Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Tooth removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single image super-resolution rebuilding method

InactiveCN103617607AGood effectImprove visual effectsImage enhancementGeometric image transformationDictionary learningPattern recognition

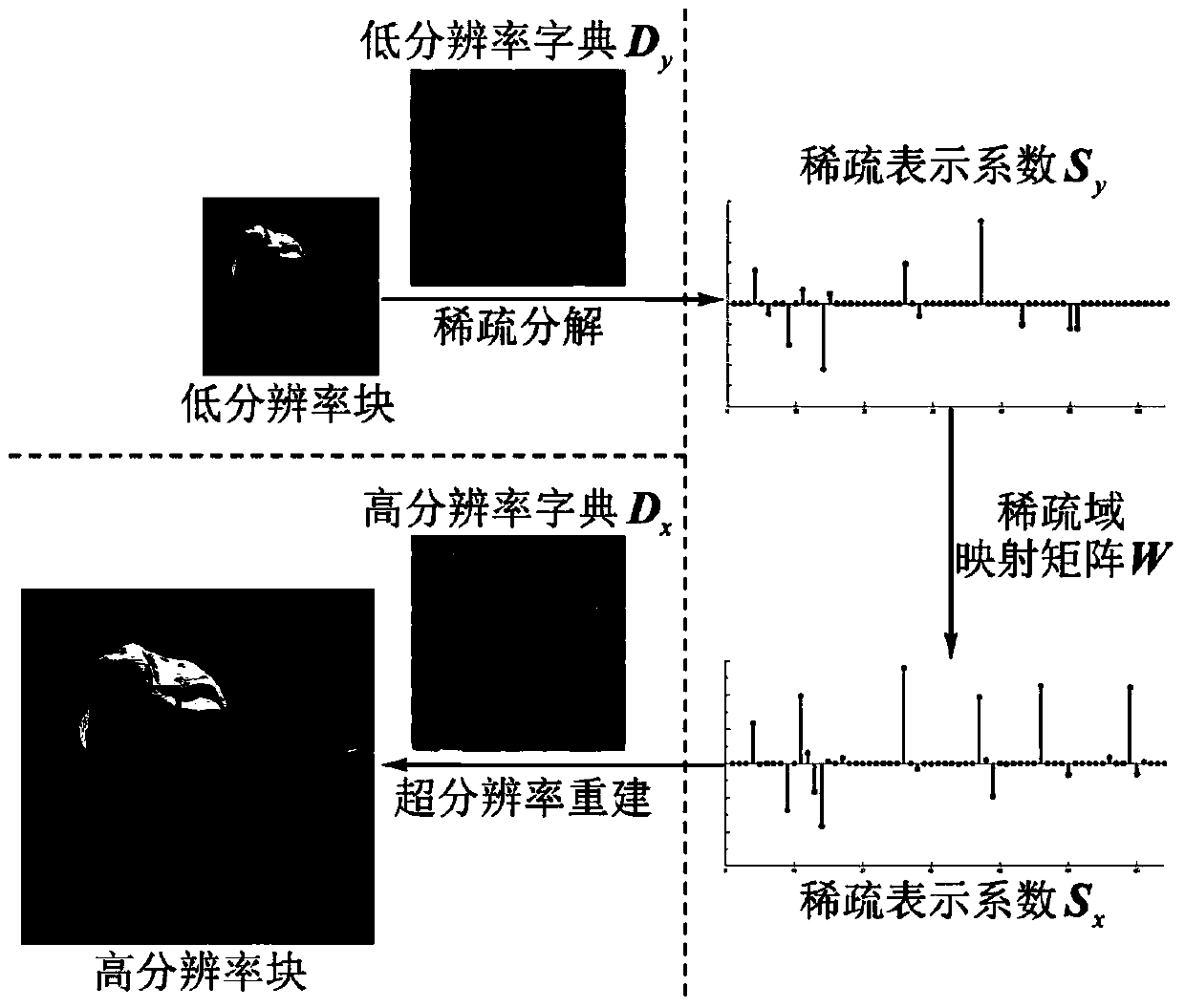

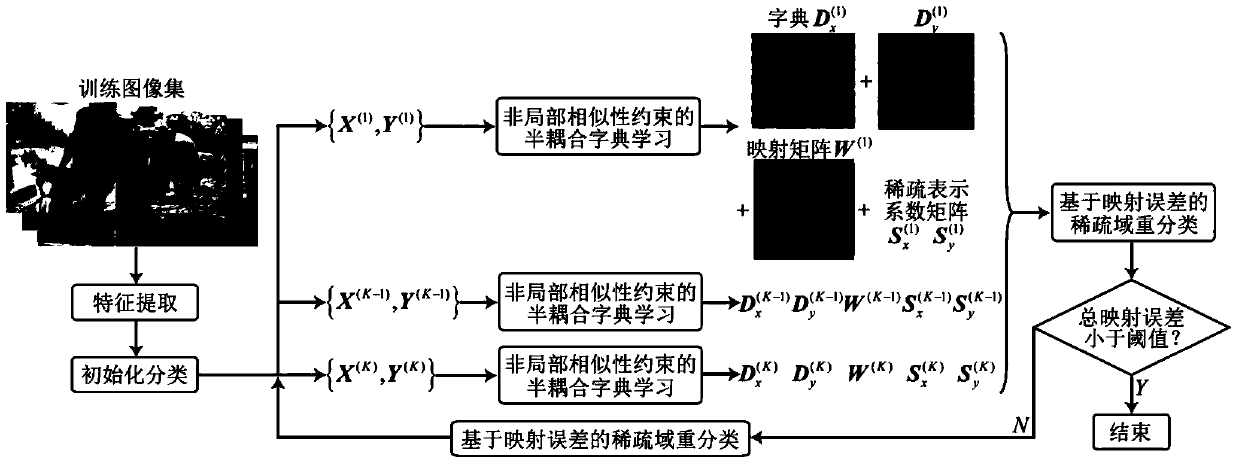

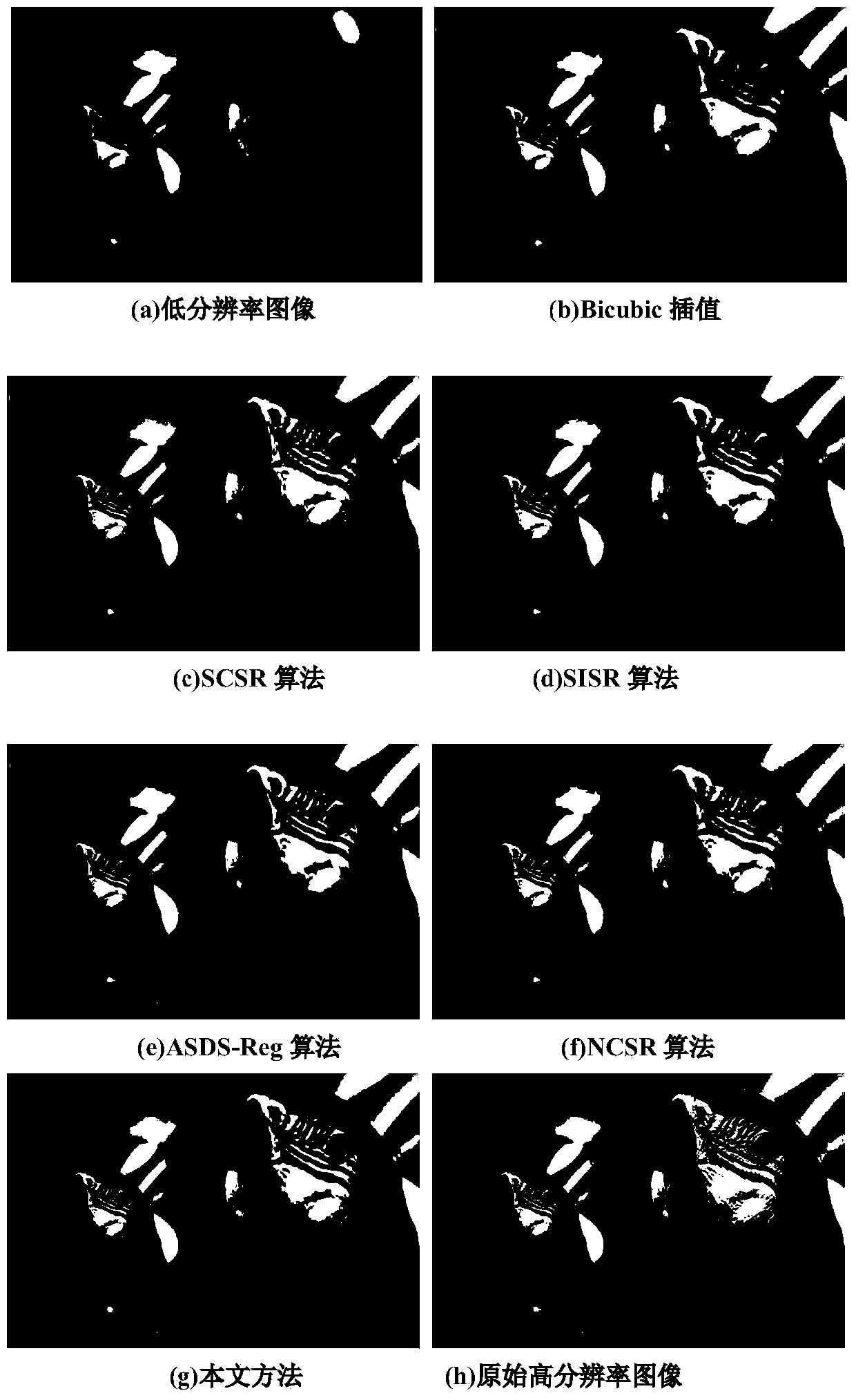

The invention discloses a single image super-resolution rebuilding method. Based on non-local similarity and a classification half-coupling dictionary learning algorithm, the method comprises a training stage and a rebuilding stage. According to the method, the half-coupling dictionary learning algorithm is used as a framework, training image block sparse domain classification based on mapping errors is introduced, and a heuristic method strategy conducted alternatively through the sparse domain classification and the half-coupling dictionary learning is adopted; sparse domain non-local similarity restriction items are introduced, structural information of training image block space is excavated in the sparse domain so as to rebuild more high-frequency details; the sparse representation algorithm based on non-local restriction is improved to meet the requirements of the half-coupling dictionary learning algorithm overall framework; further, an error compensation mechanism is introduced into the rebuilding stage to further improve the super-resolution rebuilding quality. Compared with the prior art, the method improves rebuilt texture details and forge edge and saw tooth removal, achieves good effects, and achieves best subjective visual effect in the prior art.

