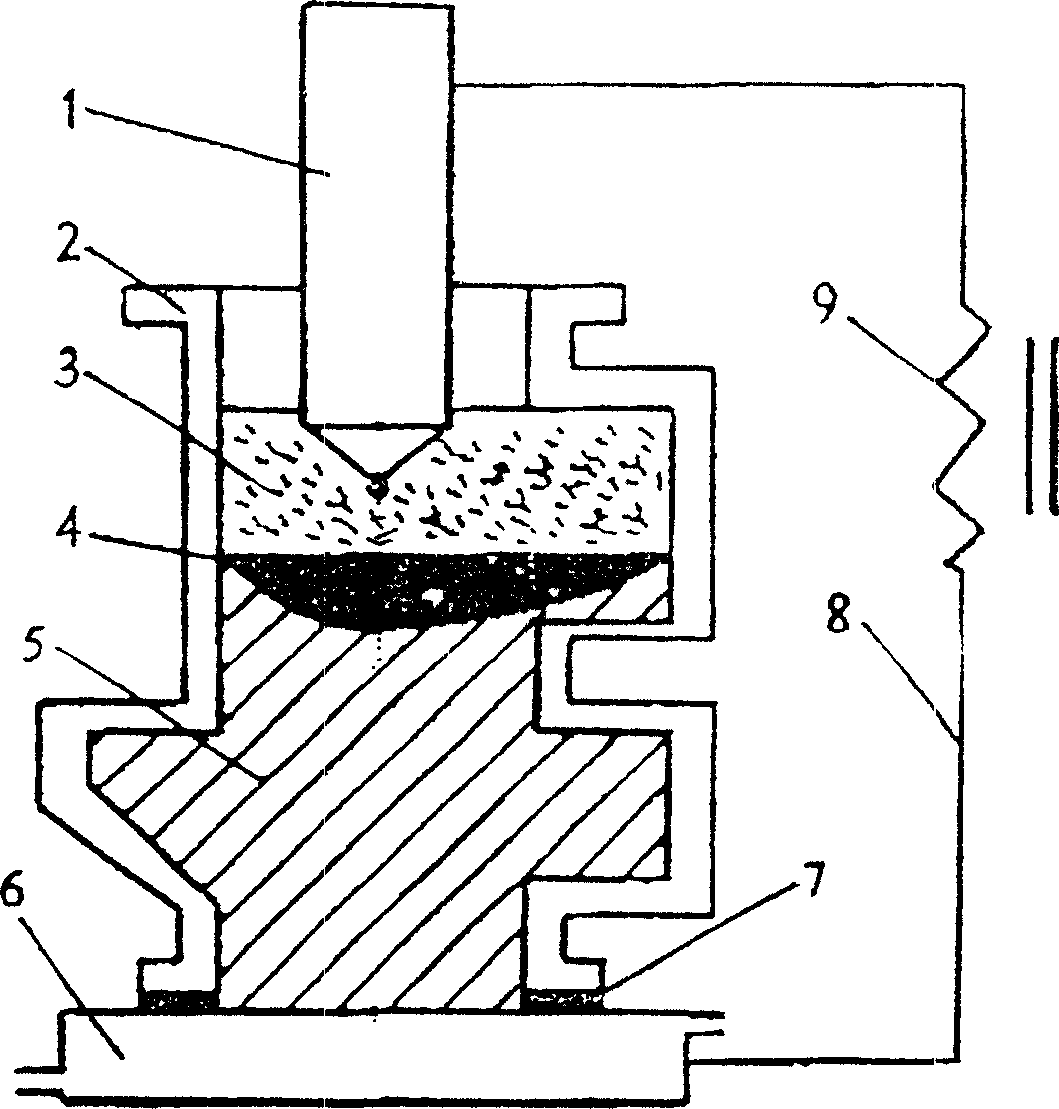

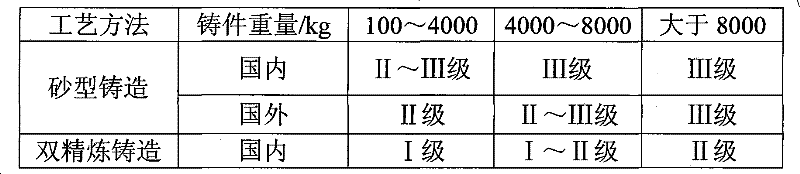

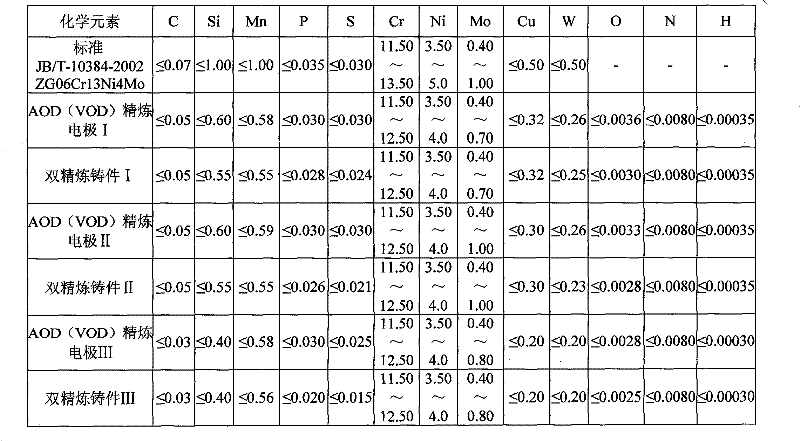

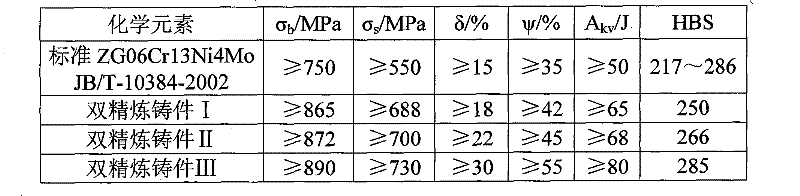

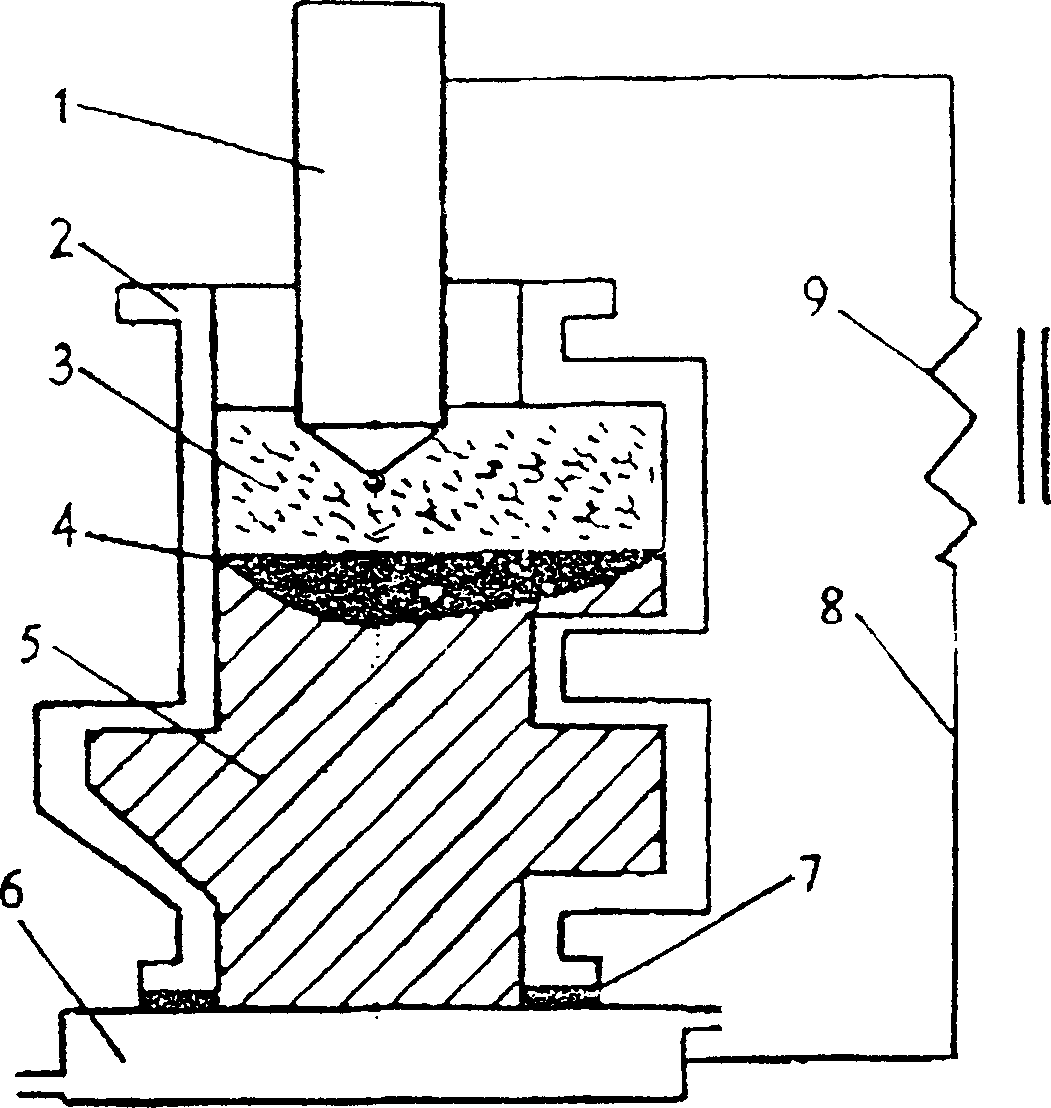

Turbine wicket gate double-refining casting technique

ActiveCN101450376BQuality improvementReduce in quantityFurnace typesHeat treatment furnacesHydraulic turbinesRaw material

The invention provides a hydraulic turbine guiding blade double refining casting process, which adopts an AOD or VOD refining method to prepare a raw material consumable electrode, and the weight percentages of chemical compositions of the prepared raw material consumable electrode are : less than or equal to 0.05 percent of C, less than or equal to 0.6 percent of Si, less than or equal to 0.58 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 11.5 to13.5 percent of Cr, 3.5 to 5.0 percent of Ni, 0.4 to 1.0 percent of Mo, less than or equal to 0.5 percent of Cu, less than or equal to 0.008 percent of N, less than or equal to 0.00035 percent of H and the balance Fe. Then a prepared consumable electrode is made into a hydraulic turbine stainless guiding blade component by electroslag smelting casting method; and the double refining casting process can refine and purify steel liquid completely and effectively so as to remove the gas and non-metallic inclusions in steel greatly. The crystal structure of the casting is uniform and compact, and has low sulfur and phosphorus content, less non-metallic inclusions, higher toughness, anti-fatigue performance and good welding performance.

