Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "SA copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyether-modified polysiloxanes with block character and use thereof for producing cosmetic formulations

InactiveUS20070128143A1Easy to combineGood skin feelCosmetic preparationsHair cosmeticsType distributionSA copolymer

The invention provides a method of producing organomodified siloxanes with domain-type distribution obtained by partial or complete reaction of A) hydrogensiloxanes with a degree of distribution (persistency ratio) (η) of components [A] and [B] in the copolymer [AB]η=[A][B][AB]of η>1, preferably >1.1, in particular ≧1.2, with B) olefinically and / or acetylenically unsaturated compounds, the compounds resulting therefrom and their use.

Owner:EVONIK GOLDSCHMIDT GMBH

Super plasticizer of polyether for rapid hardening concrete

ActiveCN101066853AReduce drying shrinkageOvercoming the defect of increasing concrete drying shrinkageWater basedPlasticizer

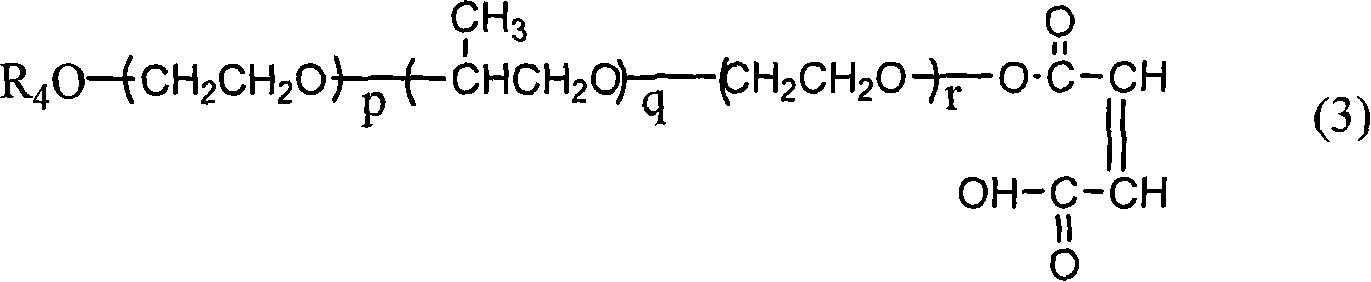

The present invention relates to one kind of super plasticizer of polyether for rapid hardening concrete. The super plasticizer is prepared through the first free radical copolymerization of monomer A in 84-94 wt%, monomer B in 5-15 wt% and monomer C in 1-3 wt% in water-base medium; and the subsequent neutralization reaction of the copolymer and alkoxyl organic amine to regulate the pH value of the copolymer to 6.0-7.5. The super plasticizer has excellent dispersing performance and reinforcing effect, especially obvious early reinforcing effect, and is favorable to raise construction speed and raising the durability of concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

Copolymer of olefin and conjugated diene, and process for producing the same

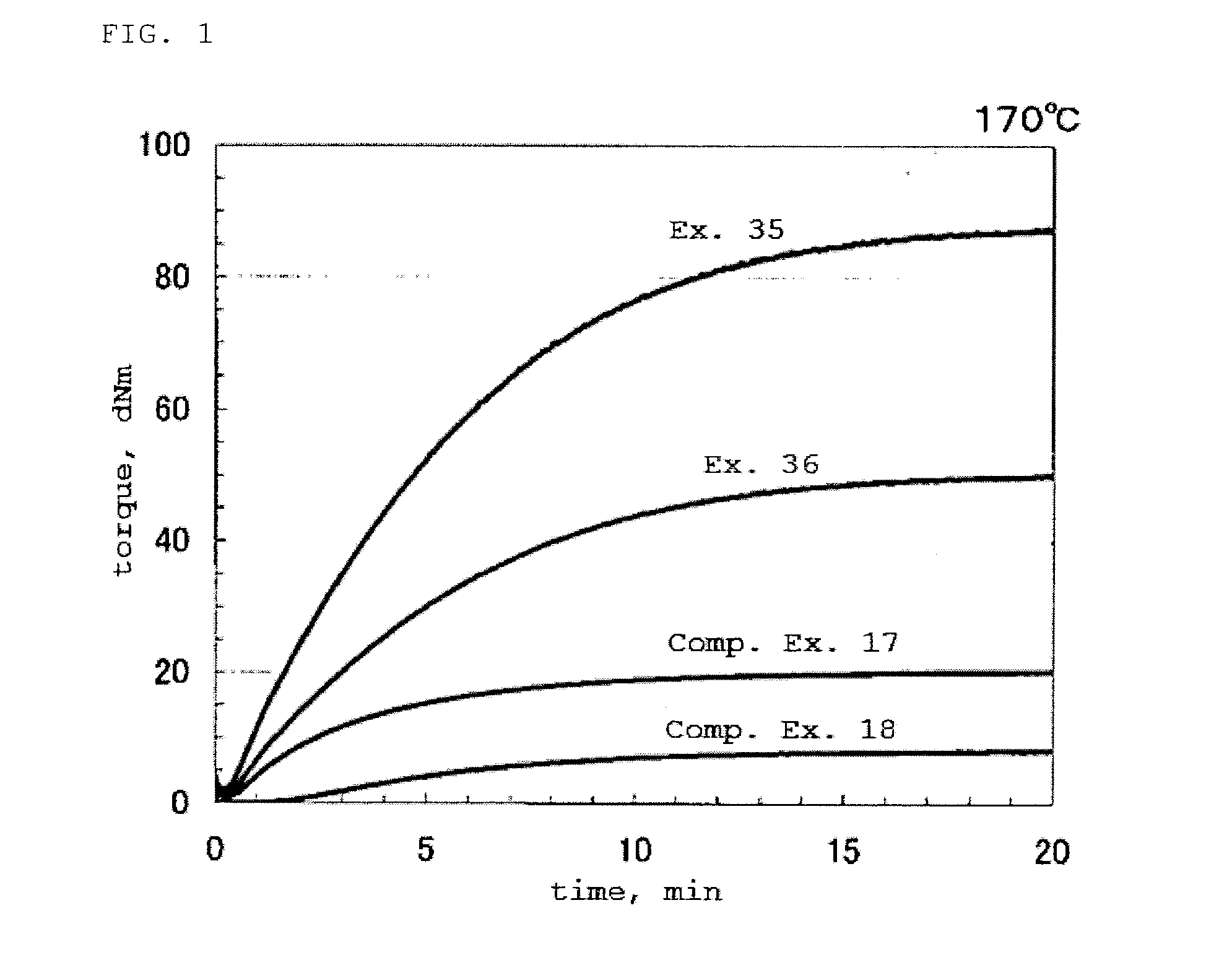

ActiveUS20120059135A1Maintain good propertiesLower glass transition temperatureSide chainSA copolymer

An object of the invention is to provide copolymers which have a double bond in a side chain and are substantially free of unsaturated bonds in the main chain, copolymers which have a cyclic structure and are substantially free of unsaturated bonds in the main chain, and processes for economically synthesizing these copolymers.A copolymer of the invention is obtained by copolymerizing at least ethylene and a conjugated diene. In the copolymer, structural units derived from the conjugated diene represent 1 to 90 mol %. Structural units resulting from 1,2-addition of the conjugated diene and having a side-chain double bond represent 0 to 90 mol %, structural units resulting from 1,4-addition of the conjugated diene represent 0 to 3 mol %, structural units resulting from 1,3-addition of the conjugated diene represent 0 to 3 mol %, and the total of structural units resulting from 1,2-addition of the conjugated diene and having a 1,2-cyclopropane skeleton and structural units resulting from 1,2-addition of the conjugated diene and having a 1,2-cyclopentane skeleton represent 4 to 100 mol %.

Owner:MITSUI CHEM INC

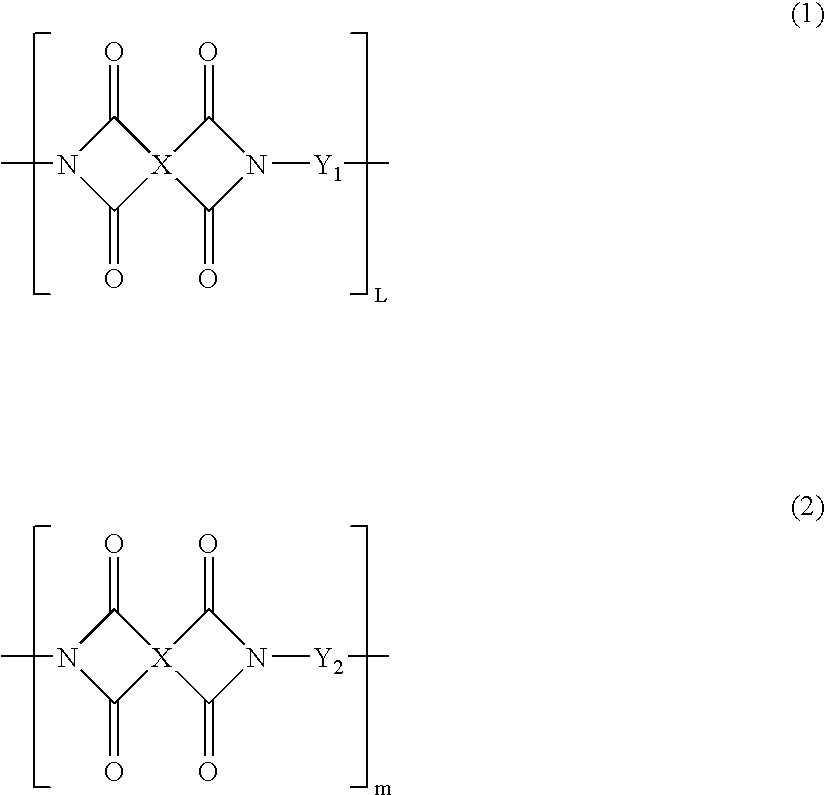

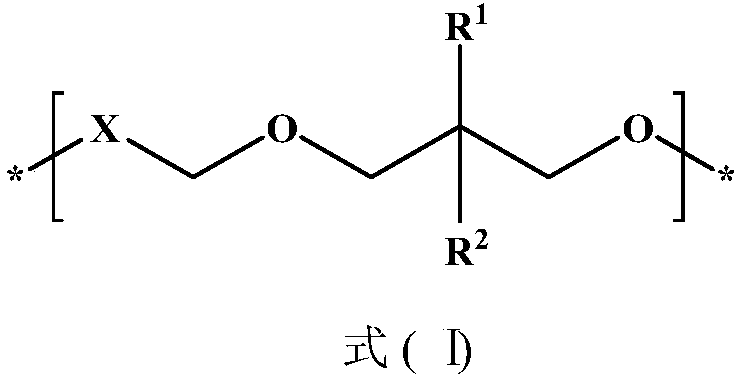

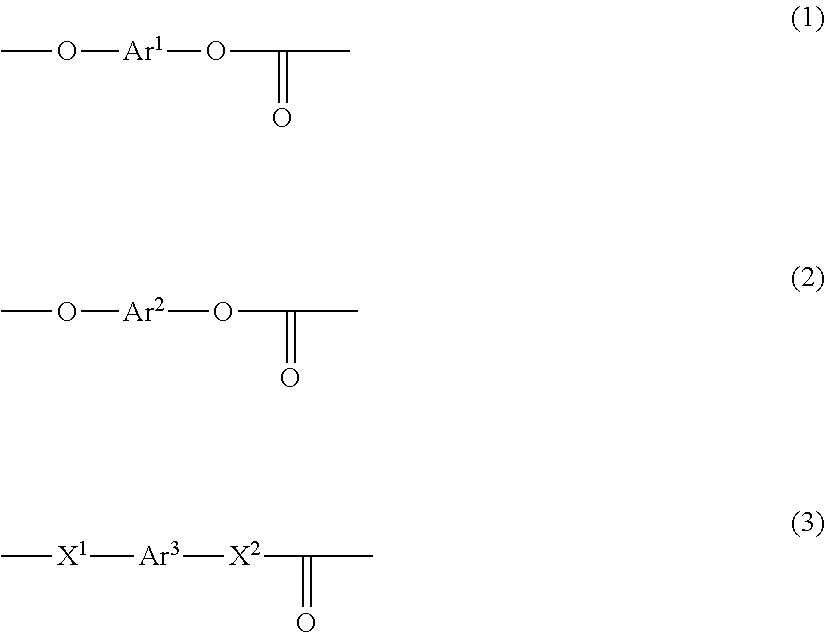

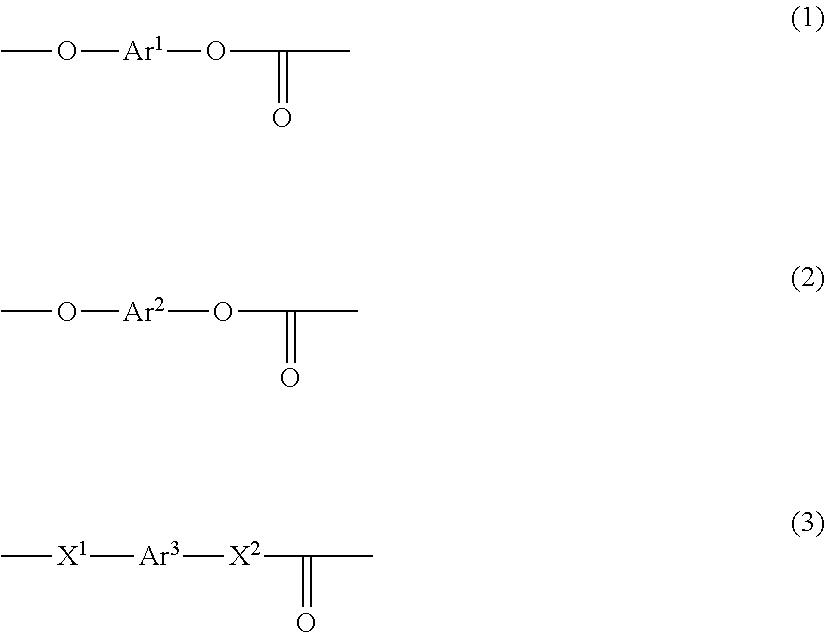

Partial block polyimide-polysiloxane copolymer, making method , and resin composition comprising the copolymer

A partial block polyimide-polysiloxane copolymer is provided comprising repeat unit structures having structural formulae (1) and (2) wherein X is an aromatic or aliphatic ring-containing tetravalent organic radical, Y1 is a diamine residue, Y2 is a diaminosiloxane residue, Y1 and Y2 are contained in the copolymer in amounts of 99-20 mol % and 1-80 mol %, respectively, L and m each are an integer of 2-50. The copolymer has good adhesion to substrates, moisture-proof reliability and a low modulus of elasticity.

