Electroslag smelting casting method of fixed blades of water turbine

A technology of fixing guide vanes and electroslag casting, which is applied in the field of electroslag casting, can solve problems such as affecting the operating life of hydraulic turbines, unstable internal quality of products, and difficulty in meeting high performance indicators, and achieves small deformation, dendrite refinement, The effect of dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

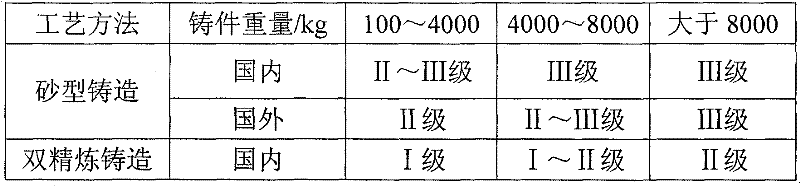

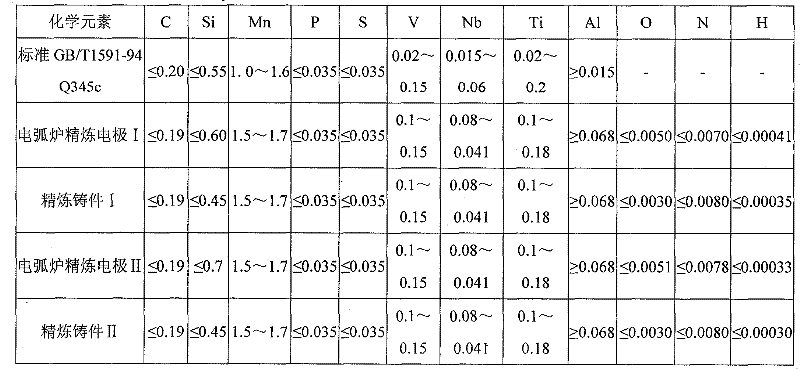

[0051] The low-alloy steel consumable electrode is prepared by the electric arc furnace refining process, and then the secondary refining is carried out by the electroslag casting process, and the fixed guide vane casting I of the water turbine is cast.

[0052] 1. Preparation of Q345C steel consumable electrodes

[0053] The raw materials are: pure iron, ferrosilicon, ferromanganese, scrap steel, aluminum ingots, ferrotitanium, ferrovanadium and ferroniobium.

[0054]First, use the electric arc furnace refining process to prepare consumable electrodes, put scrap steel and pure iron into the furnace, and blow oxygen to boost the melting of about 70% of the furnace charge. , P, S. Slag removal after melting and clearing, additional slag material with 3-4% of furnace charge weight, when the molten pool temperature reaches 1540-1550°C, oxidation boiling is carried out. Boiling deoxidation starts when the molten pool temperature is ≥1560°C, the oxygen pressure is 6-8kg, slag flo...

Embodiment 2

[0068] The consumable electrode of Q345C steel was prepared by electric furnace refining process, and then secondary refining was carried out by electroslag casting process to cast the turbine refining fixed guide vane casting II.

[0069] 1. Preparation of Q345C steel consumable electrode

[0070] The raw materials are: pure iron, ferrosilicon, ferromanganese, scrap steel, aluminum ingots, ferrotitanium, ferrovanadium and ferroniobium.

[0071] First, use the electric arc furnace refining process to prepare consumable electrodes, put scrap steel and pure iron into the furnace, and blow oxygen to boost the melting of about 70% of the furnace charge. , P, S. Remove slag after melting and cleaning, add 3-4% slag material, and carry out oxidation boiling when the temperature of molten pool reaches 1540-1550°C. Boiling deoxidation starts when the molten pool temperature is ≥1560°C, the oxygen pressure is 6-8kg, slag flows automatically during boiling, the oxygen blowing decarbur...

Embodiment 3

[0085] The 20SiMn steel consumable electrode was prepared by electric furnace refining process, and then secondary refining was carried out by electroslag casting process to cast out the turbine refining fixed guide vane casting III.

[0086] 1. Preparation of 20SiMn steel consumable electrode

[0087] The raw materials are: pure iron, ferrosilicon, ferromanganese, scrap steel, aluminum ingot.

[0088] First, use the electric arc furnace refining process to prepare consumable electrodes, put scrap steel and pure iron into the furnace, melt 70% of the charge, blow oxygen from left and right to help the melting, oxygen pressure is 3-4kg, check the bottom to confirm that the charge is completely melted, stir fully, and take samples for analysis C, P, S. Remove slag after melting and cleaning, add 3-4% slag material, and carry out oxidation boiling when the temperature of molten pool reaches 1540-1550°C. When the temperature of the molten pool is ≥1560°C, take samples and analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com