Novel silicone polyether copolymers and process for preparation thereof

A technology of polysiloxane polyether copolymer and polysiloxane polyether, which is applied in the field of novel polysiloxane polyether copolymer and its preparation, and can solve problems such as release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

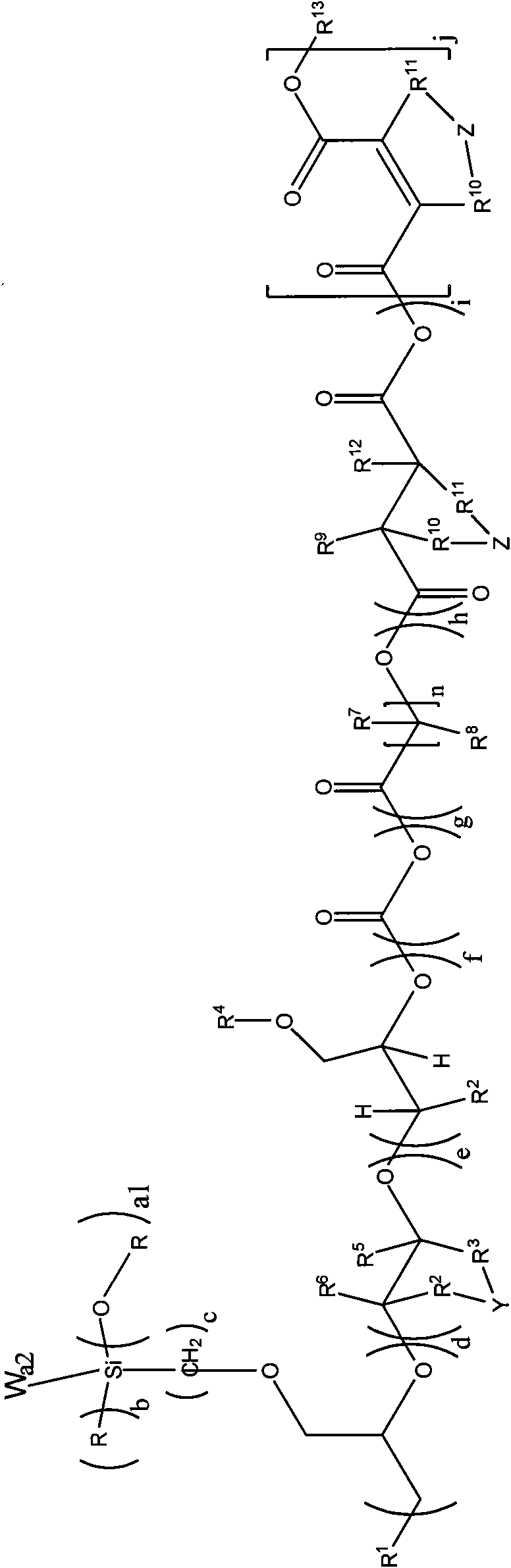

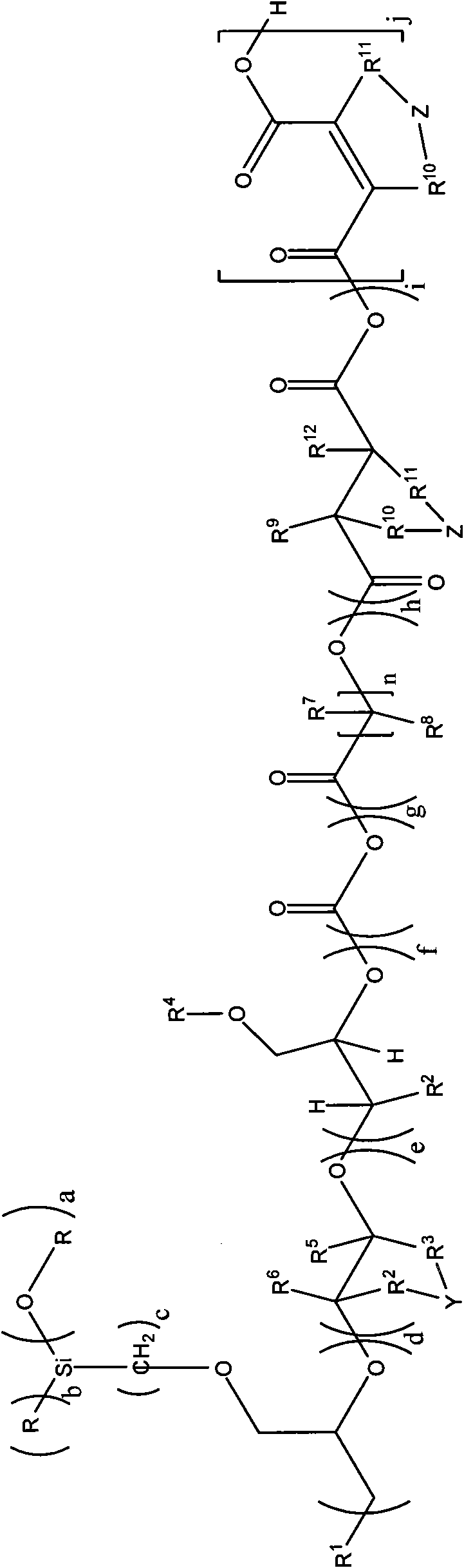

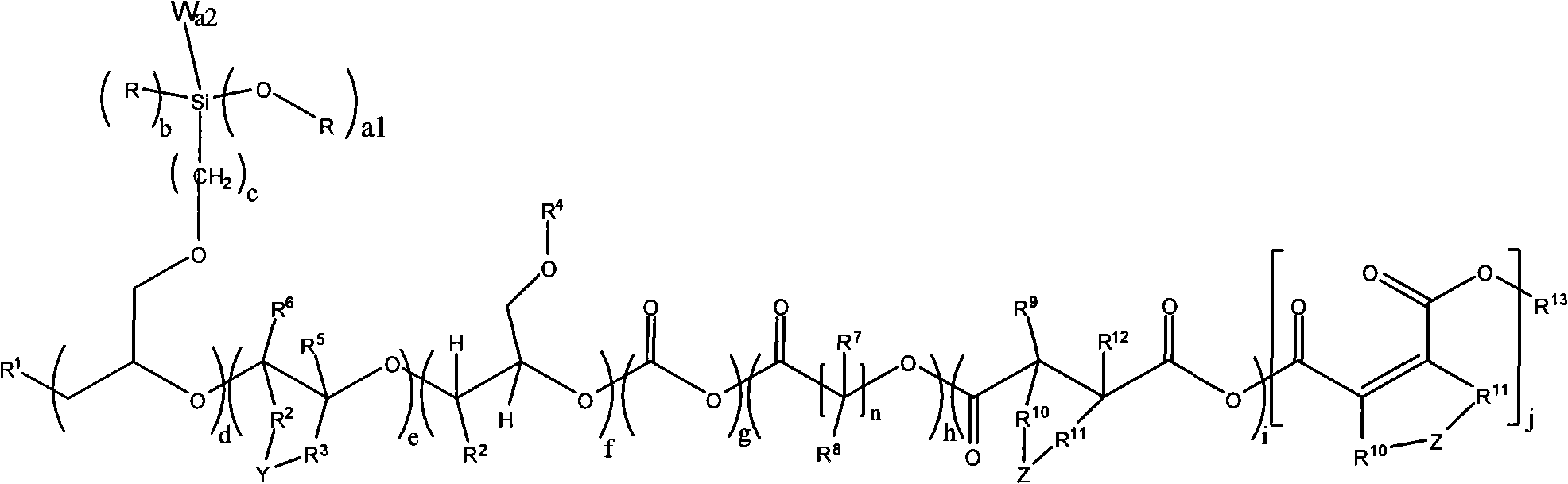

Method used

Image

Examples

Embodiment 1

[0185] Embodiment 1 (the present invention)

[0186] Into a 250 ml four-necked flask equipped with a precision glass stirrer, internal thermometer, dropping funnel and distillation apparatus was initially charged with 30 g of trimethylethoxysilane at room temperature, and 0.45 ml of trifluoroacetic acid was added with stirring. After heating to 60° C., a mixture of 37.2 g of silyl polyether SP-1 and 20.16 g of deionized water was added dropwise within 1 hour. After the dosing had ended, the cloudy reaction mixture was stirred at 60° C. for 3 hours. 3 g of sodium bicarbonate was added, and the mixture was stirred at room temperature for half an hour. After filtration through a tank filter, a clear solution was obtained. The ethanol formed in the reaction was distilled off within 45 minutes at 70° C. and 5-15 mbar. A transparent homogeneous low viscosity (29 In the Si NMR spectrum, the signal of the initial compound is no longer recognized. The ratio of M units to T units is...

Embodiment 2

[0187] Embodiment 2 (the present invention)