Owner:SHIN ETSU CHEM IND CO LTD

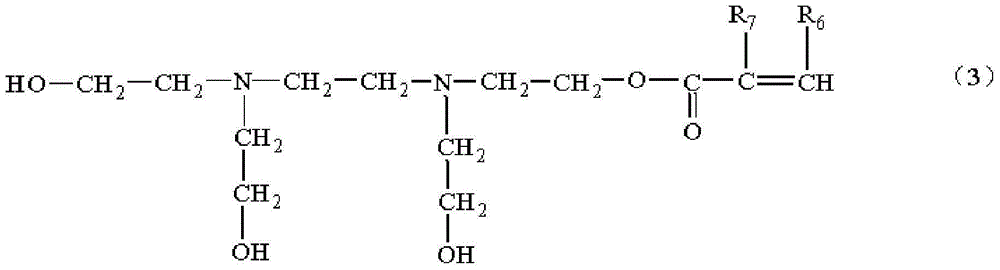

Polyethers ultra early and strong type concrete superplasticizer

The invention relates to a polyether early- strength super-plasticizing agent. The preparation method comprises following steps: (1) copolymerization of water- borne free radical: 5%- 15% monomer a, 82%- 92% monomer b, 2%- 8% monomer c, and 1%- 3% monomer d copolymerizes in water- borne medium, the total amount of said monomers is 100%; (2) neutralizing reaction: adding alkoxy organic amine e showed in general formula (6) and (7) into copolymer after polymerizing reaction for neutralization, moderating the copolymer pH to be between 6.0- 7.5. The invention is characterized in that: (1) the dispersing performance and strengthening effect are outstanding at very low amount, and the strengthening effect at normal temperature or lower temperature at early stage is excellent, and the effect at middle and later stage grows stably; (2) it can reduce the concrete contract, and the contract rate is less than 90% of that of standard concrete; (3) it barely contains no chloride ion and is helpful for concrete durability increase.

Owner:JIANGSU SOBUTE NEW MATERIALS

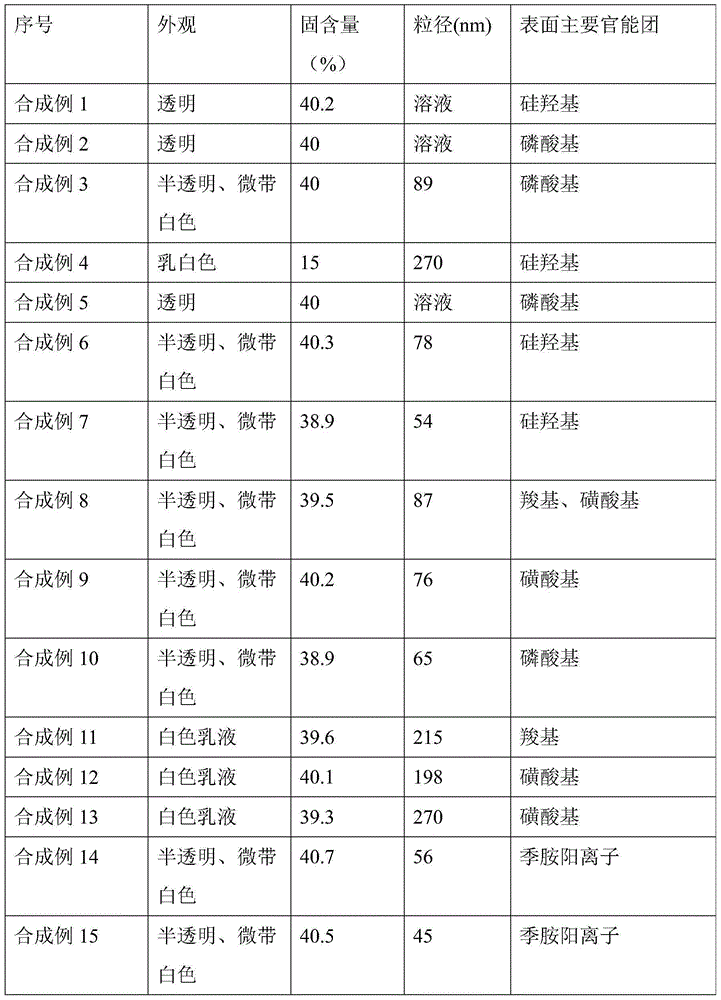

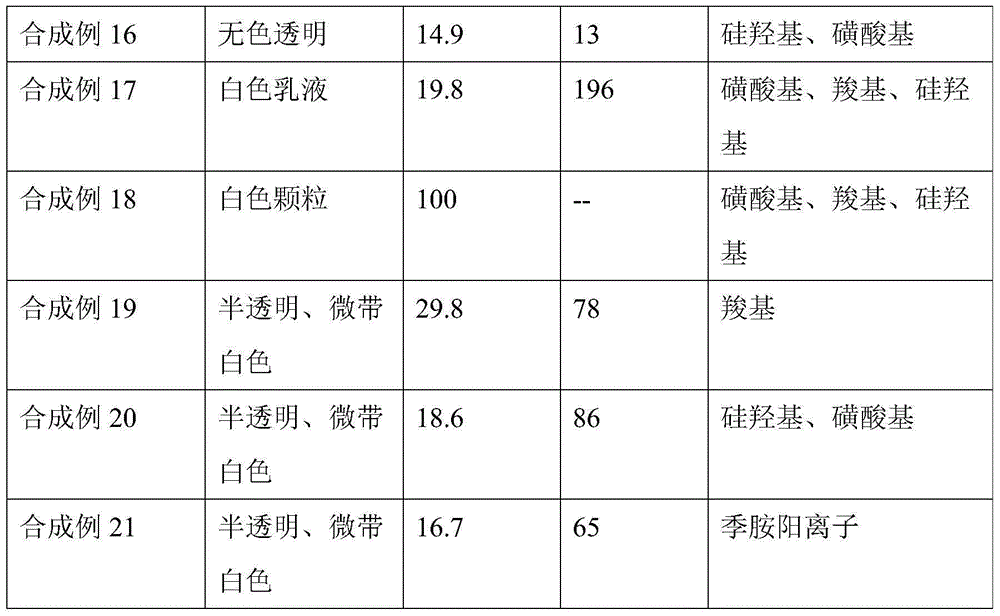

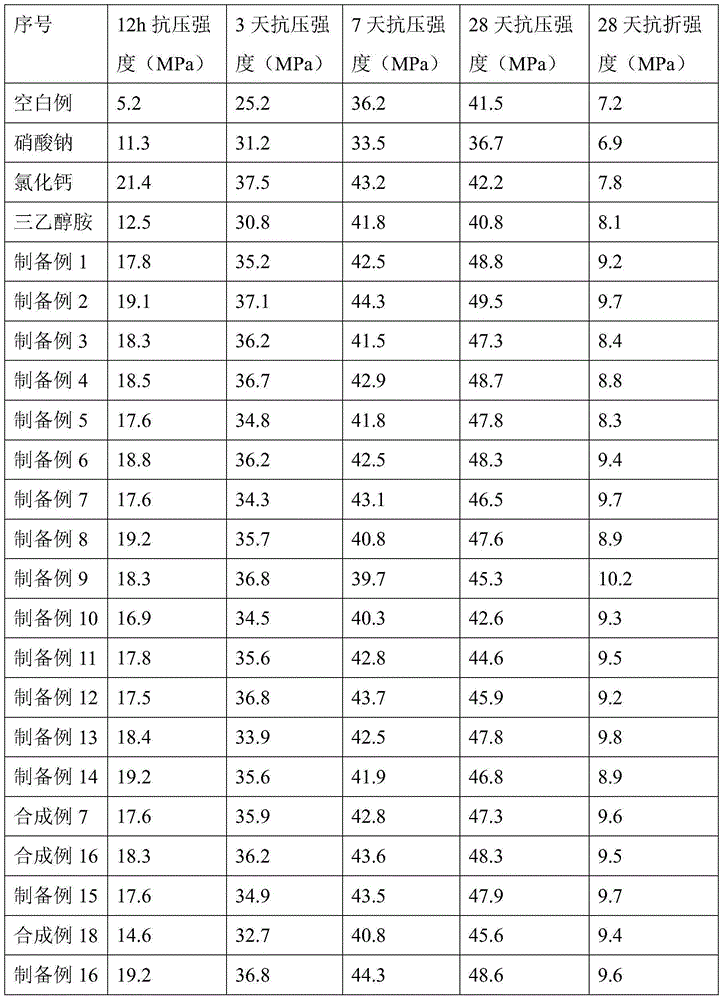

Polymer nano / micro particle additive and preparation method thereof

A polymer nano / micro particle additive is prepared from a main monomer and functional monomers by copolymerization. The functional monomers contain carboxylic group, sulfate group, sulfonate group, phosphate group, phosphite group, silane functional group, silicon hydroxyl functional group, and quaternary amine, quaternary phosphonium and tertiary sulfur functional groups; and the polymer nano / micro particle additive is a dry powder, or an aqueous dispersion. Under certain circumstances, the polymer does not contain main monomer but necessarily contains the above functional monomers. By introducing functional groups or anaphase modification, the polymer nano / micro particles have the effects of promoting hydration and nucleation of cement and greatly improving the early hydration rate of cement, so as to achieve improve the early strength of the cement-based materials and improve the toughness of cement-based materials.

Owner:北京水木佳维新材料技术研究院有限公司 +1

Early-strength polycarboxylate superplasticizer having slump-loss prevention function and preparation method thereof

Owner:SHENZHEN MAIDI CONCRETE ADDITIVES

Inkjet recording ink, ink cartridge, inkjet recording method, inkjet recording device and ink recorded matter

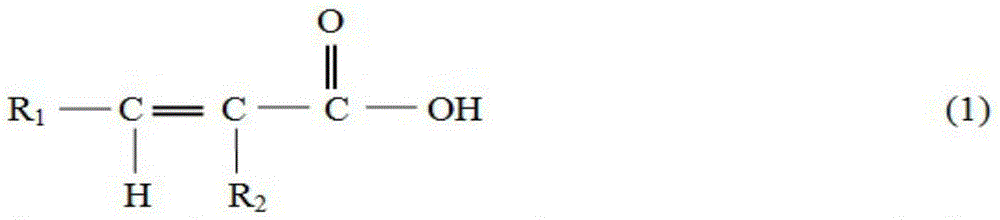

ActiveUS20150376425A1High image densityGood storage stabilityLayered productsInksOrganic solventHydrogen atom

