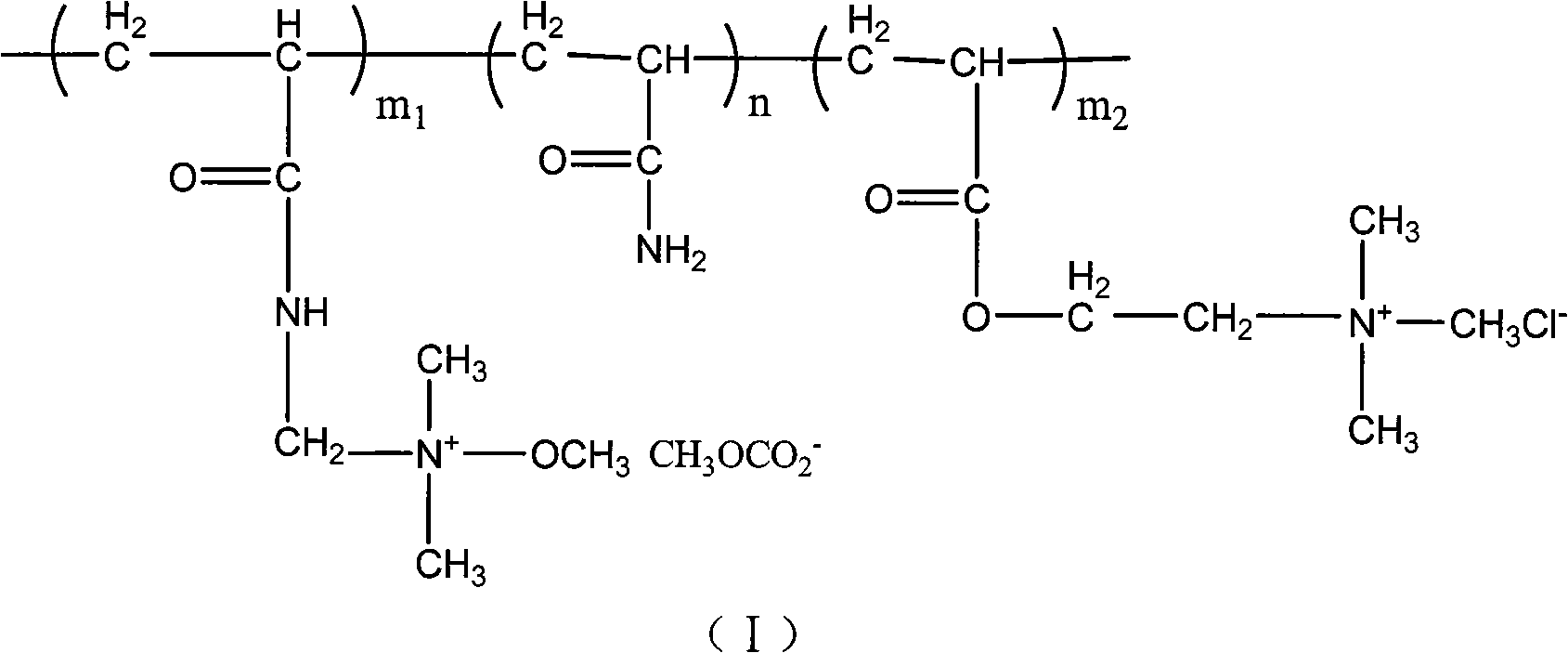

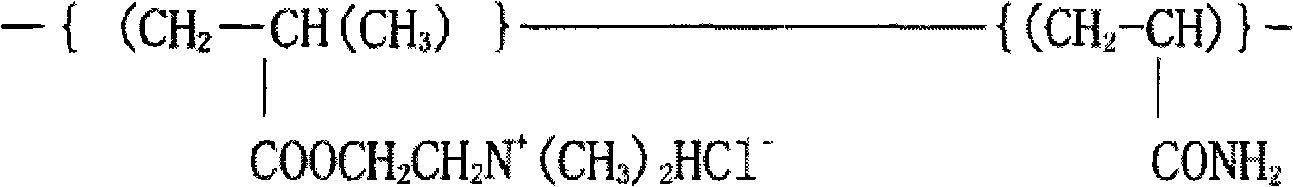

Dication polyacrylamide flocculating agent and preparation method thereof

A polyacrylamide and dication technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unsuitable for high-concentration printing and dyeing wastewater treatment, limited flocculation effect, waste of active groups, etc., and achieve excellent stability and flocculation High efficiency, good flocculation effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the double cationic polyacrylamide flocculant according to this embodiment includes the following steps:

[0027] (1) Take 71g of acrylamide and dissolve it in 100g of distilled water to obtain an acrylamide solution, add the solution to a 1L four-necked flask, and then adjust the pH of the acrylamide solution to 8 with 1mol / L sodium hydroxide aqueous solution ~9.

[0028] (2) At room temperature, add 80g of 38% formaldehyde solution dropwise to the above acrylamide solution over 40 minutes, heat the solution to 50°C, and after reacting for 2.5 hours, add 120g of 40% formaldehyde solution dropwise to the flask. For the methylamine solution, continue to react at 50°C for 2.5 hours, then add 90 g of 98% dimethyl carbonate solution, and react at 50°C for 1.5 hours to obtain a semi-finished product solution.

[0029] (3) Take 146g of semi-finished product solution, mix it with 200g 79% trimethacryloxyethyl ammonium chloride solution, heat to 60℃, add 1...

Embodiment 2

[0031] The preparation method of the double cationic polyacrylamide flocculant according to this embodiment includes the following steps:

[0032] (1) Take 71g of acrylamide and dissolve it in 100g of distilled water to obtain an acrylamide solution, add the solution to a 1L four-necked flask, and then adjust the pH of the acrylamide solution to 8 with 1mol / L sodium hydroxide aqueous solution -9.

[0033] (2) At room temperature, add 80g of 38% formaldehyde solution dropwise to the above acrylamide solution over 40 minutes, heat the solution to 50°C, and after reacting for 2.5 hours, add 120g of 40% formaldehyde solution dropwise to the flask. The methylamine solution continues to react at 50°C for 2.5 hours, then 90 g of 98% dimethyl carbonate solution is added, and the reaction is carried out at 50°C for 1.5 hours to obtain the semi-finished product solution of the present invention.

[0034] (3) Take 146g semi-finished product solution and mix it with 190g 79% trimethacryloxyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com