Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Removal Difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of halloysite supported needle-like Fe3O4 nanocomposite

ActiveCN107088398AOvercoming activityOvercoming pollutionOther chemical processesWater/sewage treatment by magnetic/electric fieldsHalloysiteIron salts

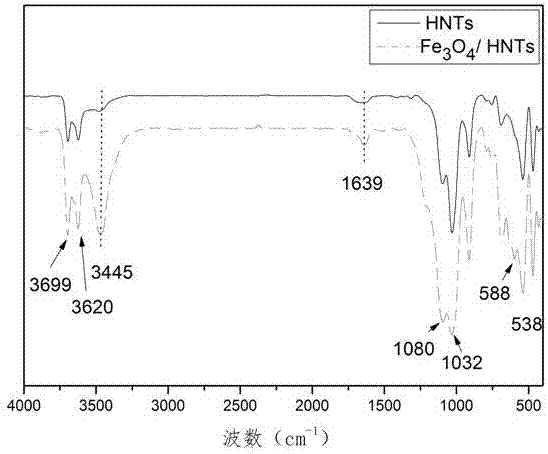

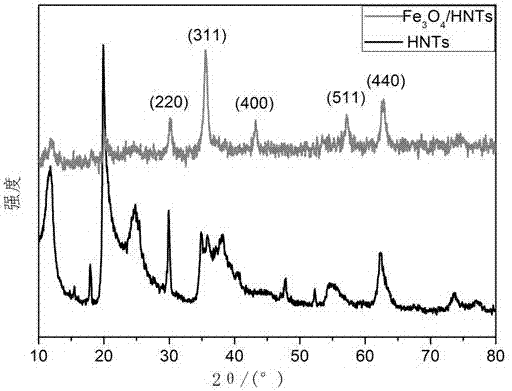

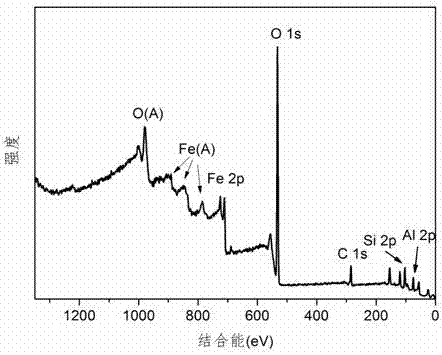

The invention provides a preparation method of a halloysite supported needle-like Fe3O4 nanocomposite and belongs to the technical field of water treatment. Natural ore, namely, halloysite is mixed with an aqueous iron salt solution, then aqueous alkali is added to the solution, the mixture is subjected to a reaction in inert gas atmosphere, a reaction product is subjected to magnetic separation, and a solid-phase material is obtained; the solid-phase material is washed with deionized water and ethanol to neutral and subjected to freeze drying, and the halloysite supported needle-like Fe3O4 nanocomposite is obtained. The prepared nanocomposite has the advantages that the problems of agglomeration inactivation and secondary water pollution of a nanomaterial and arsenic removal difficulty at present are solved, water arsenic adsorption property is better, water arsenic removal efficiency is higher, As (III) can be removed effectively, the preparation process is simple and reliable, and the production cycle is shorter.

Owner:YANGZHOU UNIV

Process for repair-welding steel casting through flux-cored wire CO2 gas shielded welding

The invention relates to the cast steel industry, particularly to a process for repair-welding a steel casting through flux-cored wire CO2 gas shielded welding. During the application, the process for repair-welding steel casting products is characterized by selecting a flux-cored wire matched with a casting base material, determining welding process parameters reasonably, selecting a welding current of 150-300 A, a welding voltage of 23-40 V, a wire extension length of 15-25mm, a welding speed of 45-90 mm / s, a gas flow of 20-25 L / min, and performing WPQ (welding procedure qualification ) according to the IX volume of ASME (American Society of Mechanical Engineers). The process for repair-welding the steel casting through the flux-cored wire CO2 gas shielded welding solves the problem of low efficiency, high labor intensity, multiple joints and slag removal difficulty of manual SMAW (shielded metal arc welding), eliminates defects such as microcracks, porosity and slag inclusion of a repair-welding area, when compared with the SMAW, can improve the working efficiency to 3-5 times, reduces production costs to more than 50%, enables the hydrogen content of weld metal to be lower than 2.0 ppm and corrosion resistance to be strong, guarantees that physical and chemical properties accord with and exceed requirements of corresponding cast steel material standards, and is applicable to high-grade, precise and top-notch steel castings and steel castings of high pressure hydrogen valves.

Owner:江苏万恒铸业有限公司

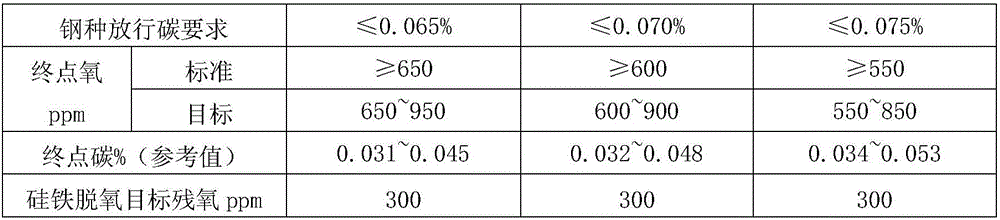

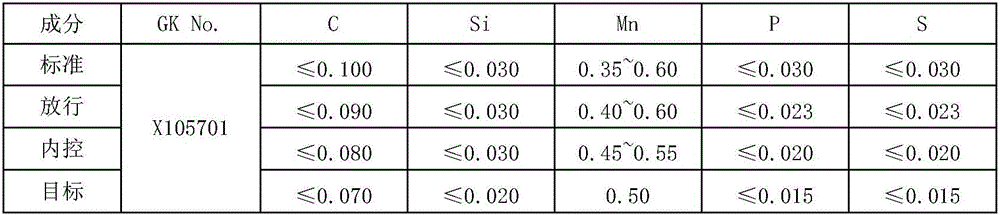

Deoxidation process for H08 steel-grade silicon

The invention relates to a deoxidation process for H08 steel-grade silicon, and belongs to the technical field of steel refining furnace external refining processes. The deoxidation process is characterized in that when oxygen content of molten steel at a converter endpoint is higher than upper limit of a steel tapping target, a converter can adopt part of silicon iron to replace an aluminum deoxidant to perform pre-deoxidation, and therefore, requirements of steel-grade silicon components are relatively low; and converter silicon iron adding time and adding amount must be strictly controlled to further achieve the silicon iron deoxidation effect and guarantee steel-grade components to be qualified, so that quantity of Al2O3 impurities generated by aluminum alloy deoxidation is reduced, impurity removal difficulty can be effectively reduced, degree of purity of molten steel is improved, and castability of molten steel is improved, and therefore, alloy cost is reduced.

Owner:BENGANG STEEL PLATES

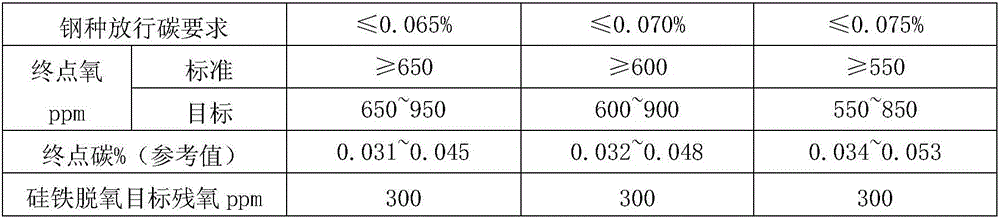

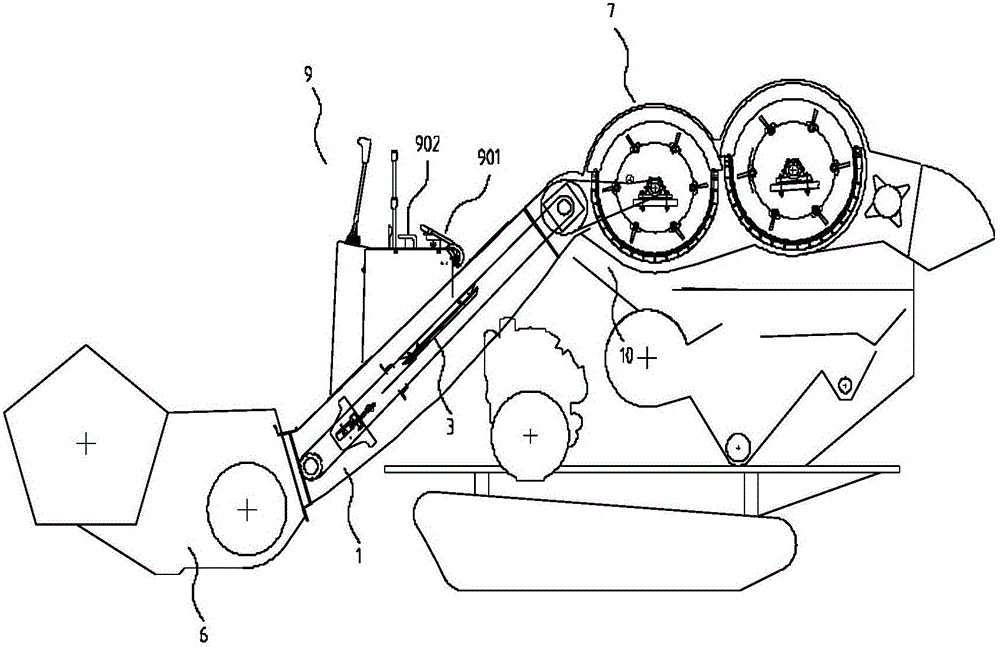

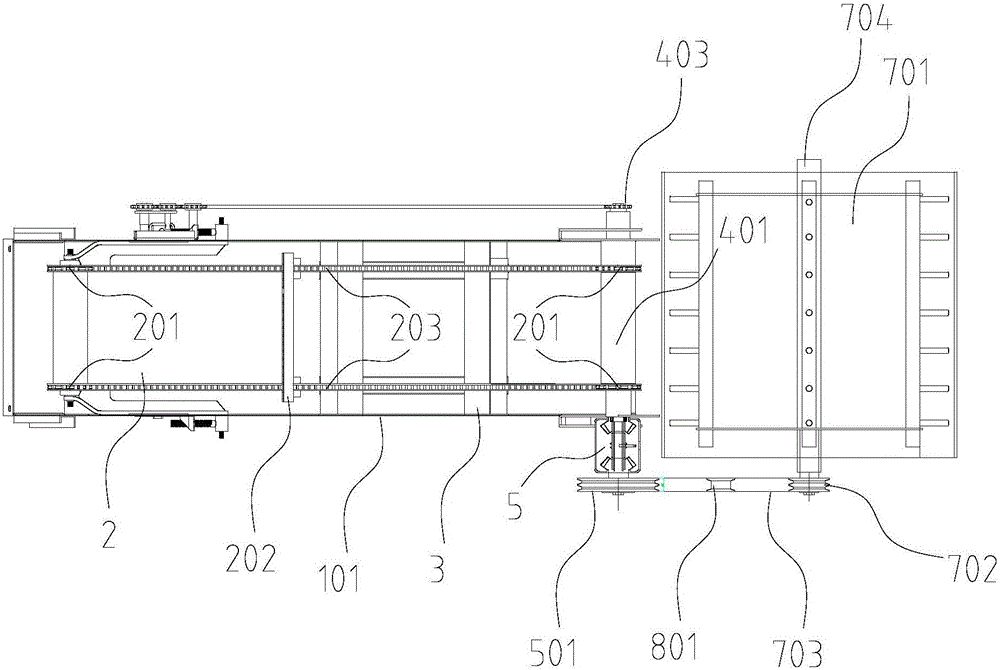

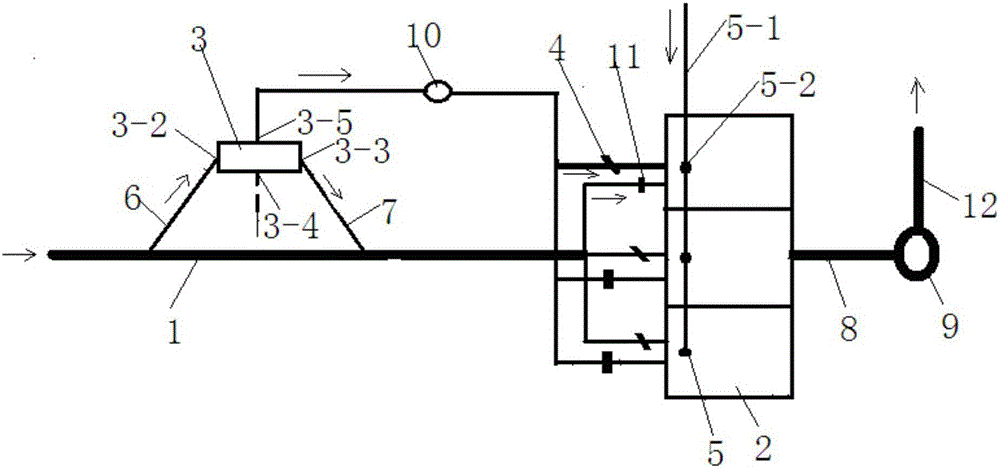

Combined harvester conveying trough with forward rotation conveying function and reverse rotation grass discharge function

ActiveCN106068899AThere will be no tooth skipping phenomenonReduce the difficulty of troubleshootingMowersThreshersDriver/operatorGear wheel

The invention provides a combined harvester conveying trough with a forward rotation conveying function and a reverse rotation grass discharge function. The conveying trough comprises a conveying trough shell, a chain harrow, a supporting plate, a transmission mechanism and a tensioning mechanism. By means of a tension wheel mechanism, power between a power output shaft of a combined harvester threshing cylinder and a power input shaft of the conveying trough is cut and connected, the power is transmitted in the mode that a bevel gear in a forward rotation transmission box and a bevel gear in a reverse rotation transmission box are always meshed, reversing operation of power connection shafts in the forward rotation transmission box and in the reverse rotation transmission box is controlled in the mode that a driver pulls a handle on a driving console, a transmission system of the forward rotation and reverse rotation conveying trough of a combined harvester is simplified, the grass blocking problem in the conveying trough can be quickly solved, and obstacle removal difficulty of grass blocking of the conveying trough in the combined harvester during harvesting is reduced. The conveying trough is simple in structure, convenient to operate and capable of greatly improving efficiency and safety when applied to the combined harvester.

Owner:JIANGSU UNIV

Purification and cobalt removal method for zinc leaching solution

InactiveCN109536715AStrong antimagneticStrong paramagnetismElectrolysis componentsPhotography auxillary processesPregnant leach solutionField conditions

The invention relates to the technical field of hydrometallurgy, in particular to a purification and cobalt removal method for a zinc leaching solution. Zinc leachate is directly electrolyzed under amagnetic field condition, and the magnetic field intensity is accurately controlled and is kept at 7-9A / m, so that the content of cobalt in electrolyzed liquid is greatly reduced, the removal rate ofthe cobalt is improved, the circulation use capability of the electrolyzed liquid is realized, and the cobalt removal difficulty of the zinc leachate is reduced.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG +1

