A screw rotating device for automatic tooth removal

A technology of rotating device and screw, applied in the direction of transmission device, slip coupling, belt/chain/gear, etc., can solve the problem of increasing production cost and labor intensity, wire damage of screw and slider, screw rotation accuracy Difficult to control and other problems, to achieve the effect of convenient and effective connection, reduce distance installation accuracy, and ingenious and effective design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

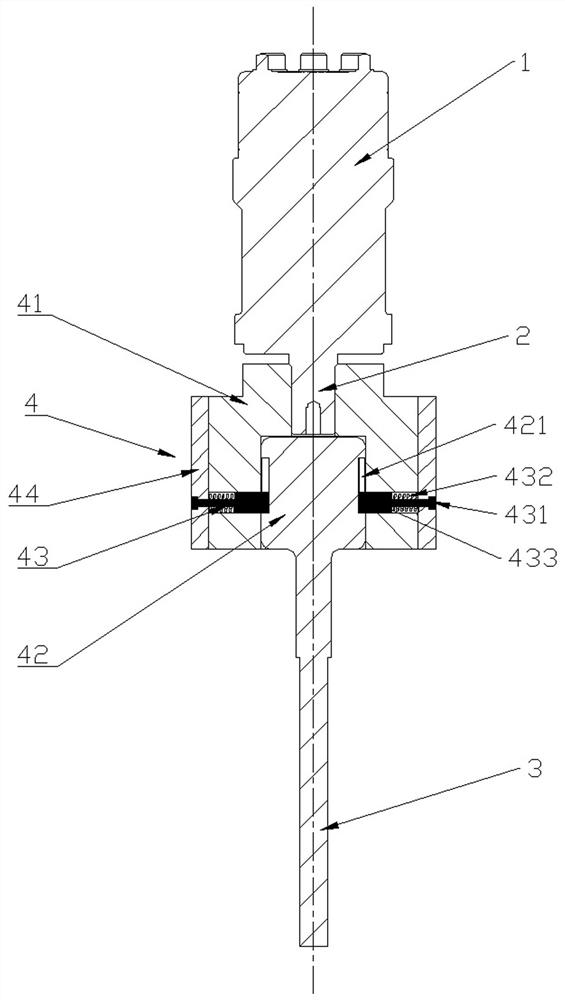

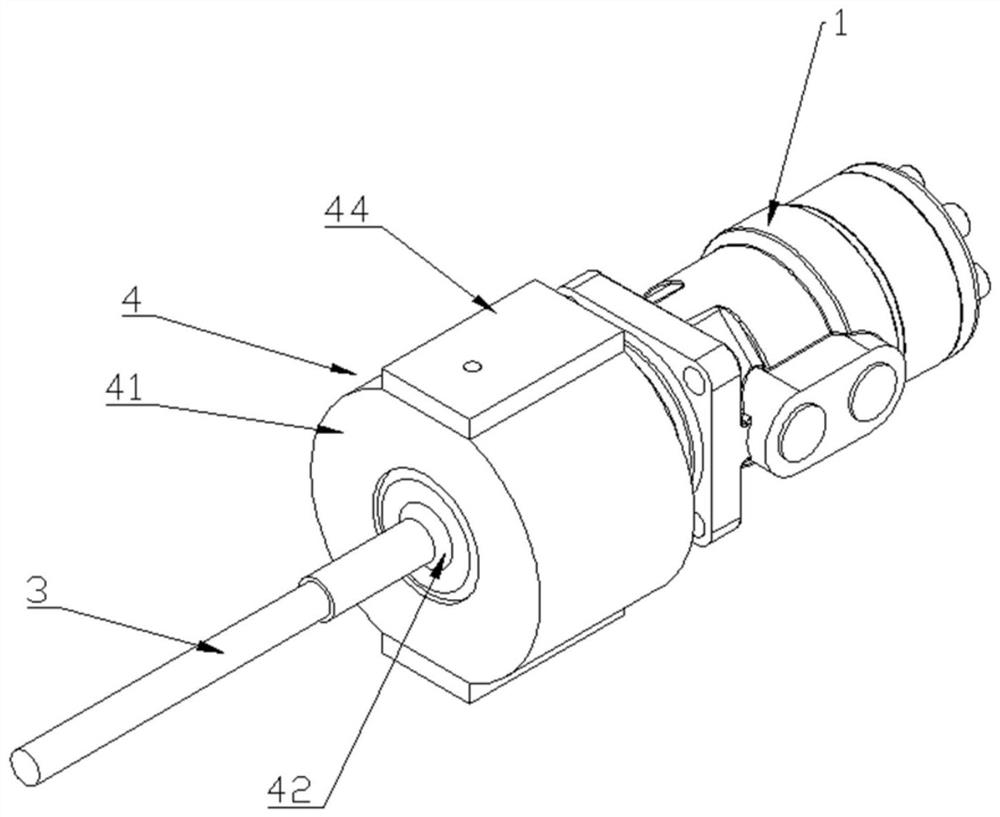

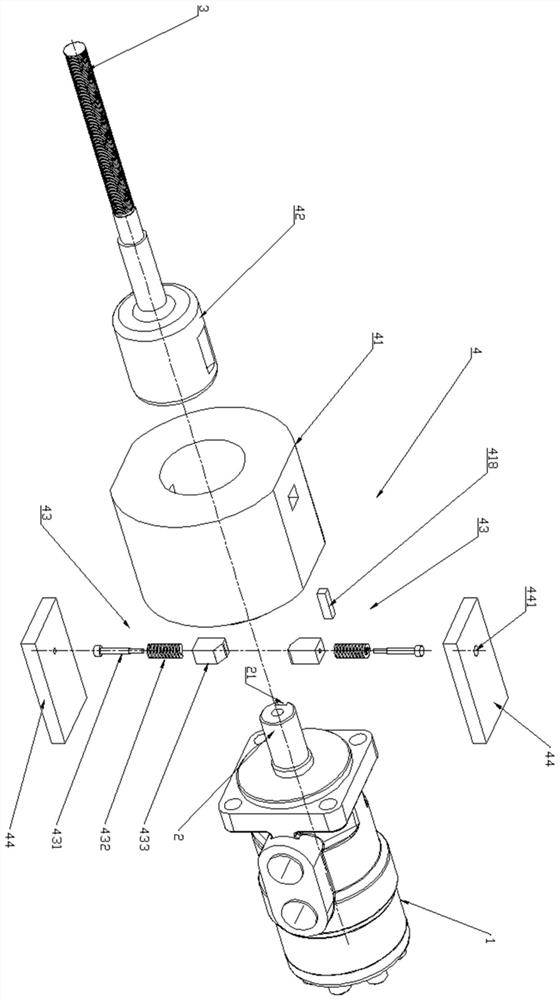

[0040] like Figure 1-9 As shown, this embodiment provides a screw rotating device for automatic tooth removal, including a motor 1, a transmission shaft 2 and a screw 3, and the transmission shaft 2 and the screw 3 are connected by an automatic tooth removal component 4, wherein the automatic tooth removal component 4 includes an outer sleeve 41 and an inner cylinder 42, the outer sleeve 41 is fixedly connected with the transmission shaft 2, the screw 3 is fixedly connected with the inner cylinder 42, and the outer sleeve 41 is sleeved outside the inner cylinder 42 and is relatively fixedly connected by an elastic member 43; In the normal state, the motor 1 drives the transmission shaft 2 to rotate, which in turn drives the outer sleeve 41, the inner cylinder 42, and the screw 3 to rotate synchronously. When the rotation of the screw 3 is limited, the inner cylinder 42 and the outer sleeve 41 are disconnected from the fixed connection state. , the outer sleeve 41 can slip and...

Embodiment 2

