The method of removing the teeth of the sintering machine trolley stuck in the tail star wheel

A processing method and technology for a sintering machine, which are applied to furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of increasing maintenance costs and operating costs, affecting the working efficiency of the sintering machine, and long maintenance processing time, so as to reduce maintenance costs. and operating costs, shortening maintenance time, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

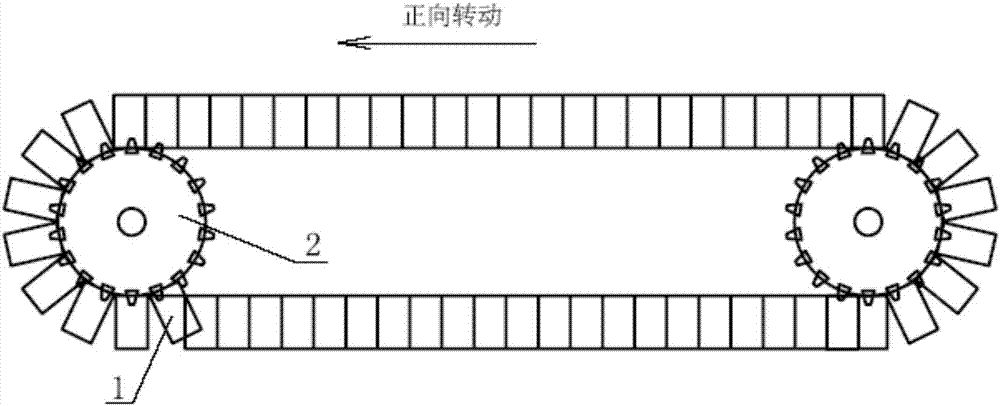

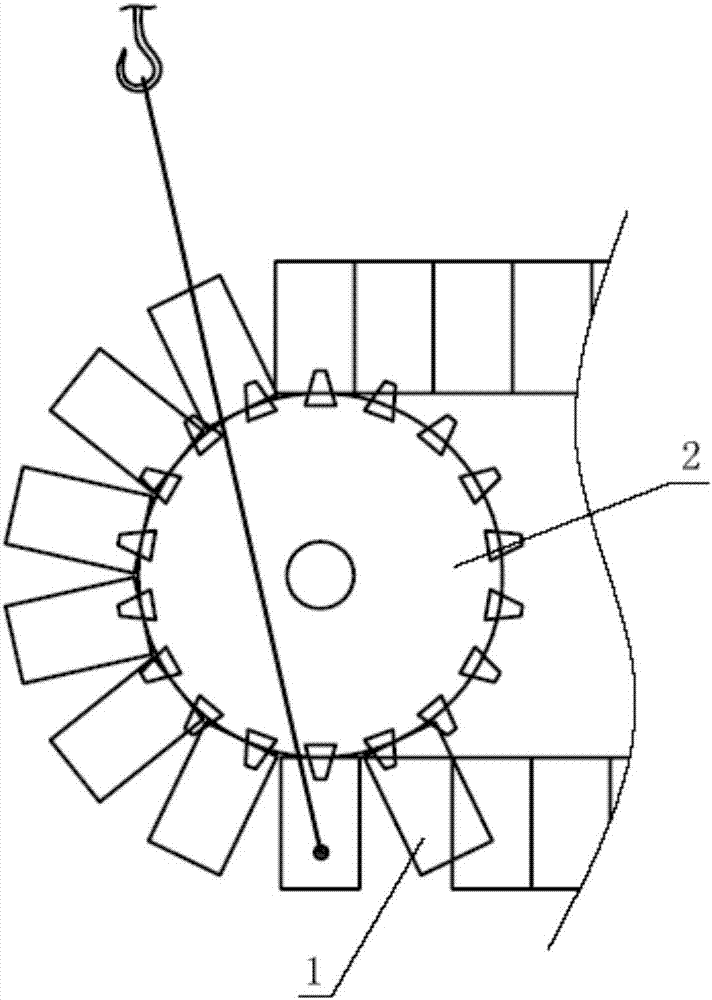

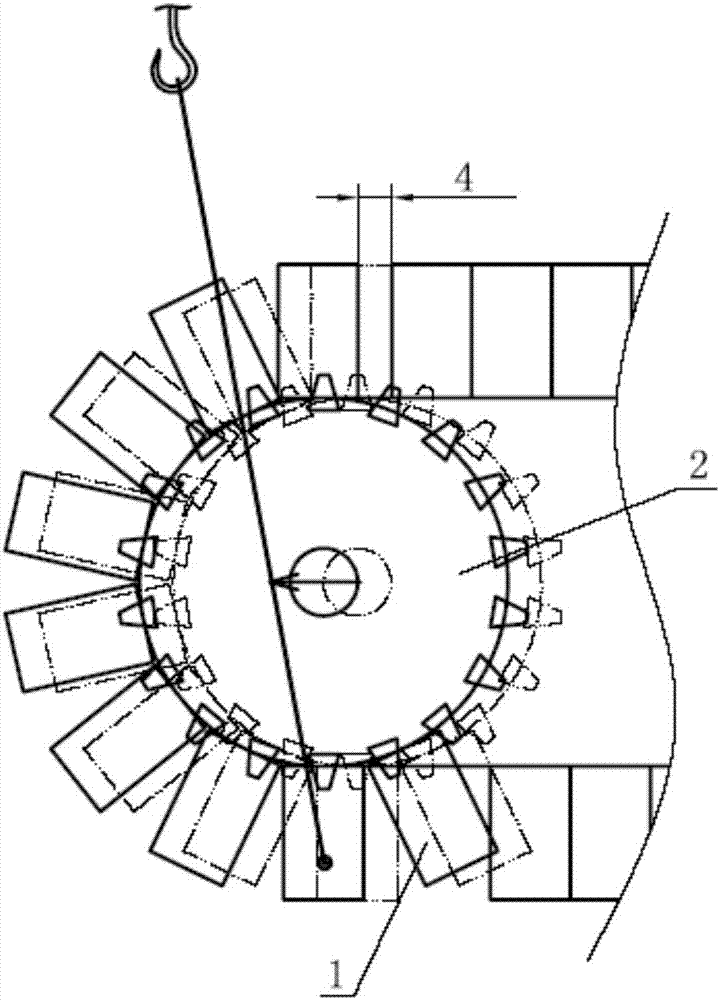

[0024] The sintering machine trolley that the present invention refers to is stuck on the tail star wheel, which refers to figure 1 and figure 2 In the state shown, the sintering machine trolley is still hanging on the tail star wheel 2 of the sintering machine when the tail star wheel of the sintering machine is not on the rotary plane approach, that is, it does not enter the lower running track 3 Up and down has been stuck, its front and back up and down can no longer move. The method of the present invention is aimed at the tooth removal treatment method when the above-mentioned trolley stuck accident occurs, and the method is carried out as follows:

[0025] The first step is to stop the sintering machine and hang the tail crane on the left and right rails of the trolley below the star wheel 2 at the tail end of the sintering machine to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com