Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Affect surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

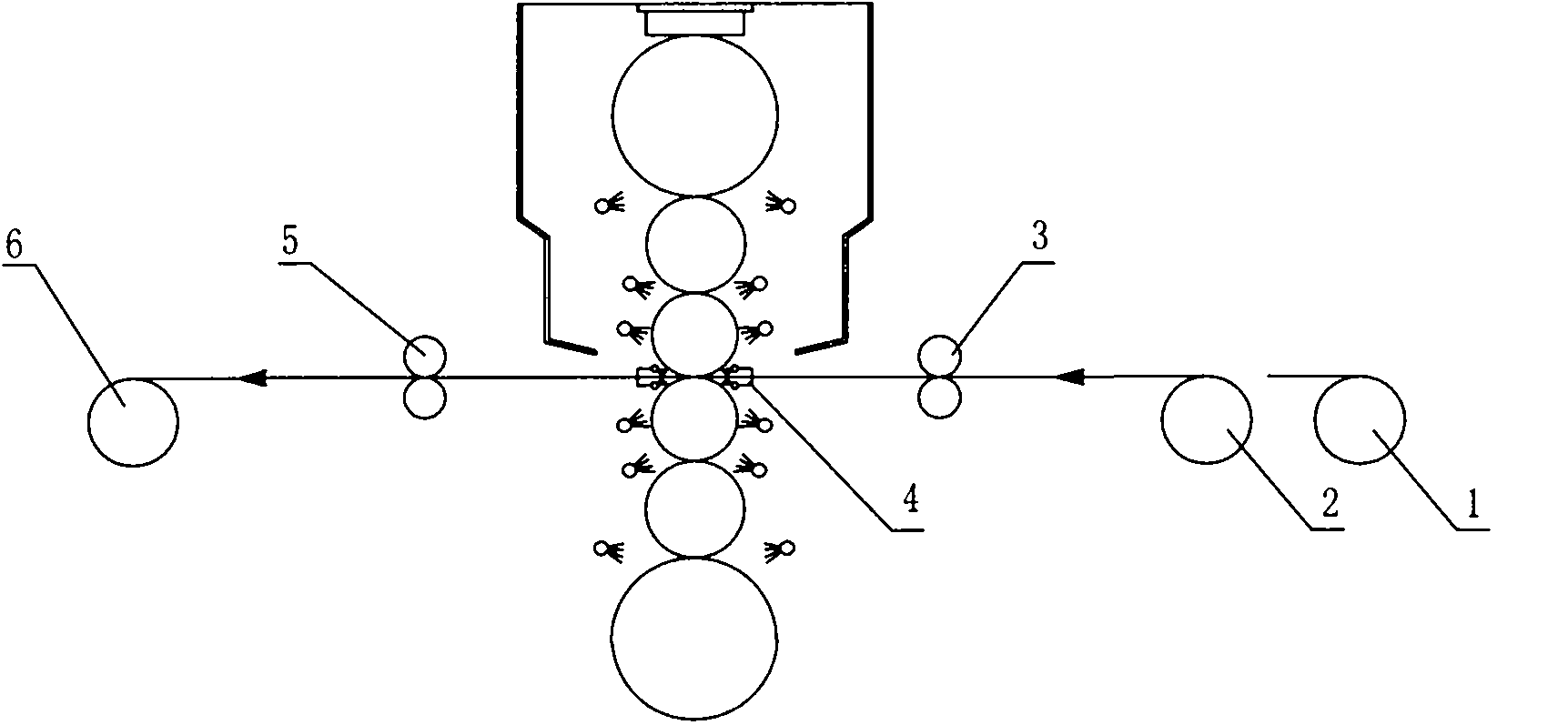

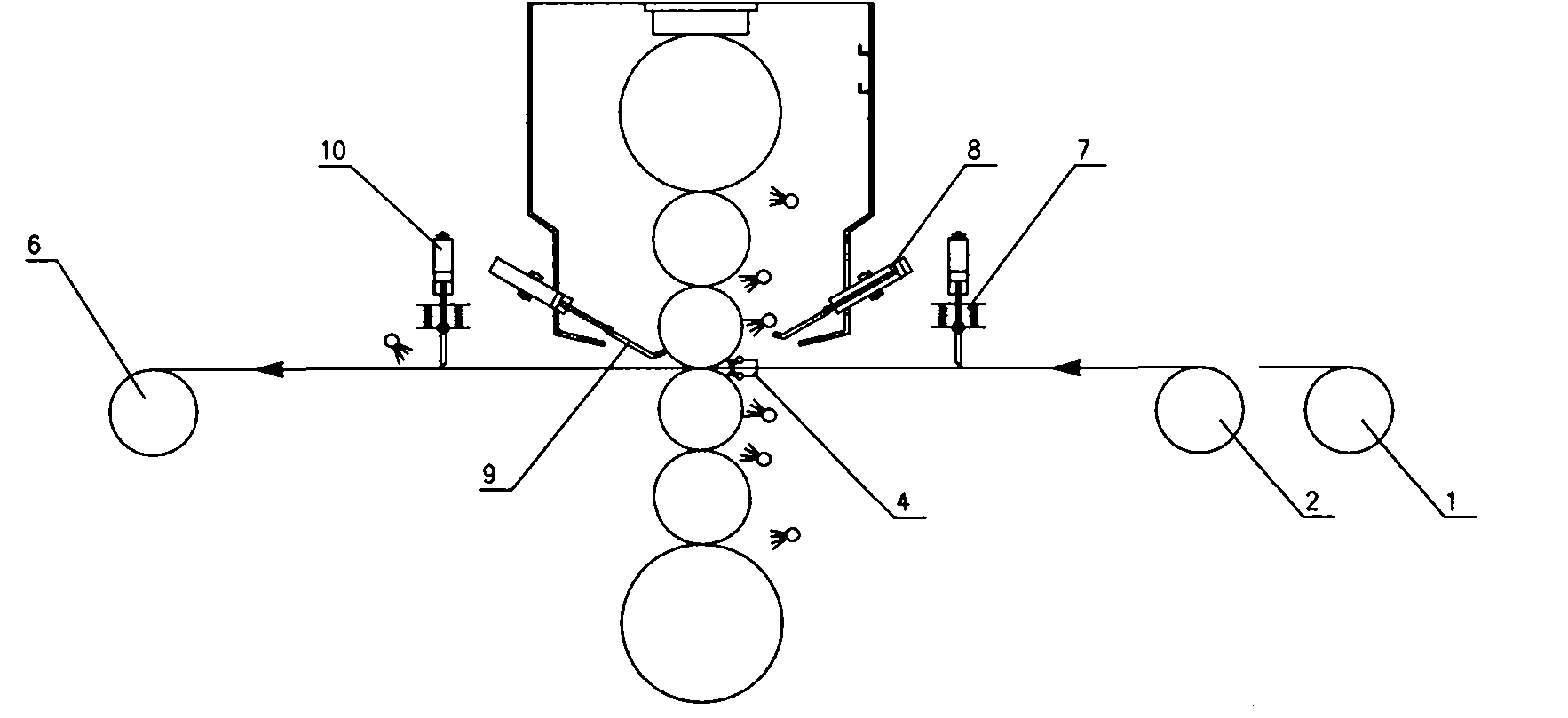

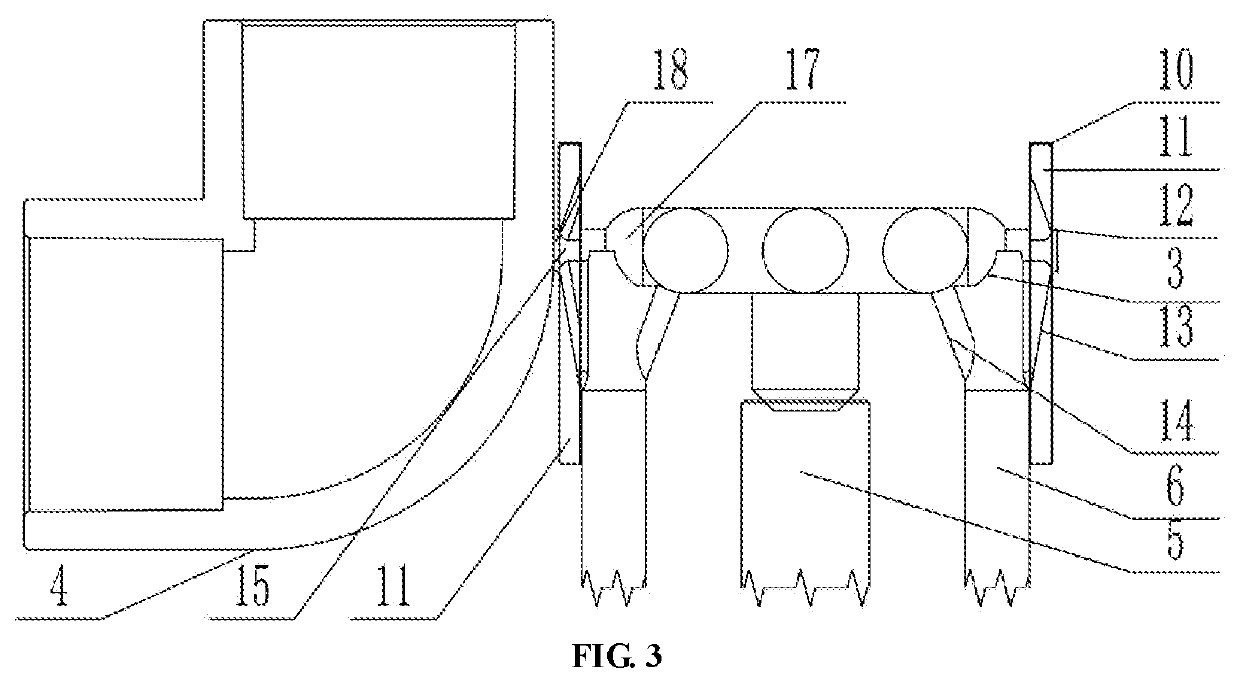

Blowing-free emulsion residue removal method

ActiveCN101829693AImprove surface qualityReduce noise pollutionRollsWork cleaning devicesEmulsionRolling mill

The invention belongs to the technical field of cold-rolled emulsion spot treatment, and in particular relates to a blowing-free emulsion residue removal method, which is applied to various cold-rolling mills. The blowing-free emulsion residue removal method is characterized by comprising the following steps of: 1) blocking low inertia force return of the emulsion; 2) blocking side fluid channeling of the emulsion; 3) blocking fluid channeling of intermediate roll shifting empty emulsion; 4) blocking the condensate of the emulsion; 5) rapidly draining the injection beam of the emulsion; and 6) preventing splashing. The blowing-free emulsion residue removal method has the advantages of simpleness and excellent treatment efficiency.

Owner:WISDRI ENG & RES INC LTD

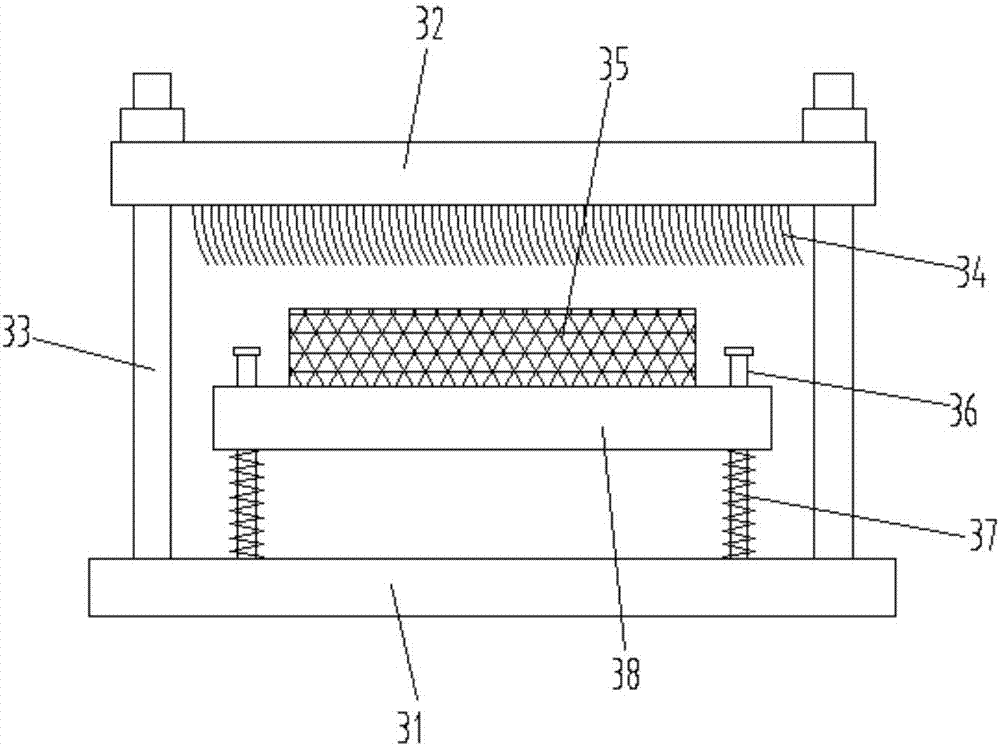

Abrasive flow micropore polishing device

ActiveCN104999379AHigh energyPromote aggregationAbrasive machine appurtenancesAbrasive blasting machinesHigh accelerationEngineering

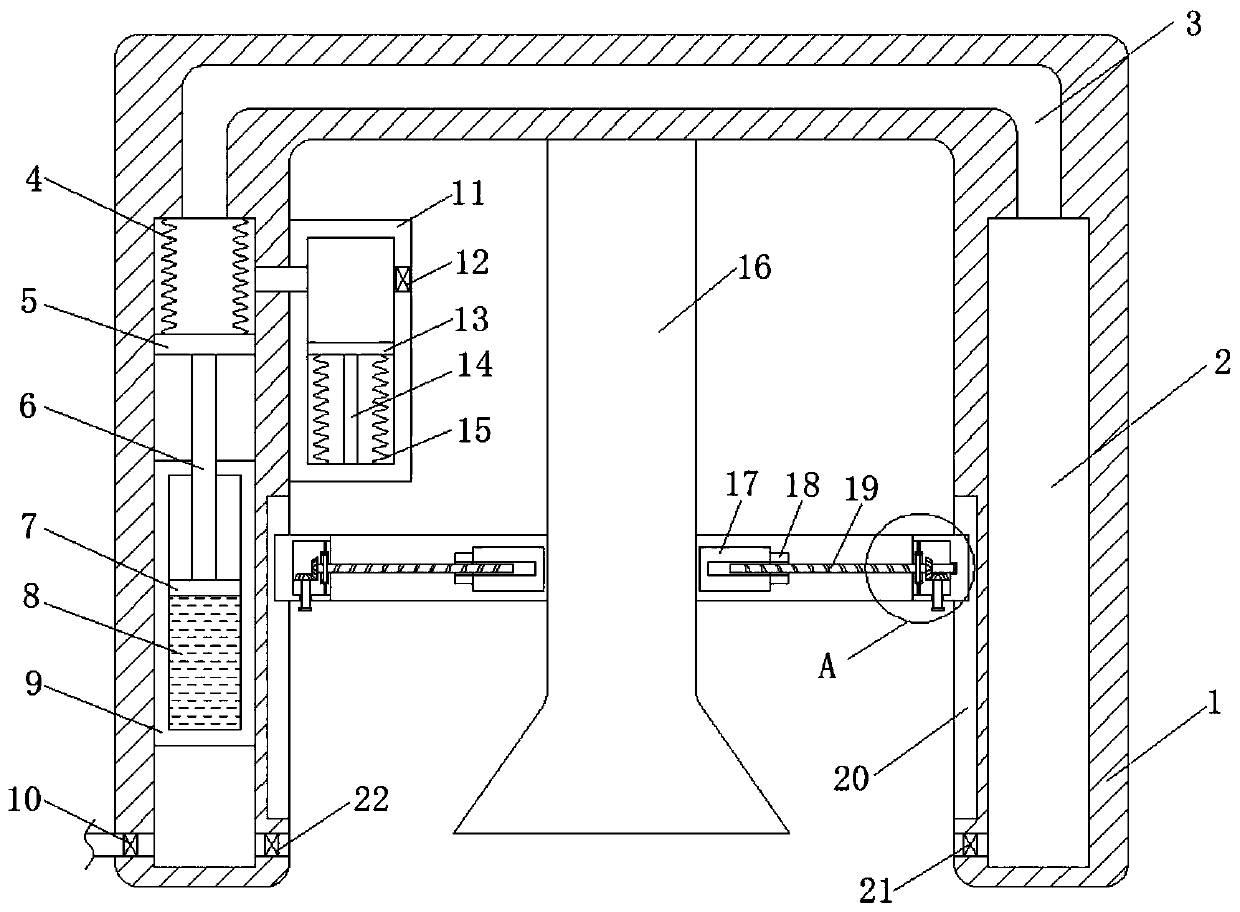

The invention provides an abrasive flow micropore polishing device. The device comprises a workpiece supporting base, a pressurization vibration base, an upper bracket, an adapter, a high-pressure jet pump, an abrasive flow feeding box and an abrasive flow collecting box, wherein an ultrasonic vibrator is arranged at the lower end of an abrasive flow channel in the pressurization vibration base. By arranging the ultrasonic vibrator at the lower end of the abrasive flow channel in the pressurization vibration base, high acceleration energy can be provided for abrasive flow flowing through under the high-frequency vibration of the ultrasonic vibrator, so that more energy is gathered by the abrasive flow and the abrasive flow enters a workpiece; before the abrasive flow enters the workpiece, a certain buffering effect is realized in an abrasive flow channel in the workpiece supporting base, so that the situation that as adverse effect is generated on the workpiece by the abrasive flow with overhigh vibration frequency, the surface quality of workpiece micropores is affected is avoided. A temperature sensor and a heater are arranged inside the abrasive flow feeding box, so that the situation that due to the fact that the viscosity of the abrasive flow is affected by temperature, the machining precision of the micropore workpiece is affected is avoided.

Owner:CHANGCHUN UNIV OF SCI & TECH

Preparation method of 80-100mm extra-thick EH36 steel for offshore wind power

ActiveCN111455255AGuaranteed StrengthGrain refinementFurnace typesHeat treatment furnacesMetallurgyOffshore wind power

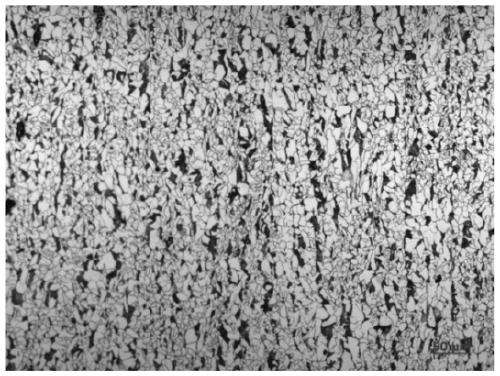

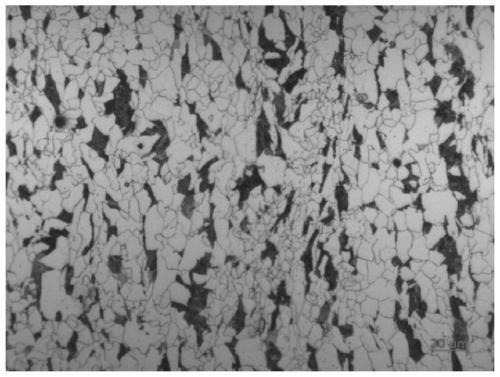

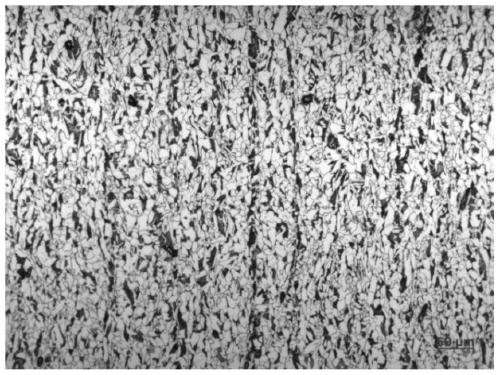

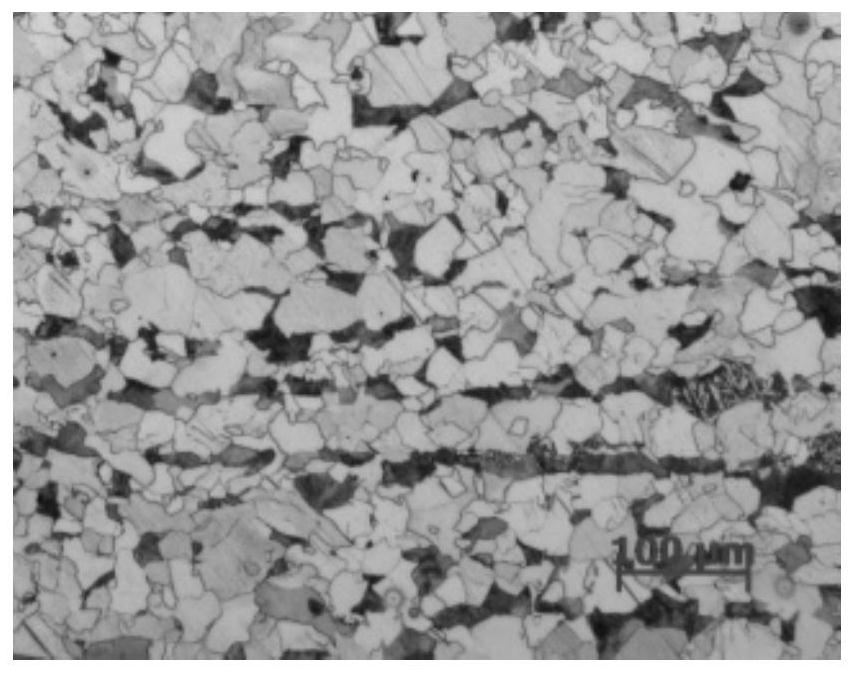

The invention relates to a preparation method of 80-100mm extra-thick EH36 steel for offshore wind power. The preparation method comprises the following steps of: converter processing-LF refining-RH vacuum degassing-Ca treatment-continuous casting-casting blank hydrogen diffusion-heating-normalizing rolling-air cooling-steel plate stacking and slow cooling- unstacking, wherein the normalizing rolling adopts two stages of rough rolling and finish rolling; the initial rolling temperature of the rough rolling is 1050-1100 DEG C, the single-pass reduction rate of three passes after the rough rolling is greater than or equal to 15%, and the cumulative reduction rate in the rough rolling stage is greater than or equal to 50%; and the initial rolling temperature of the finish rolling is 860-890 DEG C, the austenite non-recrystallization interval is expanded by adding sufficient Nb, the initial rolling temperature of the finish rolling is above the austenite ferrite equilibrium transformationpoint Ac3, the total rolling pass is 8-12, air cooling is carried out after rolling, Nb is separated out in the steel plate in the air cooling process, and the triangular grain boundary, the grain boundary and the grain interior of ferrite grains are pinned to limit the rapid growth of the ferrite. Therefore, the normalized and rolled EH36 steel plate for offshore wind power is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Lamp for textile workshop

ActiveCN110608425ALower the heatExtended service lifeLighting applicationsLighting heating/cooling arrangementsPositive pressureBoiling point

The invention discloses a lamp for a textile workshop. The lamp for the textile workshop comprises a lampshade and a bulb connected to the inner top of the lampshade in a threaded manner. Two first gas cavities are formed in the opposite side walls of the lampshade. The inner wall of the lampshade is provided with a first annular groove. The first gas cavities are internally provided with a drivedevice for cleaning the surface of the bulb. A fixing device for mounting and fixing the bulb is arranged in the first annular groove. Low-boiling point evaporation liquid in a liquid storage cylindergenerates steam when being heated, a second piston is made to move upward, a first piston is made to move upward, so that the inside of the first gas cavity on the left side is at the negative pressure, the inside of the first gas cavity on the right side is at the positive pressure, a first one-way valve and a second one-way valve are opened at the same time, dust on the bulb is cleaned and recycled, a bimetal sheet in a heat absorption box is heated and bent to enable a third piston to move downwards, so that hot gas in the lampshade is sucked d into the heat absorption box, hot gas is discharged through the first one-way valve of the first gas cavity communicating with the heat absorption box, and moisture on the bulb is evaporated.

