Electroslag fusion casting manufacturing method for annular plate of hydraulic generator

A hydro-generator and electroslag casting technology, applied in the field of electroslag casting manufacturing, can solve the problems of inability to produce similar steel plates with high yield strength, increased use costs, steel waste, etc., and achieve excellent laminar tear resistance, cooling The effect of fast speed and reduced cutting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Slag ingredients are used: CaF 2 70%, Al 2 O 3 30%. The amount of slag was 3% by weight of the casting.

[0029] 2. Ignition method: the consumable electrode is ignited by solid slag in the mold, TiO 2 : 50%, CaF 2 : 50%.

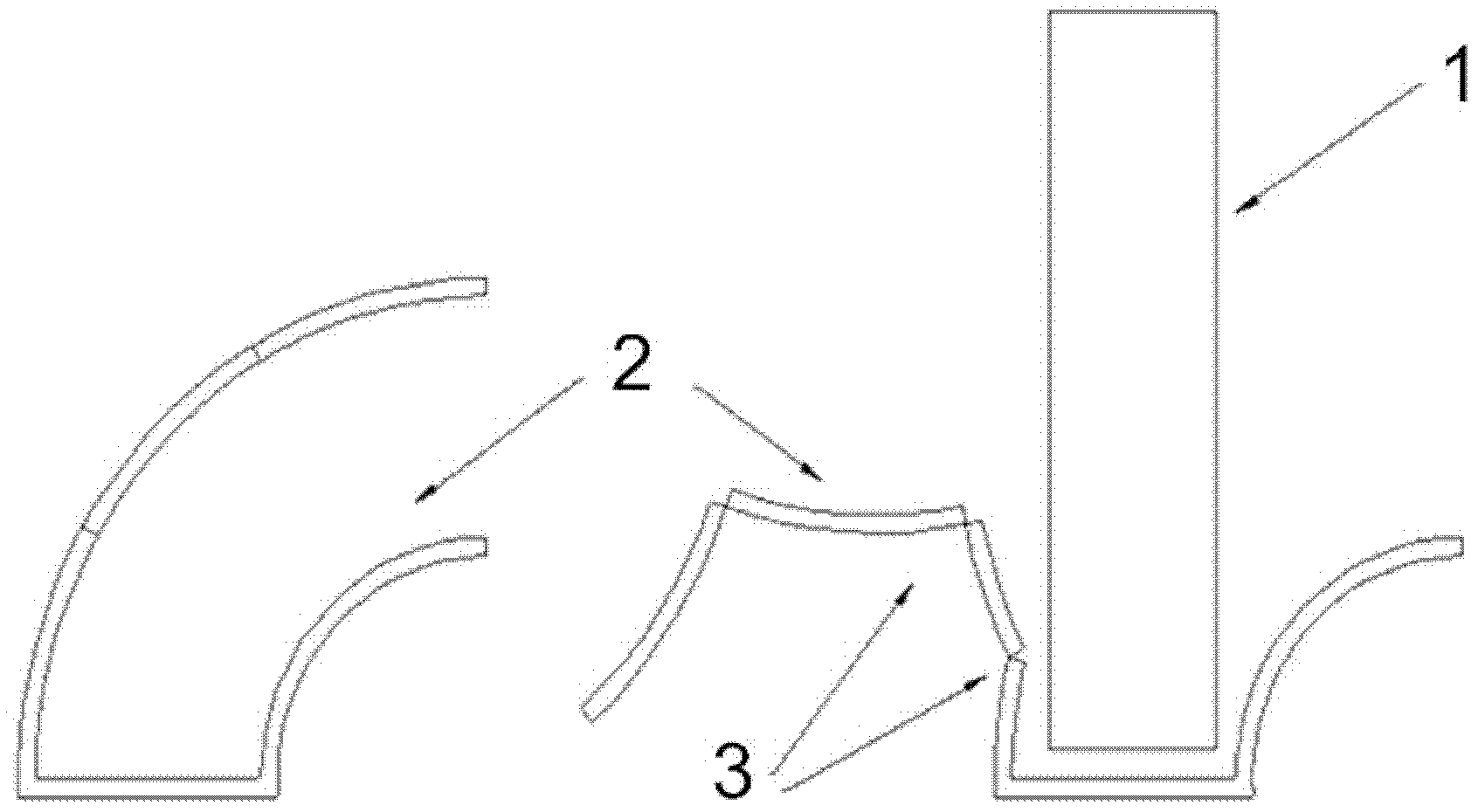

[0030] 3. Selection of crystallizer: The copper-steel combined crystallizer is used, and its structure adopts the outer arc side as the gradually closed cooling surface ( figure 1 ).

[0031] 4. Electrical parameters: According to the casting size, electrode and mold geometry, the casting voltage is 55V, and the current is 6500A.