Owner:TIANJIN UNIV

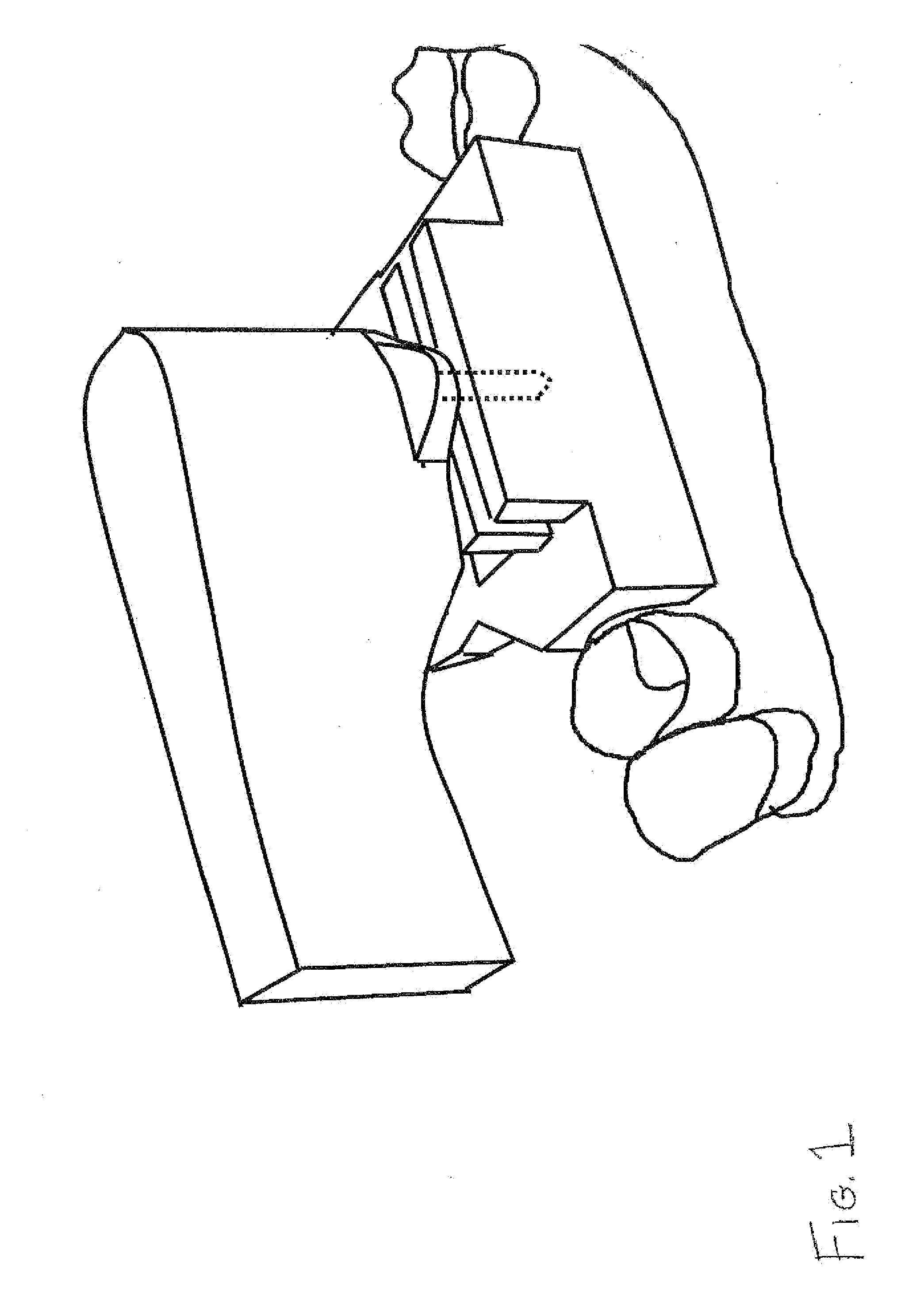

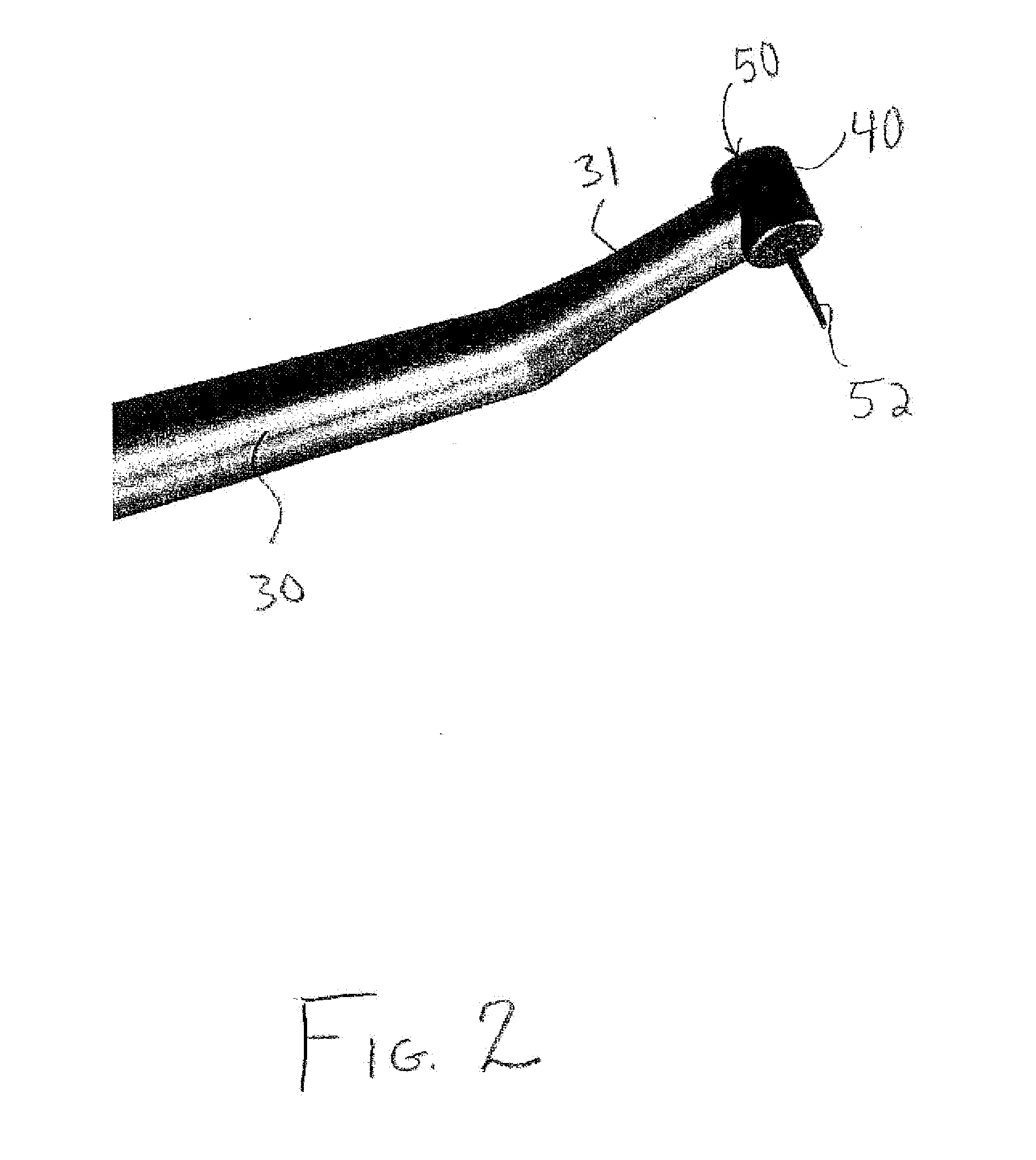

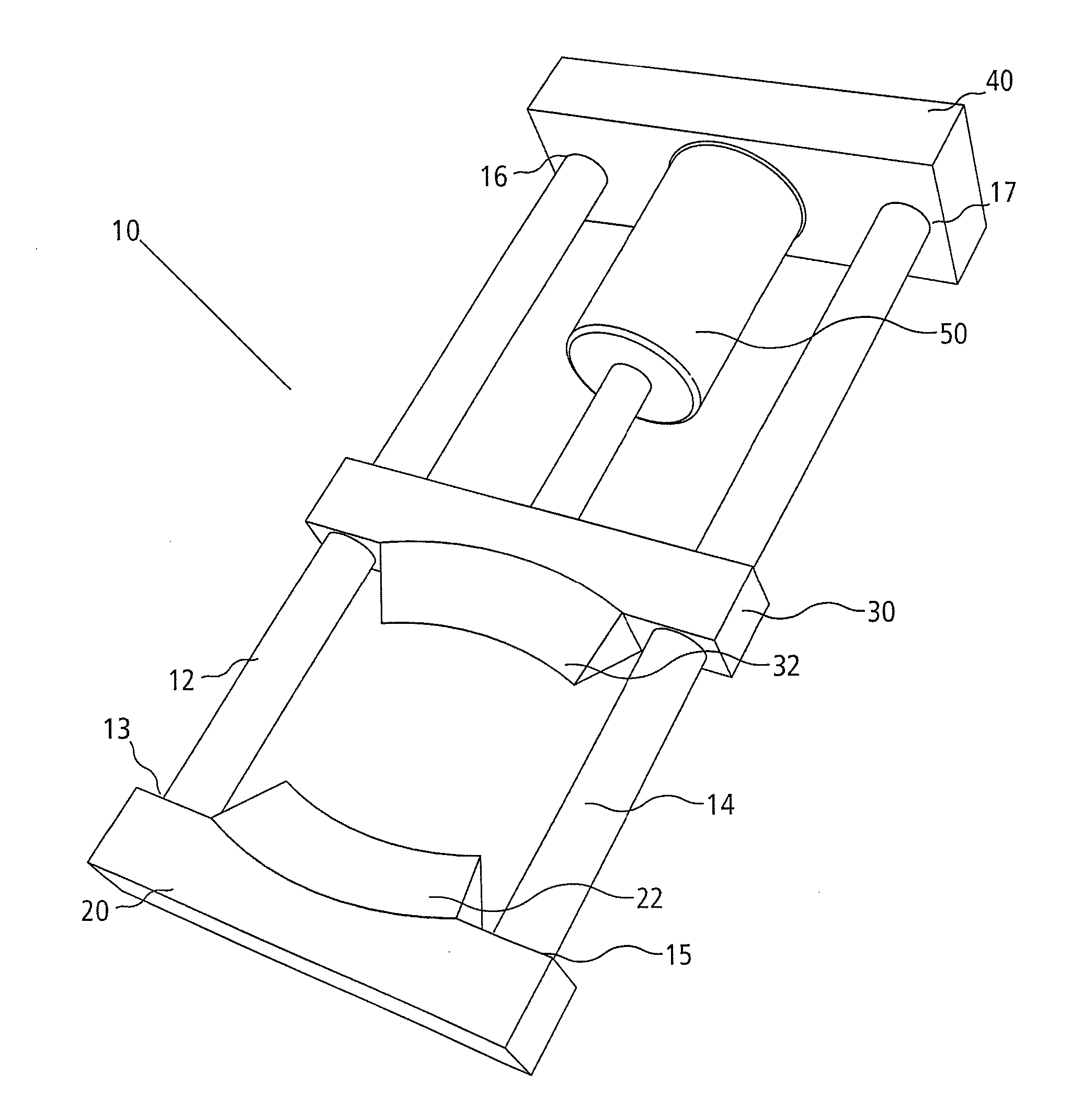

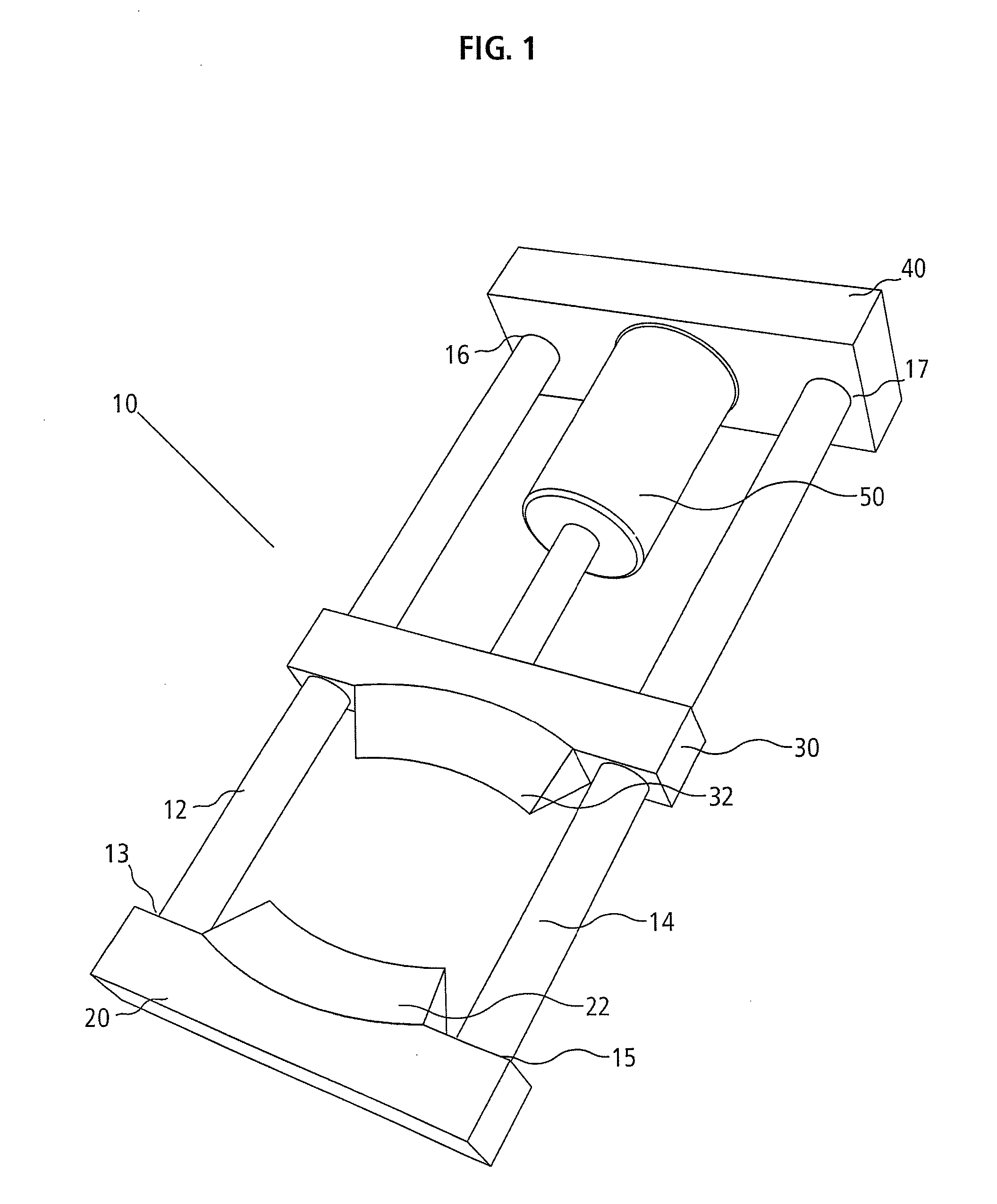

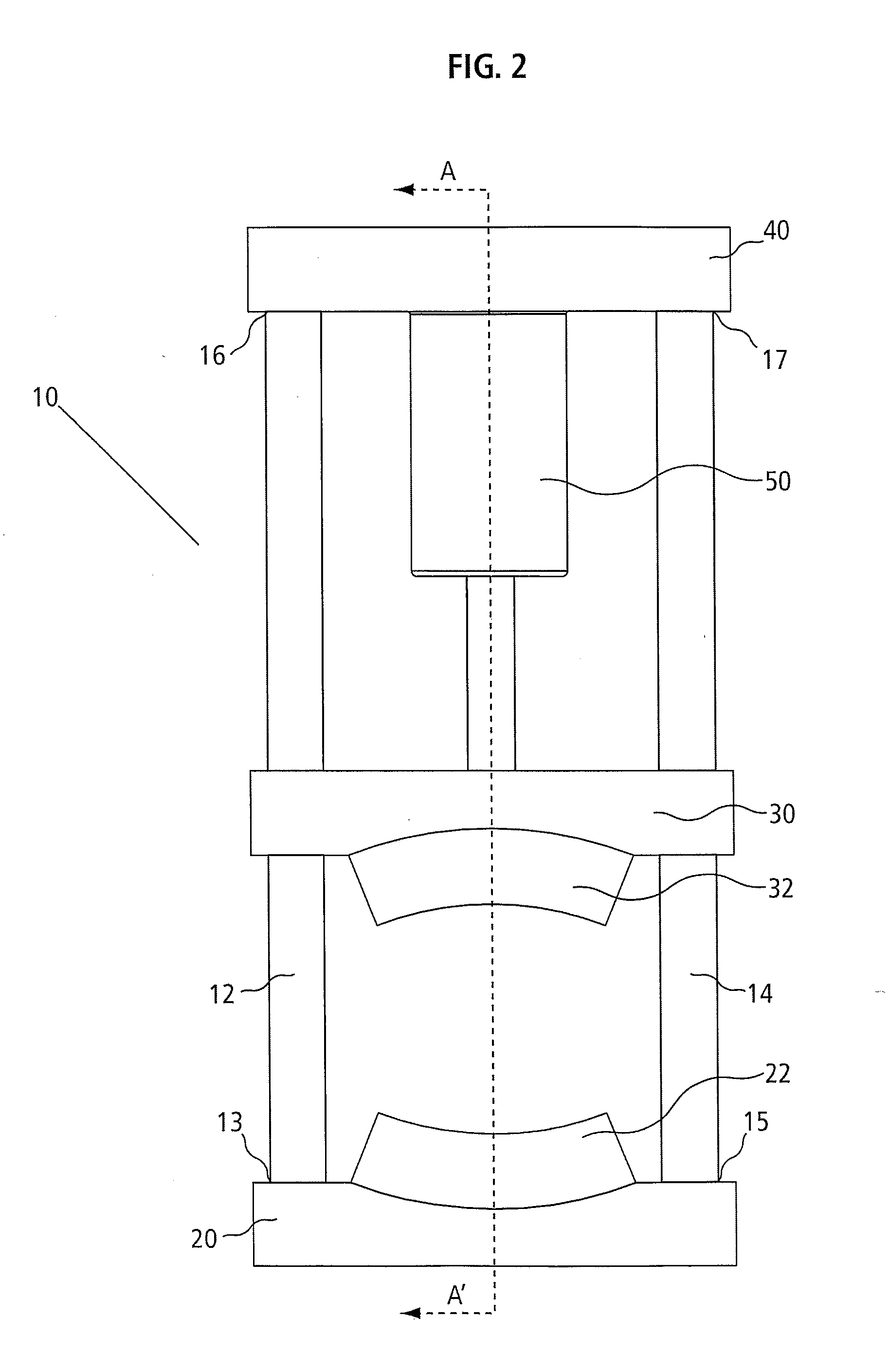

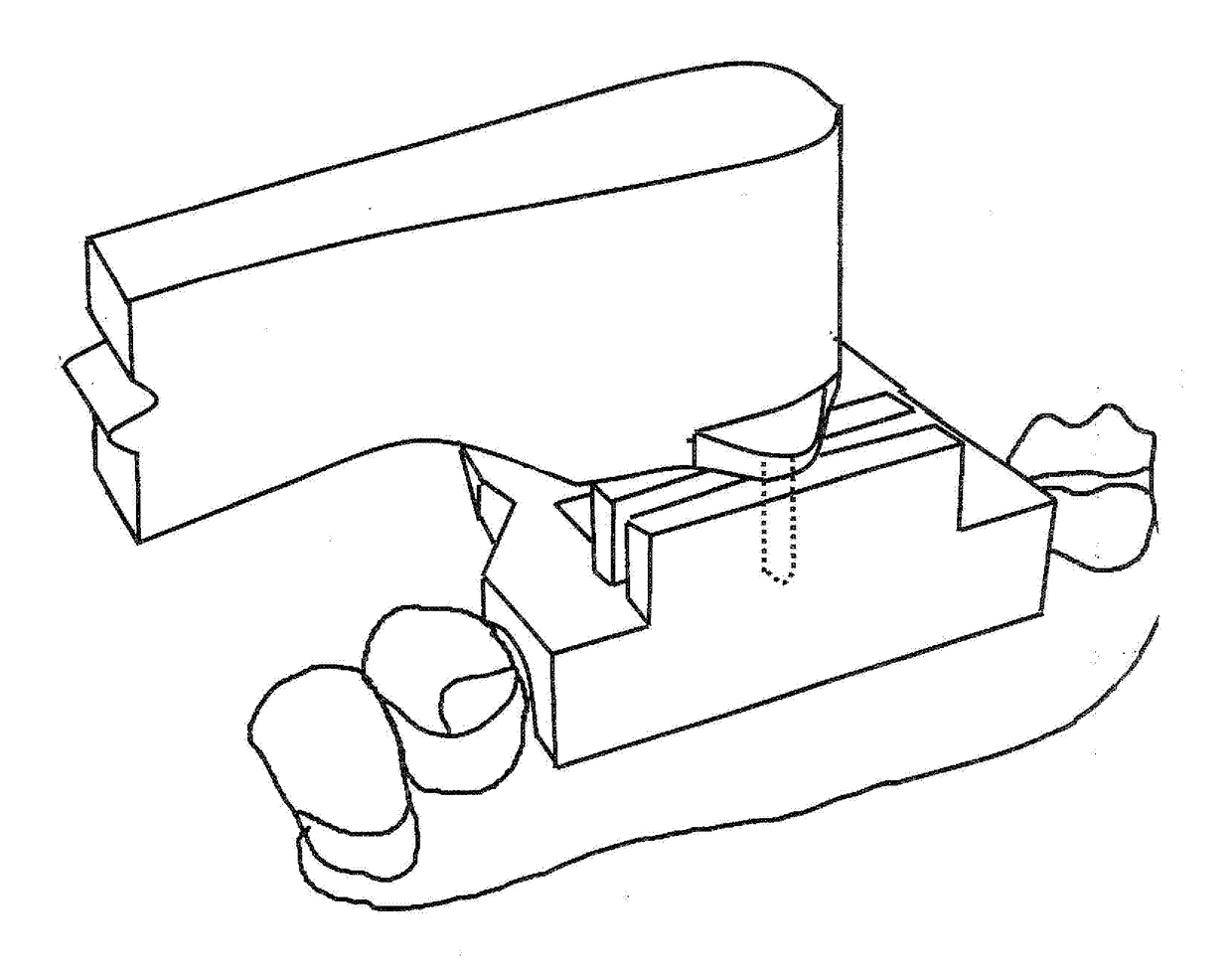

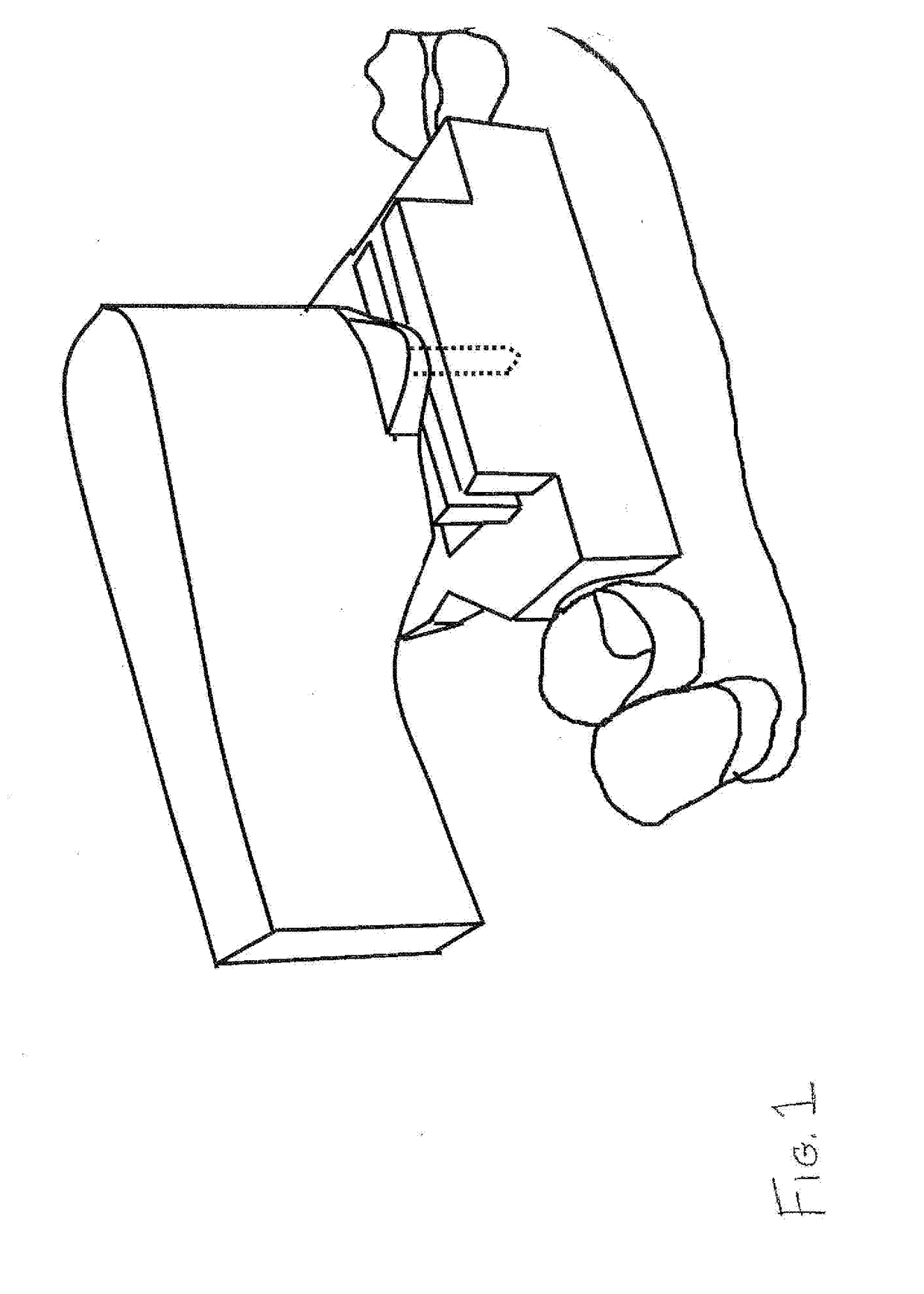

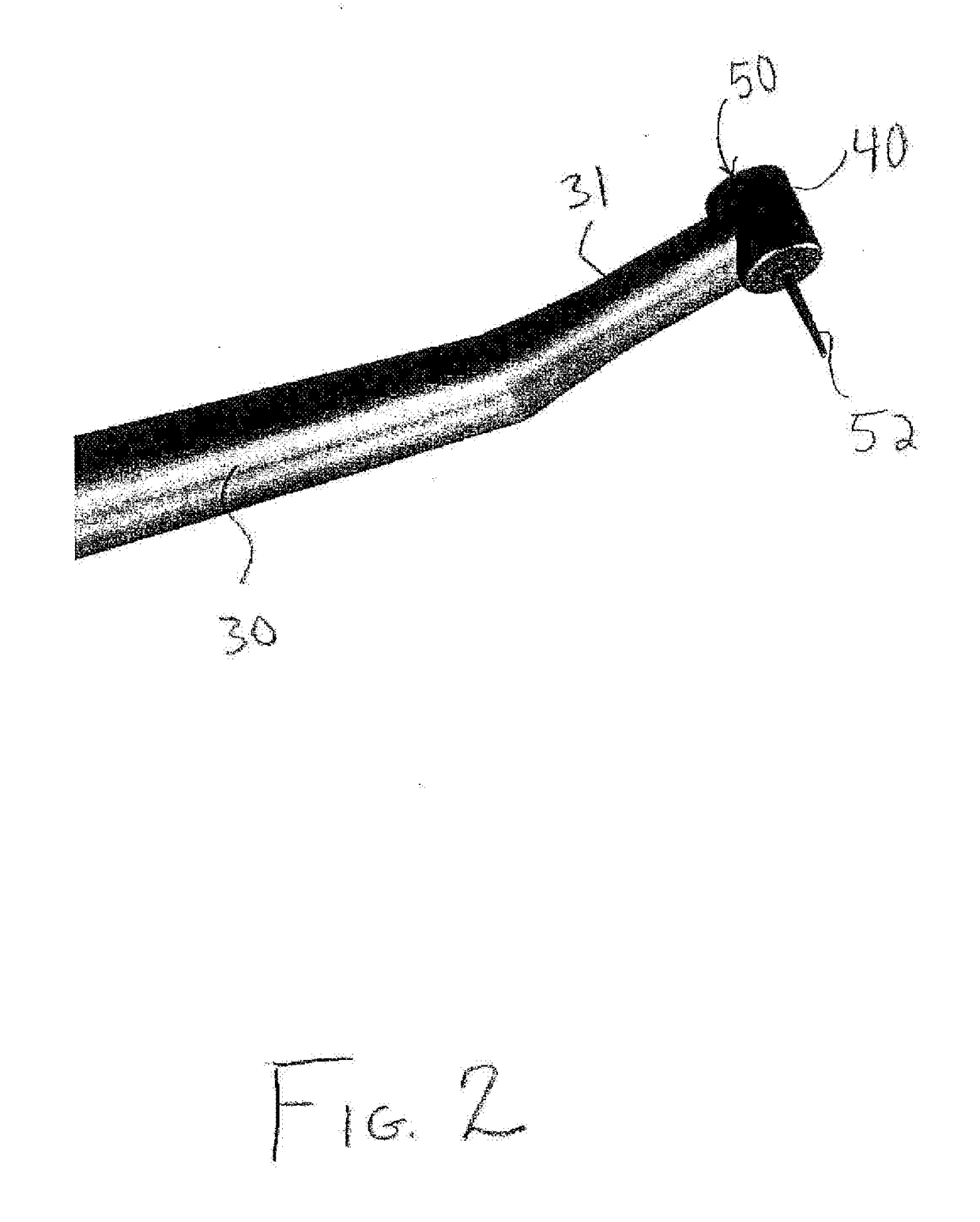

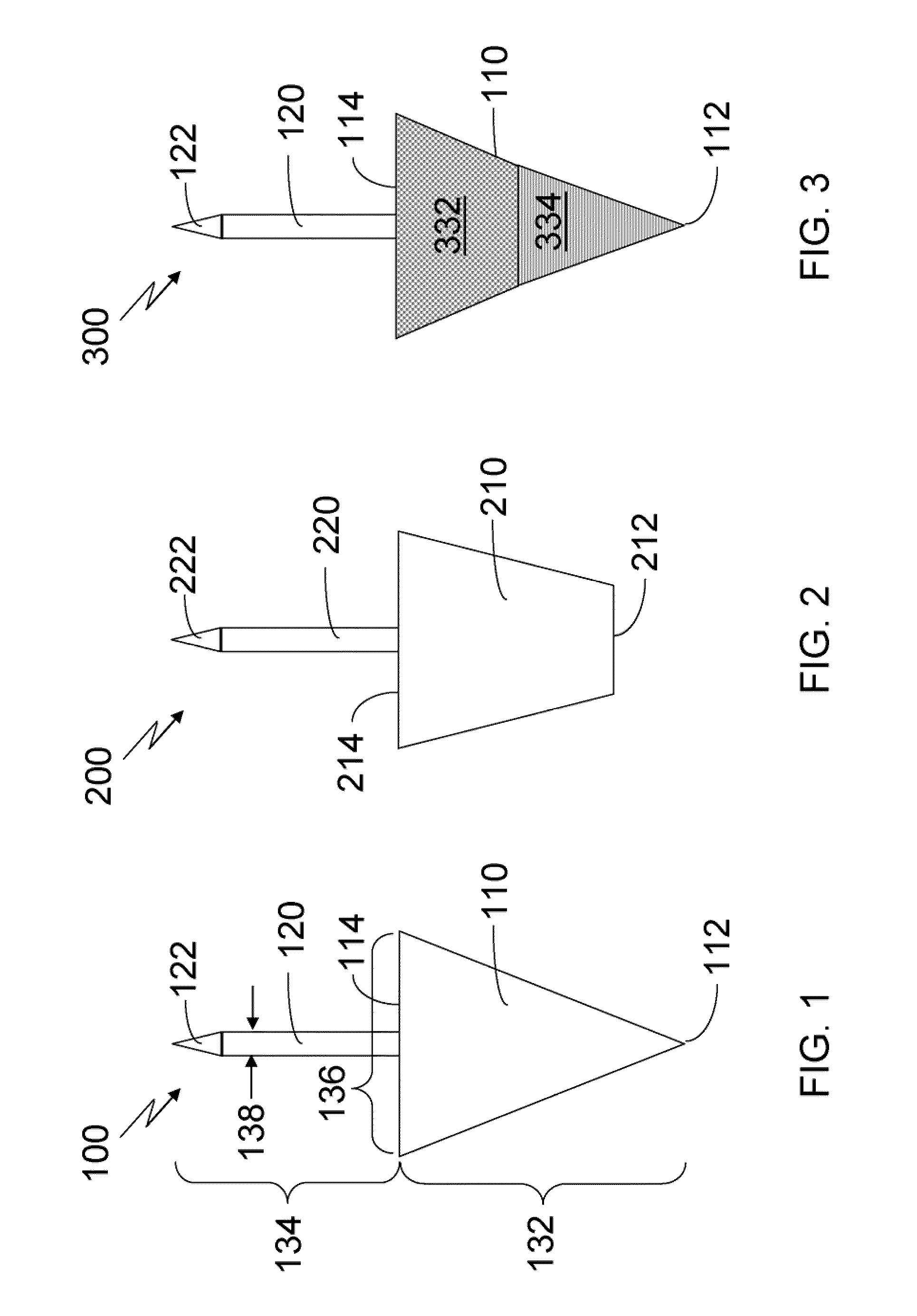

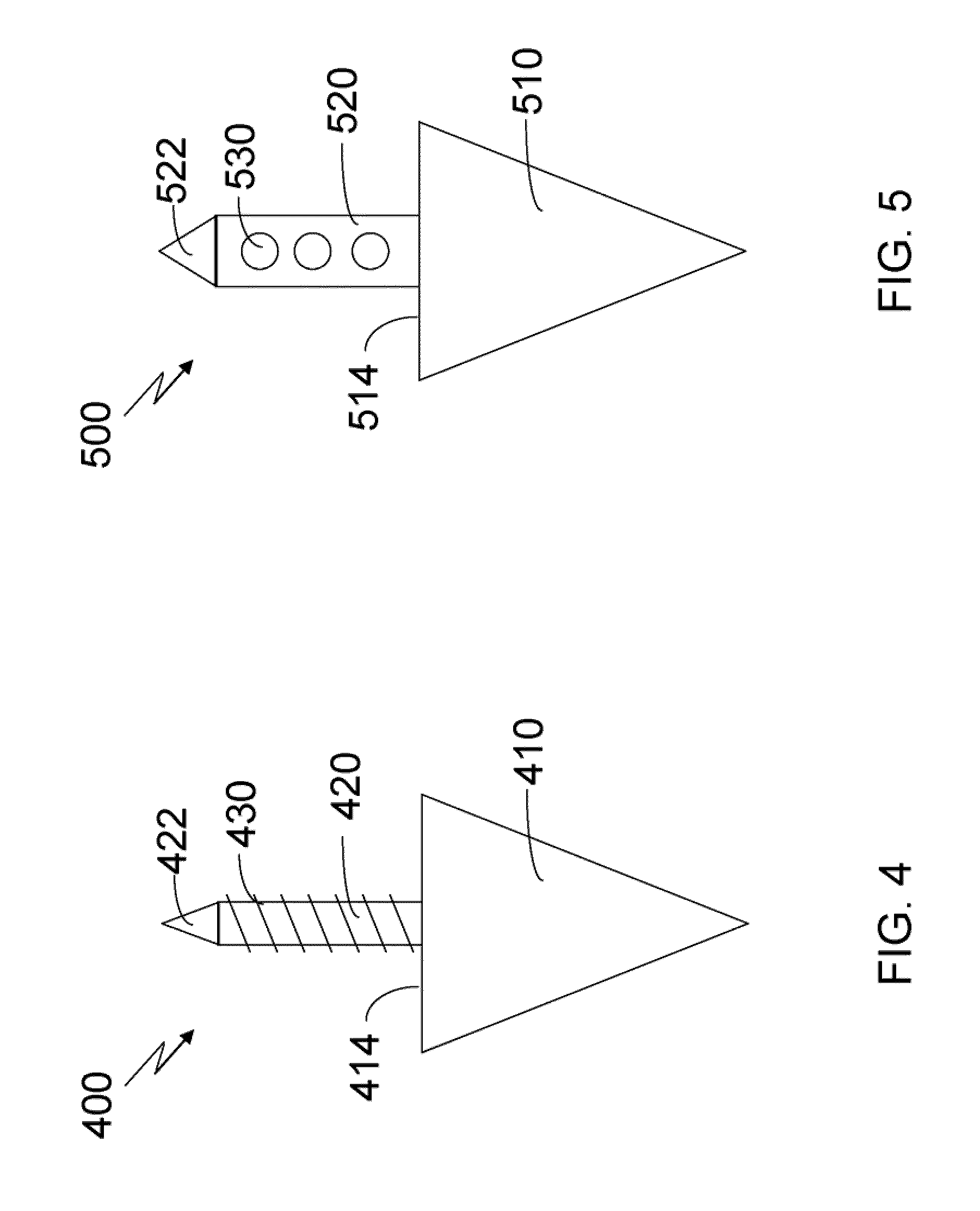

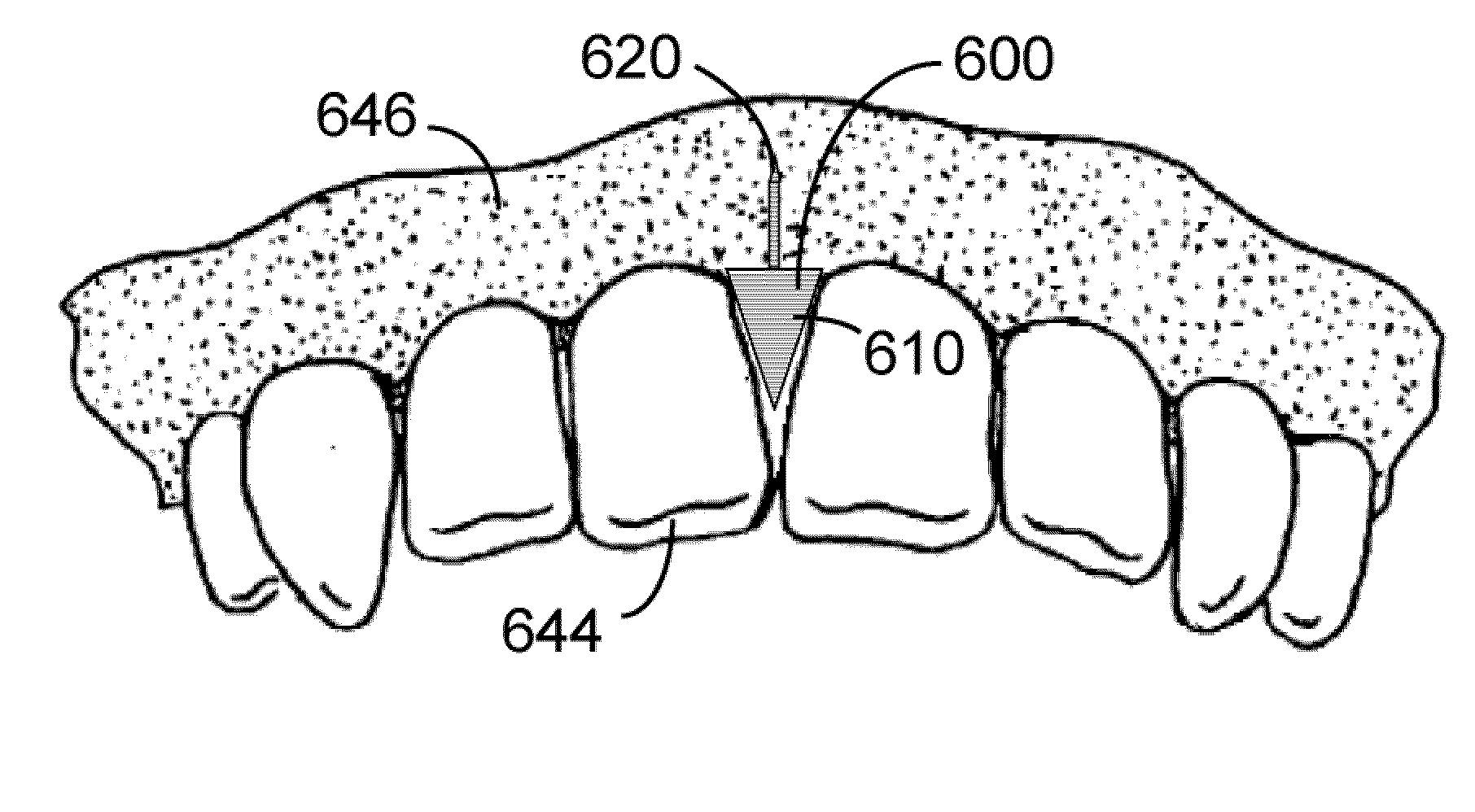

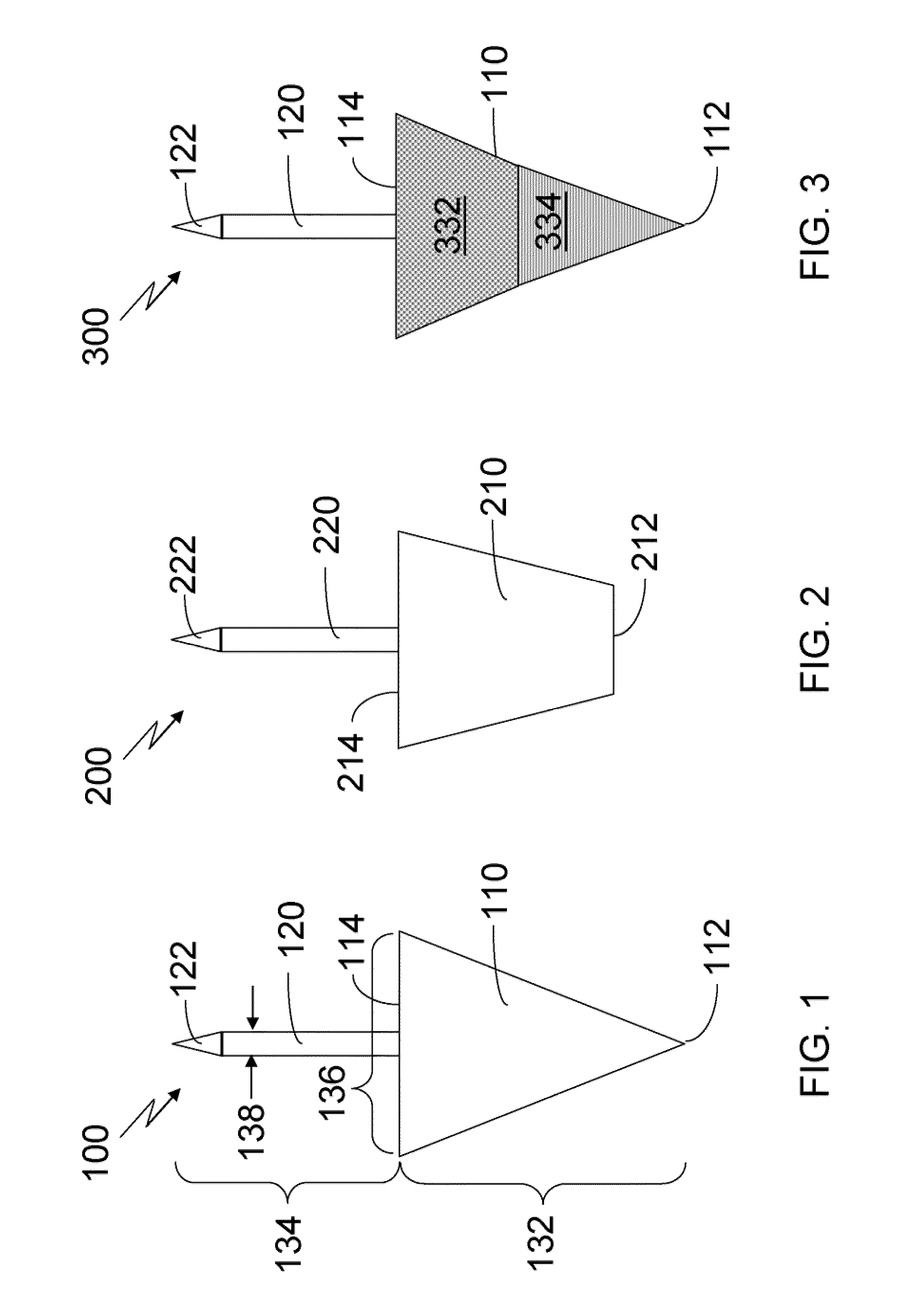

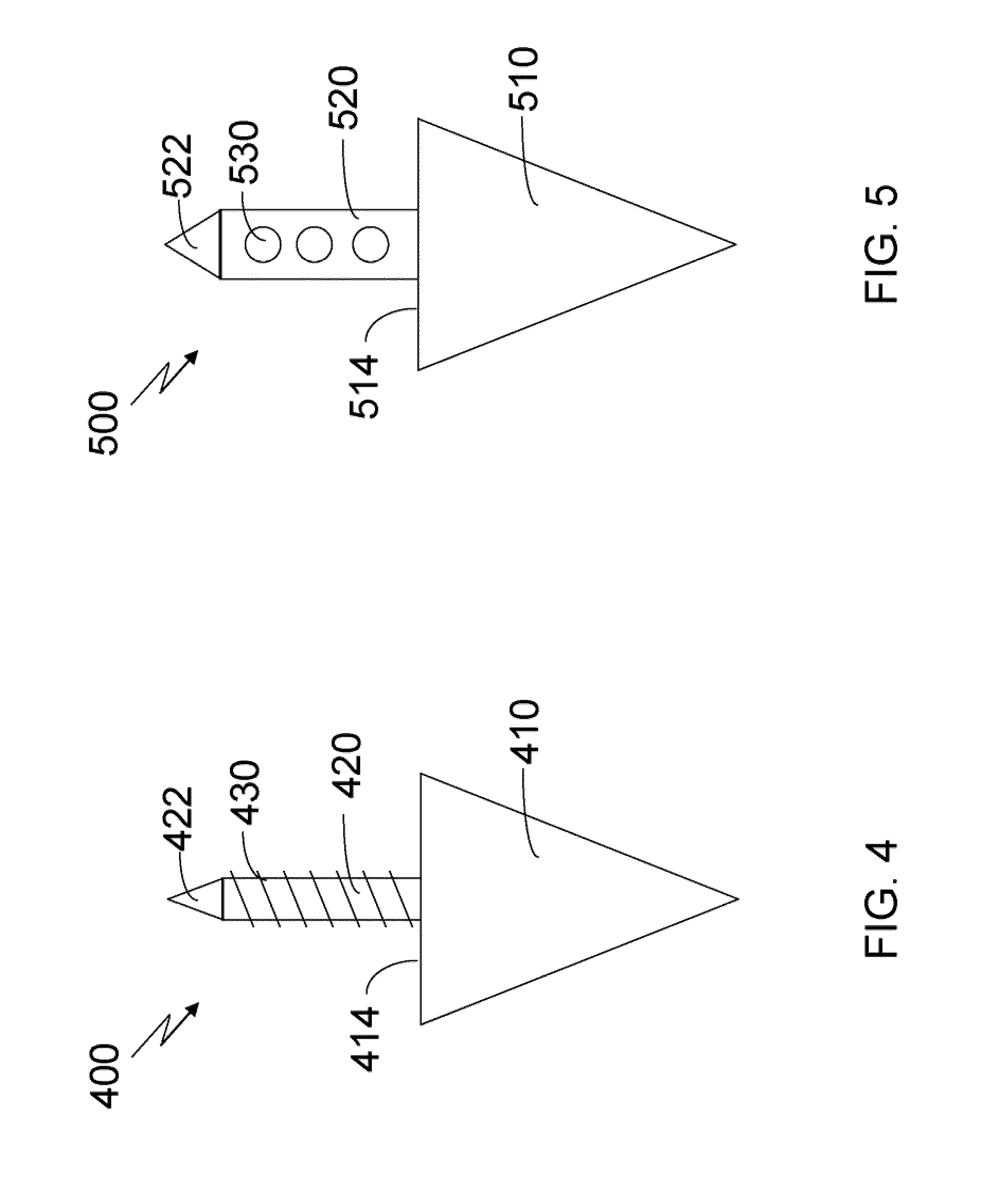

Dental tool and guidance devices

ActiveUS20140248577A1Precise preparationSimpler and reliable and convenientTeeth fillingDental toolsDental instrumentsEngineering

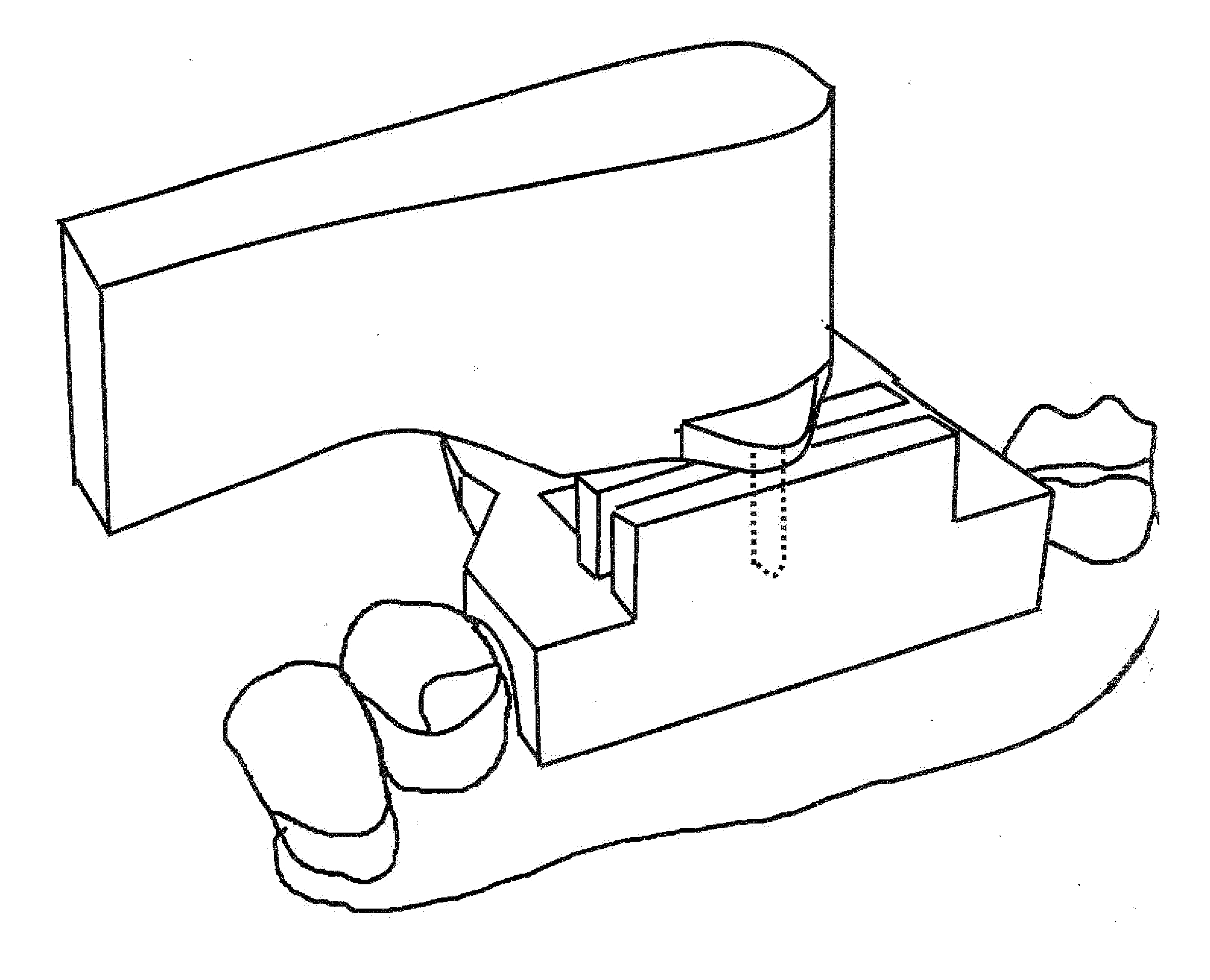

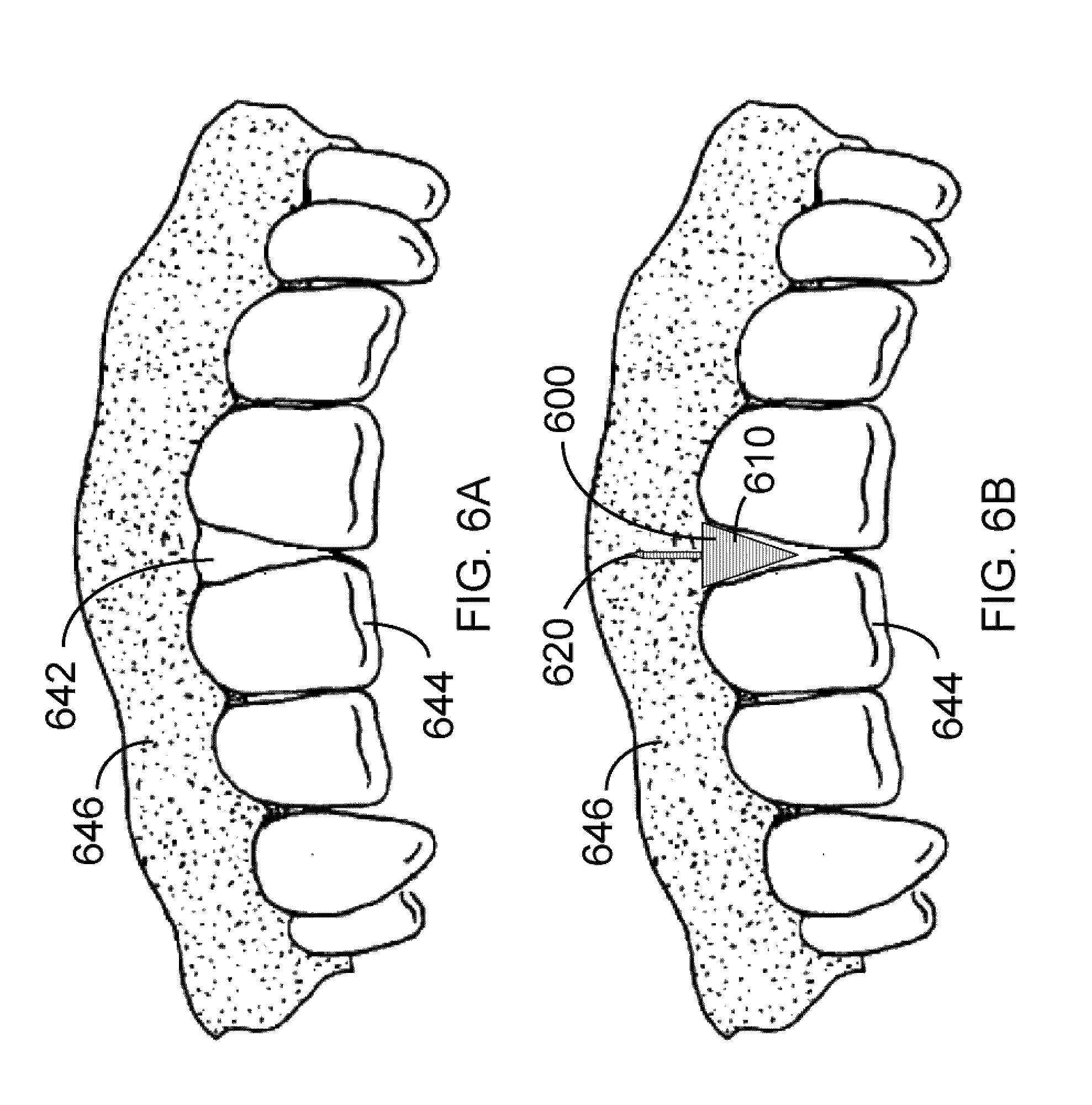

The present invention is directed to a system of devices and a method for preparing a tooth to receive a restoration. The system includes a dental instrument for removal of portions of a tooth in the mouth of a patent and an overlay for guiding the dental instrument during the step of tooth removal. The overlay is designed for temporary installation into the mouth of the patient to guide the dental instrument to remove tooth material. The overlay has one or more sets of guide walls, with a predetermined configuration capable of contacting one or more guide projections of the dental instrument, and a receptacle capable of receiving and attaching to the dental instrument.

Owner:VIAX DENTAL TECH LLC

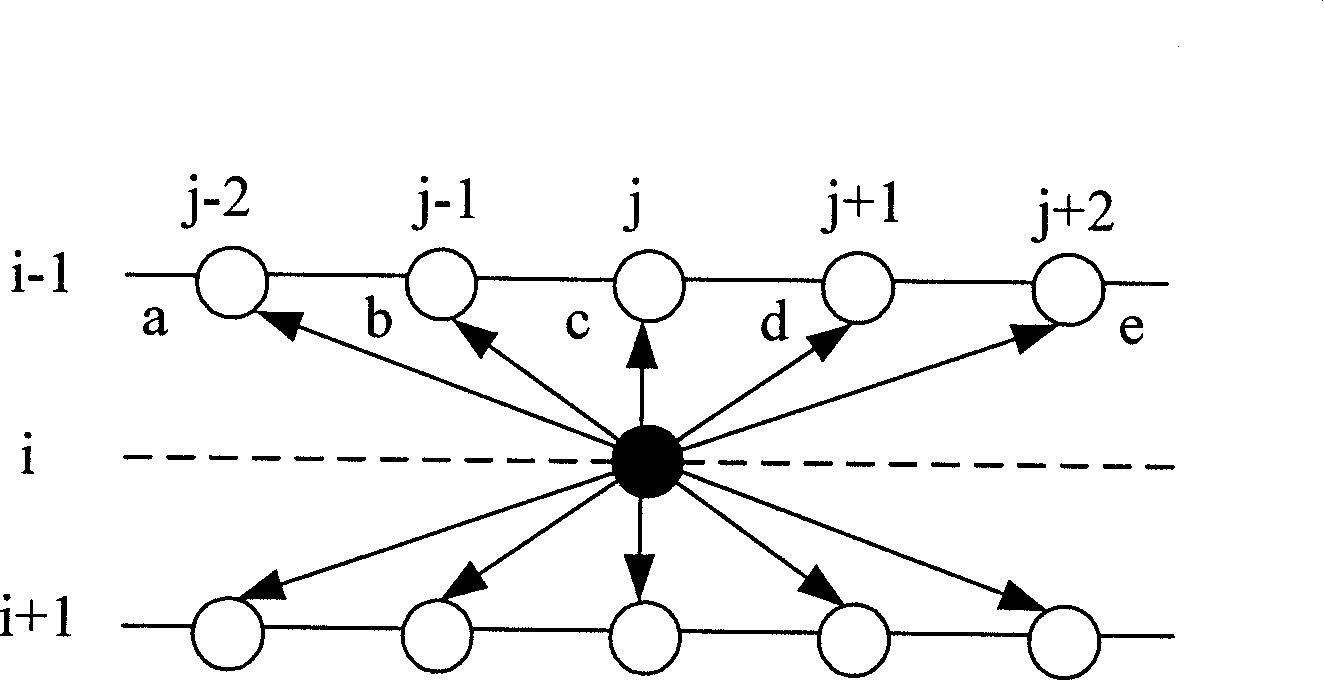

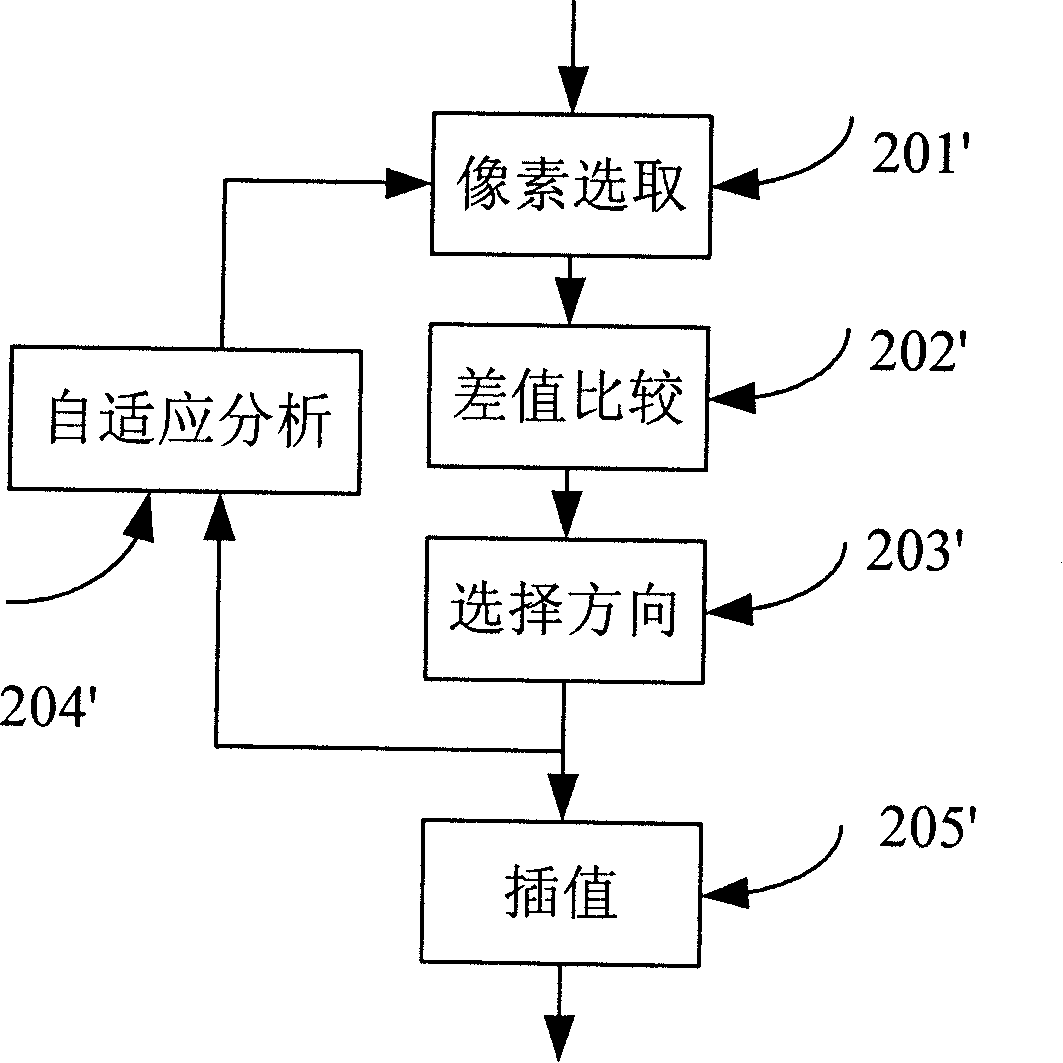

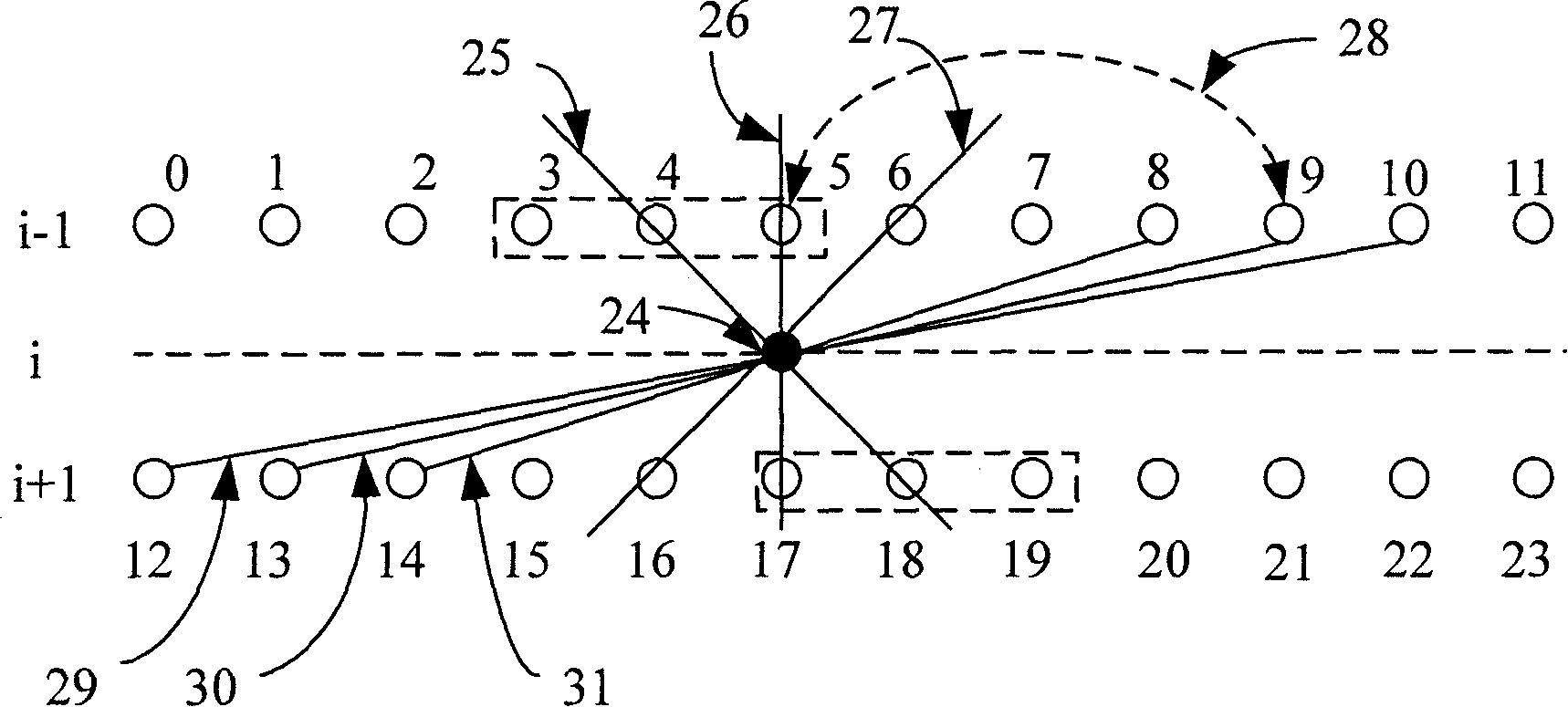

Edge self-adapting de-interlacing interpolation method