Owner:SHENYANG RES INST OF FOUNDRY

Electroslag casting manufacturing method of hydraulic turbine blade compact

An electroslag casting production method for a waterwheel blade green compact is characterized by comprising the following steps: confirming the outline of the blade green compact according to the intelligent three-dimensional expanded size of a water turbine blade; producing a crystallizer and a consumable electrode of the blade green compact; preparing the qualified blade green compact of the electroslag casting water turbine by optimizing electroslag casting process parameters and the anti-cracking heat treatment process. The method has the advantages that the detects of the conventional blade green compact of the water turbine can be overcome; a near-net forming green compact producing process is provided for the water turbine blade formed through heated-die pressing process; the produced blade green compact material is high in degree of purity, uniform in chemical constituents, compact in structure, free of defects such as looseness, slag inclusion and hole shrinkage, favorable in mechanical property, and higher in fatigue resistance performance, anti-cracking performance and expansibility, and can reach the mechanical property of forge pieces made of the same material and meet the requirements of flaw detection indexes.

Owner:SHENYANG RES INST OF FOUNDRY

Technology of slag fused casting train shaft

An electroslag casting technology for manufacturing the wheel axle of high-speed train includes using the water bottom tray of crystallizer as electrode, using the axle billet as consummable electrode, choosing slag system and filling ratio, and electroslag casting. Its advantages are high mechanical performance and long endurance life.

Owner:潘明忠 +2

A kind of high damping mg‑mn‑ce‑al‑zn‑y magnesium alloy and preparation method thereof

The invention relates to a high-damping Mg-Mn-Ce-Al-Zn-Y alloy which comprises the following alloying element components, distributed in an alloy, in percentage by weight: 1.3-2.2% of Mn, 0.15-0.35% of Ce, 0.1-0.3% of Al, 0.25-0.55% of Zn, 0.5-1.5% of Y and the balance magnesium and inevitable impurities. The high-damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy is prepared by the following process: adding the alloy elements in proportion, smelting and ingoting the alloy elements in vacuum, and carrying out water quenching on the smelted alloy to the room temperature, thereby obtaining the high-damping magnesium alloy. According to the process, by virtue of the synergistic effect in many ways, the alloy has relatively high damping capacity and very good plasticity. The damping capacity (Q<-1>) of the material prepared by the alloy can reach 0.2 at a room temperature when strain is 10<-3>. The preparation method is simple in process, is strong in transportability, is easy to operate, and is low in cost, so that the room-temperature damping capacity of the alloy is remarkably improved, and the applied range of the magnesium alloy is expanded.

Owner:CHONGQING UNIV

Fitness entertainment rowing machine

InactiveCN108031058AImprove the extrusion effectGrain refinementMovement coordination devicesCardiovascular exercising devicesRare earthEngineering

The invention discloses a fitness entertainment rowing machine which comprises a rowing machine body, a computer, a display screen and a power module. A pull wire is arranged in the rowing machine body and formed by stranding seven pull wires, six pull wires surround the rest pull wire in the middle, the pull wires are closely fitted, and the pull wire comprises, in total weight percent of 100%, 0.4-0.5% of C, 0.5-0.7% of Si, less than or equal to 0.025% of S, less than or equal to 0.025% of P, 0.1-0.2% of Cu, 0.08-0.09% of Cr, 0.05-0.13% of Ca, 0.1-0.3% of Mo, 0.02-0.04% of B, 0.1-0.3% of Ti,0.1-0.2% of Mo, 0.01-0.02% of lanthanide rare earth and the balance Fe and unavoidable impurities. The invention further discloses a fitness safety balance roller treatment process which is simple and easy. A treated balance roller has good performances, the service life of the balance roller can be prolonged, and the cost can be reduced.