Owner:浏阳市恒信包装印刷有限公司

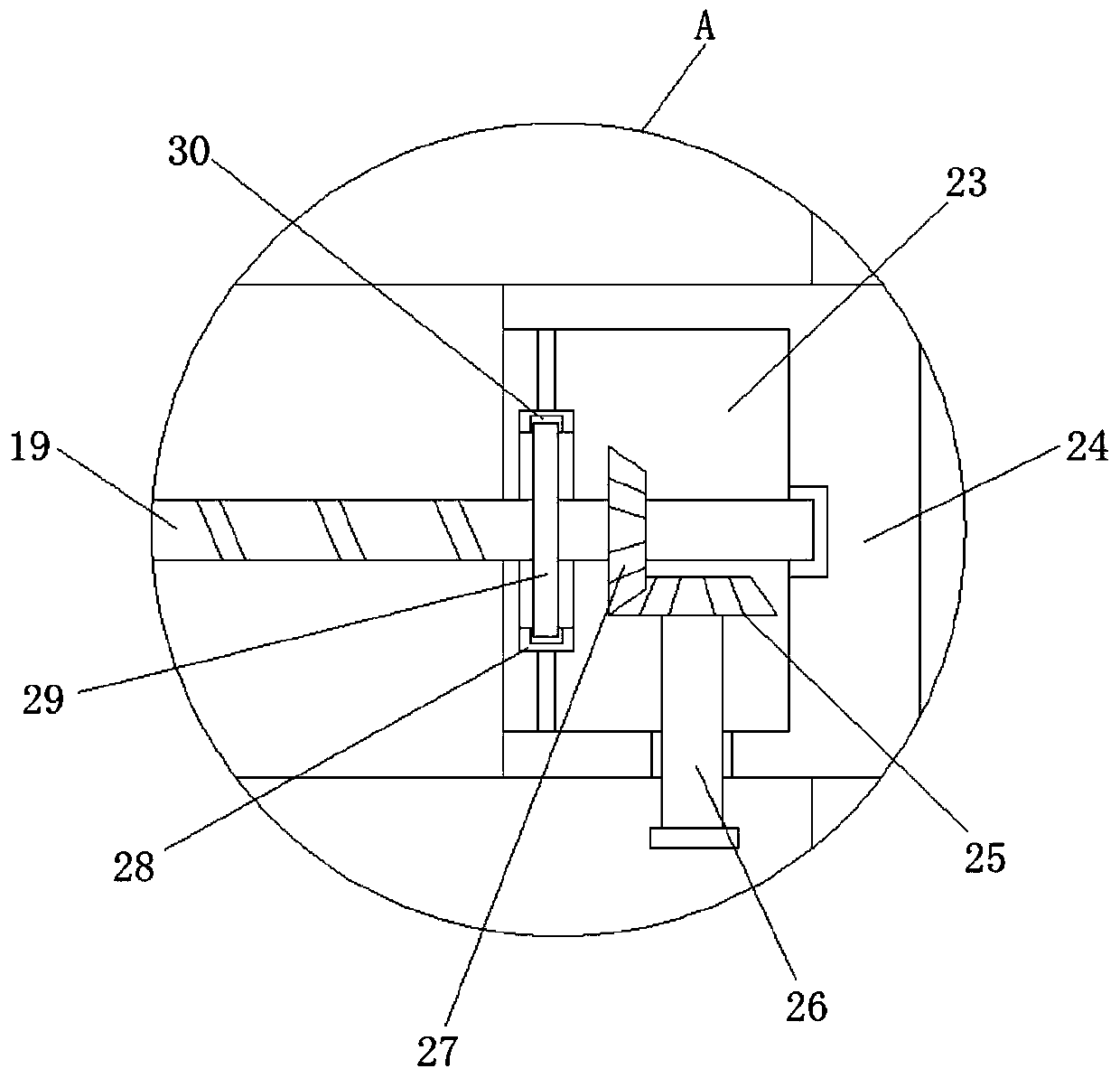

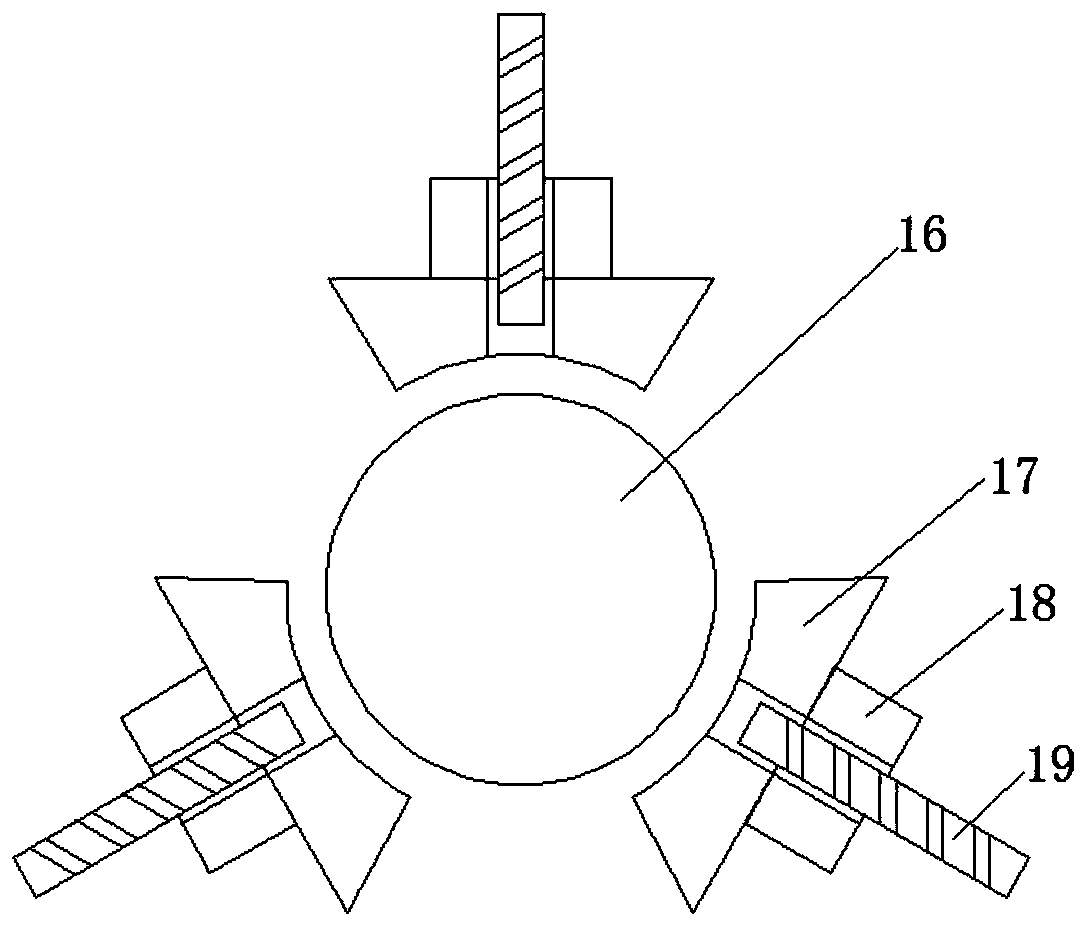

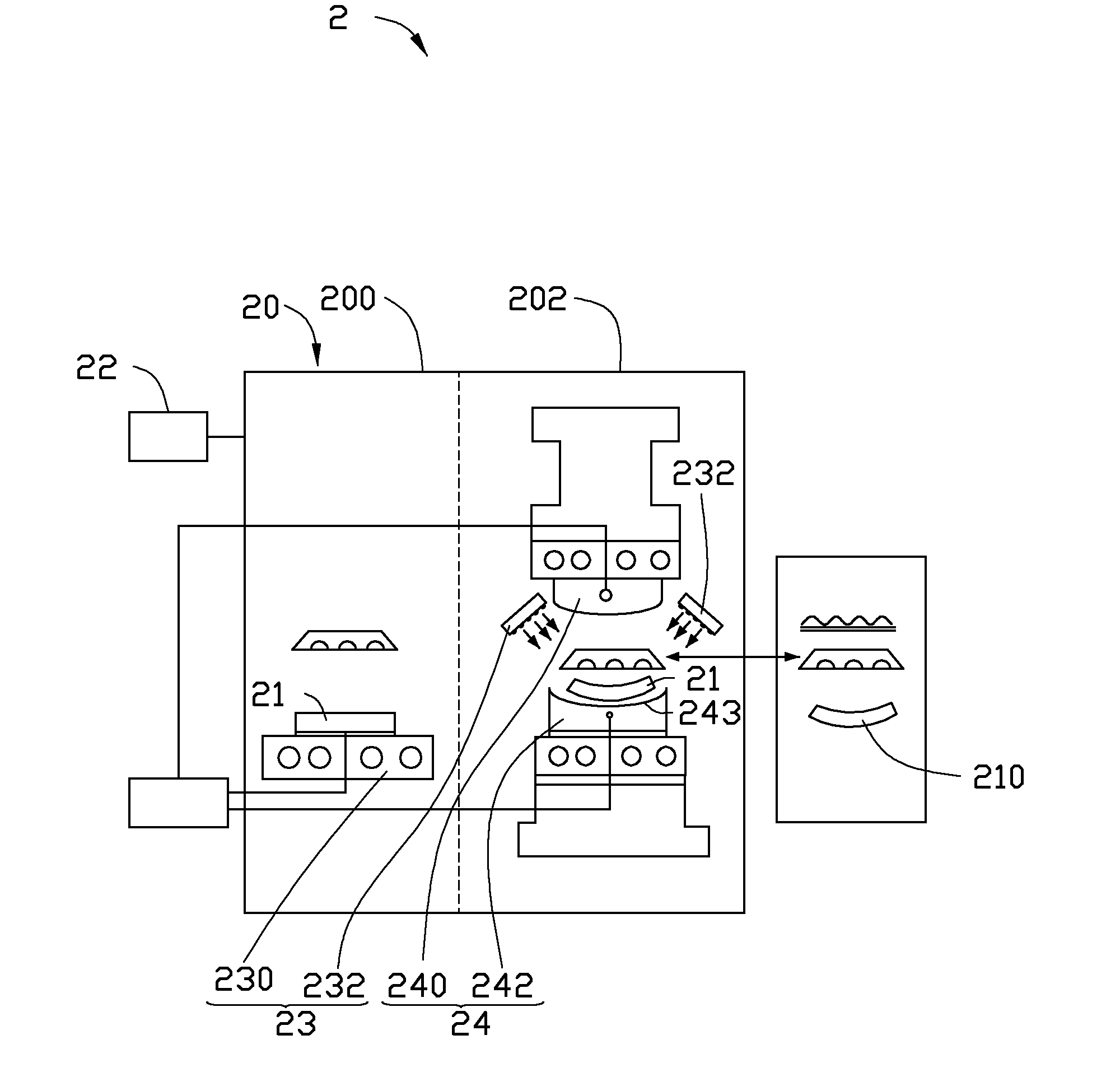

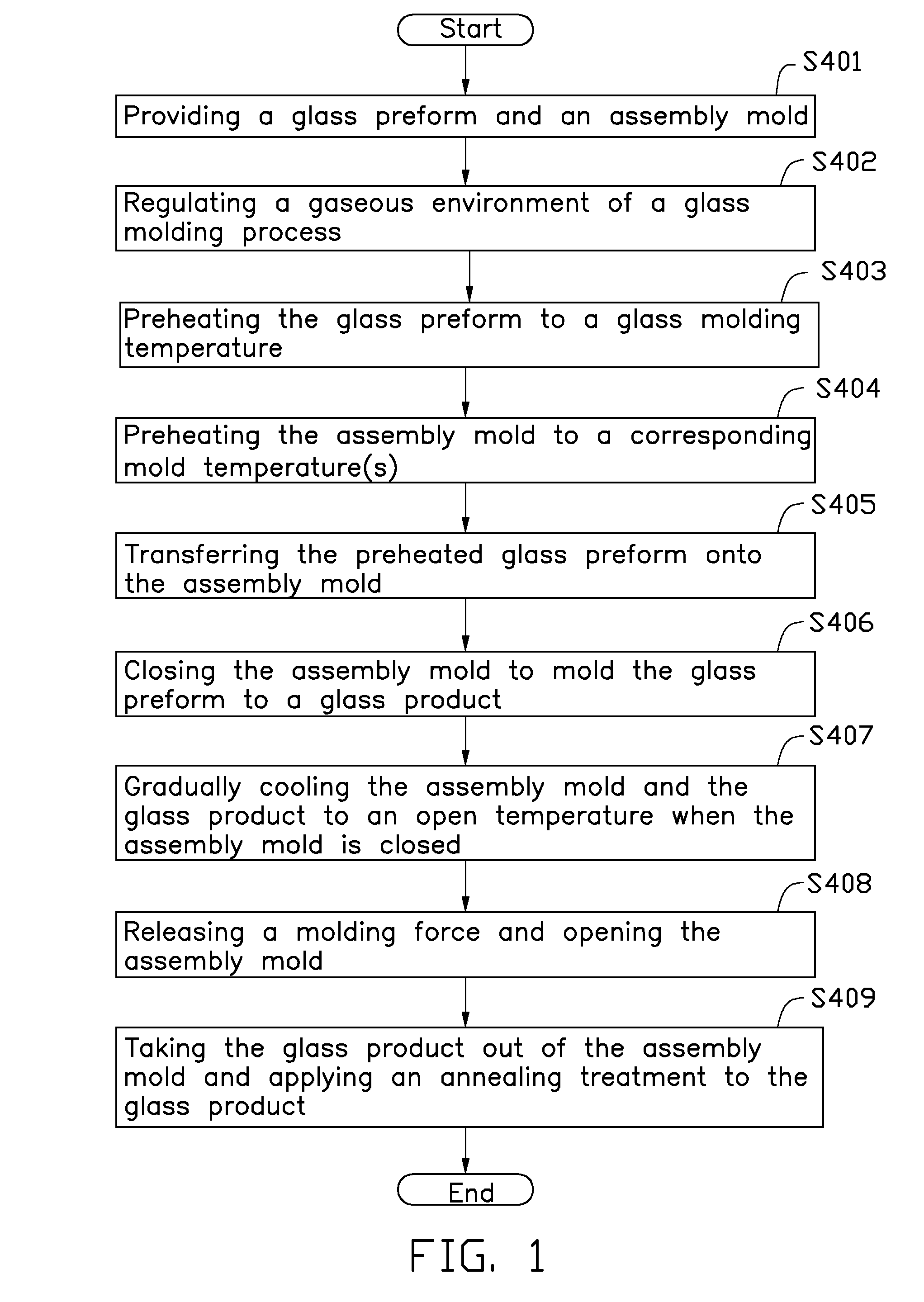

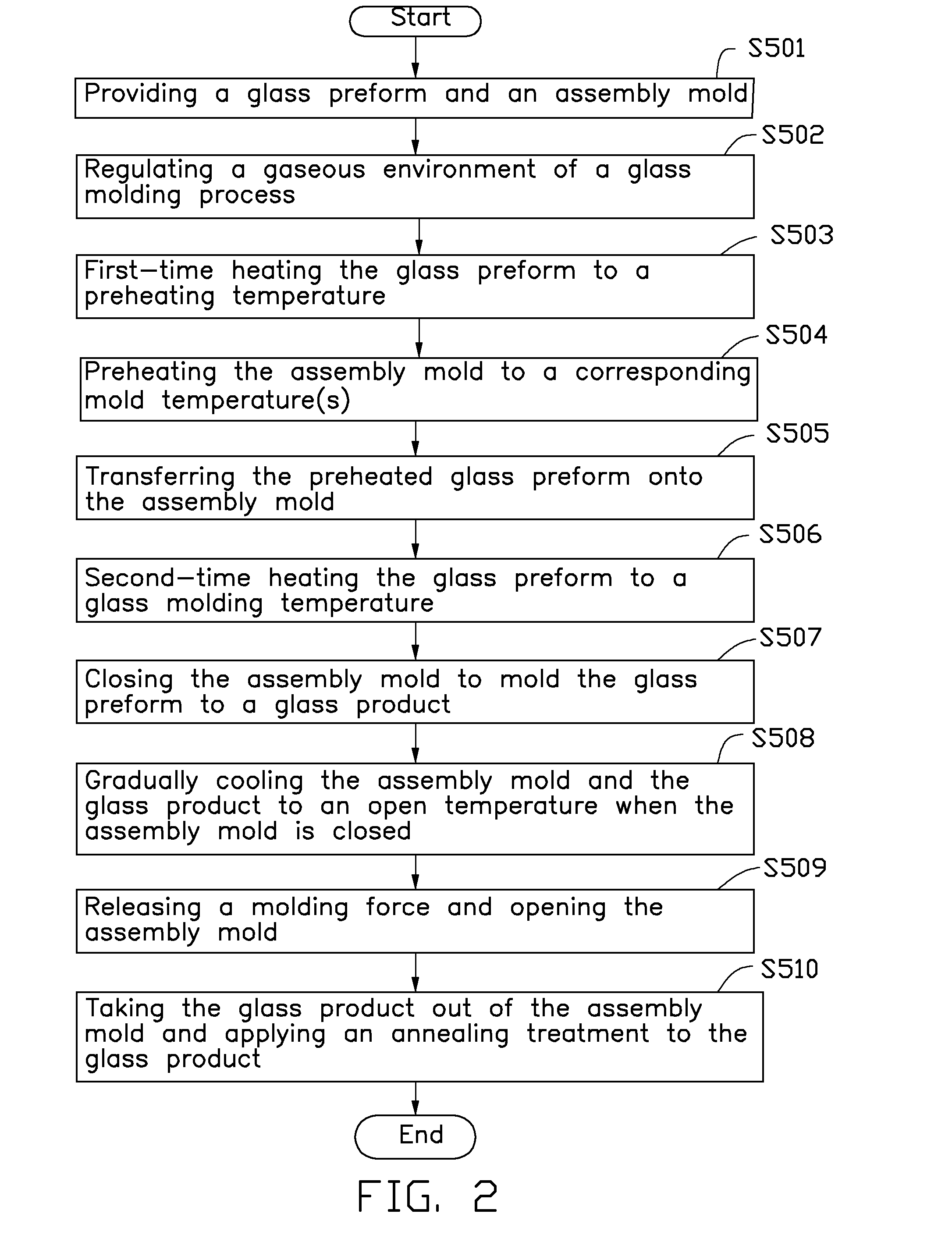

Glass molding method and glass molding device used in the method

InactiveUS20150107305A1Quality improvementLow efficiencyGlass furnace apparatusGlass transportation apparatusShell moldingMaterials science

A glass molding method for molding a glass preform to a glass product via an assembly mold includes the following steps. The glass preform is preheated to a glass molding temperature. The assembly mold is heated to a predetermined mold temperature lower than the glass molding temperature and maintained at the mold temperature. The preheated glass preform is transferred to the assembly mold. The assembly mold is closed together for molding the glass preform to the glass product. The glass product and the assembly mold are gradually cooled to an open temperature. Then the assembly mold is opened to take the glass product out of the assembly mold.

Owner:WEIS LTD

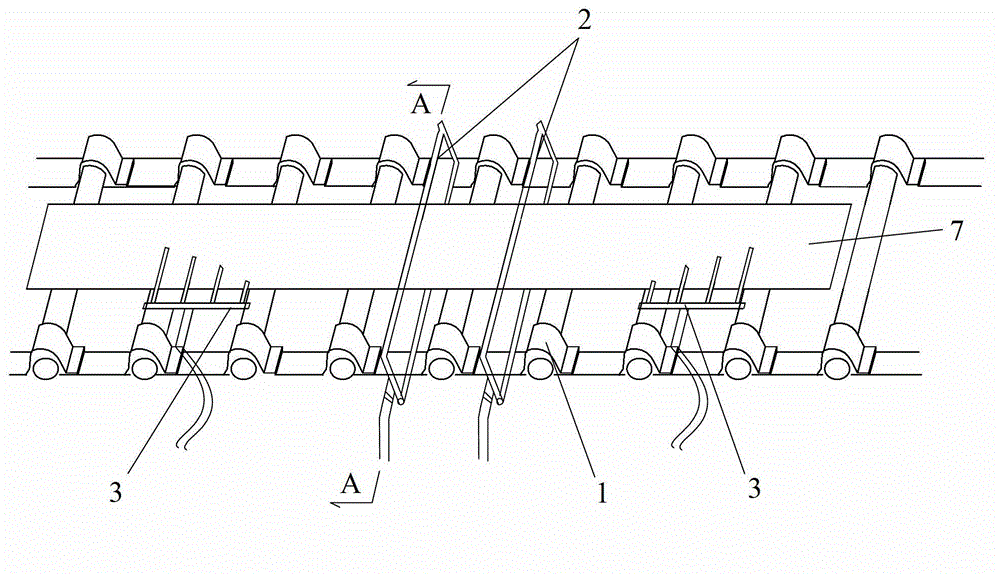

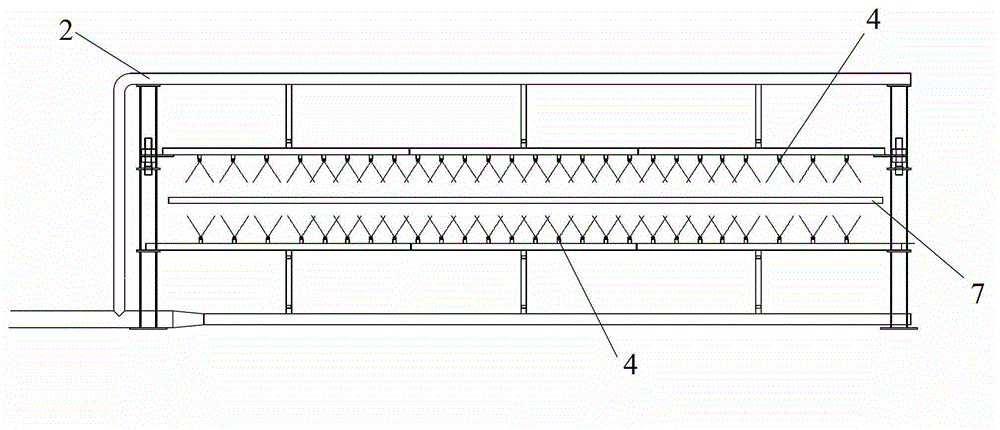

Method and cooling system for improving comprehensive mechanical property of normalized steel plate

ActiveCN102912091AImprove comprehensive mechanical propertiesAvoid austenite grain growthFurnace typesHeat treatment process controlThermal insulationSteel plates

The invention discloses a method for improving the comprehensive mechanical property of a normalized steel plate. The running time of the steel plate in a heating region in a normalizing furnace is reasonably prolonged and the running time of the steel plate in a thermal insulation region in the normalizing furnace is reasonably shortened, so that the austenite grain growth is avoided to provide favorable conditions for subsequent accelerated cooling. The steel plate is quickly cooled to be 600-700 DEG C from the normalizing temperature in a way of normalizing, atomizing and cooling, so that the mist cooling with higher heat exchange efficiency increases the supercooling degree of the structural transformation of the steel plate and effectively prevents the austenite grain growth; and grains are refined, so that the effect of improving the strength by structure refinement in the heat treatment process of the steel plate is given full play. The invention further provides a cooling system for improving the comprehensive mechanical property of the normalized steel plate. Therefore, the equipment is simple, the investment is low, the surface quality of the steel plate can be improved, and the practicality is better.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