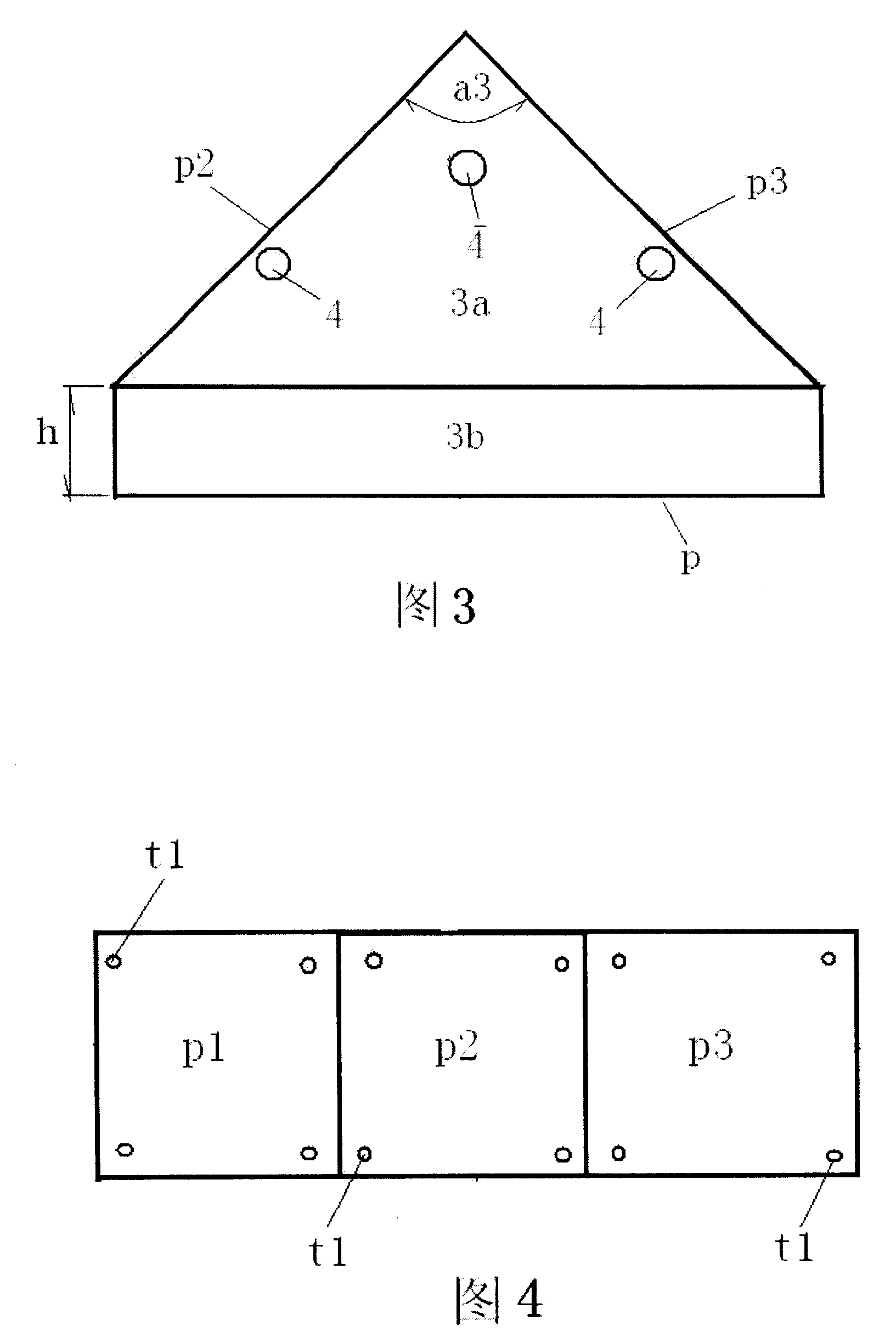

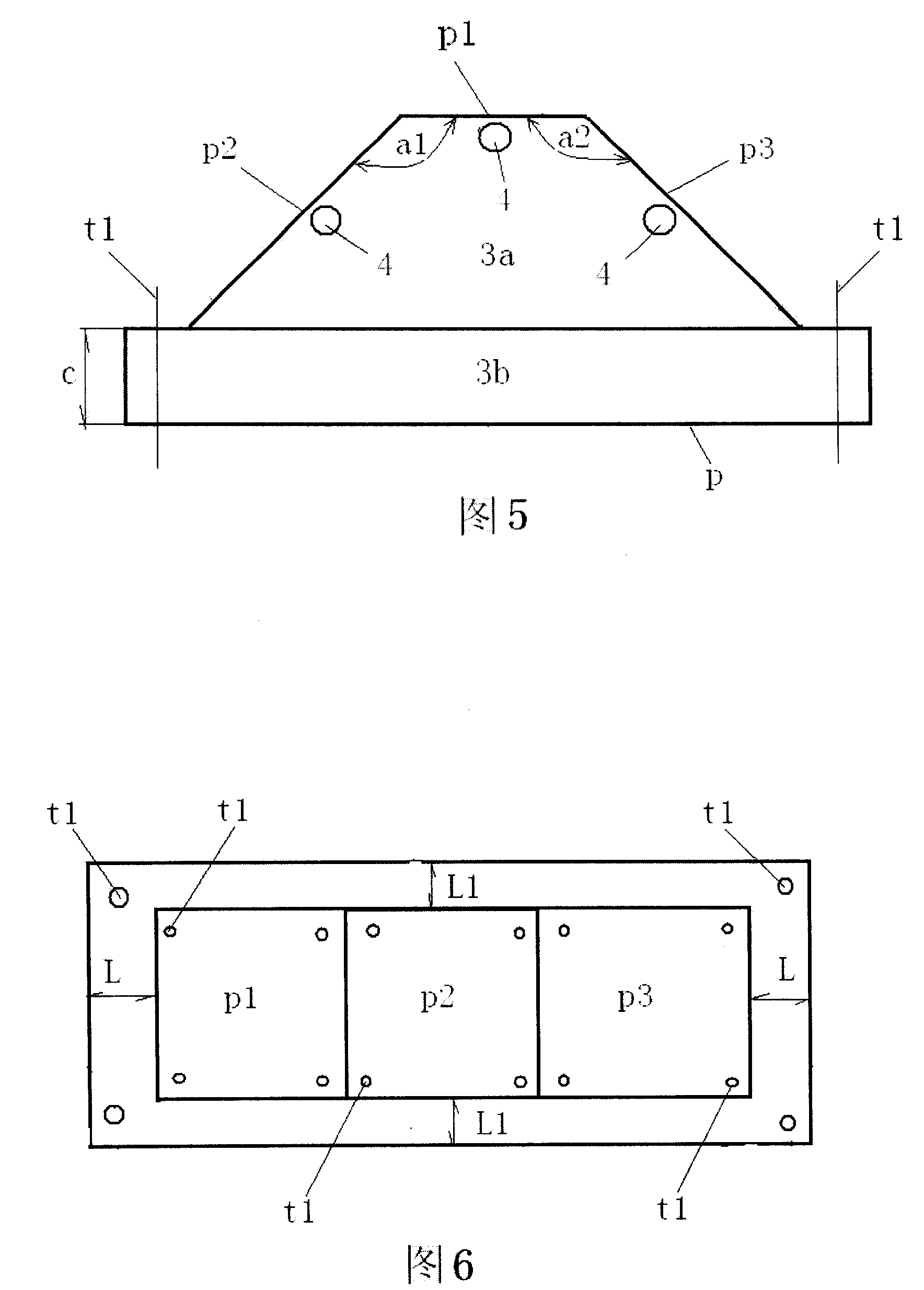

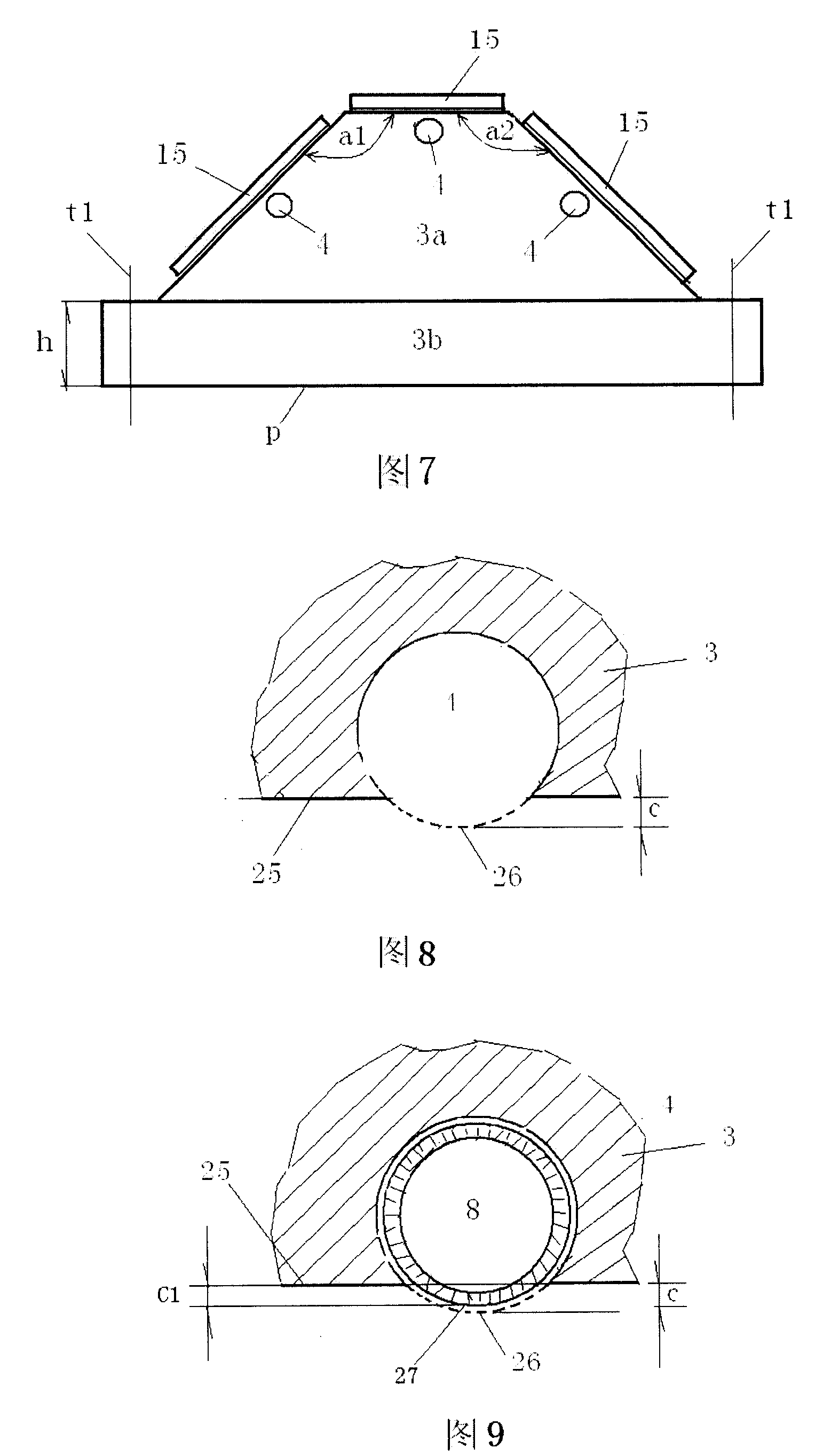

LED lamp socket and lamp cap

InactiveCN101251243AImprove performanceLow costLighting support devicesPoint-like light sourceRemoval DifficultiesEngineering

The present invention provides an LED lamp holder and a lamp cap thereof, aiming at the problem that the light emitted by the LED lamp is uneven due to directivity of the light. The LED lamp holder has a trapezoidal structure, or the LED lamp holder can be designed to have a tower-type structure, a triangular structure, a pyramid structure or a conic structure. At least 2 LED lamp mounting positions which are the necessary component elements of the LED lamp are arranged on the LED lamp holder. Preferably, a proposal and a structure of a light concentration system are designed, which are used for being combined with and matching the LED lamp so as to effectively solve the problems of the unevenness of the light emitted by the lamp and the heat removal difficulty of high-power LED lamps due to the directivity of the light emitted by the LED of the LED lamp. The LED lamp holder and the LED cap are capable of realizing industrialized mass production and utilization of the high-power LED lamps.

Owner:DONGGUAN CLED OPTOELECTRONIT TECH

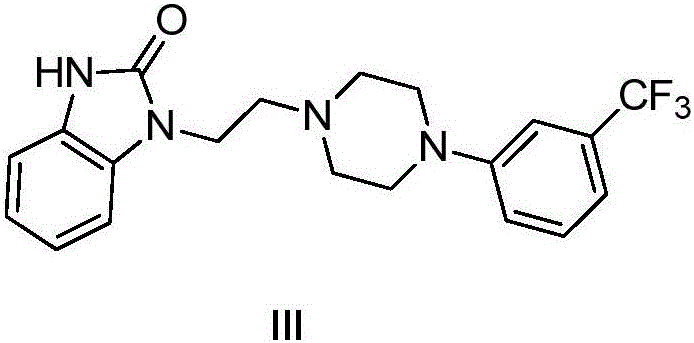

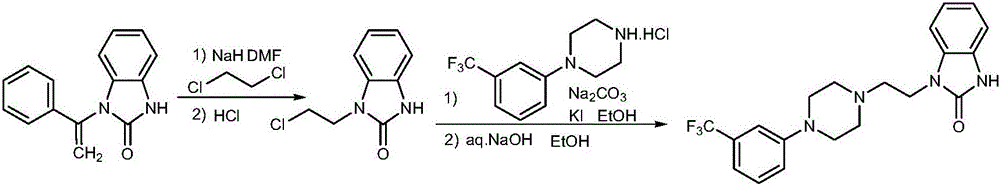

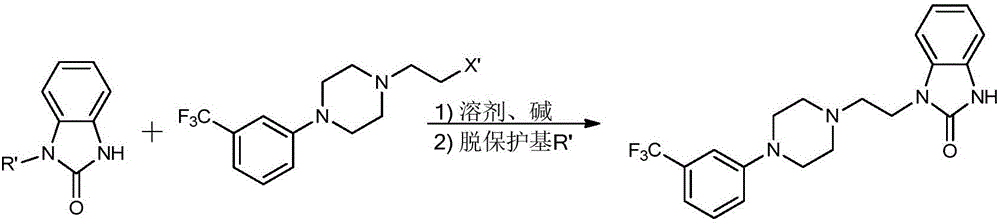

Benzimidazole compound and preparation method and application thereof

The invention discloses a benzimidazole compound as shown in a formula (I), a preparation method of the benzimidazole compound, and application of the benzimidazole compound used for preparing flibaserin or pharmaceutically acceptable salts of flibaserin. The benzimidazole compound as shown in the formula (I) is used for preparing flibaserin, and the defects of high cost, low yield, impurity removal difficulty and the like in the prior art are overcome. The structural formula is as shown in the specification.

