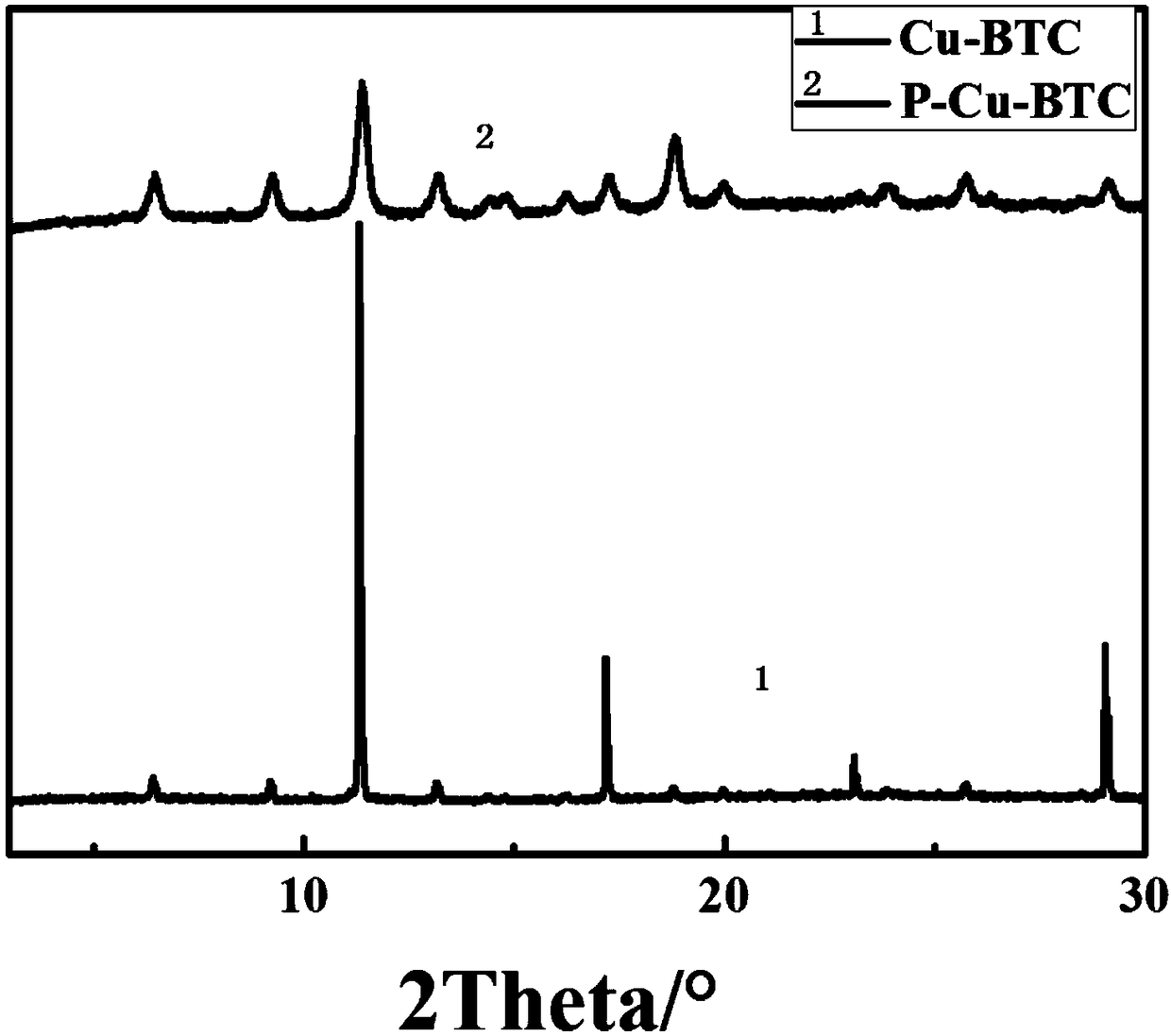

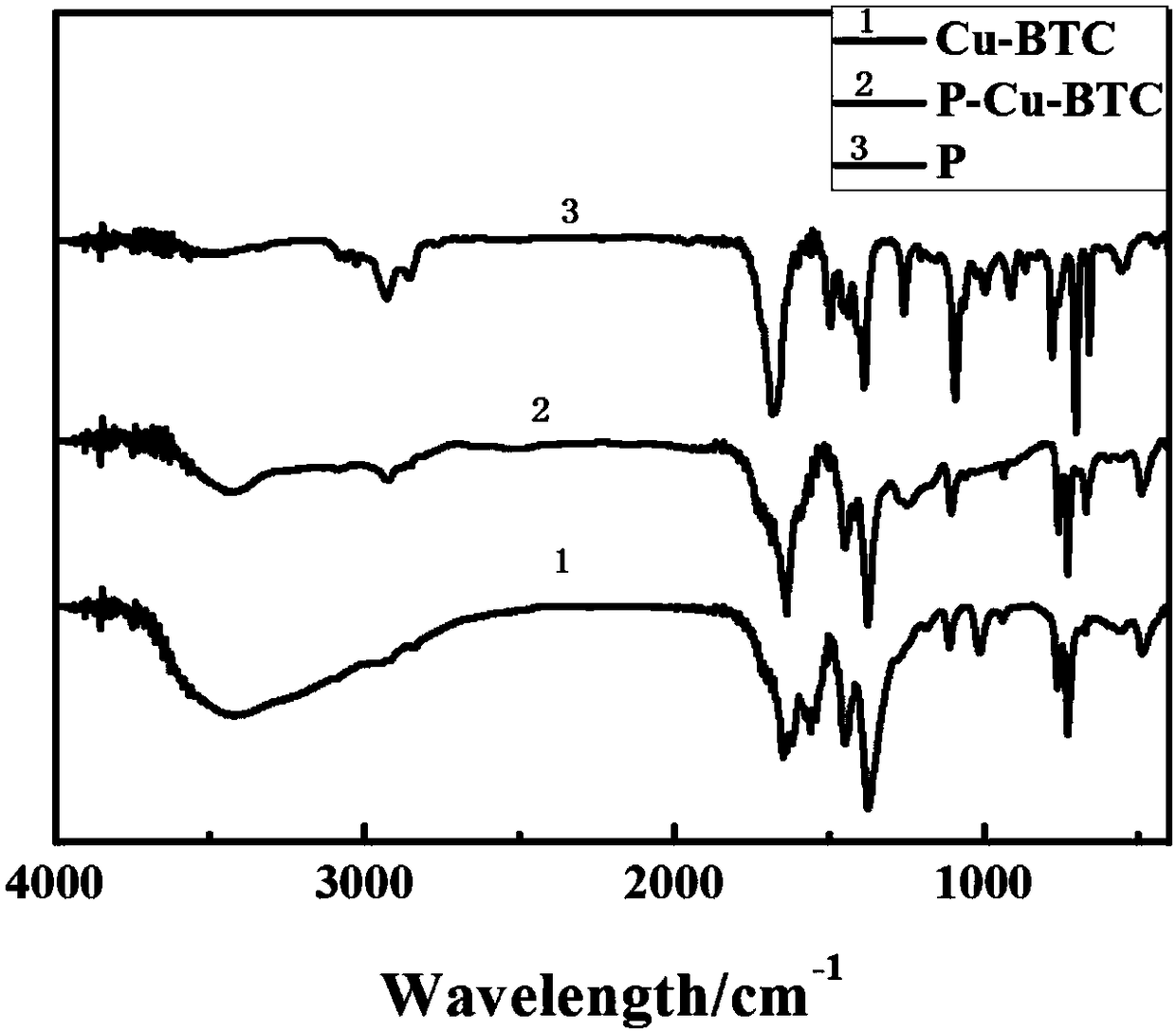

Method for preparing copolymer/HKUST-1 hybrid material by in-situ polymerization

A HKUST-1, hybrid material technology, applied in the field of framework materials, can solve problems such as poor water stability, and achieve the effects of strong plasticity, improved dispersion and compatibility, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] With 0.38g (1.5mmol) copper methacrylate, 0.16g (1.5mmol) styrene, 0.01g (amount: 2% of the total mass of the polymer) azobisisobutyronitrile and 25mL (0.3mol) N, N-dimethylformamide was added into a 50 mL three-necked flask, stirred at room temperature for 60 min, and then placed in an oil bath at 70° C. for 4 hours. After the reaction was stopped, it was left to stand and filtered to obtain a polymer containing copper methacrylate.

Embodiment 2

[0026] The polymer obtained from the reaction in Example 1, 0.11 g (0.5 mmol) of trimesic acid and 25 mL (0.6 mol) of methanol were added into a 50 mL reactor and reacted for 24 hours at room temperature. After the reaction stopped, it was left to stand for crystallization, filtered and dried to obtain the copolymer / HKUST-1 hybrid material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com