The invention discloses an edge adaptive de-interlacing interpolation method which proposes improvements aiming at solving the problems of the prior ELA interpolation method. The interpolation method which adopts an edge adaptive technique and interpolates loss information between two lines by making use of the correlativity of the two lines is characterized in that: the direction with greatest correlativity is selected as an interpolation direction through respective detections on a plurality of directions, and a plurality of groups of data in each direction are further selected for associate judgment, thereby improving the accuracy of the judgment. The method which is a de-interlacing interpolation algorithm with low cost, easy hardware realization, good edge protection and edge saw tooth removal ability can adjust interpolation directions adaptively and bring about good interpolation results in any direction. The method is effective not only two-dimensional interpolation but also for three-dimensional interpolation.

Owner:ARKMICRO TECH

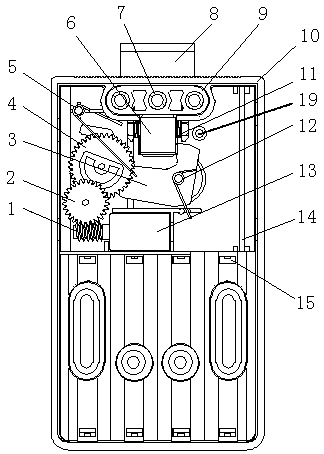

Zipper tooth collector and zipper sizing tooth remover using same

InactiveCN101524206AEfficient collectionWill not affect the working environmentSlide fastenersEngineeringTooth removal

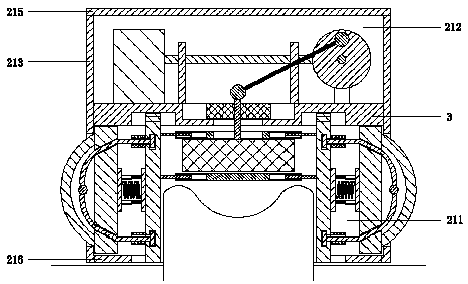

The invention relates to a zipper tooth collector and a zipper sizing tooth remover using the same. The zipper tooth collector is used for removing teeth of a zipper strip and collecting zipper tooth fragments, and comprises a box body and a tooth removing mechanism arranged in the box body, wherein the box body is provided with an inlet and an outlet for the zipper strip of which zipper teeth are cut to pass through respectively; the tooth removing mechanism is used for removing the cut zipper teeth on the zipper strip; and the box body is used for collecting the zipper tooth fragments falling from the zipper strip. The tooth collector can effectively collect the zipper tooth fragments generated by tooth removal, and the zipper sizing tooth remover has the advantage of simple structure.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