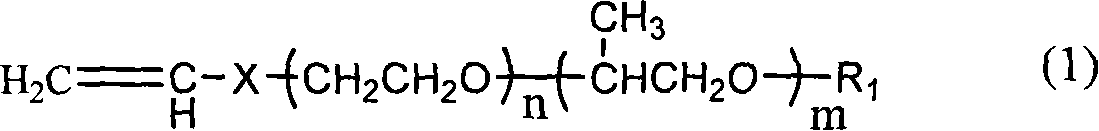

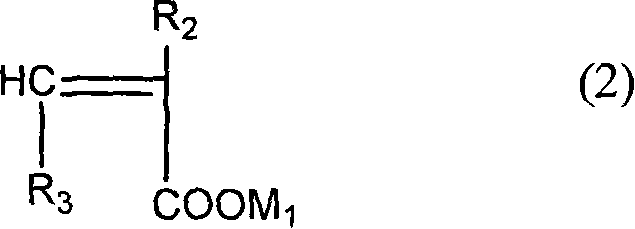

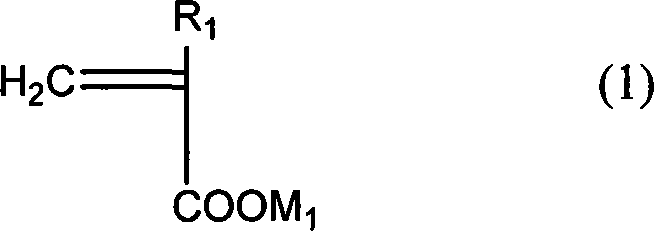

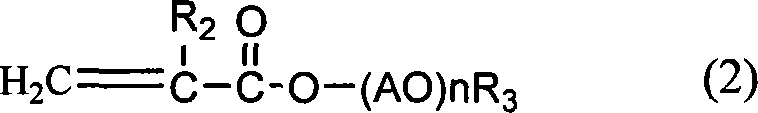

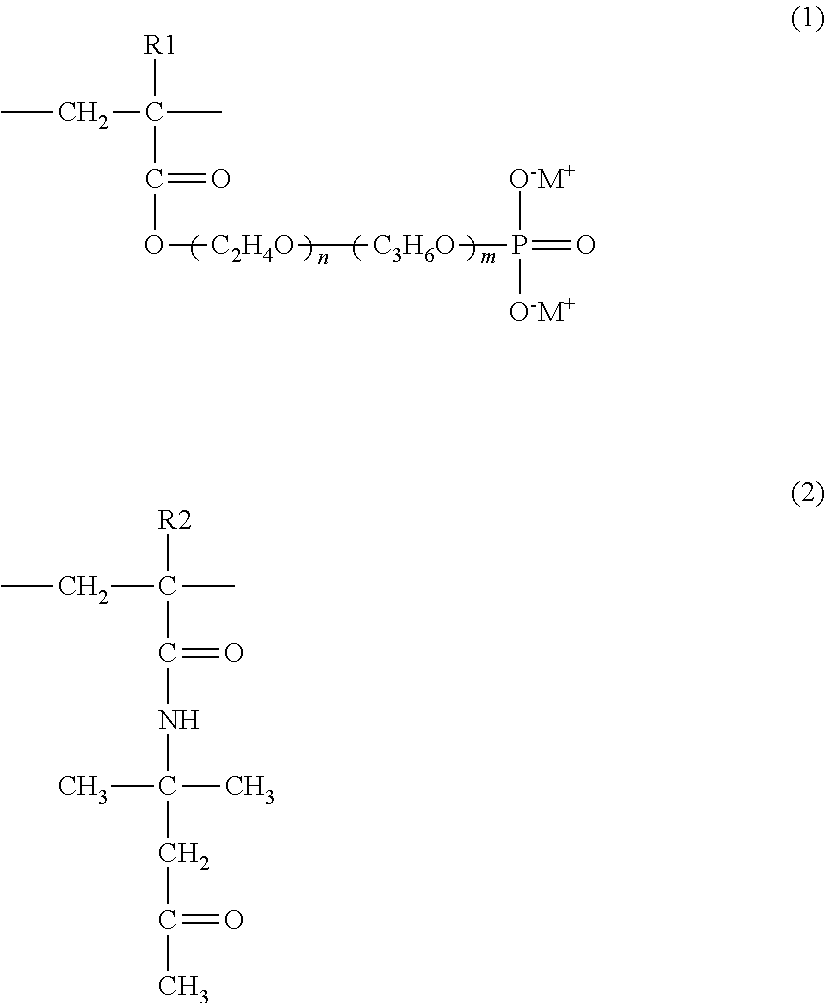

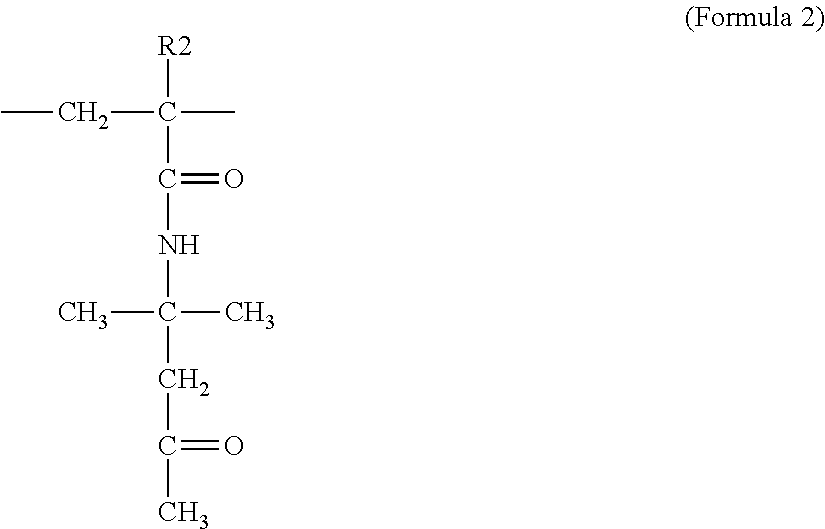

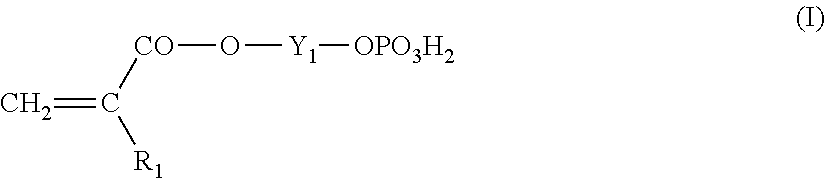

An inkjet recording ink, including: water; a water-soluble organic solvent; a pigment; and a phosphate group-containing copolymer, wherein the phosphate group-containing copolymer contains a structural unit represented by the following General Formula (1) and a structural unit represented by the following General Formula (2): where R1 denotes a hydrogen atom or a methyl group; M+ denotes an alkali metal ion, an organic amine ion, or a hydrogen ion; half or more of M+ in the copolymer is the alkali metal ion or the organic amine ion, the remainder of M+ is the hydrogen ion; n and m each denote an integer of 0 to 6, provided that both of n and m are not 0; and a block of (C2H4O) and a block of (C3H6O) may be exchanged with each other, where R2 denotes a hydrogen atom or a methyl group.

Owner:RICOH KK +1

Rate controlled release of a pharmaceutical agent in a biodegradable device

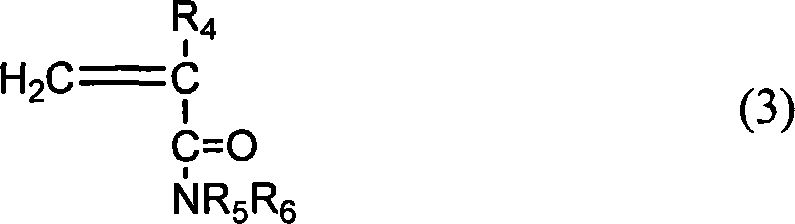

Matrix controlled diffusion drug delivery systems comprising a therapeutically effective amount of one or more pharmaceutically active agents entrapped in a copolymer which is a reaction product of a monomeric mixture comprising one or more acrylate ester and / or methacrylate ester-containing monomers and one or more acrylamido-containing monomers are disclosed. Also disclosed are processes for their preparations and methods for their use.

Owner:BAUSCH & LOMB INC

Cotton-polyester fabric burn-out printing gum and preparation method thereof

InactiveCN101942771AQuality improvementGood printing paste fluidityDyeing processPolyesterPotassium persulfate

The invention relates to cotton-polyester fabric burn-out printing gum and a preparation method thereof. The raw materials of the gum comprise the following components in parts by weight: 115-120 parts of acrylic acid, 8-10 parts of acrylamide, 17-19 parts of itaconic acid, 76-80 parts of sodium ethylenesulfonate, 220-240 parts of ammonia water, 3.0-3.5 parts of potassium persulfate, 1.8-2.5 parts of sodium bisulfite, 112-116 parts of corn starch and 480-510 parts of water. The preparation method comprises the following steps: performing solution polymerization, then adding corn starch in the copolymer to perform gelatinization and filtering to obtain the gum. The gum of the invention has good fluidity and stability, high permeability, good permeability, high definition of printing patterns and wide range of application temperature, is easy to wash with water and can obviously increase the quality of the printing product.

Owner:LIAONING FIXED STAR FINE CHEM

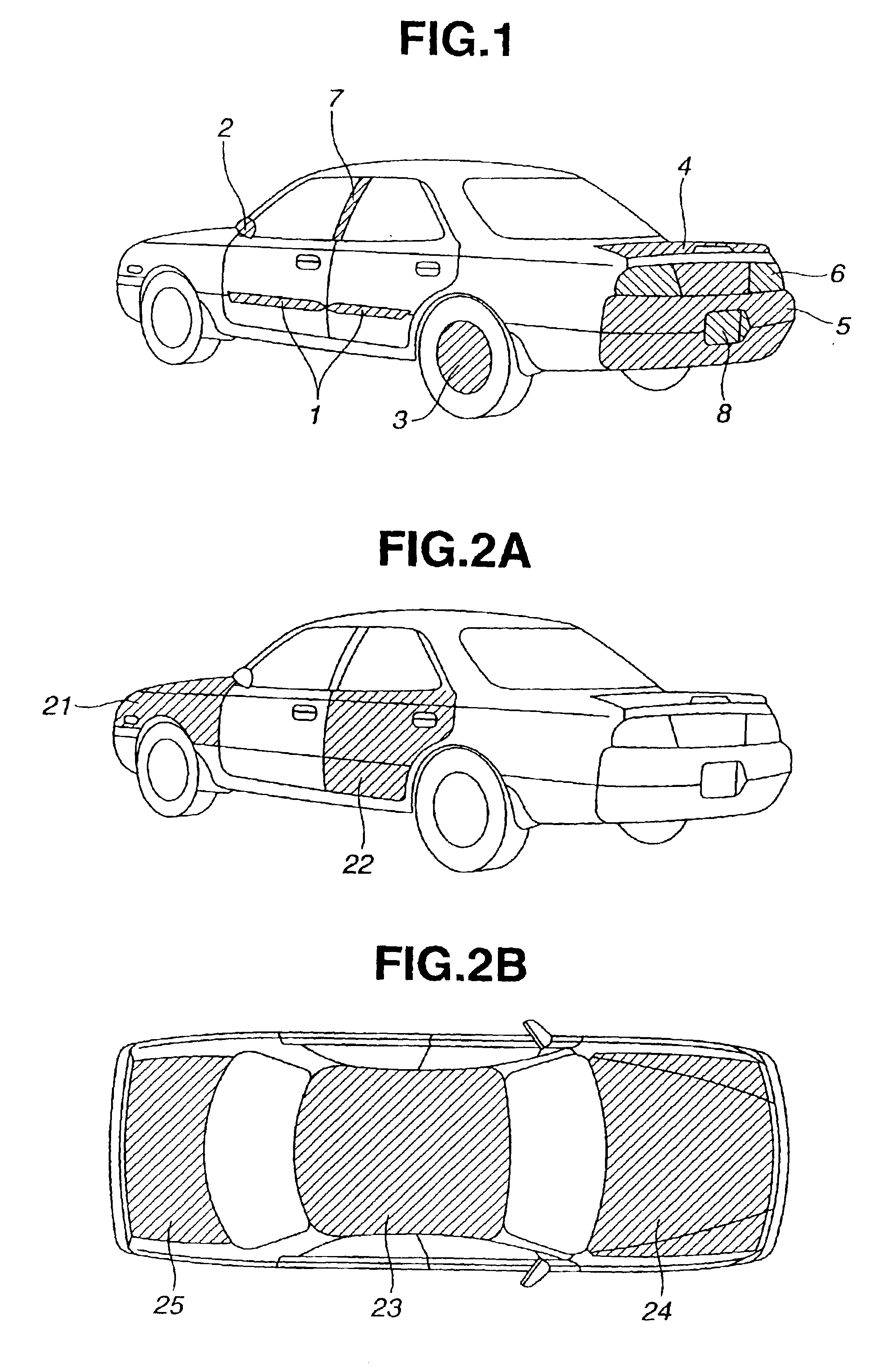

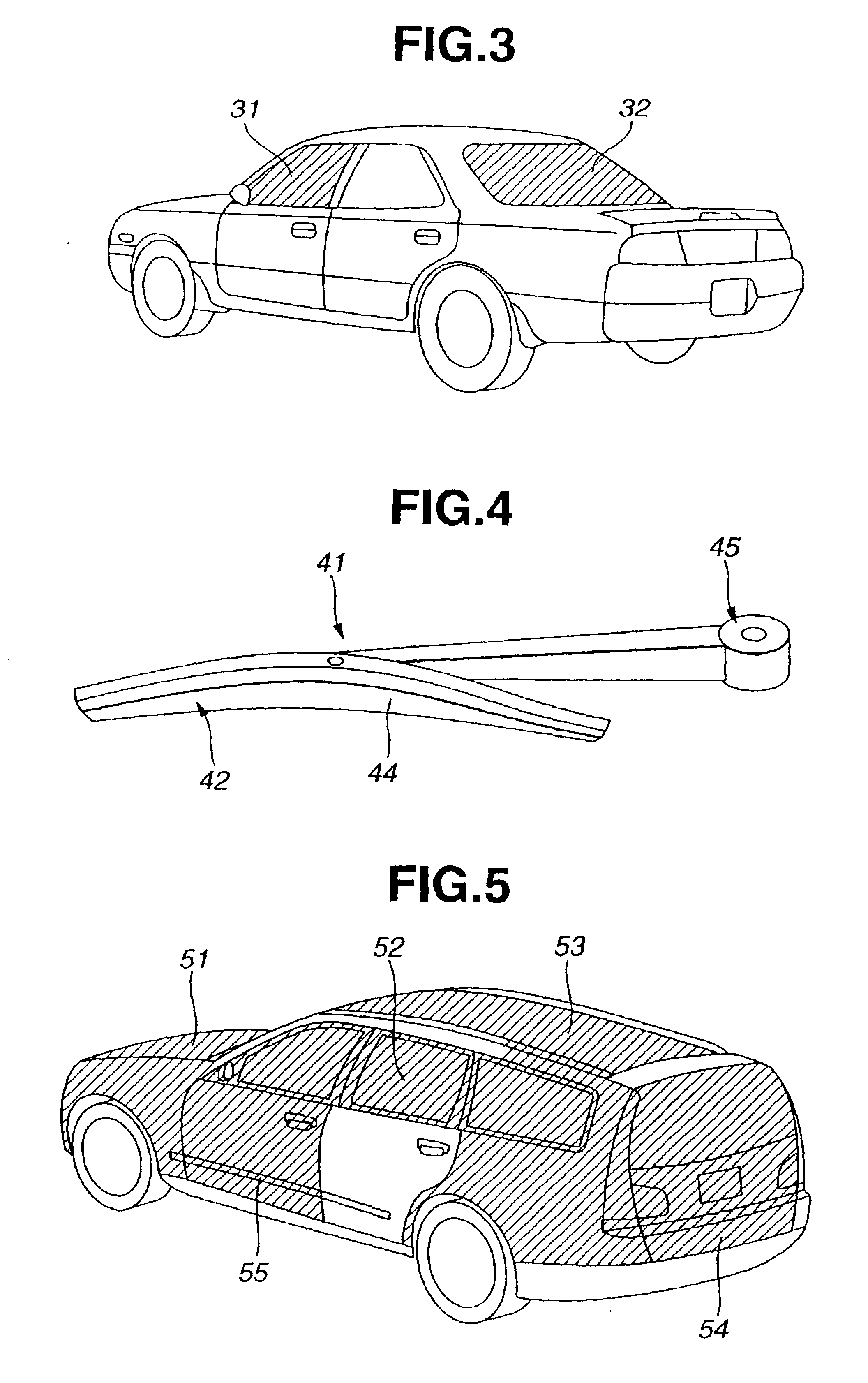

Resin composition, thermoplastic resin laminate, and production methods thereof

InactiveUS6916545B2Improve impact resistanceImprove rigidityLiquid surface applicatorsUnderstructuresHydroxy groupPolymer chemistry

A resin composition to be used as a material for a various part of an automotive vehicle. The resin composition comprises a copolymer (A) formed by copolymerization of a first unsaturated monomer (a) and a second mononer (b). The first unsaturated monomer has a functional group which is bondable by hydrogen bond to a hydroxyl group. The second monomer is copolymerizable with the first unsaturated monomer. A metal oxide (B) is dispersed in the copolymer and having hydroxyl groups and hydrophobic groups at surface of the metal oxide.

