Method for preparing ultra-low-oxygen bearing steel cast ingot through vacuum induction smelting

A technology of vacuum induction smelting and ultra-low oxygen bearing, applied in the field of metallurgy, can solve the problems of lack of refining slag adsorption and removal of inclusions, increase the smelting cost of bearing steel, the size and distribution characteristics of inclusions cannot be effectively controlled, etc., to improve solidification The effect of organizing, promoting floating, and refining dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] According to the ingredients of the M50 aerial bearing steel, prepare raw materials industrial pure iron, metal chromium, molybdenum strips, metal vanadium, electrolytic manganese, graphite, aluminum beans (metal aluminum), rare earth metal and magnesium alloy; rare earth metal is made of metal, purity greater than 99 %; Magnesium alloys with magnesium nickel alloy, magnesium content is 20.62%;

[0059] The graphite is divided into first partial graphite and second part of graphite; the first part of graphite accounts for 60% of the quality of the graphite;

[0060] The industrial pure iron, metal chromium, molybdenum bar and the first partial graphite are placed in a crucible of the vacuum induction furnace;

[0061] The second part of graphite, electrolytic manganese, metal vanadium, aluminum beans, magnesium nickel alloy, and metal ruthenium are sequentially placed in different silos of vacuum induction furnace;

[0062] Start vacuum induction furnace, vacuum to air pres...

Embodiment 2

[0074] Methods to Example 1, different points lies in:

[0075] (1) The first part of graphite accounts for 50% of the quality of the graphite;

[0076] (2) When the material in the crucible begins to melt, the vacuum is stopped, and the argon is charged to the air pressure of 30000 Pa;

[0077] (3) Insulation 40min for vacuum deoxidation;

[0078] (4) Insulation 10min for aluminum deoxidation;

[0079] (5) Turn 6 min for rare earth magnesium deoxidation;

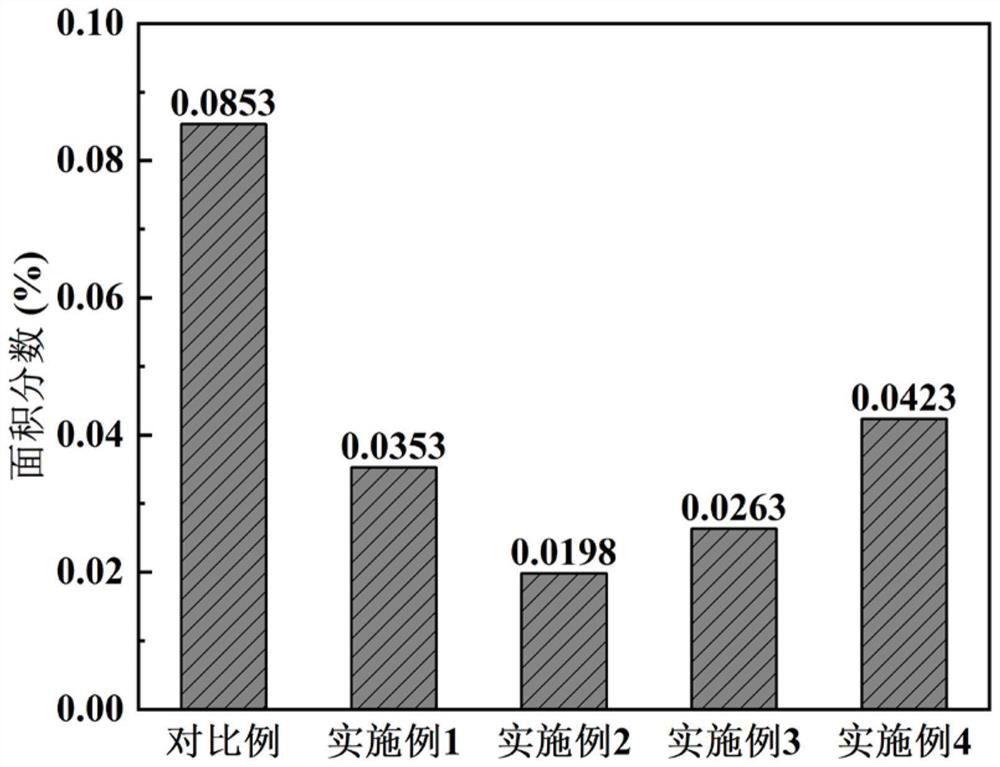

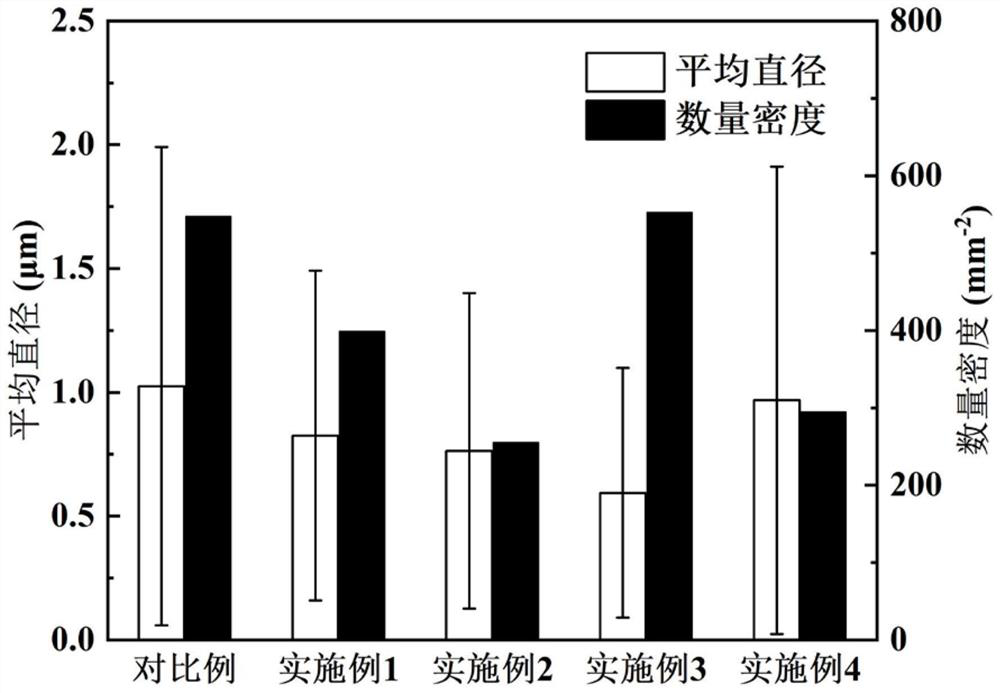

[0080] (6) Metal 铈 量 量 量 = =);;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; The O content of the low oxygen bearing steel ingot is 0.00027%, and the S content is 0.0015%.

Embodiment 3

[0082] Methods to Example 1, different points lies in:

[0083] (1) Metal rare earth uses metal lanthanum, purity greater than 99%; the first part of graphite accounts for 40% of the quality of the graphite;

[0084] (2) When the material in the crucible begins to melt, the vacuum is stopped and the argon is charged to the air pressure of 20000 Pa;

[0085] (3) Insulation 30min for vacuum deoxidation;

[0086] (4) Insulation 3min for rare earth magnesium deoxidation;

[0087] (5) Metal ruthenium added amount M3 = 0.25a / (50% * 99%) = 0.51kg / t; magnesium nickel alloy adding amount M4 = 0.02A / (5% * 20.62%) = 1.94kg / t; super The oxygen bearing steel ingot has an O content of 0.00016% and the S content is 0.0010%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com