Topological optimization structure ceramic matrix and nickel-based high-temperature alloy integrated component and preparation method thereof

A technology of nickel-based high-temperature alloy and ceramic matrix, which is applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of complex structure solidification, metal droplets can not be completely filled, etc., to improve strength and stability , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

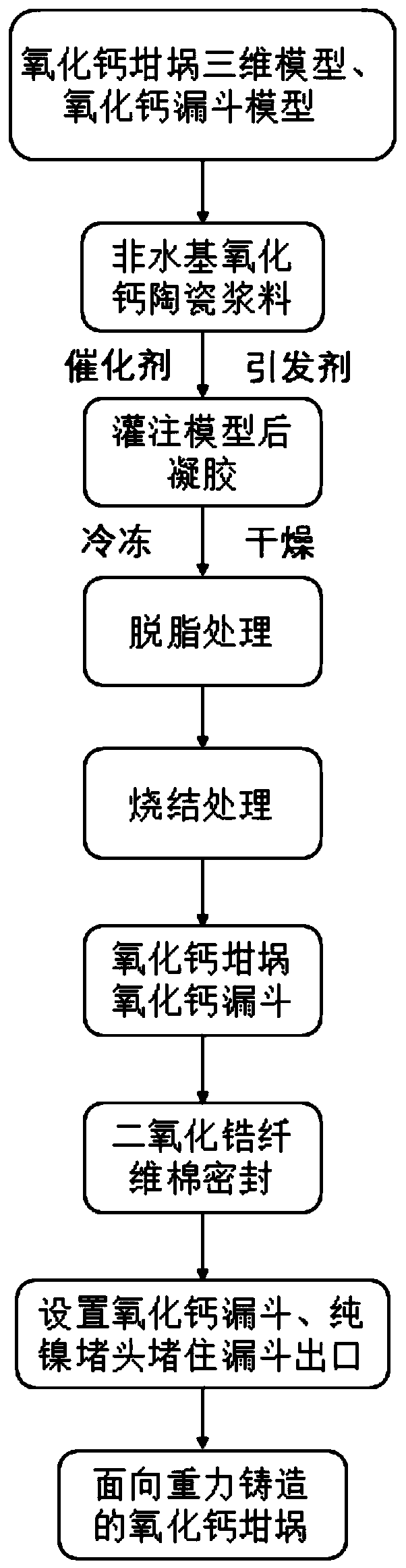

[0053] In this embodiment, when processing a composite component of a ceramic matrix with a complex topology optimization structure and a nickel-based superalloy, the steps for making a calcium oxide-based ceramic mold with hydration resistance and a calcium oxide funnel are as follows:

[0054] The first step is to obtain the three-dimensional model of the calcium oxide casting mold by performing Boolean operations on the three-dimensional model of the ceramic matrix with topology optimization, and then prepare the mold of the calcium oxide casting mold by photocuring;

[0055] The second step is to configure the non-water-based premix and non-water-based calcium oxide ceramic slurry required for calcium oxide casting gel injection molding. The non-water-based calcium oxide ceramic slurry is made by mixing calcium oxide powder, additives and dispersants, then adding them to the non-water-based premix and mixing them evenly; the non-water-based premix is composed of tert-buta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com