Owner:SUZHOU VIGONVITA LIFE SCIENCES CO LTD +1

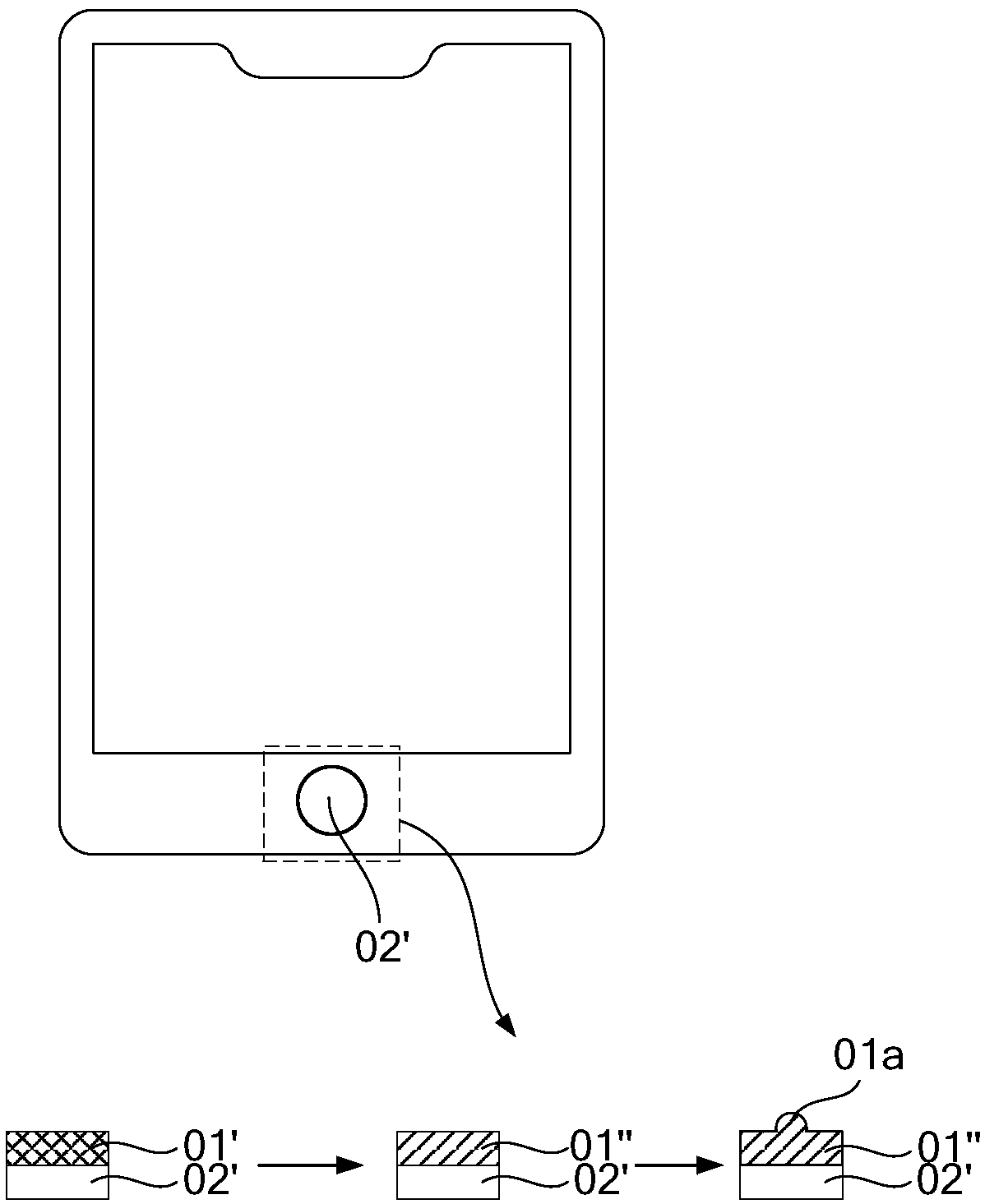

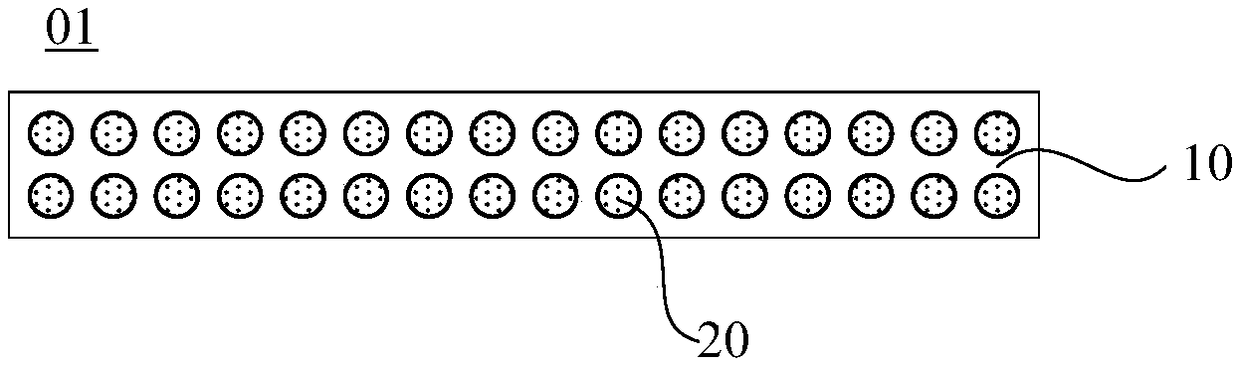

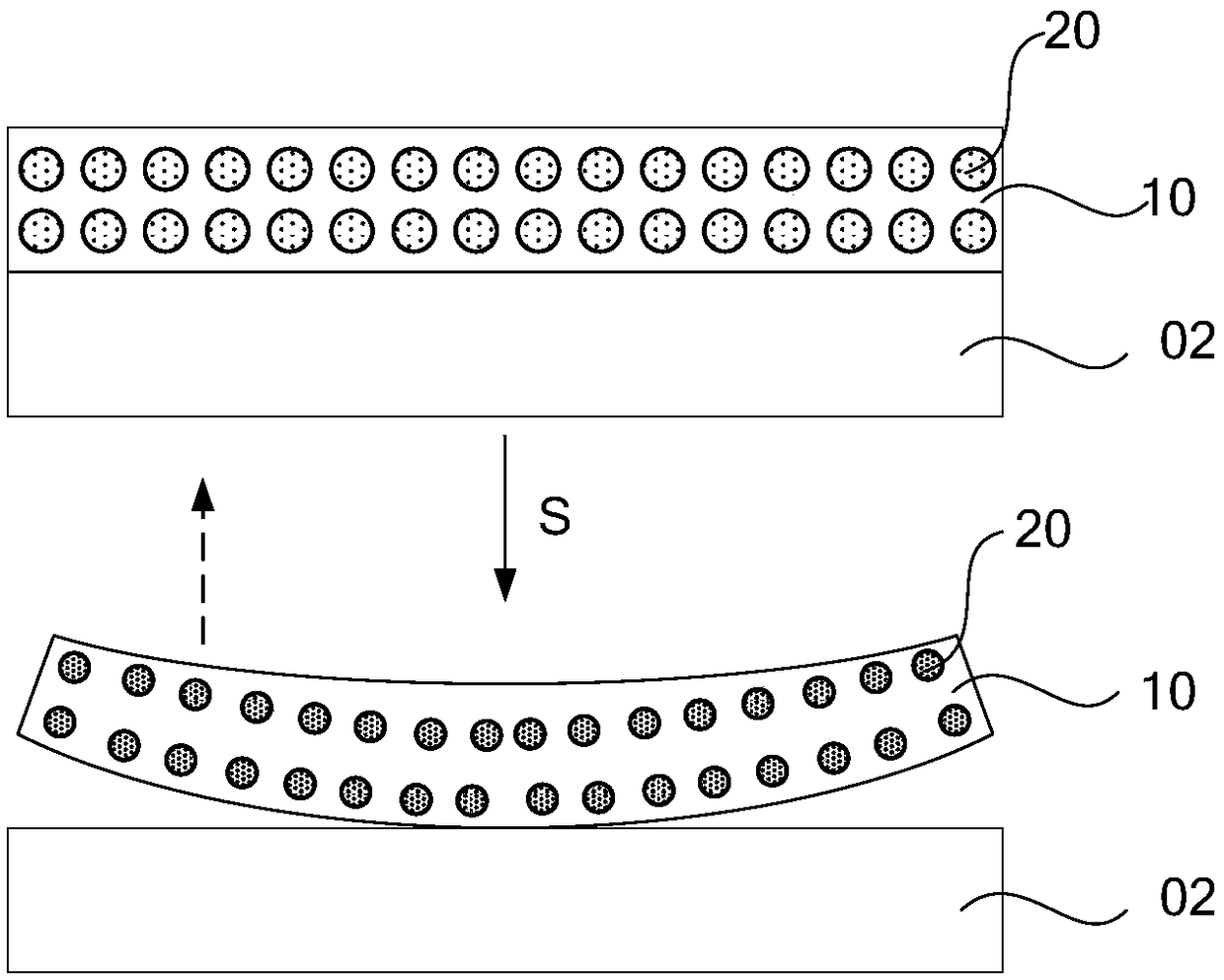

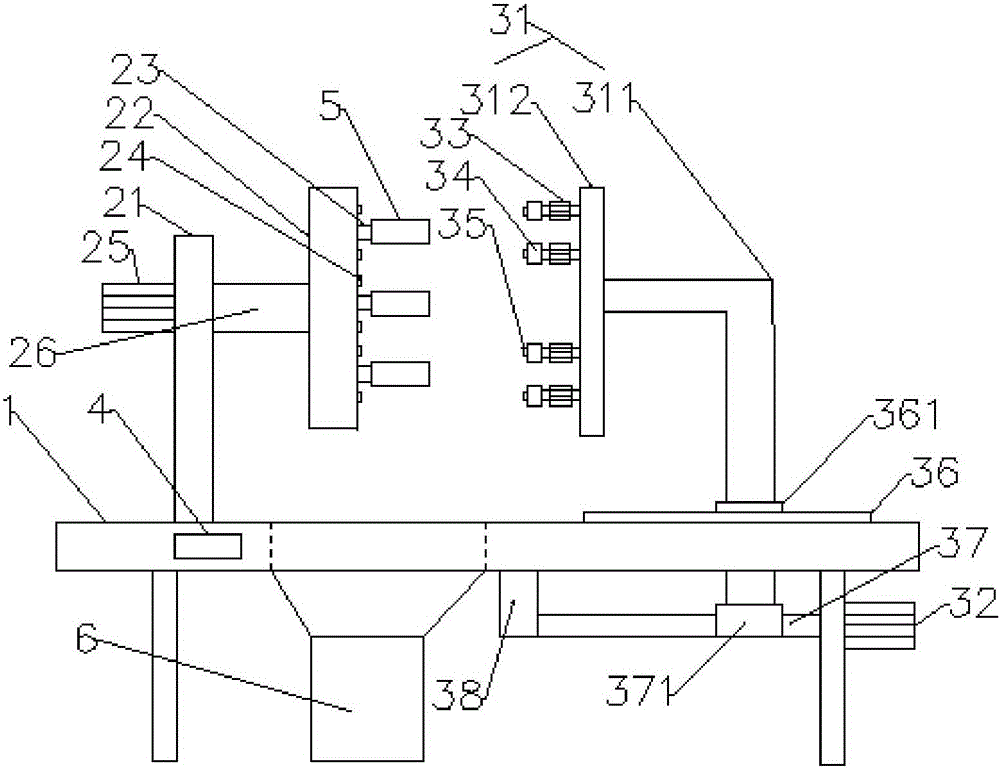

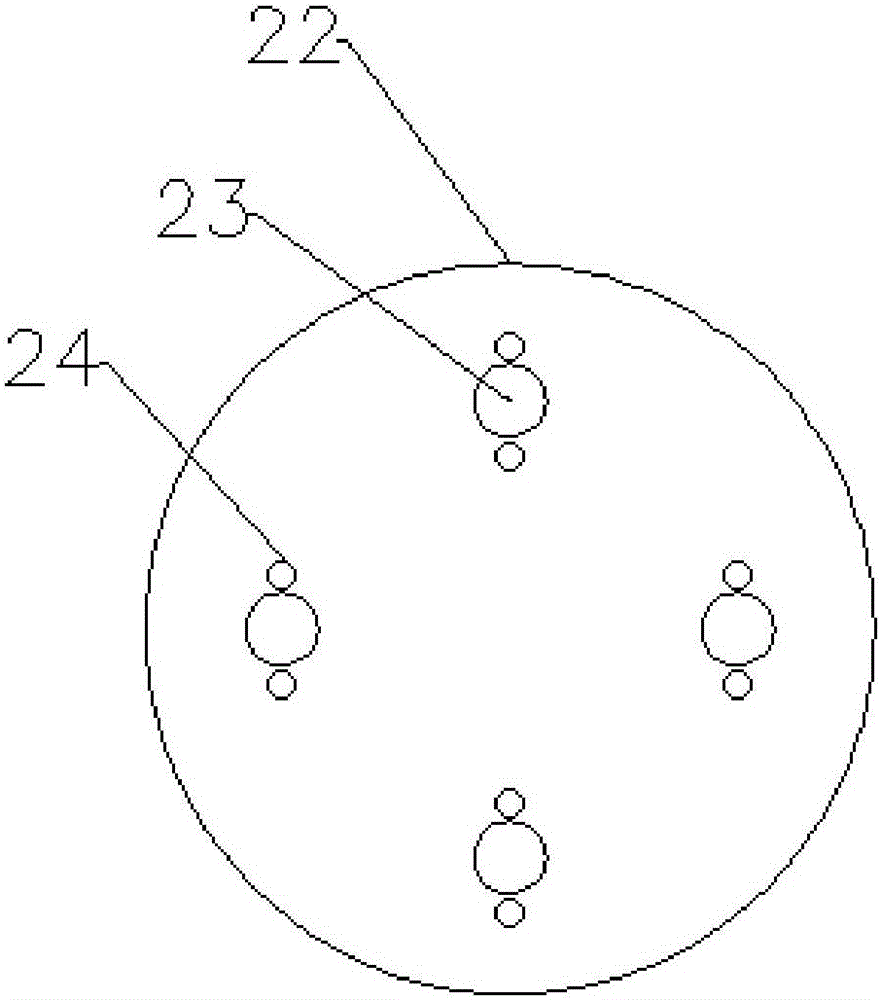

Glue film, preparation method of glue film, display device and method for removing glue film

ActiveCN109449080AReduce difficulty of removalEasy to separateLayered productsSemiconductor/solid-state device detailsDisplay deviceRemoval Difficulties

The invention provides a glue film, a preparation method of the glue film, a display device and a method for removing the glue film, and relates to the technical field of display. The removal difficulty of the glue film can be reduced, so that the glue film and a glued object can be effectively separated, and the problems of glue material residues and the like are avoided. The glue film comprisesa glue film body and deformed particles dispersed in the glue film body, wherein the volume of the deformed particles can be contracted. The method is used for removing the glue film.

Owner:BOE TECH GRP CO LTD +1

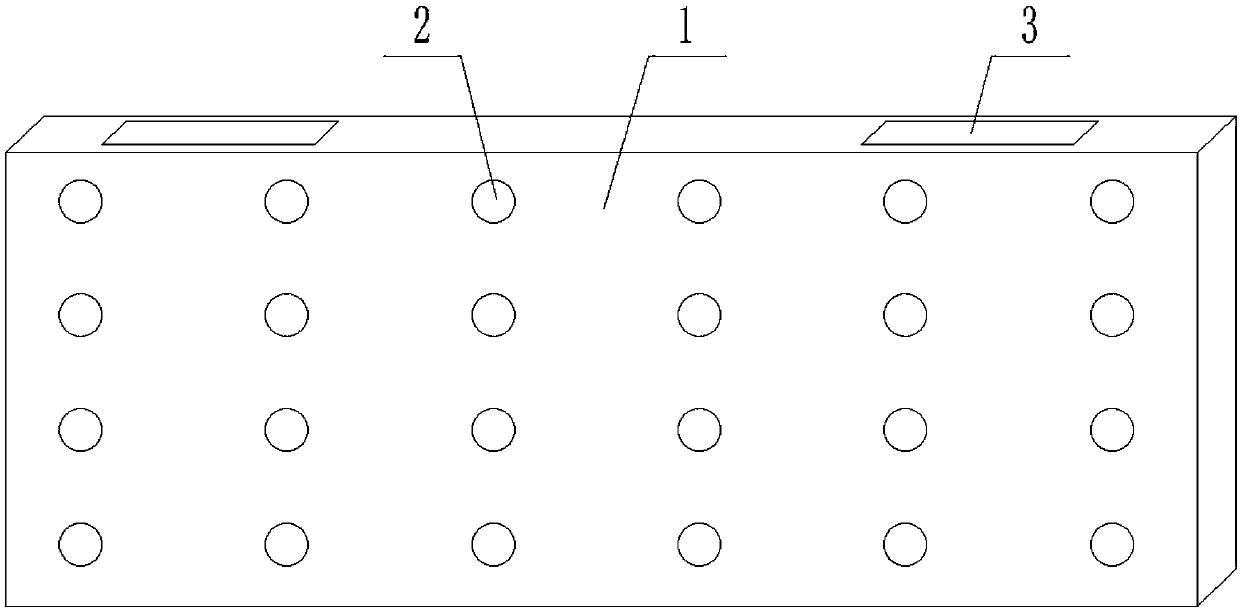

Steel pipe derusting device with rust chip collection function

InactiveCN105773371AWith rust collection functionImprove rust removal efficiencyGrinding carriagesGrinding machinesRemoval DifficultiesElectric machinery

The invention provides a steel pipe derusting device with a rust chip collection function. The steel pipe derusting device comprises a base, a fixed part, a moving part and a controller. The fixed part and the moving part are arranged at the two ends of the base correspondingly. The bottom of a fixed support is arranged at one end of the base, and a rotary shaft penetrating the fixed support is arranged on the upper portion of the fixed support. One end of the rotary shaft is provided with a first motor, and the other end of the rotary shaft is connected with the back face of a rotary disc. A plurality of fixing mechanisms for steel pipes are arranged on the front face of the rotary disc. The vertical part of an L-shaped part of a moving support is connected with a moving mechanism, and a fixed seat is arranged at the tail end of the horizontal part of the L-shaped part of the moving support and provided with two pairs of dedrusting mechanisms. An opening is formed in the position, right opposite to the fixing mechanisms, of the base. A rust chip collection bin is arranged below the opening. The controller is connected with the first motor, the moving mechanism, the dedrusting mechanisms and a rust chip collection mechanism. The derusting efficiency is improved through the multiple fixing mechanisms for the steel pipes; the controller acquires steel pipe derusting information through two piezoelectric sensors, and the intelligent degree is high; and the rust chip removal difficulty is reduced through the rust chip collection mechanism.

Owner:TIANJIN ZHENGAN SEAMLESS STEEL TUBE

Al2O3-MgO-SiAlON common steel heat treatment anti-oxidation coating and use method thereof

InactiveCN106634559ALower sintering temperatureShorten sintering holding timeFireproof paintsPotassiumBoron carbide

The invention discloses an Al2O3-MgO-SiAlON common steel heat treatment anti-oxidation coating and a use method thereof. The coating comprises, by weight, 30-50 parts of Al2O3-MgO-SiAlON powder, 3-5 parts of Cr2O3, 20-30 parts of compound binders, 0.5-1.5 parts of potassium fluoborate and 0.5-1.5 parts of boron carbide. The Al2O3-MgO-SiAlON powder serves as a filler of the coating, high-temperature resistance and chemical stability of the coating are improved, high-temperature stability and viscosity of the compound binders prepared from phthalocyanine resin prepolymer are enhanced, the coating does not easily crack or fall off, and high-temperature oxidation resistance of the coating is enhanced. The coating can be sprayed or brushed on the surface of a steel billet at the temperature ranging from room temperature to 500 DEG C, the coating can naturally fall off in the cooling process after hot processing, and phosphorus removal difficulty is reduced.

Owner:长兴天晟能源科技有限公司

Metal additive material manufacturing support method and device based on shape following base plate

ActiveCN110421164ASpeed up design timeExtended production timeAdditive manufacturing apparatusIncreasing energy efficiencyRemoval DifficultiesEngineering

A metal additive material manufacturing support method based on a shape following base plate is used for reducing the distance between a supporting point and a base plate, various generated support areas serve as a base, the shape following base plate related to the surface of a formed component is downwards established, a new support is generated on the shape following base plate, and accordinglythe support height is lowered. The shape following base plate can guarantee the generated support forming quality along with constant changes of the height, the shape and the thickness of the formedface. A metal additive material manufacturing support device based on the shape following base plate is provided. When formed components are complex in shape and structure and the support areas are high, on one hand, a conical support can be continuously utilized, materials are saved, and the removal difficulty is lowered; and on the other hand, the height of the support, making contact with the formed bottom face, of the base plate can be effectively reduced, and the component bottom face and structure forming quality is improved.

Owner:ZHEJIANG UNIV OF TECH

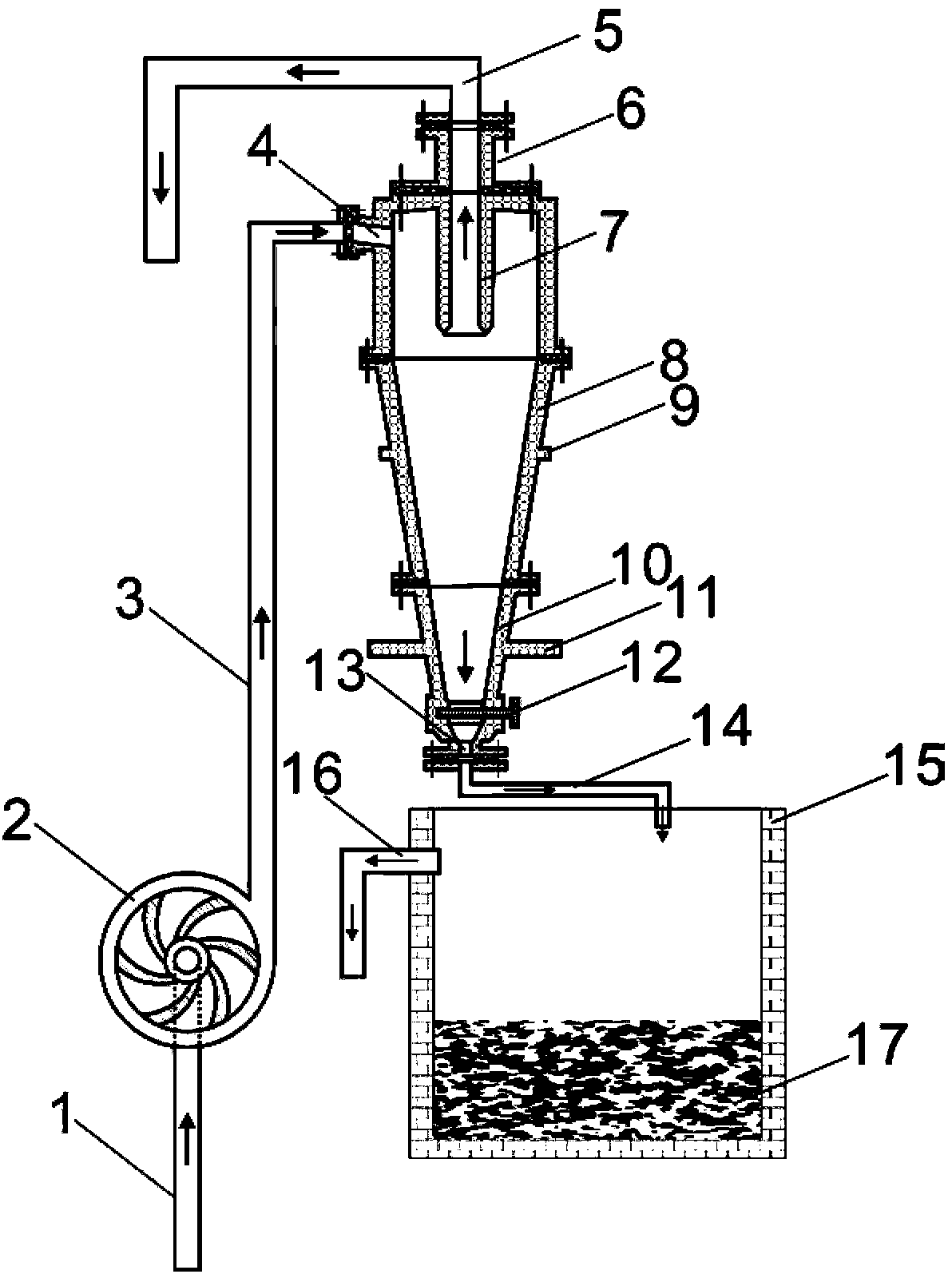

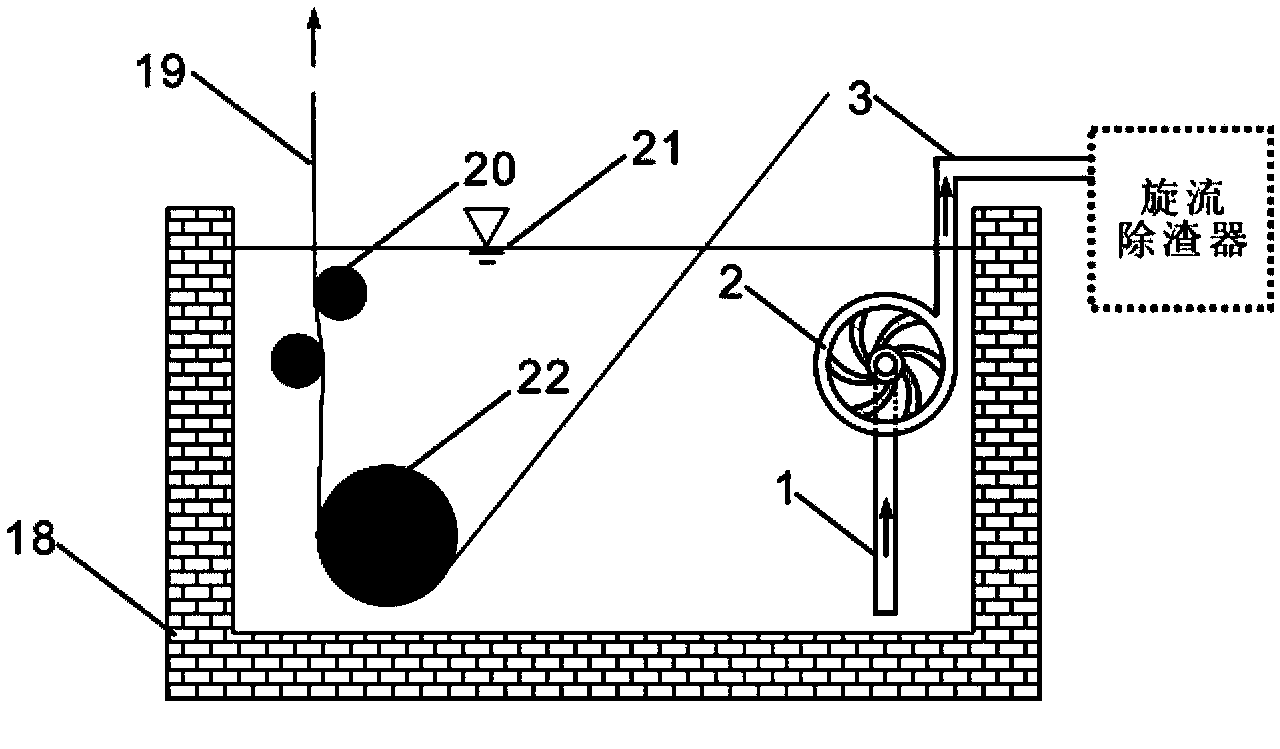

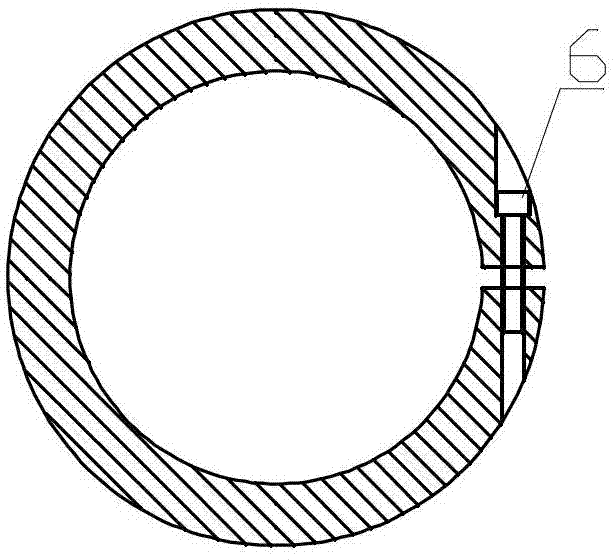

Continuous hot-dip galvanized centrifugal cyclone slag removal device

ActiveCN103014586BSolve the problem of slag removalReduce manufacturing costHot-dipping/immersion processesSlagRemoval Difficulties

The invention discloses a continuous hot dip aluminum-zinc plating centrifugal cyclone slag removing device, which comprises an aluminum-zinc liquid pipe, a high-speed aluminum-zinc pump, a centrifugal cyclone, an overflow pipe, a slag discharging pipe and an aluminum-zinc slag collector, wherein all the components are made of stainless steel and ceramic which can resist aluminum-zinc corrosion. The high-speed aluminum-zinc pump injects aluminum-zinc liquid comprising slag into the centrifugal cyclone by the aluminum-zinc liquid pipe; the head cover of the centrifugal cyclone is provided with an overflow port which is connected with the overflow pipe to discharge the aluminum-zinc liquid which is subjected to slag removal; and the base of the centrifugal cyclone is provided with an outlet which is connected with the aluminum-zinc slag collector by the slag discharging pipe. The device can remove slag for aluminum-zinc liquid in an on-line way, solves the slag removal difficulty of the continuous aluminum-zinc plating production process, reduces the production cost of continuous aluminum-zinc plating, and improves the product quality of the continuous aluminum-zinc- plated plate.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