Owner:NISSAN MOTOR CO LTD +2

Reactive dye-white discharge printing paste and preparation method thereof

The invention relates to a reactive dye--white discharge printing paste and a preparation method thereof. The white discharge printing paste comprises the following raw materials by weight: 75 to 80 parts of acrylic acid, 9 to 11 parts of acrylamide, 57 to 62 parts of methacrylic acid, 78 to 82 parts of 2-acrylamide-2-methylacrylsulfonate, 360 to 380 parts of 20 % ammonia, 3.5 to 4.0 parts of ammonium persulfate, 1.9 to 2.6 parts of sodium bisulfite, and 490 to 520 parts of water. The method comprises the following steps: polymerizing all the liquors, adding 114 to 118 parts of starch to the copolymer, pasting, and filtering. As thiourea dioxide is taken as a white discharge agent, a fabric is easy to wash with water after print discharging; and no methanal is left on the fabric, so as tobe more environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

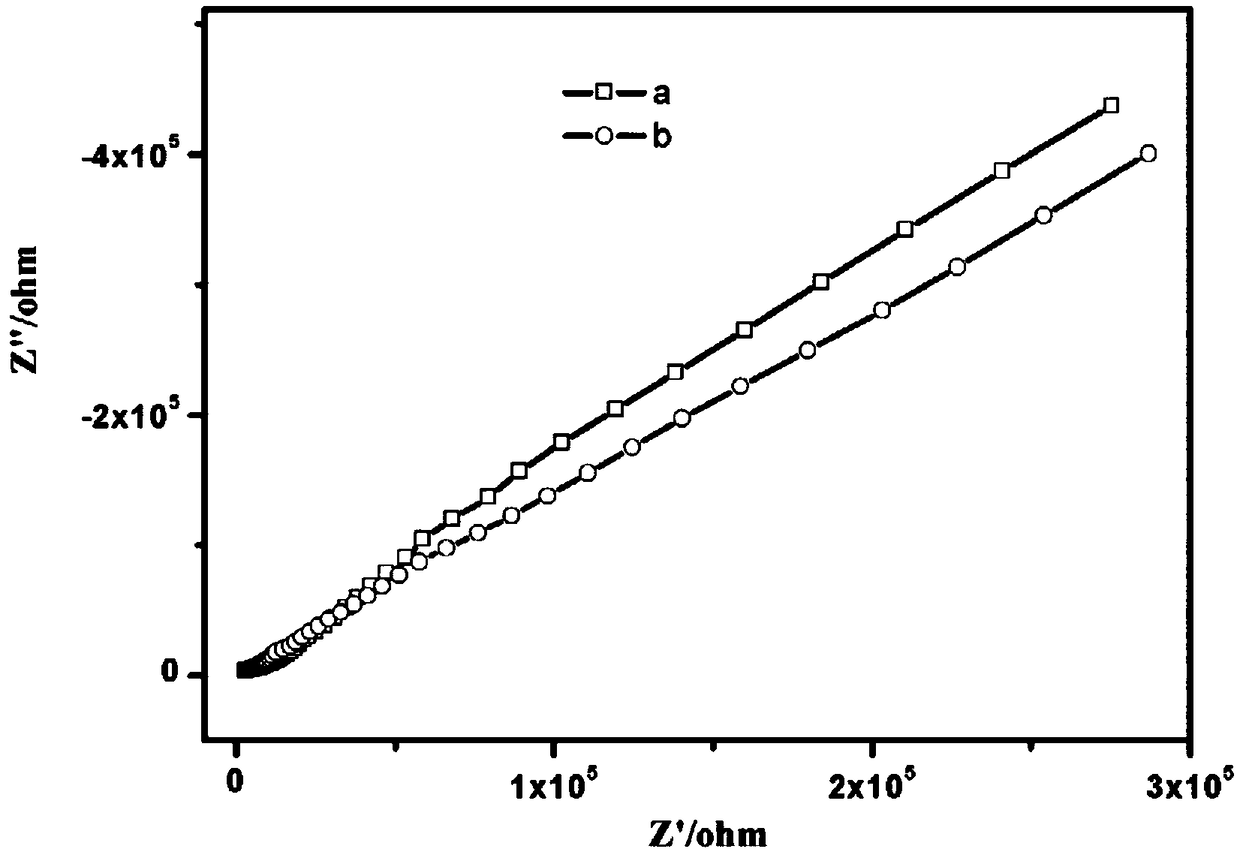

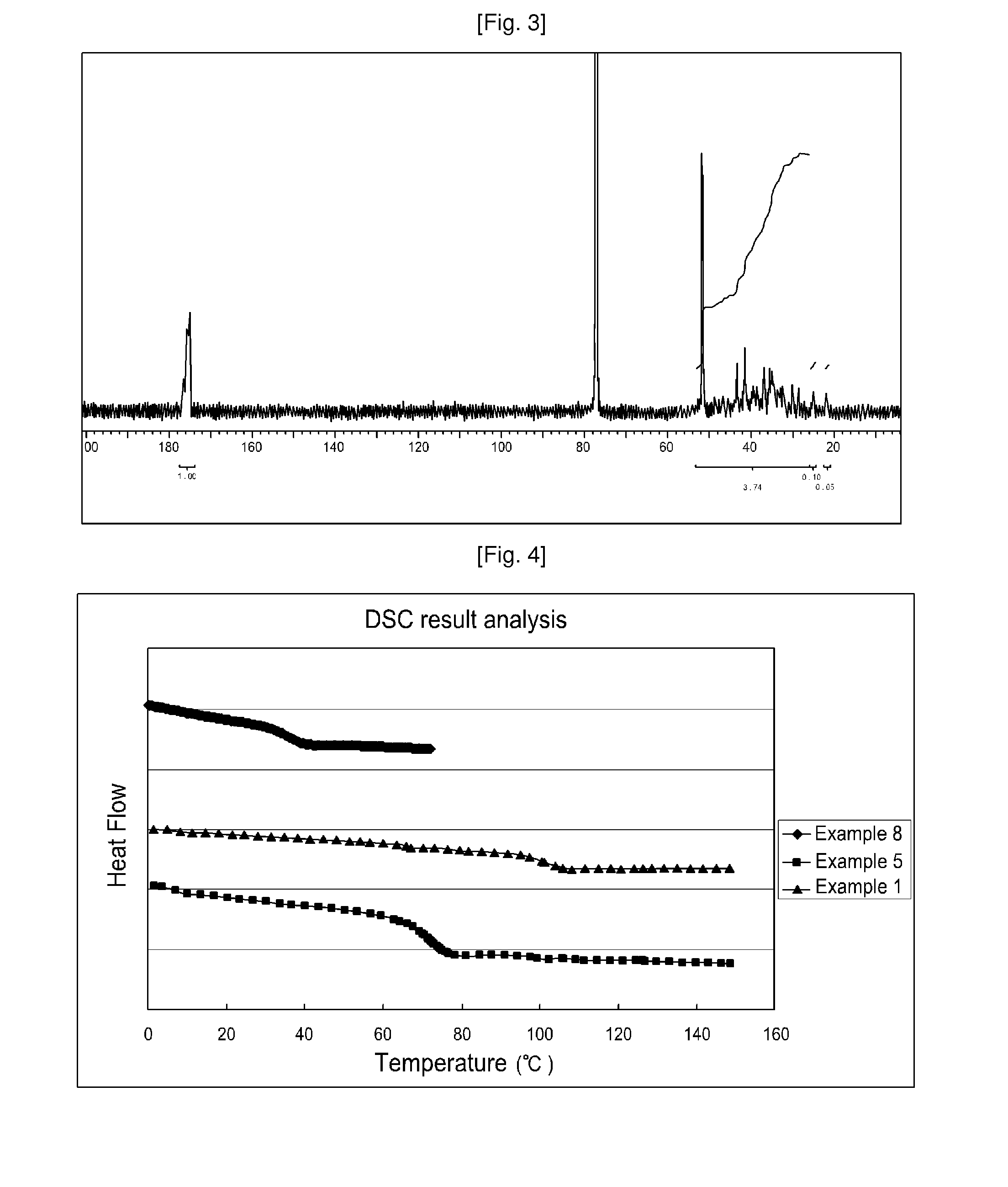

Alkyd resin modified polymer electrolyte as well as preparation method and application thereof

ActiveCN109401693AImprove flexibilityHigh mechanical strengthNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolymer science

The invention relates to an alkyd resin modified polymer electrolyte as well as a preparation method and application thereof. The preparation method comprises the following steps that alkyd resin andone or more monomers of acrylamide, methacrylamide, acrylonitrile, methyl acrylate, methyl methacrylate and monofunctional or polyfunctional polyethylene glycol acrylate / polyethylene glycol methacrylate are subjected to copolymerization in an organic solvent under the action of an initiator, then an electrolyte body, a plasticizer and ionic non-conductive or ionic conductive inorganic nano-particles or nano-fibers are added into a copolymer, and uniform mixing is carried out so as to obtain the alkyd resin modified polymer electrolyte; or the alkyd resin and an ionic conductive polymer are dissolved in the organic solvent, the electrolyte body, the plasticizer and the ionic non-conductive or ionic conductive inorganic nano-particles or the nano-fibers are added to perform blending, and uniform mixing is carried out so as to obtain the alkyd resin modified polymer electrolyte. The invention provides the novel high-performance polymer electrolyte and the preparation method thereof.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

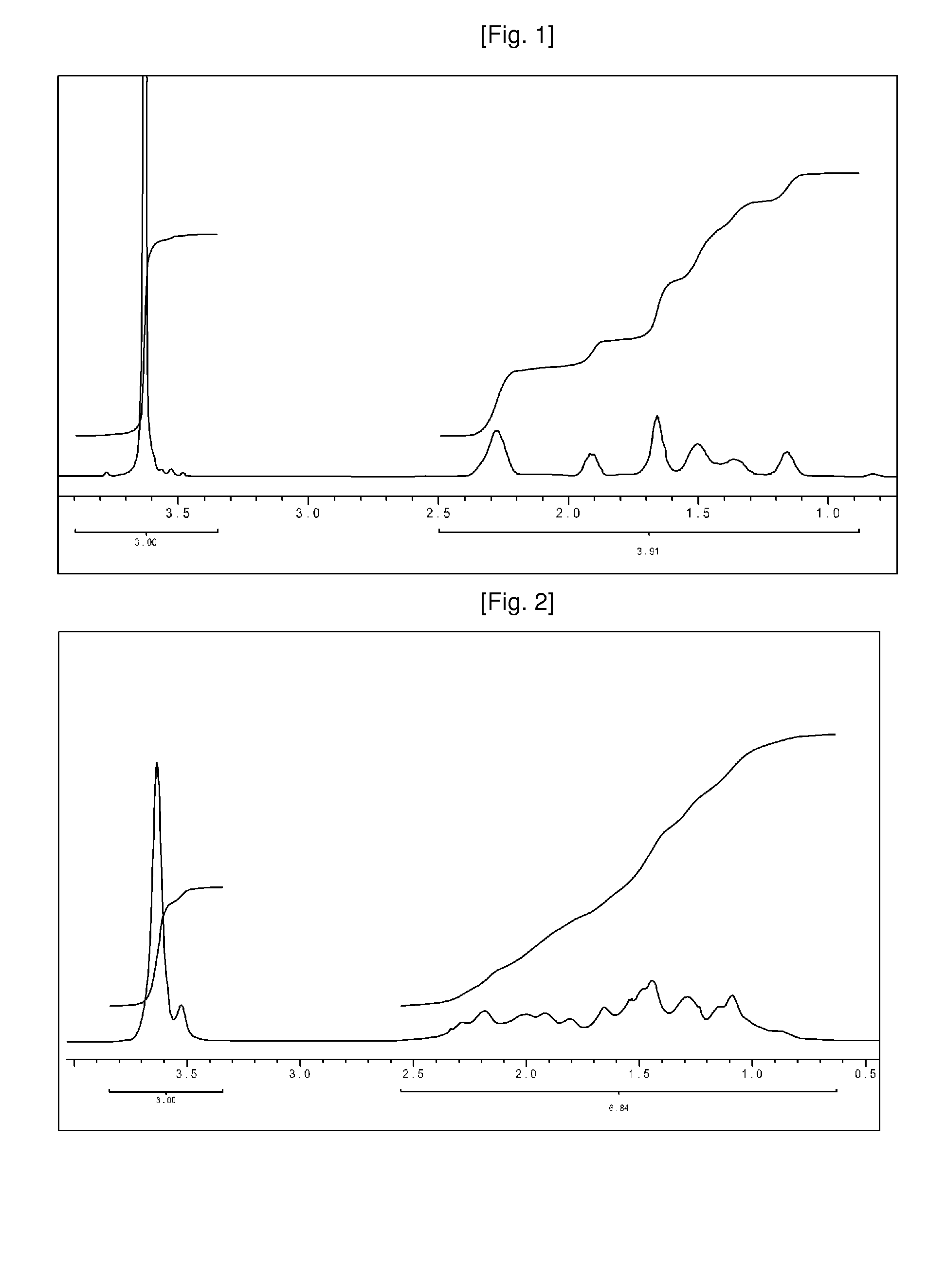

Method for preparation of 1-alkene-acrylate based copolymer

The present invention provides a method for preparation of an 1-alkene-acrylate based copolymer comprising a step of a radical polymerization reaction of 1-alkene and acrylate based monomer under presence of a metal oxide or Lewis acid, and a method for preparation of an alkene-acrylate based copolymer comprising reacting alkene with an acrylate based monomer under presence of a metal oxide. In the method of preparation according to the present invention, the process is simple and properties of the copolymer can be easily controlled by preparing the copolymer in a mild condition of 100° C. or less and 200 bar or less. In addition, the amount of the polar group of the copolymer prepared by the method is so high that the copolymer can be used for transparent optical products. Since the alkene-acrylate based copolymer prepared by the method is a random copolymer of ethylene and a polar monomer and the amount of the polar group of the polar monomer so high that the crystallinity of the ethylene monomer does not remain in the copolymer, the ethylene-acrylate based copolymer is not affected from a transparency of the polymer and thus may be used for optical products.

