Cotton cloth gluing equipment for surface flattening treatment

A technology for smoothing the surface and cotton cloth, which is applied to the device for coating liquid on the surface, trimming the surface of the fabric, coating and other directions, can solve the problems such as the generation of fluff and cotton balls, the unevenness of cotton cloth, and the unclean removal of cotton balls on the surface, etc. Achieve the effect of improving quality and enhancing surface aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

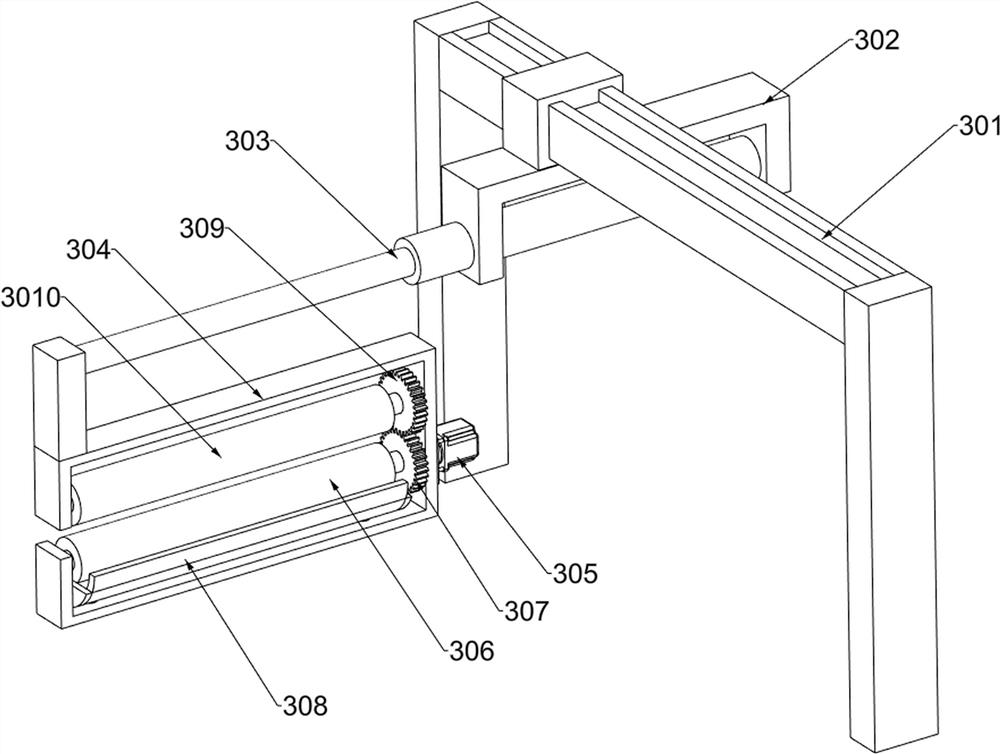

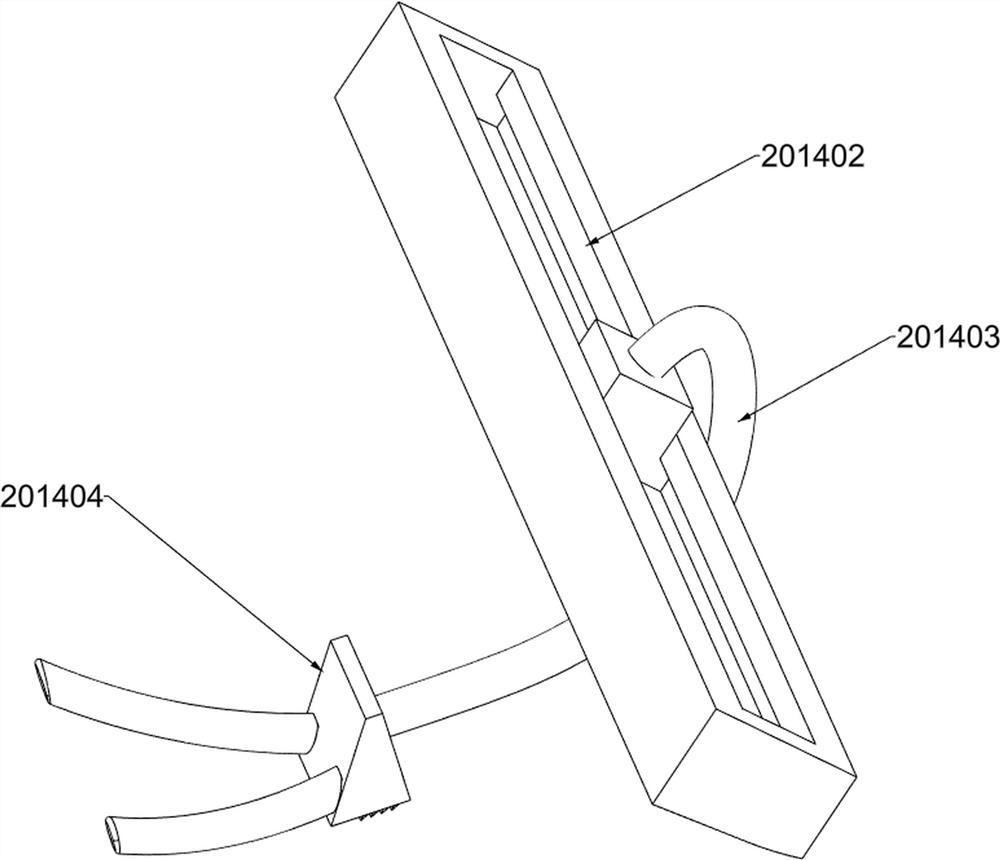

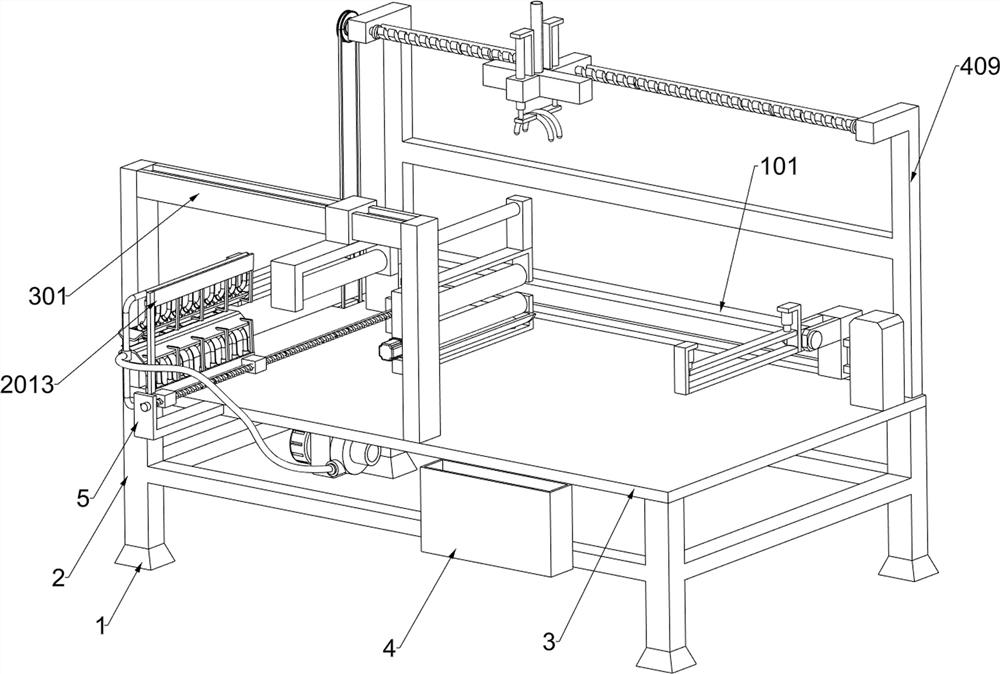

[0033] A cotton cloth gluing equipment for smooth surface treatment, such as Figure 1-3 As shown, it includes anti-slip mat 1, chassis 2, bottom plate 3, storage box 4, fixing plate 5, surface lint treatment system and glue absorption system; bottom chassis 2 is provided with four sets of anti-skid mats 1; chassis 2 A bottom plate 3 is installed above; a storage box 4 is installed on the right side in front of the bottom frame 2; the storage box 4 is affixed to the bottom plate 3; A surface lint treatment system for removing the ball; a glue absorption system for homogenizing the glue on both surfaces of the polyester-cotton cloth is installed on the rear side above the bottom plate 3; the fixed plate 5 is fixedly connected to the surface lint treatment system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com