Zipper tooth collector and zipper sizing tooth remover using same

A technology of fixed-size tooth removal and tooth collection, which is applied in the direction of application, sliding fastener components, fasteners, etc., can solve the problems of complex structure and many actions required, and achieve the effect of simple structure and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

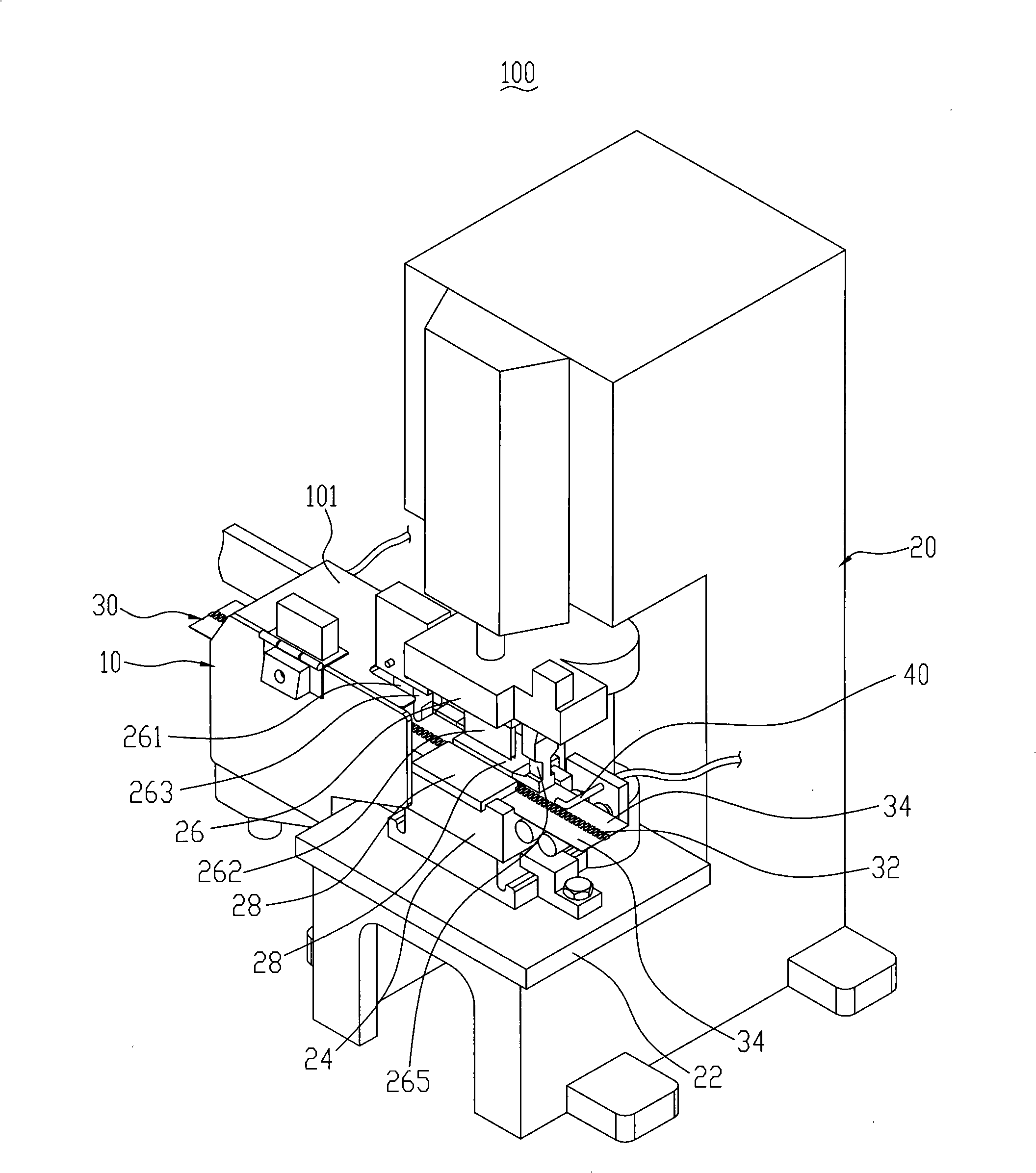

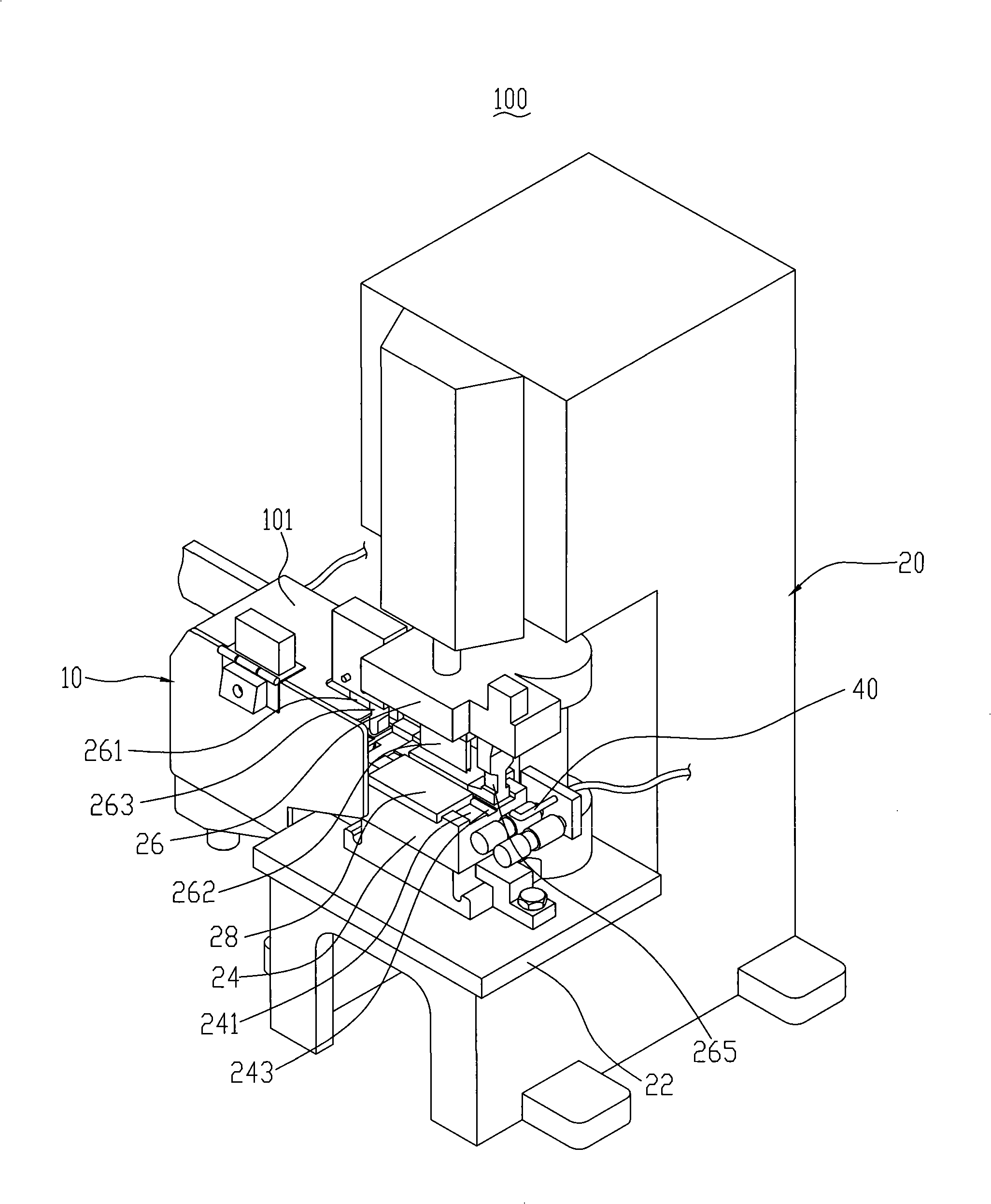

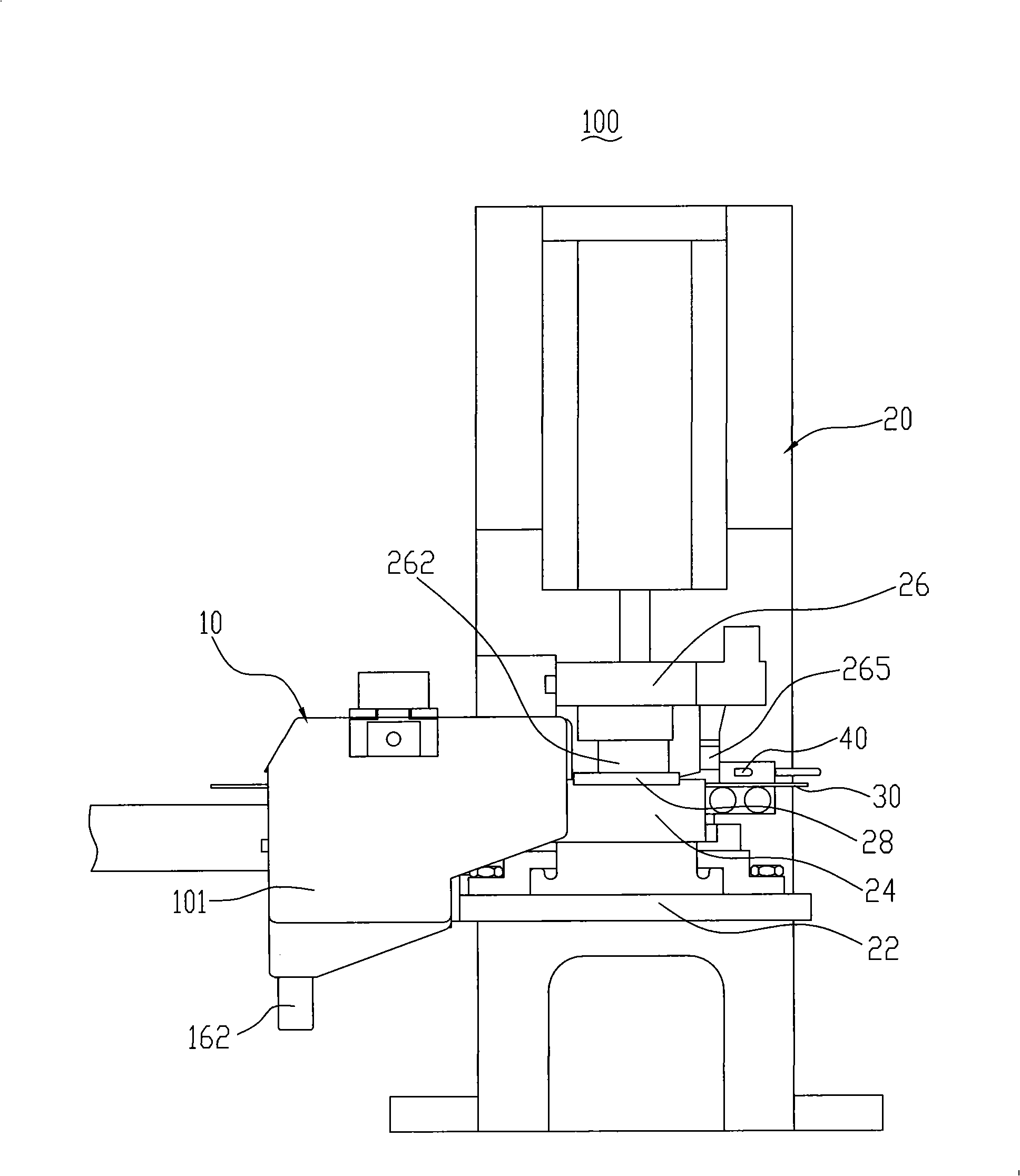

[0019] figure 1 Shown is a perspective view of the first embodiment of the zipper measuring and removing machine of the present invention. The zipper measuring and removing machine 100 is used for measuring and removing teeth on a zipper chain belt 30 . The zipper fixed size gear removal machine 100 includes a zipper gear collector 10 and a fixed size gear cutting device 20 . The chain belt 30 is continuously provided with a plurality of sprocket teeth 32 meshing with each other and two cloth belts 34 respectively connected with these sprocket teeth 32 . The gear collector 10 is fixed on one side of the size cutter device 20 , and the chain belt 30 passes through the size cutter device 20 and the gear collector 10 in sequence. This sizing and cutting tooth device 20 is used for processing the sprocket 32 on this chain belt 30, and this sprocket 30 is sized and cuts a section of sprocket 32 on it into sprocket fragments 32a (as Figure 4 shown). The gear collector 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com