Position control device and control method for free loop of thin strip continuous casting strip steel

A control device and looper technology, which is applied in the field of continuous casting technology and equipment in the metallurgical industry, can solve problems such as transverse cracks on the surface of the casting belt, and achieve the effect of smooth running and bonding of the casting belt and the guide device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

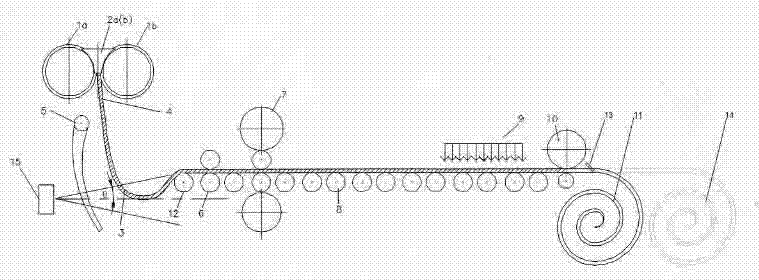

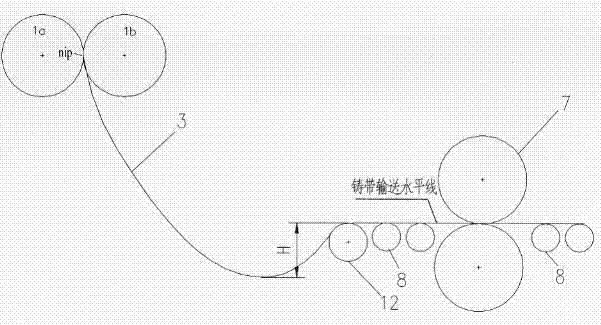

[0040] see Figure 3 to Figure 5 , the present invention provides a free looper position control device for thin strip continuous casting strip steel, which includes cooling roll 1, side sealing plate 2, looper 3, casting belt 4, guide plate 5, pinch roll 6, rolling mill 7, Conveying roller table 8, spray cooling device 9, crimper pinch roller 10, crimper 11, looper guide roller 12 and looper position control device.

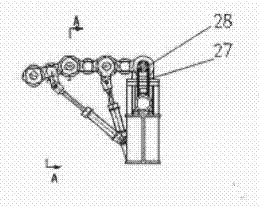

[0041]The looper position control device is mainly composed of a drive motor 20, a first rocker arm 21, 21', a second rocker arm 22, 22', a number of encoders 23a, 23b, 23c, 23d, 23e, 23f, 23g, bearing blocks 24, Active guide roller 26, several passive guide rollers 25, 32, 33, 34, 35, 36, transmission chain 27, sprocket wheel 28, base 29 and hydraulic cylinder 30, 31 form.

[0042] The driving guide roller 26 is fixed on the base 29 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com