Electroslag casting manufacturing method and device for special-shaped castings with three-dimensional changes

A technology of electroslag casting and manufacturing method, which is applied in the field of electroslag casting to produce special-shaped castings with three-dimensional changes, which can solve the problems of inability to cast complex special-shaped parts, achieve high resistance to crack formation and expansion, reduce pollution, and have high dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

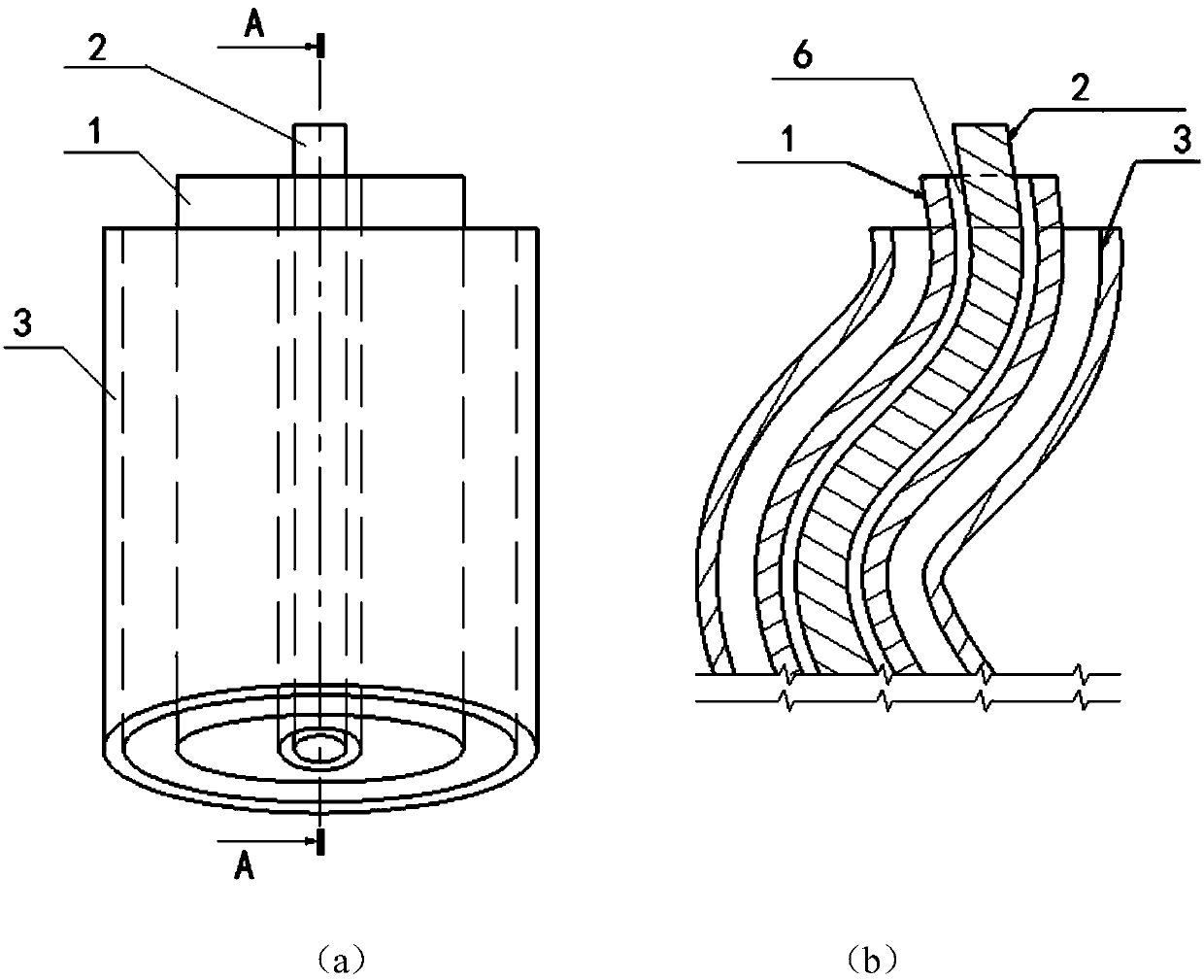

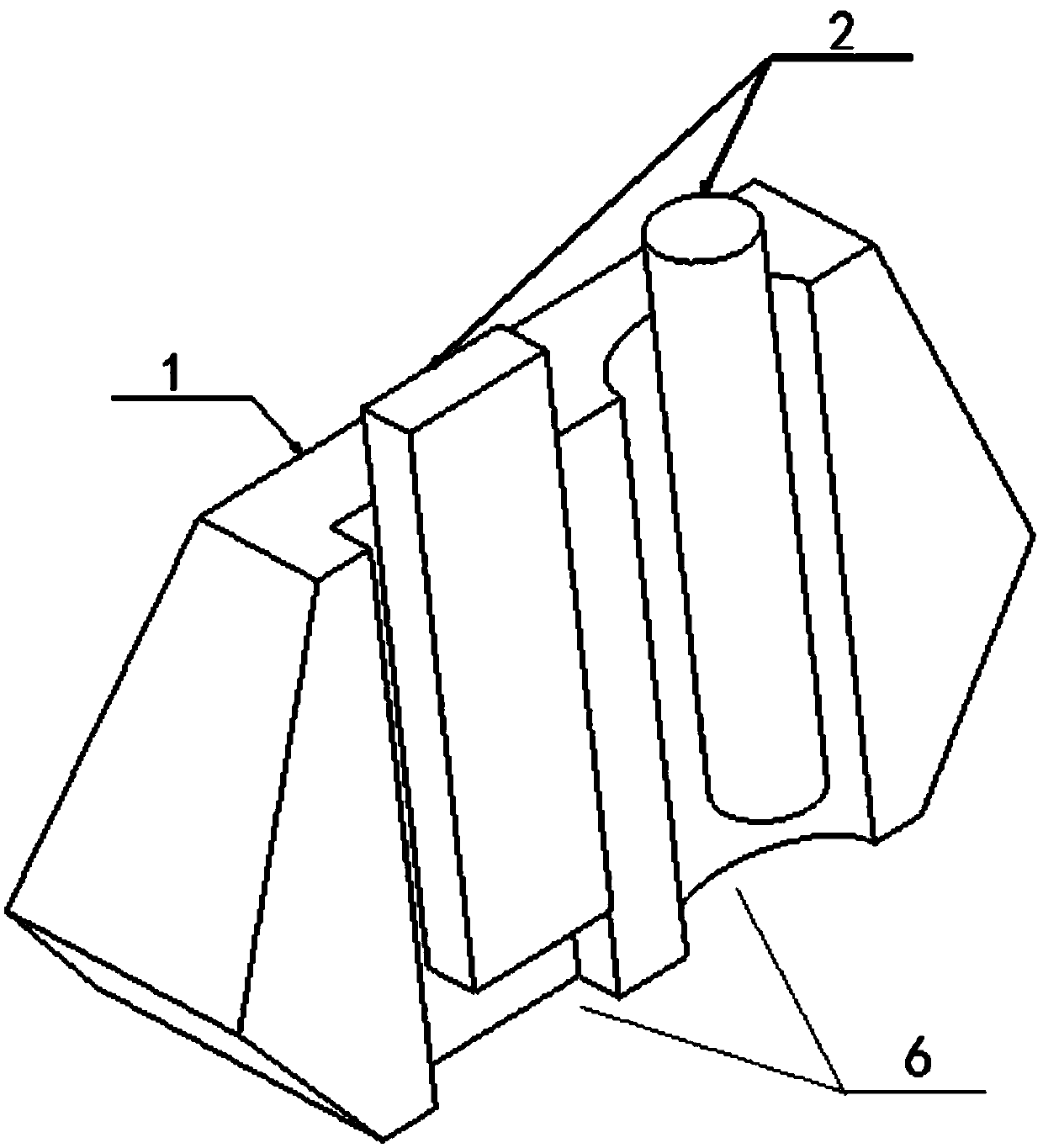

[0048] Such as figure 2 As shown, in this embodiment, the two-lobed crystallizer and the follow-up guide electrode are assembled according to the process requirements. The guide electrode 1 is a split assembly type, and only half of the guide electrode is shown in the guide electrode 1 diagram. The guiding electrode 1 is provided with two guiding channels 6 (the cross sections are respectively circular or rectangular), and two supplementary electrodes 2 (the cross sections are respectively circular or rectangular) are arranged in the guiding channels 6 corresponding to the cross section shapes , the two supplementary electrodes 2 continuously supplement the consumable electrodes in the casting process through the guide channel 6 respectively.