Owner:苏州胤宗智能科技有限公司

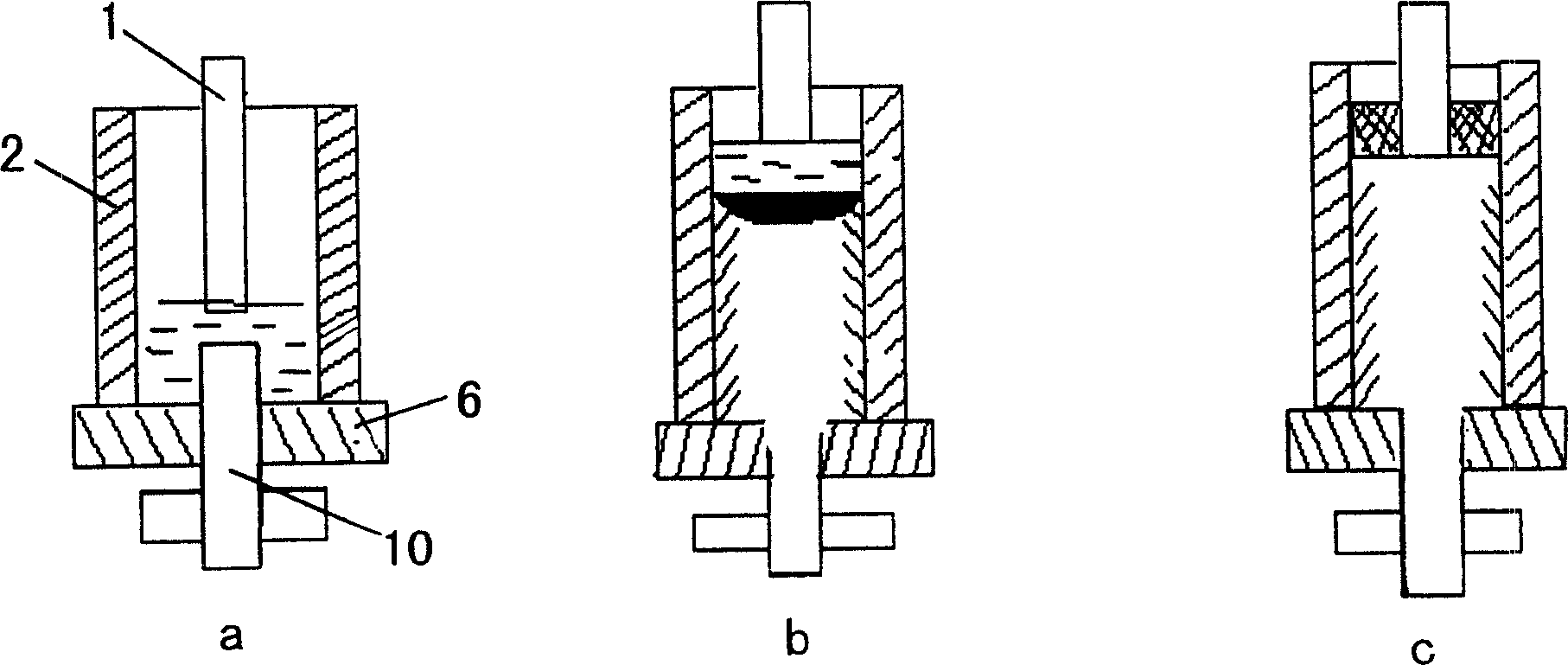

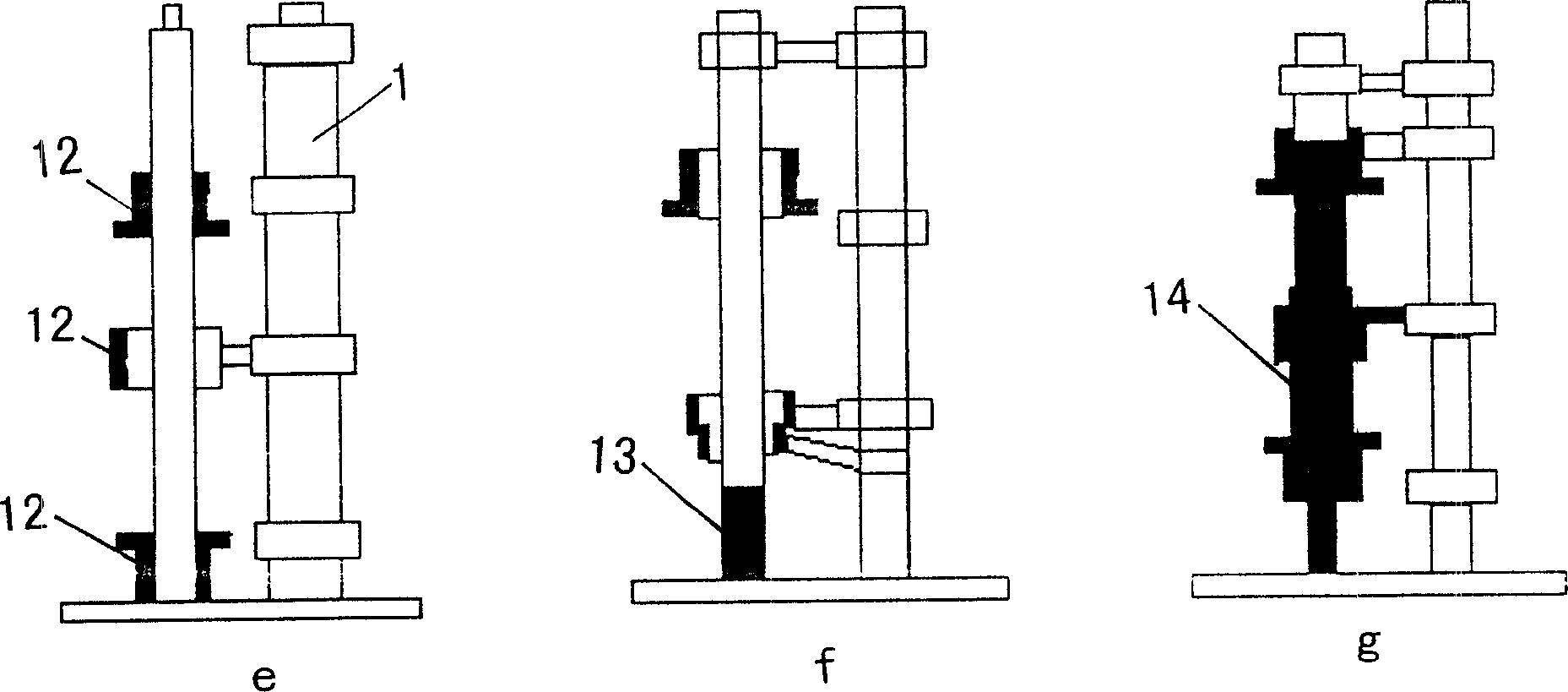

