Gas-liquid microreactor, device, system and method

A technology of micro-reactors and reactors, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., can solve the problem of difficult to generate phase boundary area, gas-liquid stratified flow , unfavorable reactions and other issues, to achieve the effect of less processing difficulty, increase the contact area of the two phases, and enhance mass transfer and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

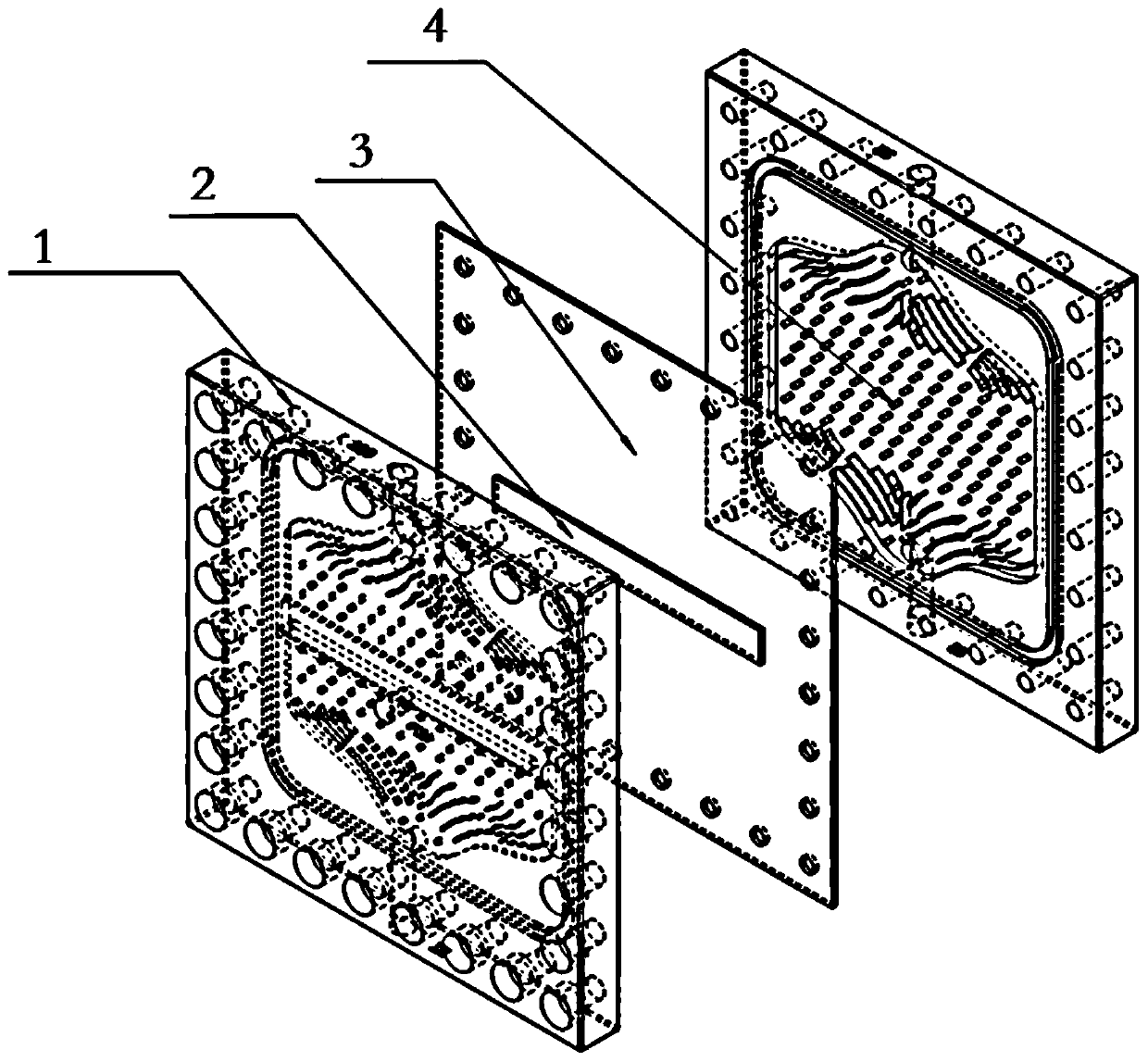

[0063] Embodiment one, such as figure 1 As shown, the gas-liquid reactor is mainly composed of a reaction plate (1), a microporous plate (2), a separator (3) and a heat exchange plate (4).

[0064] The reaction plate (1) mainly provides the reaction space. In order to ensure the effect of reaction and heat exchange, the reaction space is formed by multiple reaction channels set on the reaction plate (1). , Sealed connection, forming a closed reaction space.

[0065] Of course, in the present embodiment, the sealed connection between the reaction plate (1) and the dividing plate (3) is through a plurality of bolt holes arranged around the circumference of the reaction plate (1) and the dividing plate (3), and Bolt fixing through bolt holes. In order to ensure the sealing effect on the reaction space, a sealing ring can be arranged between the reaction plate (1) and the partition plate (3). Nice response environment.

[0066] In other embodiments, other connecting / sealing me...

Embodiment 2

[0111] Provide a more complete gas-liquid reaction device, such as Figure 6 As shown, it includes gas source, gas-liquid reactor, heat exchange device and liquid supply mechanism. Among them, the gas source supplies gas, and the gas has a certain pressure after passing through the pressurizing device, and the gas with pressure is controlled by the flow controller and then input Gas inlet B of the gas-liquid reactor;

[0112] The liquid supply mechanism supplies liquid with a certain flow rate to the liquid inlet A of the gas-liquid reactor;

[0113] The heat exchange device is connected to the heat exchange medium inlet F and the heat exchange medium outlet G of the heat exchange plate (4).

[0114] Of course, the gas-liquid reactor can also be connected with post-processing equipment.

[0115] In this embodiment, existing equipment can be used for the gas source, heat exchange device, pressurizing device, flow controller, liquid supply mechanism, etc., and will not be repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com