Embodiment 2

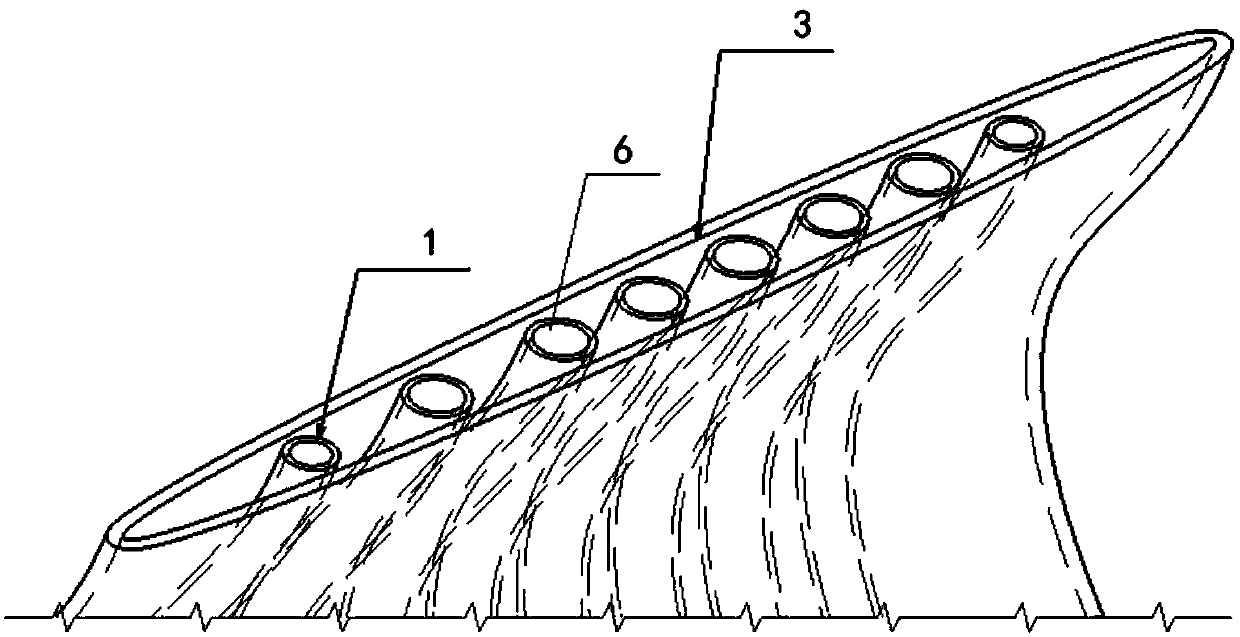

[0050] Such as image 3 As shown, in this embodiment, the electroslag casting of the blade blank of the Francis turbine generator uses 8 pipe-type guide electrodes 1 in the crystallizer cavity 3, and the supplementary electrode is a flexible cylinder, and the supplementary electrode passes through the pipe-type guide electrode. 1 inner guide channel 6 lead-in. Before the crystallizer assembly box, fix the guide electrode 1 at the designated position of the mold cavity 3, after the guide electrodes 1 are installed in place, their positions are fixed with each other, and the supplementary electrodes are continuously directed to the casting through the guide channel 6 in the guide electrode 1. process to replenish the consumable electrodes.

Embodiment 3

[0052] Such as Figure 4 As shown, in this embodiment, the electroslag casting manufacturing device includes: supplementary electrode 2, crystallizer cavity 3, fixed guide electrode 4, movable guide electrode 5, etc., and the crystallizer has an upper and lower two-layer structure, respectively responsible for blade flange section Forming and blade part forming. The crystallizer cavity 3 located on the upper layer has a circular cross section, in which a movable guiding electrode 5 is arranged, and a supplementary electrode 2 is arranged in the guiding channel inside the movable guiding electrode 5 . The crystallizer cavity 3 located in the lower layer has a strip-shaped cross-section, and a fixed guiding electrode 4 is arranged therein.

[0053] For the electroslag casting of the blade blank of the axial-flow hydroelectric generator, the fixed guide electrode 4 or the supplementary electrode 2 and the movable guide electrode 5 are respectively assembled in the mold cavity 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com