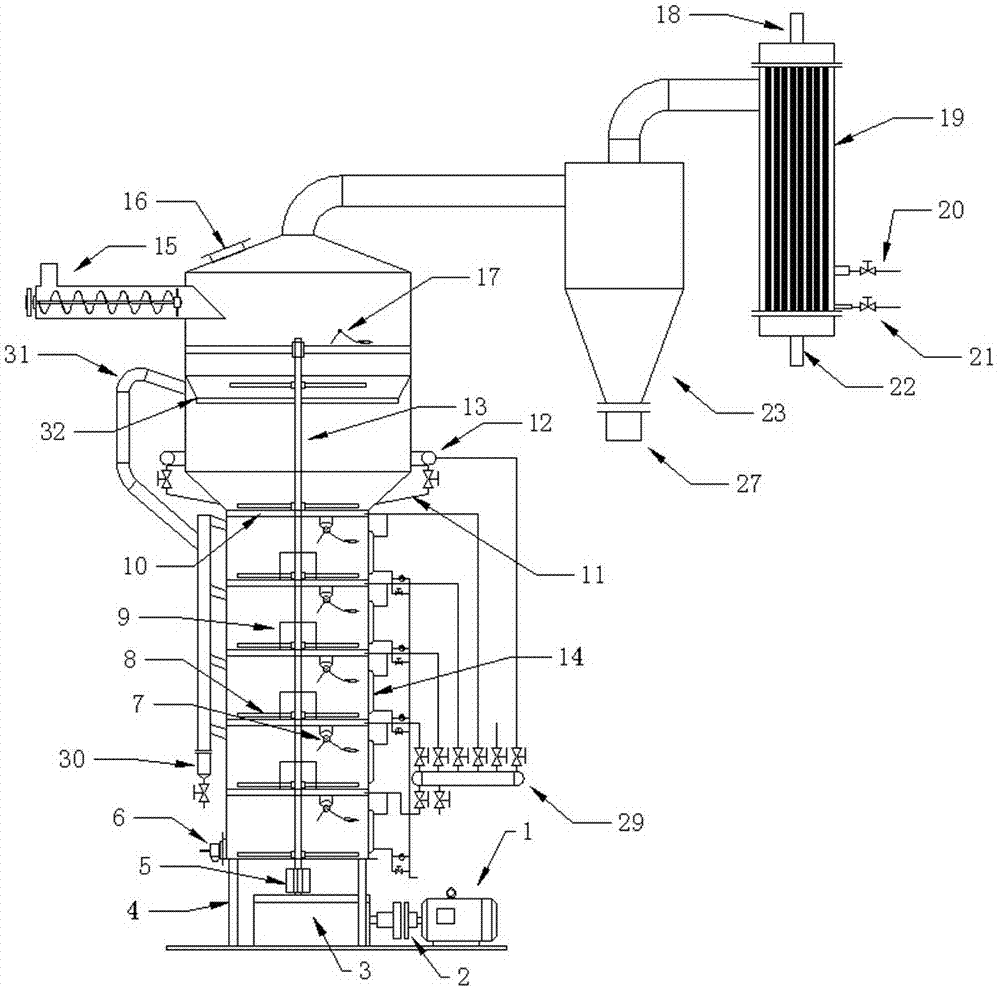

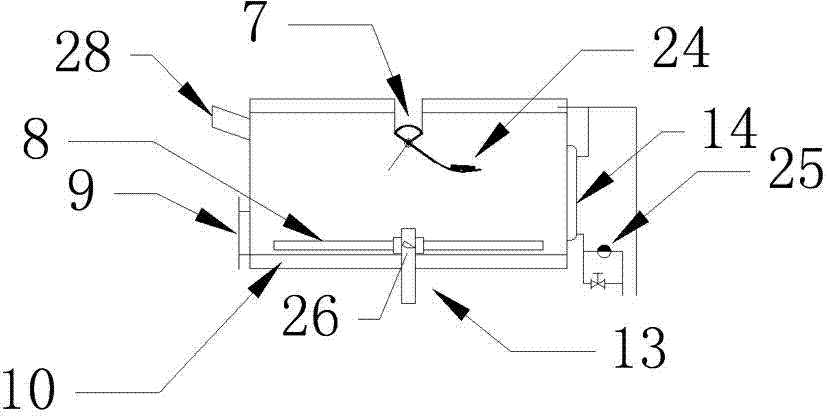

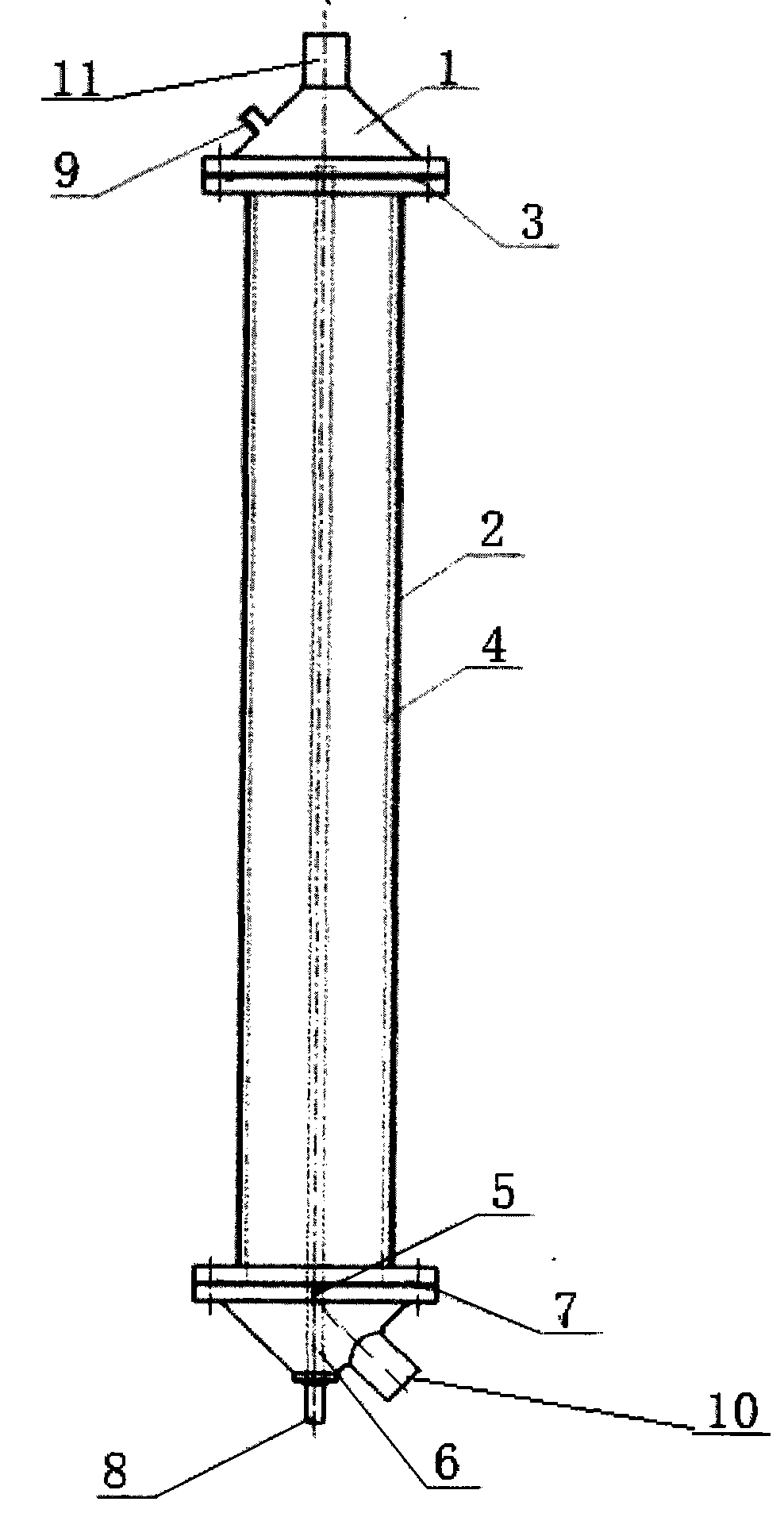

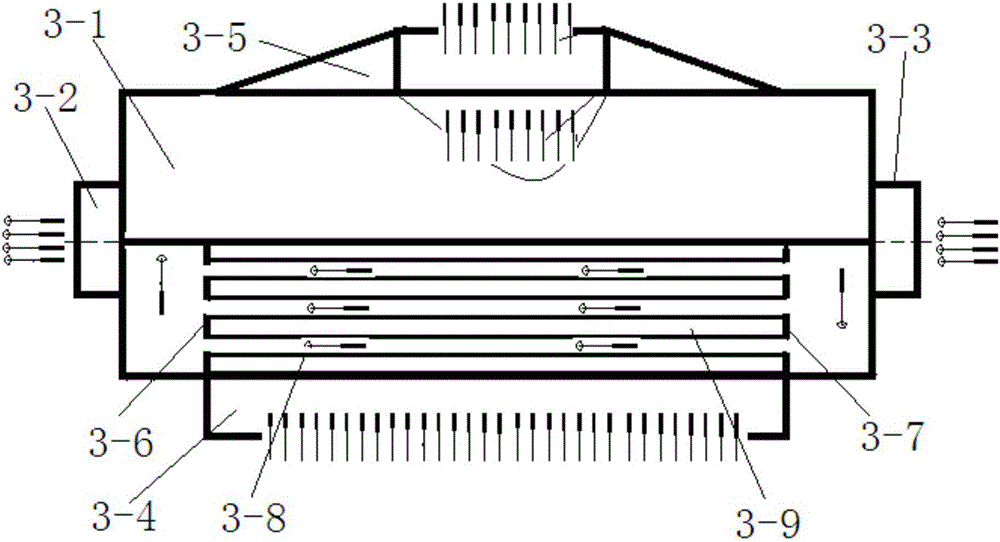

Vertical steam removal device for residual solvent in rapeseed meal

ActiveCN103966017AImprove cooling effectEasy to operateFatty-oils/fats productionRemoval DifficultiesEngineering

The invention discloses a vertical steam removal device for a residual solvent in rapeseed meal. The vertical steam removal device comprises a vertical steam removal machine composed of six layers of box bodies, wherein the bottom plates and side walls of the lower five layers of box bodies are provided with heated steam jackets, the bottom of the topmost layer of box body is provided with an annular steam pipe on which a plurality of steam pipes are obliquely arranged; each layer of box body is internally and respectively provided with a material height indicator and an automatic material door capable of automatically regulating the dropping speed of an upper-layer material according to the height of a local-layer material; a material seal conveying stranding cage is connected with the upper end of the topmost layer of box body, and the bottommost layer of box body is provided with a cock discharging valve; each layer of box body is provided with an agitating scraper, the agitating scrapers are fixed on a main shaft, and the main shaft is fixed in the box bodies and can rotate; and the topmost layer of box body is connected with a shell pass of a tubular heat exchanger through a cyclone dust catcher and is finally connected with a connecting pipe of a water distribution tank. The vertical steam removal device is used for solving the technical problems of rapeseed meal steam removal difficulty, high steam consumption in steam removal and high extraction solvent consumption and is suitable for large-scale industrial processing; and in addition, the automatic material door is simple in working principle, reliable and convenient to operate.