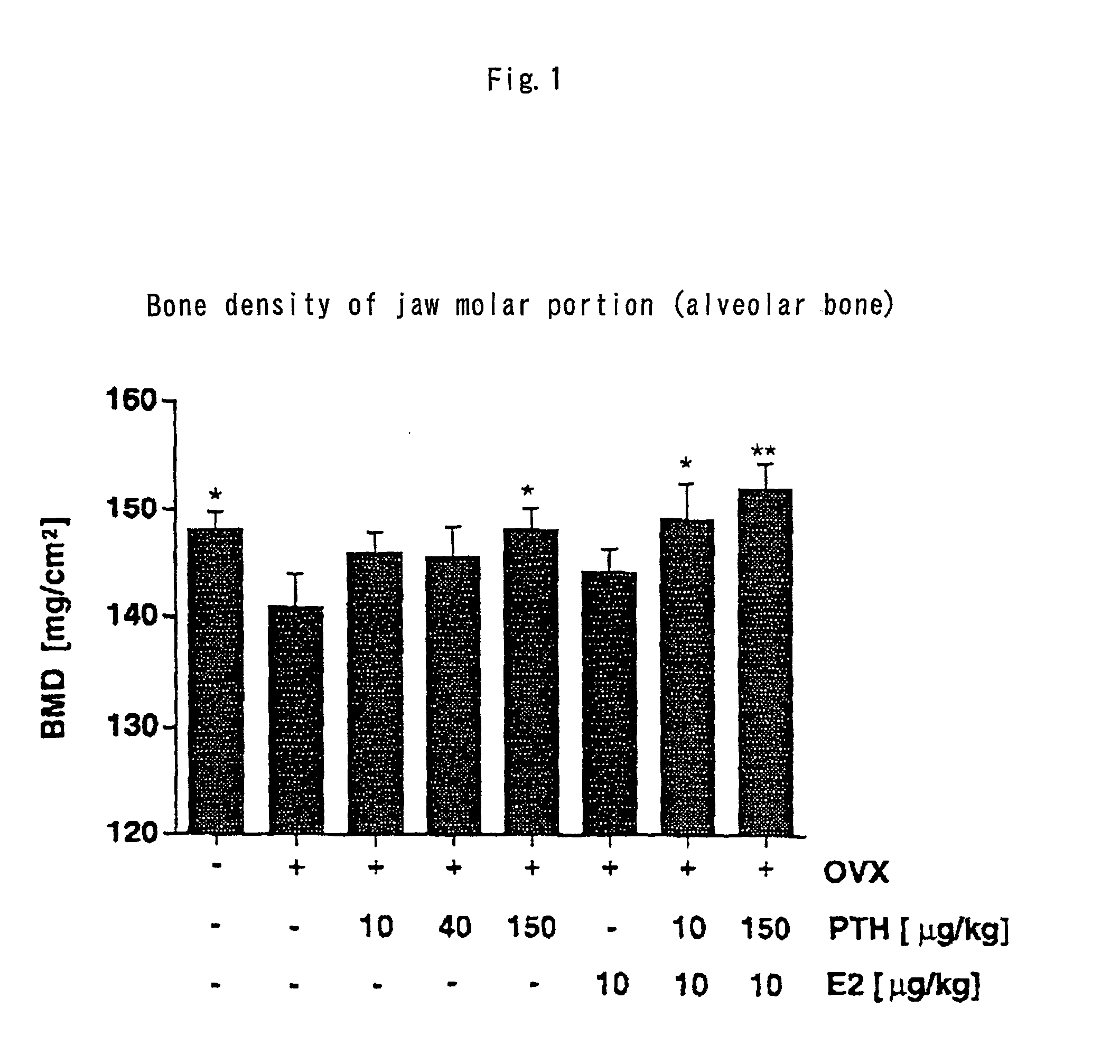

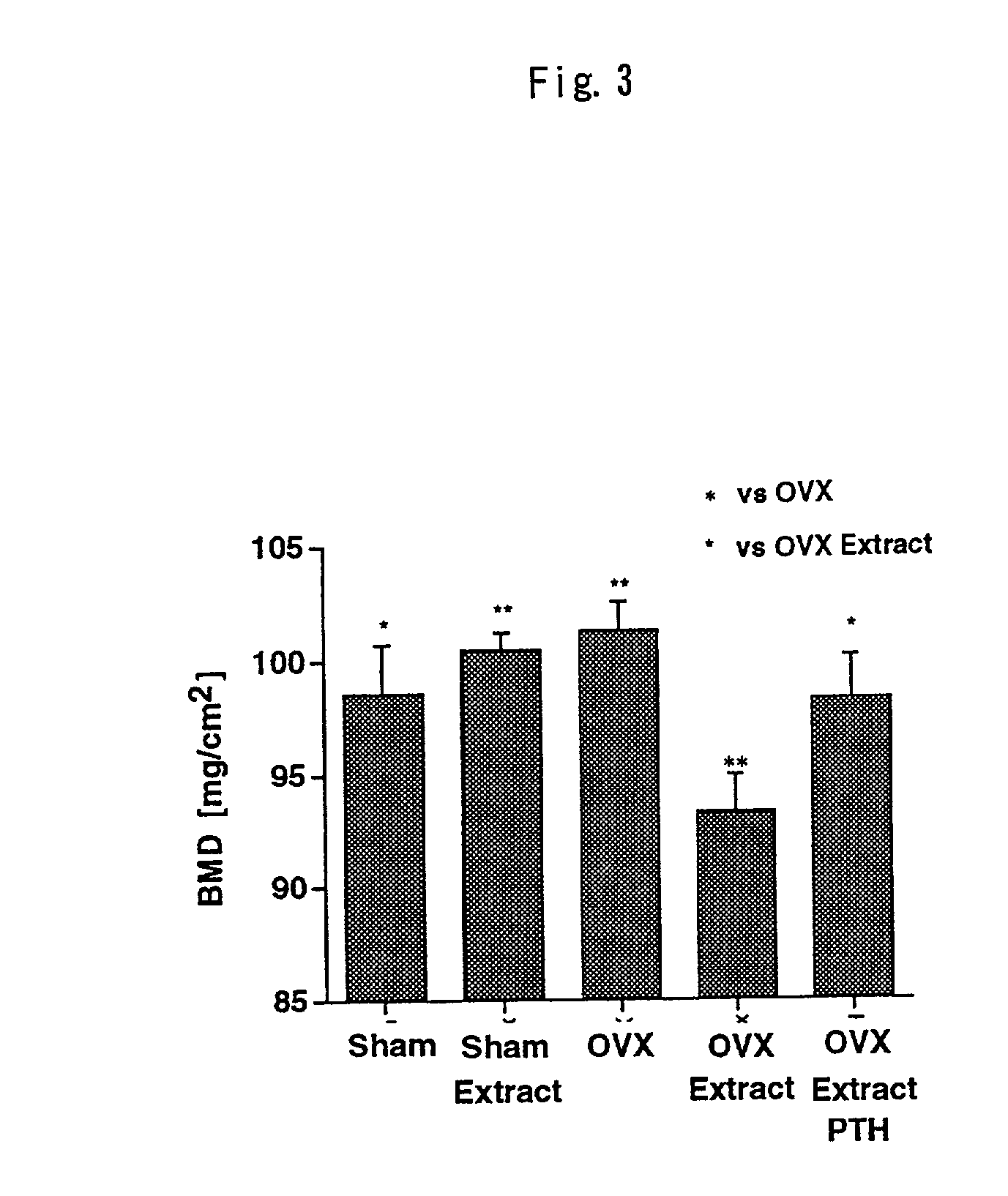

Dental remedies containing pth

InactiveUS20020094951A1Increase bone densityBiocidePeptide/protein ingredientsClinical efficacyBone density

Dental therapeutics containing (1) parathyroid hormone (PTH) or one or more PTH derivatives or (2) parathyroid hormone (PTH) or one or more PTH derivatives and estrogen as an active ingredient or active ingredients have various actions such as increasing the bone density of the jaw alveolar bone portion, particularly the one in the upper jaw or the lower jaw, preventing or treating the weakening of the jaw alveolar bone portion, particularly the one in the upper jaw or the lower jaw, promoting the regeneration of the jaw alveolar bone portion, particularly the one in the upper jaw or the lower jaw, and increasing the bone densities of the whole mandibular bone and the mandibular molar portion after tooth removal; hence, they are clinically effective.

Owner:CHUGAI PHARMA CO LTD

Crusher tooth removal tool

A crusher tooth removal tool is provided having a guide comprising a pair of substantially parallel elongate guide members, said guide having a first end and a second end; a first wedge assembly attached at or near the first end of the guide, said first wedge assembly having a first wedge; a second wedge assembly having a second wedge, said second wedge assembly slideably attached to the guide so that the second wedge and the first wedge are facing each other; a brace fixedly attached at or near the second end of the guide; and a force exerting device connected between the second wedge assembly and the brace such that the force exerting device is operative to force the second wedge assembly along the guide towards the first wedge assembly.

Owner:SYNCRUDE CANADA LTD

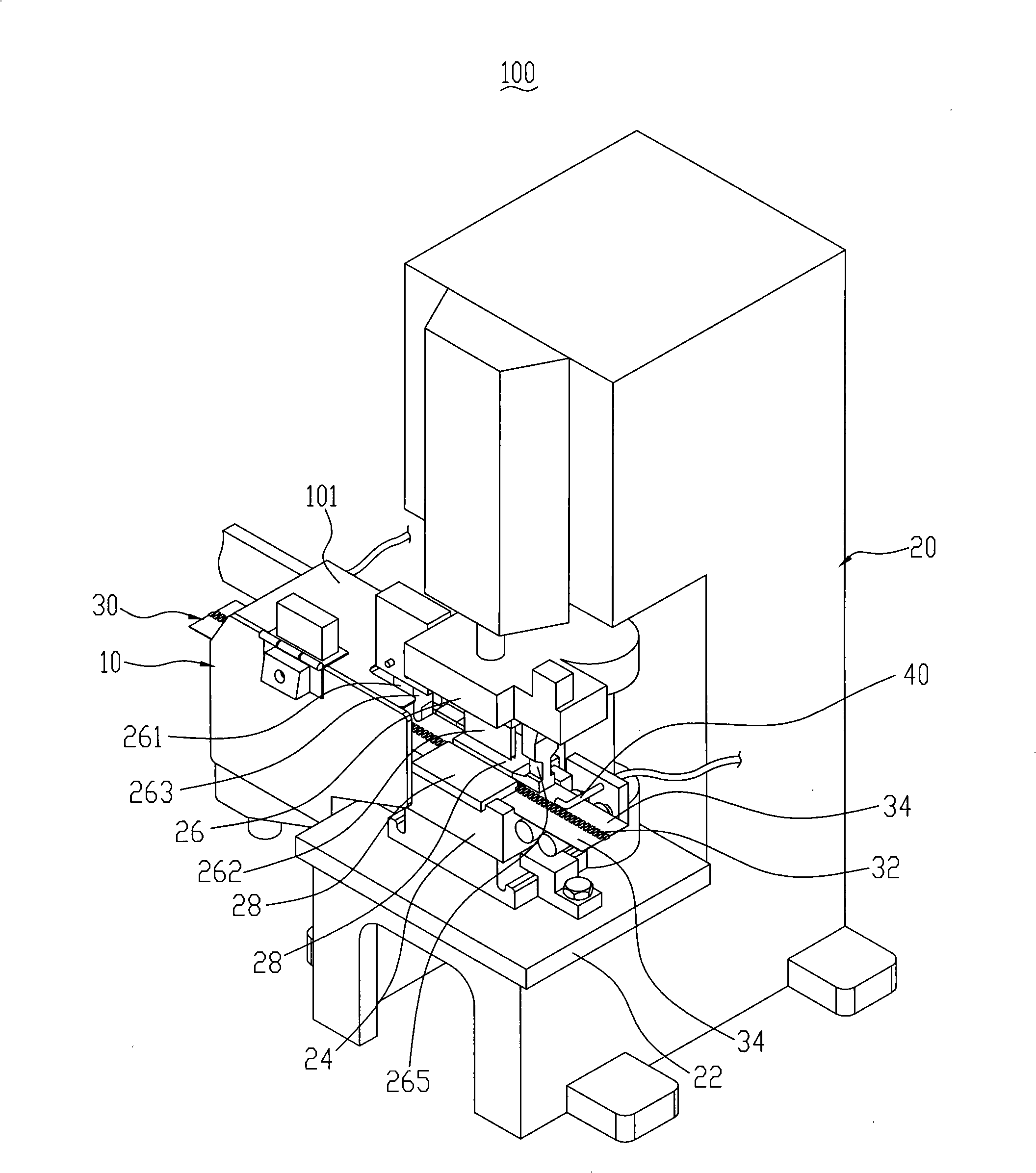

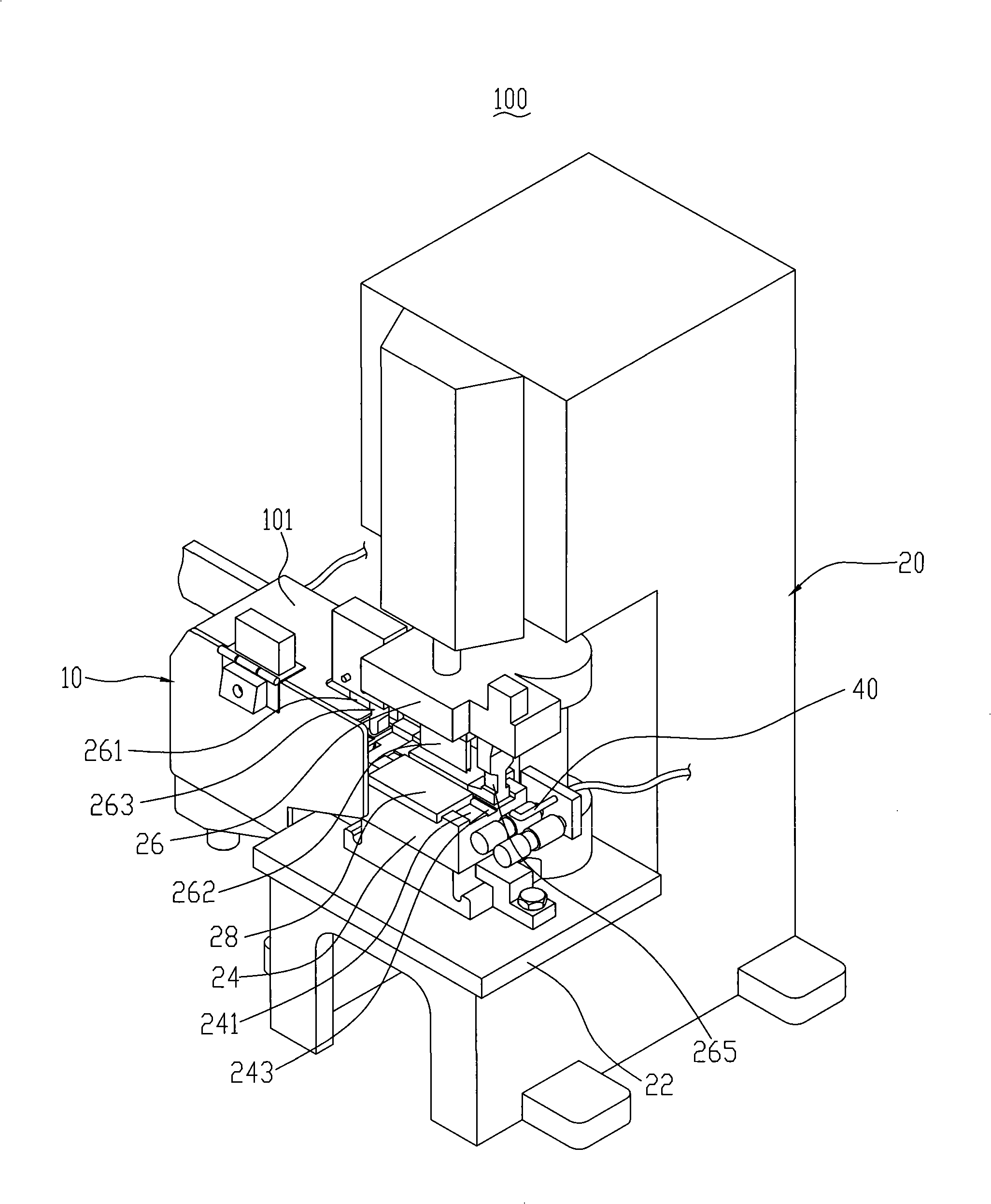

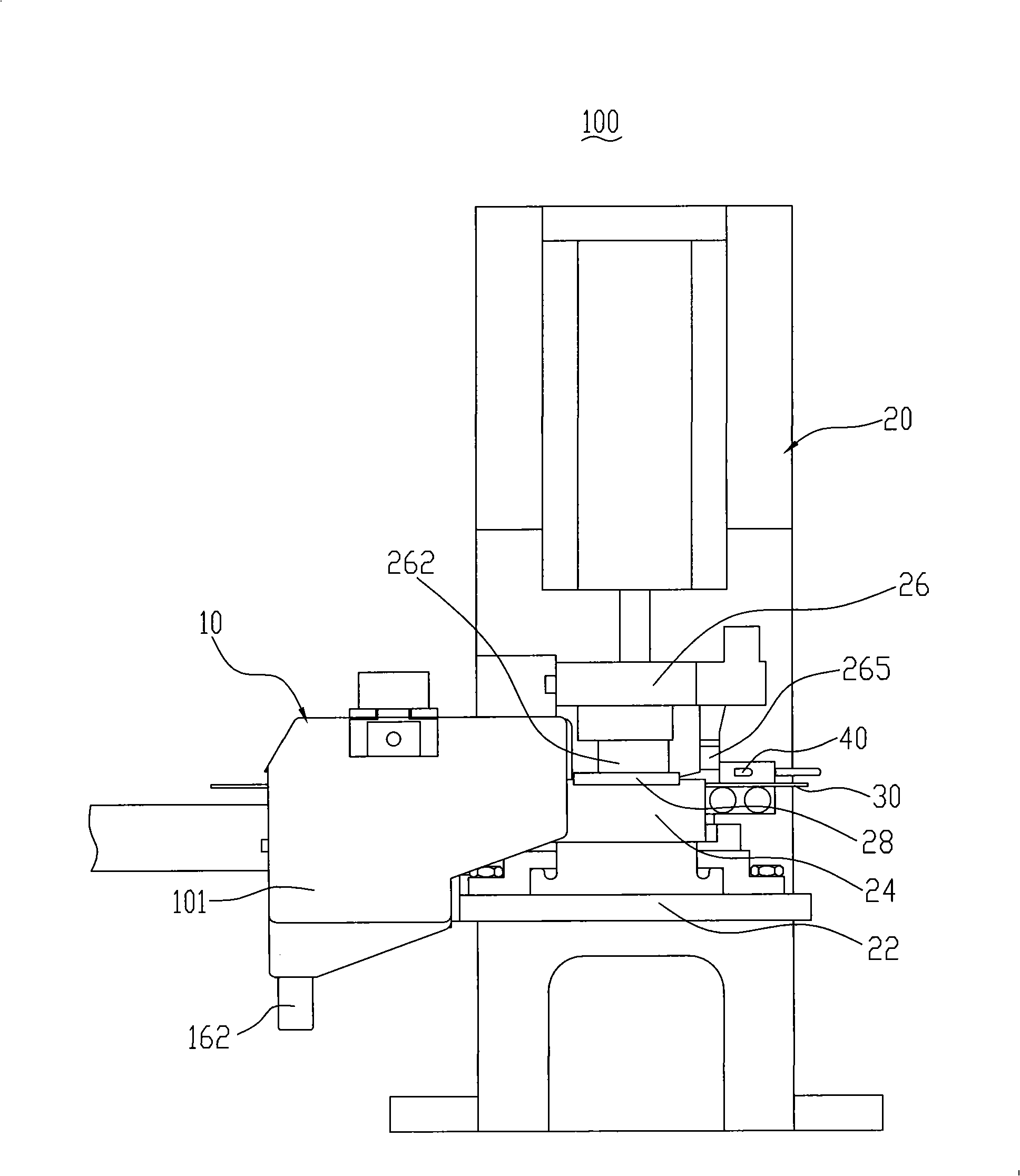

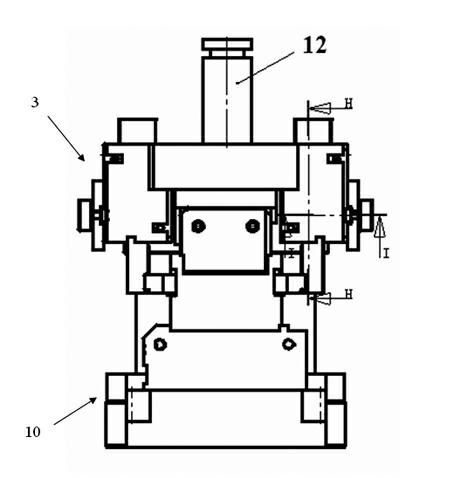

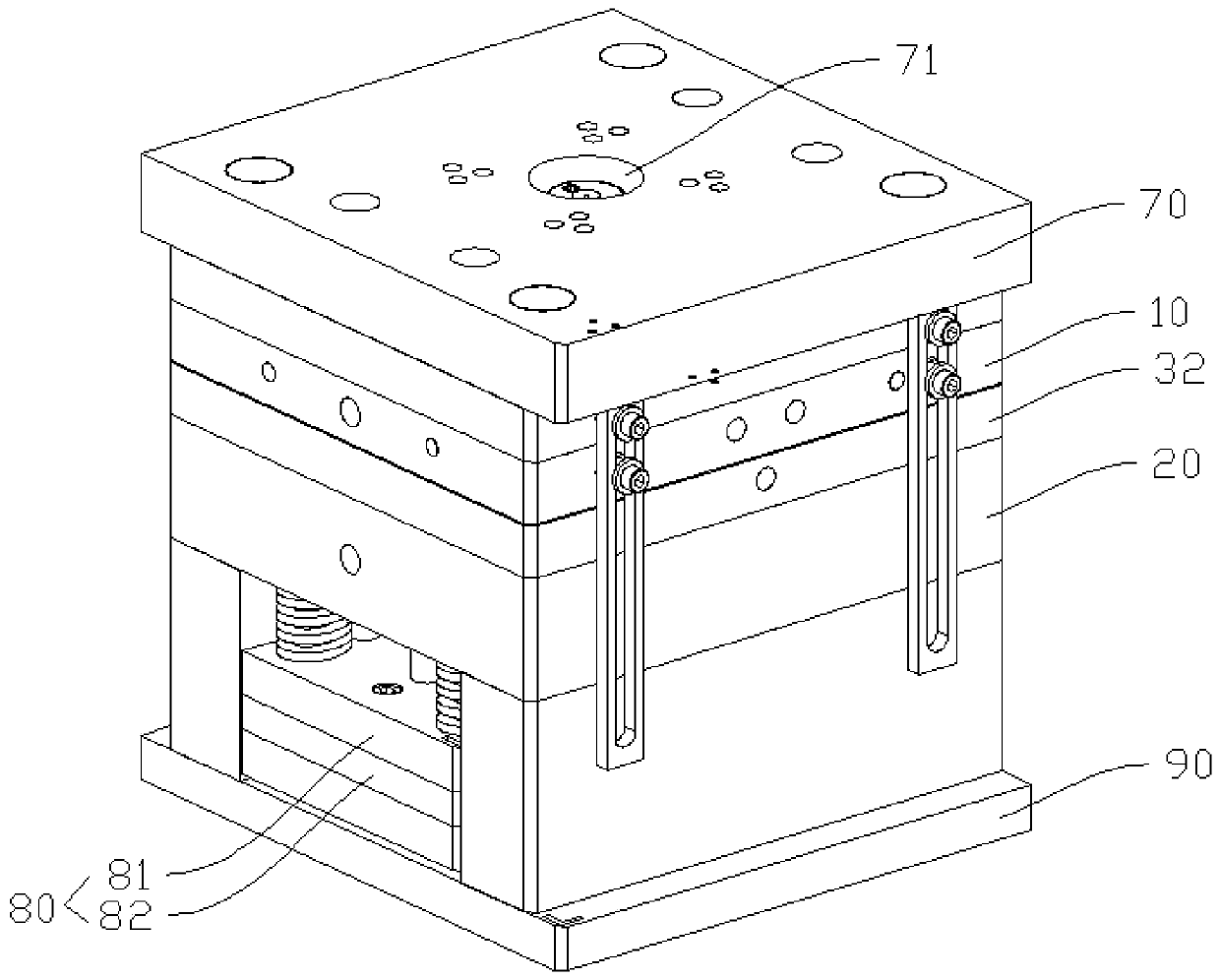

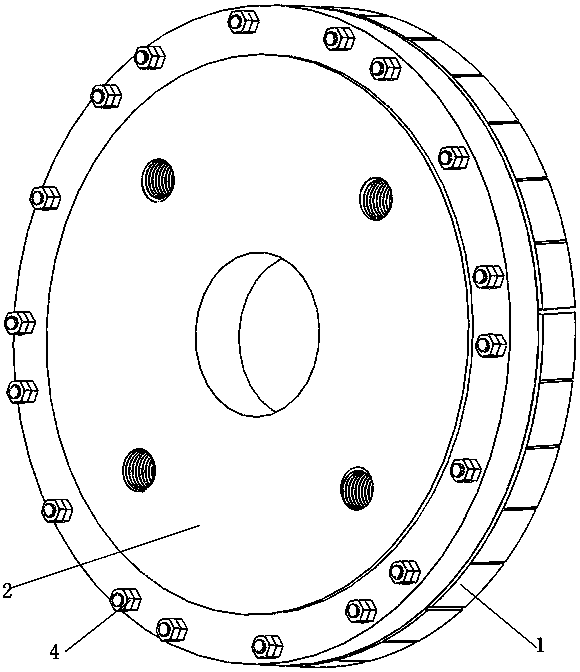

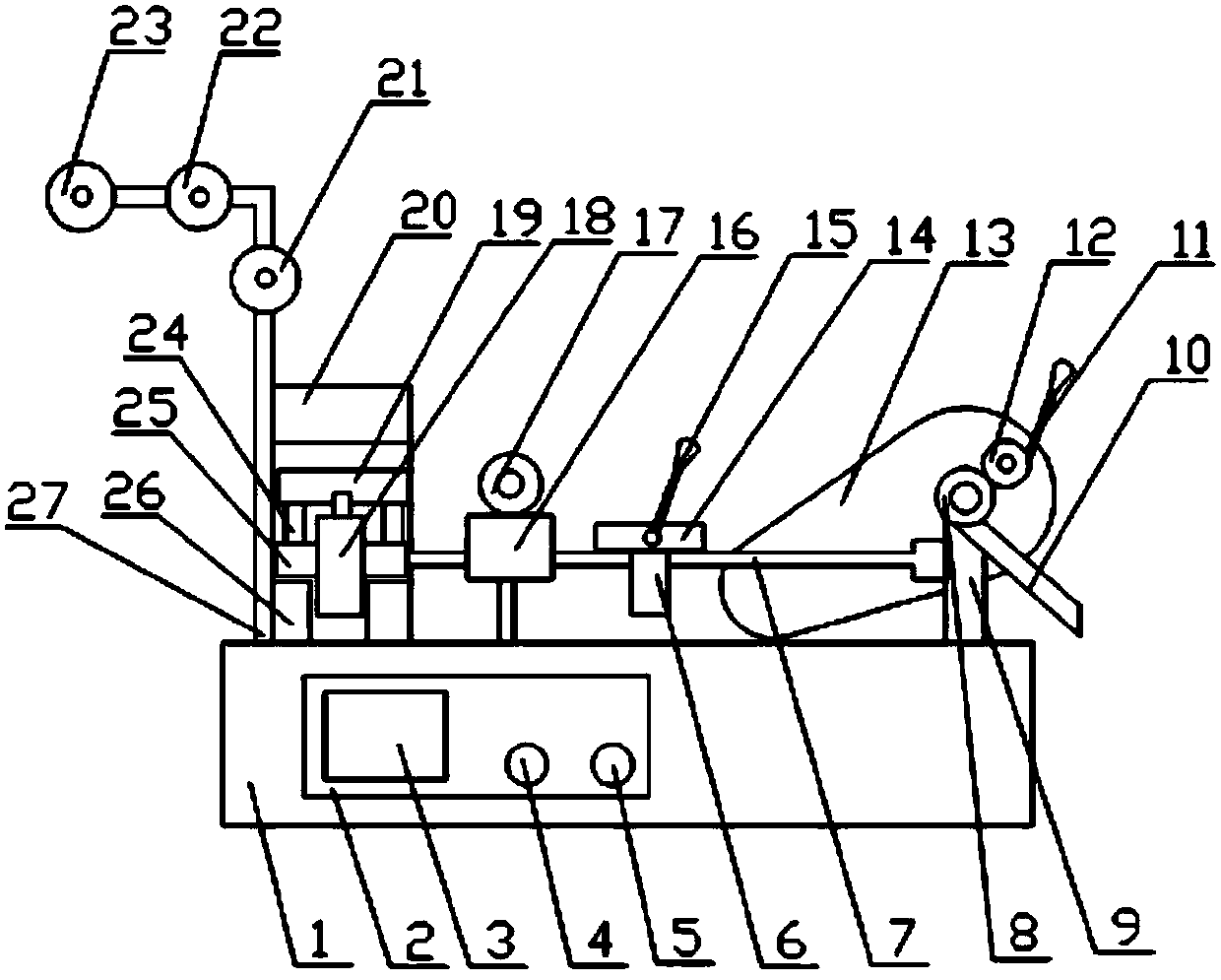

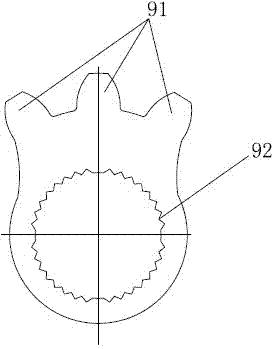

Tooth removal device for metal zipper sizing and cleaning and tooth removal method thereof

ActiveCN102554013AIn line with the production and processing technologyIncrease production speedSlide fastenersMetal-working feeding devicesEngineeringTooth removal

The invention discloses a tooth removal device for metal zipper sizing and cleaning, which comprises an upper die holder, a lower die holder, an upper punch tool, a lower die, a plurality of positioning devices and a power connecting rod. The lower die holder is arranged below the upper die holder correspondingly, the upper punch tool is fixed to the bottom of the upper die holder, the lower die is fixed to the top of the lower die holder and corresponds to the upper punch tool, the positioning devices are respectively arranged on two sides of the upper die holder, and the power connecting rods are fixed to the top of the upper die holder. Zippers can be positioned by the positioning devices so as to be subjected to sizing and cleaning processes, teeth in specified quality and at specified positions can be removed accurately after the sizing and cleaning processes so that the produced zippers can meet requirements of processing technology, the manual operation easy to make workers tired is replaced, both production speed and efficiency are increased, and labor cost is lowered.

