Vertical face turning device for cylindrical workpiece

A cylindrical workpiece and flipping technology, which is applied in the field of automatic flipping devices, can solve the problems of low cost and achieve the effects of low cost, simple and reliable flipping process, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

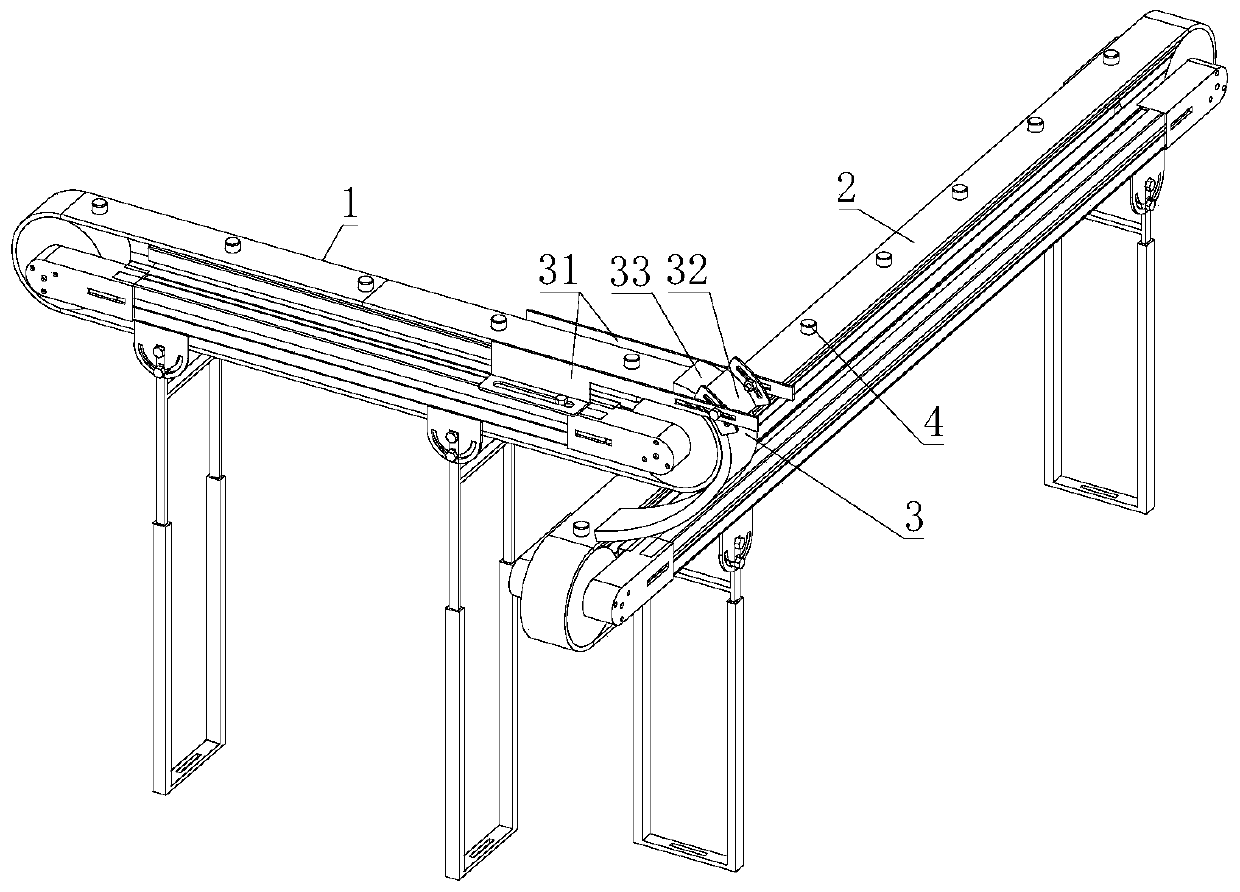

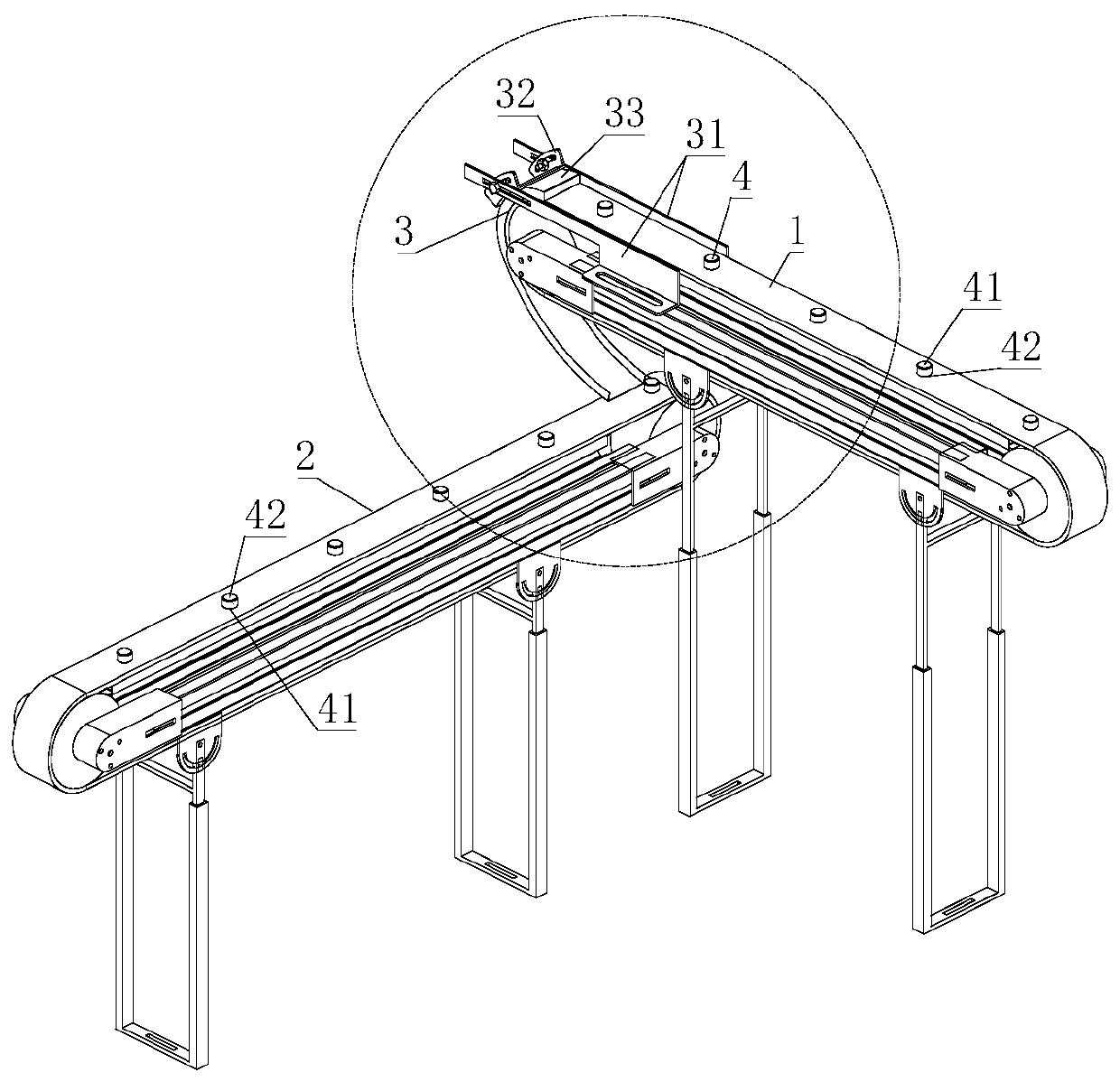

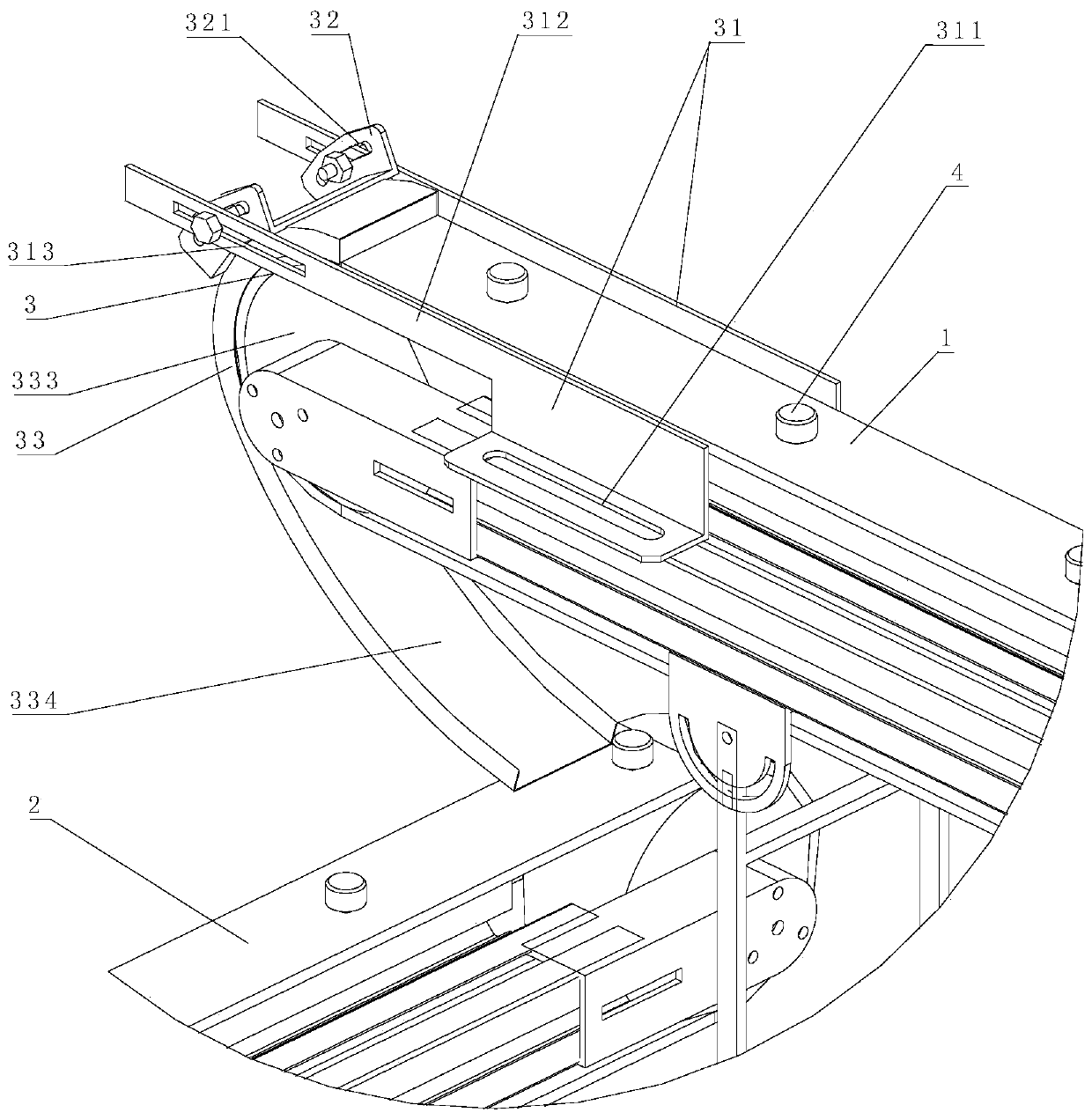

[0030] see Figure 1-5 , the up and down turning device of the cylindrical workpiece of the present invention comprises an upper conveyor belt 1 and a lower conveyor belt 2; the feeding end of the upper conveyor belt 1 is located above the feeding end of the lower conveyor belt 2; The end is connected with the feeding end of the lower conveyor belt 2 through the turning device 3; the turning device 3 includes an arc-shaped turning slide 33, and the entrance of the arc-shaped turning slide 33 is connected with the feeding