Owner:泰州市海鑫高新技术投资发展有限公司

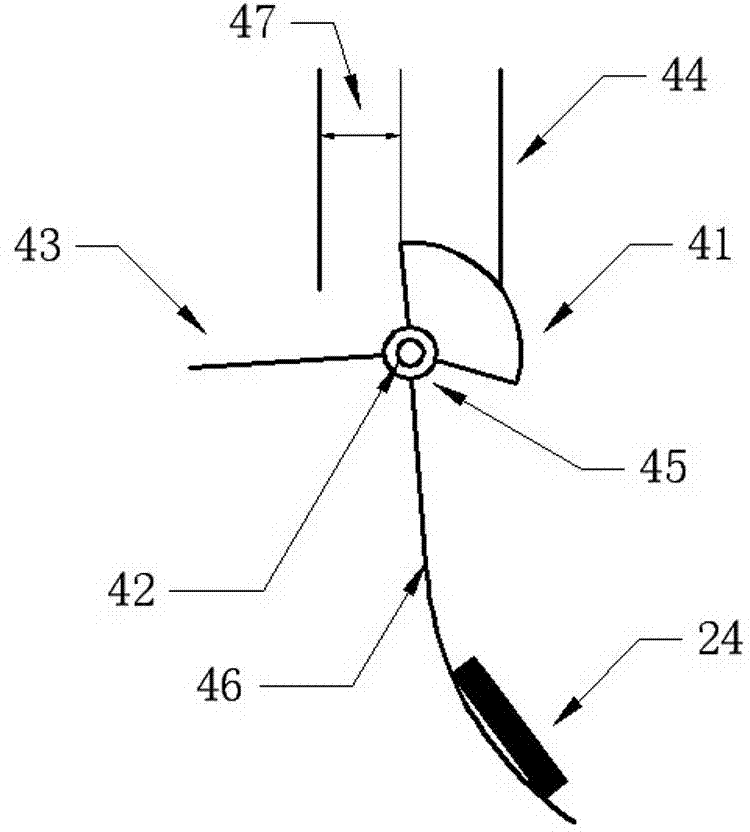

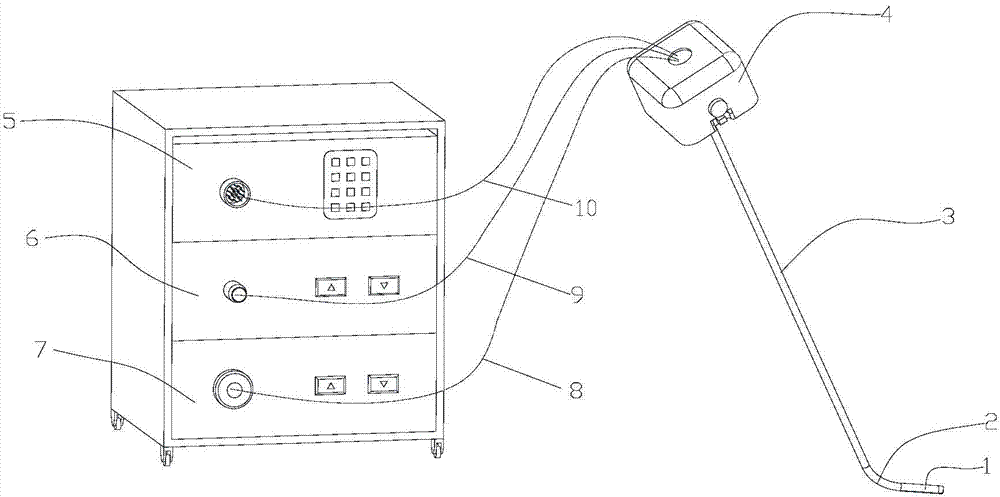

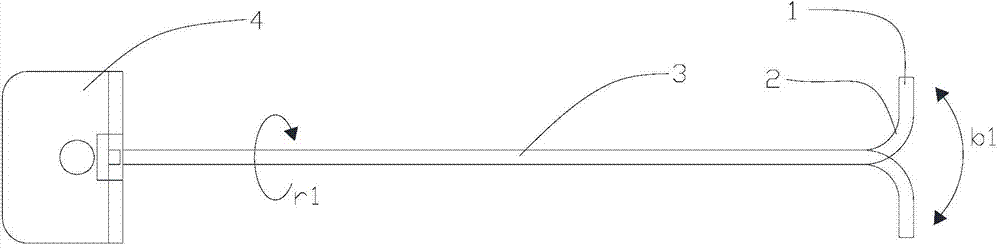

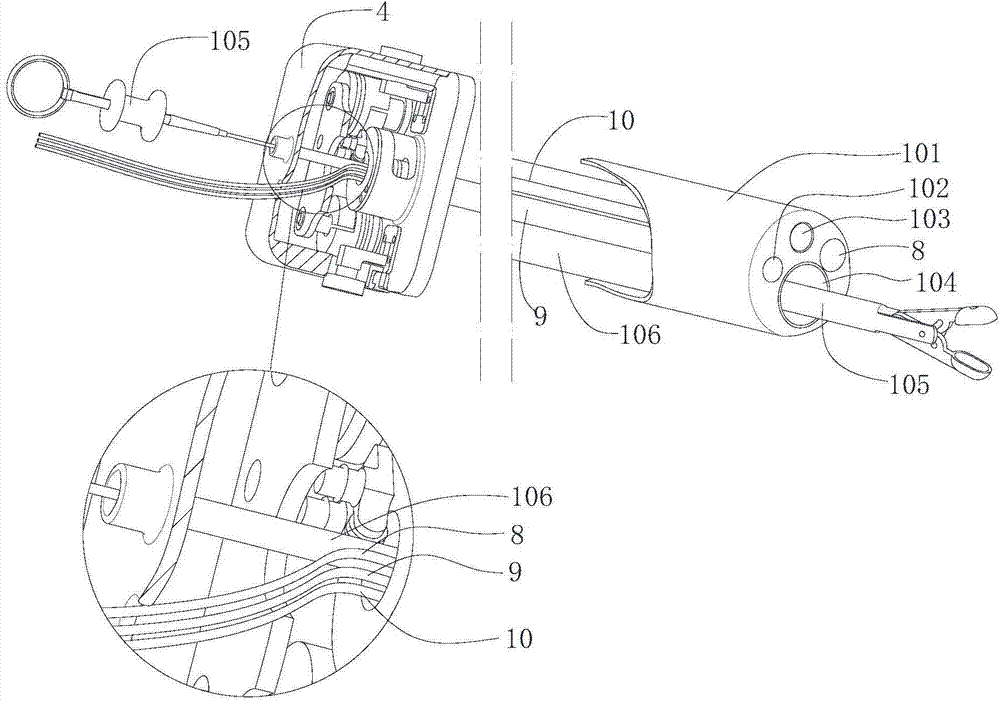

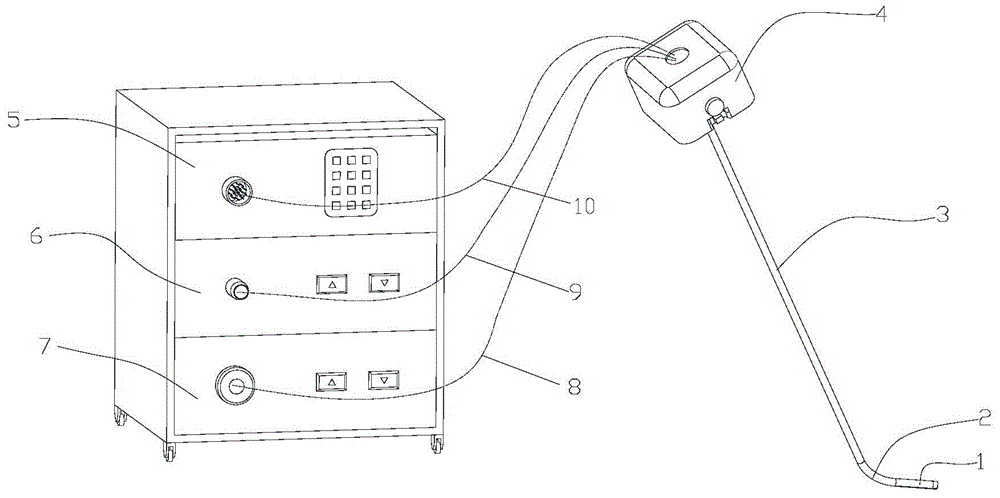

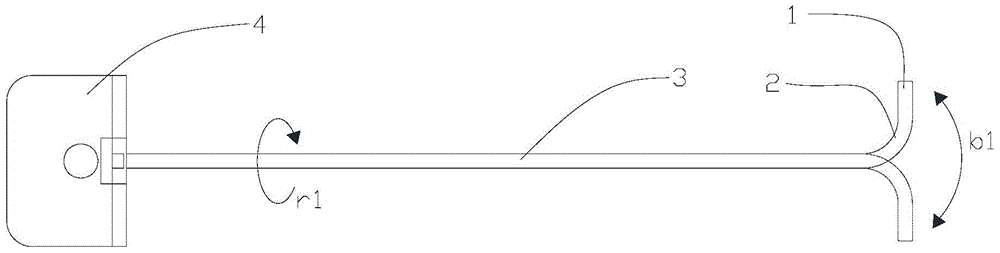

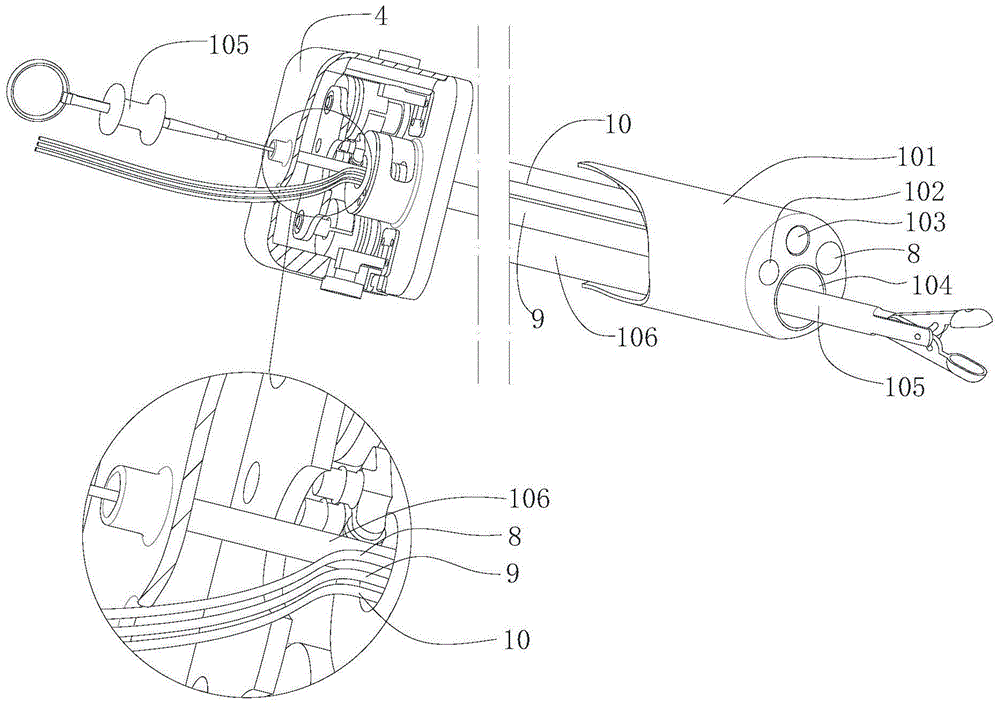

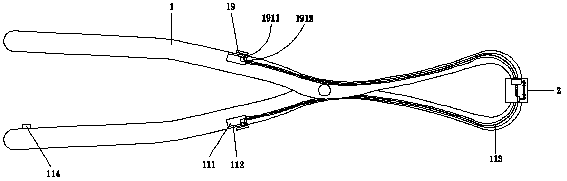

Choledochoscope for minimally invasive surgery robot

InactiveCN104757931AIncrease success rateRich and comprehensive visual informationSurgeryLaproscopesMini invasive surgeryRemoval Difficulties

A choledochoscope for a minimally invasive surgery robot is controlled by the minimally invasive surgery robot to achieve examination and treatment in hepatic ducts. The choledochoscope for the minimally invasive surgery robot comprises a choledochoscope body and accessory equipment. The choledochoscope body comprises a front end assembly, a bent assembly, a rigid connecting rod and a choledochoscope box, wherein one end of the bent assembly is fixedly connected to the front end assembly, and the other end of the bent assembly is fixedly connected to the rigid connecting rod; the other end of the rigid connecting rod is rotatably installed on the choledochoscope box; the bent assembly achieves bent movement in one direction; spin motion of the rigid connecting rod of the choledochoscope body is achieved between the rigid connecting rod and the choledochoscope box; the choledochoscope box is mainly used for enabling the choledochoscope body to be fixedly connected with the minimally invasive surgery robot and transmitting driving force for controlling other assemblies of the choledochoscope to move. The choledochoscope for the minimally invasive surgery robot has the advantages of improving the success rate of surgery, relieving the fatigue of doctors, having enough flexibility, shortening surgery time and reducing calculus removal difficulty, thereby having the potential of being applied to the other medical fields.

Owner:周宁新

A kind of choledochoscope for minimally invasive surgery robot

InactiveCN104757931BIncrease success rateRich and comprehensive visual informationSurgeryLaproscopesMini invasive surgerySurgical robot

A choledochoscope for a minimally invasive surgery robot is controlled by the minimally invasive surgery robot to achieve examination and treatment in hepatic ducts. The choledochoscope for the minimally invasive surgery robot comprises a choledochoscope body and accessory equipment. The choledochoscope body comprises a front end assembly, a bent assembly, a rigid connecting rod and a choledochoscope box, wherein one end of the bent assembly is fixedly connected to the front end assembly, and the other end of the bent assembly is fixedly connected to the rigid connecting rod; the other end of the rigid connecting rod is rotatably installed on the choledochoscope box; the bent assembly achieves bent movement in one direction; spin motion of the rigid connecting rod of the choledochoscope body is achieved between the rigid connecting rod and the choledochoscope box; the choledochoscope box is mainly used for enabling the choledochoscope body to be fixedly connected with the minimally invasive surgery robot and transmitting driving force for controlling other assemblies of the choledochoscope to move. The choledochoscope for the minimally invasive surgery robot has the advantages of improving the success rate of surgery, relieving the fatigue of doctors, having enough flexibility, shortening surgery time and reducing calculus removal difficulty, thereby having the potential of being applied to the other medical fields.

Owner:周宁新

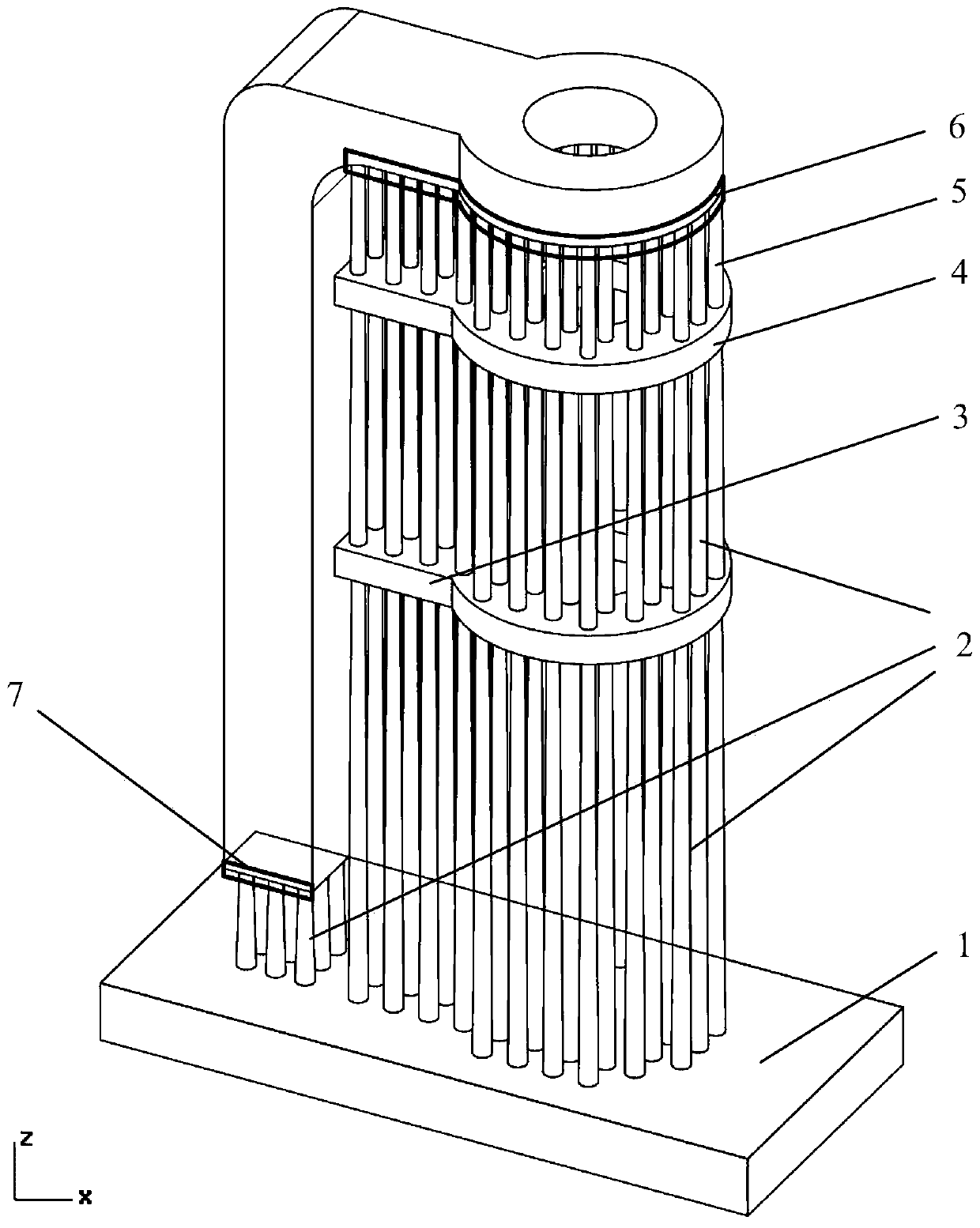

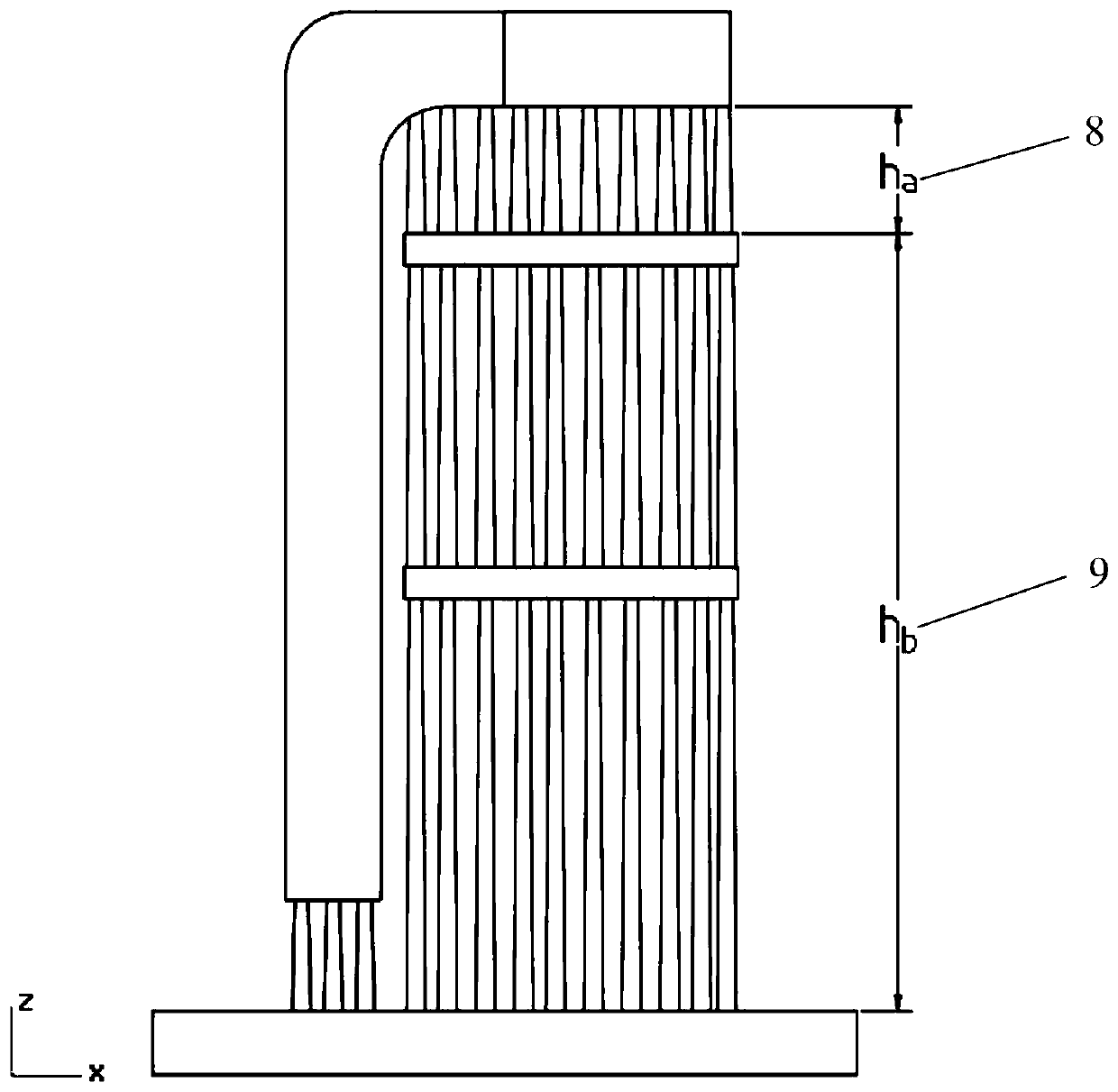

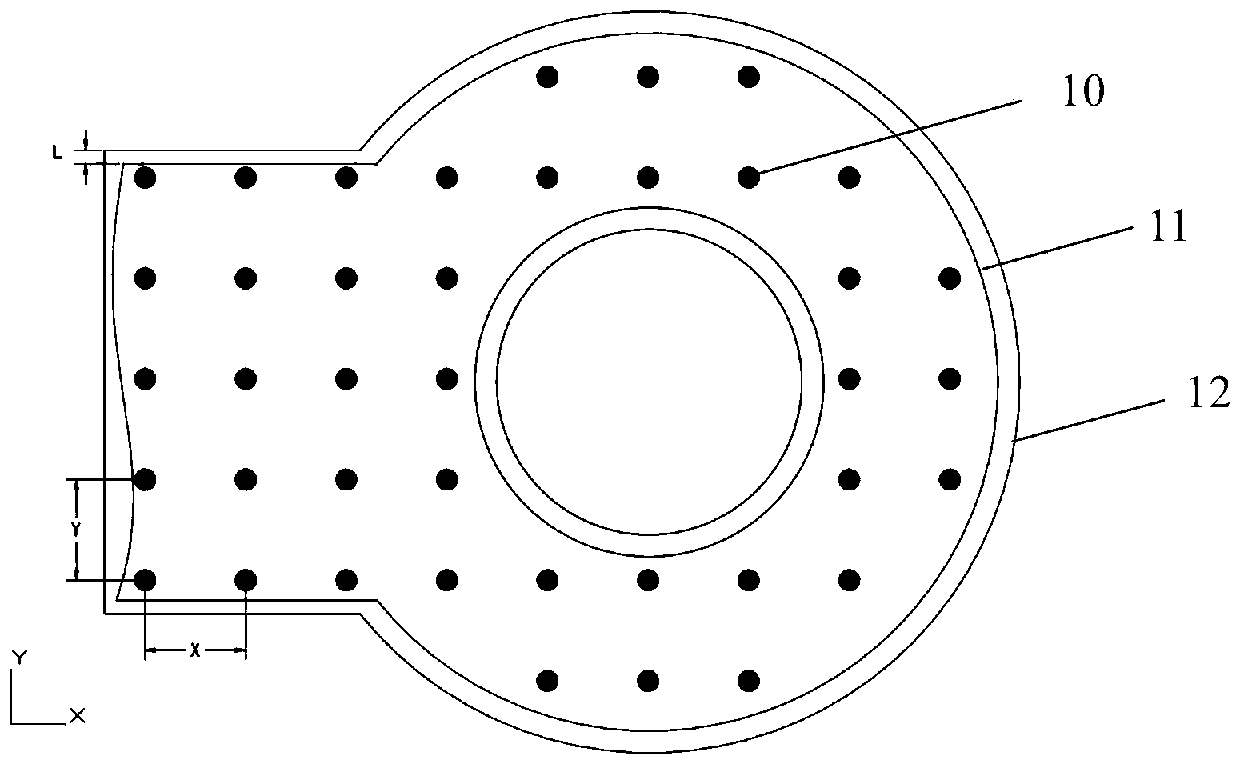

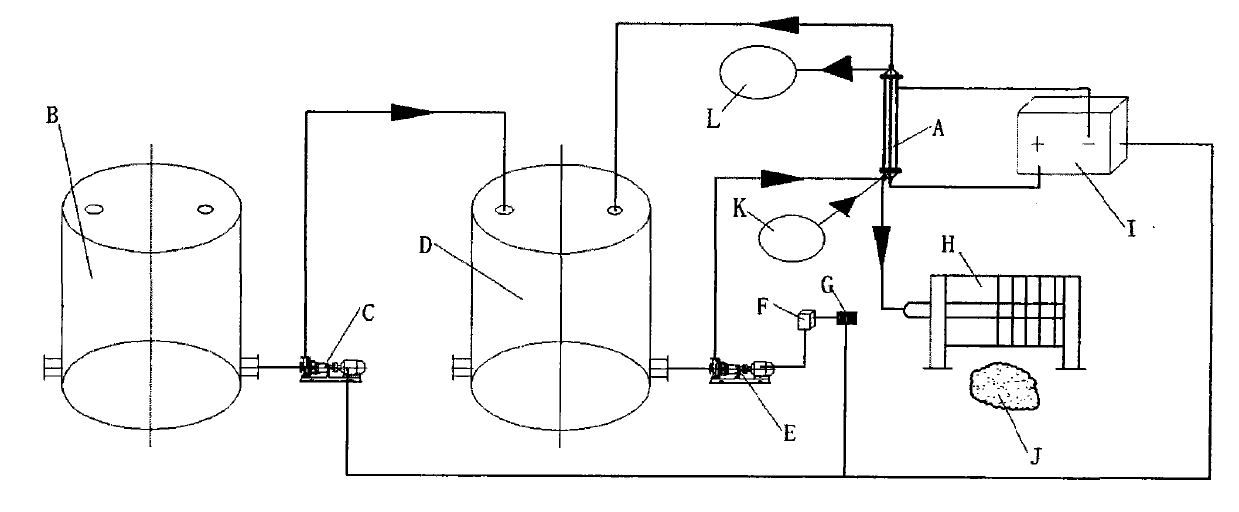

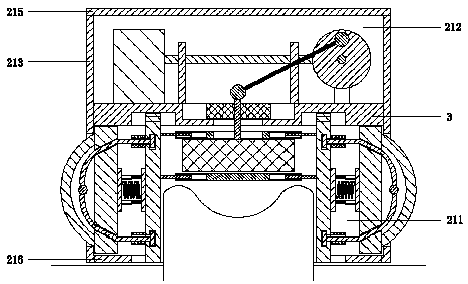

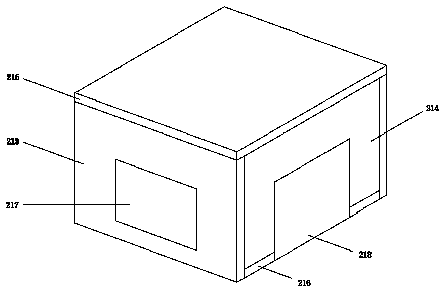

Electrolysis system based on fully sealed selective powder electrolysis device

ActiveCN104357881AWide adaptability of raw materialsSpiritual diversityElectrodesRemoval DifficultiesEngineering

The invention relates to an electrolysis system based on a fully sealed selective powder electrolysis device. The electrolysis system comprises the fully sealed selective powder electrolysis device (A) and an auxiliary device, wherein the auxiliary device comprises a catholyte storage tank (B), a solution conveying pump (C), a solution circulation tank (D), a solution circulation pump (E), a silicon rectification direct-current power supply (I), a compressed air tank (K) and a waste gas collection tank (L). The electrolysis system can be used for effectively improving the problems of low electrolysis current density, non-uniform current distribution, high solution impurity removal difficulty, long process flow, high production cost, high difficulty in product collection, low overall efficiency and the like of the traditional flat (frame)-type electrolysis device during an electrolysis process; electrolysis can be carried out under the condition of complex solution ingredients; in addition, the electrolysis system is efficient, reliable, simple in process flow, simple and convenient to operate, and low in cost.