Owner:LG CHEM LTD

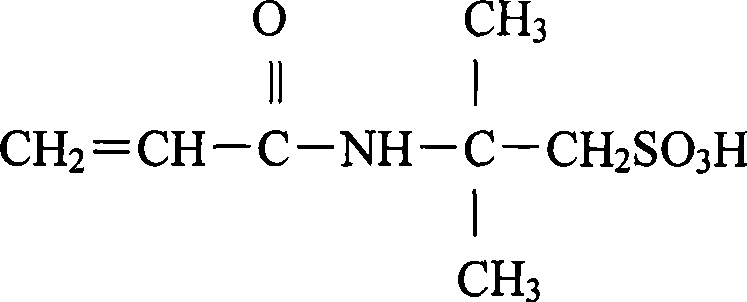

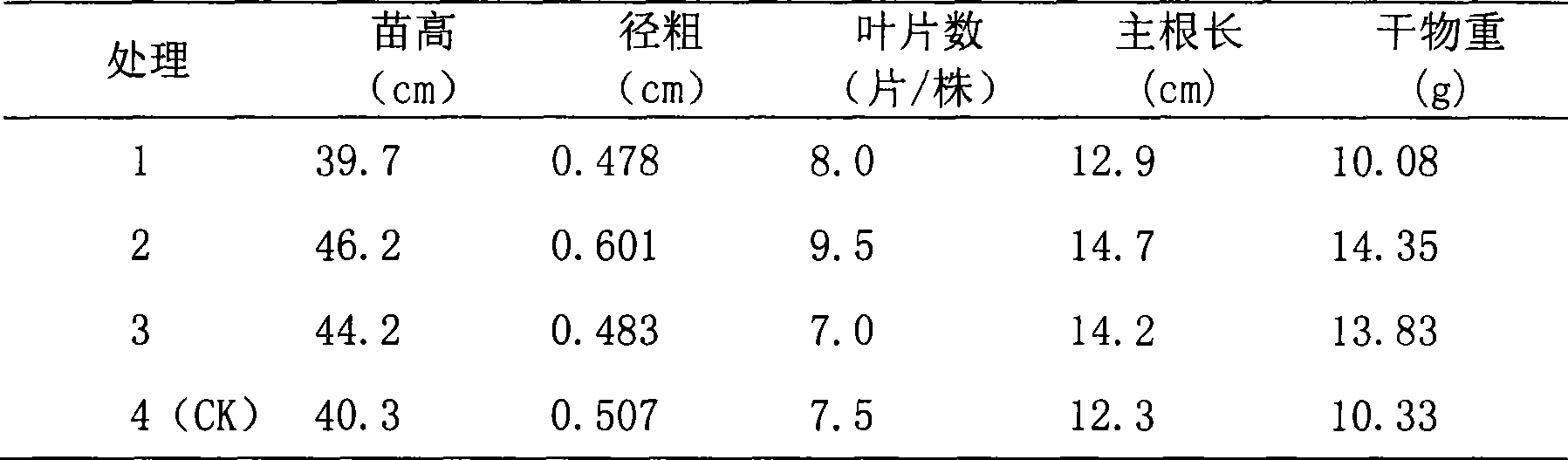

A film-builder used for seed-coating agent

InactiveCN101444206AEasy to filmFunction increaseBiocideAnimal repellantsMethacrylateBiocompatibility Testing

The present invention discloses a film-builder used for seed-coating agent, which is a copolymer produced by initiation and co-polymerization of AMPS monomer and at least one vinyl monomer. In the co-polymer, mole percentage of AMPS monomer is from 0.5% to 30%, and the balance is vinyl monomer, wherein the vinyl monomer is chosen from acrylic ester or metacrylic acid ester or vinyl acetate or phenyl ethylene or acrylic amide. The film-builder has good film building and sustained-release function, high film building strength, water adsorb and resistance, and chemical stability, and favorable biocompatibility with agronomic crop. The shedding rate of seed lagging cover after drying low, film after absorbing water and expansion ventilated and not dissolvable, active ingredient can be released slowly, and favorable growing microenvironment for plant especially crops can be produced.

Owner:安徽省农业科学院原子能农业应用研究所 +1

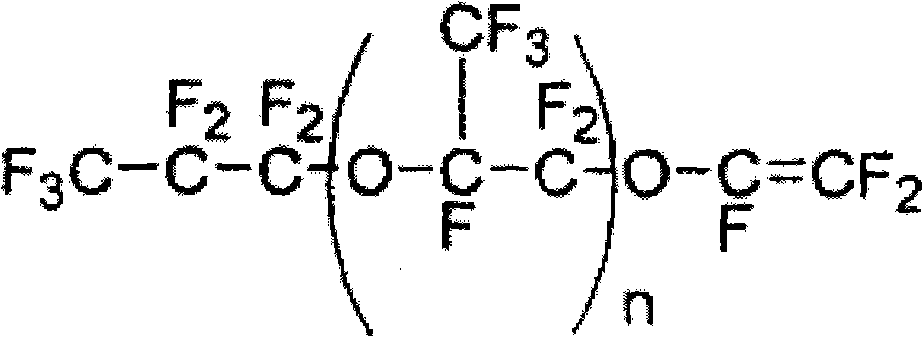

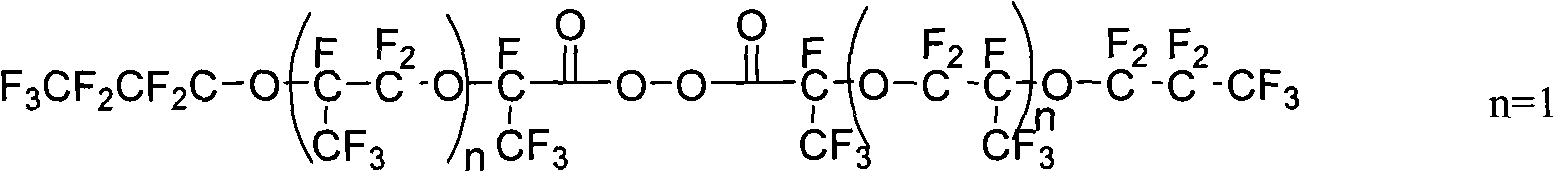

High-flexibility quaternary copolymerization fluorine-containing resin as well as preparation method and application thereof

InactiveCN102161723ASimple packaging processHigh bonding strengthPhotovoltaic energy generationSemiconductor devicesVinyl etherSolar cell

The invention relates to a high-flexibility quaternary copolymerization fluorine-containing resin as well as a preparation method and an application thereof, belonging to the technical field of solar photovoltaic cell materials. The high-flexibility quaternary copolymerization fluorine-containing resin used for the packaging film of a solar cell is characterized by being copolymerized by the following monomers in the molar percentage by weight in a copolymer: 30-45% of ethylene, 40-60% of tetrafluoroethylene, 1-10% of perfluoroalkylation vinyl ether and 1-10% of 2-(perfluor propyl group) perfluor propyl group trifluoroethylene ether. A film prepared from the high-flexibility quaternary copolymerization fluorine-contained resin has the advantages of good flexibility and transparency, good weather fastness, good self-cleaning capability, high mechanical strength and excellent bonding property, and can serve as a packaging film to replace packaging glass in the solar cell assembly, thereby solving the problems that glass is easily broken and polluted, is difficult to maintain and transport, have small possibility of bonding and the like, and widening the application field of the solar cells.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Preparation method of olefin-acrylate copolymer

The invention discloses a method for preparing an olefin-acrylate copolymer by catalyzing copolymerization between an olefin monomer and an acrylate monomer with a Lewis acid catalyst. In the copolymer, molar content of a non-polar unit (olefin unit) is 0-50% and molar content of a polar unit (acrylate unit) is 50-100%; the number-average molecular weight of the copolymer is 20,000-500,000. In addition, a bifunctional monomer, as a crosslinking point for further processing of the polymer, can be introduced to the olefin-acrylate copolymerization system.

Owner:SICHUAN UNIV

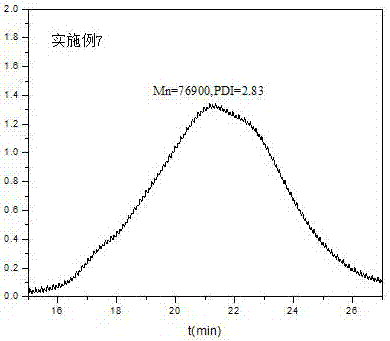

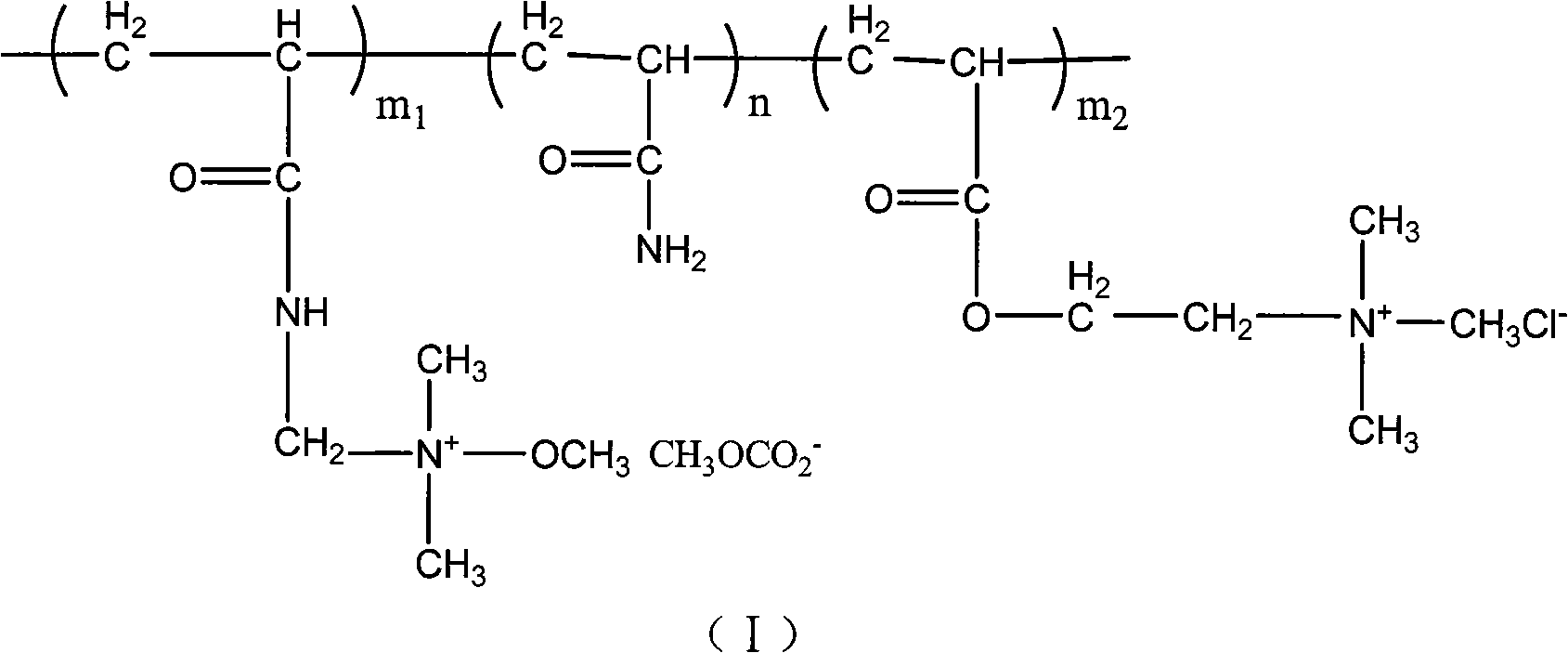

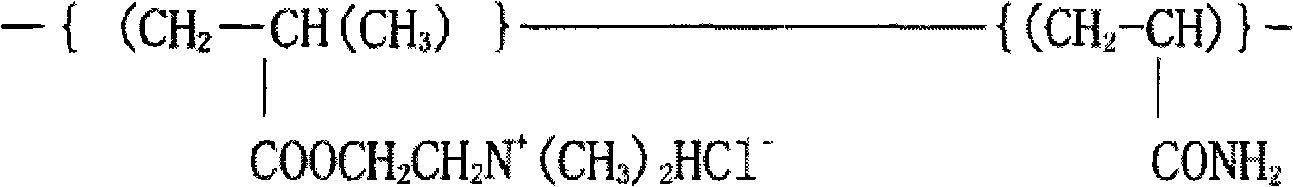

Dication polyacrylamide flocculating agent and preparation method thereof

InactiveCN101575132AImprove hydrophobicityGood flocculation effectWater/sewage treatment by flocculation/precipitationHigh concentrationSide chain

The invention relates to a dication polyacrylamide flocculating agent and preparation method thereof. More than two-thirds of structural units of flocculating agent copolymer are cationization acrylamide, and methyl carbonate quaternary amine ions are introduced into the copolymer. The flocculating agent of the invention has higher hydrophobic nature, favorable flocculation effect, acid resistance, alkali resistance and wide range of suitable pH value, and can be used for treating high concentration dyeing and desizing wastewater; and besides, the inventory rating of the flocculating agent is low, and therefore the use cost can be reduced. The preparation method of the invention simultaneously utilizes the two active groups, namely side-chain amido of acrylamide to generate methyl carbonate quaternary ammoniated cationic acrylamide monomer by Menez reaction, a main chain and trimethyl acyloxy ethide trimethyl ammonium chloride cationic monomer are copolymerized, and the method of environmentally friendly one pot boiling is adopted; and the operation is simple, the cost is low, and the obtained flocculating agent has favorable stability and flocculation effect.

Owner:WUJIANG HENGMAO ELECTRIC

Pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveUS20110256393A1Excellent characteristicsIncreased durabilityCyclodextrin adhesivesPolyureas/polyurethane adhesivesMethacrylatePolyrotaxane

A pressure-sensitive adhesive composition including: a (meth)acrylate copolymer (A) obtained by copolymerizing a (meth)acrylate and a reactive group-containing monomer, such that a ratio of the reactive group-containing monomer (constituent unit derived from the monomer) in the copolymer ranges from 0.01 to 15 wt %; a polyrotaxane (B) having at least two cyclic molecules and a linear-chain molecule passing through opening portions of the cyclic molecules wherein the cyclic molecules have each one or more reactive groups and the linear-chain molecule has blocking groups at both ends thereof; and a crosslinking agent (C) having a reactive group capable of reacting with the reactive group of the (meth)acrylate copolymer (A) and with the reactive group of the polyrotaxane (B).