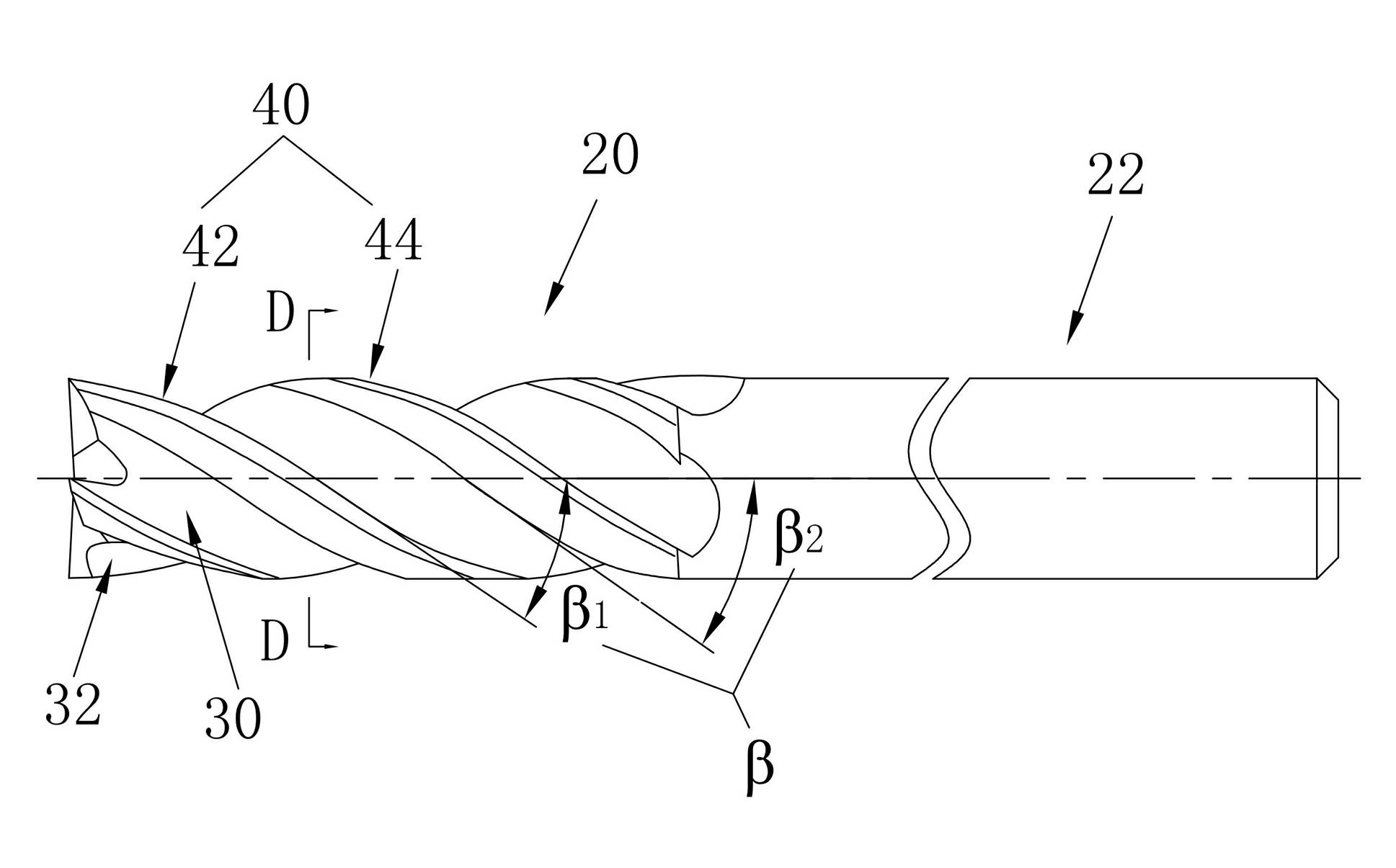

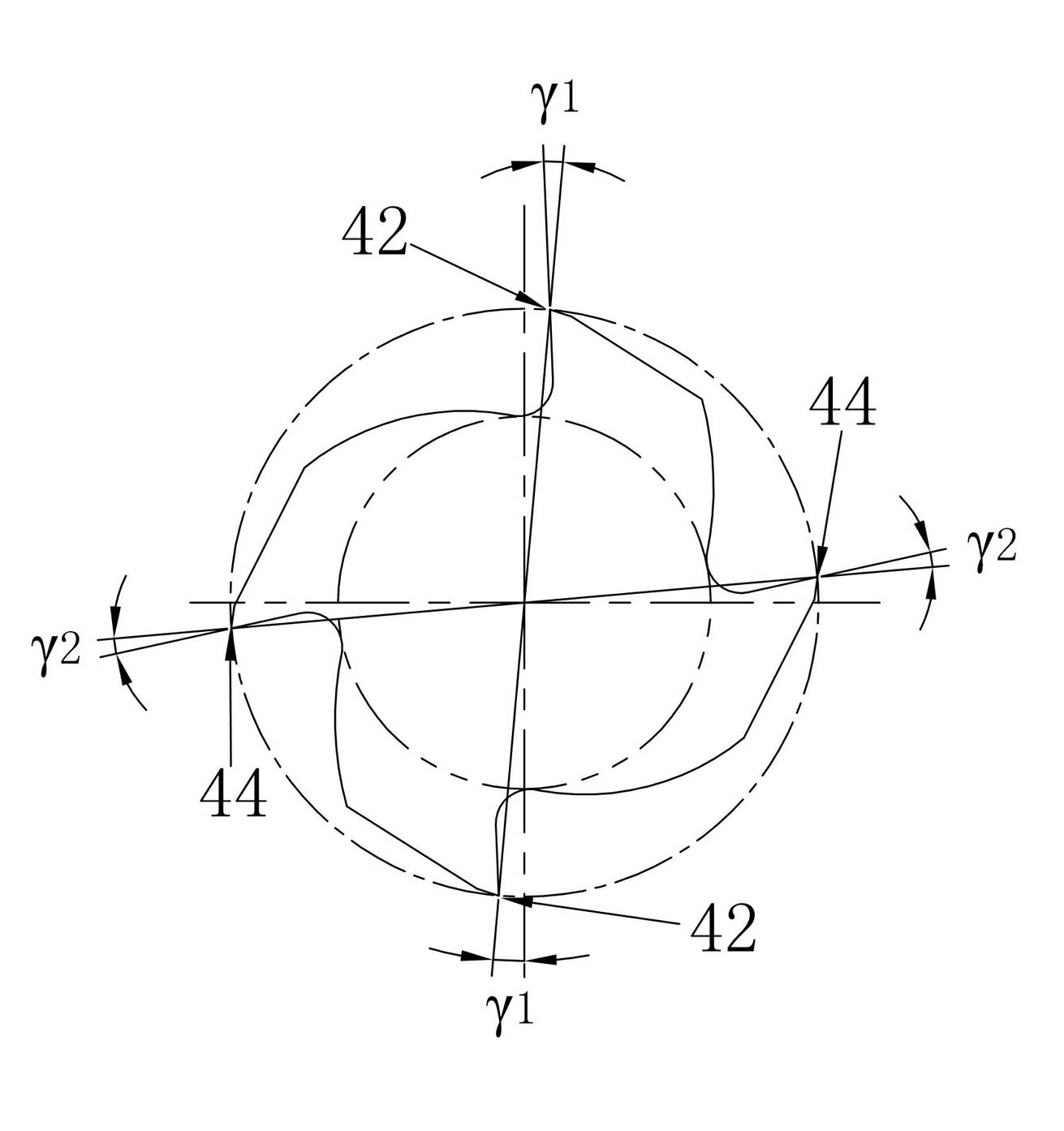

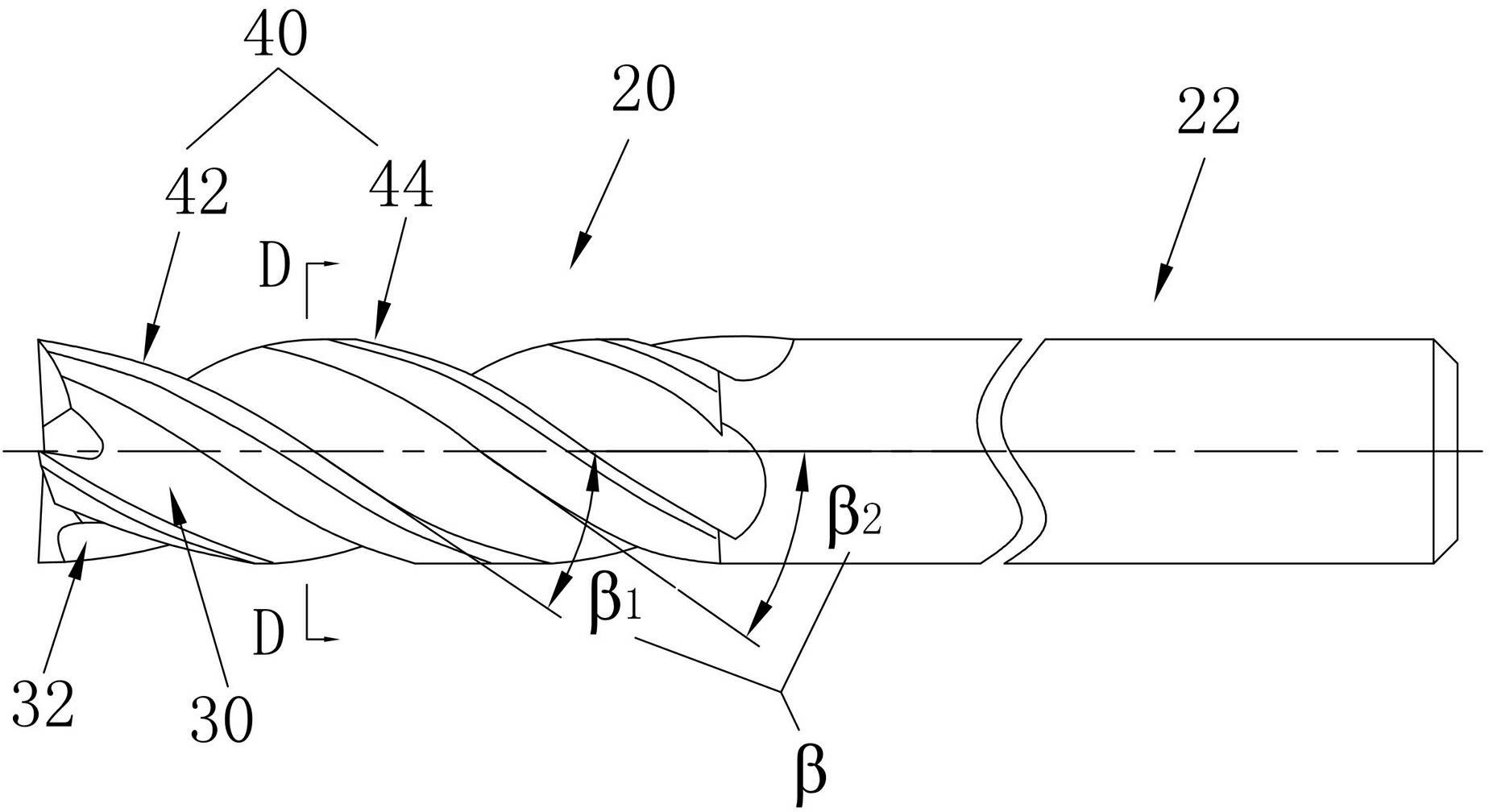

End milling cutter with equal actual rake angles and unequal spiral angles

The invention discloses an end milling cutter with equal actual rake angles and unequal spiral angles. The end milling cutter comprises a cutting part and a handle part, wherein the whole cutting part is provided with a plurality of chip removal grooves which spirally extend from the bottom end to the handle part; the surfaces, which face the cutting rotation direction, of the chip removal grooves are front cutter surfaces; the front cutter surfaces are intersected with the peripheral surface of the cutting part to form peripheral blades; the spiral angle beta of at least one peripheral bladeis different from that of other peripheral blades; the radial rake angle gamma of at least one peripheral blade is different from that of other peripheral blades; and the actual rake angles gamma n of the peripheral blades are equal and accord with a formula: sine gamma n is equal to the sum of sine 2beta and cosine 2beta sine gamma. The end milling cutter with equal actual rake angles and unequal spiral angles can inhibit vibration during milling and improve milling stability and the collapse-resistant and wear-resistant comprehensive properties of the peripheral blades, so that the processing efficiency of the cutter is improved, and the service life of the cutter is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

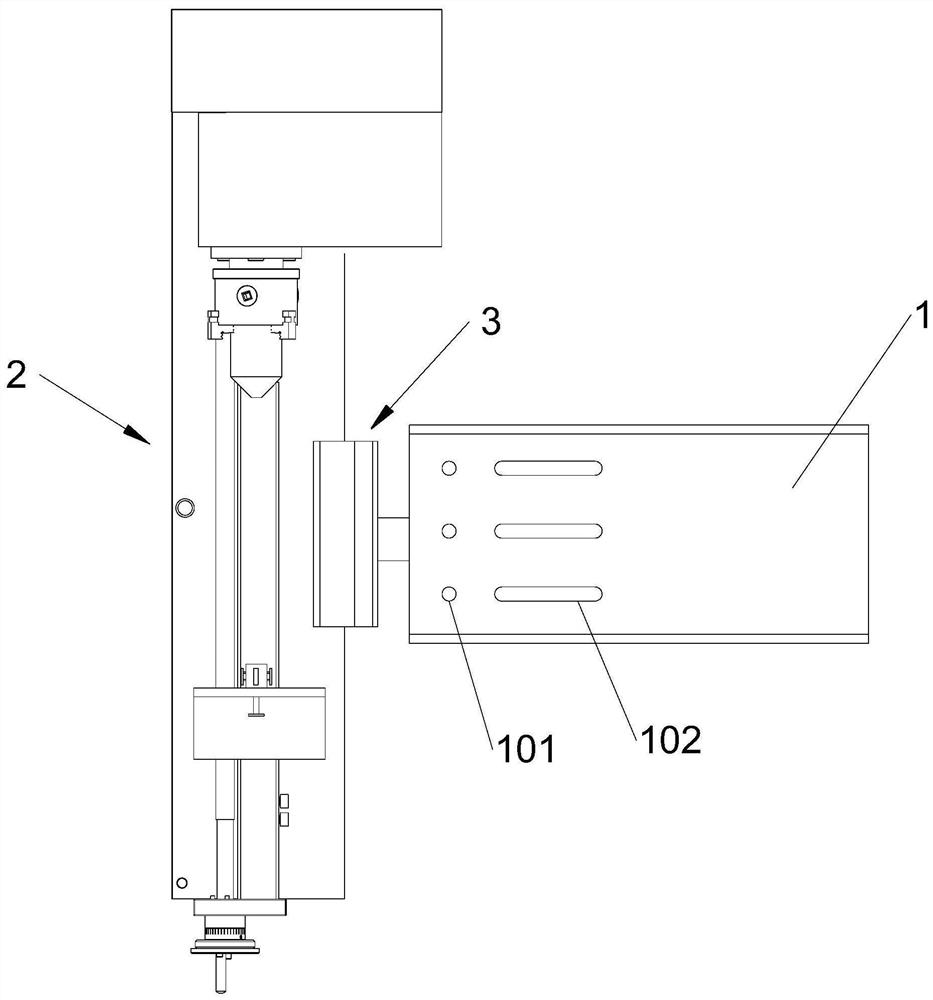

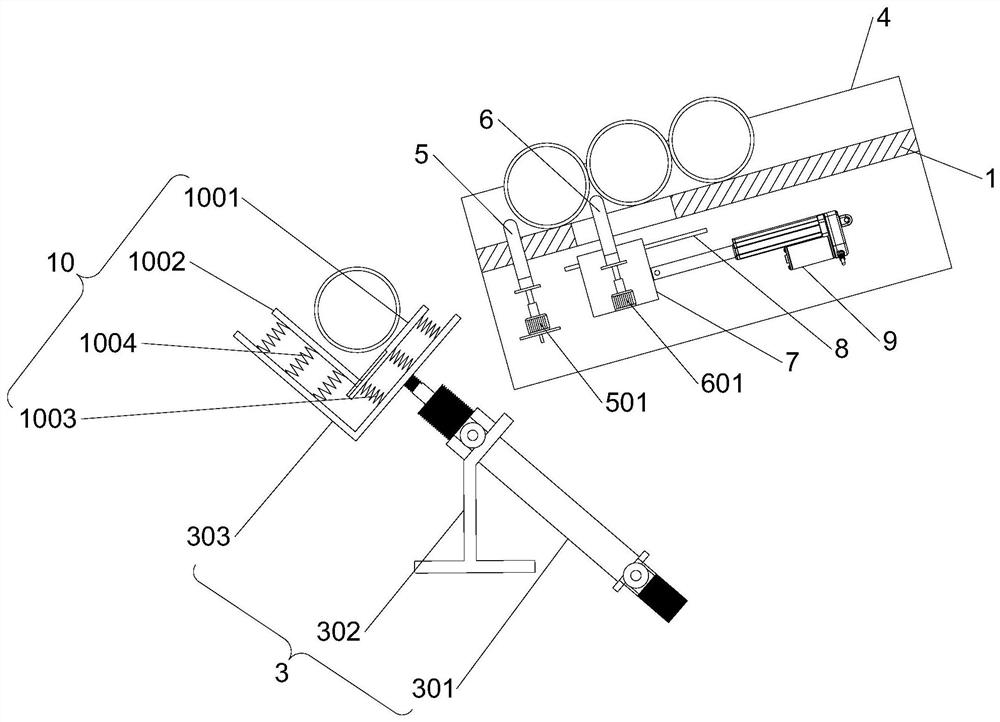

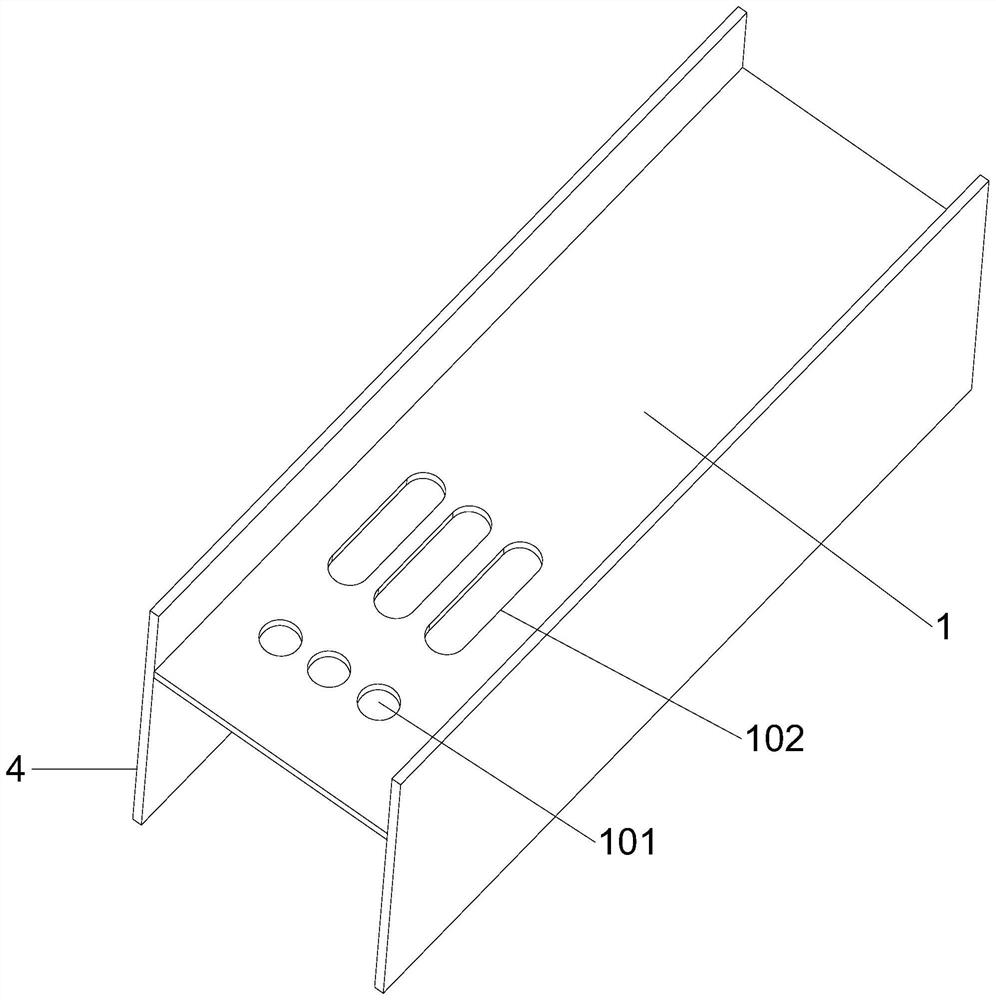

Auxiliary device for steel pipe machining

PendingCN113020640AAct as a barrierAchieving hindranceExpansion mandrelsChucksClassical mechanicsMachining

The invention discloses an auxiliary device for steel pipe machining, and relates to the technical field of auxiliary devices for steel pipe machining. The auxiliary device comprises a clamping tool and a conveying plate which are arranged side by side, the conveying plate inclines downwards in the direction close to the clamping tool, side protection plates are arranged on the two sides of the conveying plate, a through hole is formed in the lower end of the conveying plate in a penetrating mode, a first limiting rod capable of moving in a lifting mode is arranged in the through hole in a penetrating mode, a sliding groove is further formed in the conveying plate in a penetrating mode, a second limiting rod capable of moving in a lifting mode is arranged in the sliding groove in a penetrating mode, a fixing box is arranged at the lower end of the second limiting rod, a power assembly used for pushing the fixing box to move in the direction of the sliding groove is arranged on the outer wall of the fixing box, and a transferring assembly is further arranged between the clamping tool and the conveying plate. The auxiliary device has the advantages that steel pipes with different pipe diameters can be conveyed and discharged, it is guaranteed that one steel pipe is discharged at a time, the steel pipe carrying time is shortened, the clamping and fixing time of adjacent steel pipes is shortened, and the working efficiency is improved.

Owner:山西兴达通机电设备有限公司

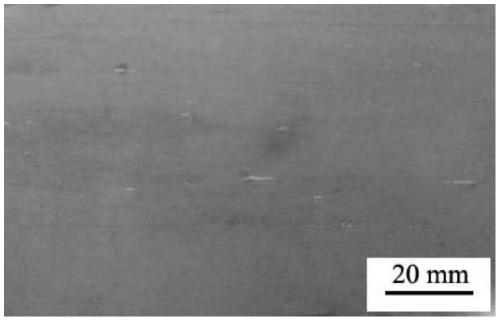

100 mm-120 mm Q460D extra-thick high-strength steel and preparation method thereof

ActiveCN113249641AReduce production pressureImprove efficiencyFurnace typesHeat treatment furnacesChemical compositionDehydrogenation

The invention relates to 100 mm-120 mm Q460D extra-thick high-strength steel which comprises the following chemical components including, by mass, 0.10% to 0.13% of C, 0.30% to 0.50% of Si, 1.40% to 1.60% of Mn, less than or equal to 0.0070% of P, less than or equal to 0.0020% of S, 0.020% to 0.050% of Nb, 0.008% to 0.020% of Ti, 0.020% to 0.040% of Al, 0.10% to 0.20% of Cu, 0.10% to 0.20% of Cr, 0.10% to 0.20% of Ni and the balance Fe and inevitable impurity elements. The production process flow comprises the following steps of converter smelting, LF refining, RH vacuum degassing, Ca treatment, continuous casting, casting blank dehydrogenation treatment, heating, normalizing rolling, air cooling, steel plate stacking and slow cooling and unstacking. The yield strength of a steel plate ranges from 430 MPa to 470 MPa, the tensile strength ranges from 550 MPa to 570 MPa, the ductility is larger than or equal to 20%, and the Charpy impact energy at the 1 / 4 position and the 1 / 2 position of the thickness of -20 DEG C is larger than or equal to 200 J. The flaw detection result meets the ASTM A 578C level requirement, and the surface of the steel plate has no defect.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Control method for hot rolled SPA-H strip steel surface spot-like peeling defects

InactiveCN110306115AImprove surface qualitySolve the problem of surface point warping defectsWork cooling devicesWork heating devicesChemical compositionStrip steel

The invention discloses a control method for hot rolled SPA-H strip steel surface spot-like peeling defects. The control method sequentially comprises the following steps of S1, molten iron KR desulfurization; S2, converter smelting; S3, LF refining, and controlling the mass percentages of chemical components in molten steel at the end of LF refining; S4, slab continuous casting and controlling the superheat degree of molten steel in a tundish to be 20-30 DEG C with the continuous casting and drawing speed of 1.0-1.2m / min; S5, heating in a heating furnace and placing a continuous casting slabin a heating furnace for heating treatment with the steel loading temperature of the heating furnace not higher than 600 DEG C; S6, primary descaling; S7, roughing; S8, secondary descaling; S9, finishrolling; S10, laminar cooling; and S11, coiling. The control method has the advantages that under the condition of not improving existing equipment and not changing the production flow, the problem of spot-like peeling defects on the surface of hot rolled SPA-H strip steel is effectively solved by using the existing equipment, and the yield is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