Owner:江苏万途思睿环境科技有限公司

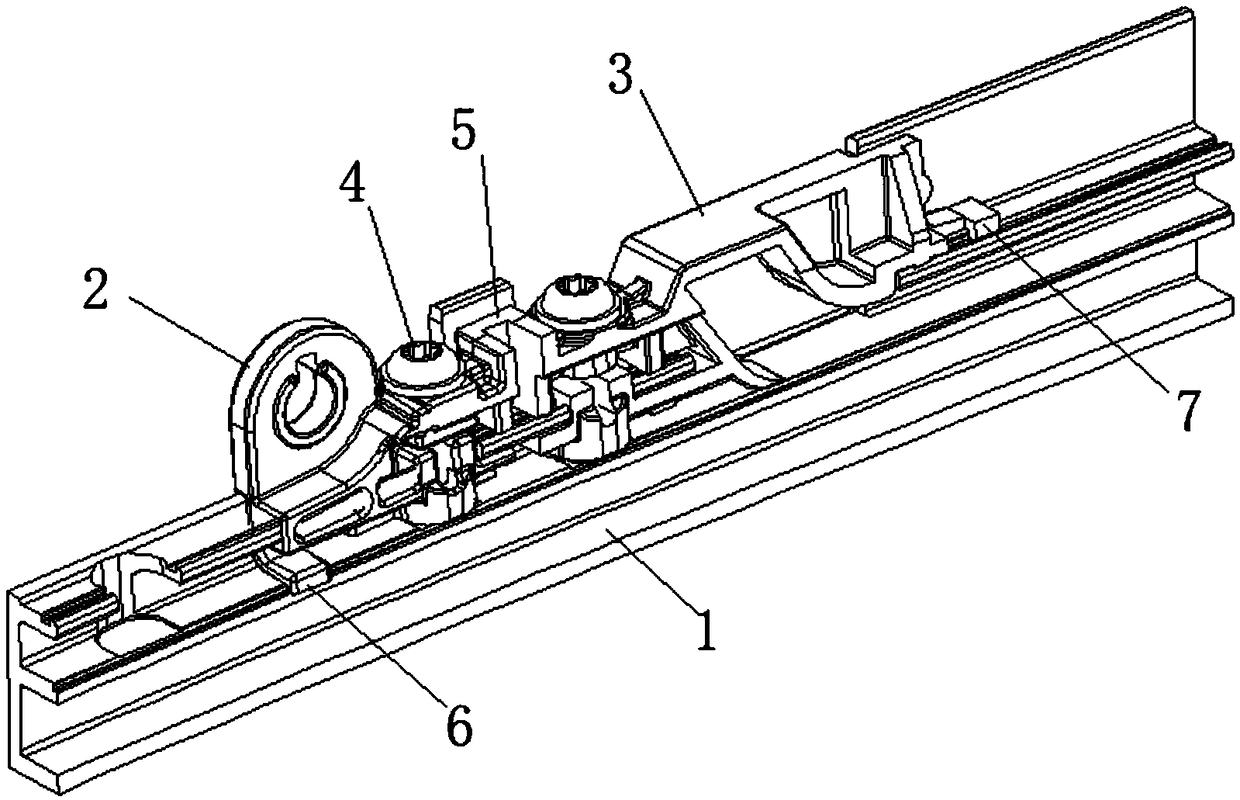

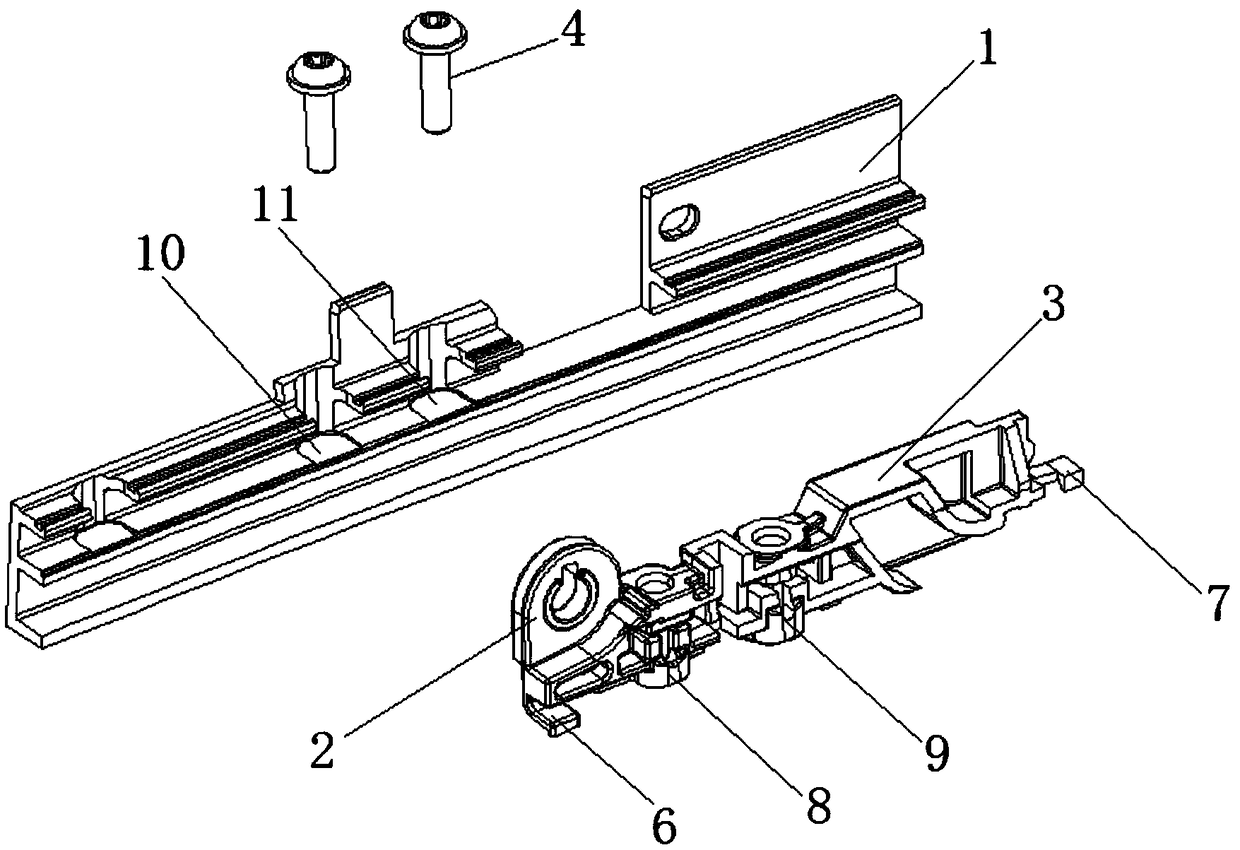

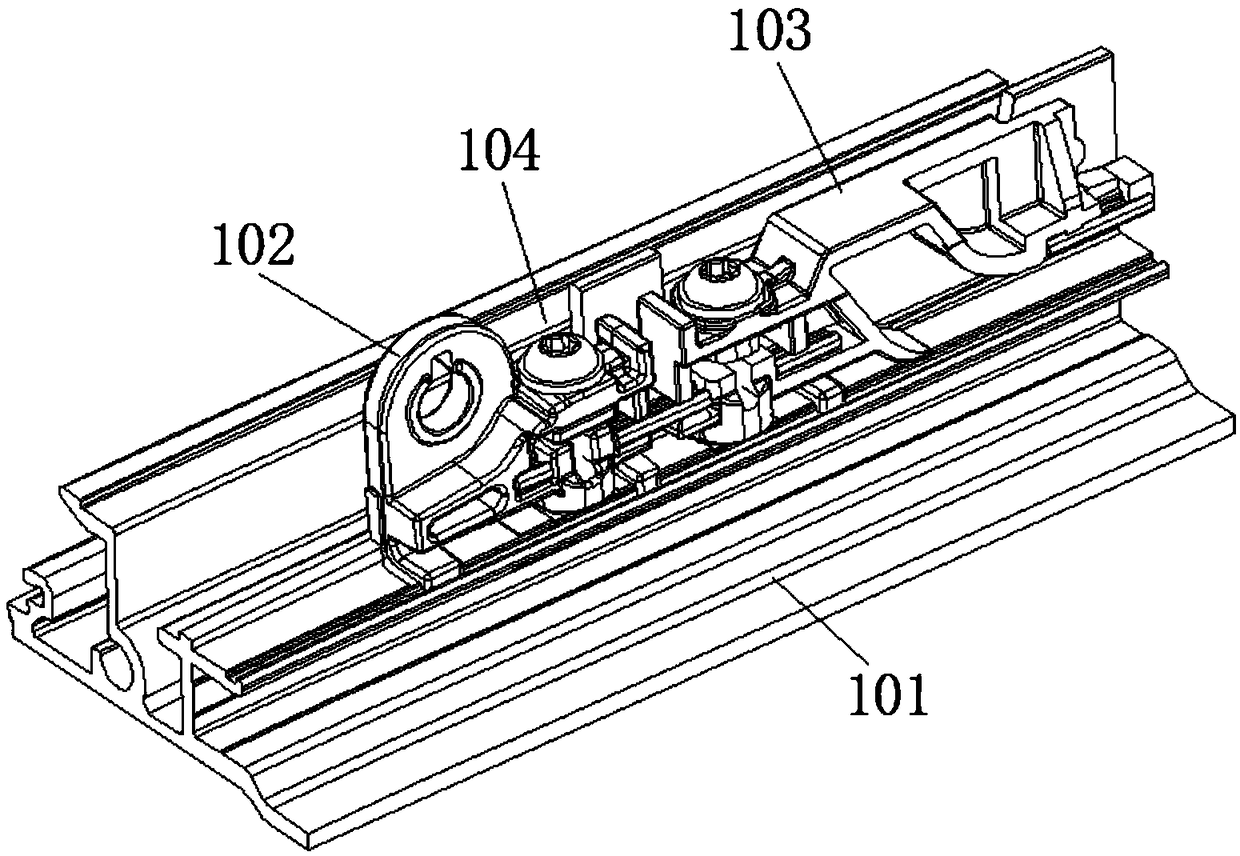

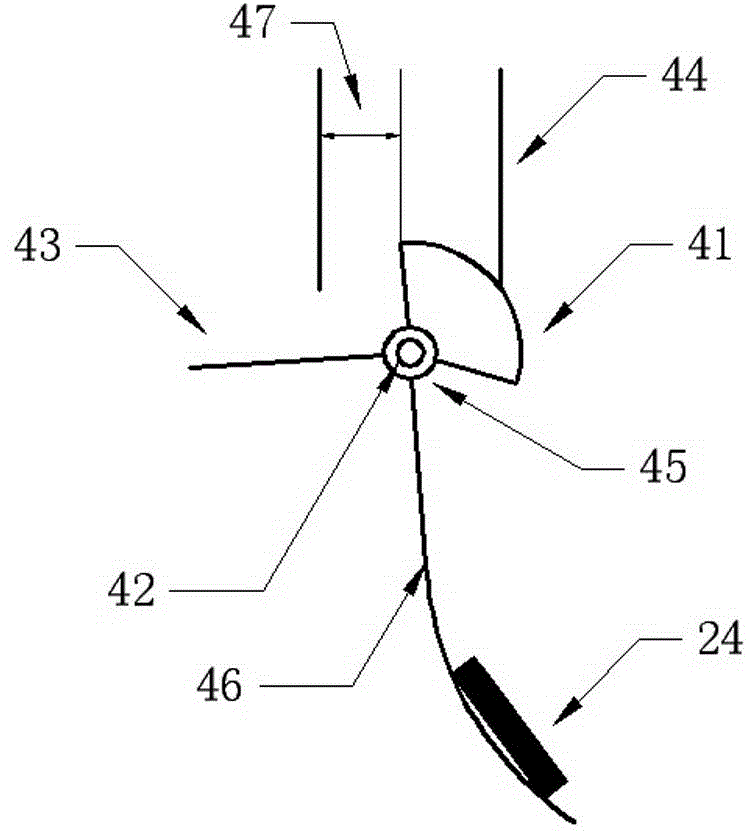

Windshield support arm integrated type central positioning block mechanism

The invention discloses a windshield support arm integrated type central positioning block mechanism, and belongs to the field of positioning block equipment. The windshield support arm integrated type central positioning block mechanism comprises a multi-rail datum plate. A first bonding semicircular groove and a second bonding semicircular groove are sequentially formed in the multi-rail datum plate from the left to the right. A central positioning block is fastened to one end of the multi-rail datum plate near the first bonding semicircular groove, and the right side of the central positioning block is provided with a windshield support arm. The central positioning mechanism and the windshield support arm having the linkage relationship can be designed as an integrated structure to reduce the abnormal sound condition during reversing after the components are installed. Further, due to the integrated structure, the component composition is simplified, the assembly performance betweenthe components is improved, the difficulty of the overall components in the production process is simplified, the efficiency of the components in the transportation and goods circulation links is improved, the installation and removal difficulty of the components is reduced, and the user experience of users is improved.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

Novel self-rotating large-current MAG (Magnetic) welding composite nozzle welding gun for removing slag and slag removing method thereof

ActiveCN101829839AObvious advantagesObvious effectElectrode accessoriesWelding accessoriesSlagRemoval Difficulties

The invention provides a novel self-rotating large-current MAG (Magnetic) welding composite nozzle welding gun for removing slag and a slag removing method thereof. The invention aims at solving the slag removal difficulty of the welding gun in large-current MAG welding process and further optimizing a nozzle structure. The invention mainly comprises a welding gun structure which can remove welding spattering slag in a composite nozzle in a self-rotating way as well as a self-rotating slag-removing method of the welding gun. The welding gun structure and the self-rotating slag-removing method are suitable for thickwire large-current MAG welding.

