Encapsulation construction for silicon crystal microphone

A technology of microphone and silicon crystal, which is applied in the field of packaging structure of silicon crystal microphone, can solve the problems of bulky packaging structure, unsuitable for industrial use, and impracticality, etc., and achieve the effect of simple packaging process, wide adaptability, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

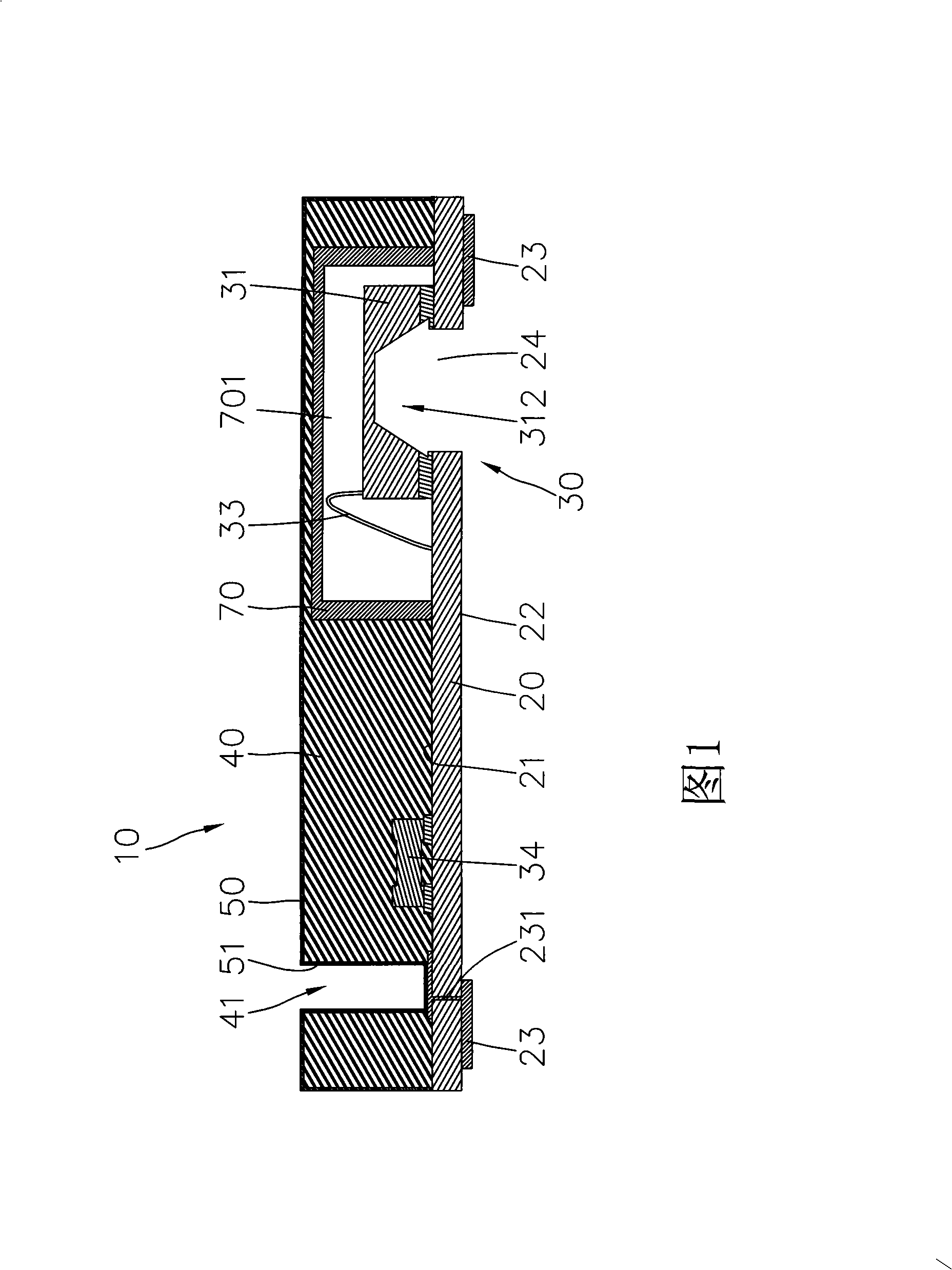

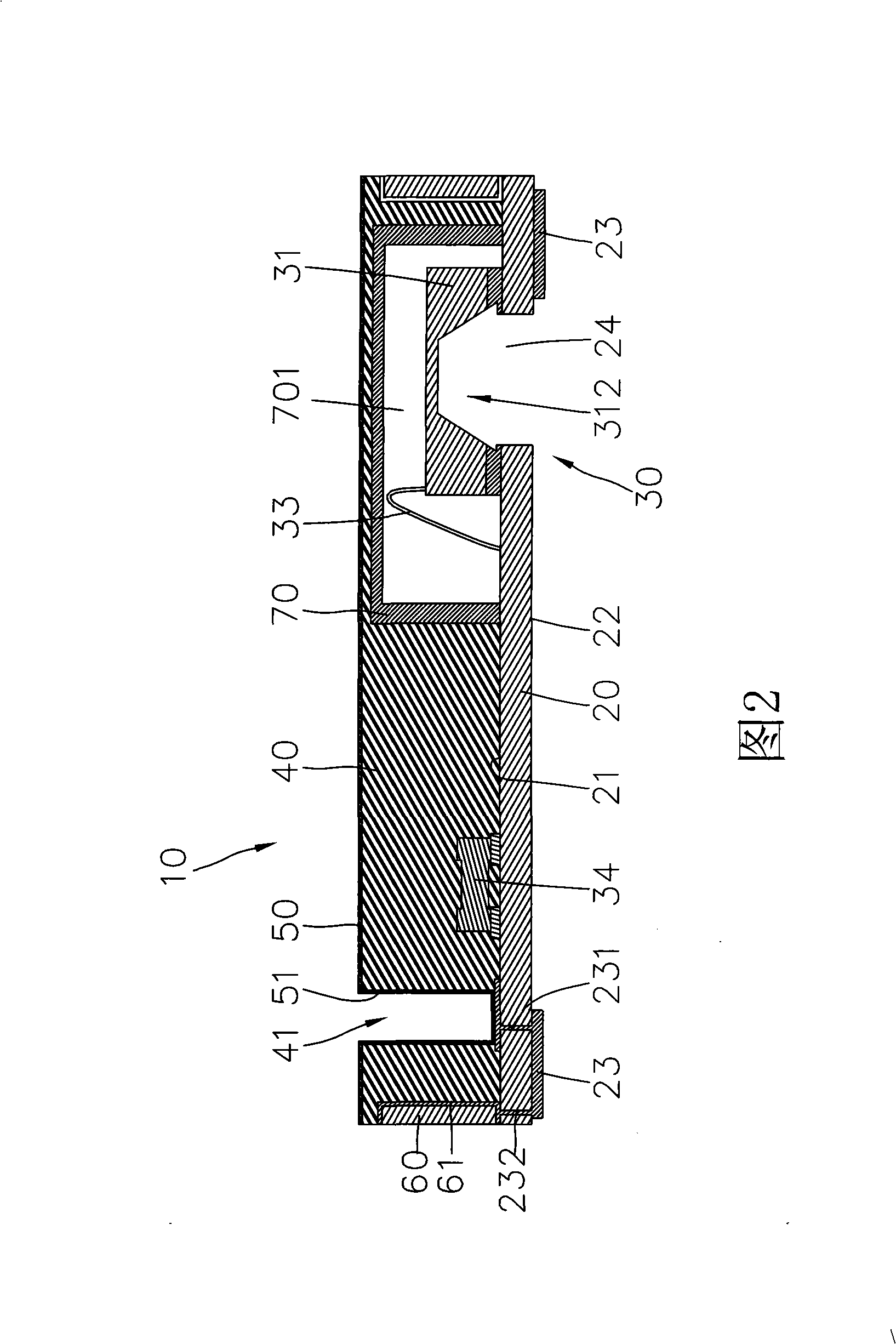