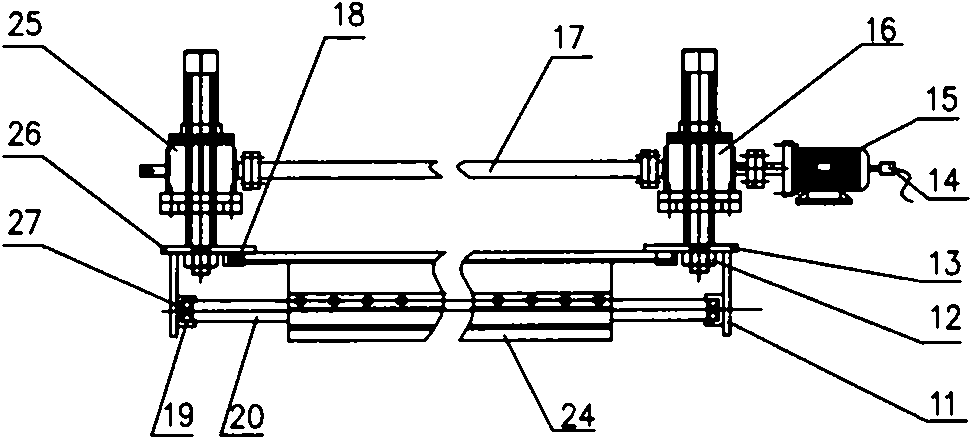

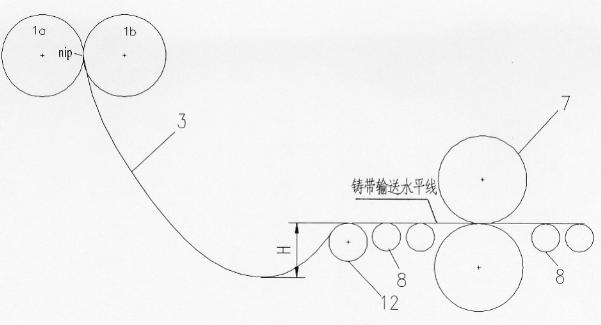

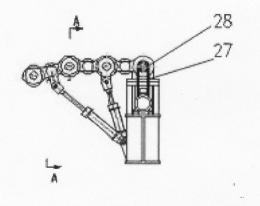

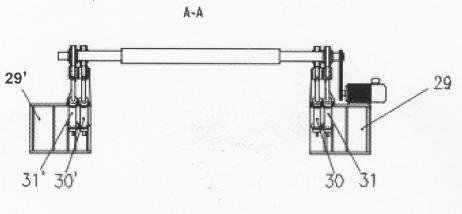

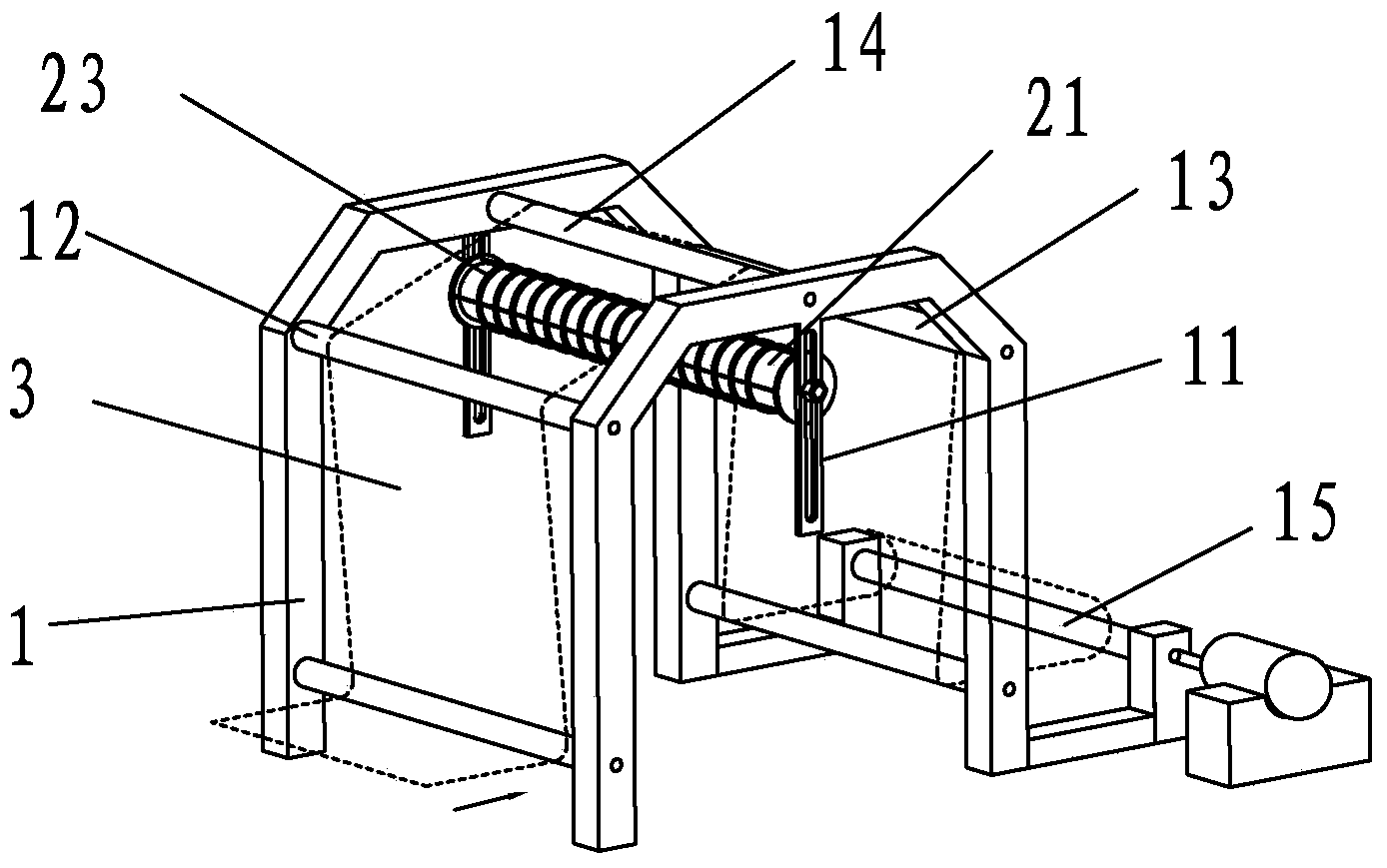

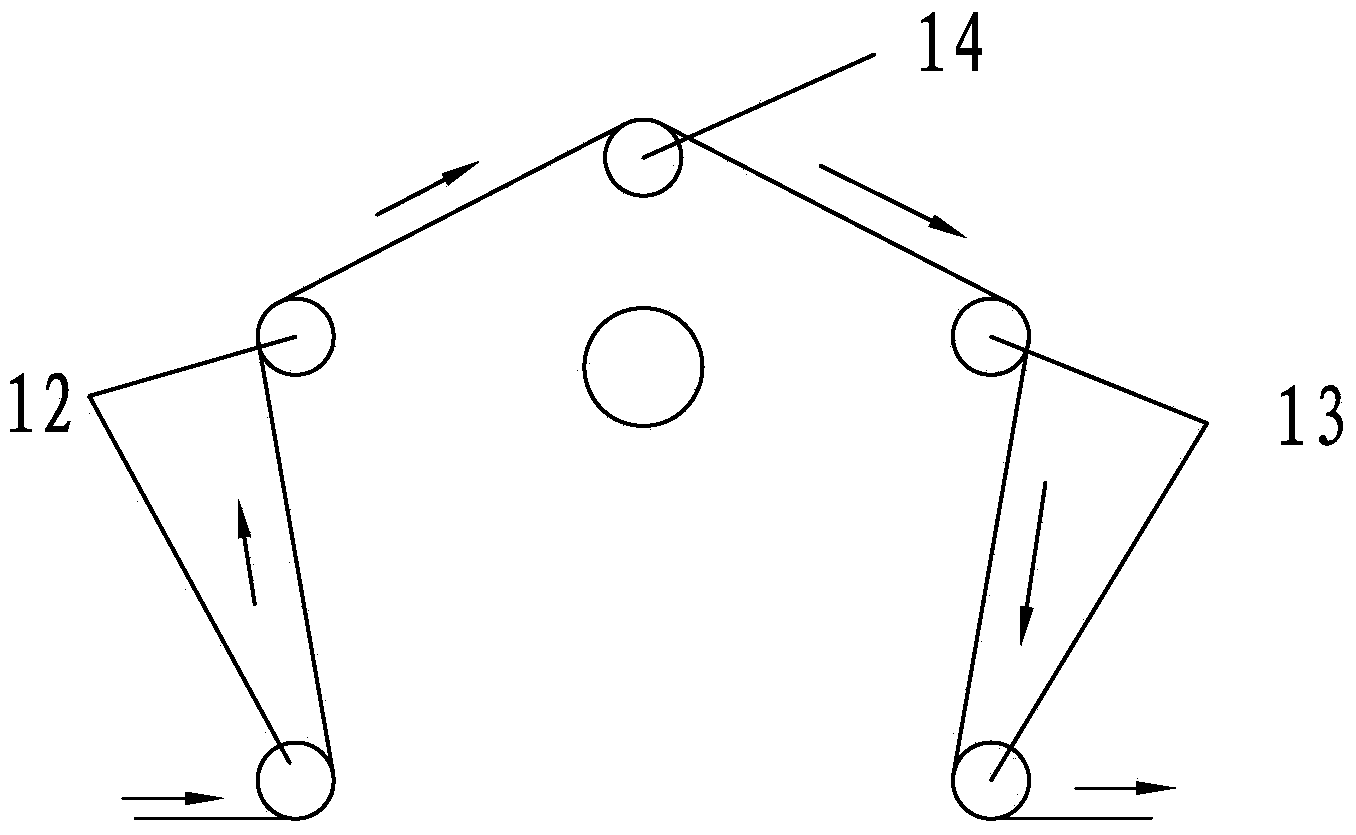

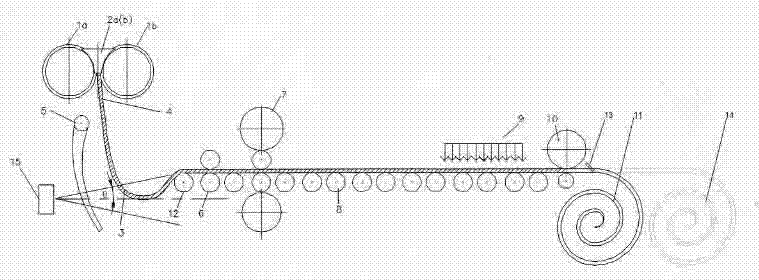

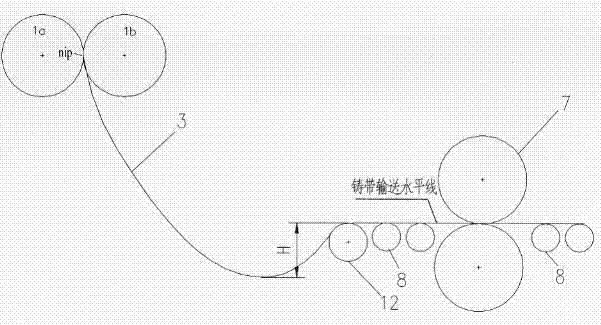

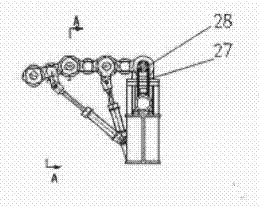

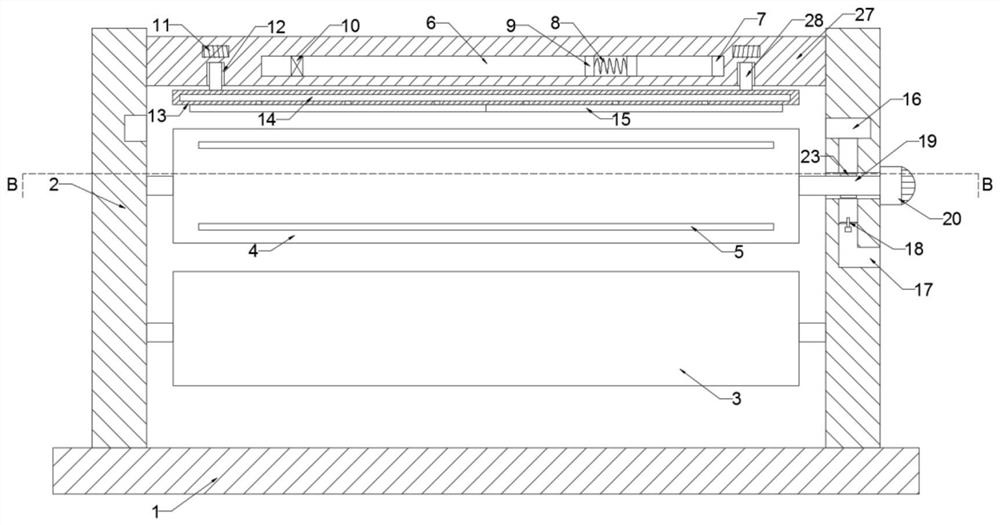

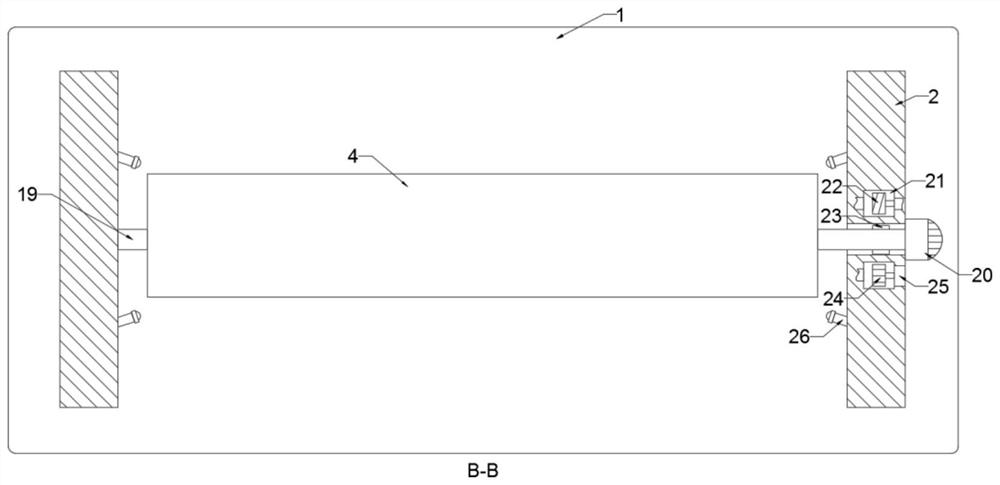

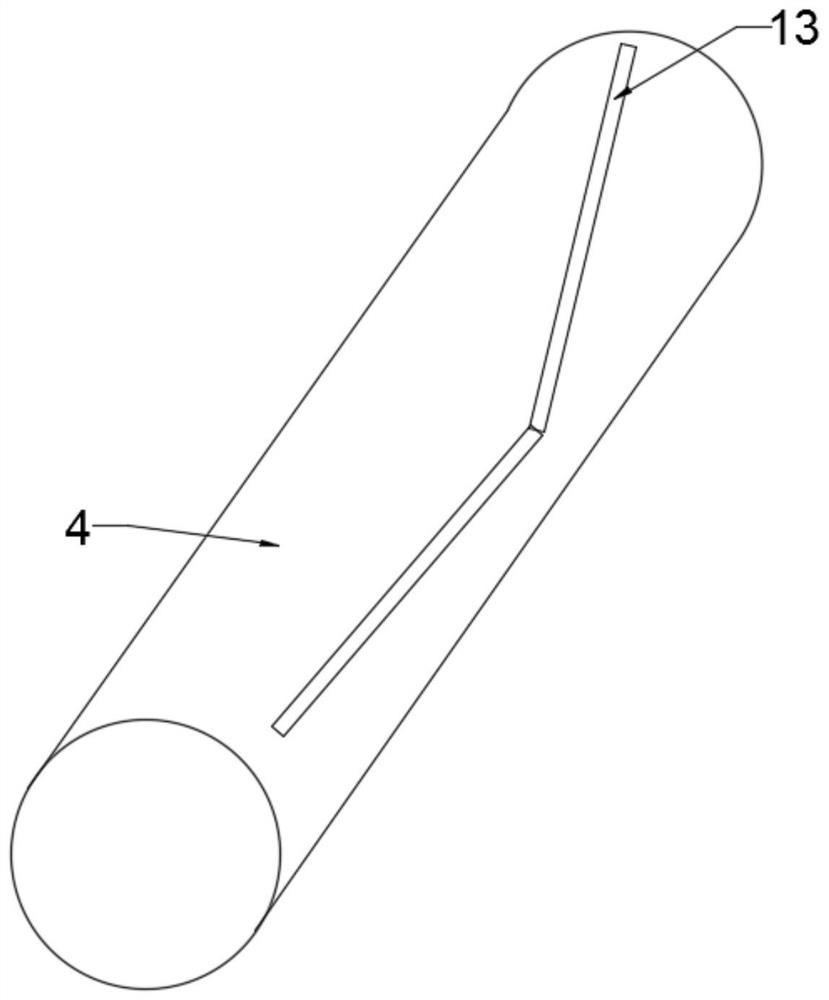

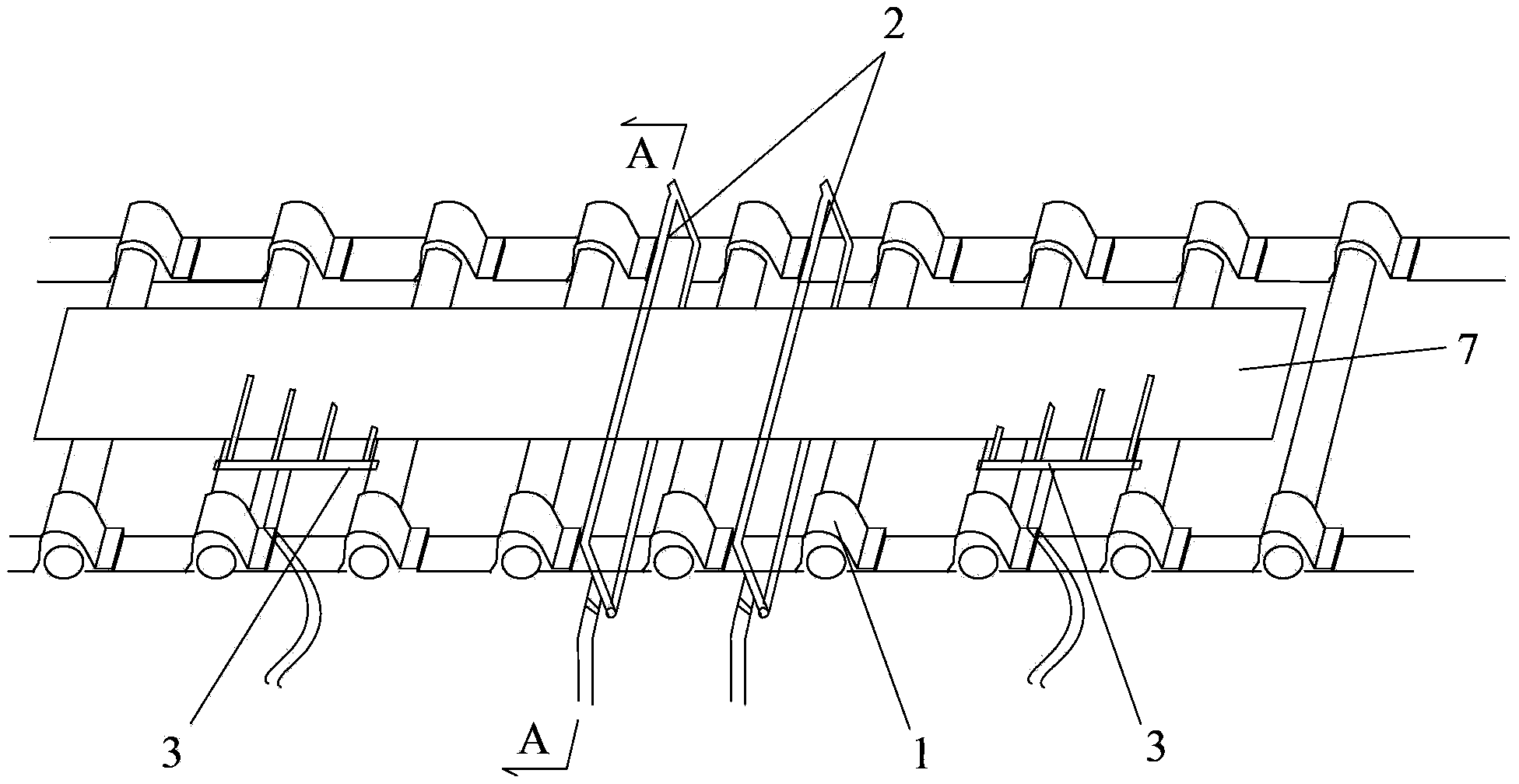

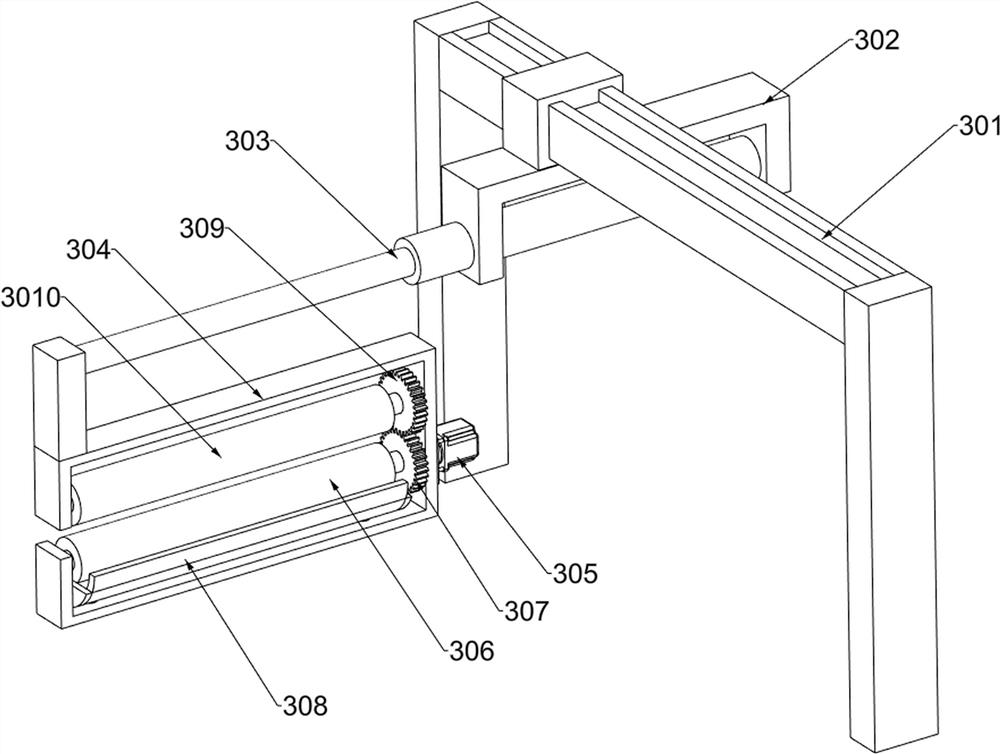

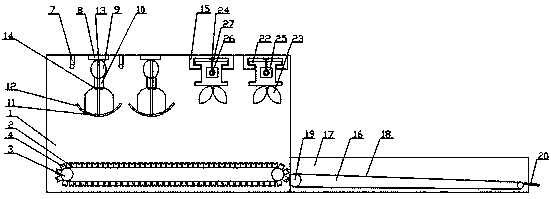

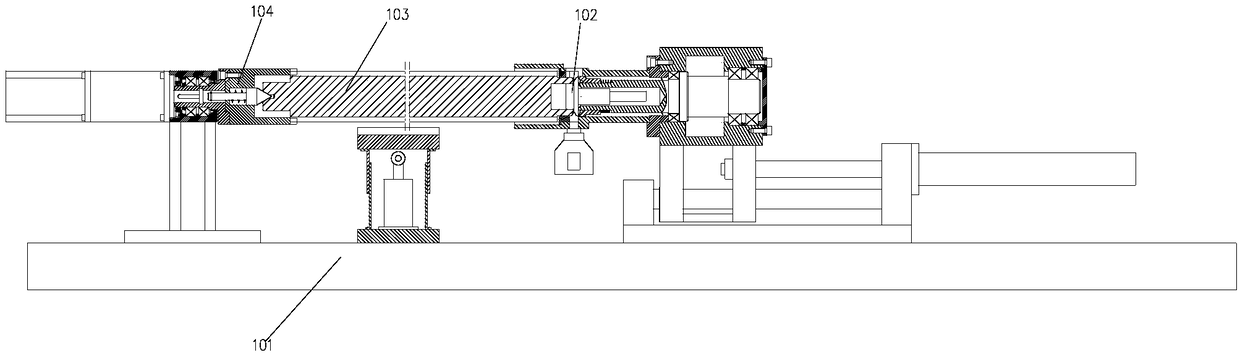

Position control device and control method for free loop of thin strip continuous casting strip steel

The invention relates to a position control device and a position control method for a free loop of thin strip continuous casting strip steel. A driving guide roller is fixed on a base through a bearing seat; a chain wheel is arranged at one end of the driving guide roller and is connected with a driving motor through a transmission chain; two groups of first rocker arms are arranged at two ends of the driving guide roller; one side of each first rocker arm is connected with the driving guide roller, and the other side of each first rocker arm is connected with a driven guide roller; the first rocker arms vertically swing around the driving guide roller under the drive of hydraulic cylinders; a driven guide roller is fixed on the first rocker arms and connected with second rocker arms; the second rocker arms vertically swing around the driven guide roller under the drive of hydraulic cylinders; and a plurality of driven guide rollers are arranged on the second rocker arms. The device and the method are suitable for detecting and controlling the free loop of the casting strip steel; and a detecting instrument detects the position of a casting strip on a guide roller way, and the curvature of a guide profile of the casting strip is adjusted simultaneously, so that the curved shape of the guide profile is consistent with that of the casting strip, and the casting strip is attached to a guide device and walks stably.

