High-flexibility quaternary copolymerization fluorine-containing resin as well as preparation method and application thereof

A quaternary copolymerization, fluorine-containing resin technology, applied in electrical components, photovoltaic power generation, circuits, etc., can solve the problems of low strength, easy cracking, poor flexibility, etc., and achieve good bonding performance, not easy to bond, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

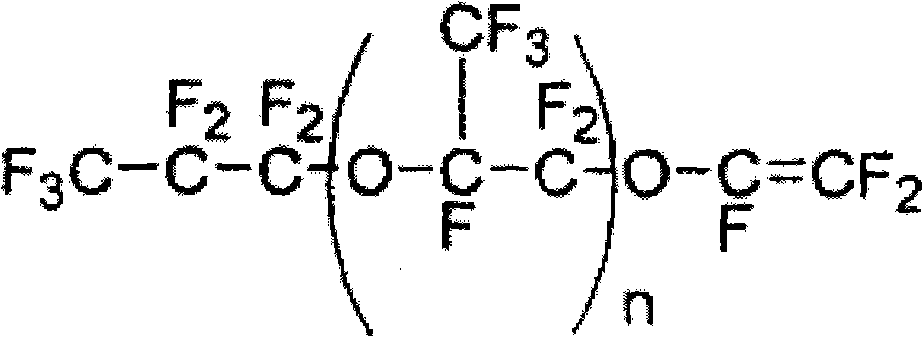

[0033] A quaternary copolymerized fluorine-containing resin for highly flexible solar cell encapsulation films, which is formed by copolymerizing the following monomers, all in molar percentages in the copolymer:

[0034] Ethylene 39.5%, tetrafluoroethylene 50.4%, perfluoro-n-propyl vinyl ether 4.9%, 2-(perfluoropropoxy) perfluoropropyl trifluorovinyl ether 5.2%.

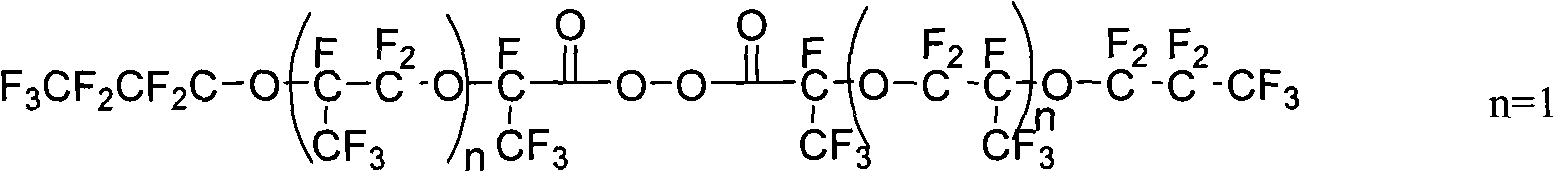

[0035] The above-mentioned highly flexible solar cell encapsulation film is made of quaternary copolymerized fluorine-containing resin by solution polymerization method, using fluorocarbon solvent:

[0036] The 10L stainless steel autoclave equipped with stirring, temperature control, circulating heating and circulating cooling water devices was cleaned and fully dried, then vacuumed, replaced with nitrogen three times until the oxygen content was less than 10ppm, and then vacuumed to 0.0001Mpa. Add 6.2L of perfluoroheptane solvent, 266g (1mol) of perfluoro-n-propyl vinyl ether and 432g (1mol) of 2-(perfluoropropoxy...

Embodiment 2

[0042] A quaternary copolymerized fluorine-containing resin for highly flexible solar cell encapsulation films, which is formed by copolymerizing the following monomers, all in molar percentages in the copolymer:

[0043] Ethylene 41.6%, tetrafluoroethylene 53.3%, perfluoro-n-propyl vinyl ether 2.6%, 2-(perfluoropropoxy) perfluoropropyl trifluorovinyl ether 2.5%.

[0044] The above-mentioned highly flexible solar cell packaging film is made of quaternary copolymerized fluorine-containing resin, which is prepared by suspension polymerization, and water is used as the dispersion medium:

[0045] Clean the 10L stainless steel high-pressure reactor equipped with stirring, temperature control, circulating heating, and circulating cooling water devices and then vacuumize it. Add 15g of perfluoropropoxy ammonium carboxylate dispersant and 3400g of pure water to the reactor, and then vacuumize it. Replace with nitrogen three times until the oxygen content is less than 10ppm, and vacuu...

Embodiment 3

[0051] A quaternary copolymerized fluorine-containing resin for highly flexible solar cell encapsulation films, which is formed by copolymerizing the following monomers, all in molar percentages in the copolymer:

[0052] Ethylene 34.9%, tetrafluoroethylene 49.1%, perfluoromethyl vinyl ether 6.8%, 2-(perfluoropropoxy) perfluoropropyl trifluorovinyl ether 9.2%.

[0053] The above-mentioned highly flexible solar cell packaging film is made of quaternary copolymerized fluorine-containing resin by emulsion polymerization, and the polymerization reaction is carried out in the water phase:

[0054] After cleaning the 10L stainless steel high-pressure reactor equipped with stirring, temperature control, circulating heating and circulating cooling water devices, add alkylsulfonate sodium emulsifier and pure water into the reactor, the concentration of the emulsifier is 0.2-3% , the ratio of water to the total weight of the monomer is 60:40. Vacuumize the reactor until 0.0001Mpa, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com