Preparation method of olefin-acrylate copolymer

A technology of acrylate and copolymer, applied in the field of polymer synthesis, can solve the problems of increasing the danger of chemical production, limiting the accuracy of feeding amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

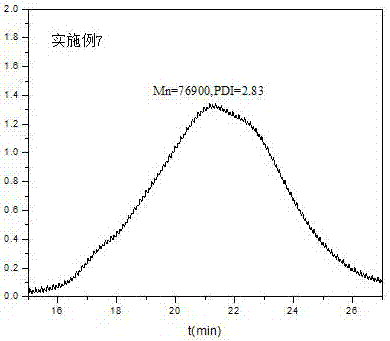

Examples

Embodiment 1

[0026]Methyl acrylate 5mL, 1-octene 5mL, aluminum trichloride 3.68g, azobisisoheptanonitrile 0.1g, dichloromethane 50mL, react in a water bath at 40°C for 7h under the condition of sealing and stirring to obtain a viscous polymer solution , Pour the solution into methanol hydrochloric acid solution to obtain a polymer, dissolve the polymer in acetone and precipitate twice with methanol hydrochloric acid solution to obtain a purified polymer.

Embodiment 2

[0028] Methyl methacrylate 5 mL, 1-hexene 5 mL, zinc chloride 0.64 g, benzoyl peroxide 0.1 g, methyl acetate 10 mL, react in a water bath at 80°C for 3 h under sealed conditions with stirring to obtain viscous polymerization The polymer solution was poured into the hydrochloric acid methanol solution to obtain a polymer, which was dissolved in acetone and precipitated twice with hydrochloric acid methanol solution to obtain a purified polymer.

Embodiment 3

[0030] 5 mL of butyl acrylate, 5 mL of 1-hexene, 0.21 g of ferric chloride, 0.1 g of benzoyl peroxide, and 20 mL of xylene, react in a water bath at 80°C for 3 h under sealed conditions with stirring to obtain a viscous polymer solution , Pour the solution into methanol hydrochloric acid solution to obtain a polymer, dissolve the polymer in acetone and precipitate twice with methanol hydrochloric acid solution to obtain a purified polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com