Owner:BAOSTEEL ENG & TECH GRP +1

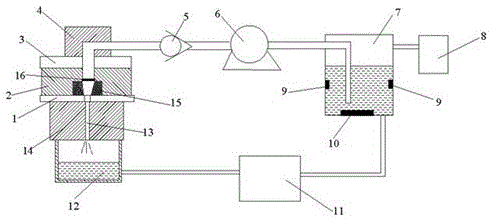

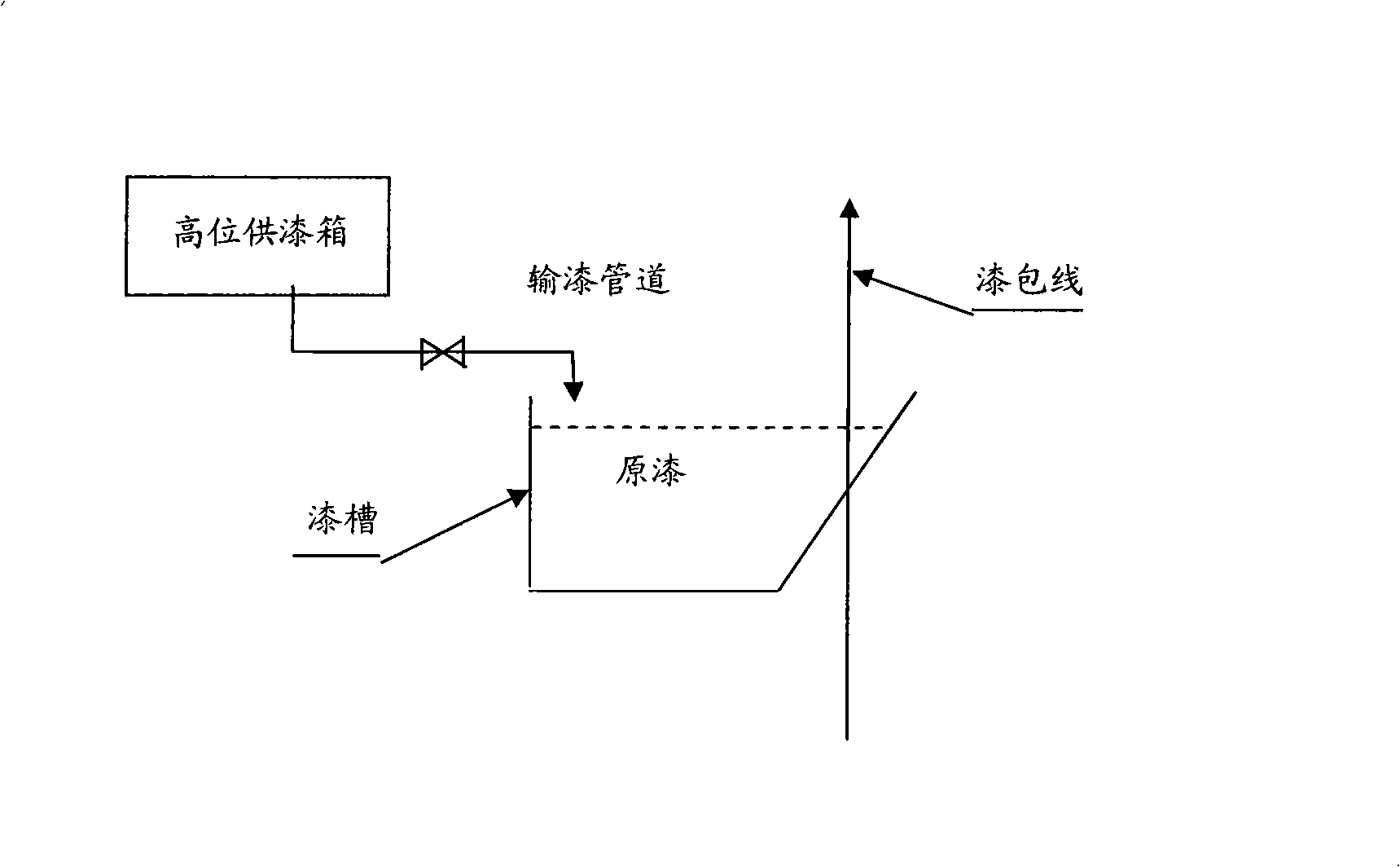

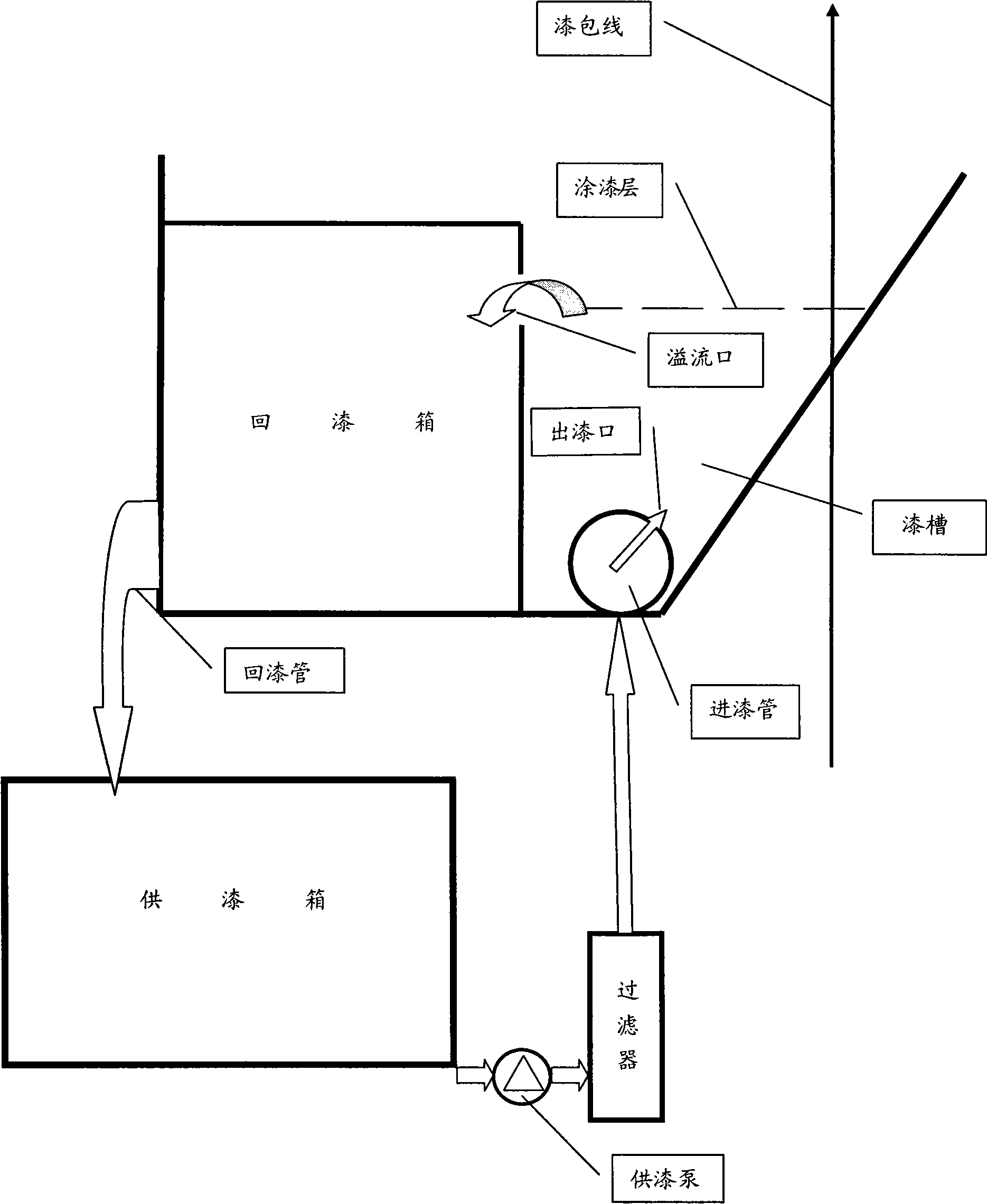

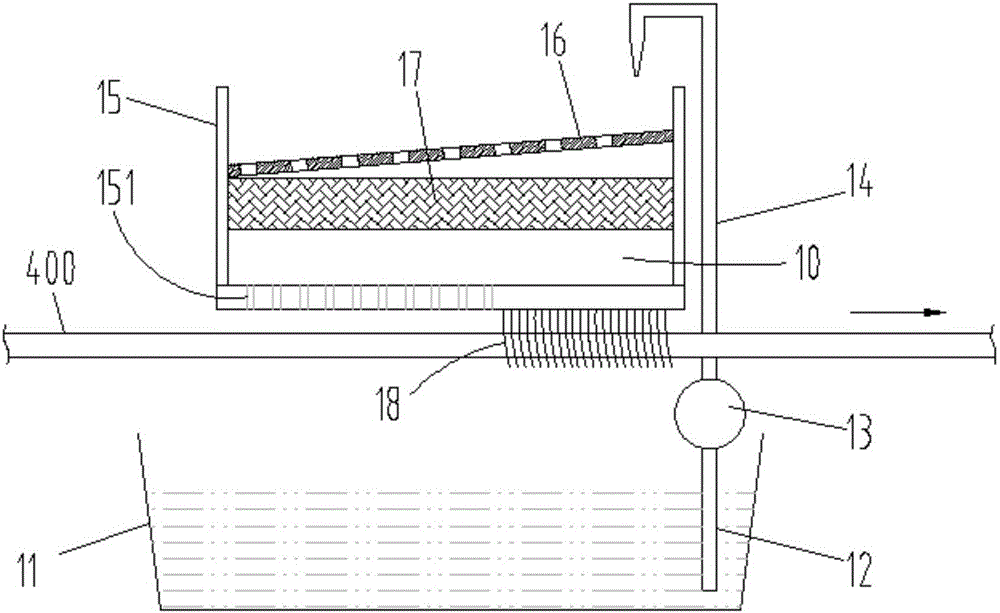

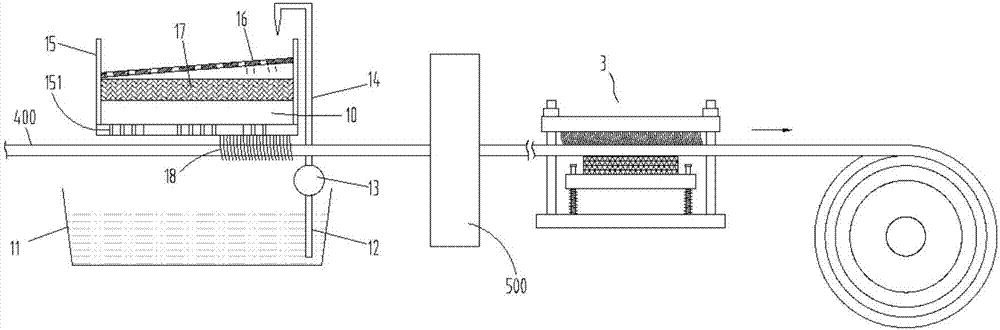

Method and apparatus for cleanness continuously supplying paint to varnished wire painting groove

InactiveCN101299360AUniform viscosity distributionLow variabilityInsulating conductors/cablesLacquerEvaporation

The invention provides a continuous cleaning paint supply method of the enameled wire paint groove, wherein a paint supply case is provided. The original paint is continuously pressed into a filter through a paint supply pump. Two sets of pipe filters are provided at the outside of the paint supply pump. The compound filtering is performed through using a melting spray filter core, so that the original paint is transmitted to paint intake pipes after being filtered. The original paint flows into a paint groove evenly from a paint outlet arranged axially of the paint intake pipes. A paint return chamber is arranged on one side of the paint groove. An overflow port is arranged above a baffle plate arranged between the paint return chamber and the paint groove. When the height of the paint is higher than the overflow port, the original paint flows into the paint return chamber from the overflow port and then returns to the paint supply case through the paint return pipe, which completes a primary circulation. Since the paint intake pipes are arranged along the length direction at the bottom of the paint groove, the original paint flows into the paint return chamber along the length direction of the paint return chamber. Thus, the viscosity of the original paint in the paint groove keeps in line. The paint return chamber is made of steel plate, connected with the paint supply case through the paint return chamber, without exposing the return paint in the air, thereby reducing the evaporation of the original paint for more than1 / 2. When reflowing, the original paint on the coating layer turns over the overflow port, and carries the paint with impurity into the paint return chamber, enters the paint intake pipe again through the paint supply pump and the filter from the paint supply case, which ensures the cleaness of the original paint and increase the quality of the paint surface.

Owner:NANXIANG GROUP

Acid pickling process for TC4 titanium alloy sheet strip

The invention discloses an acid pickling process for a TC4 titanium alloy sheet strip and belongs to the field of a surface treatment process of metals. The acid pickling process comprises the following steps of: firstly, annealing the TC4 titanium alloy sheet strip; subsequently implementing shot blasting treatment on the plate strip, afterwards washing the shot-blasted plate strip and then implementing acid pickling on the plate strip in an acid tank, wherein the acid in the acid tank is mixed acid of HNO3 and HF; and finally washing the acid-pickled plate strip by using clean water and drying the plate strip by using a drier. According to the acid pickling process disclosed by the invention, by implementing annealing and shot blasting treatment on the TC4 titanium alloy plate strip, theoxide skin on the surface of the TC4 titanium alloy plate strip is crushed to form a rough surface; in a subsequent acid pickling process, the incompact oxide skin can have full contact reaction withacid pickling liquid, thus the reaction efficiency is improved, and whether the reaction is ended or not can be judged quite simply, so excessive acid pickling is prevented, the surface quality of the plate strip is not affected, and finally the surface smoothness of the plate strip is improved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

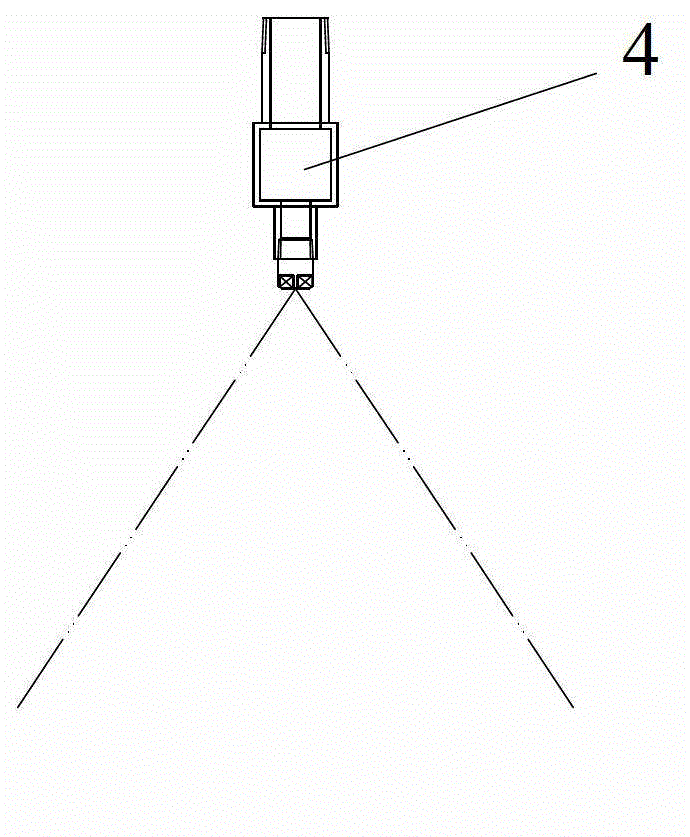

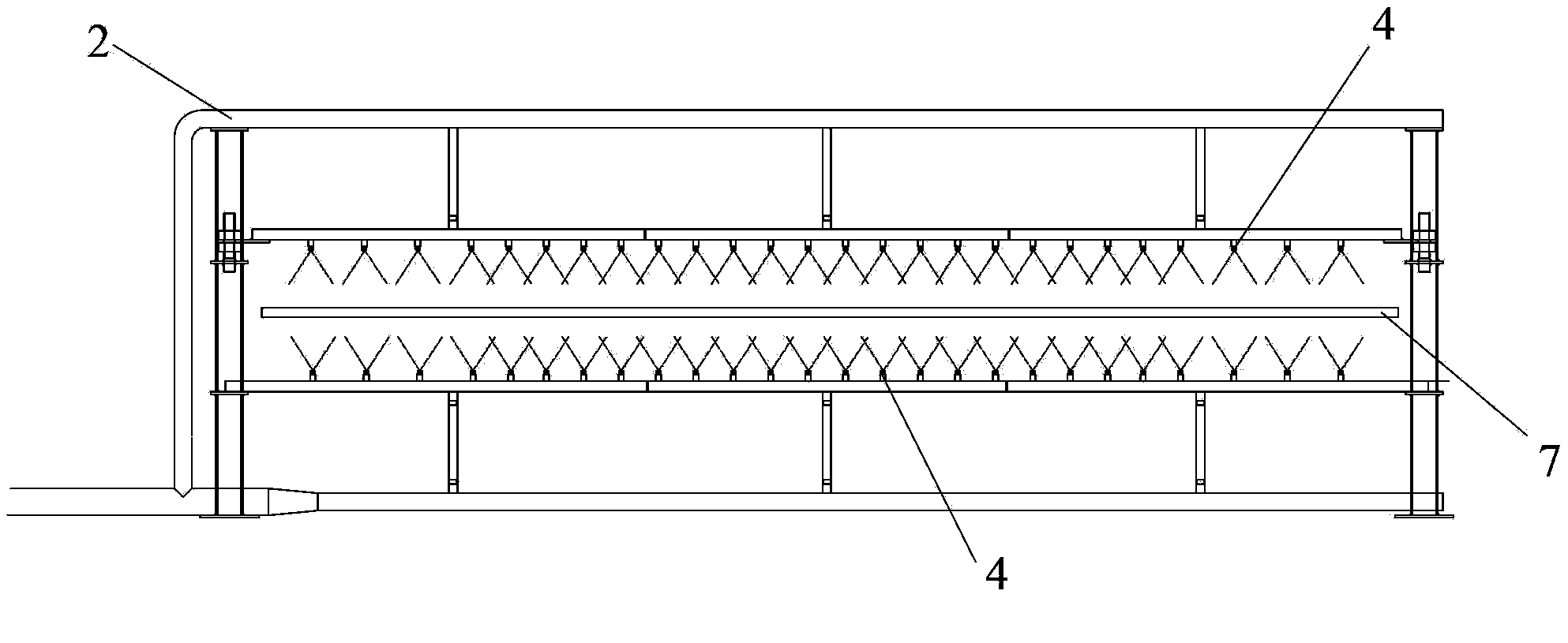

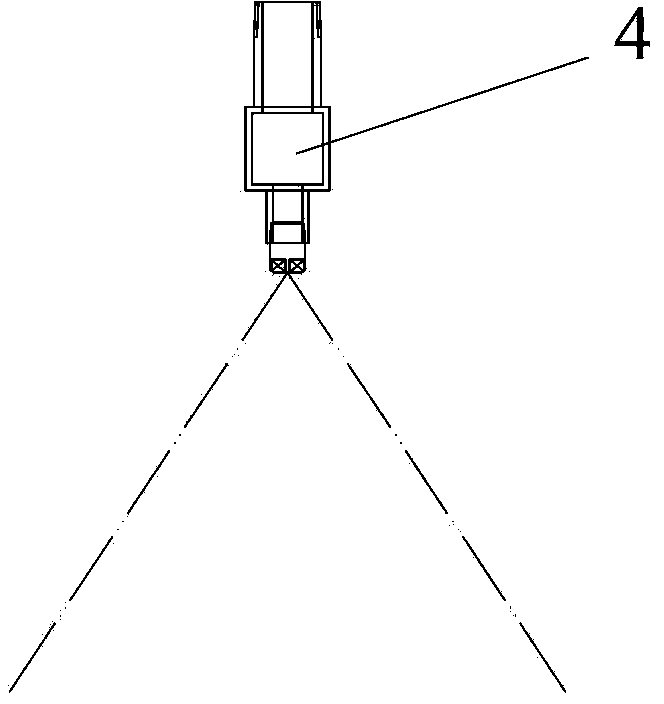

Medium-thickness steel plate air purging device

ActiveCN103934292AAdjustable spray angleQuality improvementWork treatment devicesMetal rolling arrangementsAir filterSpray nozzle

The invention provides a medium-thickness steel plate air purging device. The medium-thickness steel plate air purging device is installed on a controlled cooling device and comprises a compressed air branch pipe, an air filter, an air reducing valve, a pneumatic cut-off ball valve and a jet header, wherein the jet header is connected with the pneumatic cut-off ball valve, the pneumatic cut-off ball valve is connected with the air reducing valve, the air reducing valve is connected with the air filter, the air filter is connected with the compressed air branch pipe, the jet header comprises two steel pipes and a right-angle connector, one steel pipe is welded to one end of the right-angle connector, the other steel pipe is welded to the other end of the right-angle connector, a plurality of fixing connectors are sequentially arranged on each steel pipe, a ball connector is connected to at least one fixing connector, a jet nozzle is installed on the ball connector, and the jet angle of the jet nozzle can be adjusted by the ball connector. Compressed air in a workshop enters the jet header through the compressed air branch pipe and then is jet to the surface of a medium-thickness steel plate through the jet nozzle, and therefore water and oxidized scale on the surface of the medium-thickness steel plate are removed, and the quality of the medium-thickness steel plate is improved.

Owner:WISDRI ENG & RES INC LTD

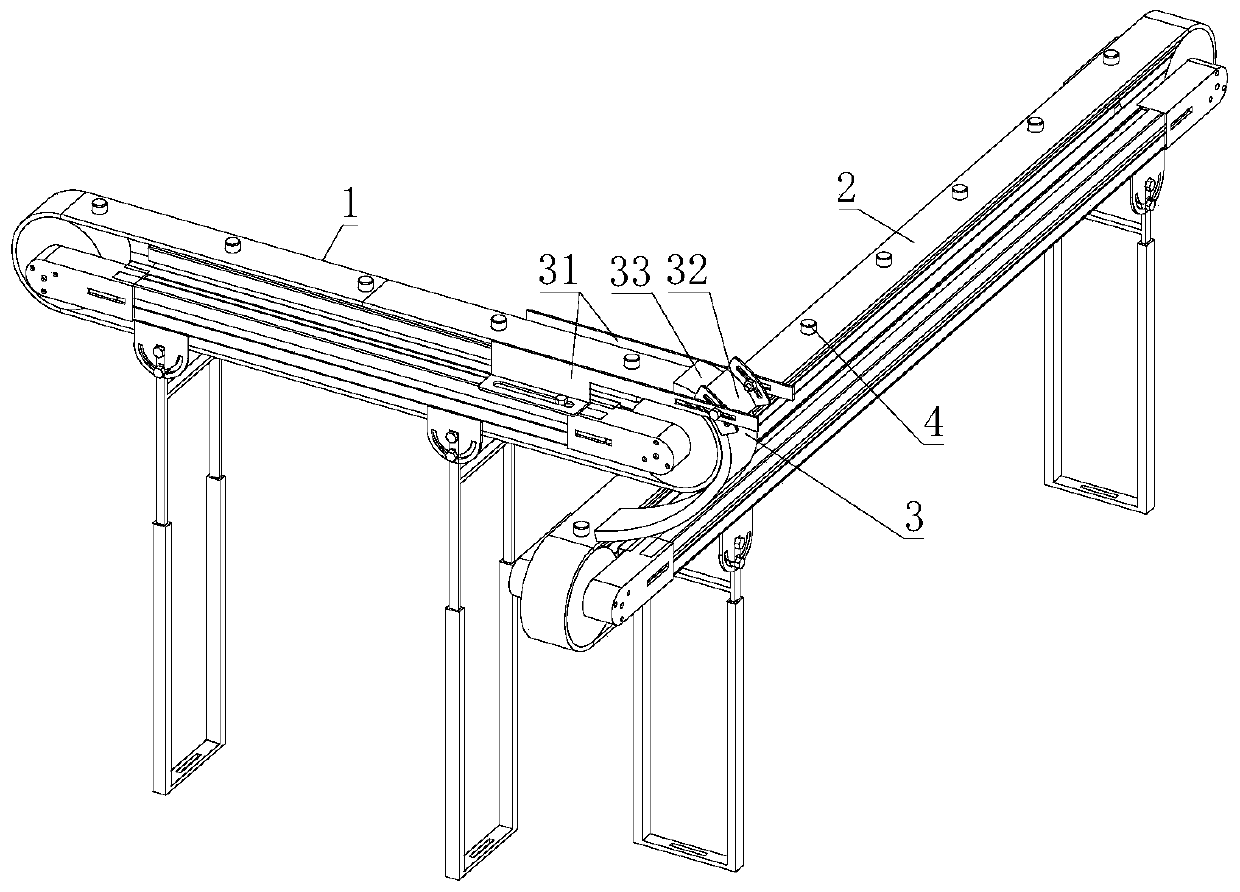

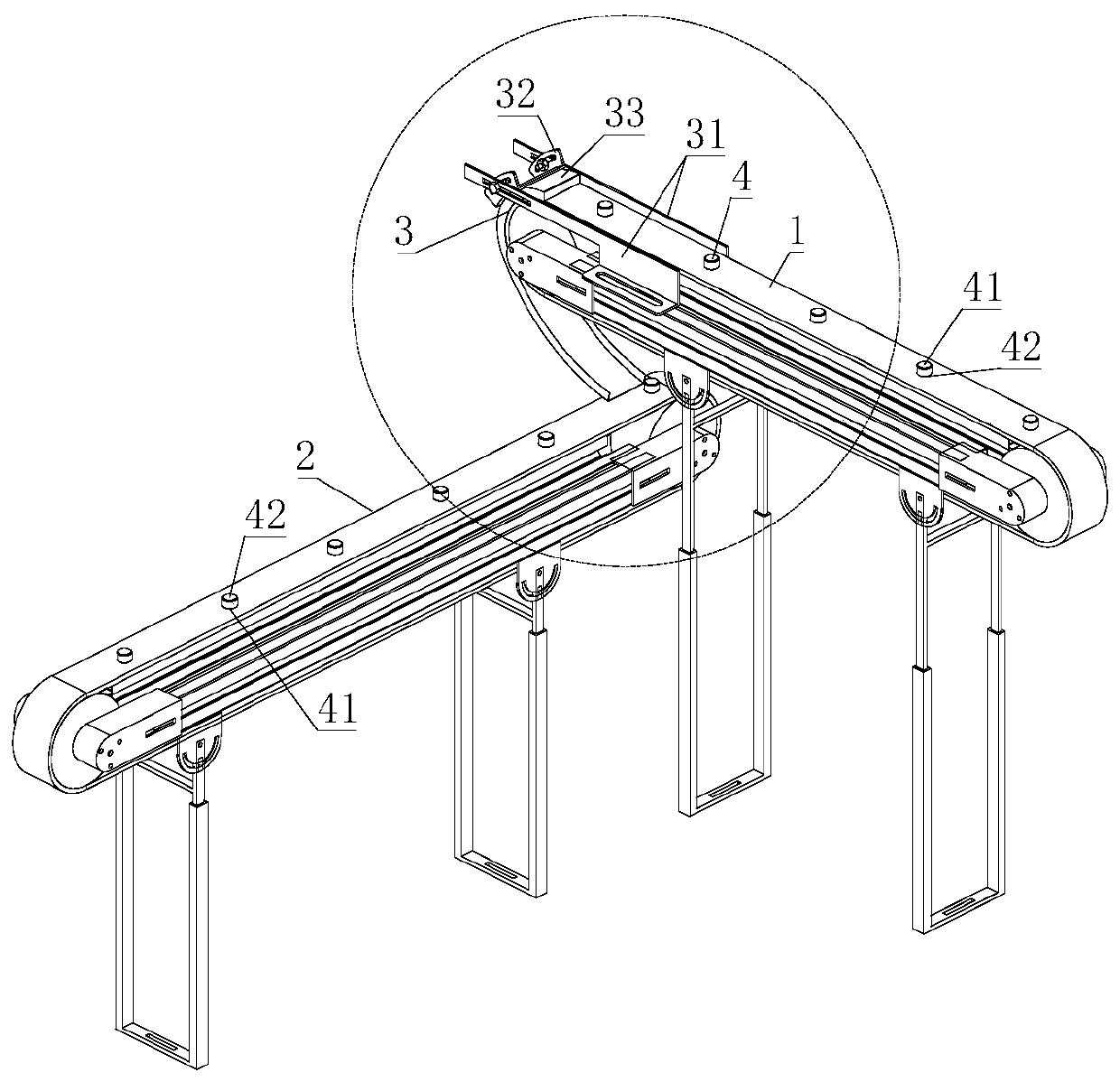

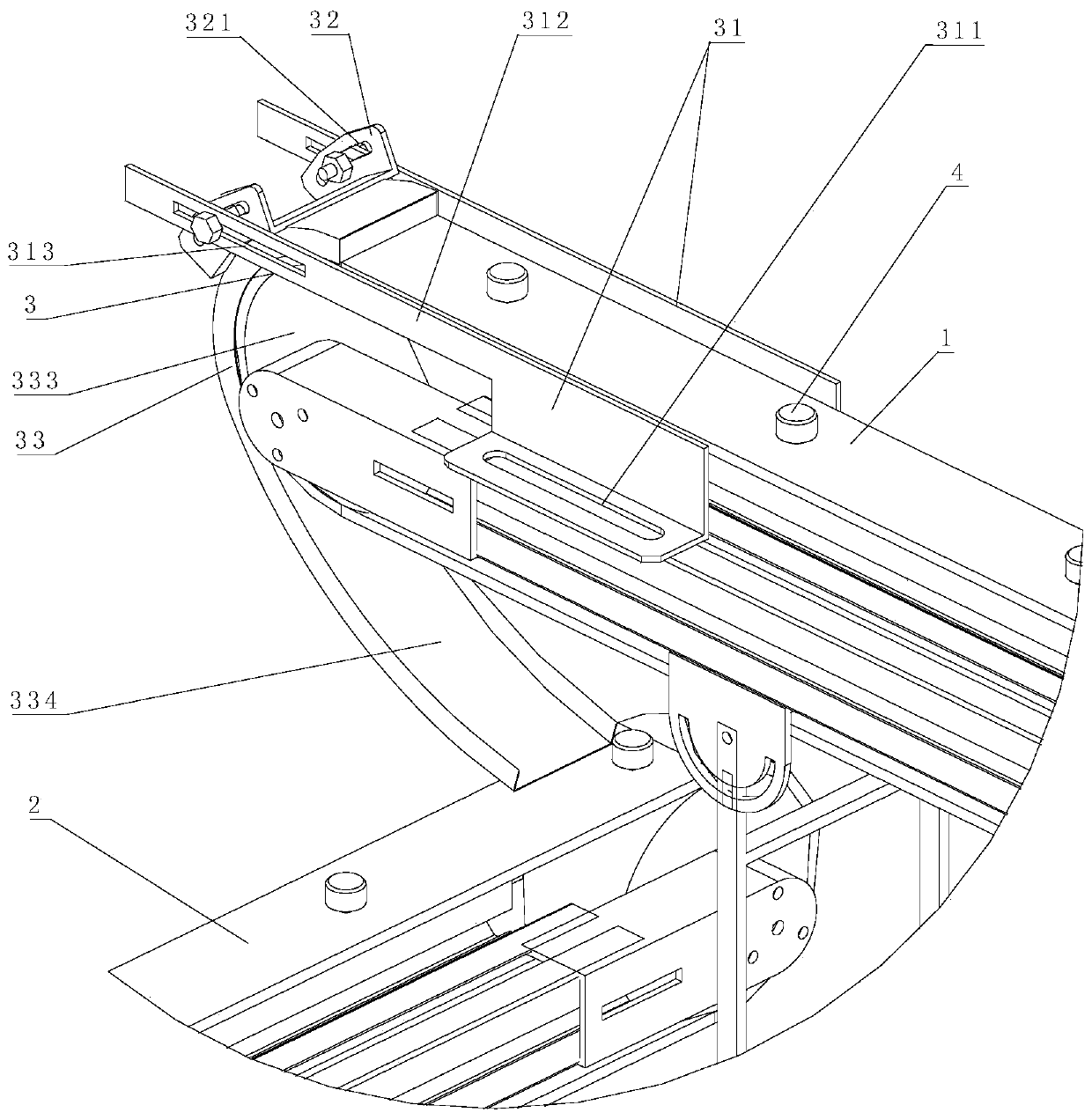

Vertical face turning device for cylindrical workpiece

PendingCN110255136ASignificant progressThe structural design is exquisite and simpleConveyorsConveyor partsDiameter ratioEngineering

