Effective method for preventing scorching in electroplating process

A technology of electroforming and conductive parts, applied in the direction of electrolysis, electroforming, electrodes, etc., can solve problems affecting corporate reputation and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

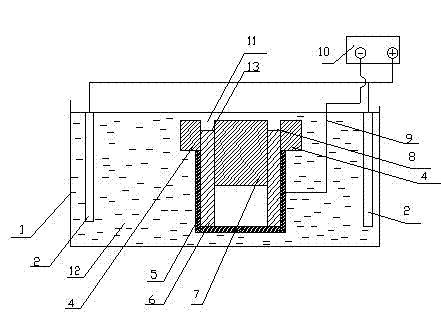

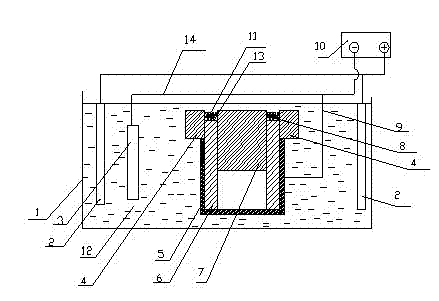

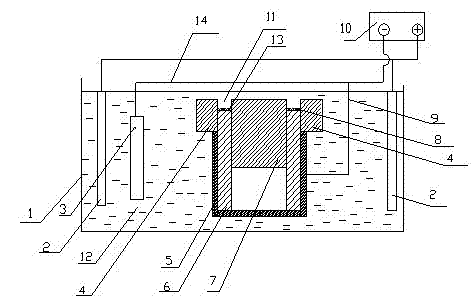

[0021] The implementation takes the electroformed diamond geological drill bit as an example, such as figure 1 As shown, the electroforming solution (12) is filled in the electroplating tank (1), and the basic formula is as follows:

[0022] NiSO 4 ·7H 2 O 180—350g / l

[0023] NiCL 2 ·6H 2 O 10—55g / l

[0024] CoSO 4 ·7H 2 O 3—30g / l

[0025] h 3 BO 3 15—40g / l

[0026] Softener 0—40g / l

[0027] Additives a little

[0028] Temperature 30-56 degrees

[0029] PH value 3.2 - 5.8

[0030] Solution stirring and solution circulation Yes.

[0031] This formula uses nickel-cobalt alloy as the matrix material of the geological drill bit. An anode (2) is provided in the electroplating tank (1). The anode (2) is connected to the positive pole of the rectifier power supply (10). 6), the cathode (6) is connected to the negative pole of the rectified power supply (10).

[0032] The steel body of the geological drill bit (6) insulates the part that does not need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com