A kind of high damping mg‑mn‑ce‑al‑zn‑y magnesium alloy and preparation method thereof

A magnesium alloy and high damping technology, which is applied in the field of high damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy and its preparation, can solve the problems of not being able to ensure sufficient uniformity, reducing alloy preparation efficiency, increasing labor costs, and the like, Achieve the effect of easy operation, low cost and lower alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

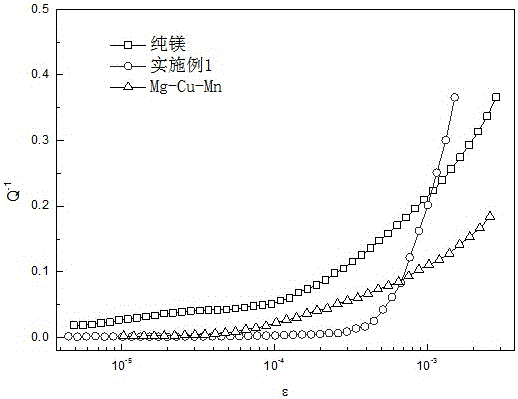

Embodiment 1

[0028] Embodiment 1: A kind of high damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy, alloy composition (weight percentage): Mn-1.37%, Ce-0.30%, Al-0.11%, Zn-0.35%, Y -0.64%, less than 0.1% of impurity elements, and the rest is Mg.

[0029] The manufacturing method of the high damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy is carried out as follows:

[0030]Step 1: In a vacuum melting furnace, melt the ingot and pass it into argon for protection, and add alloys according to the weight percentage Mn-1.37%, Ce-0.30%, Al-0.11%, Zn-0.35%, Y-0.64% element. Among them, Mg, Mn, Ce, Al, Zn, and Y are respectively added in the form of industrial pure magnesium, Mg-Mn master alloy, Mg-Ce master alloy, industrial pure aluminum, industrial pure zinc, and Mg-Y master alloy.

[0031] Insulate at 850°C and stir with electromagnetic induction to fully melt the raw materials. After the alloy is completely melted, continue to stand at 850°C for 10 minutes, and then water quench to room temperature.

[003...

Embodiment 2

[0035] Embodiment 2: A kind of high damping Mg-Mn-Ce-Al-Zn-Y alloy, alloy composition (weight percentage): Mn-0.92%, Ce-0.28%, Al-0.27%, Zn-0.30%, Y- 1.42%, less than 0.1% of impurity elements, and the rest is magnesium.

[0036] The manufacturing method of this high-damping Mg-Mn-Ce-Al-Zn-Y alloy is the same as that in Example 1.

Embodiment 3

[0037] Embodiment 3: A kind of high damping Mg-Mn-Ce-Al-Zn-Y alloy, alloy composition (weight percentage): Mn-1.78%, Ce-0.23%, Al-0.24%, Zn-0.44%, Y- 1.36%, the impurity element is less than 0.1%, and the rest is magnesium.

[0038] The manufacturing method of this high-damping Mg-Mn-Ce-Al-Zn-Y alloy is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com