Owner:SHANGHAI EASTDRAGON FABRIC & GARMENT

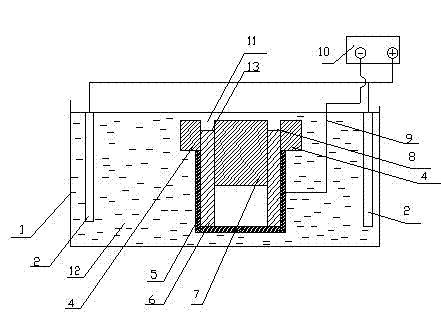

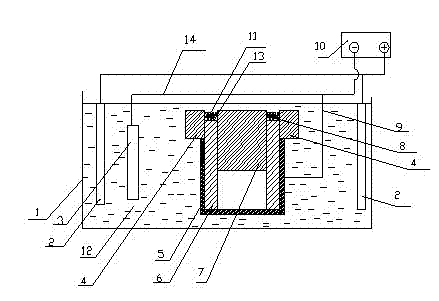

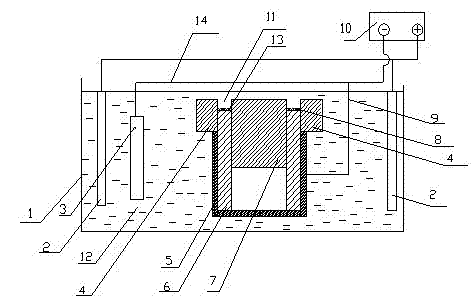

Effective method for preventing scorching in electroplating process

InactiveCN103088373AImprove pass rateReduce manufacturing costElectroforming processesElectrodesPower flowTooth loss

The invention provides an effective method for preventing scorching in an electroplating process. The method is characterized in that an auxiliary electrode is used in the electroforming process, and the auxiliary electrode is in parallel with a workpiece to be plated and is connected with the cathode of a rectification power supply through a copper bar and a lead in the sanding and fixing initial-stage-thickening operation of the workpiece, so the auxiliary cathode effectively shares a current, thereby the surface of the workpiece is prevented from scorching, phenomena comprising tooth breakage, tooth loss, tooth removal, delamination, cracking and peeling are fundamentally solved, the product qualification rate is improved by 27%, and the production cost is reduced by above 14%.

Owner:肖云捷

Dental tool and guidance devices

ActiveUS20170172702A1Precise preparationSimpler and reliable and convenientDental toolsBoring toolsDental instrumentsTooth removal

The present invention is directed to a system of devices and a method for preparing a tooth to receive a restoration. The system includes a dental instrument for removal of portions of a tooth in the mouth of a patent and an overlay for guiding the dental instrument during the step of tooth removal. The overlay is designed for temporary installation into the mouth of the patient to guide the dental instrument to remove tooth material. The overlay has one or more sets of guide walls, with a predetermined configuration capable of contacting one or more guide projections of the dental instrument, and a receptacle capable of receiving and attaching to the dental instrument.

Owner:VIAX DENTAL TECH LLC

Zipper tooth manufacturing device and method and tooth arranging device

ActiveCN110193568AImprove material cutting efficiencyPrevent flying outSlide fastenersPunchingEngineering

The invention belongs to the technical field of zipper manufacturing, and particularly relates to a zipper tooth manufacturing device and method and a tooth arranging device. The zipper tooth manufacturing device comprises a sliding base, a cutting knife, a punching head and a stripping piece, wherein the cutting knife, the punching head and the stripping piece are arranged above the sliding base,a cutting plane is arranged on the upper side of the sliding base, the sliding base is internally provided with a wire rod channel, the front side of the sliding base is connected with a blanking die, a forming part is arranged on the blanking die, the wire rod channel is intermittently conveyed to the upper part of the cutting plane at a preset supply amount for each time, the sliding seat movesback and forth in a reciprocating mode, the cutter is in sliding contact with the cutting plane, a cutting edge is arranged at the front end of the cutting knife, the punching head is arranged abovethe cutting edge in a lifting mode, the stripping piece is arranged on the front side of the punching head in a lifting mode. According to the zipper tooth manufacturing device, when the device is used for cutting, the part of the wire rod protruding cutting plane enters the cutting edge along with the backward movement of the sliding seat, the material removing part is descended to the front sideof the wire rod in the cutting edge, the wire rod in the cutting edge is at least partially shielded, the wire rod is prevented from being thrown out instantly, the phenomenon that the wire is missing during subsequent tooth removal is avoided, the production efficiency is effectively improved, and the reworking rate is reduced.

Owner:广东顺德三扬科技股份有限公司

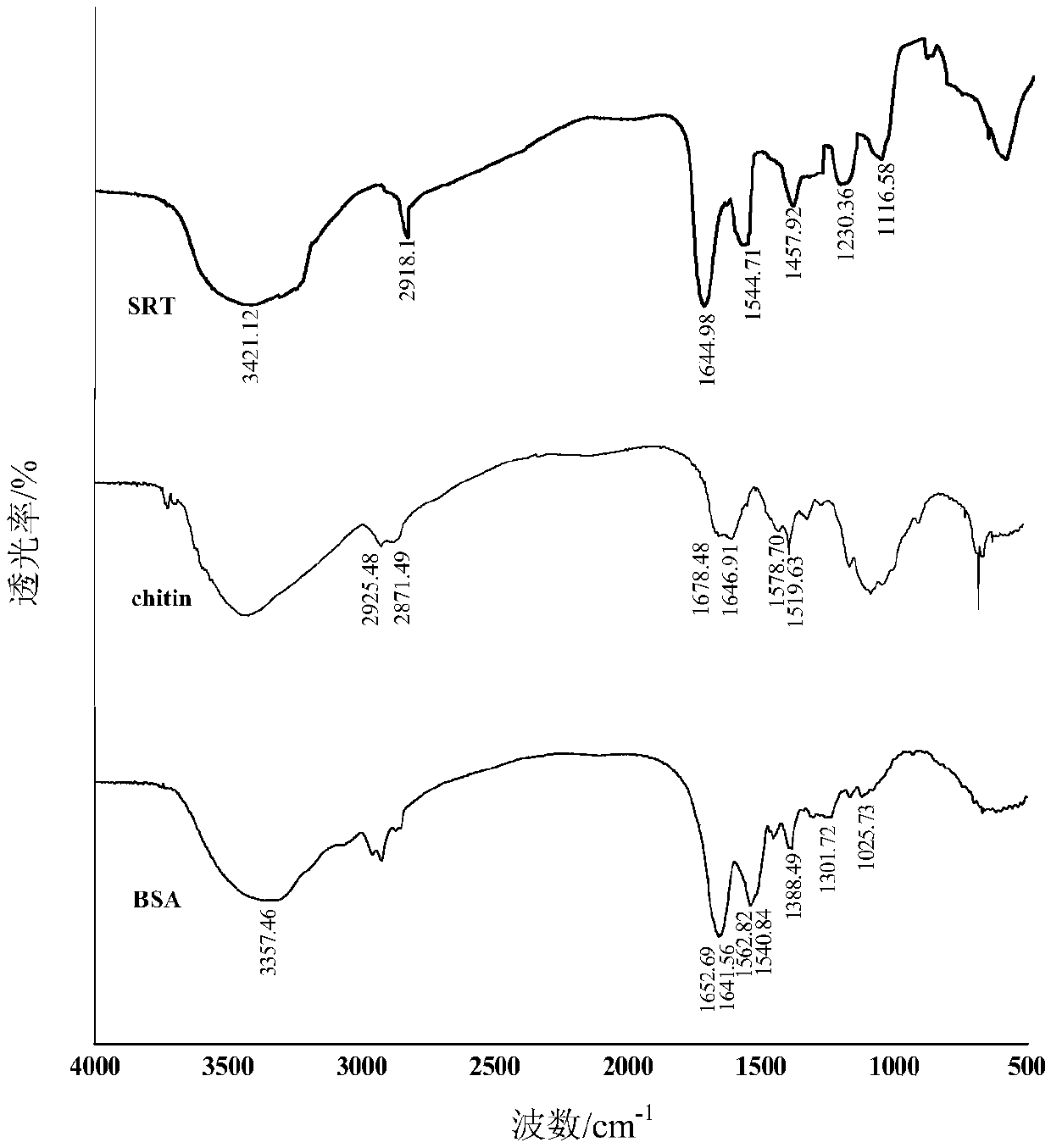

Processing technology of Peruvian squid whiskers

The invention relates to a processing technology of Peruvian squid whiskers. The method includes the following steps of pretreatment, osmosis treatment, pre-separation, rapid cooling, rolling tooth removal and enzymolysis and sucking-disc separation. Compared with a traditional method, the tooth removal rate is greatly improved (the tooth removal rate is higher than 96%), a physical means is usedfor tooth removal, the tooth removal cost is low, the process is environmentally friendly and free from pollution, the conditions of the Peruvian squid whiskers after tooth removal is good, and the quality of the Peruvian squid whisker products after tooth removal can be effectively ensured. Moreover, after tooth removal, biological enzymes are used for sucking-disc separation, the sucking-disc separation rate can reach 100%, residual ring teeth in the sucking disc can be effectively avoided, the separated sucking disc can be utilized, and thus a theoretical basis is provided for further development of squid production.

Owner:ZHEJIANG OCEAN UNIV

Normal-temperature instant sea cucumber millet porridge and preparation method thereof

The invention discloses normal-temperature instant sea cucumber millet porridge and a preparation method thereof. The preparation method comprises the following steps that (1) sea cucumbers are subjected to tooth removal and cleaning one by one and placed in a plate after being drained and enter a high-pressure cabin at 110 DEG C for 10 minutes, water-cooling desalting is conducted for 24 hours, and purified water is replaced 3-4 times for later use; (2) millet is cleaned and water is added for porridge cooking for later use; the sea cucumbers are subjected to 100-DEG C water blanching for 3 seconds, the sea cucumbers and the millet porridge are packaged in a bag or a food-grade plastic model together, air is exhausted, sealing is conducted, and the product is sterilized at 95 DEG C for 5minutes and at 110 DEG C for 10 minutes and then cooled and taken out of the cabin. The porridge is easy to prepare, and protein is retained through high temperature and high pressure, so that sea cucumber collagen is solidified instantly; the millet is easier to absorb by the human body after long-time cooking.

Owner:吴强

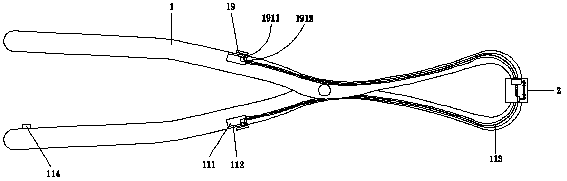

Vibration dentarpage

The invention discloses a vibration dentarpage which comprises a pair of dental forceps and a vibrator fixed on the pair of dental forceps, wherein the pair of dental forceps comprises a forceps headand a forceps handle; the vibrator is sequentially divided into a vibration device for fixing and vibrating teeth and a power device provided with a motor by a partition; the vibration device comprises vibration element arranged on the two sides of the teeth and a power element connecting the vibration elements on the two sides; the vibration elements comprise vibration plates clung to the teeth,springs fixed with the vibration plates and push plates; one side of each push plate is fixed with the forceps head; the other side of each push plate is fixed with each spring; the power element comprises an extension cylinder connecting the vibration elements on the two sides, a vibration block located in the extension cylinder, and a driving rod connecting the vibration block and the power block; the power device comprises a transmission device; one end of the transmission device is connected with the motor; and the other end of the transmission device connected with the power block. The dentarpage loosens tooth roots by reciprocated impacting of dental crowns, and therefore reduces wisdom tooth and decayed tooth removal difficulty.

Owner:HUNAN UNIV OF CHINESE MEDICINE

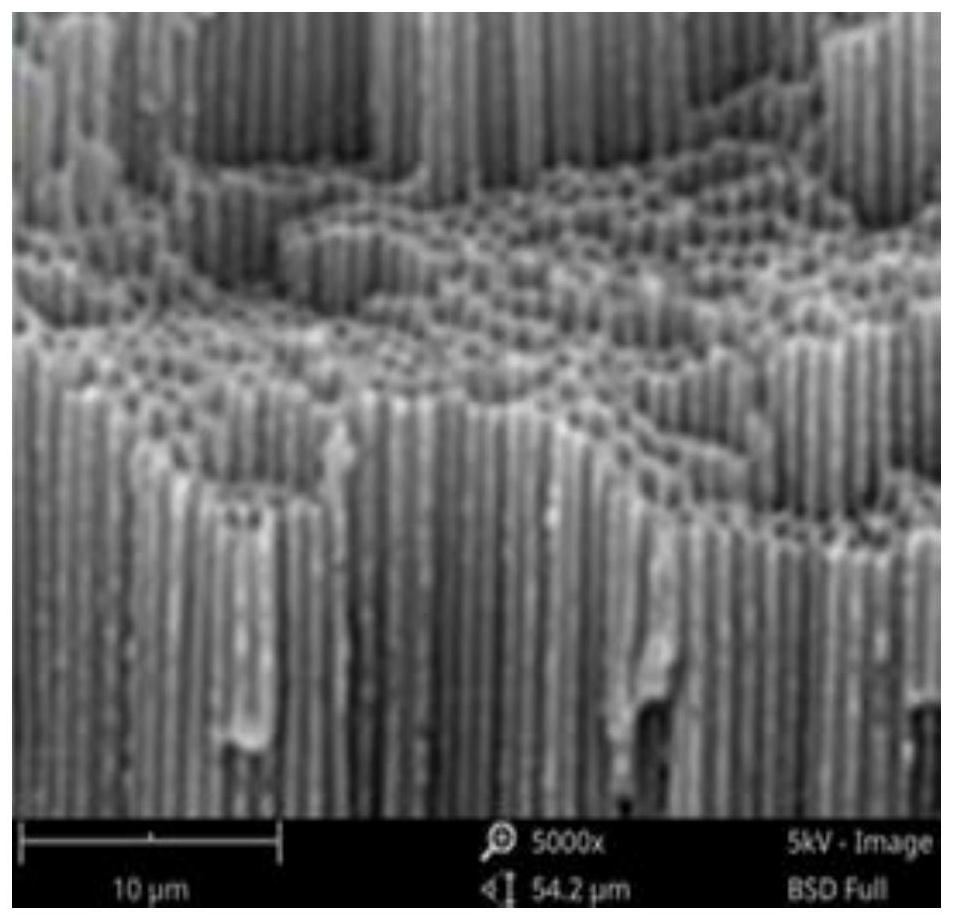

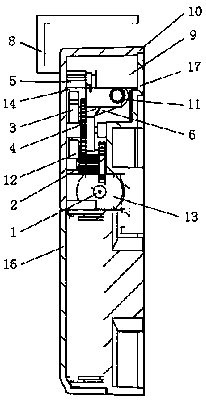

Implants and methods for performing gums and bone augmentation and preservation

ActiveUS8142194B2Promote growthFacilitate regrowth of the gumsDental implantsImpression capsExtraction siteBreast augmentation

Embodiments described herein are related to fillers that are placed within an extraction site in need of bone augmentation and preservation. The fillers encourage sufficient new bone growth in order that normal jaw bone deterioration following tooth removal is prevented. The fillers create, arrange, and assemble an ideal growth environment for new bone growth to rapidly grow and preserve the original contours of an individual's jaw bone. Further embodiments described herein are related to dental implants that are arranged to provide a scaffold upon which a damaged or missing dental papilla may regrow. The dental implants may include a micro-pattern to facilitate directional cell growth.

Owner:INNOVATIVE HEALTH TECH

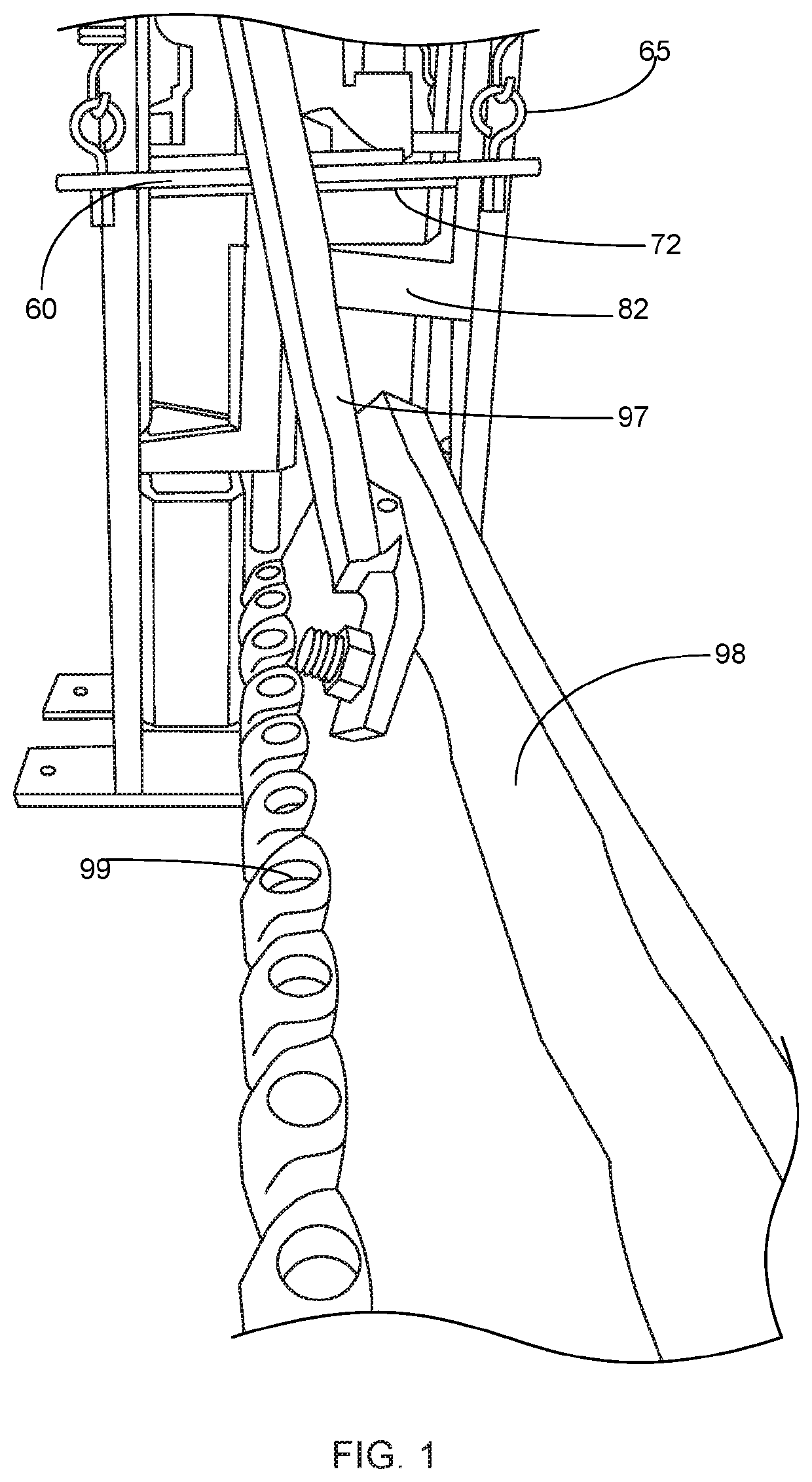

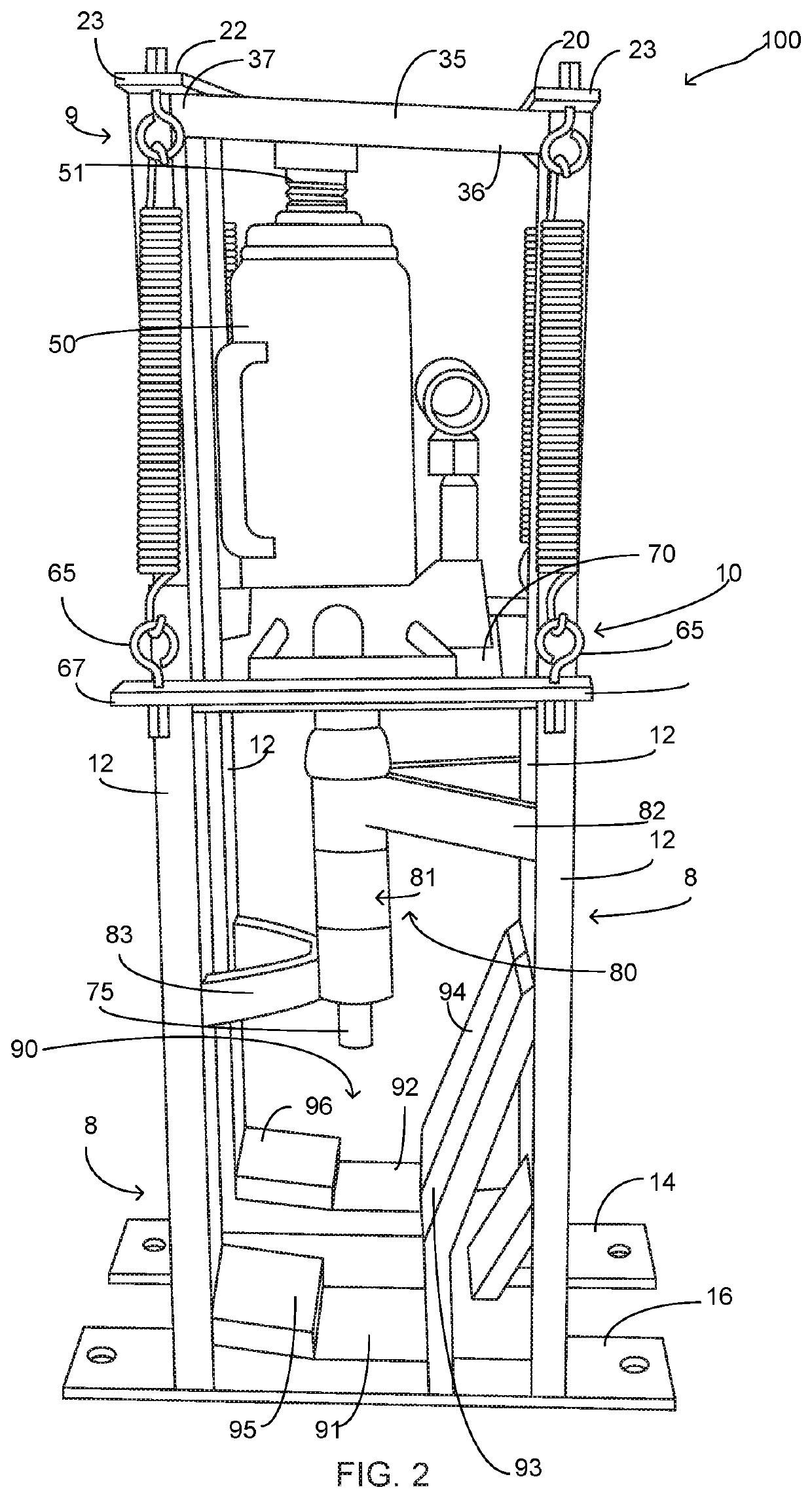

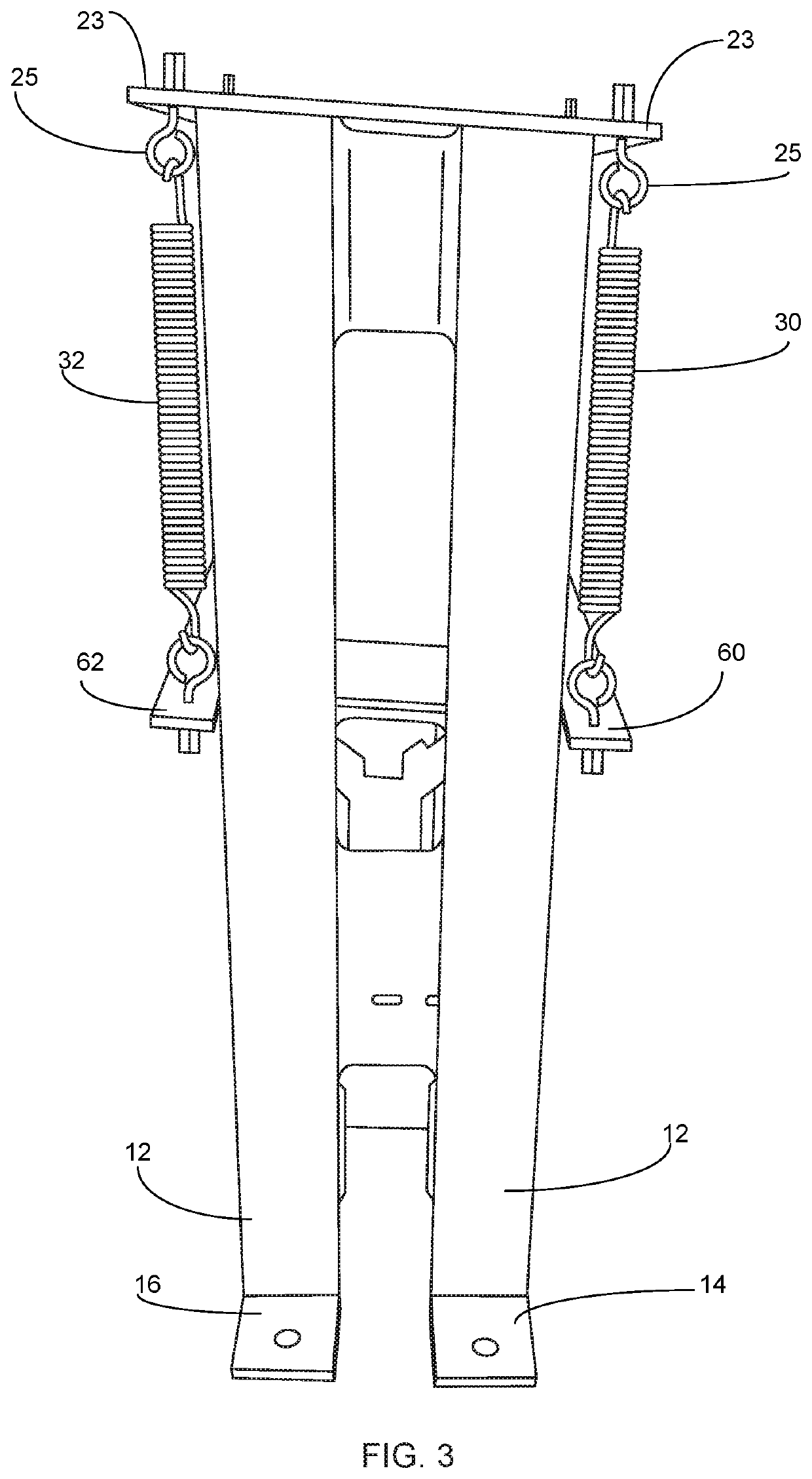

Road grader blade teeth removal apparatus

ActiveUS11274423B2Mechanical machines/dredgersMetal-working hand toolsStructural engineeringTooth removal

A road grading blade teeth removal apparatus operable to provide removal of teeth from a road grader blade. The apparatus of the present invention includes a frame having an upper end and a lower end. The upper end of the frame has a pair of upper spring mounts secured thereto on opposing sides of the frame. The upper spring mounts have springs suspended downward therefrom and are operably coupled to a pair of lower spring mounts that are axially aligned with each of the upper springs mounts on opposing sides of the frame. A center force plate is secured intermediate the lower spring mounts and has a movement member superposed thereon. The movement member is further operably coupled to a cross member proximate the top of the frame and is configured to leverage thereagainst to move the center force plate downward. A pin assembly is located underneath the mounting plate.