Owner:LINTEC CORP

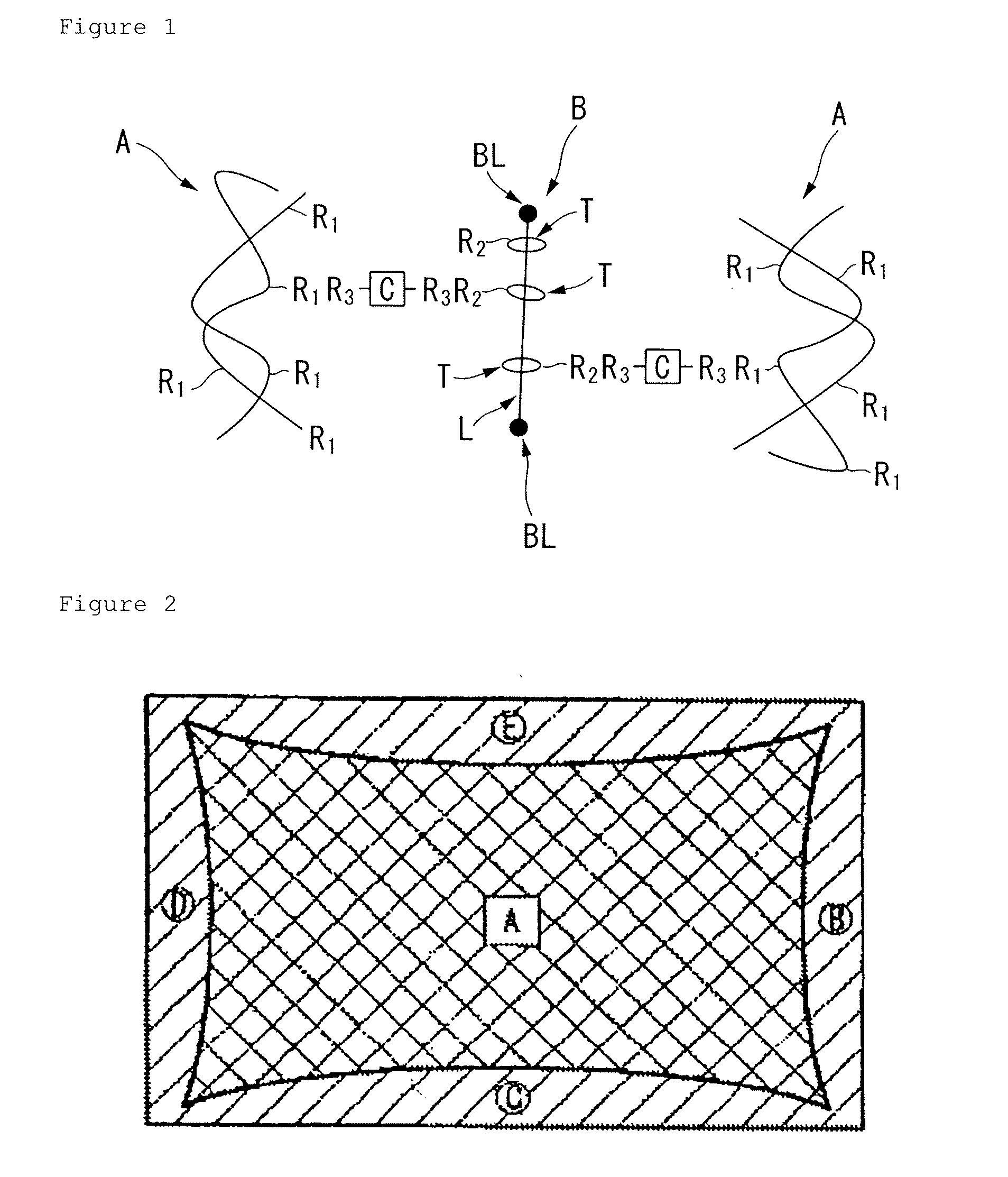

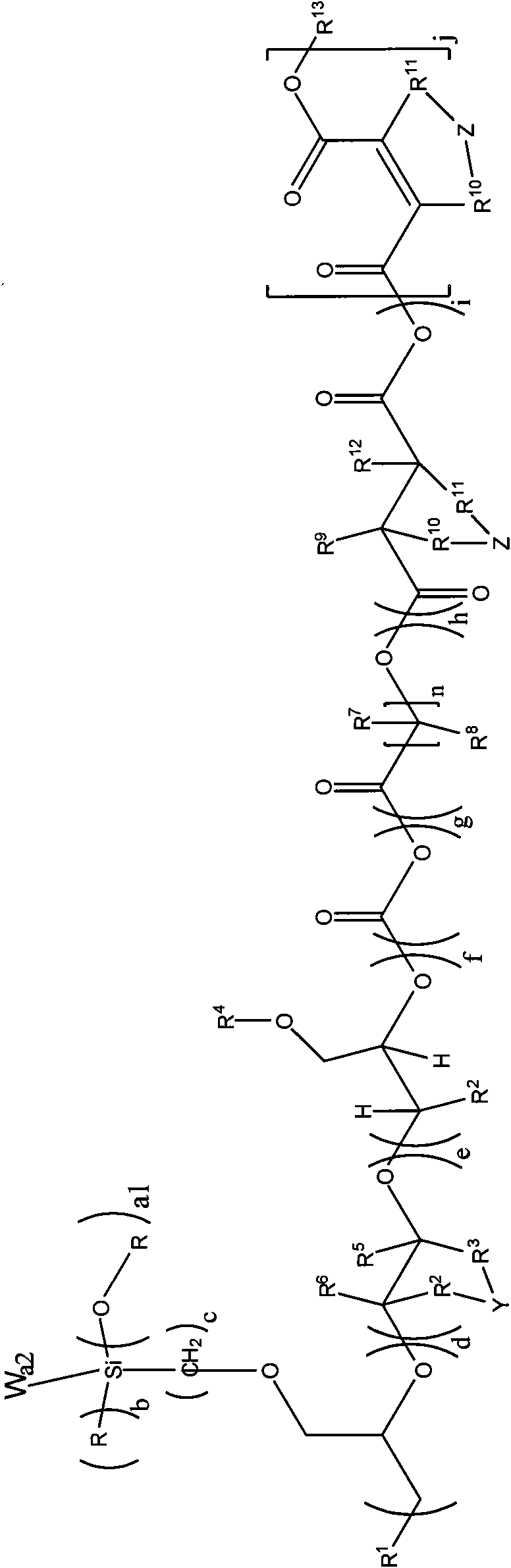

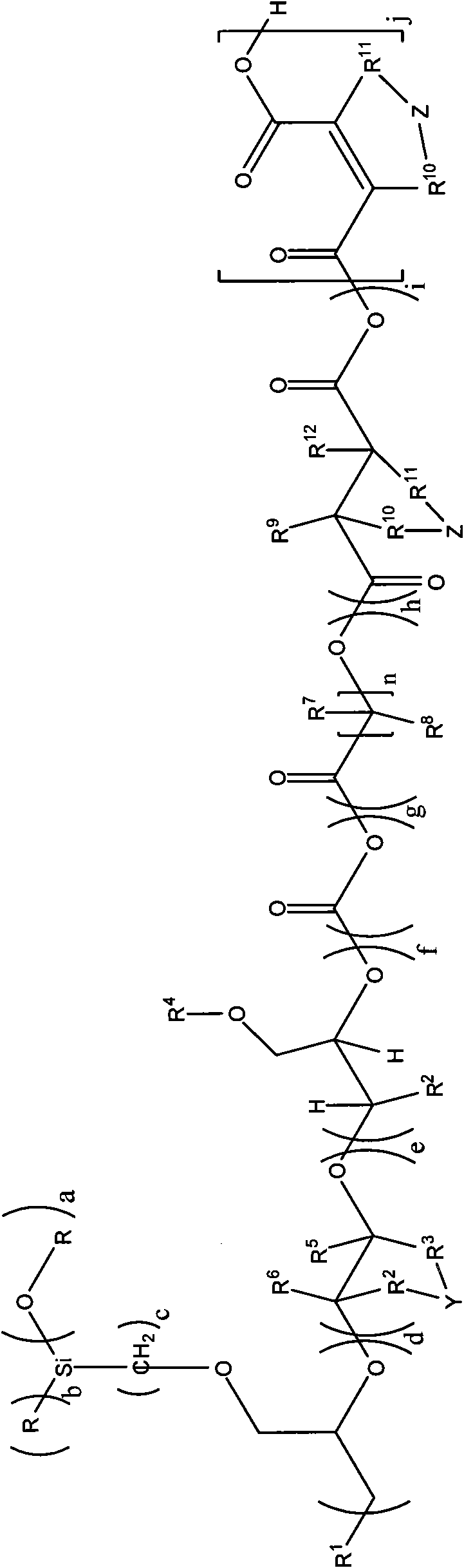

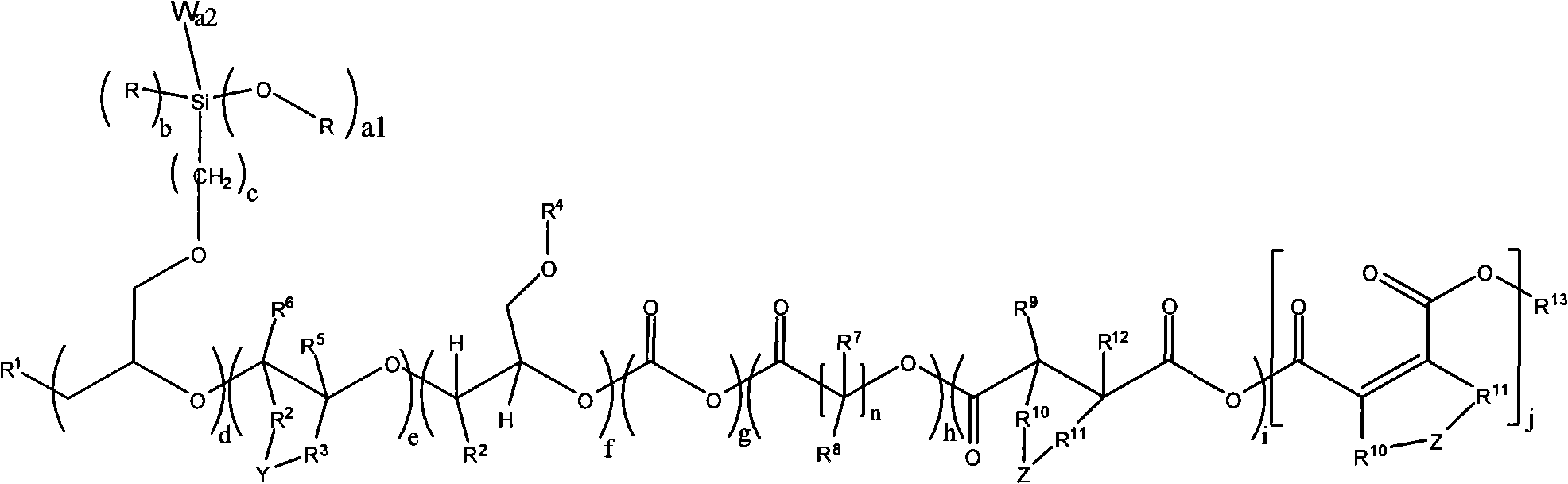

Novel silicone polyether copolymers and process for preparation thereof

The invention relates to novel silicone polyether copolymers and a process for preparation thereof. Novel silicone polyether copolymers of inverse structure of the formula 1, characterized in that no unsaturated functional groups caused by side reactions or conversion products thereof are present in the copolymer, and a process for preparation thereof, in which a polyether modified terminally and / or laterally with alkoxysilyl groups is reacted with silanes and / or siloxanes which bear one or more hydrolysis-labile groups, in a hydrolysis and condensation reaction.

Owner:TH GOLDSCHMIDT AG

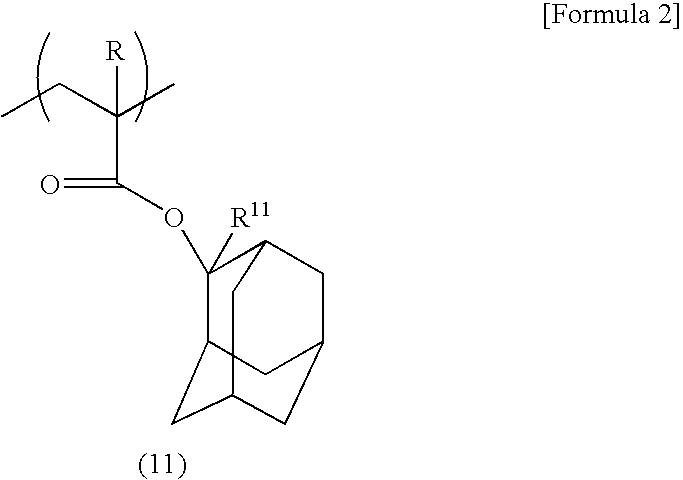

Positive Resist Composition and Method for Resist Pattern Formation

ActiveUS20080268375A1High sensitivityHigh resolutionPhotosensitive materialsRadiation applicationsSolubilityPolymer science

A positive-working resist composition of a wide level of DOF and a method for resist pattern formation are provided. This composition is a positive-working resist composition comprising a resin component (A) which, upon action by an acid, increases alkali solubility and an acid generating agent component (B) which produces an acid upon exposure. The component (A) is a copolymer comprising n (n=an integer of 4 to 6) types of constitutional units different from each other in structure, and the proportion of each constitutional unit in the copolymer is more than 0% by mole and not more than 100 / (n−1)% by mole.

Owner:TOKYO OHKA KOGYO CO LTD

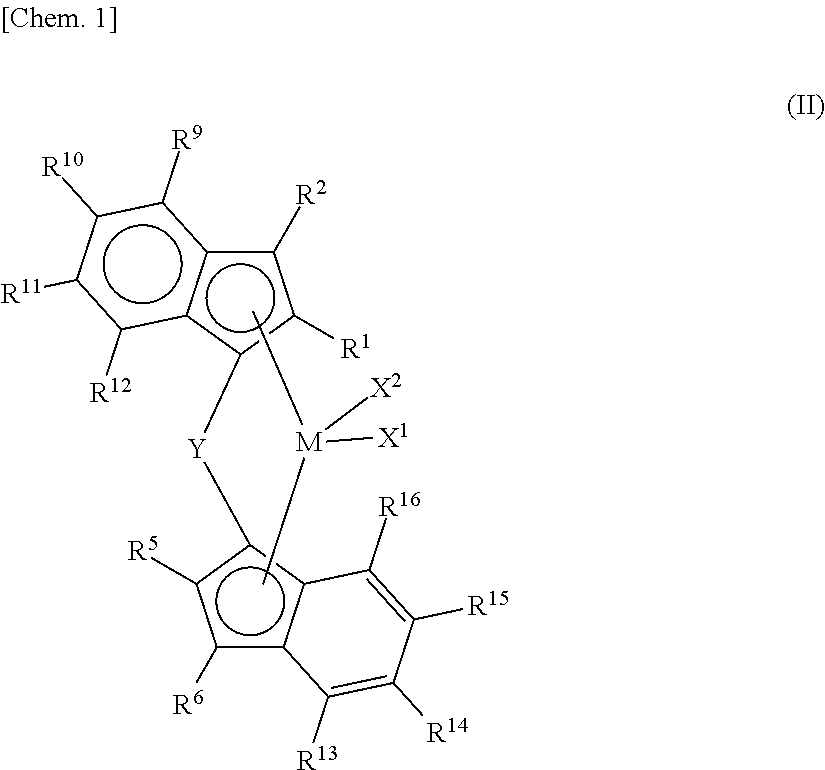

Copolymer Of Ethylene And A Conjugated Diene, And Process For Its Production

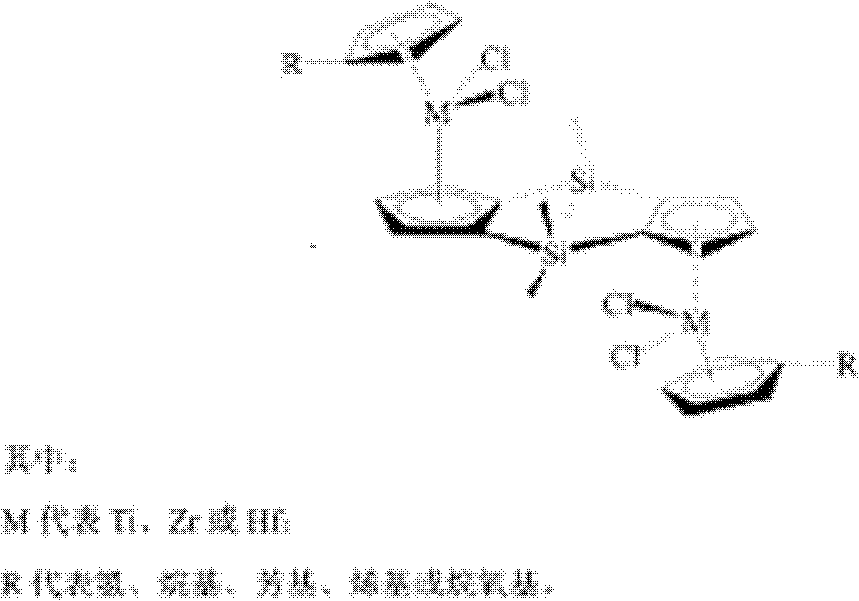

A copolymer of ethylene and a conjugated diene is provided, in which ethylene content in the copolymer is greater than 20 mol %, the copolymer has a glass transition temperature between −110° C. and −90° C., and continuous methylene sequence lengths (MSL) in the copolymer are in a range of 12-162 methylene units. A method for producing the copolymer, comprising copolymerizing ethylene and a conjugated diene in the presence of a catalyst system to obtain the copolymer is also provided, in which the catalyst system comprises a heterocyclic-fused cyclopentadienyl rare-earth metal complex, an organoboron salt compound and an organoaluminum compound, wherein the heterocyclic-fused cyclopentadienyl rare-earth metal complex is represented by the structural formula:

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-transparency quinary copolymerization fluorine-containing resin as well as preparation method and application thereof

InactiveCN102161724BHigh light transmittanceGood flexibilityPhotovoltaic energy generationSemiconductor devicesSA copolymerTransmittance

The invention relates to a high-transparency quinary copolymerization fluorine-containing resin as well as a preparation method and an application thereof, belonging to the technical field of solar photovoltaic cell materials. The high-transparency quinary copolymerization fluorine-containing resin is characterized by being copolymerized by the following monomers in the molar percentage by weightin a copolymer: 30-45% of ethylene, 40-50% of tetrafluoroethylene, 1-7% of vinyl fluoride, 2-10% of vinylidene fluoride and 3-15% of trifluorochlor oethylene. Vinyl fluoride, vinylidene fluoride and trifluorochlor oethylene are added into the binary copolymerization system of ethylene and tetrafluoroethylene in the prior art, and the light transmittance, the flexibility and the processing liquidity of the copolymer can be effectively improved by the synergistic action.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Acrylate adhesive with network interpenetrating structures and method for preparing acrylate adhesive

ActiveCN107523244AGood adhesionLower glass transition temperatureGraft polymer adhesivesAdhesiveAcrylate polymer

The invention discloses environment-friendly acrylate emulsion adhesive with network interpenetrating structures and a method for synthesizing the environment-friendly acrylate emulsion adhesive. The environment-friendly acrylate emulsion adhesive comprises modified polyvinyl alcohol, mixed monomers, composite emulsifiers and initiators. The modified polyvinyl alcohol is a component I, and the mixed monomers are components II. The environment-friendly acrylate emulsion adhesive and the method have the advantages that polyvinyl alcohol macromolecular chains are led into copolymers, and accordingly the water resistance of the environment-friendly acrylate emulsion adhesive can be effectively improved; movement of acrylate polymer molecules can be inhibited by the aid of the network interpenetrating structures formed by polyvinyl alcohol macromolecules, and accordingly the purpose of improving the hardness and the adhesive strength of polymers can be achieved; raw materials for the environment-friendly acrylate emulsion adhesive are non-toxic and pollution-free, accordingly, the environment-friendly acrylate emulsion adhesive and the method conform to current green chemistry development trend, and the environment-friendly acrylate emulsion adhesive is applicable to industrial production.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Lithographic printing plate precursor

InactiveUS20120070779A1Satisfactory characteristicSatisfactory restart toning recovery propertiesPhotosensitive materialsLithographyArylHydrogen atom

The present invention provides a lithographic printing plate precursor which exhibits satisfactory ink cleanup and restart toning characteristics during printing.Disclosed is a lithographic printing plate precursor comprising a substrate having thereon in order an interlayer containing a copolymer comprising K units and L units, and an image-forming layer, whereinsaid K unit is derived from a monomer of the formula I:wherein R1 represents a hydrogen atom, a C1-22 linear, branched or cyclic alkyl group, a C1-22 linear, branched or cyclic, substituted alkyl group, a C6-24 aryl group or substituted aryl group, wherein the substituent is selected from a C1-4alkyl group, an aryl group, a halogen atom, a keto group, an ester group, an alkoxy group, or a cyano group; Y represent a single bond, or a C1-22 linear, branched or cyclic alkylene; orCH2═CHPO(OH)2; andsaid L unit is derived from a monomer of the formula II:CH2═CRCONH2 (II)wherein R is H or CH3, andsaid K units are present from more than 3% and less than 40% and said L units are present from more than 60% and less than 97% in the copolymer.

Owner:EASTMAN KODAK CO

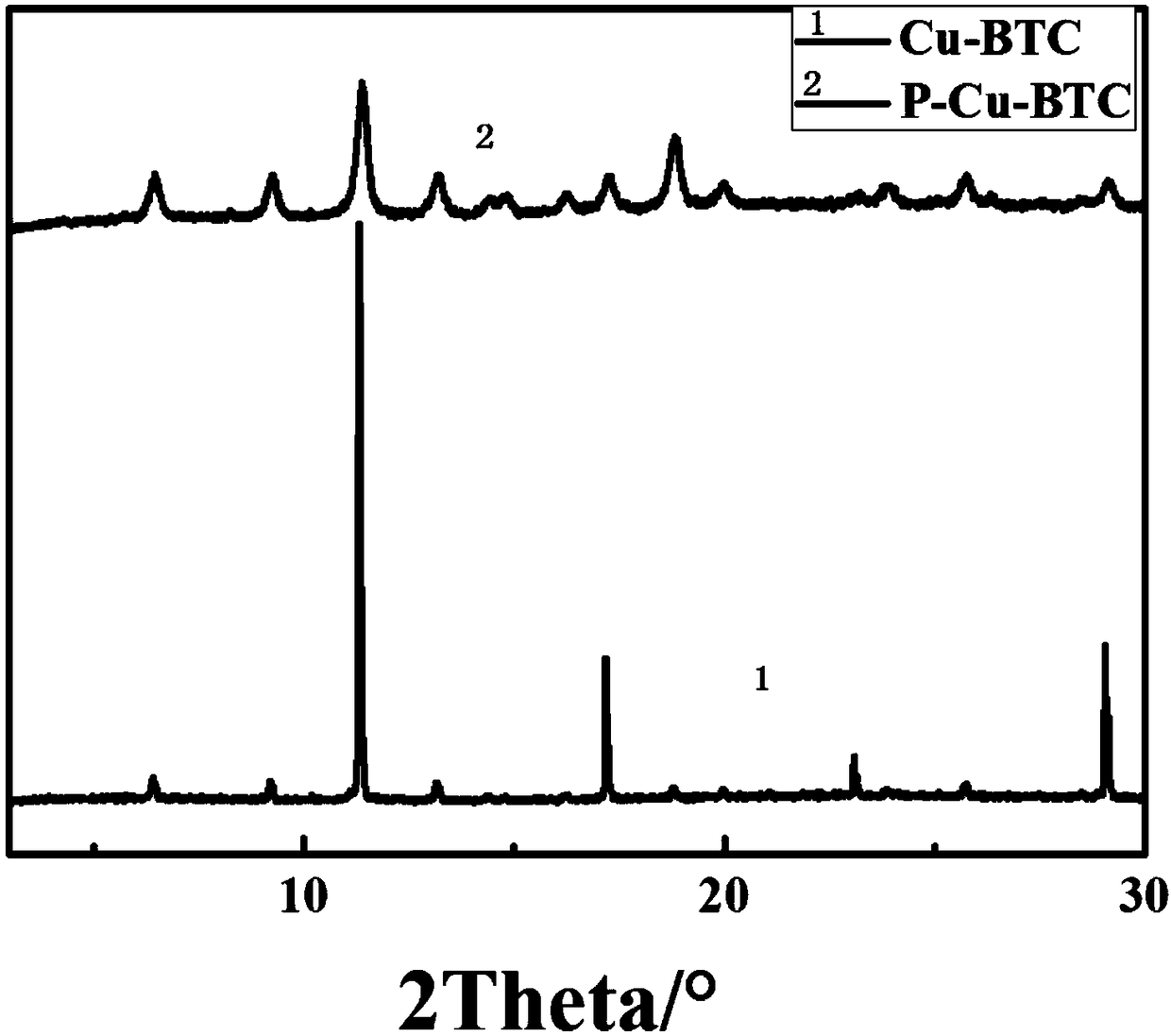

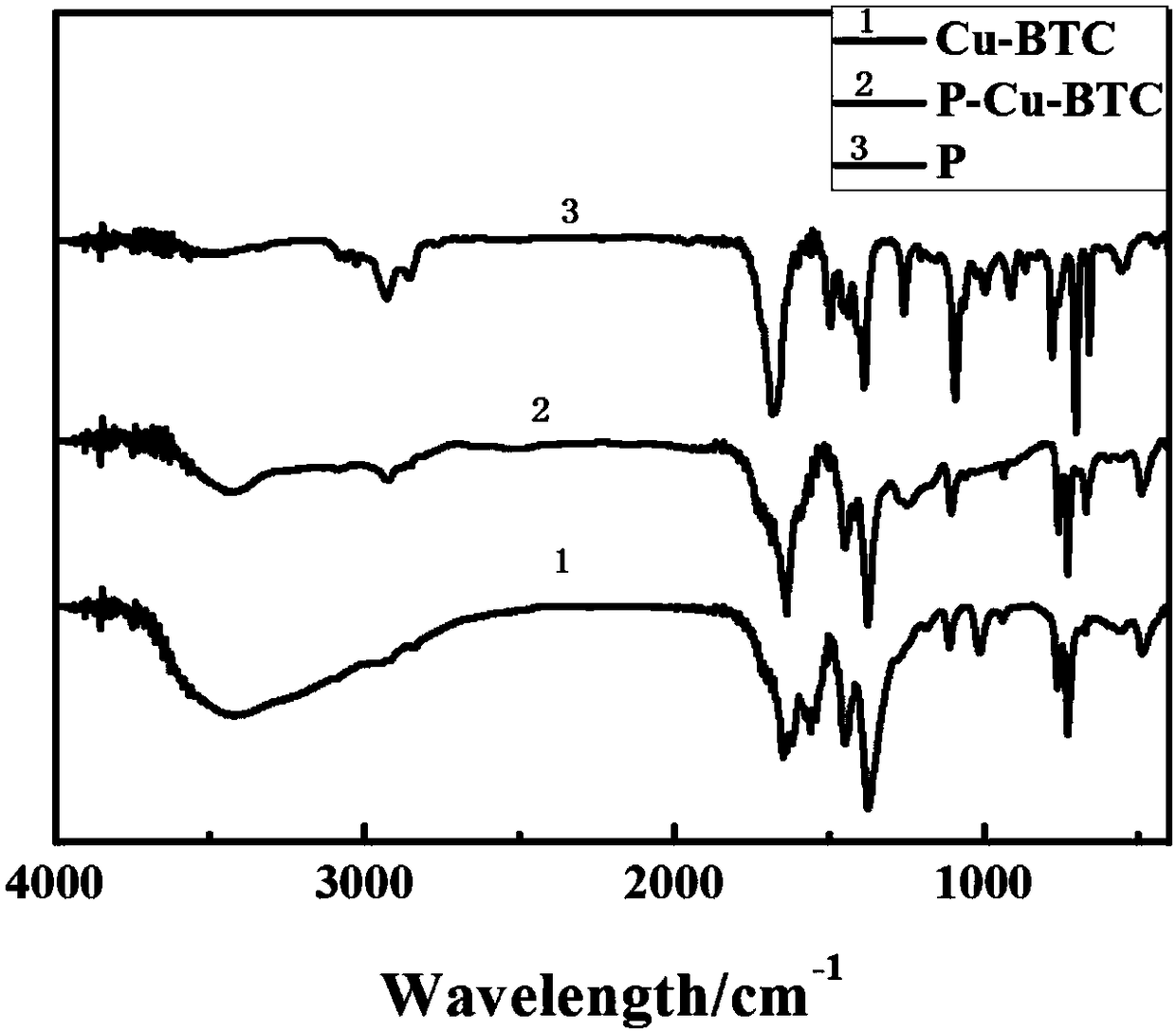

Method for preparing copolymer/HKUST-1 hybrid material by in-situ polymerization

The invention discloses a method for preparing a copolymer / HKUST-1 hybrid material by in-situ polymerization and belongs to the technical field of skeleton materials. Specifically, the invention relates to a classical porous metal-organic skeleton material prepared from trimesic acid as an organic ligand, a copper methacrylate monomer for providing metal ions and a styrene monomer through polymerization and coordination chemistry self-assembling at the normal temperature. The method improves the stability of HKUST-1. The copolymer / HKUST-1 hybrid material combines functions of a polymer and anorganic skeleton material and has wide application values. The produced HKUST-1 and the polymer are bonded through a covalent bond so that the agglomeration of a large amount of MOF particles is avoided and the MOF is uniformly dispersed in the copolymer. The hybrid material realizes the integration of functions of the metal-organic skeleton HKUST-1 and the polymer.

Owner:BEIJING UNIV OF TECH

Supported catalyst for olefin polymerization, as well as preparation method and application thereof

The invention relates to a supported catalyst for olefin polymerization, as well as a preparation method and an application thereof. The catalyst comprises a double-silicon double-bridge metallocene compound, an aluminum alkyl or aluminoxane compound or a mixture thereof and an inert inorganic compound carrier. The preparation method comprises steps of: completing the reaction of the inorganic compound carrier with the aluminum alkyl or aluminoxane compound at a reaction temperature of 80 DEG C-110 DEG C according to a weight ratio of (1:1)-(1:5); dissolving the double-silicon double-bridge metallocene compound into a methylbenzene solvent, adding the mixture into the liquid of the inorganic compound carrier and the aluminum alkyl or aluminoxane at the reaction temperature of 0 DEG C-60 DEG C according to a weight ratio of double-silicon double-bridge metallocene compound to inorganic compound carrier of (1:3)-(1:10), then removing the solvent, filtering, washing and pumping at reduced pressure so as to obtain the catalyst. The catalyst can be used for olefin polymerization or the polymerization of ethylene and alpha-olefin with 3-20 carbon atoms, and the content of the alpha-olefin in a copolymer is high.