[0060] like Figure 10-11 , Compared with the first embodiment, the difference between this embodiment is the connection method between the outer sleeve 41 and the transmission shaft 2 . In this embodiment, the end of the transmission shaft 2 is provided with a shaft end through hole (not shown in the figure), the coupling section 411 is provided with a radial coupling through hole 415 correspondingly, and the pin rod 419 is provided to pass through the shaft end The through hole and the coupling through hole 415 are used to realize the axial and circumferential fixed coupling of the transmission shaft 2 and the outer sleeve 41 . The pressure plate 44 can be additionally installed on the outer sleeve 41 by screws, and the outer sleeve 41 is provided with a flat surface to facilitate the installation of the pressure plate; when the transmission shaft 2 and the outer sleeve 41 are connected by pins, the pin 419 can be provided with threads, and the pressure plate Corresponding ...

Embodiment 3

[0063] This embodiment provides a specific application scenario of the screw rotating device for automatic tooth extraction.

[0064] like Figure 12-13 As shown in the figure, in this embodiment, the screw rotating device for automatic tooth removal is applied in the field of mold processing, but it is not limited to this field. To be connected, it is necessary to rotate the screw 3 to drive the insertion device 6 to move forwards and backwards as a whole, so that other components connected to the insertion device 6 can move forwards and backwards to assemble with the main device 9 .

[0065] The mounting seat 5 is an annular structure with an inner circle and an outer square, and the middle part is an axial mounting through hole 51. The mounting seat 5 is provided with a mounting screw hole 52 corresponding to the motor 1. The mounting seat 5 and the motor 1 are fixedly connected by bolts. 2 is connected to the automatic tooth removal assembly 4 through the installation thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com