The invention relates to a vertical face turning device for a cylindrical workpiece. The vertical face turning device for the cylindrical workpiece comprises an upper conveyer belt, a lower conveyer belt and a face turning device arranged between the discharging end of the upper conveyer belt and the feeding end of the lower conveyer belt; the upper conveyer belt and the lower conveyer belt are vertically arranged in a staggered mode, the conveying directions of the upper conveyer belt and the lower conveyer belt are perpendicular to each other, and the discharging end of the upper conveyer belt and the feeding end of the lower conveyer belt correspond to each other and are connected end to end through the face turning device; and the face turning device comprises arc-shaped face turning slide position adjusting brackets arranged on the two sides of the discharging end of the upper conveyer belt, an arc-shaped face turning slide inclination angle adjusting bracket arranged between the two arc-shaped face turning slide position adjusting brackets and an arc-shaped face turning slide fixedly connected with the arc-shaped face turning slide position adjusting brackets. According to the vertical face turning device for the cylindrical workpiece, the structural design is exquisite and simple, manual or complex manipulator operation is not needed, the cost is low, the working efficiency is high, and industrialization is convenient to achieve; and the adaptability is high, an element to be subjected to face turning is not limited by the material, vertical face turning operation of a roller with the very small height-diameter ratio can be completed, and the face turning efficiency is high.

Owner:新昌浙江工业大学科学技术研究院

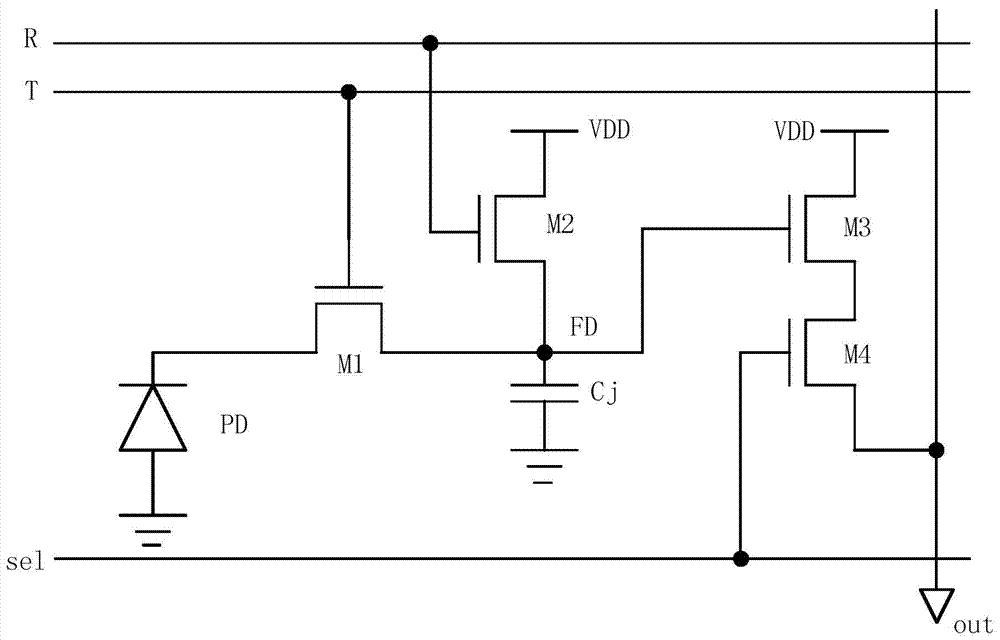

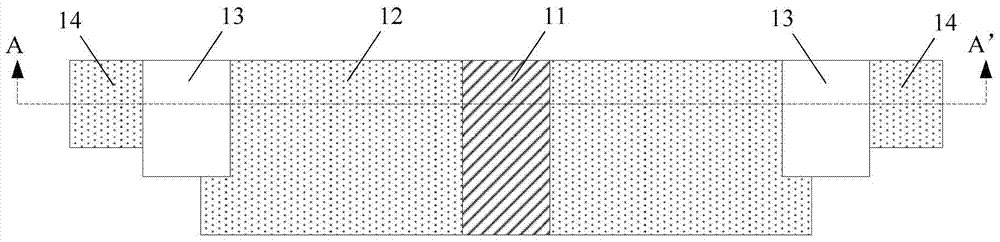

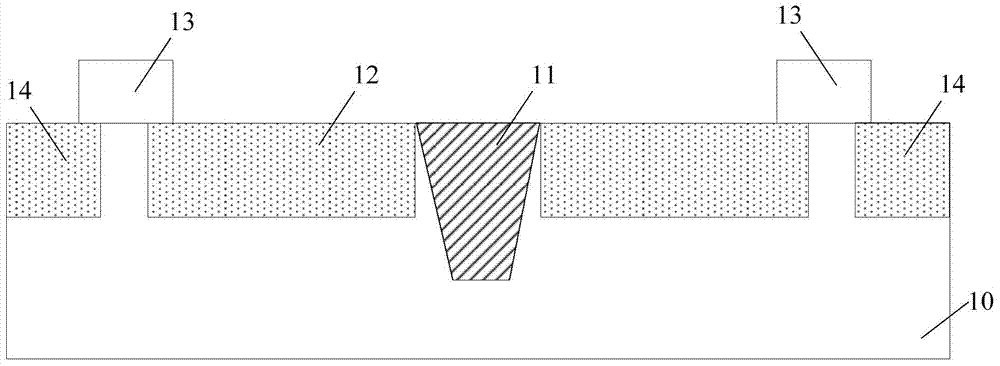

Image sensor and formation method thereof

ActiveCN104332481AImprove performanceReduce the occupied pixel areaRadiation controlled devicesFill factorEngineering

The invention discloses an image sensor and a formation method thereof. The image sensor comprises a semiconductor substrate; a shallow trench isolation structure disposed in the semiconductor substrate; photodiodes disposed in the semiconductor substrate at the two sides of the shallow trench isolation structure; a groove disposed in the shallow trench isolation structure, the side wall of the groove exposing a part of the semiconductor substrate; and a grid structure disposed in the groove, the side wall of the grid structure being disposed on the surface of the side wall of the groove. The fill factor of the image sensor is improved.

Owner:GALAXYCORE SHANGHAI

Oiling device for aluminum wire drawing forming

The invention discloses an oiling device used in aluminum wire drawing and forming, which includes an oil tank, an oil pipe, a pump, an oil injection pipe, an oil collection tank, a filter plate, a sponge and a brush, and the bottom end of the oil pipe extends in the oil tank , the top is connected with the liquid inlet end of the pump, the liquid outlet end of the pump is connected with the oil injection pipe, the liquid injection port of the oil injection pipe is set above the oil collection tank, the filter plate and sponge are arranged in the oil collection tank, and the filter plate is inclined Placed above the sponge, there is an oil collection chamber formed between the bottom of the sponge oil collection tank, and there are several oil leakage holes on the bottom surface of the oil collection tank. The brush is fixed on the lower end surface of the oil collection tank, and the brush is located in the oil leakage hole on the right side; there are several filter holes evenly distributed on the filter plate. The invention has good use effect and simple structure.

Owner:NANJING TONGWANG ALMINIUM CO LTD

Improvement structure of synthetic leather inspection device

ActiveCN103454281ALow fault toleranceIncrease productivityOptically investigating flaws/contaminationObservation pointEngineering

The invention discloses an improvement structure of a synthetic leather inspection device. The improvement structure comprises a frame, wherein synthetic leather is conveyed inside from the left side of the frame, a lighting device is arranged in the middle of the internal part of the frame and comprises a light tube; a tubular lampshade is sleeved outside the light tube; an insulated vacuum layer is arranged between the inner wall and the outer wall of the tubular lampshade; a left roller, a right roller and an upper roller are arranged at the left side, the right side and the upper end of the lighting device; the synthetic leather is orderly attached through the left roller, the upper roller and the right roller from the left, and outputs to enter an automatic rolling shaft from the right side; two observation points are simultaneously formed when the synthetic leather is conveyed from the frame. Therefore, the problem of leak detection of a single observation point can be prevented; the inspected synthetic leather also can be automatically rolled into a product; meanwhile, the insulated tubular lampshade arranged on the lighting device can prevent the surface of the synthetic leather from being affected by high temperature of the light tube.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

Position control device and control method for free loop of thin strip continuous casting strip steel

The invention relates to a position control device and a position control method for a free loop of thin strip continuous casting strip steel. A driving guide roller is fixed on a base through a bearing seat; a chain wheel is arranged at one end of the driving guide roller and is connected with a driving motor through a transmission chain; two groups of first rocker arms are arranged at two ends of the driving guide roller; one side of each first rocker arm is connected with the driving guide roller, and the other side of each first rocker arm is connected with a driven guide roller; the first rocker arms vertically swing around the driving guide roller under the drive of hydraulic cylinders; a driven guide roller is fixed on the first rocker arms and connected with second rocker arms; the second rocker arms vertically swing around the driven guide roller under the drive of hydraulic cylinders; and a plurality of driven guide rollers are arranged on the second rocker arms. The device and the method are suitable for detecting and controlling the free loop of the casting strip steel; and a detecting instrument detects the position of a casting strip on a guide roller way, and the curvature of a guide profile of the casting strip is adjusted simultaneously, so that the curved shape of the guide profile is consistent with that of the casting strip, and the casting strip is attached to a guide device and walks stably.

Owner:BAOSTEEL ENG & TECH GRP +1

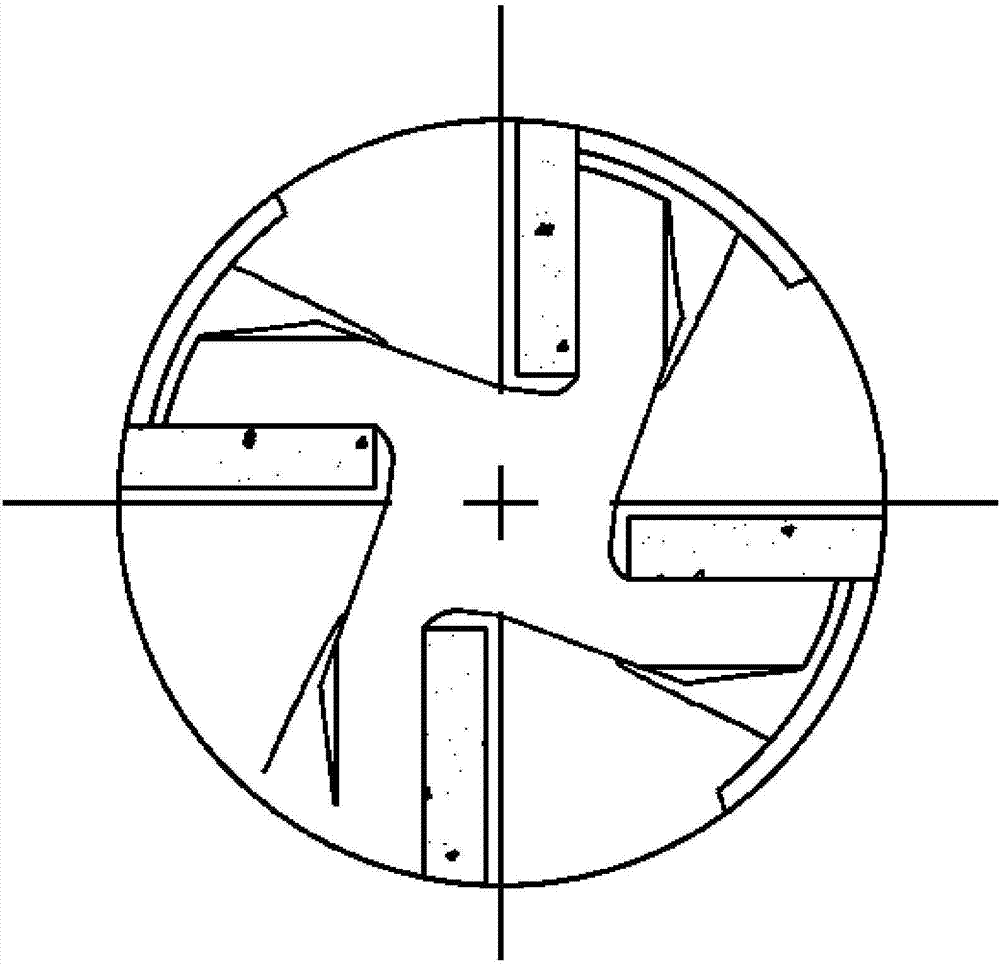

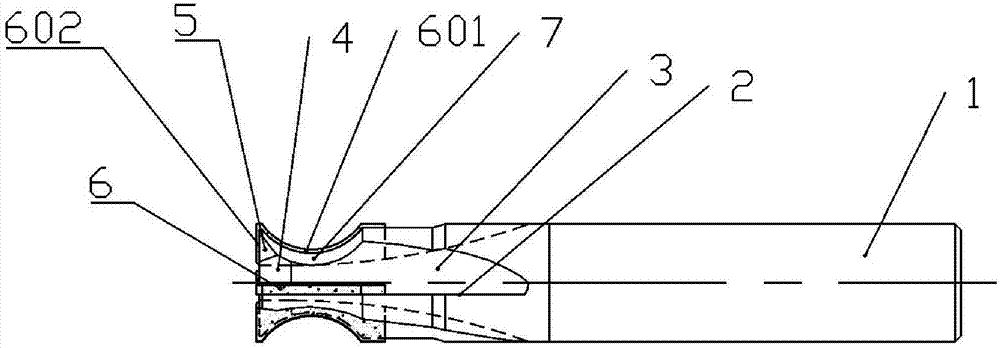

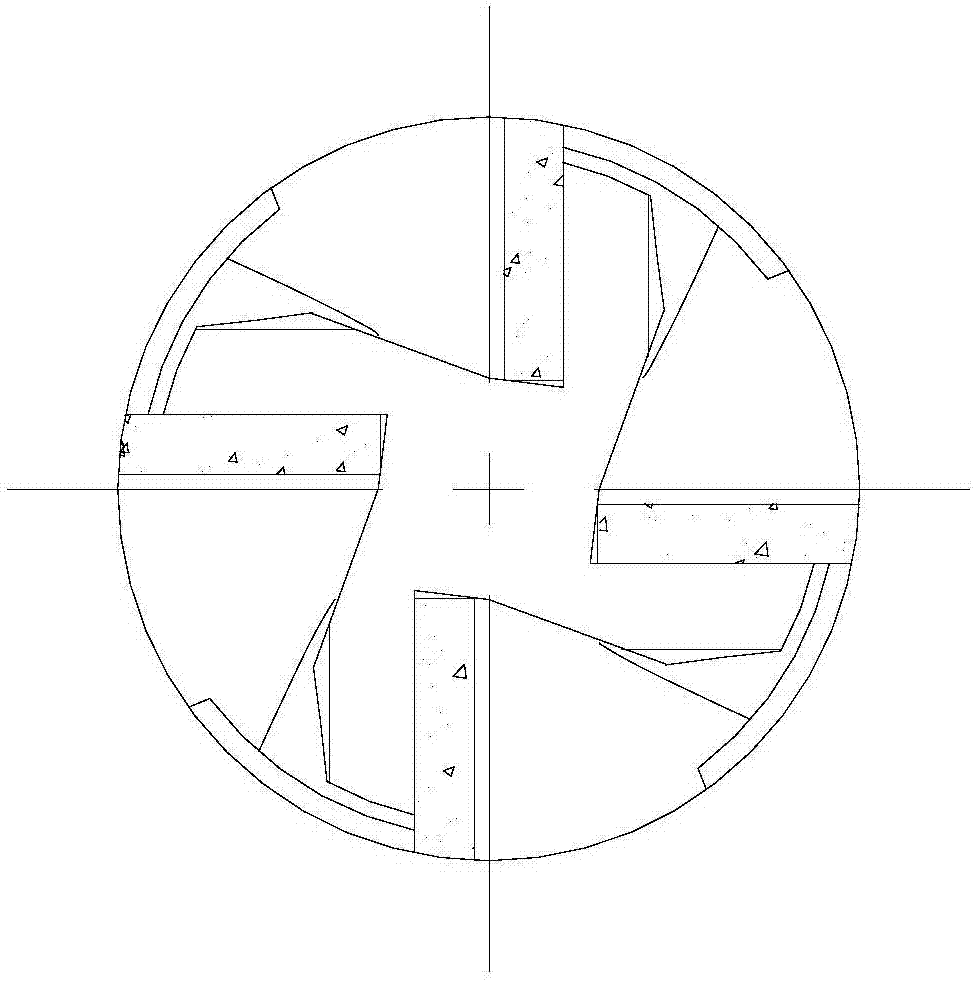

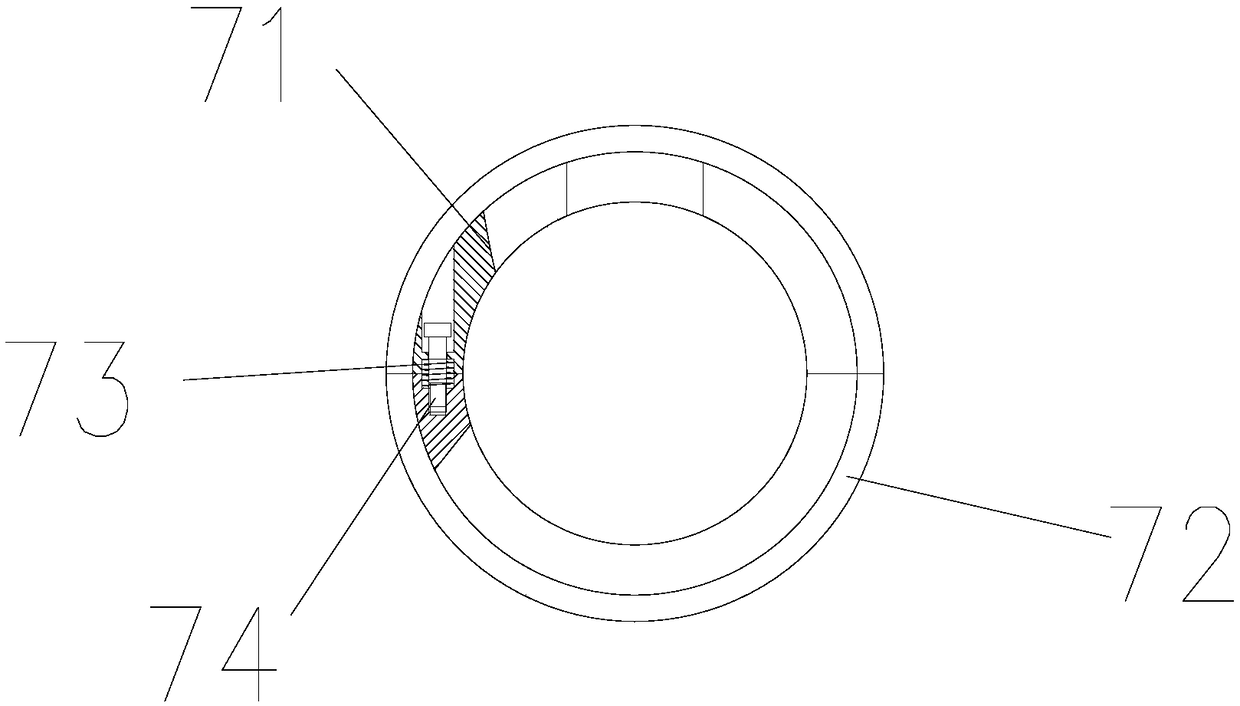

Highlight PCD appearance milling cutter

InactiveCN107414158ATool structure is simple and reliableEasy to installMilling cuttersAgricultural engineeringMilling cutter

The invention discloses a highlight PCD appearance milling cutter. The highlight PCD appearance milling cutter comprises a tool body (1) and PCD blades (6). The highlight PCD appearance milling cutter is characterized in that four cutter grooves are formed in the front end of the tool body (1); a cutter groove concave arc (7) is arranged on the outer side face of each of the cutter grooves; each of the cutter grooves is composed of a groove bottom face (2), a first groove side face (3), a second groove side face (4) and a third groove side face (5); the PCD blades (6) are welded between the groove bottom faces and the first groove side faces; a blade concave arc (601) is arranged on the outer side of each of the PCD blades; and the blade concave arc (601) is matched with the cutter groove concave arc in structure.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

Auxiliary cooling and cleaning system for cold rolling mill

ActiveCN112808776AImprove air intake efficiencyUniform surface cooling effectRollsCleaning using gasesHeat conductingElectric machinery

The invention discloses an auxiliary cooling and cleaning system for a cold rolling mill. The auxiliary cooling and cleaning system comprises a base and supporting plates; a motor is welded and fixed to the side wall of one supporting plate; a rotating shaft is welded and fixed to the output end of the motor; a working roller is welded and fixed to the rotating shaft; a rectangular plate is welded and fixed to the tops of the two supporting plates jointly; heat conducting pieces are arranged on the inner wall of the working roller; two grooves are symmetrically formed in the bottom of the rectangular plate; magnetic bars are glidingly connected in the grooves; scraping plates are welded and fixed to the bottoms of the magnetic bars; a sliding cavity is formed in the inner wall of the rectangular plate; an electromagnetic valve is arranged at one end of the sliding cavity; a power generation component is arranged in the sliding cavity; and electromagnets are symmetrically arranged in the rectangular plate. The auxiliary cooling and cleaning system has the advantages that a fan, an air suction hole, the scraping plates and other structures are arranged, and cooling water, impurities on the working roller and the like are guided to the two ends of the working roller through the scraping plates, so that the cooling water, the impurities and the like are sucked by the air suction hole to be stored and recovered, and the condition that the surface quality of a plate is affected due to the fact that oil dirt and other impurities fall on the plate is avoided.