Owner:PETROCHINA CO LTD +1

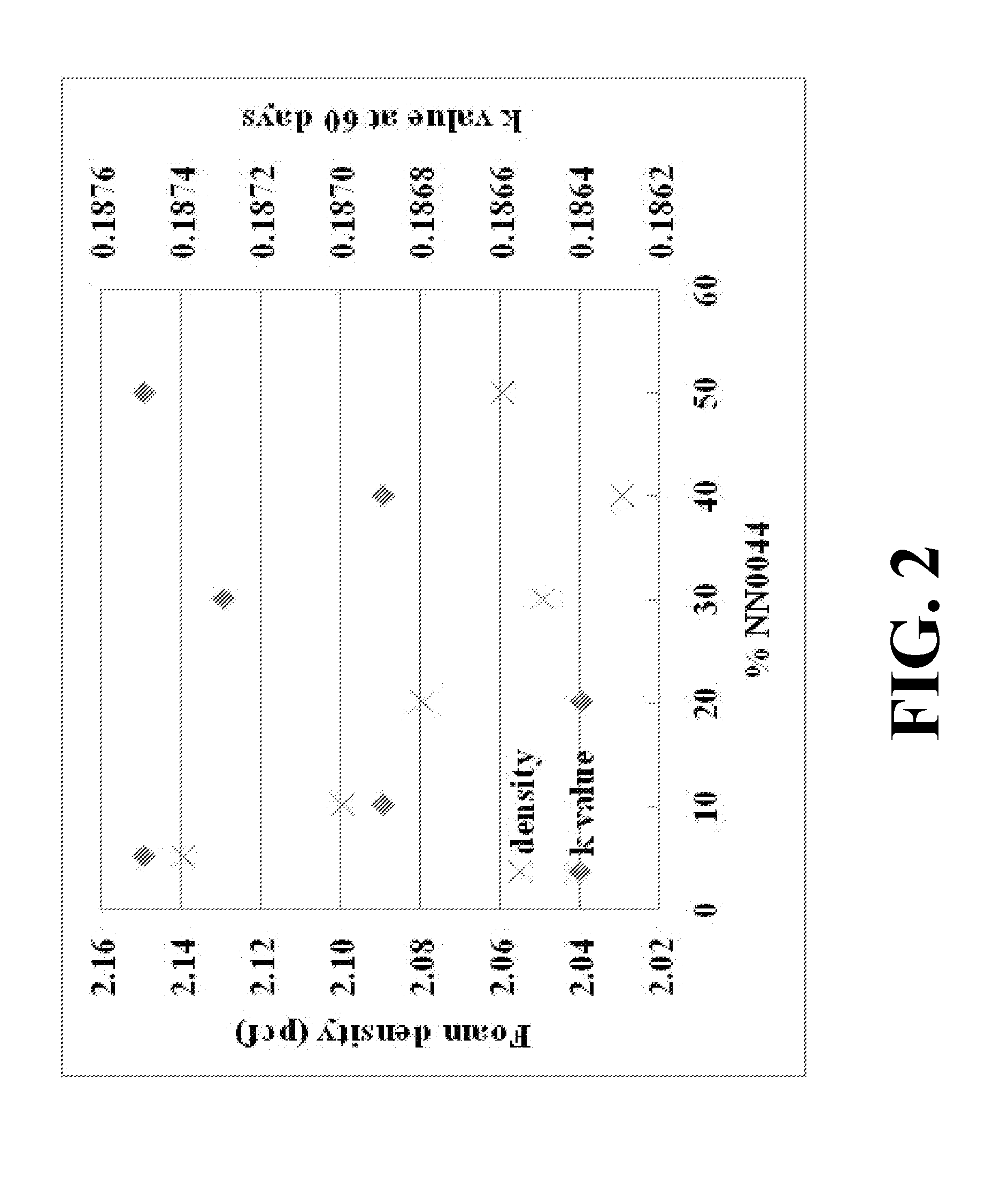

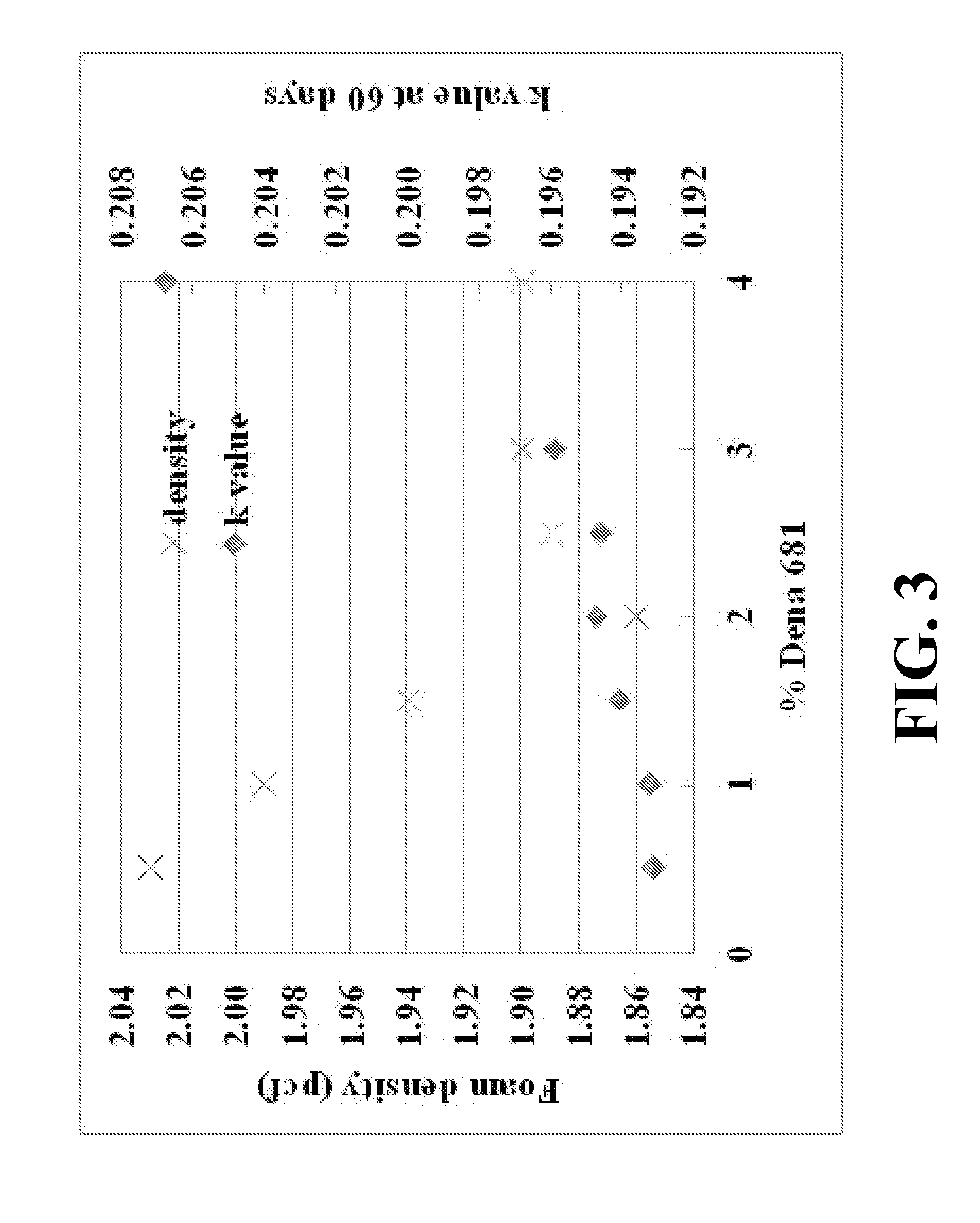

Non-voc processing aids for use in manufacturing foams using low global warming potential blowing agents

A foamable polymeric mixture is provided that includes a polymer composition, at least one blowing agent, and at least one non-VOC processing aid comprising one or more of an adipate ester; benzoate; fatty acids and their derivatives, propylene carbonate; ethylene oxide / propylene oxide block copolymer; styrene-methyl methacrylate copolymer; and a dispersion of organic salt of a fatty acid in copolymer. The blowing agent comprising at least one of carbon dioxide, hydrofluoroolefins, hydrochlorofluoroolefins and hydrofluorocarbons, and mixtures thereof.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Polycarbonate copolymer, and coating liquid and electrophotographic photosensitive body using same

ActiveUS9529285B2Increase resistanceImprove solubilityElectrography/magnetographyPolyamide coatingsPolymer scienceOrganic solvent

Owner:IDEMITSU KOSAN CO LTD

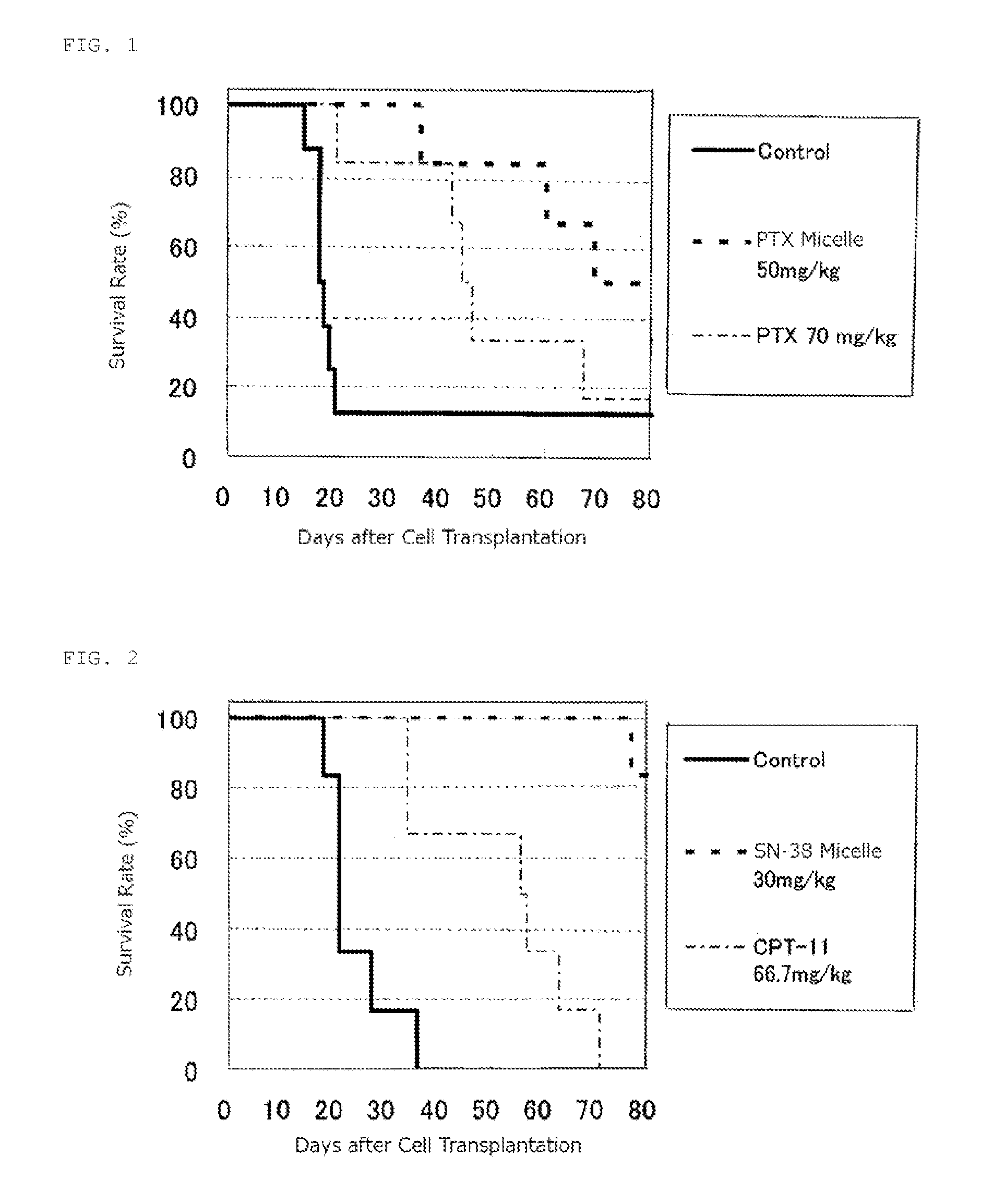

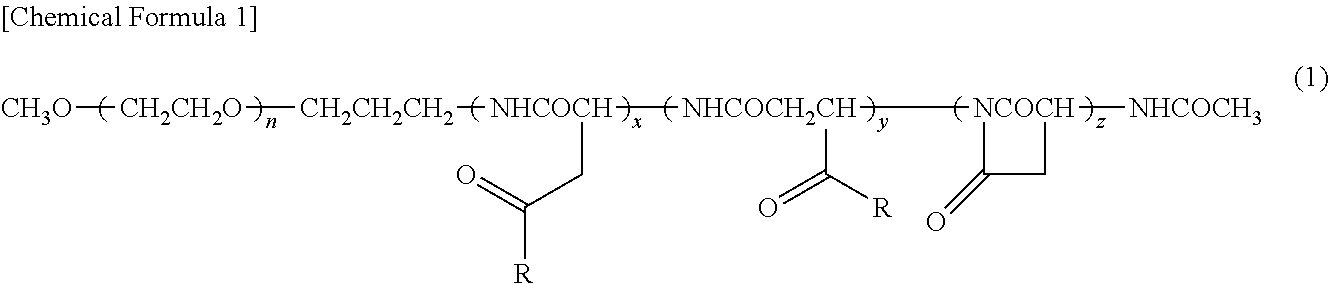

Block Copolymer For Intraperitoneal Administration Containing Anti-Cancer Agent, Micelle Preparation Thereof, And Cancer Therapeutic Agent Comprising The Micelle Preparation As Active Ingredient

InactiveUS20120231053A1Extending abdominal retention timeLess adverse side-effectsBiocidePowder deliveryAnticarcinogenSide effect

To provide a therapeutic method using a water soluble, high molecular weight block polymer to enable that an intraperitoneally administered anti-cancer agent may maintain for a long-term retention in the abdominal cavity to enoughly exert the effect of the anti-cancer agent and reduce adverse side-effects thereof.A therapeutic agent as a micelle preparation, comprising a copolymer having a hydrophilic polymeric moiety and a polycarboxylic acid derivative moiety; and an anti-cancer agent bonding to or encapsulated in the copolymer, wherein the micelle preparation may exhibit sustained drug release capability, and enables an extension of a retention time period of the anti-cancer agent in an abdominal cavity, is provided. A superior life-prolonging effect was found in an intraperitoneal administration mouse model compared with a case in which only an encapsulated drug is administered, and thus the present invention was completed accordingly.

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com