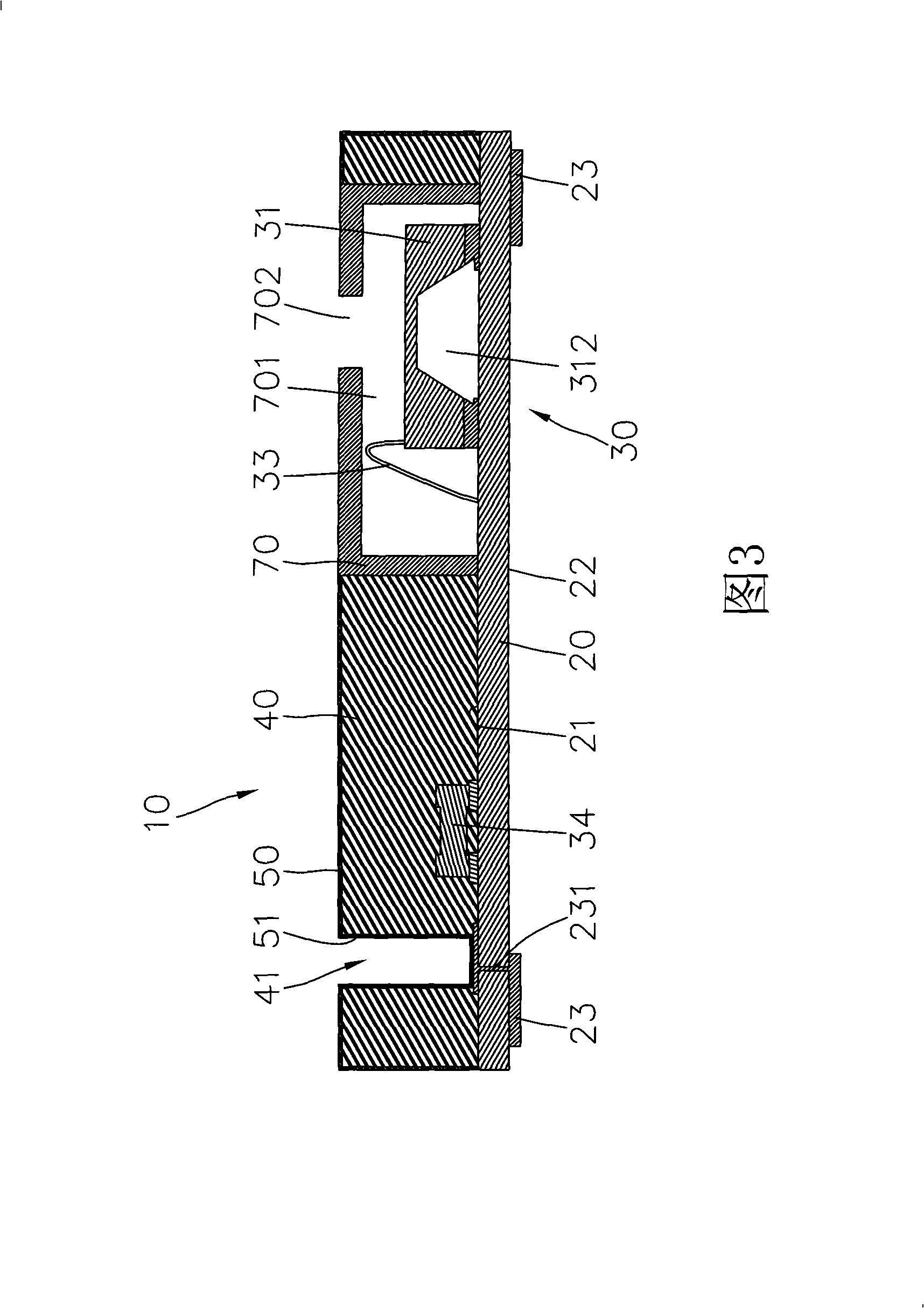

[0018] Referring to FIG. 1 , it is a schematic diagram of a first embodiment of the packaging structure of a silicon microphone according to the present invention. The packaging structure 10 of the silicon crystal microphone in this embodiment includes a substrate 20, an electronic component assembly 30 disposed on the substrate 20, a cover body 70 covering the electronic component assembly 30, a cover body 70 combined on the substrate 20 and covering The insulating filler 40 on the outer surface of the cover 70 , and a conductive layer 50 covering the outer surface of the insulating filler 40 .

[0019] The substrate 20 has an upper surface 21 and a lower surface 22. The upper surface 21 is used to hold the electronic component assembly 30, and the lower surface 22 is provided with soldering pads 23 at predetermined positions for electrical connection between the substrate 20 and the circuit board of the electronic product. And the pad 23 has a connecting portion 231 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com