Owner:GORDON G DENNIS

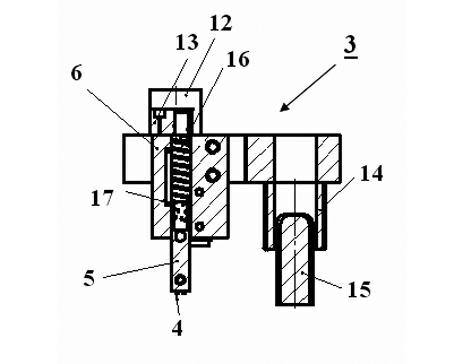

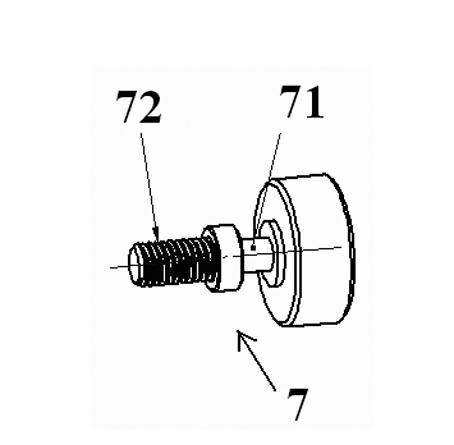

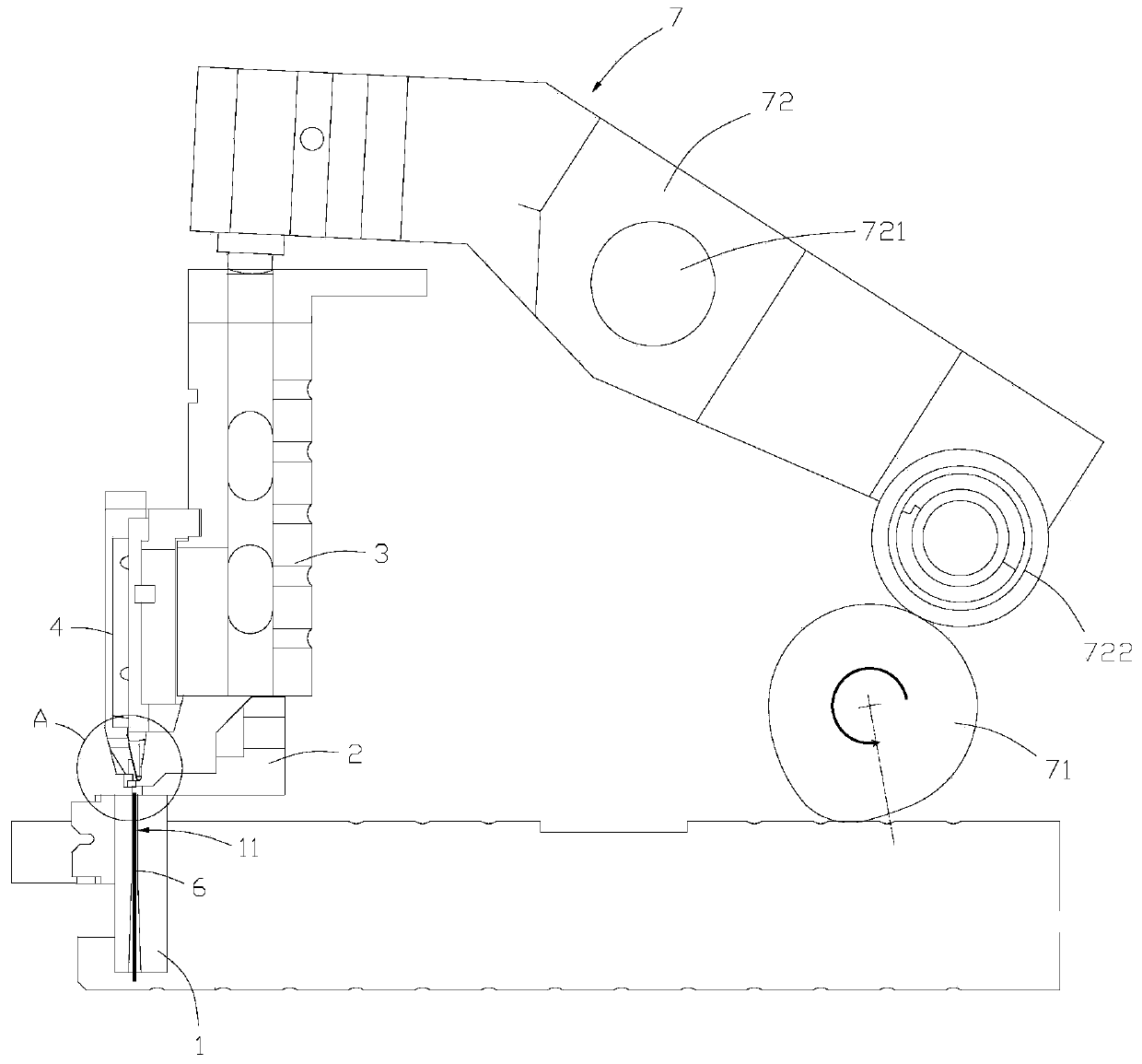

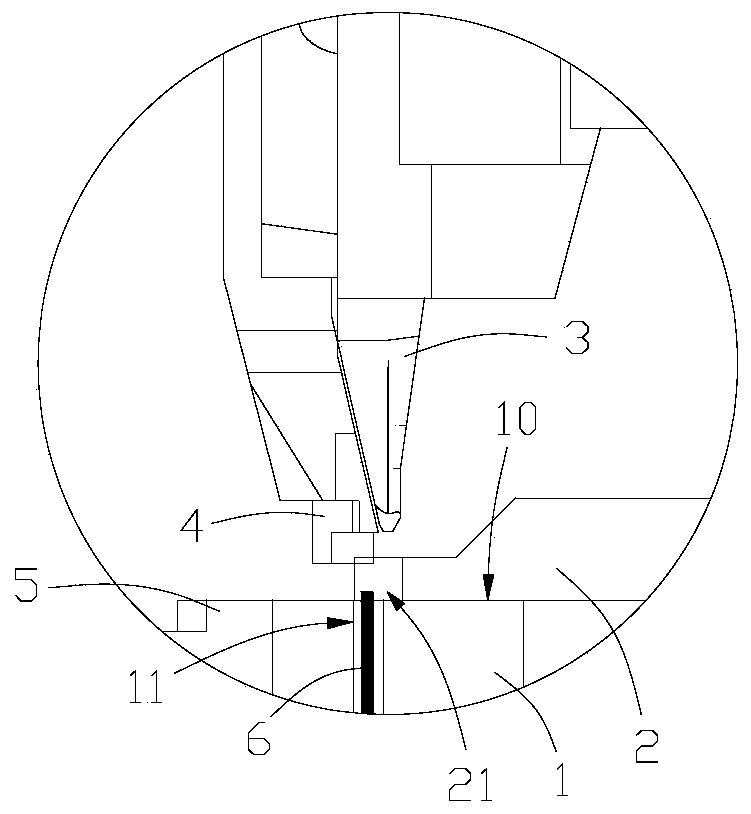

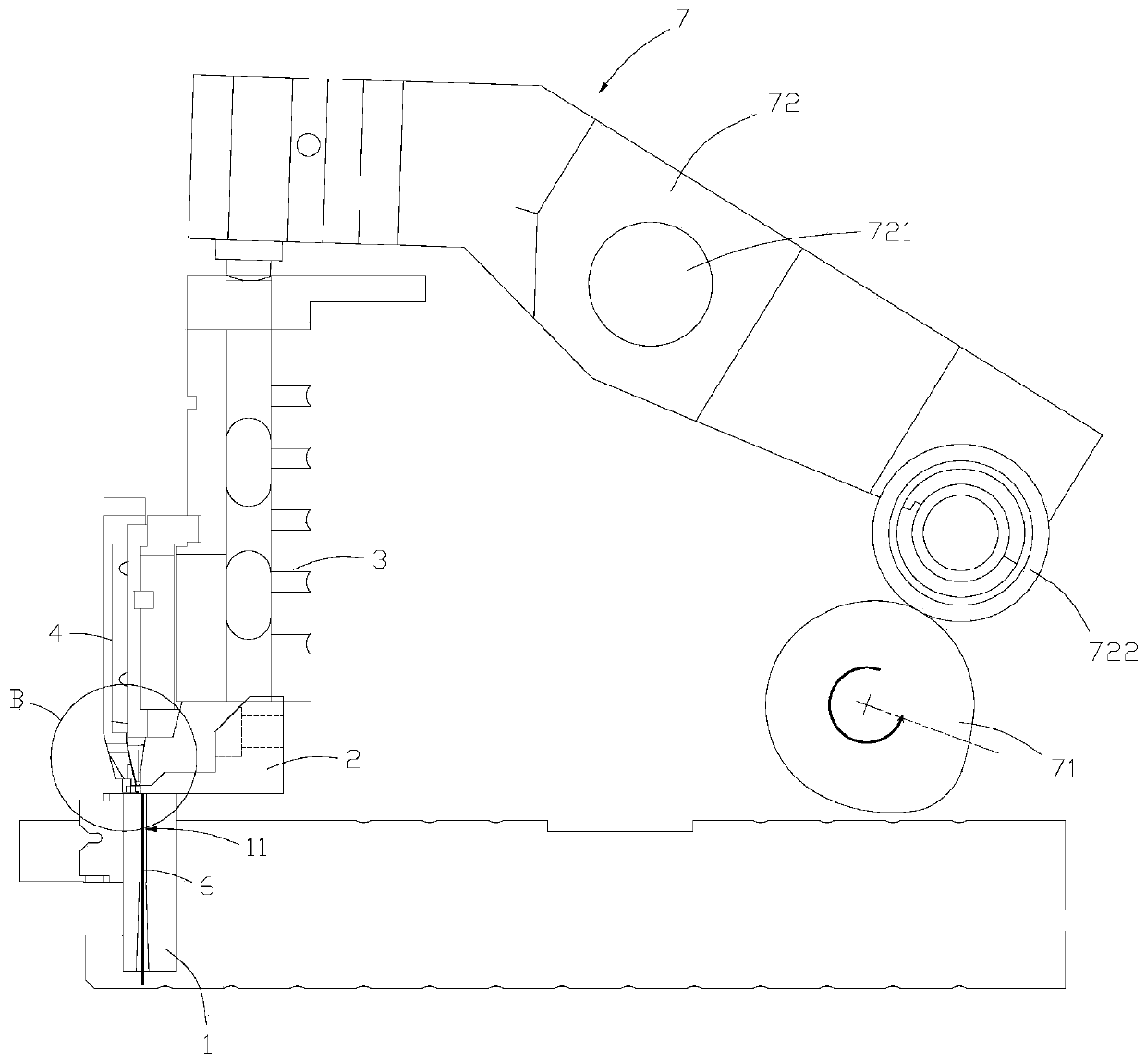

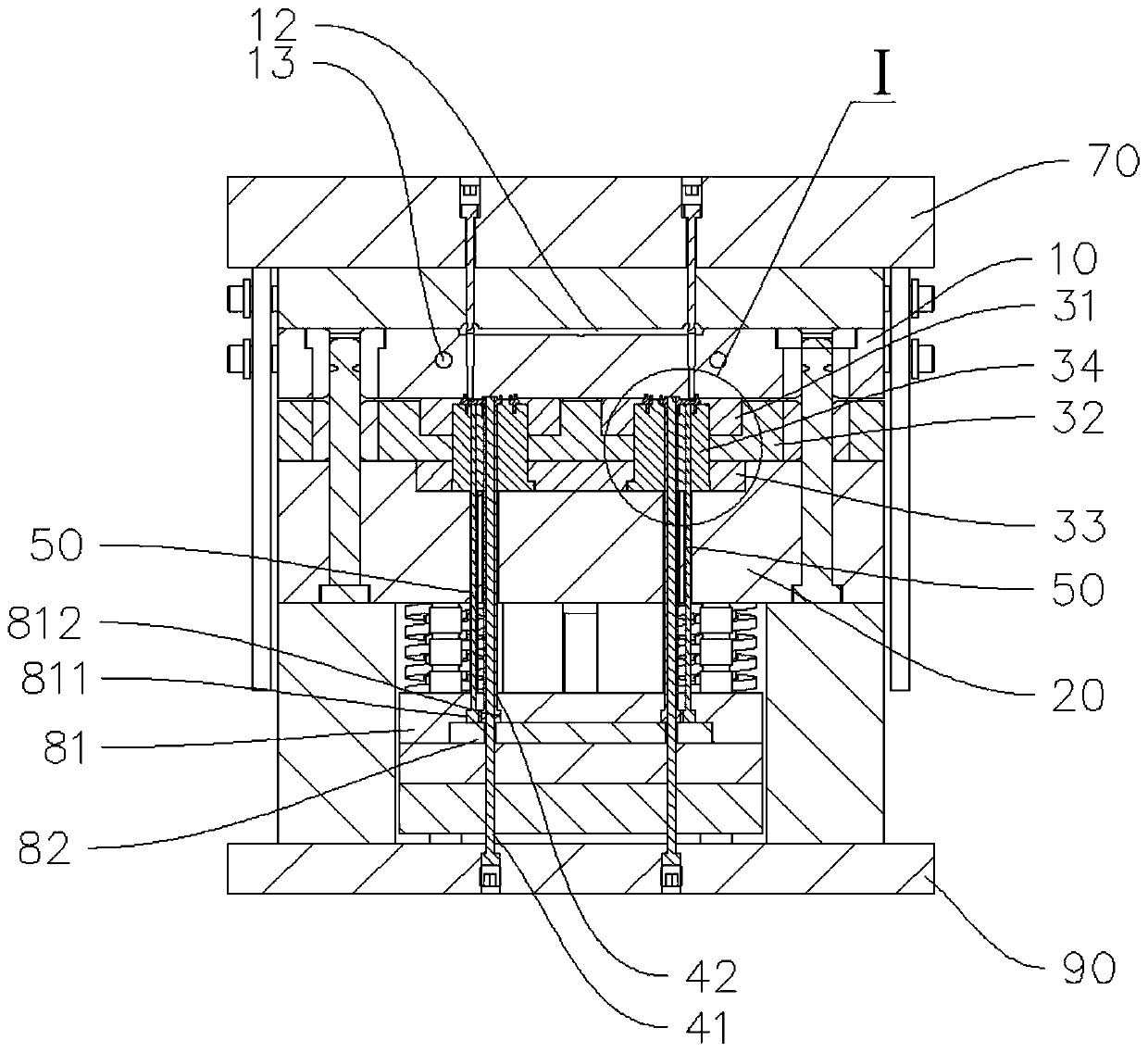

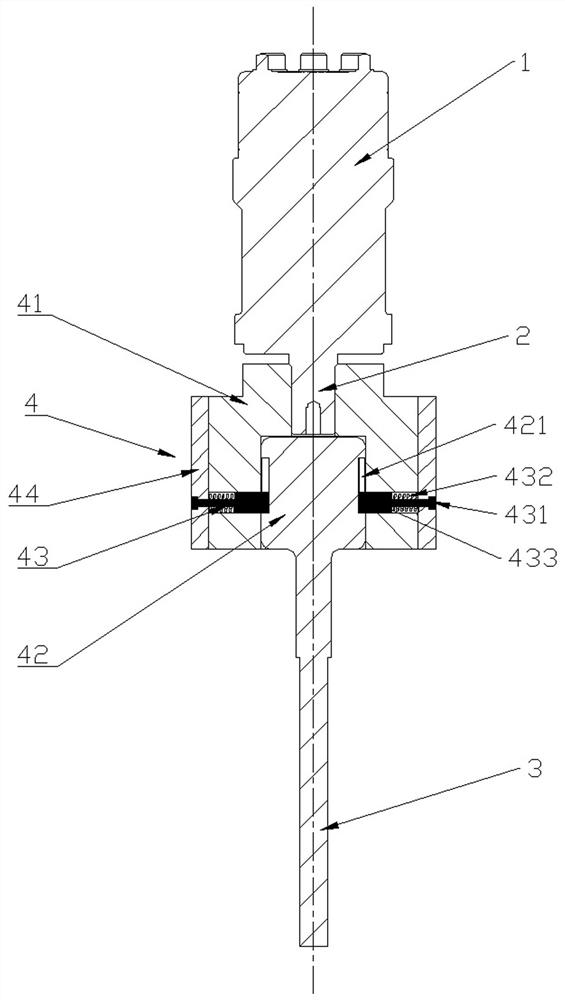

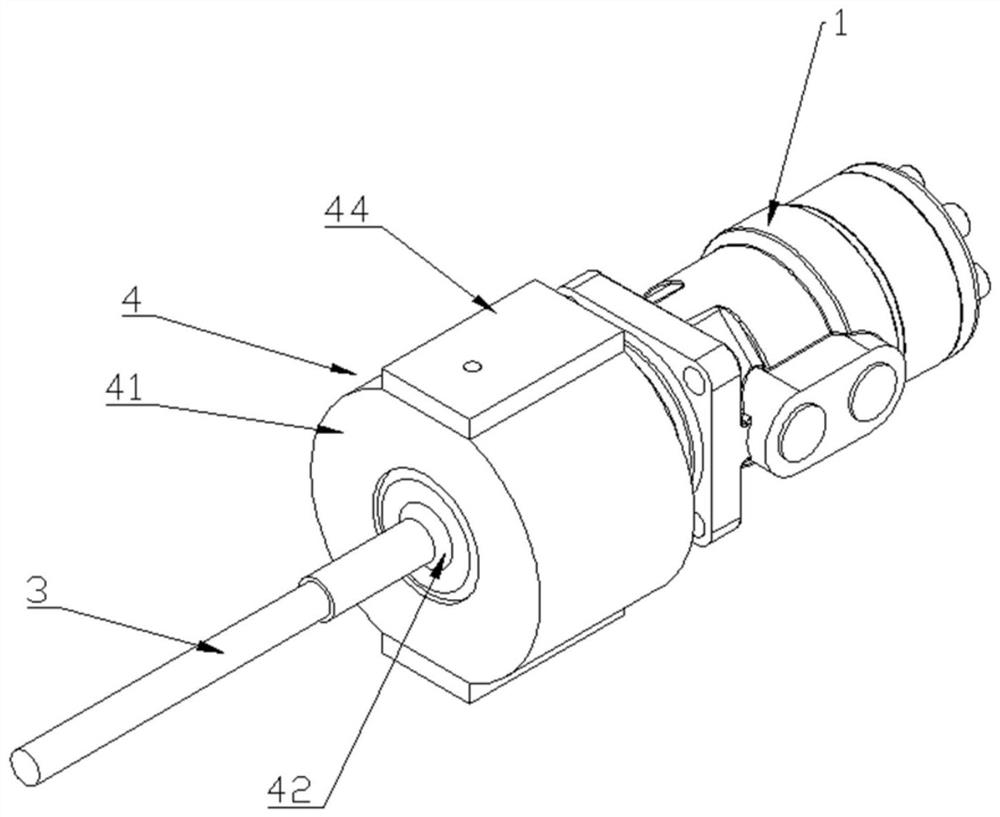

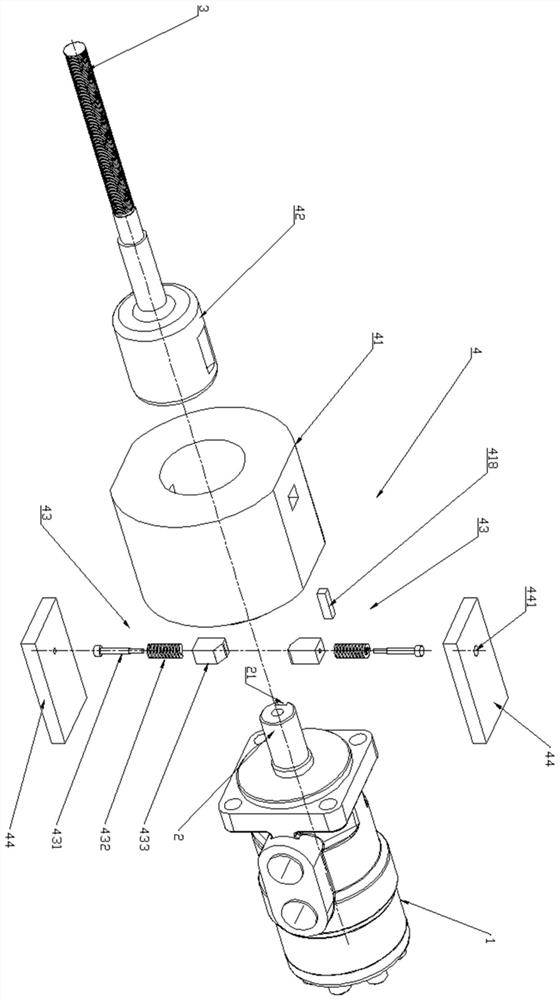

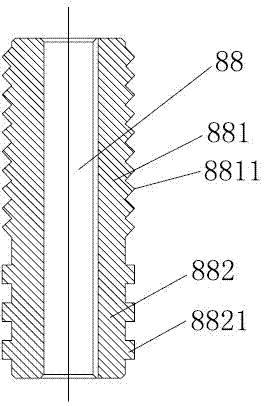

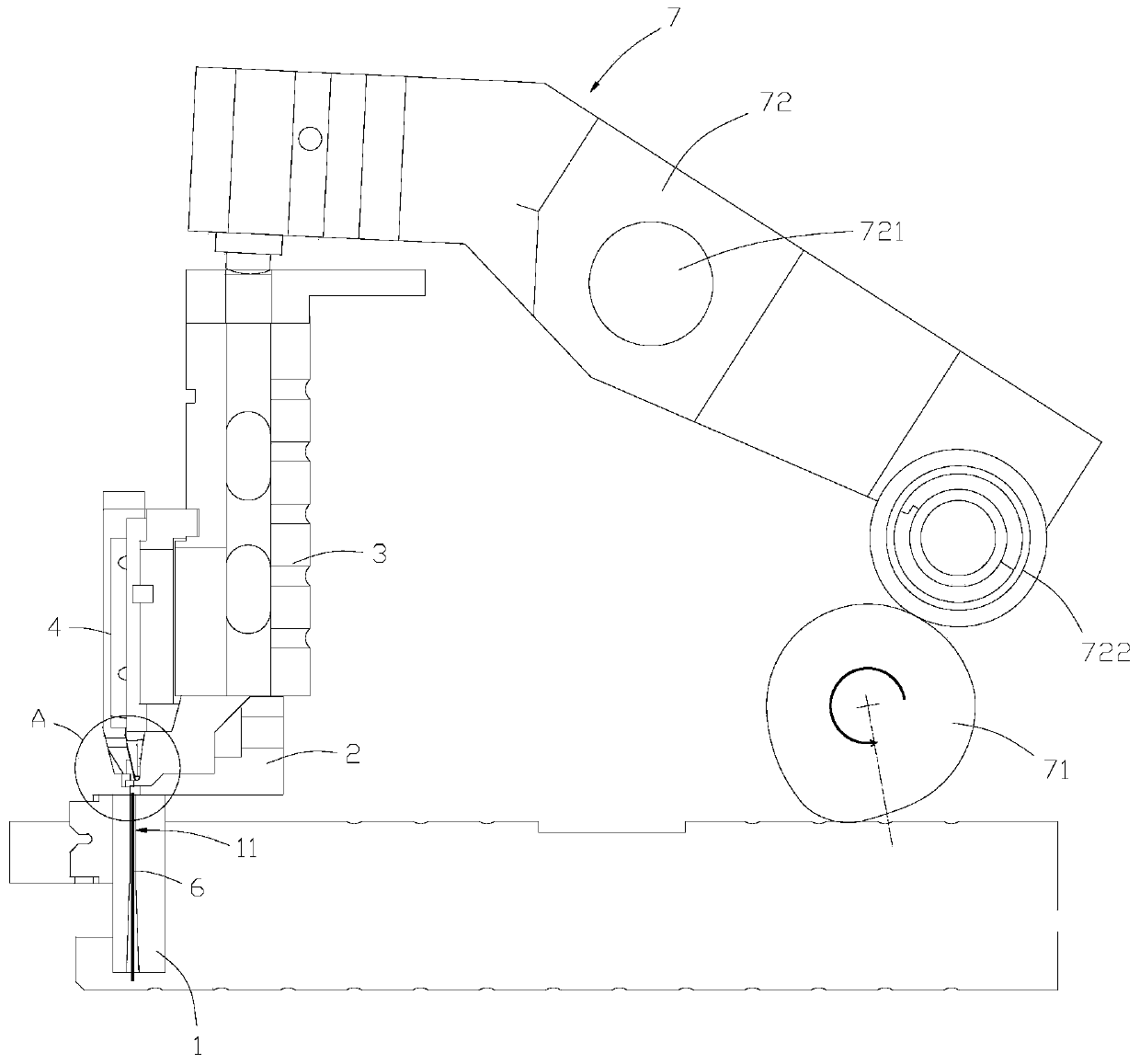

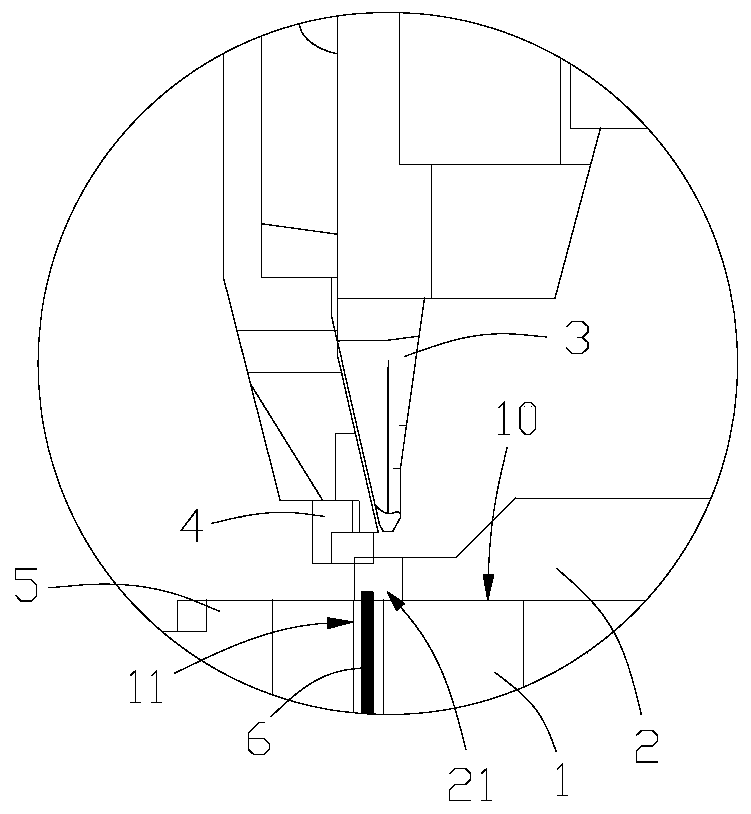

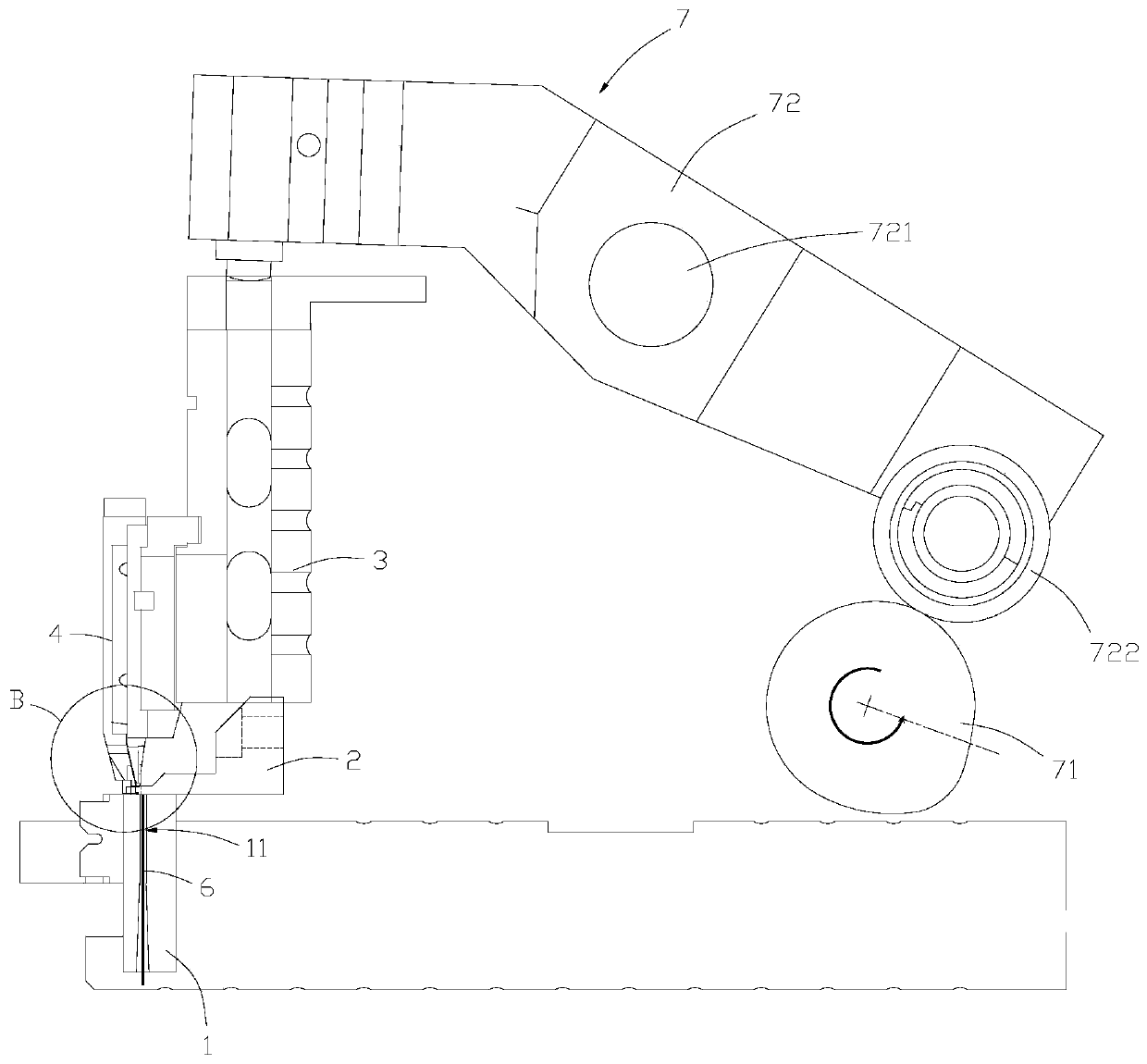

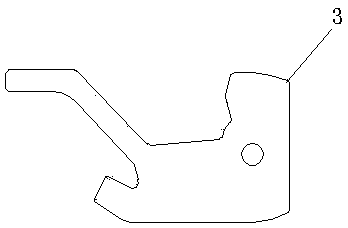

Cathode wire machining mechanism

ActiveCN110064691AReduce processing stepsImprove processing efficiencyElectrode constructionsProcess efficiency improvementEngineeringTooth removal

The invention discloses a cathode wire machining mechanism. The cathode wire machining mechanism comprises a discharge tooth machining unit and a discharge tooth removal unit, wherein the discharge tooth machining unit is arranged on a workbench of a press machine, the discharge tooth machining unit is used for machining discharge teeth, and the discharge tooth removal unit is used for removing the discharge teeth; the discharge tooth machining unit comprises a tooth forming grinding tool; and the discharging tooth removal unit comprises a tooth removing die, a movable plate, a sliding column,an elastic piece and a linkage mechanism, the sliding column is arranged on the workbench, the sliding column is connected with the movable plate in a sliding manner, the elastic piece is arranged between the movable plate and the workbench, the linkage mechanism comprises a cross rod and a stud, the cross rod is connected with a press slide block, and the stud is arranged above the movable plateand connected with a threaded hole of the cross rod. The discharge tooth machining unit and the discharge tooth removal unit are integrated to the workbench of the press machine, so that the functions of synchronously machining the discharge teeth in the middle of a cathode wire and removing the discharge teeth at the end of the cathode wire are realized, the machining efficiency is greatly improved, the field, equipment and labor use are reduced, and the production cost is reduced.

Owner:JIANGSU YONGJI CHEM EQUIP

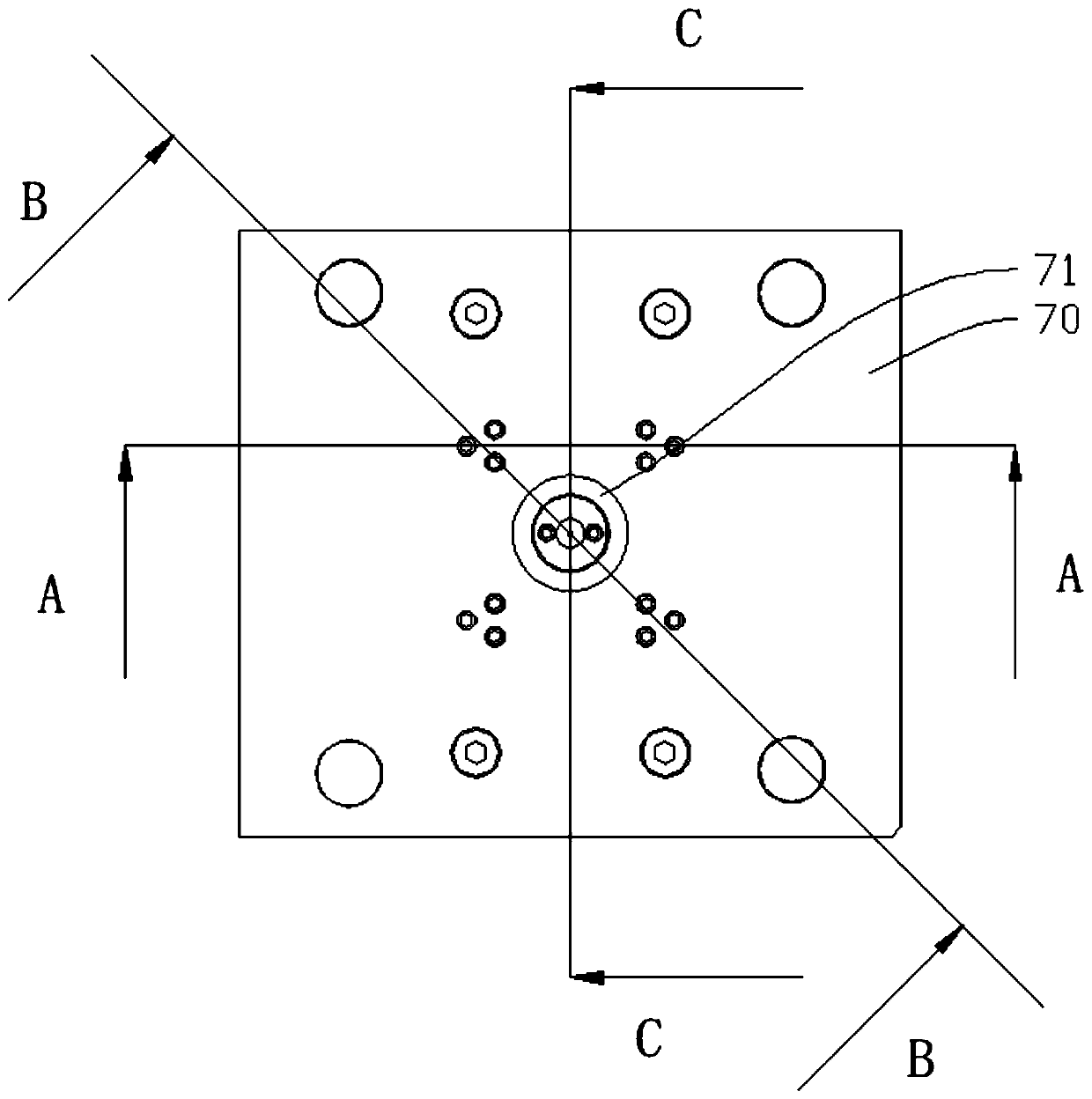

Bevel gear injection mold and bevel gear

InactiveCN111231244AAchieve demouldingPrevent rotationPortable liftingGear wheelsGear wheelTooth removal

The invention relates to the technical field of molds, and provides a bevel gear injection mold and a bevel gear. Through the arrangement of a mold core, an ejector pin, a push rod, a first mold plateand a second mold plate, during demolding, after the first mold plate is lifted, a push plate is pushed upwards firstly, and meanwhile, a forming plate and a product are pushed away from a bearing piece together; and therefore, a bevel gear product is degummed from a second concave cavity of the bearing piece and is separated from an axis rod of the push rod, and the second concave cavity is prevented from hindering the rotation of the bevel gear product when the bevel gear is disengaged. The product is ejected twice through a sleeve of the push rod, so that the tooth removal of the bevel gear product is realized, in the process, due to the fact that the bottom of the product is degummed, rotation is not affected during tooth disengaging, when the product is subjected to tooth disengaging, the product can rotate relative to the forming plate, the bevel gear rotates along an inner gear ring of the forming plate to be subjected to tooth disengaging, and product demolding is achieved.