[0188]Into a 250 ml four-neck flask equipped with a precision glass stirrer, internal thermometer, dropping funnel and distillation apparatus was initially charged with 31.8 g of trimethylethoxysilane at room temperature, and 0.42 ml of trifluoroacetic acid was added with stirring. After heating to 60° C., a mixture of 30.0 g of silylpolyether SP-2 and 21.4 g of deionized water was added dropwise within 1.5 hours. After the dosing had ended, the cloudy reaction mixture was stirred at 60° C. for 3 hours. The ethanol formed in the reaction was distilled off within 1 hour at 60° C. and 50 mbar. 1.7 g of sodium bicarbonate was added, and the mixture was stirred at room temperature for half an hour. After filtration through a tank filter, a transparent homogeneous yellow product was obtained with a viscosity of 204 mPa*s at 25°C. exist 29 In the Si NMR spectrum, the signal of the initial compound is no longer recognized. The ratio ...

Embodiment 3

[0189] Embodiment 3 (the present invention)

[0190] Into a 250 ml four-neck flask equipped with a precision glass stirrer, internal thermometer, dropping funnel and distillation apparatus was initially charged with 21.8 g of hexamethyldisiloxane at room temperature and 0.42 ml of trifluoroacetic acid was added under stirring . After stirring at 70° C. for 1 hour, a mixture of 30.0 g of silyl polyether SP-2 and 21.4 g of deionized water was added dropwise within 1 hour. After the dosing had ended, the cloudy reaction mixture was stirred at 70° C. for 3 hours. The ethanol formed in the reaction was distilled off within 1 hour at 70° C. and 20 mbar. 1.7 g of sodium bicarbonate was added, and the mixture was stirred at room temperature for half an hour. After filtration through a tank filter, a transparent homogeneous yellow product was obtained with a viscosity of 294.2 mPa*s at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com