Owner:山东达盛新材料有限公司

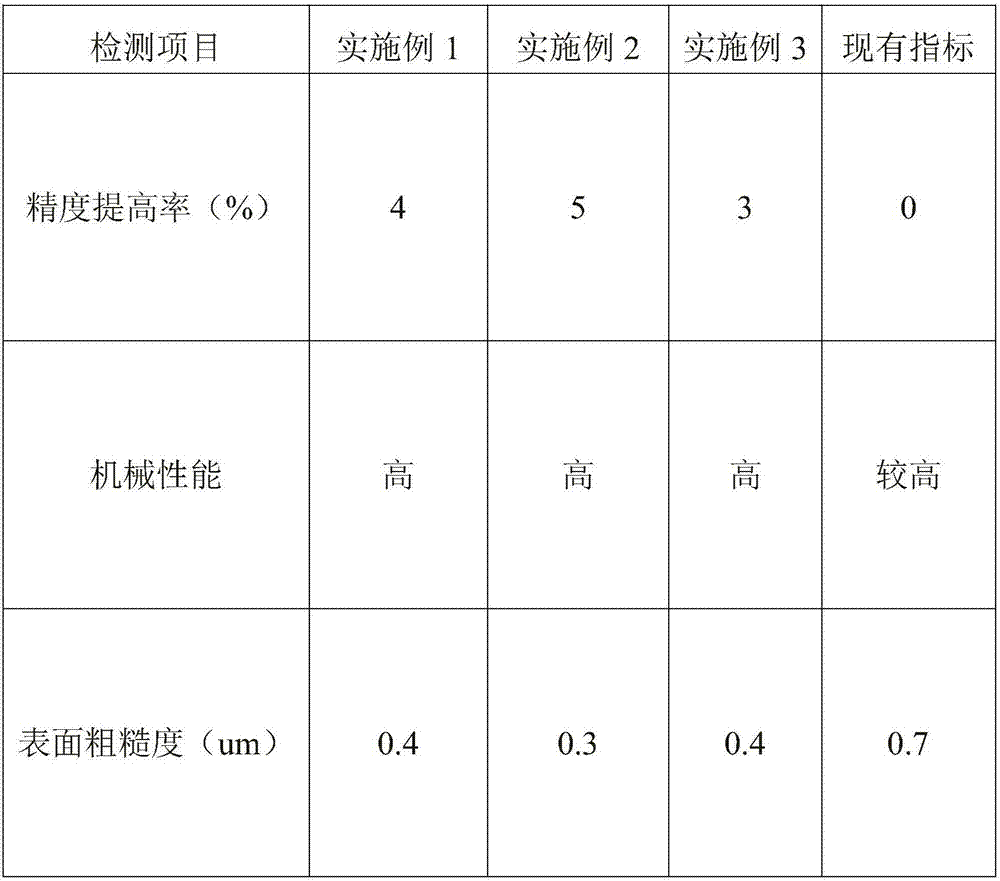

Vehicle gear cold extrusion process

InactiveCN107214287AHigh precisionImprove mechanical propertiesSolid state diffusion coatingFurnace typesPunchingEngineering

The invention discloses a cold extrusion process for automobile gears. The blanking adopts a high-precision band sawing machine and the control of the thickness of the saw blade of the high-precision band sawing machine and the gap between the saw blades can ensure the precision of blanking. The control of the semi-vacuum electric furnace , can prevent oxidation and decarburization of workpieces, and affect the surface quality of cold extrusion processed products. Carburizing treatment after the punching can improve the precision and mechanical properties of automotive gears. The cold extrusion process of automotive gears has high precision and mechanical properties. Advantages, the market prospect is broad.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Method and cooling system for improving comprehensive mechanical property of normalized steel plate

ActiveCN102912091BImprove utilization efficiencyReduce CooldownFurnace typesHeat treatment process controlAustenite grainThermal insulation

The invention discloses a method for improving the comprehensive mechanical property of a normalized steel plate. The running time of the steel plate in a heating region in a normalizing furnace is reasonably prolonged and the running time of the steel plate in a thermal insulation region in the normalizing furnace is reasonably shortened, so that the austenite grain growth is avoided to provide favorable conditions for subsequent accelerated cooling. The steel plate is quickly cooled to be 600-700 DEG C from the normalizing temperature in a way of normalizing, atomizing and cooling, so that the mist cooling with higher heat exchange efficiency increases the supercooling degree of the structural transformation of the steel plate and effectively prevents the austenite grain growth; and grains are refined, so that the effect of improving the strength by structure refinement in the heat treatment process of the steel plate is given full play. The invention further provides a cooling system for improving the comprehensive mechanical property of the normalized steel plate. Therefore, the equipment is simple, the investment is low, the surface quality of the steel plate can be improved, and the practicality is better.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

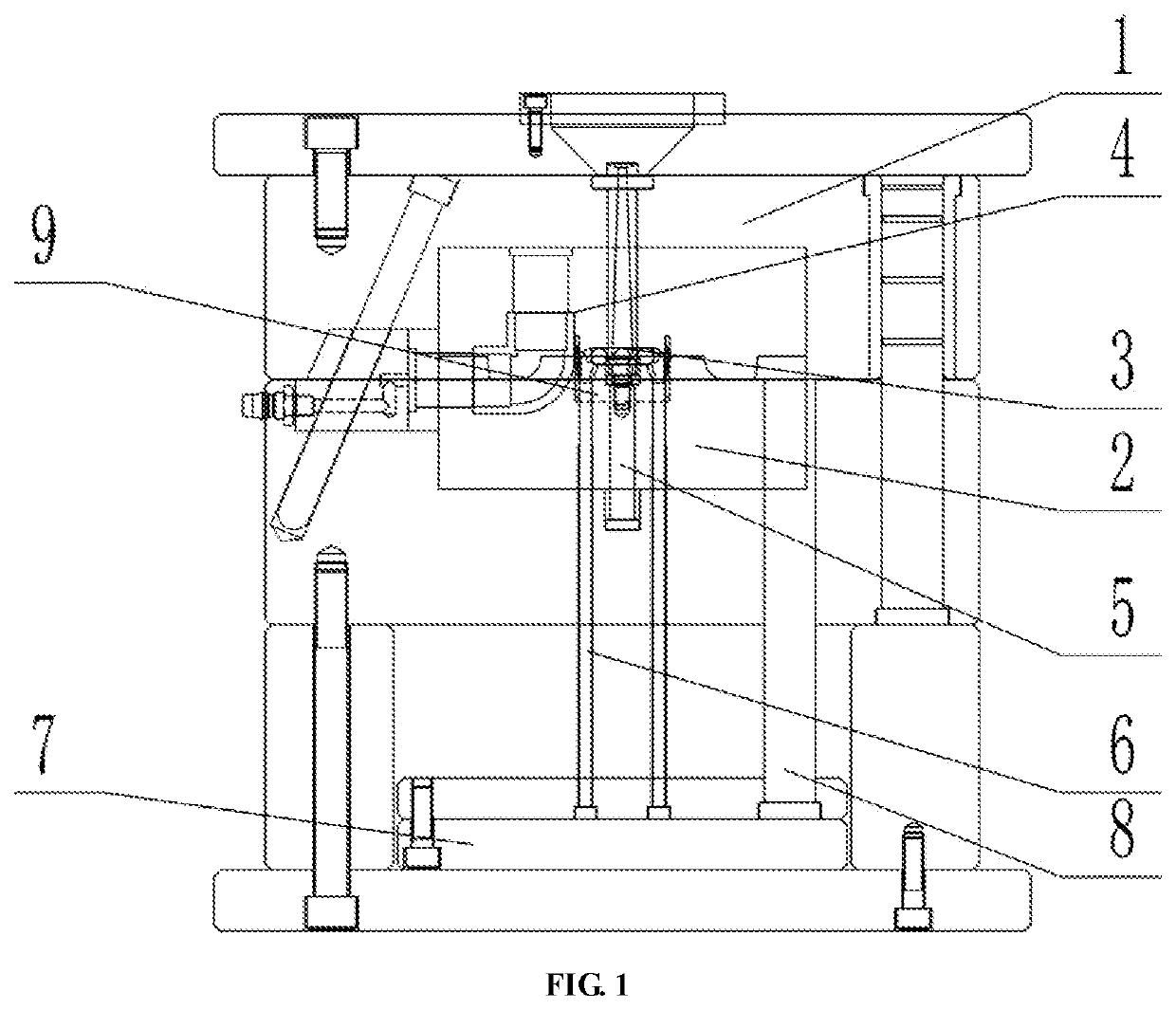

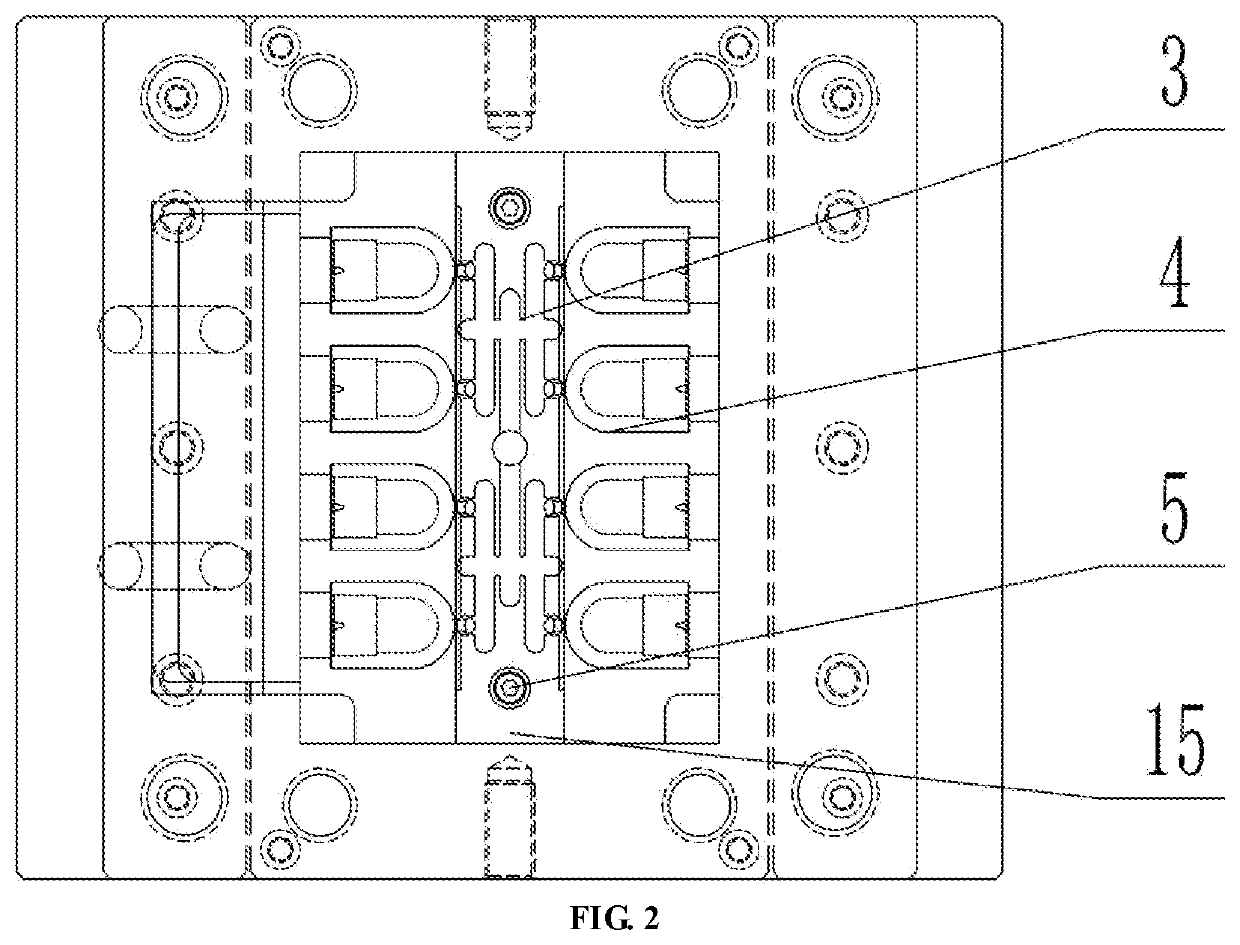

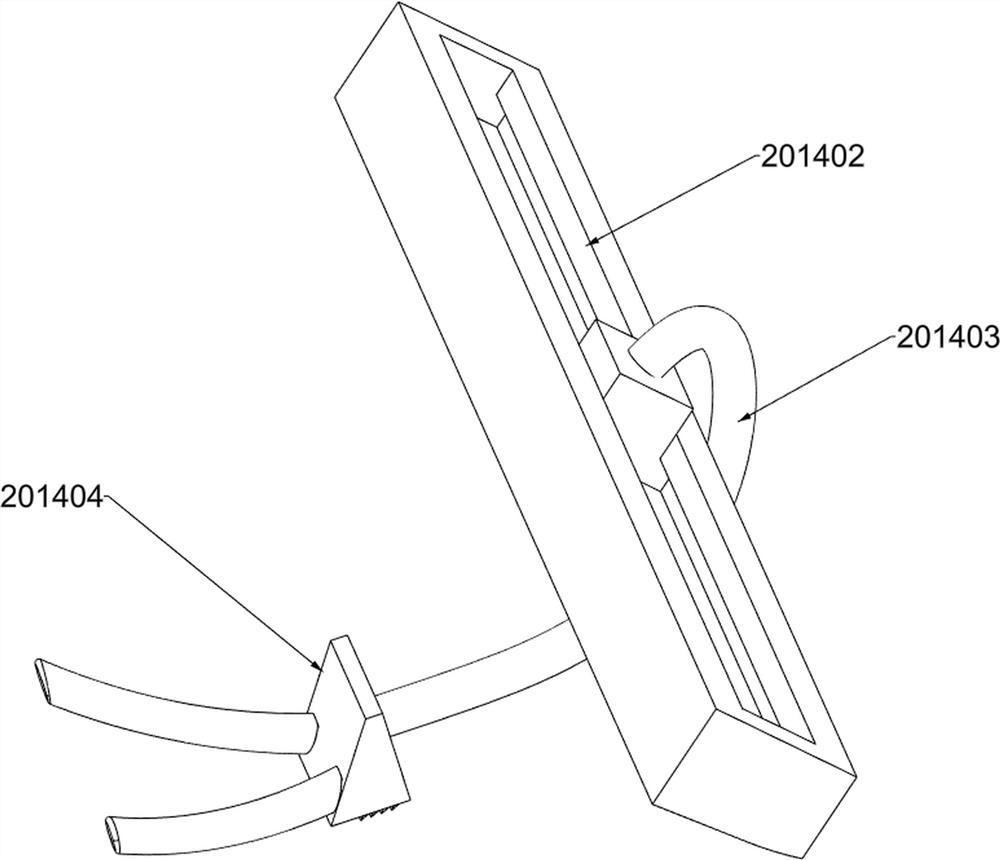

Injection Mold Capable of Planing and Cutting Gates in Inside Thereof and Planing and Cutting Method

PendingUS20220362980A1Solve the real problemReduce forceDomestic articlesStructural engineeringKnife blades

An injection mold capable of planing and cutting gates in an inside thereof and a planing and cutting method are provided. The injection mold includes a blade fixed block arranged between a moving mold and a fixed mold. Blades arranged on the blade fixed block and configured for cutting off gate condensed-material. The mold includes ejectors for ejecting out the gate condensed material and the blade fixed block. Runners formed between the blade fixed block and the fixed mold. Cut holes for communicating runners and gates are formed in blades. Ejector holes for penetrating the ejectors are formed in portions of the blade fixed block which correspond to bottoms of runners. The blade fixed block moves relative to the moving mold in a mold opening direction. The moving mold is provided with a limiting mechanism for limiting the blade fixed block after injection molding parts are separated from a cavity.

Owner:ZHUJI BIHAN FINE MOLDING

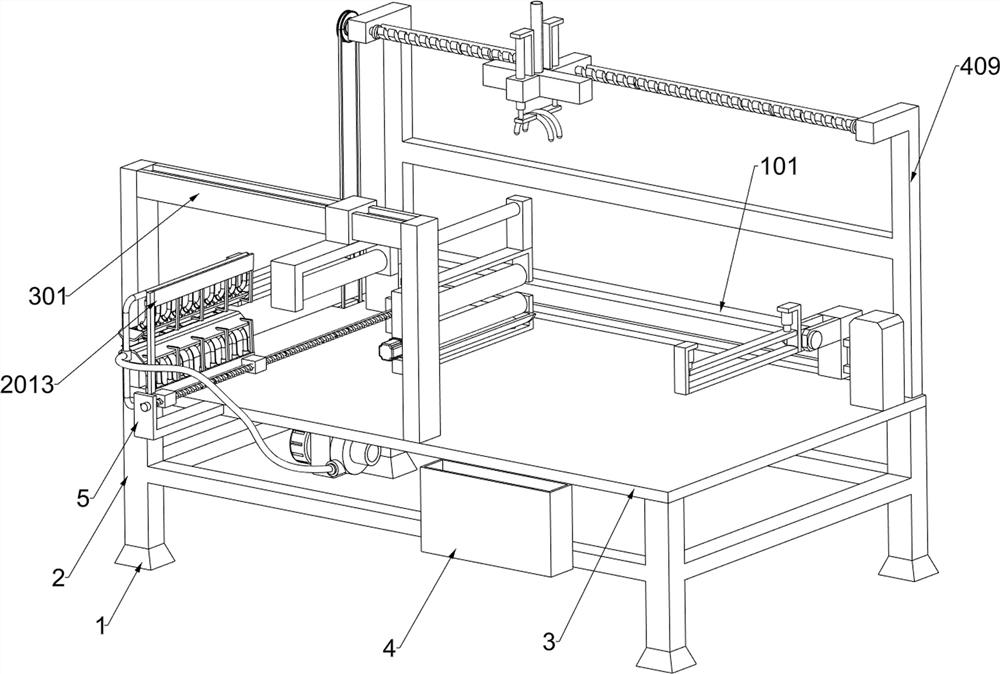

Cotton cloth gluing equipment for surface flattening treatment

ActiveCN113649234ASolve the problem that inclusions cannot flow normallySolve the problem of not flowing normallyMechanical cleaningLiquid surface applicatorsPolyesterPolymer science

The invention relates to the field of cotton cloth dip dyeing subsequent treatment, in particular to cotton cloth gluing equipment for surface flattening treatment. The cotton cloth gluing equipment for surface flattening treatment is provided. According to the technical scheme, the cotton cloth gluing equipment for surface flattening treatment comprises a bottom frame, a bottom plate and the like; and the bottom plate is installed above the bottom frame. According to the cotton cloth gluing equipment for surface flattening treatment, subsequent surface strengthening of polyester-mixed cotton cloth is achieved, a traditional method that gluing is conducted firstly and then removing is conducted is abandoned, the surface of the polyester-mixed cotton cloth is firstly subjected to fluff and cotton ball removing, and meanwhile, in the cotton ball removing process, fluff discharged from cotton balls is protected against being brought up, so that the surface quality of the polyester-mixed cotton cloth is not affected; and finally, glue liquid on the surface of the polyester-mixed cotton cloth is subjected to flattening treatment, the problem that the glue liquid cannot flow normally when the fluff is mixed with the glue liquid is solved, thus the surface attractiveness of the polyester-mixed cotton cloth is enhanced, and the quality of the polyester-mixed cotton cloth is improved.

Owner:长兴钦氏纺织有限公司

Washing device for washing gear shaft

InactiveCN108787580AIncrease the cleaning areaImprove insulation performanceDrying gas arrangementsCleaning using liquidsInductorPlastic fiber

The invention relates to a washing device for washing a gear shaft. The washing device comprises a transmission mechanism, a spray washing mechanism, an air drying mechanism and a discharging mechanism, wherein the transmission mechanism comprises a bracket and two rolling chains arranged in the bracket back and forth, a plurality of transmission groups arranged at equal intervals are arranged atthe outer side end of each rolling chain, and each transmission group comprises a transmission plate, and a concave opening which is depressed inwards is formed in the upper end surface of each transmission plate; the spray washing mechanism comprises a plurality of spray washing groups evenly arranged and an inductor placed at the position, close to the spray washing groups, on the upper portionof the interior of the bracket; the air drying mechanism is placed at a track group on the upper portion of the interior of the bracket, the track group consists of two tracks, and an air drying groupis arranged on each track; and the discharging mechanism comprises a glass reinforced plastic fiber conveying belt and a discharging shell placed on the outer side of the glass reinforced plastic fiber conveying belt, and a plurality of glass reinforced plastic fiber shaft rods longitudinally arranged are arranged above the glass reinforced plastic fiber conveying belt. The washing device has theadvantages of being convenient to discharge and thorough in washing and improving the drying effect.

