Cathode wire machining mechanism

A processing mechanism and cathode wire technology, applied in electrode structure, electrostatic effect separation, solid separation and other directions, can solve the problems of cumbersome production methods, low production efficiency, time-consuming and labor-intensive, etc., to achieve stable driving mechanism structure, improve processing efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

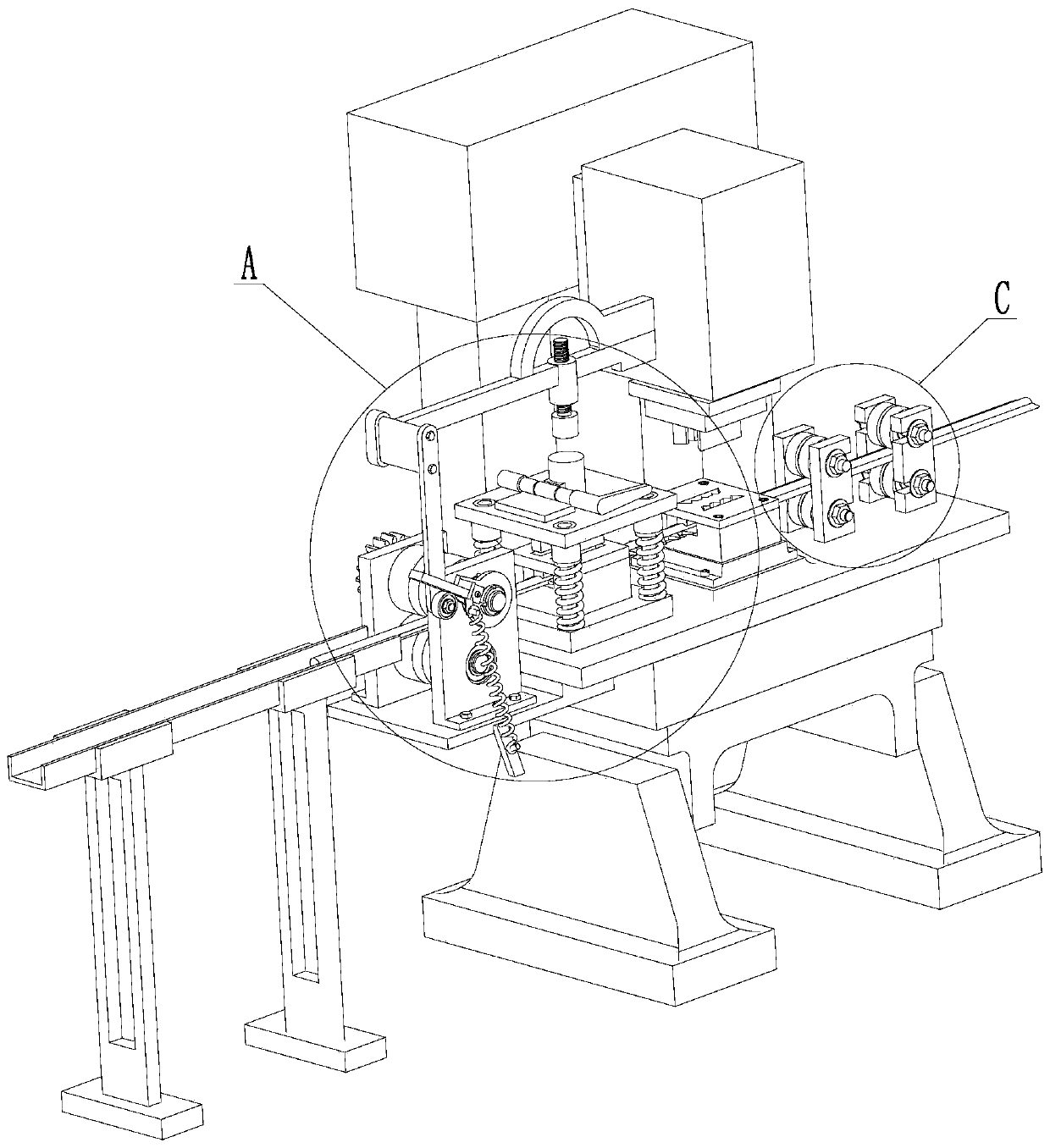

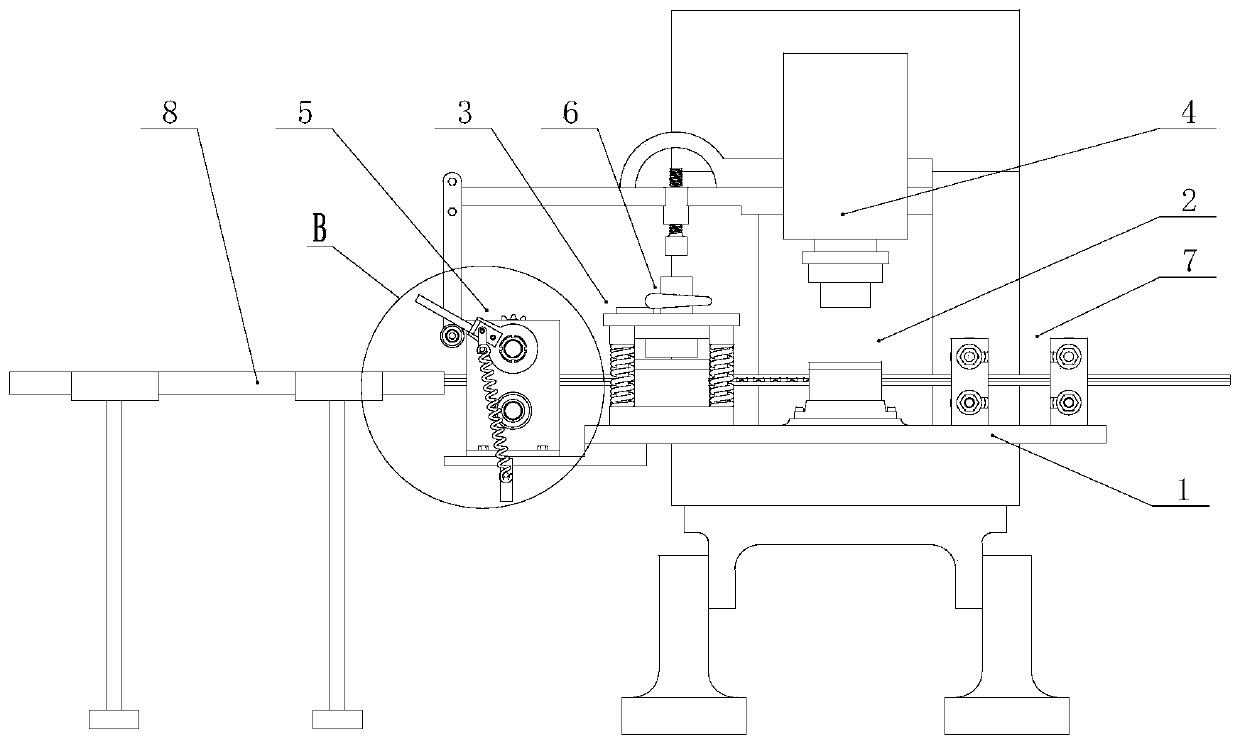

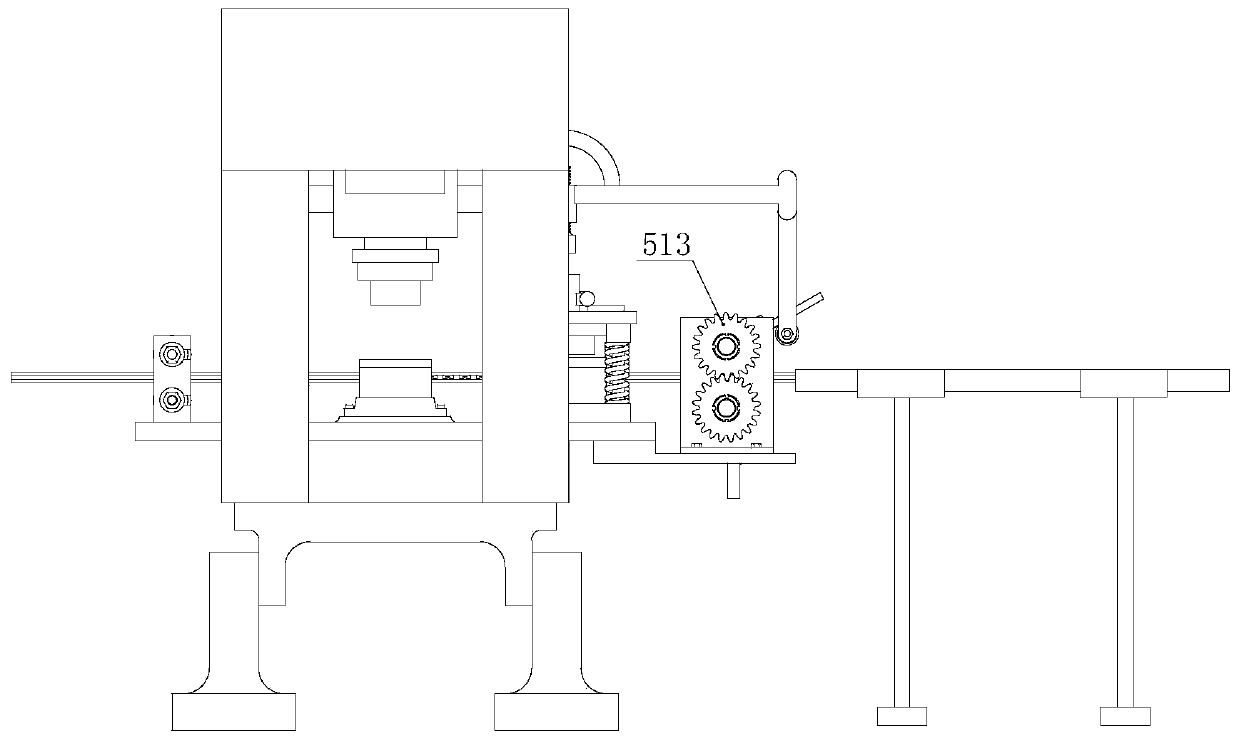

[0037] Such as figure 1 , 2 As shown in 4, a cathode wire processing mechanism includes an electric discharge tooth machining unit 2 and an electric discharge tooth removal unit 3 installed on a press workbench 1. The electric discharge tooth machining unit is used to process the electric discharge teeth of a semi-finished cathode wire, and the electric discharge tooth removal The unit is used to remove the discharge teeth at both ends of the cathode wire to facilitate the installation of the cathode wire. The electrical discharge gear processing unit and the electrical discharge gear removal unit are arranged at intervals along the feeding direction, so that the semi-finished cathode wire can be removed by the electrical discharge gear processing unit and the electrical discharge teeth in turn Unit; the electric discharge tooth machining unit includes a toothed abrasive 201, the toothed mold includes a toothed lower mold installed on the worktable and a toothed upper mold instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com