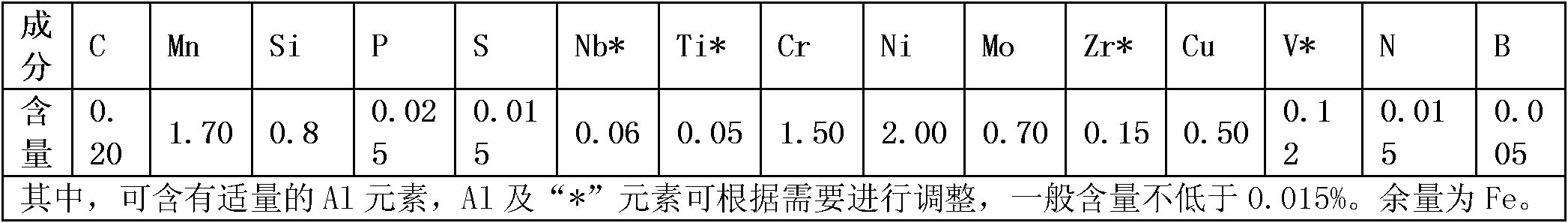

[0032] Through the electroslag casting process, the ring plate is formed by the mold of the set shape. Its chemical composition is.

[0033]

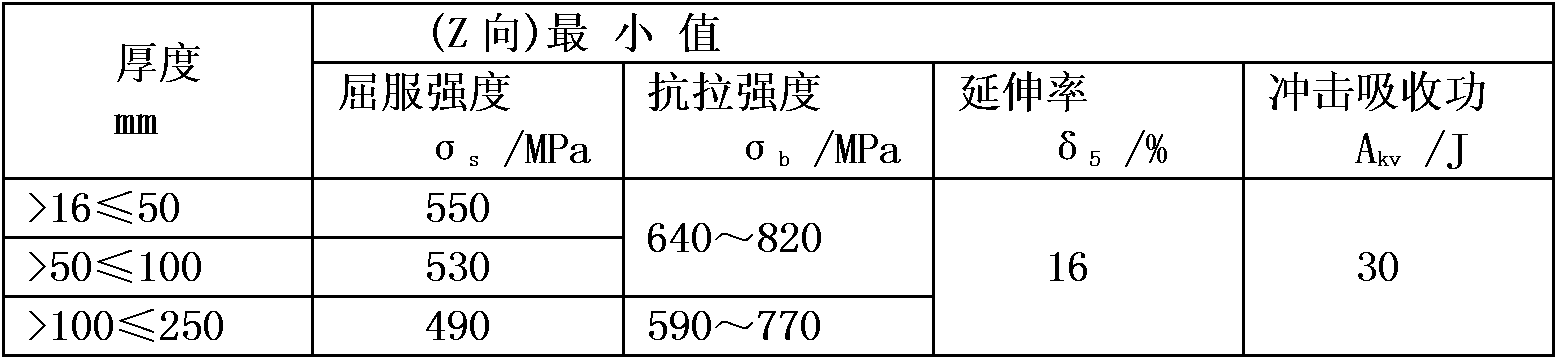

[0034] The mechanical properties of the casting after heat treatment are:

[0035]

Embodiment 2

[0037] 1. Slag ingredients are used: CaF 2 70%, Al 2 O 3 30%. The amount of slag was 3.4% by weight of the casting.

[0038] 2. Ignition method: the consumable electrode is ignited by solid slag in the mold, TiO 2 : 50%, CaF 2 : 50%.

[0039] 3. Selection of crystallizer: All-copper crystallizer is used, and its structure adopts the block-combined outer arc side as the gradually closed cooling surface.

[0040] 4. Electrical parameters: According to the casting size, electrode and mold geometry, the casting voltage is 75V, and the current is 12000A.

[0041] Through the electroslag casting process, it is formed by a mold with a set shape. Its chemical composition is.

[0042]

[0043] The mechanical properties of the casting after heat treatment are:

[0044]

Embodiment 3

[0046] 1. Slag ingredients are used: CaF 2 70%, Al 2 O 3 30%. The amount of slag was 2.5% by weight of the casting.

[0047] 2. Ignition method: the consumable electrode is ignited by solid slag in the mold, TiO 2 : 45%, CaF 2 : 55%.

[0048] 3. Selection of crystallizer: All-steel crystallizer is adopted, and its structure adopts one side of the outer arc to gradually close the cooling surface.

[0049] 4. Electrical parameters: According to the casting size, electrode and mold geometry, the casting voltage is 50V, and the current is 7500A.

[0050] Through the electroslag casting process, the ring plate is formed by the mold of the set shape. Its chemical composition is.

[0051]

[0052] The mechanical properties of the casting after heat treatment are:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com