Owner:HARBIN WELDING INST LTD

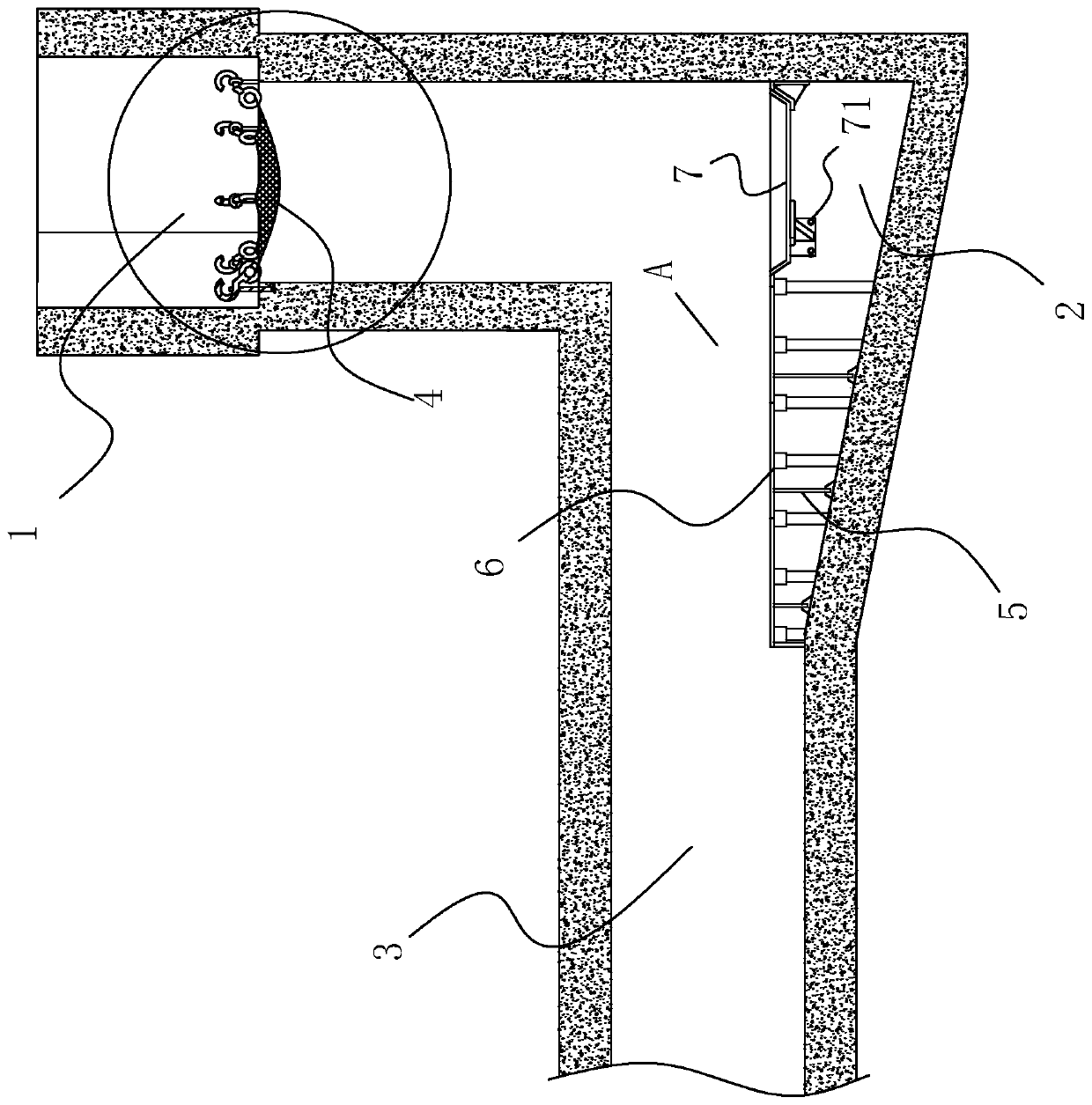

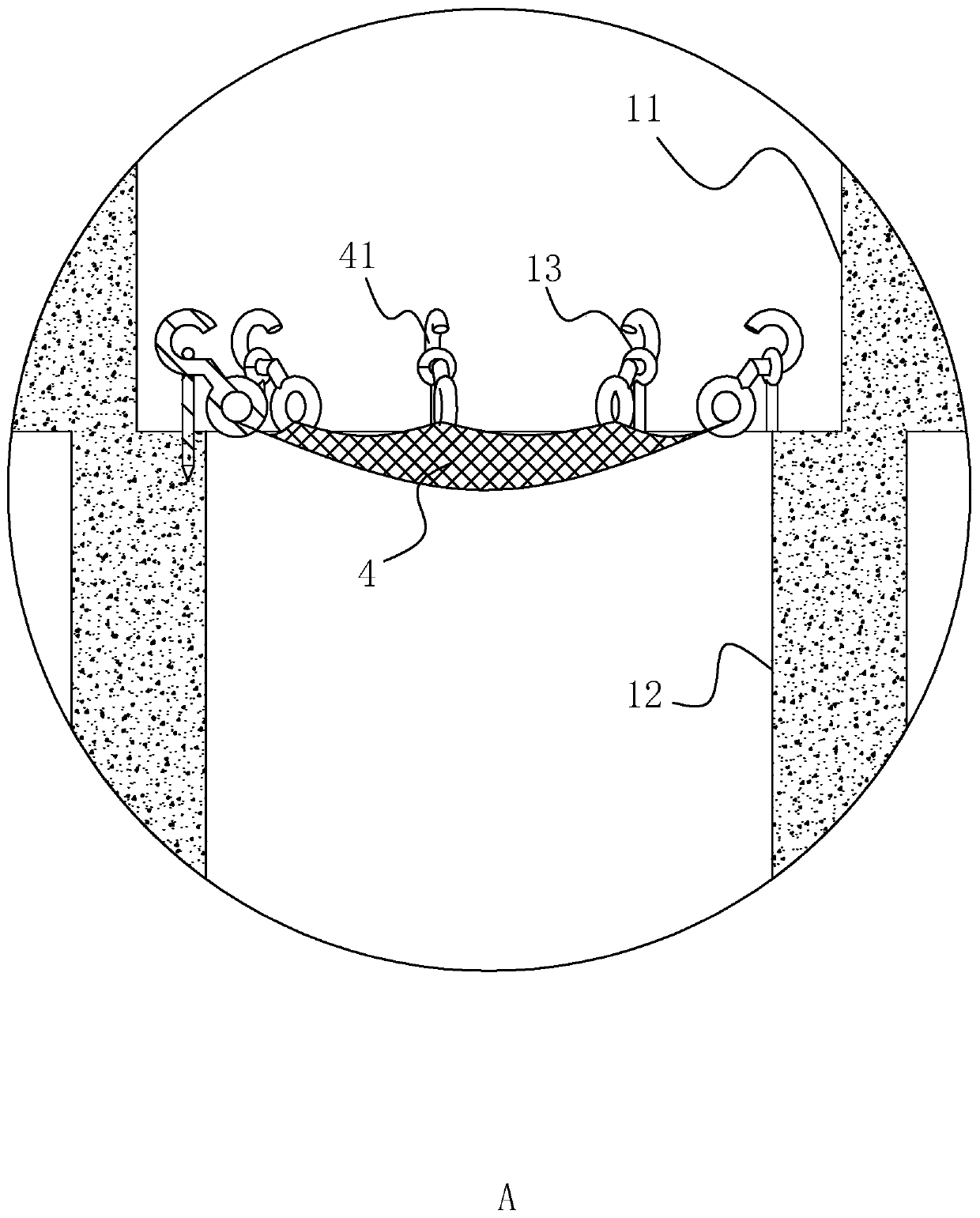

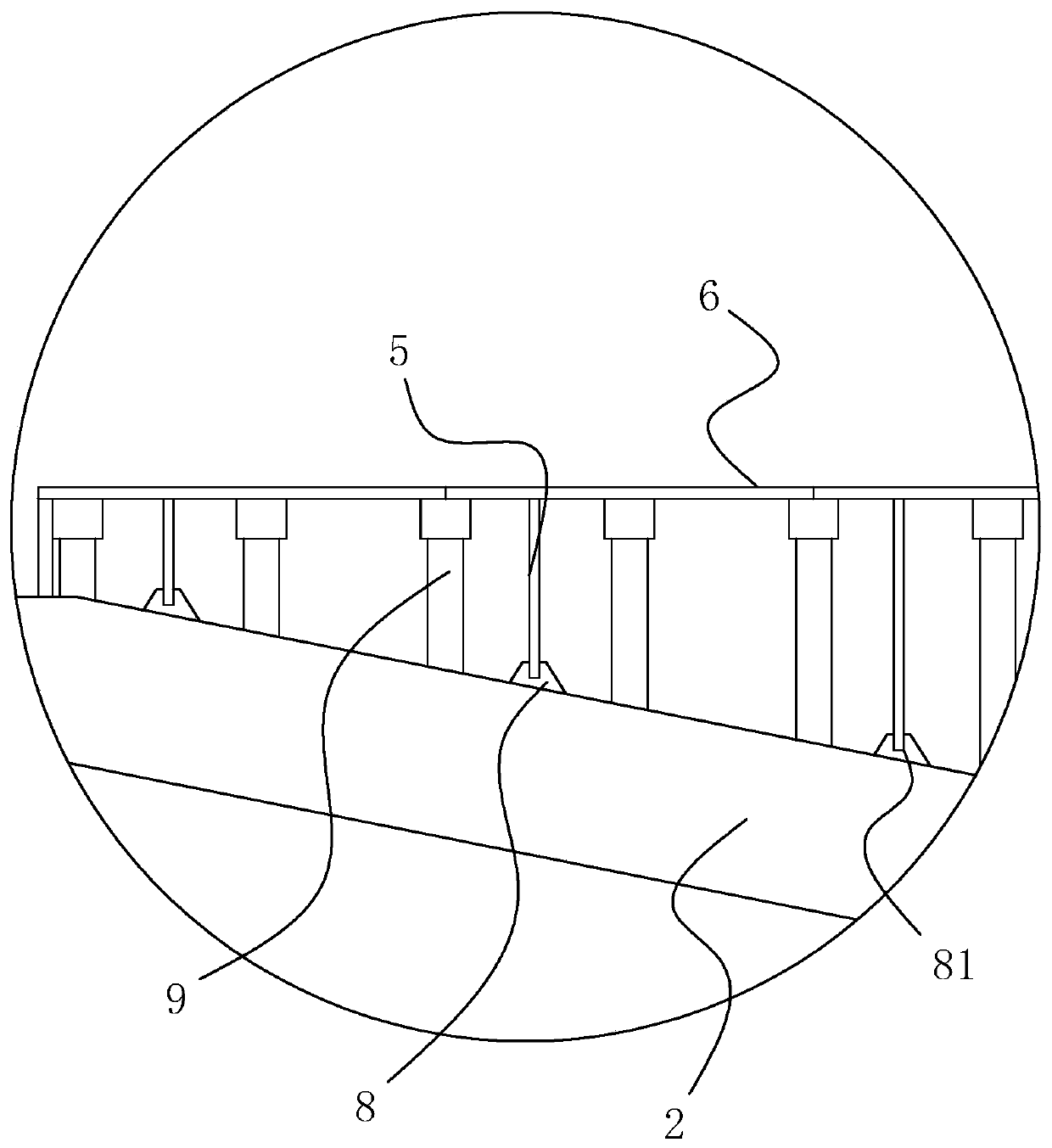

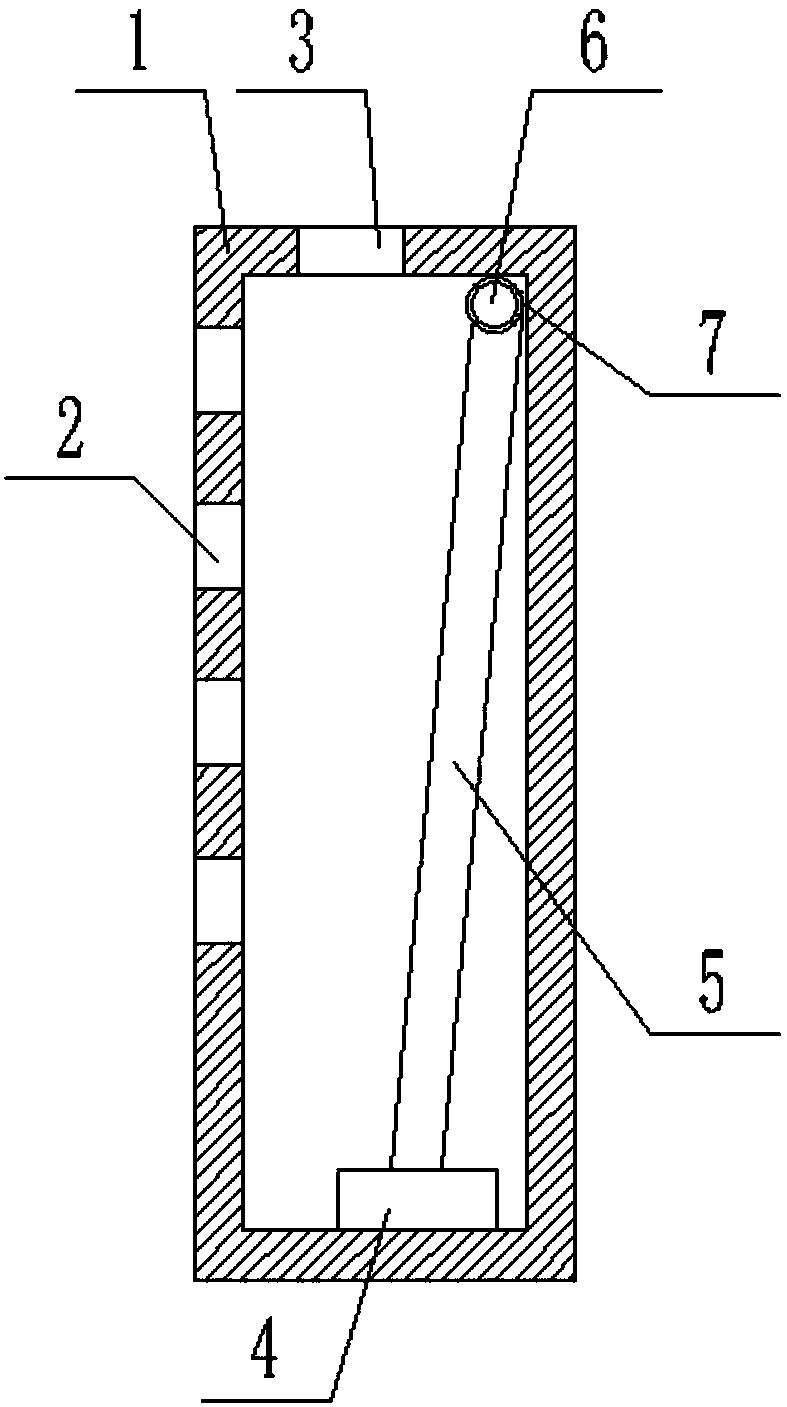

Municipal drainage system

ActiveCN110374180AConvenience to workSafe and reliable workFatty/oily/floating substances removal devicesSewerage structuresRemoval DifficultiesSilt

The invention discloses a municipal drainage system, and relates to the technical field of urban drainage and waterlogging preventing engineering. The municipal drainage system solves the technical problem of large silt removal difficulty. The municipal drainage system is characterized in that the municipal drainage system comprises a sewer, a water collecting well and a settling tank; the settling tank is arranged between the lower end of the water collecting well and the lower end of the sewer; the two ends of the settling tank communicate with the bottom of the water collecting well and thesewer correspondingly; a plurality of settling plates are arranged in the settling tank; the municipal drainage system further comprises an intercepting net, a supporting table plate and a gravel filtering net frame; the intercepting net is detachably hung on the inner wall of the water collecting well; the supporting table plate is arranged above the settling tank and is slightly higher than thelowest horizontal height of the sewer; the gravel filtering net frame is detachably arranged on the supporting table plate and is arranged in an inverted circular truncated cone shape; the gravel filtering net frame is coaxial with the water collecting well and is located under the intercepting net, and the supporting table plate is arranged in a grid plate shape; and the municipal drainage system has the advantage that no much burden is brought to silt removal by workers.

Owner:漳州市龙文第三建筑工程有限公司

Vibration dentarpage

The invention discloses a vibration dentarpage which comprises a pair of dental forceps and a vibrator fixed on the pair of dental forceps, wherein the pair of dental forceps comprises a forceps headand a forceps handle; the vibrator is sequentially divided into a vibration device for fixing and vibrating teeth and a power device provided with a motor by a partition; the vibration device comprises vibration element arranged on the two sides of the teeth and a power element connecting the vibration elements on the two sides; the vibration elements comprise vibration plates clung to the teeth,springs fixed with the vibration plates and push plates; one side of each push plate is fixed with the forceps head; the other side of each push plate is fixed with each spring; the power element comprises an extension cylinder connecting the vibration elements on the two sides, a vibration block located in the extension cylinder, and a driving rod connecting the vibration block and the power block; the power device comprises a transmission device; one end of the transmission device is connected with the motor; and the other end of the transmission device connected with the power block. The dentarpage loosens tooth roots by reciprocated impacting of dental crowns, and therefore reduces wisdom tooth and decayed tooth removal difficulty.

Owner:HUNAN UNIV OF CHINESE MEDICINE

High-temperature high-humidity flue gas bag type dust collection and ash removal method and device thereof

InactiveCN105854449AImprove work efficiencySolve cleaning difficultiesDispersed particle filtrationDrying gas arrangementsAir preheaterHigh humidity

The invention discloses a high-temperature high-humidity flue gas bag type dust collection and ash removal method and device. The device comprises a flue gas main pipe and a bag type dust collector, wherein the front end of the flue gas main pipe is connected with an air preheater; the tail end of the flue gas main pipe is respectively communicated with each bag room of the bag type dust collector; a hot air outlet of the air preheater is respectively connected with each bag room of the bag type dust collector; an ash removal structure is connected to the bag type dust collector. The air preheater is arranged on a high-temperature high-humidity flue gas pipeline, air is preheated by utilizing one part of high-temperature high-humidity flue gas, the preheated dry air is introduced into a to-be-cleaned bag room of the bag type dust collector so as to dry the bag and dust, ash removal is performed after the bag and dust are completely dried. Therefore, the ash removal difficulty in the high-temperature high-humidity flue gas bag type dust collection process is solved, air preheating energy comes from the high-temperature high-humidity flue gas, a heat source does not need to be additionally provided, an energy-saving effect is achieved, the dust removal difficulty and cost are greatly reduced, the ash removal efficiency and the dust collection efficiency are improved, and operation of the bag type dust collector can be stable.

Owner:JIANGHAN UNIVERSITY

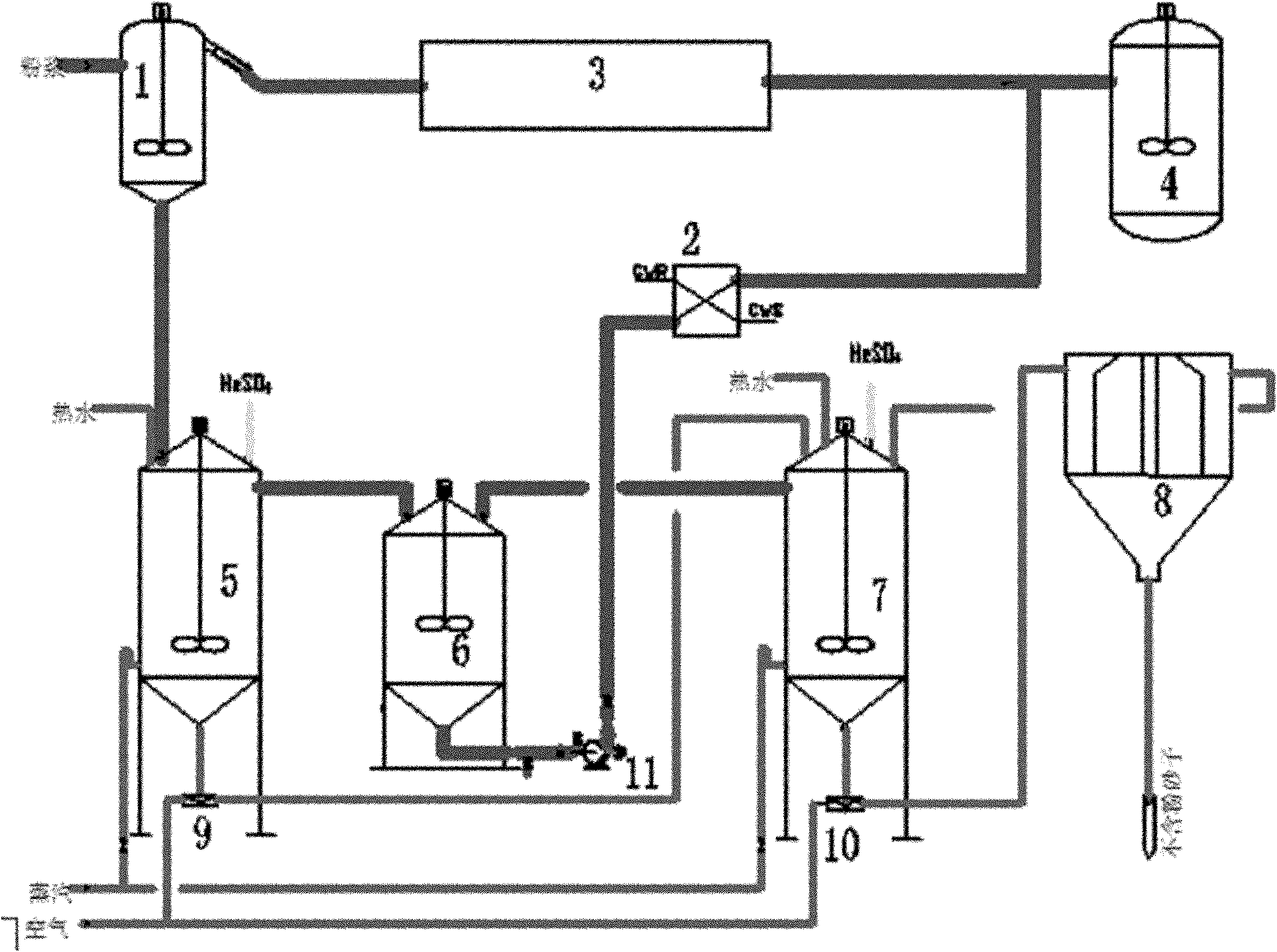

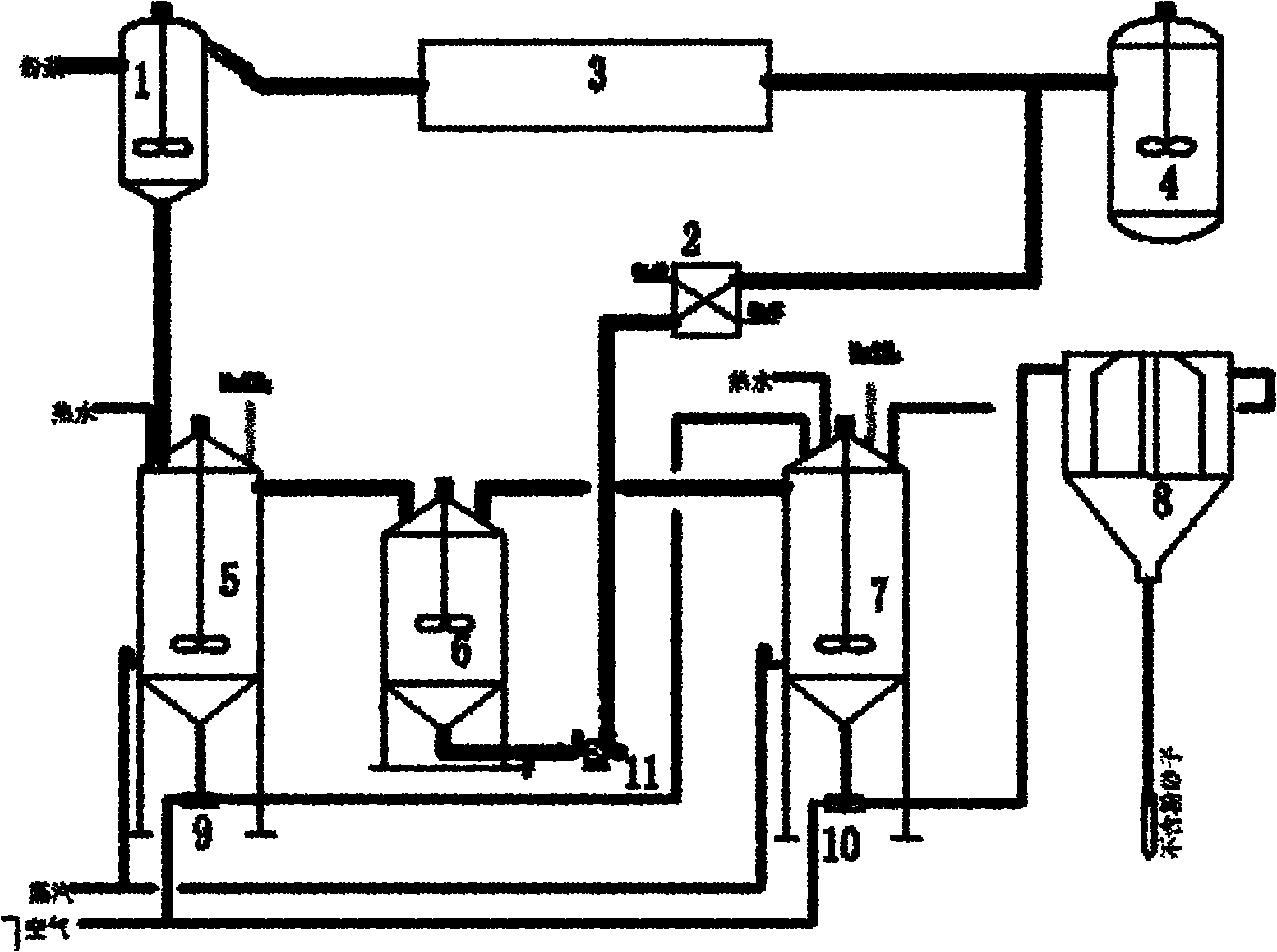

Device and method for acidifying raw materials and removing sand in ethanol production

