High-strength aluminum alloy profile for brake chamber and processing technology of high-strength aluminum alloy profile

A technology of aluminum alloy profiles and brake chambers, applied in the field of mechanical parts processing, can solve problems such as wear resistance, poor corrosion resistance, low strength level, delayed fracture, etc., and achieve good wear resistance and strong corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

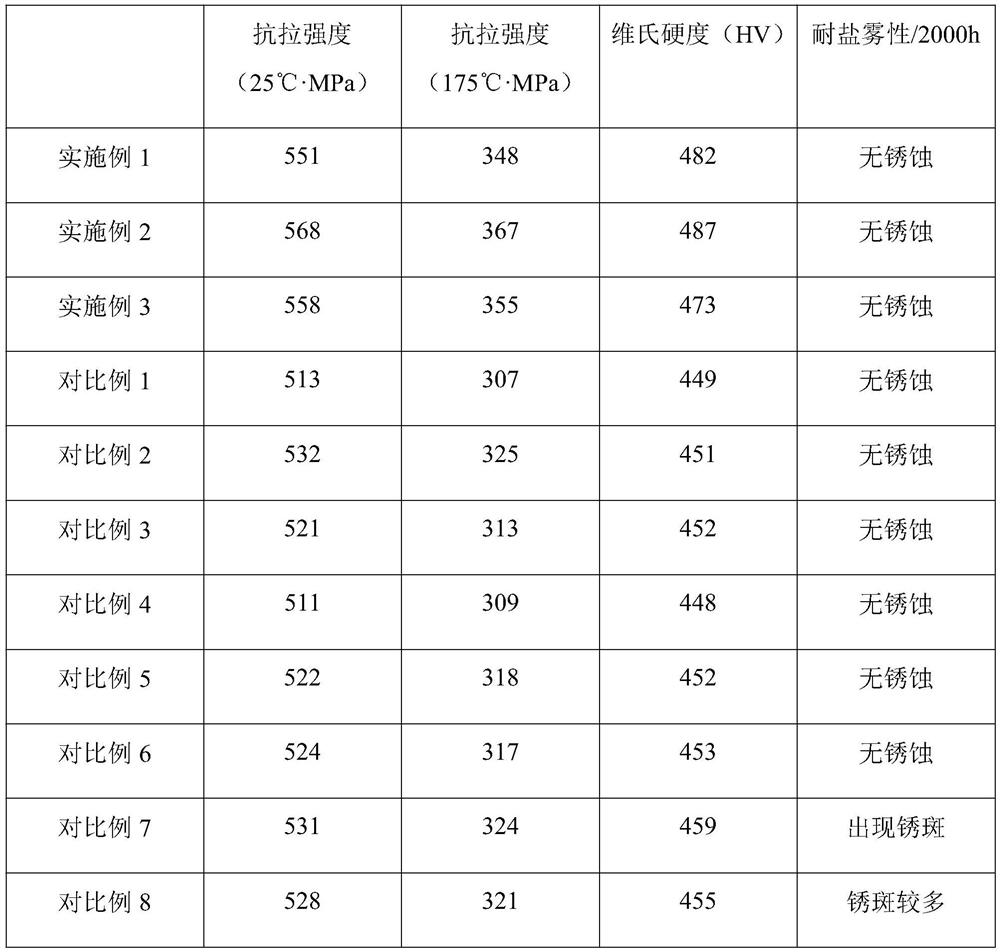

Examples

Embodiment 1

[0044] A process for processing high-strength aluminum alloy profiles for brake air chambers, comprising the following steps:

[0045] S1: Take ZL205A as the aluminum alloy base material, stir the aluminum alloy base material at 715°C for 10min, heat up to 745°C and add a modifier for 8min;

[0046] The modifier is obtained by compounding Al-10La and Al-Sc, the mass ratio of rare earth Sc element and rare earth La element is 1.4:4, and the mass fraction ratio of rare earth La element and aluminum alloy body is 0.4%;

[0047] S2: Cool down to 725°C, use refining agent for flux purification, argon gas for rotary blowing degassing purification treatment of aluminum alloy melt, sub-package treatment with aluminum foil paper, divide into 8 parts, and add to the bell jar in batches. Inside, and then continuously stirred for 15 minutes, after refining, let stand for 15 minutes, and cooled by water cooling to obtain the aluminum alloy substrate after quenching;

[0048] The refining ...

Embodiment 2

[0058] A process for processing high-strength aluminum alloy profiles for brake air chambers, comprising the following steps:

[0059] S1: Take ZL205A as the aluminum alloy base material, stir the aluminum alloy base material at 720 °C for 8 minutes, heat up to 760 °C, add a modifier for 7 minutes;

[0060] The modifier is obtained by compounding Al-10La and Al-Sc, the mass ratio of rare earth Sc element and rare earth La element is 1.5:4, and the mass fraction ratio of rare earth La element and aluminum alloy body is 0.4%;

[0061] S2: Cool down to 730°C, use refining agent for flux purification, argon gas for rotary injection degassing purification treatment of aluminum alloy melt, sub-package treatment with aluminum foil paper, divide into 9 parts, and add to the bell jar in stages. Inside, and then continuously stirred for 15min, after refining, let stand for 18min, and cooled with water to obtain the aluminum alloy substrate after quenching;

[0062] The refining agent i...

Embodiment 3

[0073] A process for processing high-strength aluminum alloy profiles for brake air chambers, comprising the following steps:

[0074] S1: Take ZL205A as the aluminum alloy base material, stir the aluminum alloy base material at 725°C for 5min, heat up to 765°C, add a modifier for 6min;

[0075] The modifier is obtained by compounding Al-10La and Al-Sc, the mass ratio of rare earth Sc element to rare earth La element is 1.8:4, and the mass fraction ratio of rare earth La element to aluminum alloy body is 0.4%;

[0076] S2: Cool down to 735°C, use refining agent for flux purification, argon gas for rotary injection degassing purification treatment of aluminum alloy melt, sub-package treatment with aluminum foil paper, divide into 10 parts, and add to the bell jar in stages. Inside, and then continuously stirred for 15min, after refining, let stand for 20min, and cooled with water to obtain the aluminum alloy substrate after quenching;

[0077] The refining agent is obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com