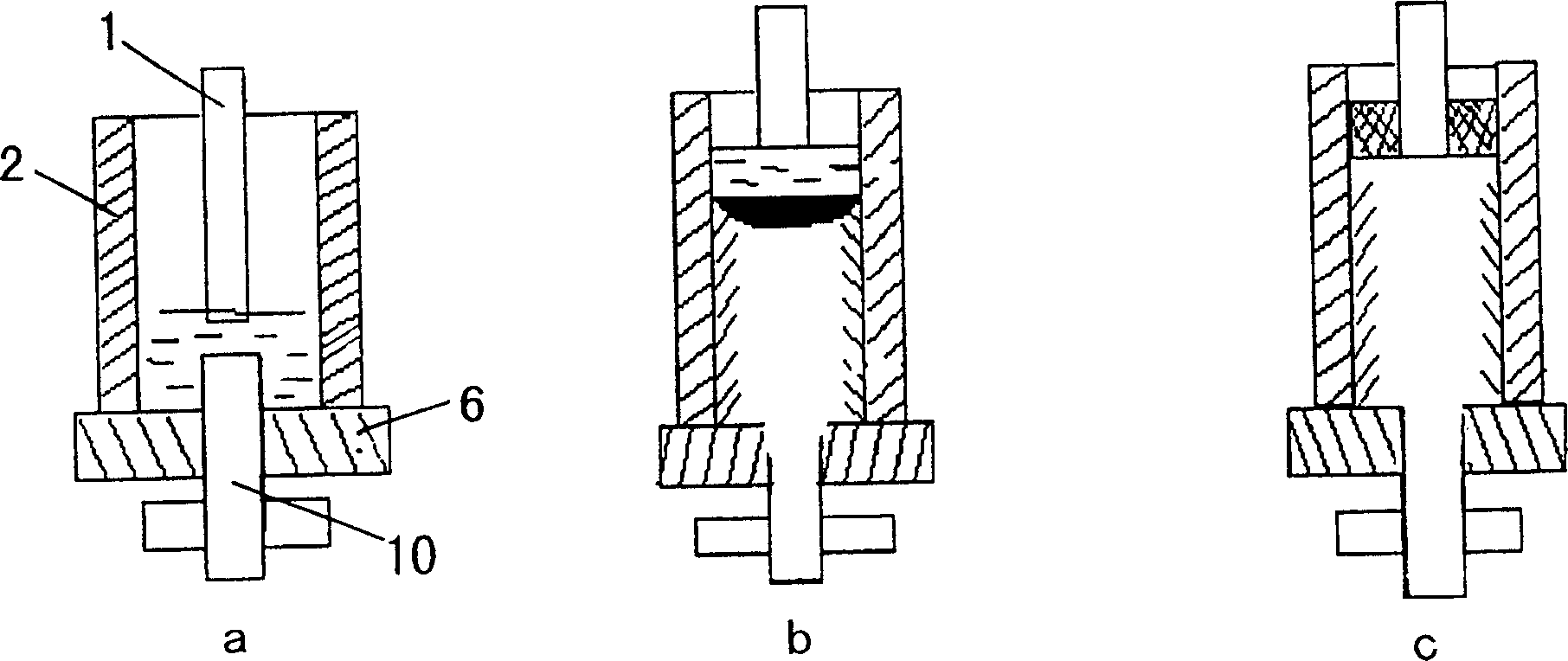

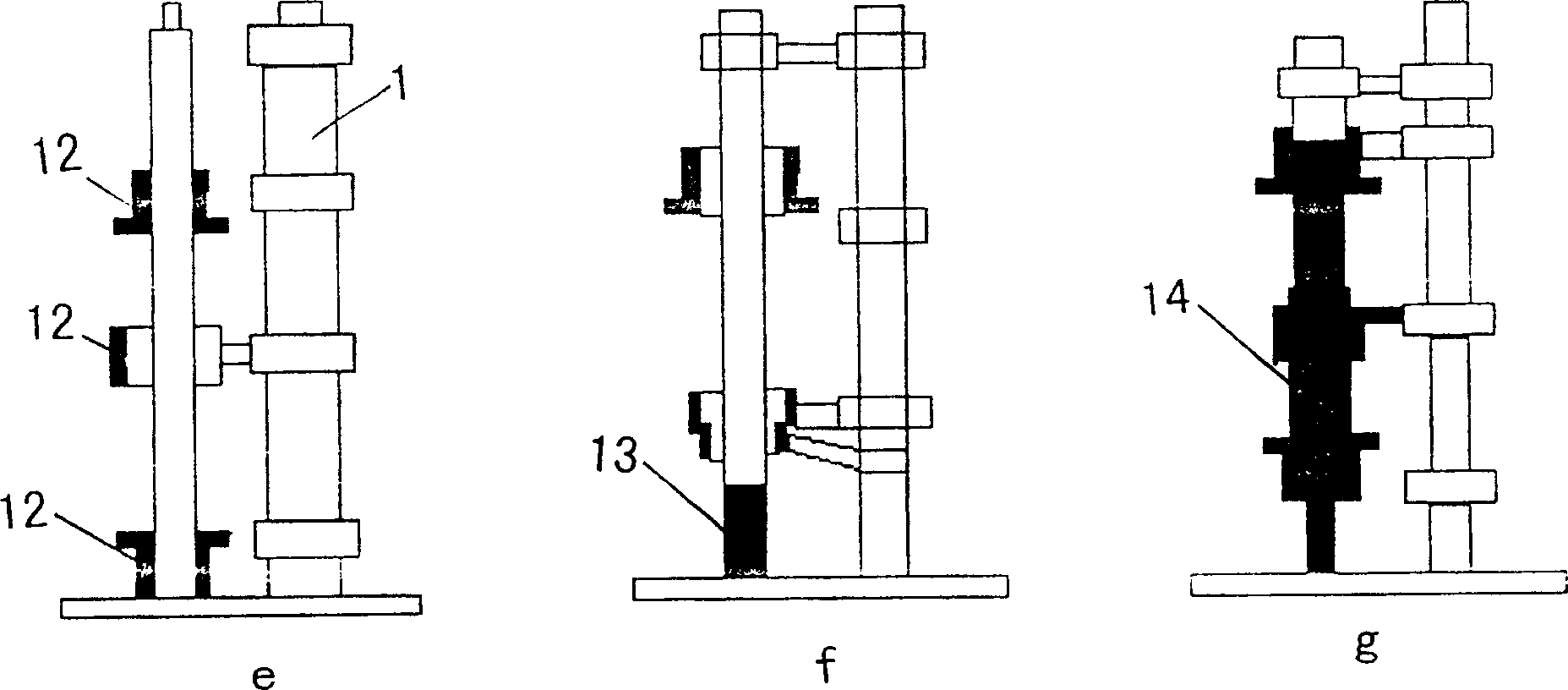

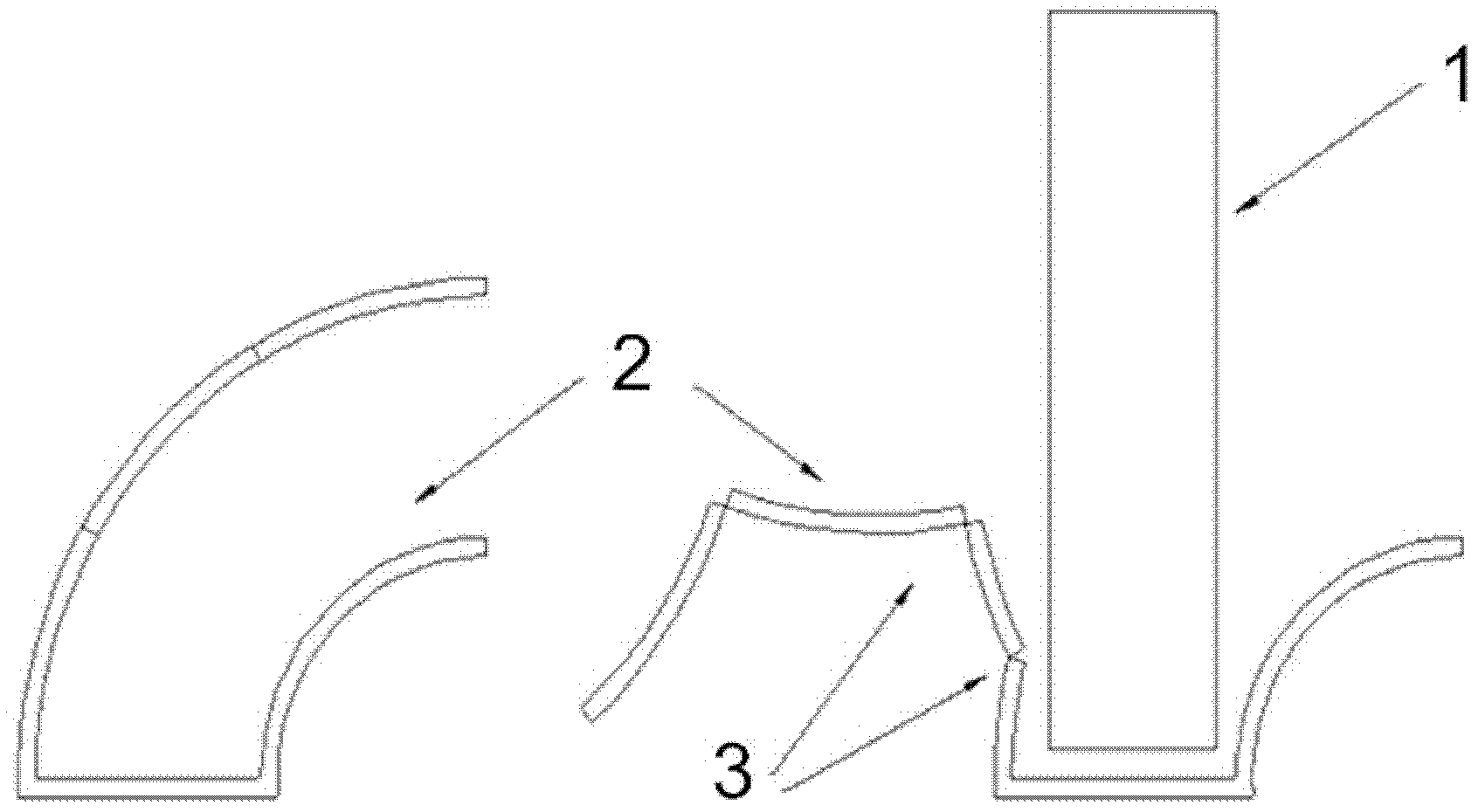

Electroslag casting manufacturing method and device for special-shaped castings with three-dimensional changes

