Supported catalyst for olefin polymerization, as well as preparation method and application thereof

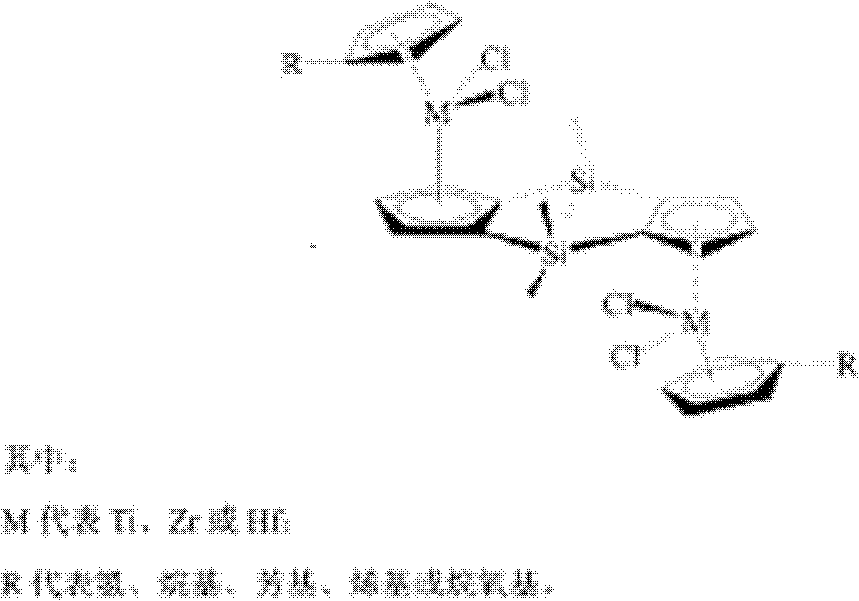

A supported catalyst and olefin polymerization technology, applied in the application field of 1-hexene and ethylene/1-octene copolymerization, can solve the problem that the new type of limited configuration double-bridge metallocene compound loading method has not been reported. , to improve the performance of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Ligand [μ, μ-(SiMe 2 ) 2 (C 5 h 4 ) 2 ]Synthesis

[0057] Ligand [μ, μ-(SiMe 2 ) 2 (C 5 h 4 ) 2 ] The synthetic route is as follows:

[0058]

[0059]Add 50mL (0.42mol) of dimethyldichlorosilane to a 500mL three-neck flask, then add 100mL of n-hexane, and stir evenly. Add 260mL (0.84mol) of 1.6M sodium dicyanocene dropwise under ice-water bath conditions, react for 6 hours, add 50mL distilled water to wash, use a pear-shaped separatory funnel to separate liquid to remove the organic phase, wash the aqueous phase with 3 × 20mL ether, and combine the organic phase, dried over anhydrous magnesium sulfate, filtered, and the solvent was removed in vacuo. Distilled under reduced pressure, collected fractions at 40-42°C / 2mmHg to obtain 18.05 g of a light yellow liquid product with a yield of 22.9%.

[0060] Add the above product into a 250mL Schlenk bottle and dissolve it with 80mL of n-hexane. Under an ice-water bath, about 53 mL of 1.8M n-butyllithium was add...

Embodiment 2

[0062] Catalyst I [μ, μ-(SiMe 2 ) 2 (Allyl-C 5 h 2 )(C 5 h 3 )][(C 5 h 5 )ZrCl 2 ] 2 Synthesis

[0063] 1.04 g (4.3 mmol) of the ligand disilicon-bridged dicyclopentadiene prepared in Example 1 was added into a 100 mL Schlenk bottle, and 30 mL of n-hexane was added to dissolve it. In an ice-water bath, 2.4 mL (4.3 mmol) of 1.8M n-butyllithium was added dropwise, controlled for half an hour in the ice-water bath, and then naturally rose to room temperature, and stirred for 4 hours. The solvent was drained, the solid was washed with 2×10 mL of n-hexane, and then dried, the solid was dissolved in 30 mL of tetrahydrofuran, 0.52 g (4.3 mmol) of allyl bromide was added dropwise, and the reaction was stirred overnight at room temperature. The solvent was drained, and the remaining substance was extracted with 3×20 mL of n-hexane, and then 4.8 mL (8.6 mmol) of 1.8M n-butyllithium was added dropwise and reacted for 4 hours. Drain the solvent, wash the solid with 2×10mL n-hex...

Embodiment 3

[0065] Catalyst II [μ, μ-(SiMe 2 ) 2 (Allyl-C 5 h 2 )(C 5 h 3 )][(C 5 h 5 )TiCl 2 ] 2 Synthesis

[0066] The preparation steps are the same as in Example 2, replacing 1.52g (4.3mmol) CpZrCl with 4.3mmol titanium trichloride 3 · DME, a dark red solid was finally obtained with a yield of 36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com