Owner:东莞力浦精密电子有限公司

Method for removing teeth of sea mushroom

InactiveCN109673712AAchieve separationDetoxification achievedCephalopods processingSeparated stateWater flow

The invention relates to a method for removing teeth of sea mushroom. The method comprises the following steps: firstly, raw material treatment: thawing frozen sea mushroom blocks to a half-thawed state under the action of 4 DEG C water flow; secondly, rolling treatment: carrying out rolling treatment on the sea mushroom in the half-thawed state; thirdly, ultrasonic treatment: carrying out ultrasonic treatment on the sea mushroom subjected to the rolling treatment, wherein the ultrasonic power is 400 to 800W, the ultrasonic frequency is 35 to 40 Khz, and the ultrasonic time is 30 to 40 min; fourthly, rolling and removing teeth: using a tooth removal device to treat the sea mushroom subjected to the ultrasonic treatment. According to the method disclosed by the invention, ring teeth and a sucker are enabled to reach an initial separation state through the rolling treatment and the ultrasonic treatment; then through the rolling action of the tooth removal device, the ring teeth are crushed in a brittle state and completely separate from the sucker; under the flushing of high pressure water, ring tooth fragments completely separate from the sucker, so that the separation of the ring teeth of the sea mushroom is realized and the tooth removal rate can reach about 100 percent.

Owner:ZHEJIANG OCEAN UNIV

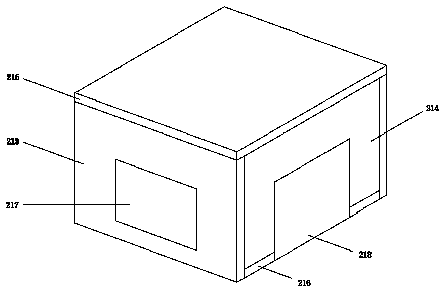

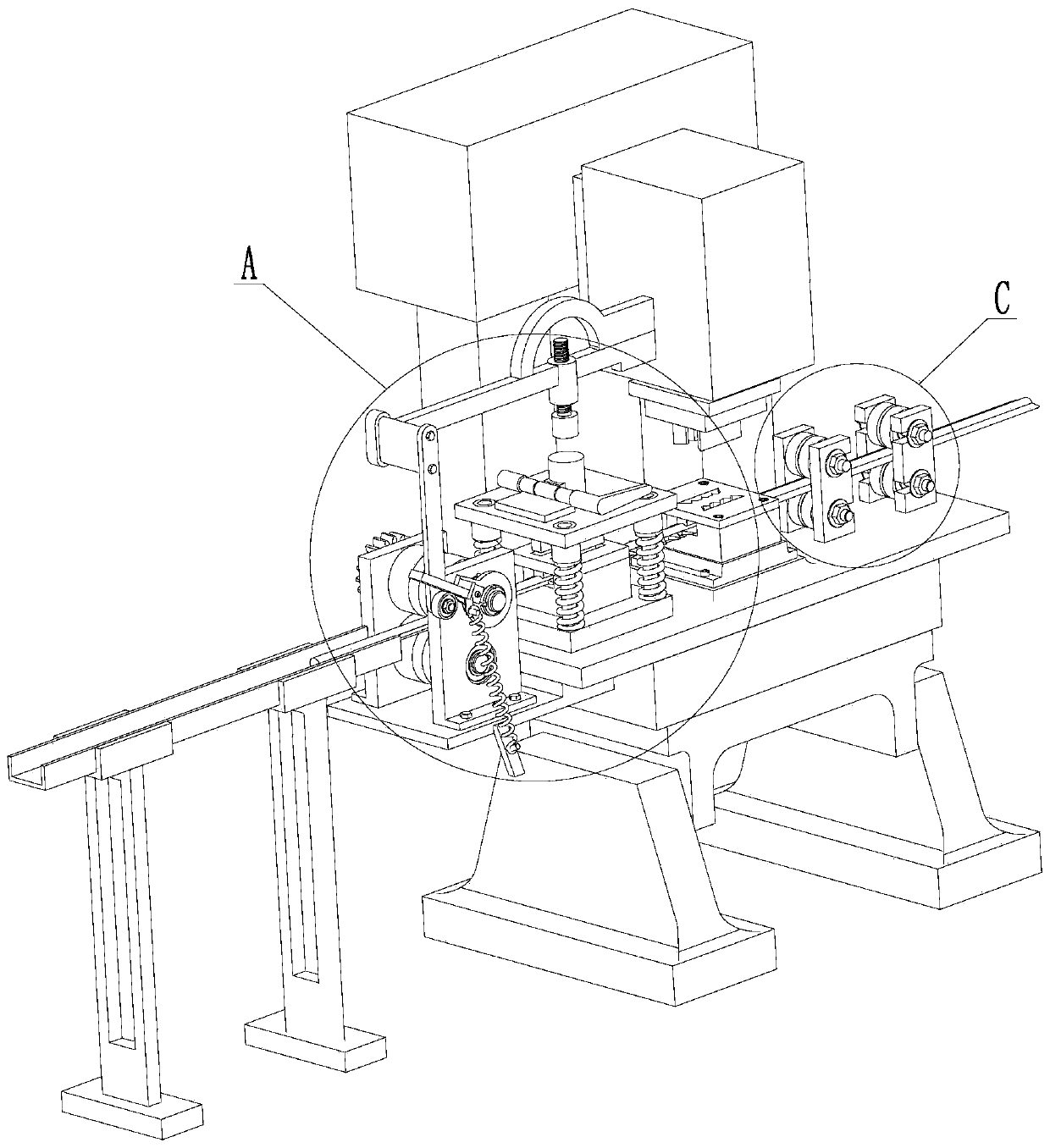

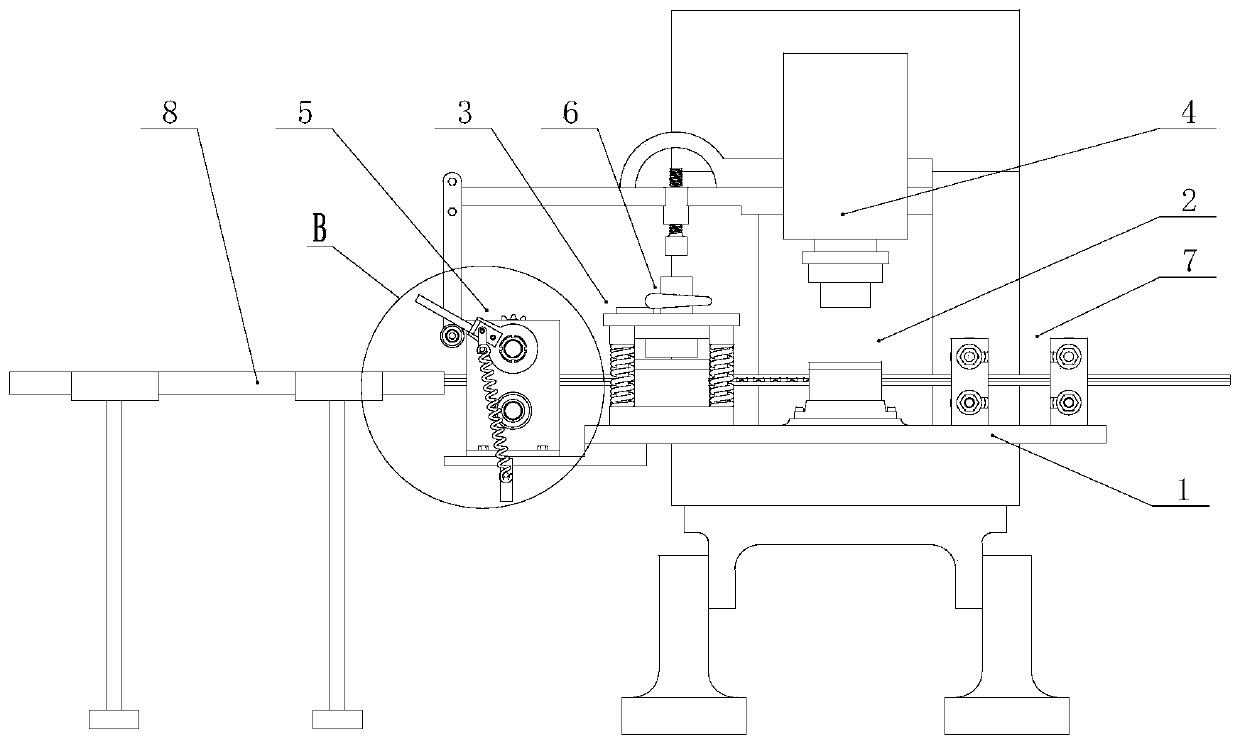

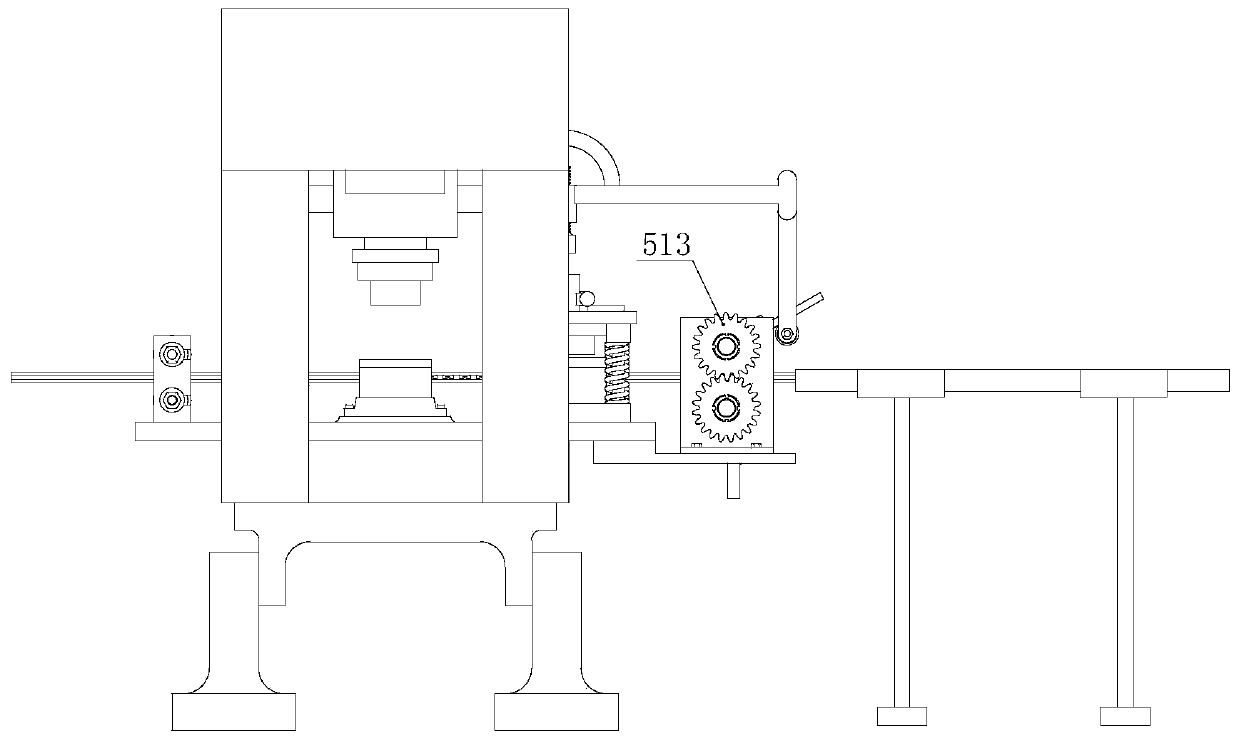

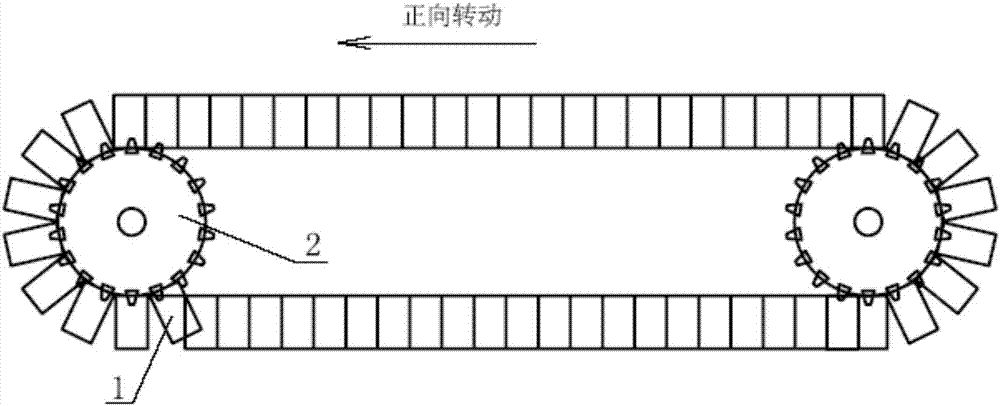

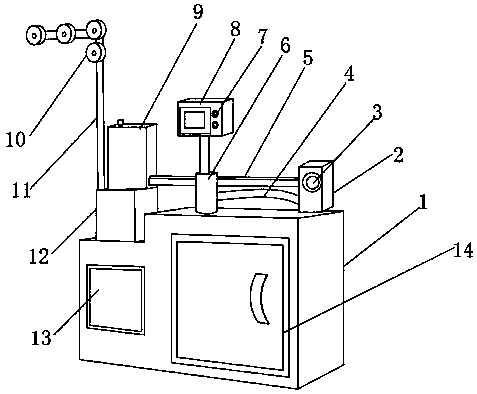

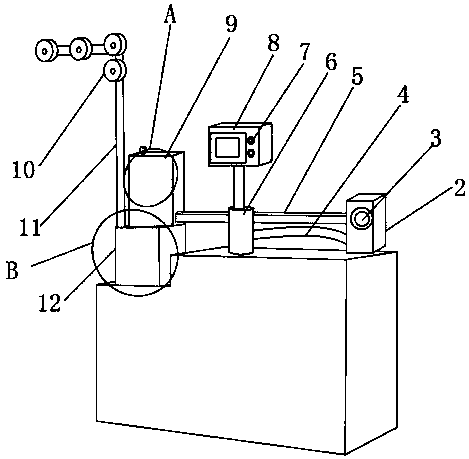

A gear removal and sizing machine for zipper production

InactiveCN104207425BAdjust the efficiency of tooth removalEfficient and precise tooth removalSlide fastenersEngineeringTooth removal

Owner:东莞市达成手袋配件科技有限公司

A treatment process for squid sucker ring teeth

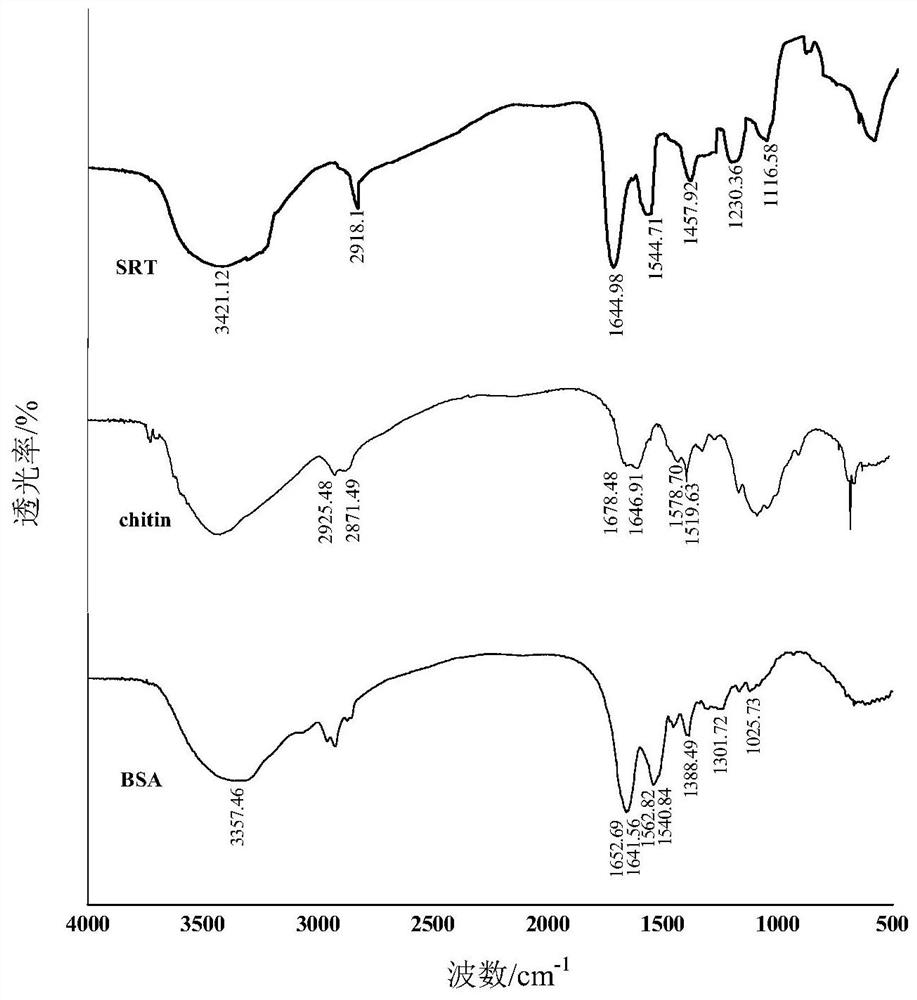

InactiveCN109619153BGood conditionGuaranteed qualityCephalopods processingPolymer scienceTooth removal

The invention relates to a treatment process for squid sucker ring teeth, which comprises the following steps: (1) pretreatment: thawing frozen squid whiskers, cleaning and draining, and standby; (2) infiltration treatment: under vacuum conditions, the pretreated Put the squid whiskers into the permeate; (3) Pre-separation: Place the pretreated squid whiskers on a heating plate, then place an extrusion plate on the squid whiskers, heat at 60°C-80°C for 2-4s, the heating process Squeeze squid whiskers with extrusion plate at the same time; (4) rapid cooling: put the squid whiskers after pre-separation into fluidized ice solution to cool; (5) enzymatic detoxification: adopt flavor enzyme and collagenase to cool The squid whiskers are enzymatically hydrolyzed to separate the ring teeth from the squid whiskers. The invention greatly improves the tooth removal rate (the tooth removal rate is higher than 96%), and adopts the combination of physical means and biological means for tooth removal, which has low cost of tooth removal, environmental protection and no pollution, and the appearance of squid whiskers after tooth removal is good. The added value of the product is high, which can effectively guarantee the quality of squid whiskers after tooth removal.