Owner:NANTONG ZHONGLV GEAR CO LTD

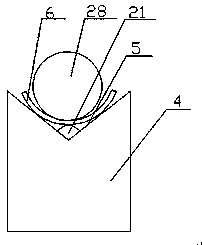

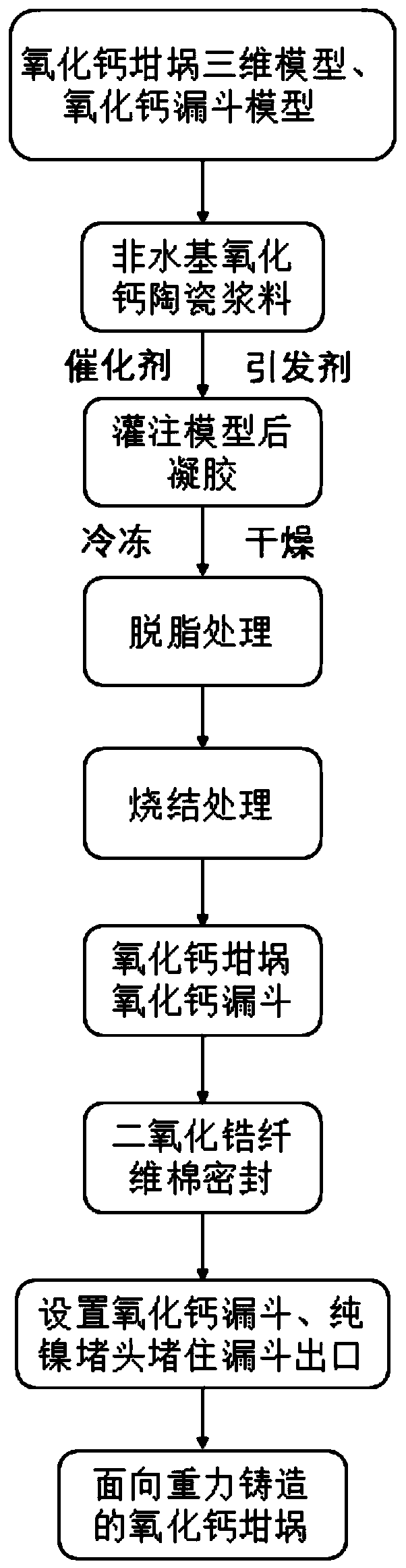

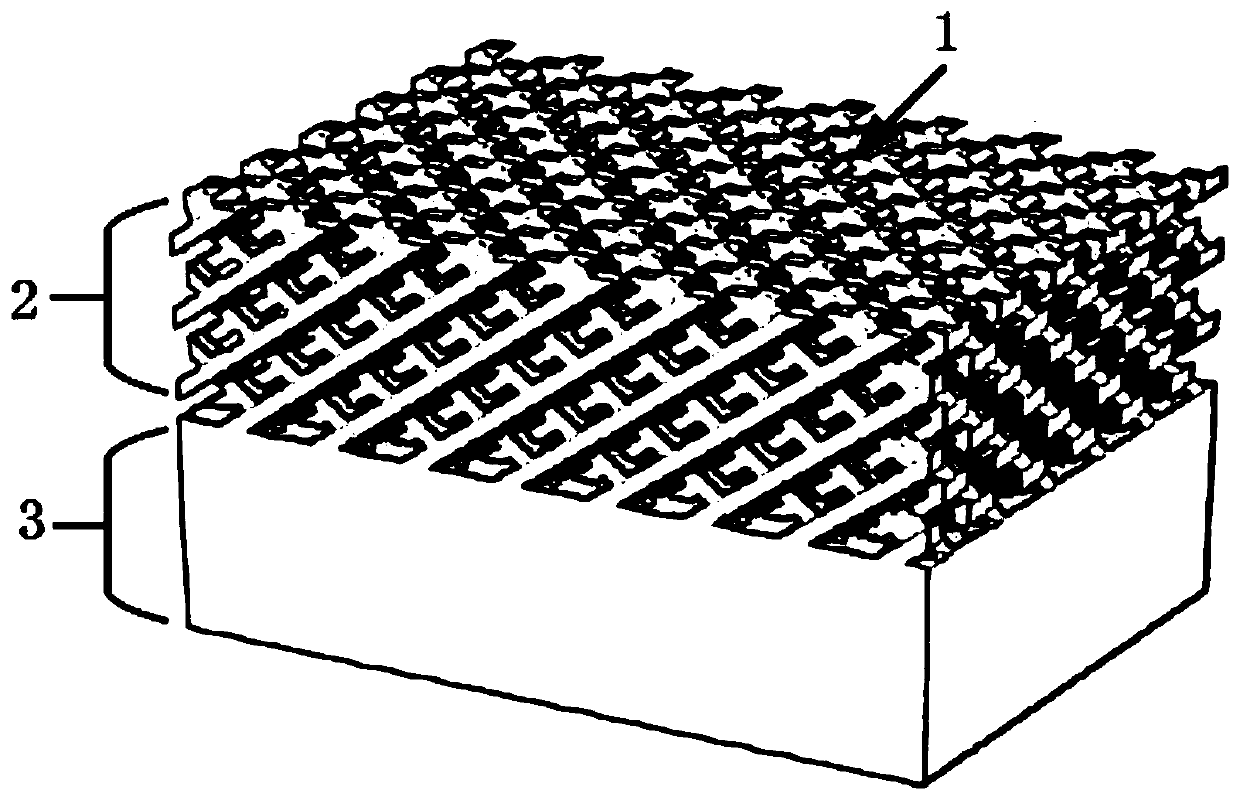

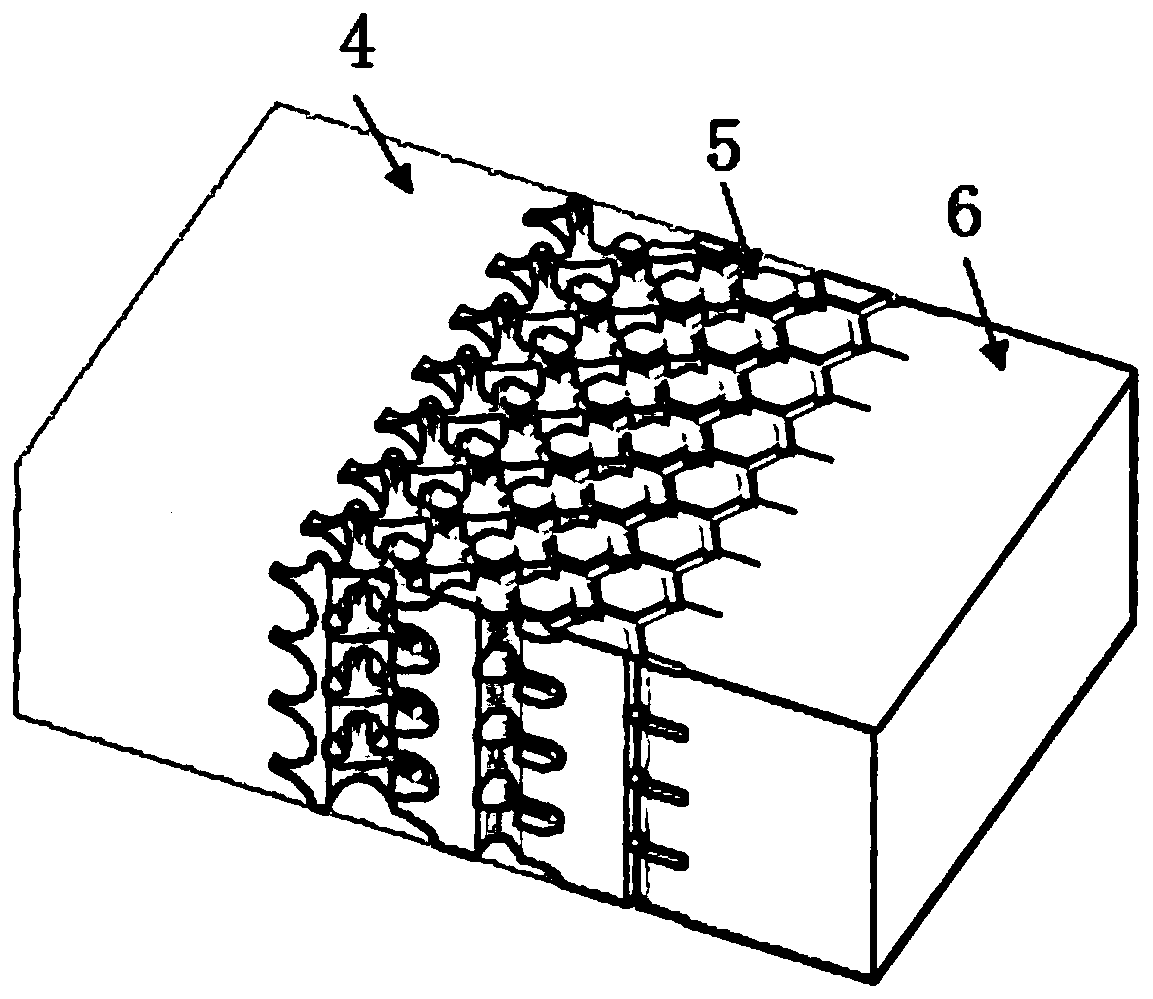

Topological optimization structure ceramic matrix and nickel-based high-temperature alloy integrated component and preparation method thereof

InactiveCN111230076ASimple processImproves strength and stabilityFoundry mouldsFoundry coresTopological optimizationZirconium oxide

The invention discloses a topological optimization structure ceramic matrix and nickel-based high-temperature alloy integrated component and a preparation method thereof. A calcium oxide ceramic basedcasting mould with hydrating resistance is prepared; a ceramic matrix is placed in the bottom space of the calcium oxide based ceramic casting mould, and the periphery of the ceramic matrix and the casting mould are sealed through zirconium dioxide cellucotton; a calcium oxide funnel is arranged at an opening of the calcium oxide based casting mould, an outlet of the funnel is blocked by a pure nickel plug, and a solid-state nickel-based high-temperature alloy is placed in the funnel; and the calcium oxide based casting mould is heated under the vacuum environment, a nickel-based high-temperature alloy phase is firstly made to become a liquid state, then the pure nickel plug is smelted, the liquid-state nickel-based high-temperature alloy falls down onto the ceramic matrix, a ceramic matrix topological structure is filled with the liquid-state nickel-based high-temperature alloy, the liquid-state nickel-based high-temperature alloy is solidified, and the composite component is obtained. By means of the component and the preparation method, the problems that under the action of gravity, metal liquid drops cannot achieve complete mold filling, and the surface quality is influenced by the complex structure and solidification can be solved.

Owner:XI AN JIAOTONG UNIV

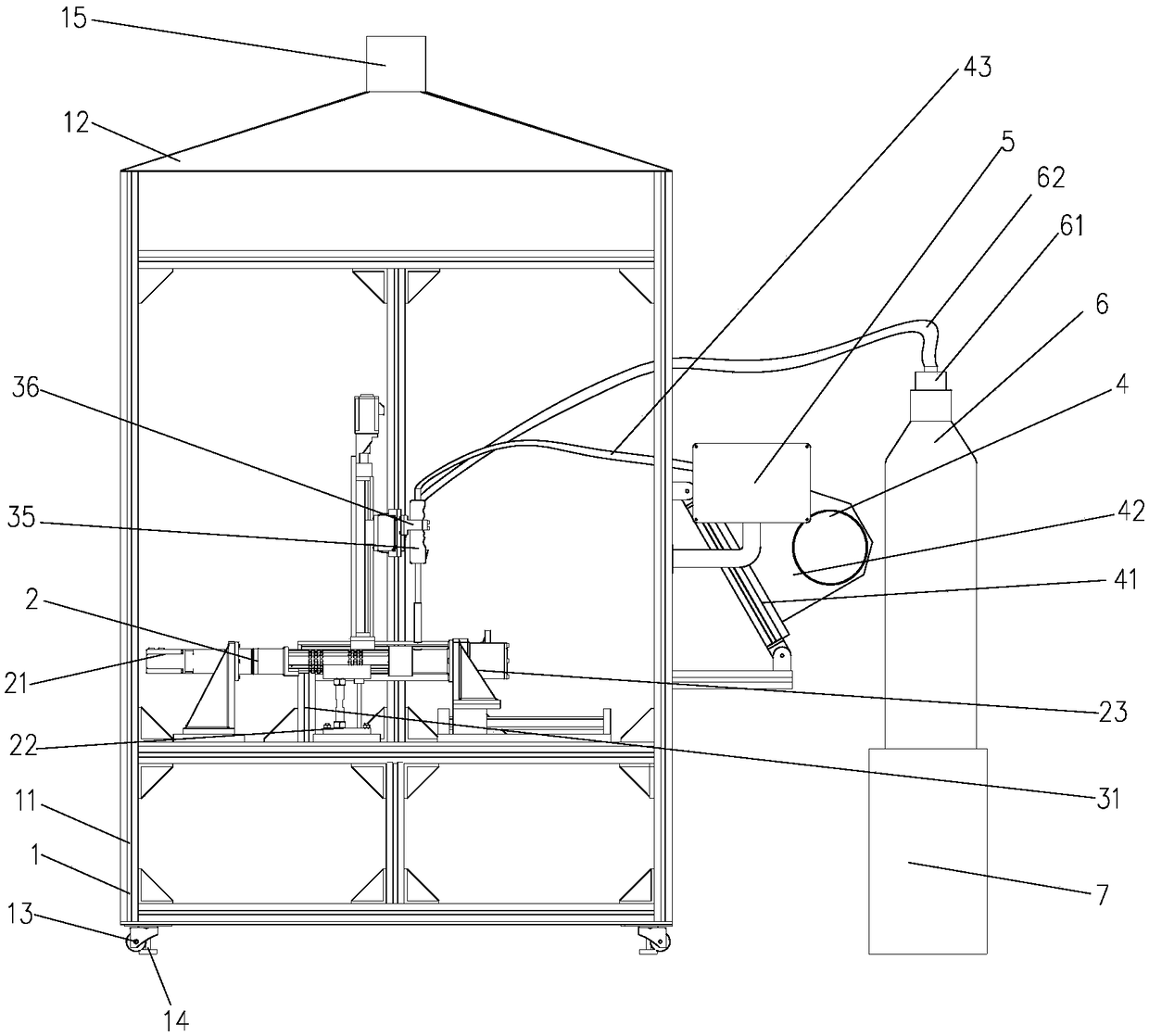

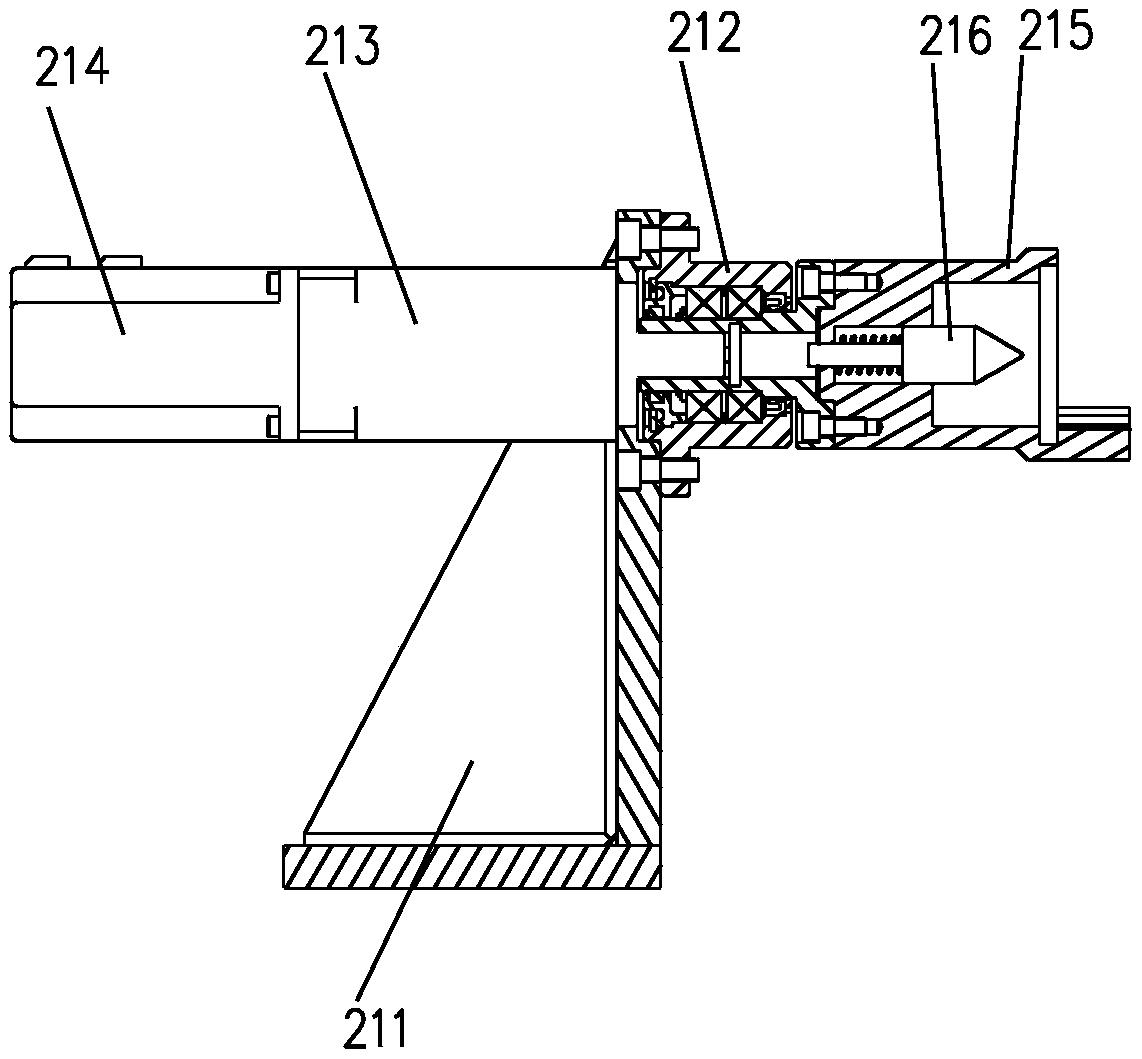

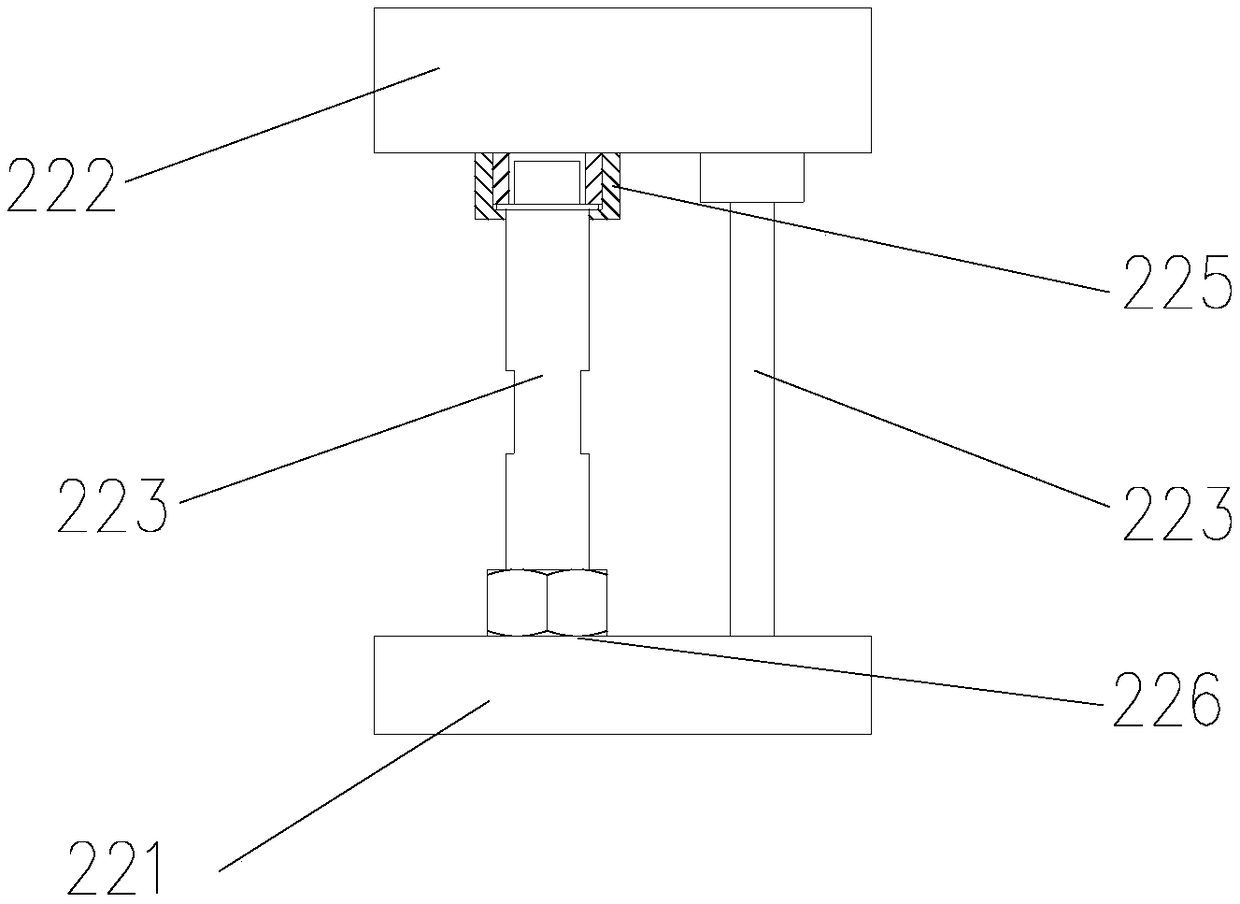

Automobile shaft head assembly welding device

InactiveCN108942008AAffect surface qualityEasy to withstandWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an automobile shaft head assembly welding device. The automobile shaft head assembly welding device comprises an equipment box, a clamping system arranged in the equipment box,a welding gun adjusting device and a wire conveying system. According to the automobile shaft head assembly welding device, by arranging a tip cone centering mechanism in the center of a driving sleeve, the cone head of a tip cone can jack a center hole of a workpiece conveniently so that the workpiece can be subjected to centering guiding, and then, the left end surfaces of tool withdrawal grooves of driving teeth and a right-side jacking device jack the workpiece; the workpiece is driven to rotate together with the driving sleeve through the multiple driving teeth arranged on the end surface of the driving sleeve; by arranging a workpiece storage frame adjustable in height, the position of a top plate is conveniently adjusted according to the size of the outer diameter of the workpiece,and clamping or disassembling of the workpiece is facilitated; and by arranging a smoke exhaust fan at the top of a smoke collecting hood, smoke generated during welding can be conveniently conveyedto a waste gas processing device for centralized processing.

Owner:CHONGQING UNIV OF ARTS & SCI

Oil wiping unit for aluminum wire drawing and forming device

The invention discloses an oil rubbing unit used in an aluminum wire drawing forming device, which includes an oil tank, an oil pipe, a pump, an oil spray pipe, an oil collection tank, a filter plate, a sponge, a brush and an oil rubbing unit. The bottom end extends into the oil tank, the top end is connected to the liquid inlet end of the pump, and the liquid outlet end of the pump is connected to the fuel injection pipe. Inside, and the filter plate is placed obliquely above the sponge, an oil collection cavity is formed between the bottom of the sponge oil collection tank, a number of oil leakage holes are arranged on the bottom surface of the oil collection tank, the brush is fixed on the lower end surface of the oil collection tank, and The brush is located on the right side of the oil leak hole; the oil wiping unit is located on the right side of the oil collection tank. The invention has good use effect and simple structure.

Owner:NANJING TONGWANG ALMINIUM CO LTD

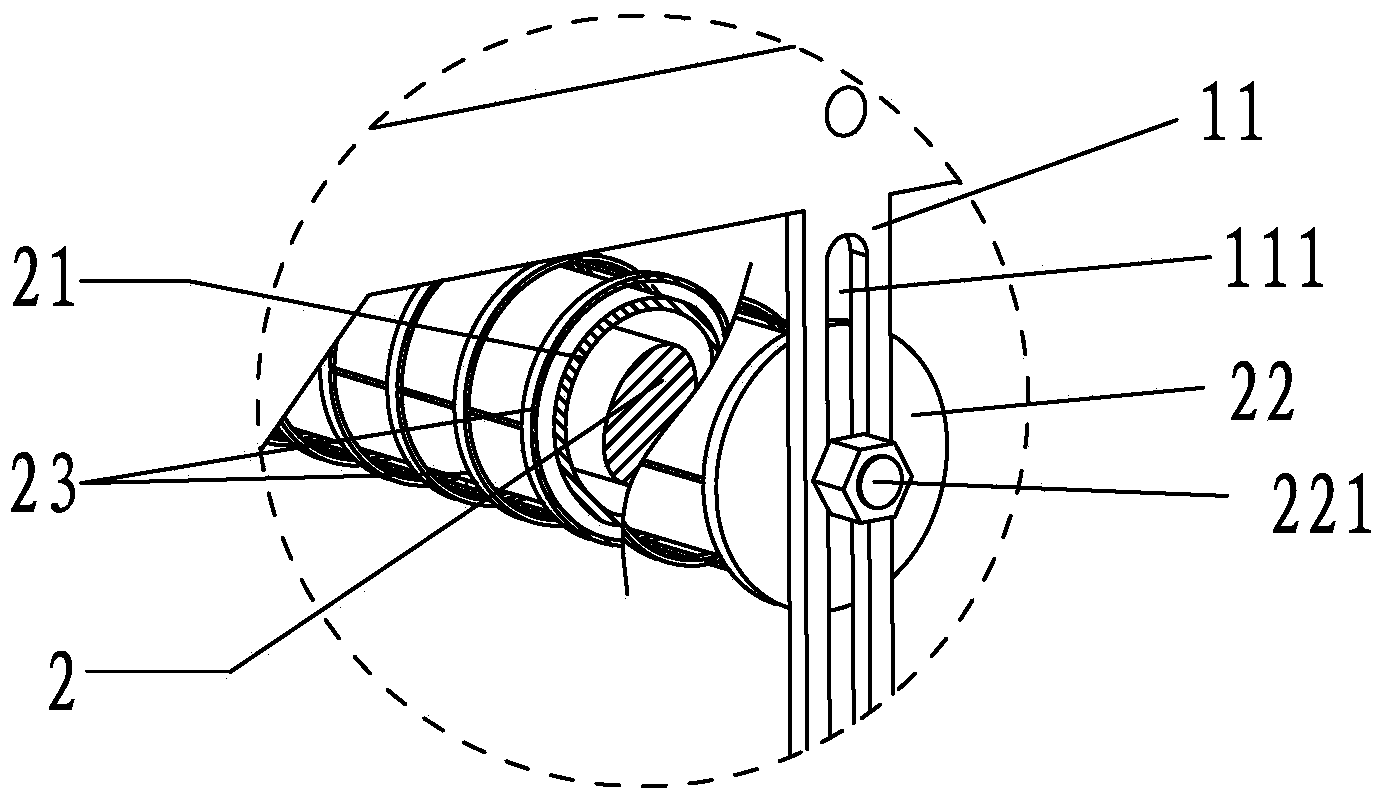

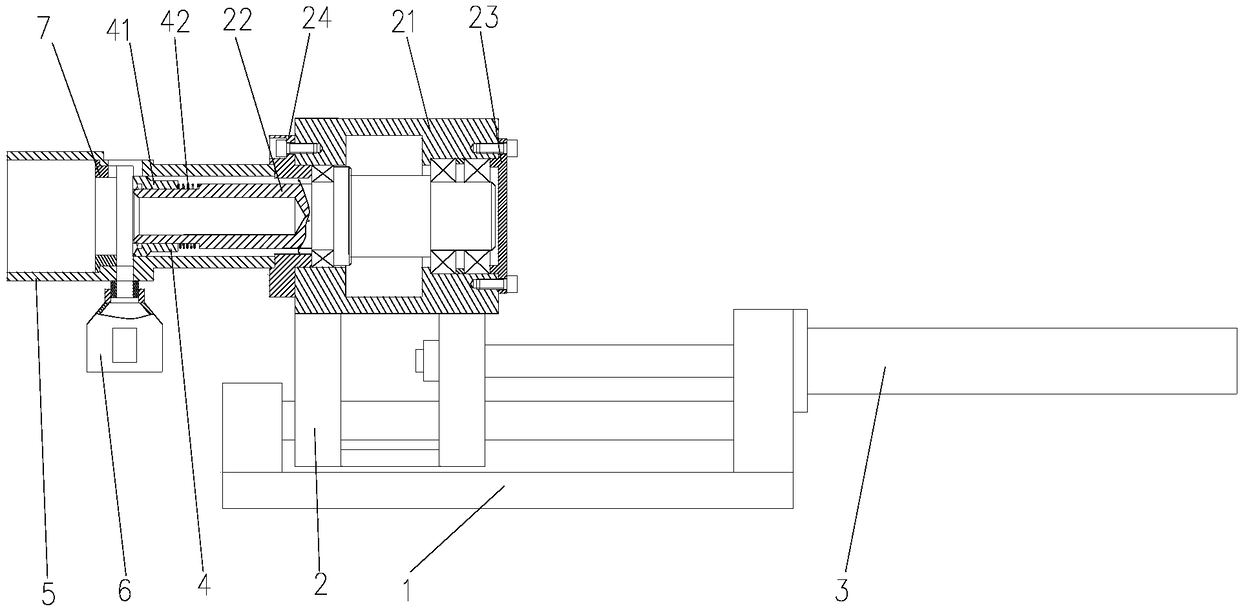

Tightening device with auxiliary centering function

InactiveCN109093311APrevent splashEasy to collectWelding/cutting auxillary devicesAuxillary welding devicesWorking environmentEngineering

The invention discloses a tightening device with an auxiliary centering function. The tightening device with the auxiliary centering function is characterized in that the tightening device comprises asliding seat, a tightening mechanism and a thrust mechanism; the tightening mechanism comprises a shell and a top shaft, wherein the left end of the top shaft extends out of the left end of the shell, the right end of the top shaft is provided with a round hole for accommodating the small end of a right workpiece, and the outer circular surface of the top shaft is provided with a centering mechanism for easy centering of the right workpiece; the left end of the top shaft is sleeved with a protective cover which is removably connected on the left end face of the face; the top of the protectivecover is provided with a welding gun hole for easy penetration of a welding torch, and the bottom of the same is provided with a collection box for easy collection of welding slag. The tightening device with the auxiliary centering function has the advantages of avoiding the welding slag from splashing everywhere and facilitating the collection of the welding slag to avoid the influence on the work environment with the arrangement of the protective cover and the collection box, and being capable of centering the end portion of the large outer circle on the right side of the right workpiece through the centering mechanism when the right workpiece is a stepped shape with the right small and the left large and a small end central hole of the right workpiece can not be centered through a topcone.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com