ActiveCN107649664BSolve the process bottleneck of melting and castingSolve process bottlenecksElectrode materialCasting

The invention relates to the field of manufacturing three-dimensionally changed special-shaped castings through electroslag smelting casting, in particular to a method and device for manufacturing a three-dimensionally changed special-shaped casting through electroslag smelting casting. Electroslag smelting casting is used for completing secondary refining purification and casting near-net formingof consumable electrode materials. The method for manufacturing the three-dimensionally changed special-shaped casting through electroslag smelting casting comprises the specific processes that (1) acasting blank crystallizer adopts a combined structural form or a split type structural form; and (2) consumable electrodes in the smelting casting process are composed of two parts, namely the guiding electrode and the supplementary electrodes; the guiding electrode is followed and fixed relative to the crystallizer and internally provided with guiding channels; the supplementary electrodes aremovable and are arranged in the guiding channels; and the working form of the electrodes in the smelting casting process is as follows: the supplementary electrodes are continuously supplemented to the molten electroslag position through the guiding channels, and thus the smelting casting process is completed. Therefore, the method and device for manufacturing the three-dimensionally changed special-shaped casting through electroslag smelting casting is mainly suitable for casting of the three-dimensionally changed special-shaped casting.

Owner:沈阳市盛华特种铸造有限公司

A Nitrogen-Containing Composite Inoculant for Greatly Improving the Properties of Cast Iron

The invention discloses a nitrogen-containing compound inoculant for greatly improving the performance of cast iron. The nitrogen-containing compound inoculant comprises, by weight percentage, 30-40%of silicon, 20-30% nickel, 8-12% of zinc, 8-12% of manganese, 5-10% of vanadium, 5-10% of strontium and 4-6% of nitrogen. According to the nitrogen-containing compound inoculant, the austenite dendrite is refined while the self-inducing ability of each of compound silicon, nickel, zinc, manganese, vanadium, niobium and nitrogen elements is exerted, and the strength of the alloy cast iron piece isimproved. The invention further discloses preparation of the nitrogen-containing compound inoculant. The preparation temperature of the inoculant is 20% lower than that of a general inoculant, and thenitrogen-containing compound inoculant has the beneficial effects of energy saving and environmental protection and can be industrially applied.

Owner:新沂永新机械配件有限公司

A kind of preparation method of mg-zn-ca series biomedical magnesium alloy

Owner:GRIMAT ENG INST CO LTD

Electroslag fusion casting manufacturing method for annular plate of hydraulic generator

ActiveCN102416463BAchieve the purpose of near-net shape in melting and castingHigh dimensional accuracyElectricityManufacturing technology

The invention discloses an electroslag fusion casting manufacturing method for an annular plate of a hydraulic generator. The method is characterized by comprising the following steps of: 1) controlling slag systems and slag amount; 2) igniting; 3) selecting a crystallizer; 4) rotating the crystallizer by using a control system; 5) selecting power supply parameters; 6) controlling casting alloy components after fusion casting; and 7) selecting a casting thermal processing process. A near-net-shape forming annular plate manufacturing technology is provided for producing annular anti-tear steel plates for hydraulic generator seat rings, top covers and bottom rings at present; a rotatable crystallizer is used for electroslag fusion casting formation, so that technical requirements on production of the annular plate are met; and the produced annular plate has high laminated tearing resistance, higher fatigue resistance and higher crack generation and expansion resistance, and the quality and the performance of the annular plate are not lower than those of a specially-forged product which is made of the same material as that of the annular plate.

Owner:沈阳市盛华特种铸造有限公司

Corrosion resistant heat exchanger and strengthening technology thereof

InactiveCN108103364AImprove the extrusion effectGrain refinementAnti-corrosive paintsEpoxy resin coatingsRare-earth elementCorrosion resistant

The invention discloses a corrosion resistant heat exchanger comprising a shell and a heat exchange pipe arranged in the shell. The shell comprises, by mass, 0.1%-0.3% of C, 0.5%-0.8% of Mn, 0.5%-0.7%of Ni, 2%-4% of Cr, 0.4%-0.6% of Nb, 0.1%-0.3% of Si, 0.2%-0.5% of Fe, 1.5%-2.0% of Mg, no more than 0.2% of Cu, no more than 0.015% of s, no more than 0.025% of p, 0.3%-0.5% of Mo, 0.3%-0.5% of Ti,0.02%-0.03% of B, 0.0018%-0.0022% of v, 0.1%-0.3% of composite rare earth, 0.2%-0.4% of rare earth elements and the balance Al. The invention provides the corrosion resistant heat exchanger and a strengthening technology thereof; and the strengthening technology is simple and practicable, and the strengthened heat exchanger is high in corrosion resistance.