ActiveCN102094047ANo waste of resourcesHigh sand removal rateBiofuelsFermentationCycloneRemoval Difficulties

The invention discloses a device and method for acidifying raw materials and removing sand in ethanol production. The method comprises the following steps: (1) stirring a pulverized starch slurry in a stirring tank until the sand-containing starch slurry settles at the bottom and flows into a primary acidification tank; (2) adding sulfuric acid and introducing steam into the primary acidification tank, heating, stirring until sand settles at the bottom of the primary acidification tank, and pumping sand slurry with starch into a secondary acidification tank for further acidification; (3) further stratifying the sand and the slurry, and pumping the sand slurry containing a small amount of starch into a cyclone, wherein the working principles of the secondary acidification tank is the same with those of the primary acidification tank; and (4) separating out the sand by using the cyclone, and returning the slurry containing a small amount of starch to a buffer tank. By using the method, the sand can be removed, and simultaneously, the starch can be completely recycled; the sand removal rate is up to 96%, thereby creating conditions for subsequent production; 20% of liquifying enzyme, a small amount of saccharifying enzyme and 10% of steam can be saved in the liquifying procedure; and the defects of high sand removal difficulty and imperfect sand removal effect in the prior art are overcome.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

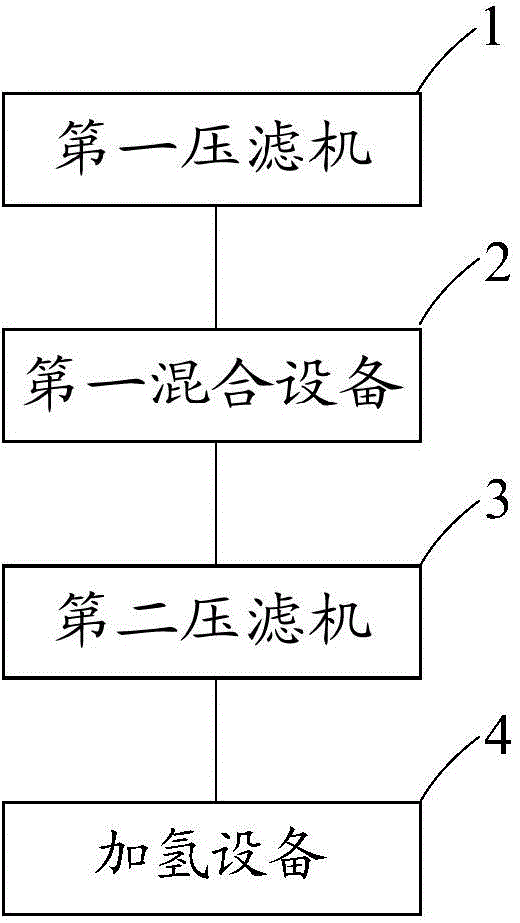

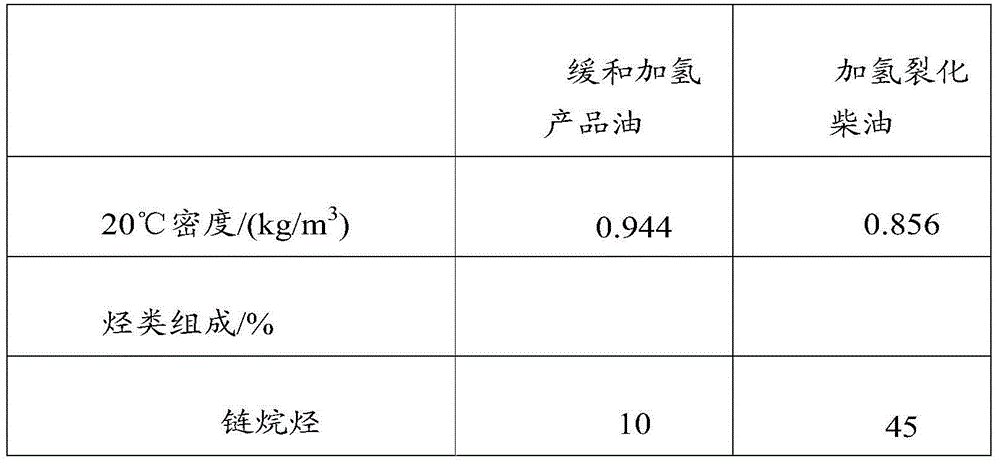

Method and system for processing coal tar

ActiveCN104673385AReduce difficulty of removalExtended operating cycleTreatment with hydrotreatment processesParticulatesMicrometer

The invention provides a method and a system for processing coal tar. The method for processing the coal tar comprises the following steps: step A, filtering to remove impurities of which the diameter is 20 to 50 micrometers in total fractions of the coal tar by using a press filter to obtain a first flow-out substance; step B, mixing the first flow-out substance with diesel fractions at a volume ratio of 1 to (0.1-5) to obtain mixed oil; step C, filtering to remove particles of impurities which are 1 to 20 micrometers in diameter and are coated inside the mixed oil by using a press filter to obtain a second flow-out substance; step D, hydrocracking the second flow-out substance. The system for processing the coal tar comprises a first press filter, first mixing equipment, a second press filter and hydrogenation equipment which are connected in sequence. The method disclosed by the invention has the advantages of reducing the removal difficulty of small-particle mechanical impurities and dust, realizing high removal rate, prolonging the operation period of the hydrogenating device, and causing no blocking of the removing equipment; meanwhile, the processing system has the advantages of being simple and easy to operate, small in floor area, low in cost, energy-saving, environment-friendly and the like.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

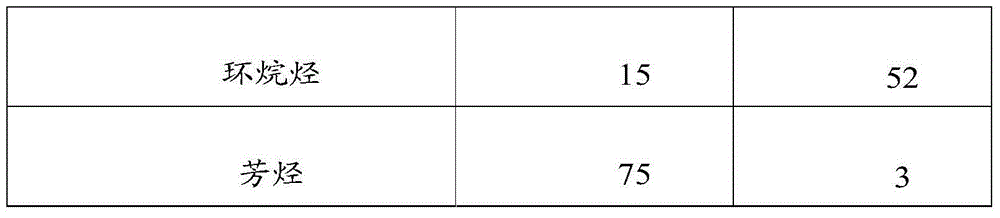

Rapid enrichment culture method for efficient anaerobic dephosphorization bacteria

InactiveCN109055224AImprove phosphorus removal effectSolve the problem of phosphorus removalMicroorganism separationTrace elementRemoval Difficulties

The invention discloses a rapid enrichment culture method for efficient anaerobic dephosphorization bacteria, the method comprises the following steps that an anaerobic dephosphorization bacteria enrichment medium is arranged at first; a trace element solution and a vitamin solution are added to the culture medium for performing anaerobic dephosphorization bacteria enrichment; then, the anaerobicdephosphorization bacteria isolation medium is arranged for purification and separation of the anaerobic dephosphorization bacteria. The enrichment culture method lays a foundation for research on physiological characteristics of the anaerobic dephosphorization bacteria by the enrichment, separation and purification of the efficient anaerobic dephosphorization bacteria, and provides theoretical support for fully understanding phosphorus circulation pathway in sewage treatment process. An efficient anaerobic dephosphorization bacteria agent can enhance dephosphorization effect in the sewage treatment process, the method provides a basis for development of a new dephosphorization process with low energy consumption and high efficiency, and solves phosphorus removal difficulties in the sewagetreatment process.

Owner:中车环境科技有限公司

Method for reduction and detoxification of hazardous waste sludge

InactiveCN110217967AIncrease concentrationHigh reduction rateBiological sludge treatmentSludge detoxificationThermal energySludge

The invention discloses a method for reduction and detoxification of hazardous waste sludge. The method comprises the steps: adding a microbial bacterial agent to the sludge, adding an auxiliary material for conditioning, providing an external heating source, performing continuous stirring, and performing aeration, wherein the sludge is chemical hazardous waste sludge with a water content of 80% or above, the water content is 70% after the auxiliary material is added, and the microbial bacterial agent is complex bacteria. According to the method, bio-thermal energy generated through degradation of organic matter in the microorganism high-temperature process and the complex bacteria are utilized to decompose the organic matter, destroy the aggregate structure and disperse the sludge particles, the interstitial moisture and surface moisture are turned into free water, the binding force is weakened, and the removal difficulty is reduced; and in addition to the auxiliary heat, the temperature inside a box body is kept at 60-80 DEG C. According to the method, the optimal control conditions in the process of reduction and detoxification are determined, the method has the advantages of ahigh degree of reduction, high detoxification efficiency, low treatment cost, a high comprehensive utilization rate, no secondary pollution, simple operation and the like, and the economy benefits, environmental benefits and social benefits are good.

Owner:NANJING NORMAL UNIVERSITY

A vertical device for steaming and removing residual solvent in rapeseed meal

ActiveCN103966017BImprove cooling effectEasy to operateFatty-oils/fats productionRemoval DifficultiesEngineering

The invention discloses a vertical steam removal device for a residual solvent in rapeseed meal. The vertical steam removal device comprises a vertical steam removal machine composed of six layers of box bodies, wherein the bottom plates and side walls of the lower five layers of box bodies are provided with heated steam jackets, the bottom of the topmost layer of box body is provided with an annular steam pipe on which a plurality of steam pipes are obliquely arranged; each layer of box body is internally and respectively provided with a material height indicator and an automatic material door capable of automatically regulating the dropping speed of an upper-layer material according to the height of a local-layer material; a material seal conveying stranding cage is connected with the upper end of the topmost layer of box body, and the bottommost layer of box body is provided with a cock discharging valve; each layer of box body is provided with an agitating scraper, the agitating scrapers are fixed on a main shaft, and the main shaft is fixed in the box bodies and can rotate; and the topmost layer of box body is connected with a shell pass of a tubular heat exchanger through a cyclone dust catcher and is finally connected with a connecting pipe of a water distribution tank. The vertical steam removal device is used for solving the technical problems of rapeseed meal steam removal difficulty, high steam consumption in steam removal and high extraction solvent consumption and is suitable for large-scale industrial processing; and in addition, the automatic material door is simple in working principle, reliable and convenient to operate.

Owner:泰州市海鑫高新技术投资发展有限公司

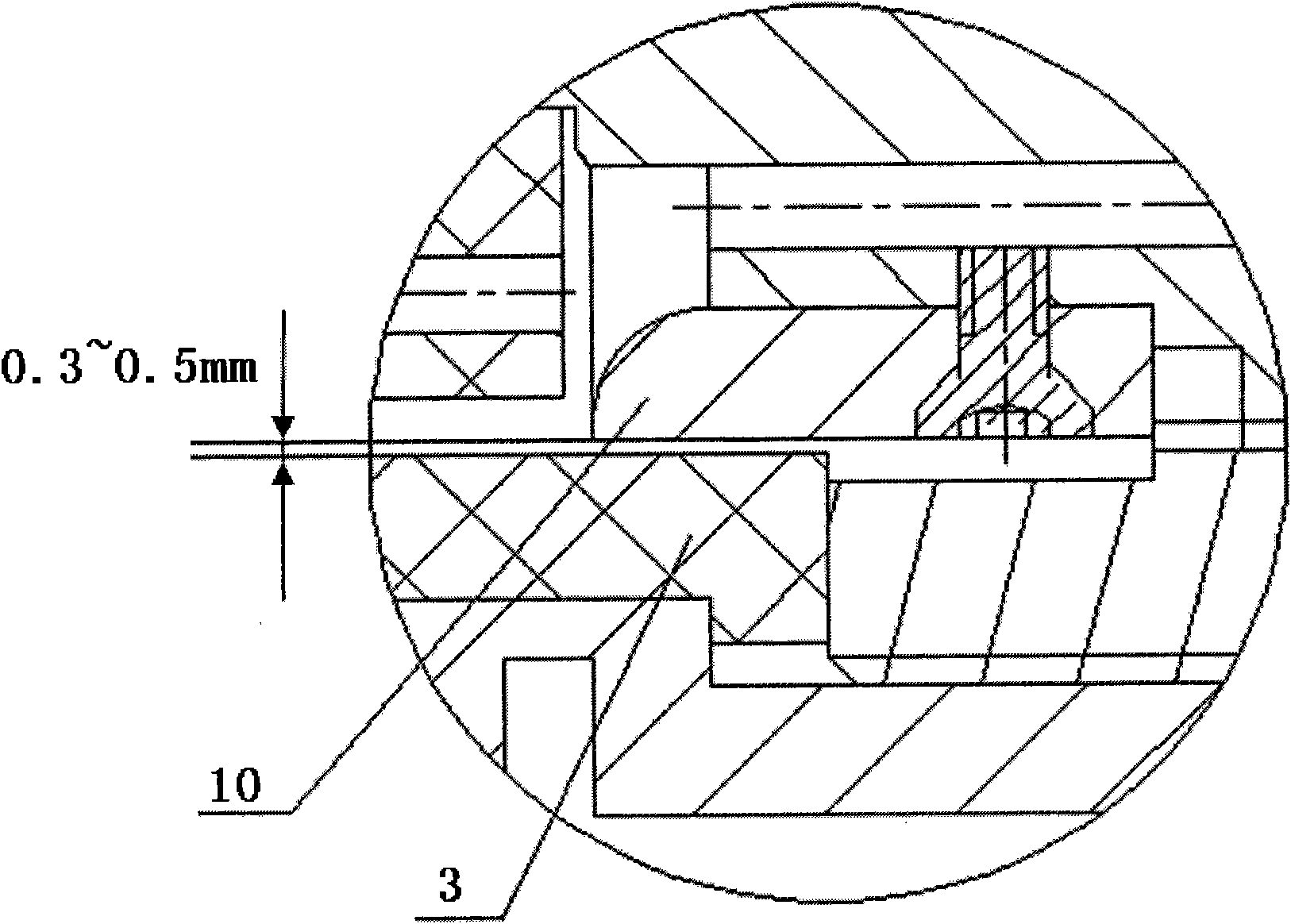

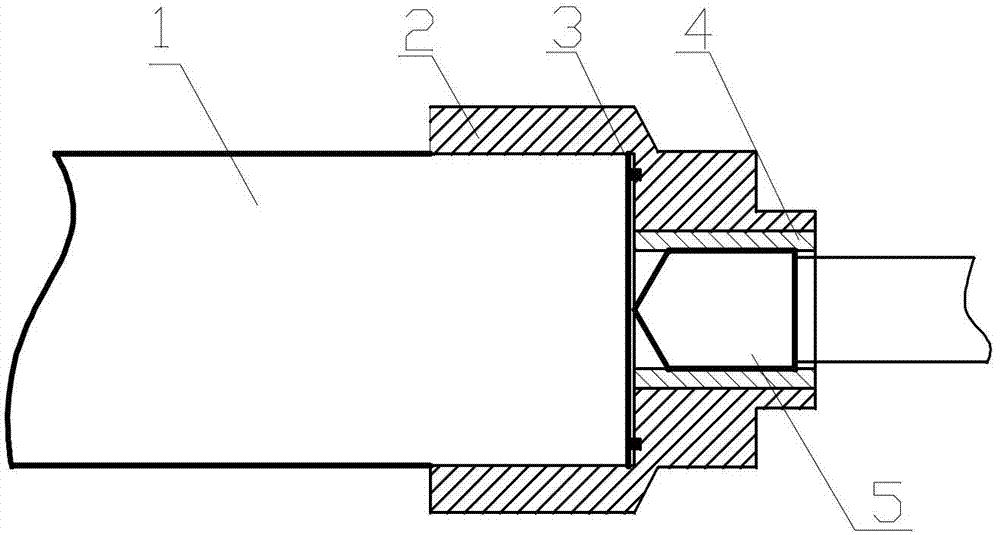

Guide device for nuclear power driving pipe seat deep hole machining

InactiveCN102962498ASolve the problem that the axis is easy to skewEnsure processing qualityDrilling/boring measurement devicesDrill jigsSurface roughnessRemoval Difficulties

The invention relates to a guide device for nuclear power driving pipe seat deep hole machining, which comprises a shaft sleeve and a bush. A workpiece is tightly sheathed at one end of the shaft sleeve. The bush is arranged in the other end of the shaft sleeve. An oil seal is arranged between contact surfaces of the shaft sleeve and the workpiece. A drill bit is inserted into the bush for guide machining. A tightening bolt is arranged on the shaft sleeve. By using the guide device, effective guide can be realized, the problems of deviation and vibration which are apt to occur during machining are solved, the deep hole machining quality and the machining progress are guaranteed, the requirements on product size accuracy and surface roughness are satisfied, the problems of great chip removal difficulty, poor heat dissipation effect and the like are solved, and the production efficiency is improved.

Owner:DALIAN CLEAN ENERGY HEAVY IND

Scavenging agent

InactiveCN100557005CClear fastLow costInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsScavengerRemoval Difficulties

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

Treatment method for flocculate of heparin sodium enzymatic hydrolysate

The invention discloses a treatment method for flocculate of heparin sodium enzymatic hydrolysate. The treatment method is characterized by comprising the following steps: preparing the heparin sodium enzymatic hydrolysate by adopting a conventional method, adding 3-5wt% of flocculant into the heparin sodium enzymatic hydrolysate, agitating the mixed liquor for 15-30min at the speed of 100-150r / min, standing for 5-6h at room temperature, sending into a centrifugal machine for centrifugal filtering for 10min at the centrifugal speed of 2000-3000r / min, and removing solid impurities to obtain heparin sodium-containing supernatant. The treatment method has the advantages that macromolecular matters of protein, nucleic acid, mycelium and the like in the enzymatic hydrolysate can be flocculated and precipitated by conducting flocculation processing to the heparin sodium enzymatic hydrolysate, thereby laying a foundation for the following separation process, and reducing the following impurity removal difficulty.

Owner:RUGAO BAXIN CASING

Tail gas flying dust removing device beneficial to environmental protection

InactiveCN110496471AAutomatic entryLow costUsing liquid separation agentRemoval DifficultiesEngineering

The invention discloses a tail gas flying dust removing device beneficial to environmental protection. The device comprises a hollow plate body, a plurality of air inlet holes are evenly formed in thesurface of one side of the plate body, and a plurality of exhaust holes are formed in the top of the plate body; a water pump is arranged in the plate body; the water inlet end of the water pump is located at a low position in the plate body, and the water outlet end of the water pump communicates with an overflow pipe through a pipeline; the overflow pipe is located at a high position in the plate body and is located on the side wall, away from the air inlet holes, in the plate body; and a plurality of overflow openings right opposite to the side wall away from the air inlet holes are formedin the overflow pipe. The invention aims to provide the tail gas flying dust removing device beneficial to environmental protection, so as to solve the problems of heavy urban flying dust and high removal difficulty in the prior art, and achieve the purpose of reducing flying dust pollution on two sides of an urban road with high efficiency and low cost.

Owner:邹伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com