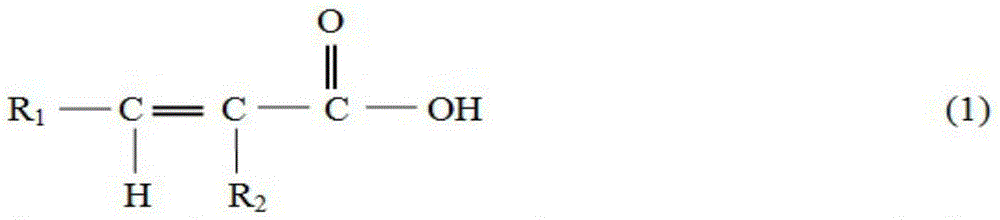

Early-strength polycarboxylate superplasticizer having slump-loss prevention function and preparation method thereof

An early-strength polycarboxylate technology, which is applied in the field of early-strength polycarboxylate water reducer and its preparation, can solve the problems of poor slump retention and other problems, and achieve the improvement of dissolution rate and diffusion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

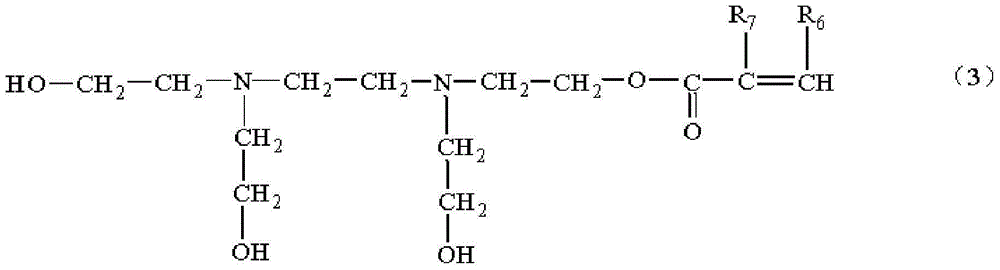

[0046] The preparation method of monomer c is as follows:

[0047] Mix one of acrylic acid, methacrylic acid, maleic anhydride or fumaric anhydride with tetrahydroxyethylethylenediamine at a molar ratio of 1:1, and add 0.001- Stir uniformly with 0.010% polymerization inhibitor and 0.005%-0.05% catalyst, slowly raise the temperature to 95-105° C. under the condition of feeding nitrogen, and stir for 5-7 hours to obtain monomer c.

[0048] Wherein, the consumption of polymerization inhibitor in the synthesized monomer c can also be 0.003%-0.008%, can further be 0.003%-0.005%, 0.005%-0.008%; The consumption of catalyst can also be 0.01%-0.03%, It can further be 0.01%-0.02%, 0.02%-0.03%.

[0049] In the process of synthesizing monomer c, after adding nitrogen gas, the temperature is slowly raised to the optimal temperature of 95°C, 98°C, 100°C, 102°C, 105°C, the optimal temperature is 100°C, and the optimal stirring time is 5-7h. It can be 5-6h, and the optimal stirring time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com