Owner:博维恩冷冻科技(苏州)有限公司

Composite additive for electroslag remelted alloy tool and die steel and adding method thereof

The invention relates to a complex additive for electroslag remelting alloy tool and die steel, and an adding method thereof. The complex additive comprises constituents by the following weight portion: 60 to 95 portions of rare earth alloys, 5 to 35 portions of silicon calcium alloys, and 2 to 5 portions of aluminum. The electroslag remelting alloy tool and die steel is treated by the complex additive, so that purity and toughness of the steel is improved, and the process service performance of materials is improved and enhanced. The adding method can prevent steel slag mixing and cinder oxidation from causing oxidation burning loss of active metamorphic elements, has high yield (more than 30 percent), and has good metamorphic effect of the steel.

Owner:ZHEJIANG ZHENGDA MOLD

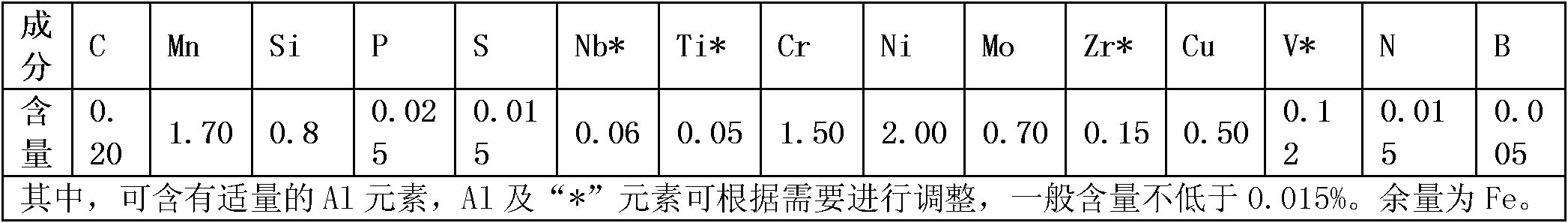

Safety balance roller for fitness and treatment process of safety balance roller for fitness

InactiveCN108060352AImprove cold resistanceImprove the protective effectFurnace typesHeat treatment furnacesEpoxyPlasticizer

The invention discloses a safety balance roller for fitness. The safety balance roller comprises a bracket, an armrest, a rotary shaft and a roller. The safety balance roller is characterized in thatthe bracket and the armrest are made of the same material, and the surface of the armrest is provided with a protective layer; and the materials of the bracket and the armrest comprise C, Mn, Si, P, S, Mo, Ni, Cr, Ca, Cu, O, Ti, Al, B, rare earth and the balance Fe, and the protective layer comprises silicone-modified epoxy resin, a cold-resistant plasticizer, a heat stabilizer, zinc oxide, an antioxidant, polyvinyl chloride, glass flakes, a filler flame retardant and zircon powder. The invention further provides a treatment process of the safety balance roller for fitness. The treatment process is simple and easy to implement, the treated roller has good performance, the service life can be prolonged, and the cost is lowered.

Owner:苏州胤宗智能科技有限公司

A process of hot-dip tin-plating alloy on the surface of stirrups

InactiveCN105586557BLow melting pointImprove corrosion resistanceHot-dipping/immersion processesTinningMetal coating

The invention discloses a hoop surface hot dip coating tin alloy process. The hoop surface hot dip coating tin alloy process comprises the steps of sanding, alkali wash oil removal, acid pickling, plating assisting, preheating, hot dip coating and analysis and detection. According to the hoop surface hot dip coating tin alloy process, no harmful heavy metal ion or phosphorus or sediment exists, heating is not needed, the treatment time is short, the number of treatment steps is small, a surface adjusting procedure can be omitted, hot drip coating can be reused, and the adhesive force of a metal coating to a substrate is effectively improved.

Owner:大连新锋钢管厂

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: 0.14-0.19 percent of C, Si <= 0.6 percent, 1.5-1.9 percent of Mn, P <= 0.035 percent, S <= 0.035 percent, 0.02-0.15 percent of V, 0.015-0.06 percent of Nb, 0.15-0.25 percent of Ti, Al >= 0.015 percent, O <= 0.0040 percent, N <= 0.0080 percent, H <= 0.00035 percent, and the balance of Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: 60-80 percent of CaF2, 40-20 percent of Al2O3, or less MgO and CaO (the total amount <= 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

Method for preparing ultra-low-oxygen bearing steel cast ingot through vacuum induction smelting

The invention discloses a method for preparing an ultra-low-oxygen bearing steel cast ingot through vacuum induction smelting. The method comprises the following steps that (1), raw materials, metal aluminum and a rare earth magnesium deoxidizing agent are prepared according to bearing steel components; (2), metal aluminum, a rare earth magnesium deoxidizer, volatile or oxidizable raw materials in the raw materials and a second part of carbon source are separately placed in a stock bin; the rest raw materials and a first part of carbon source are put into a crucible; (3), a vacuum induction furnace is started, vacuumizing is carried out, heating is carried out until the materials are melted, and argon is introduced (4), after the materials are completely molten, the second part of the carbon source is added into the crucible, and vacuumizing is carried out for vacuum deoxidation; (5), argon is introduced, the metal aluminum is added, and aluminum deoxidation is carried out; (6), the rare earth magnesium deoxidizer is put into the crucible for rare earth magnesium deoxidization; and (7), pouring is carried out. The three-step deoxidation enables the chemical reaction to be sufficient, reduces the content of oxygen and sulfur in steel, reduces the integral number of inclusions in the steel, and improves the solidification structure of the cast ingot.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com