end of the upper conveyor belt 1, The outlet of the arc-shaped turning slide 33 is connected with the feeding end of the lower conveyor belt 2, and the radius of curvature at the inlet of the arc-shaped turning slide 33 is consistent with the radius of curvature of the feeding end of the upper conveyor belt 1.

[0031] see Figure 7, the arc-shaped turning slide 33 is divided into upper and lower sections; wherein, the radius of curvature R1 of the upper sect...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the radius of curvature of the arc-shaped turning slide 33 gradually increases from the entrance to the exit. When adjusting the position of the arc-shaped turning slide 33 relative to the conveyor belt 1, the distance between the conveyor belt 1 and the slide surface of the upper section 333 does not change much, preventing the cylindrical workpiece 4 from overturning when turning over.

Embodiment 3

[0040] see Image 6 The difference between this embodiment and the above-mentioned embodiments is that the arc-shaped turning slide 33 is a long tube with a rectangular cross section, and the upper end of the arc-shaped turning slide 33 is provided with an opening groove 331 facing the upper conveyor belt 1, The end cross section of the opening groove 331 is a cylindrical workpiece butt surface 332, the cylindrical workpiece butt surface 332 is located below the cut surface of the end of the upper conveyor belt 1, and the outer edge of the cylindrical workpiece butt surface 332 is left between the upper conveyor belt 1 There is a gap, and the height of the cross section of the arc-shaped turning slide 33 is greater than the height of the cylindrical workpiece 4 . The bottom of the arc-shaped turning slide 33 is closed, and the cylindrical workpiece docking surface 332 is docked with the lower semicircle of the upper conveyor belt 1, which can effectively protect the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com