Owner:ZHEJIANG OCEAN UNIV

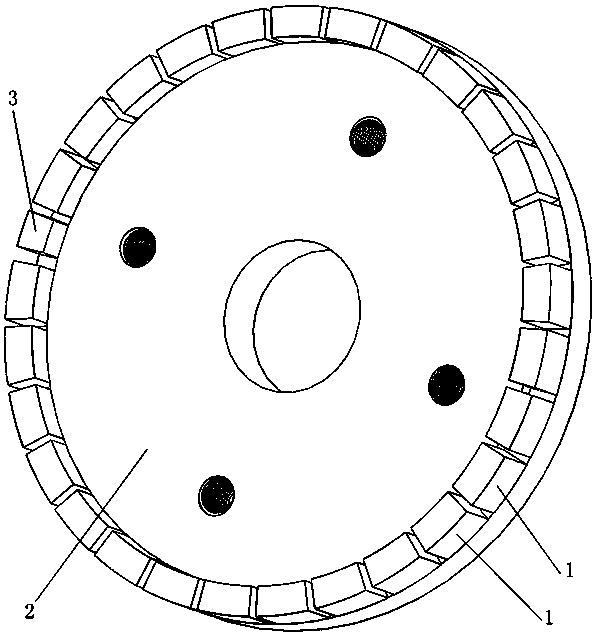

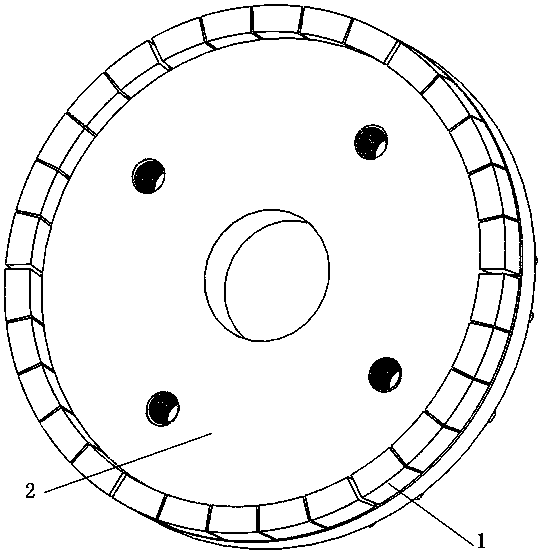

A processing technology of ceramic tile grinding tool with iron bottom

ActiveCN109848877BReduce vibrationHigh tooth connection strengthGrinding devicesAcid washingTooth removal

The invention relates to a production technology of a ceramic tile grinding tool with an iron bottom. The ceramic tile grinding tool with the iron bottom adopts a sintered grinding head and uses screws and nuts to lock the grinding head to a metal plate, grinding teeth (1), the screws (11) and the iron bottom (12) are sintered together, then the sintered grinding head is locked by the nuts, and aproduction technology of welding the grinding teeth is not adopted. The ceramic tile grinding tool produced by the production technology is high in grinding tooth connection strength, difficulty in tooth removal, uniform in distribution of the grinding teeth, uniform in stress during grinding and small in vibration of a grinding machine, expensive silver-zinc welding pieces are not needed, and thecost is saved; and time-consuming production technologies such as acid washing, water washing and air drying which are harmful to human health are not adopted, and over-welding is eliminated.

Owner:ZHANGJIAJIE INST OF AERONAUTICAL ENG

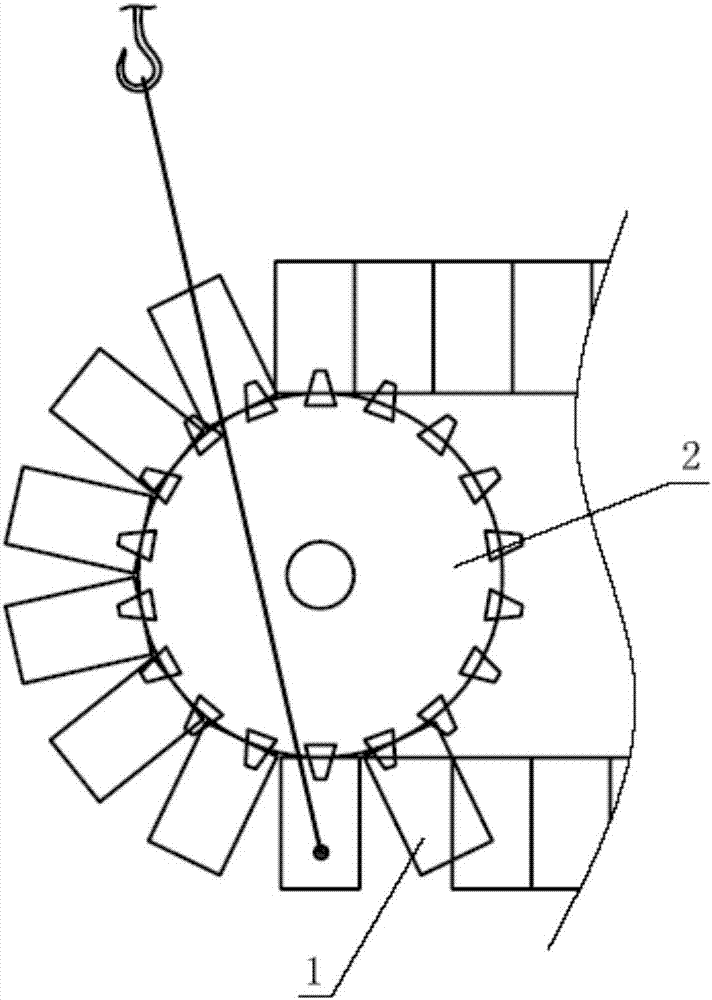

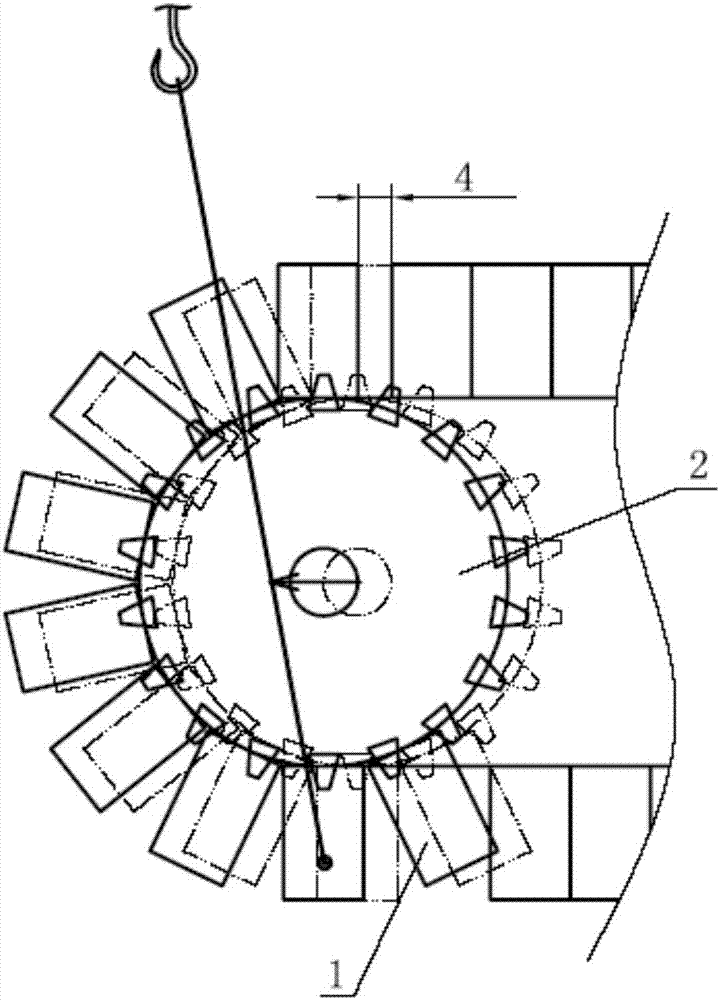

The method of removing the teeth of the sintering machine trolley stuck in the tail star wheel

ActiveCN105651054BImprove work efficiencyShorten maintenance timeFurnace typesTooth removalComputer science

The invention discloses a disengaging processing method for a trolley blocked on a tail star wheel of a sintering machine, provides the disengaging processing method capable of quickly processing the trolley blocked on the tail star wheel of the sintering machine, and belongs to the technical field of sintering machines. The disengaging processing method comprises the following steps: hanging the trolley positioned below the star wheel at the tail part end of the sintering machine by use of a tail crane; then, ejecting a tail swing frame towards the tail part by a distance being 150mm-200mm, and controlling the sintering machine to positively and negatively rotate, thereby providing an enough space for dropping a to-be-disengaged trolley; and finally, vibrating the start wheel at the tail part end for smoothly dropping the to-be-disengaged trolley onto a lower operation rail, thereby realizing the disengaging processing. According to the disengaging processing method, the maintenance time of the disengaging processing can be greatly shortened, so that the whole maintenance process only needs about 4 hours, and therefore, the working efficiency of the sintering machine can be effectively improved, and the maintenance cost and the operation cost are reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

A screw rotating device for automatic tooth removal

ActiveCN113028015BEasy to replaceReduce manufacturing costSlip couplingGearingDrive shaftElectric machinery

The invention provides a screw rotating device for automatic tooth removal, which belongs to the technical field of manufacturing equipment. It includes a motor, a transmission shaft and a screw, and the transmission shaft and the screw are connected by an automatic tooth removal component, wherein the automatic tooth removal component includes an outer sleeve and an inner sleeve, the outer sleeve is fixedly connected to the transmission shaft, and the screw is fixedly connected to the inner cylinder. The outer sleeve is set outside the inner cylinder and is relatively fixedly connected to the inner cylinder through elastic parts; in normal state, the motor drives the transmission shaft to rotate, which in turn drives the outer sleeve, inner cylinder and screw to rotate synchronously. When the screw rotation is limited, the inner The sleeve and the outer sleeve are separated from the fixed connection state, and the outer sleeve can slide and rotate outside the inner sleeve to realize the automatic tooth removal of the screw. In the present invention, the screw and the transmission shaft are not fixedly connected, but relatively fixedly connected through the automatic detooth assembly. Normally, the screw and the transmission shaft rotate synchronously. When the rotation of the screw is limited, the screw and the transmission shaft are disconnected, and the screw will not Over-rotate with the drive shaft to protect the screw.

Owner:ZHEJIANG CHIXIN IND CO LTD

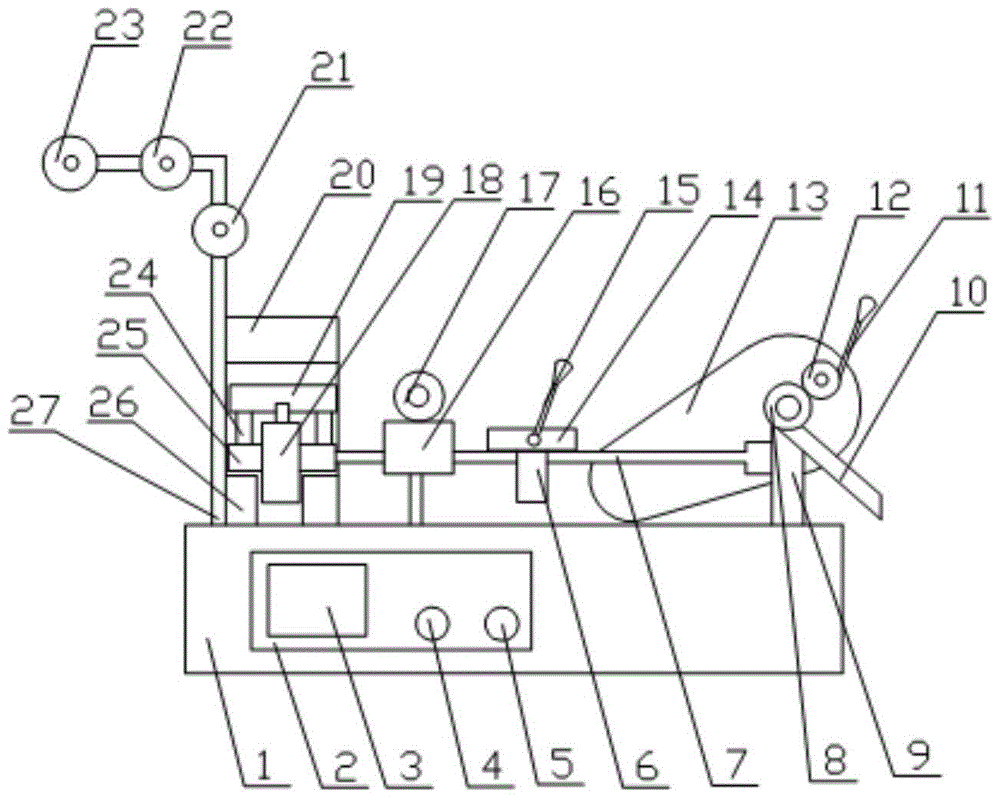

Tooth removal and size determination machine for large-scale zipper production

The invention discloses a tooth removal and size determination machine for large-scale zipper production. The tooth removal and size determination machine comprises a workbench and a waste collectionmodule, a collection cabinet is fixedly mounted on the outer surface of the front end of the workbench, and a storage cabinet is fixedly mounted on the outer surface of the front end of one side, close to the collection cabinet, of the workbench. A transmission module is fixedly mounted on the outer surface of the upper end of the workbench, a transmission wheel is movably mounted on the outer surface of the front end of the transmission module, a display screen is arranged above a controller, and the controller is fixedly mounted on the outer surface of the upper end of one side, close to thetransmission module, of the workbench. The tooth removal and size determination machine for large-scale zipper production is provided with the waste collection module, the collection cabinet and a lower tooth removal knife, waste materials can be collected to keep tidiness of an operating environment, operators can collect tools conveniently, tooth cutting speed can be increased, production efficiency is improved, and a promising application prospect is achieved.

Owner:安徽安丰五金压铸有限公司

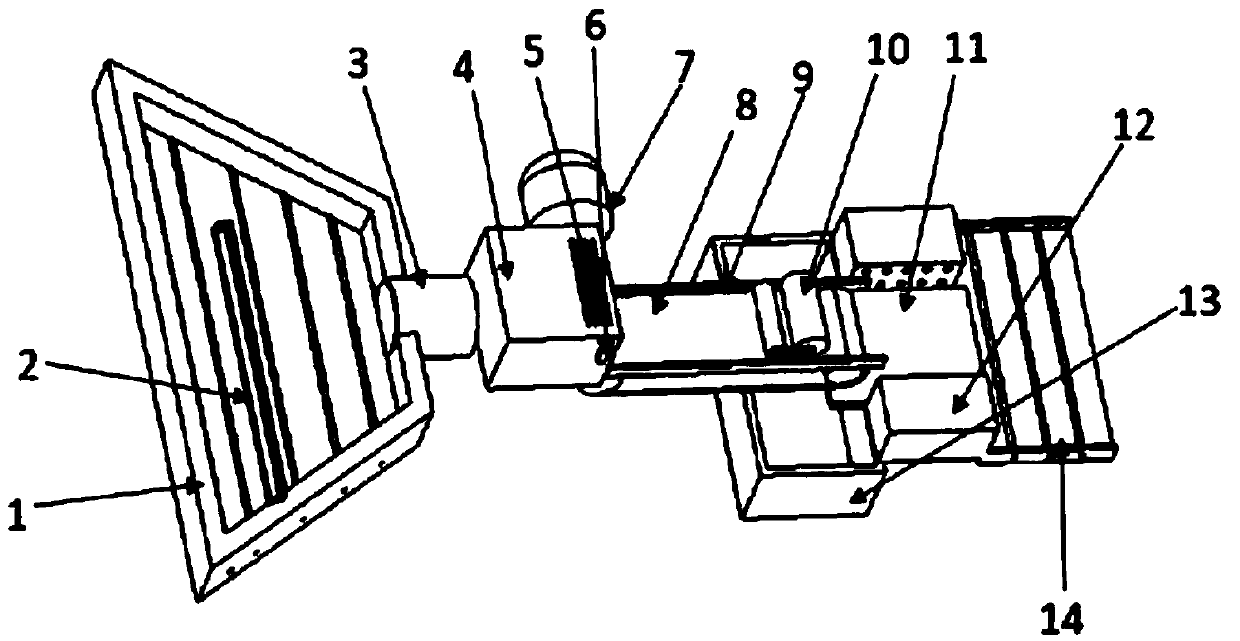

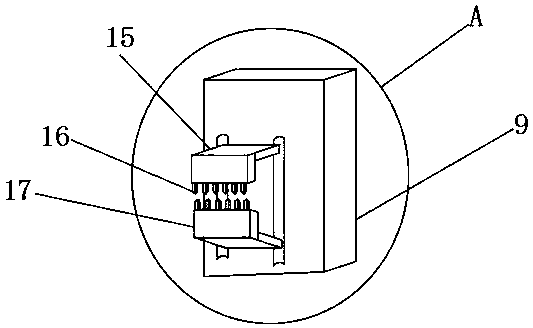

Tooth-removing size fixing machine for zipper production

InactiveCN104207425AAdjust the efficiency of tooth removalEfficient and precise tooth removalSlide fastenersManufacturing technologyEngineering

The invention relates to the technical field of zipper manufacture and particularly relates to a tooth-removing size fixing machine for zipper production. The tooth-removing size fixing machine comprises a main rack, a subrack and a supporting device and also comprises a supporting rod, a third pressing roll, a fourth pressing roll, a fifth pressing roll, a supporting frame, a supporting plate, a cutting head, a transmission rod, an upper pressing plate, a measuring ruler, a second adjusting device, a moving ring, a supporting piece, an adjusting device, a first rocking rod, a transmission device, a first pressing roll, a second pressing roll, a second rocking rod, a hopper and a control panel embedded on the side wall of the main rack. The tooth-removing size fixing machine has the advantages that the upper pressing plate drives the cutting head to remove teeth, and the tooth-removing efficiency can be adjusted by adjusting the second rocking rod and the first rocking rod, and high-efficiency and accurate tooth removal can be ensured.

Owner:东莞市达成手袋配件科技有限公司

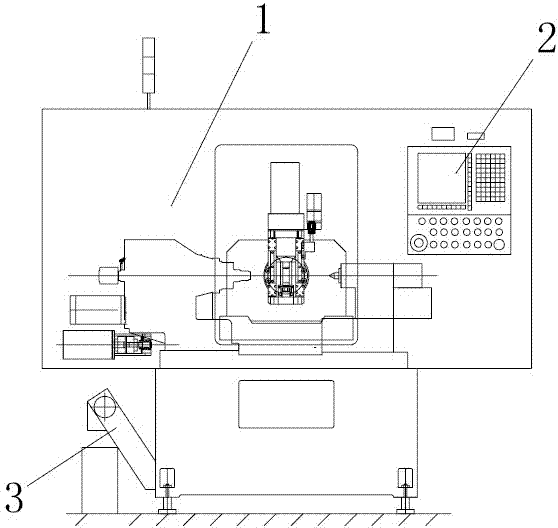

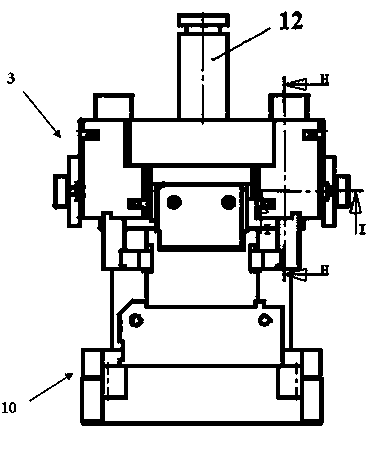

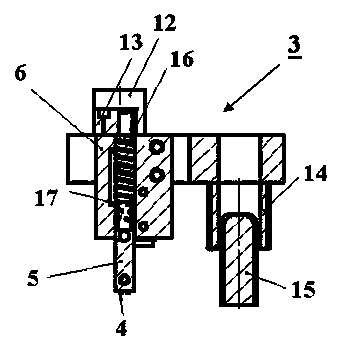

Rolling-milling combination machine

InactiveCN102049570BIncrease productivityImprove machining accuracyGear teethEngineeringTooth removal

The invention relates to a metal cutting machine tool in the field of mechatronics, in particular to a rolling-milling combination machine. The invention is realized through the following technical schemes: the rolling-milling combination machine comprises a host, an electric cabinet, a hydraulic station and an automatic cooling and chip removal device, wherein the host comprises a workpiece installation assembly, a cutter rest assembly, a cutter rest swing assembly for presetting a cutter, a horizontal axial feeding mechanism for enabling the cutter rest assembly to generate horizontal axialdisplacement, and a radial feeding mechanism for enabling the cutter rest assembly to generate radial displacement; and the cutter rest assembly comprises a cutter swing mechanism, a cutter head switching mechanism and a combination cutter formed by coaxially and integrally connecting a rolling tooth cutter and a milling tooth cutter. The combination machine provided by the invention can be used for processing a taper spline and can finish the tooth removal or tooth splicing processing. Compared with the background art, the combination machine provided by the invention can independently finish the processing of the taper spline of a swing arm shaft.

Owner:浙江振兴阿祥集团有限公司

Tooth removal device for metal zipper sizing and cleaning and tooth removal method thereof

ActiveCN102554013BIn line with the production and processing technologyIncrease production speedSlide fastenersMetal-working feeding devicesEngineeringTooth removal

The invention discloses a tooth removal device for metal zipper sizing and cleaning, which comprises an upper die holder, a lower die holder, an upper punch tool, a lower die, a plurality of positioning devices and a power connecting rod. The lower die holder is arranged below the upper die holder correspondingly, the upper punch tool is fixed to the bottom of the upper die holder, the lower die is fixed to the top of the lower die holder and corresponds to the upper punch tool, the positioning devices are respectively arranged on two sides of the upper die holder, and the power connecting rods are fixed to the top of the upper die holder. Zippers can be positioned by the positioning devices so as to be subjected to sizing and cleaning processes, teeth in specified quality and at specified positions can be removed accurately after the sizing and cleaning processes so that the produced zippers can meet requirements of processing technology, the manual operation easy to make workers tired is replaced, both production speed and efficiency are increased, and labor cost is lowered.

Owner:SHANGHAI EASTDRAGON FABRIC & GARMENT

Zipper chain element manufacturing device and method, and element arrangement device

ActiveCN110193568BPrevent flying outPlay the role of retaining materialSlide fastenersWire rodPunching

The invention belongs to the technical field of zipper manufacturing, and particularly relates to a zipper tooth manufacturing device and method and a tooth arranging device. The zipper tooth manufacturing device comprises a sliding base, a cutting knife, a punching head and a stripping piece, wherein the cutting knife, the punching head and the stripping piece are arranged above the sliding base,a cutting plane is arranged on the upper side of the sliding base, the sliding base is internally provided with a wire rod channel, the front side of the sliding base is connected with a blanking die, a forming part is arranged on the blanking die, the wire rod channel is intermittently conveyed to the upper part of the cutting plane at a preset supply amount for each time, the sliding seat movesback and forth in a reciprocating mode, the cutter is in sliding contact with the cutting plane, a cutting edge is arranged at the front end of the cutting knife, the punching head is arranged abovethe cutting edge in a lifting mode, the stripping piece is arranged on the front side of the punching head in a lifting mode. According to the zipper tooth manufacturing device, when the device is used for cutting, the part of the wire rod protruding cutting plane enters the cutting edge along with the backward movement of the sliding seat, the material removing part is descended to the front sideof the wire rod in the cutting edge, the wire rod in the cutting edge is at least partially shielded, the wire rod is prevented from being thrown out instantly, the phenomenon that the wire is missing during subsequent tooth removal is avoided, the production efficiency is effectively improved, and the reworking rate is reduced.

Owner:广东顺德三扬科技股份有限公司

Motor unidirectional control, self-spring lock with detached teeth

ActiveCN105909077BCabinet door pops openAutomatic pop upNon-mechanical controlsElectric permutation locksSelf lockingEngineering

The invention discloses a self-pop-up lock with a motor unidirectionally controlling tooth disengaging. The motor of the self-pop-up lock is fixed at an adaptive position of a partition frame at the middle part in a shell; a spiral gear on one side in the shell is connected with a motor shaft; the spiral gear meshes step by step with a driving gear and a three-layer gear on a stand column fixed on the front wall of the shell; at least one compressed spring is arranged in a spring shell of a columnar pipeline fixed at the middle part of the upper wall of the shell; an insert hole which fits with the door frame in shape is arranged at a position, corresponding to the spring shell, on the front wall of the shell; an L-shaped spring bolt is fixedly arranged on a support turning bar at an adaptive position at the lower end of the columnar pipeline; rattrap springs respectively arranged on both sides of the spring bolt are also fixed on the support turning bar; a lever and a torsional spring which successively sleeve the stand column on the front wall of the shell are arranged at adaptive positions at the lower end of the spring bolt; a groove is formed at the middle part of the lever; a finger-bending hook and an arc stop are respectively arranged at two ends of the groove; one end of the torsional spring is hooked on the lever, and the other end is stuck on a support on the inner wall of the shell. The self-pop-up lock provided by the invention is stable in performance, and realizes no wait for door opening and closing.

Owner:沈阳泰格科技发展有限公司

Implants and methods for performing gums and bone augmentation and preservation

ActiveUS20110117520A1Promote growthPromotes bone formationDental implantsImpression capsExtraction siteBreast augmentation

Embodiments described herein are related to fillers that are placed within an extraction site in need of bone augmentation and preservation. The fillers encourage sufficient new bone growth in order that normal jaw bone deterioration following tooth removal is prevented. The fillers create, arrange, and assemble an ideal growth environment for new bone growth to rapidly grow and preserve the original contours of an individual's jaw bone. Further embodiments described herein are related to dental implants that are arranged to provide a scaffold upon which a damaged or missing dental papilla may regrow. The dental implants may include a micro-pattern to facilitate directional cell growth.

Owner:INNOVATIVE HEALTH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com