Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Play the role of retaining material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

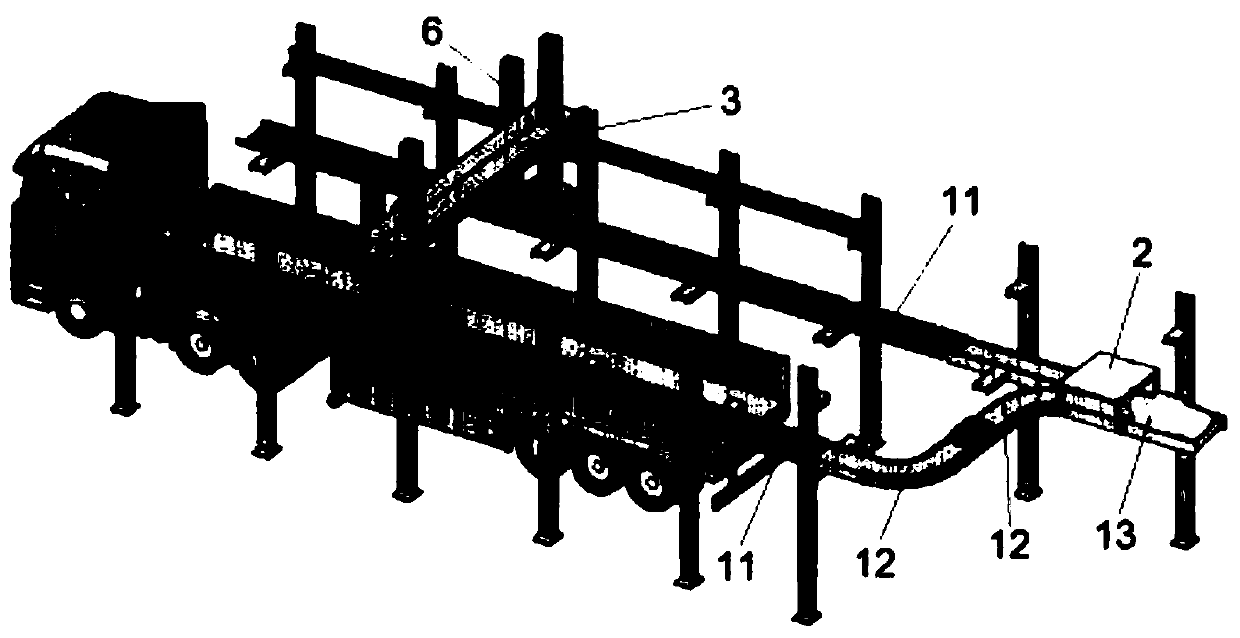

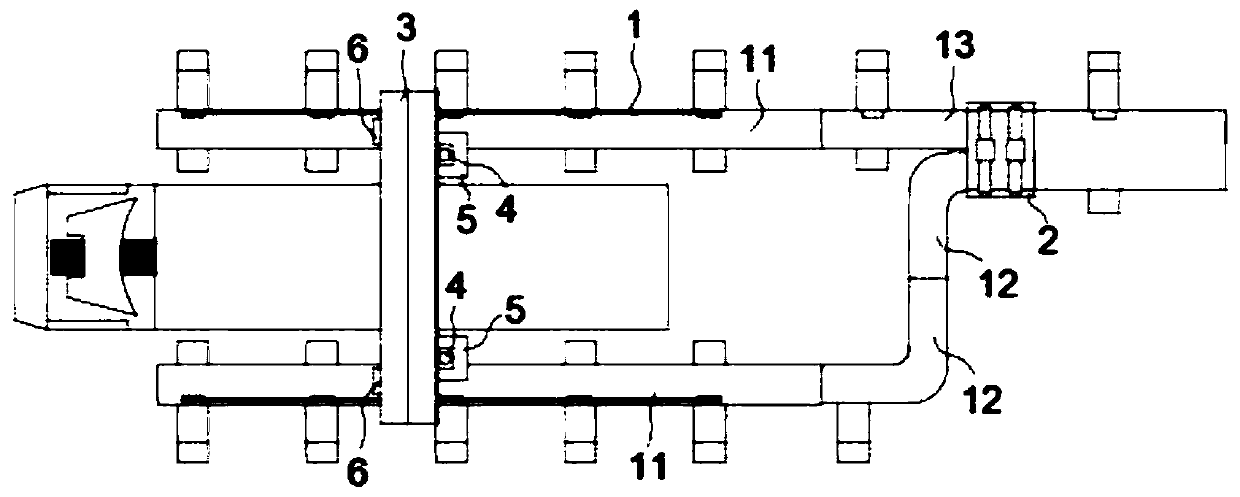

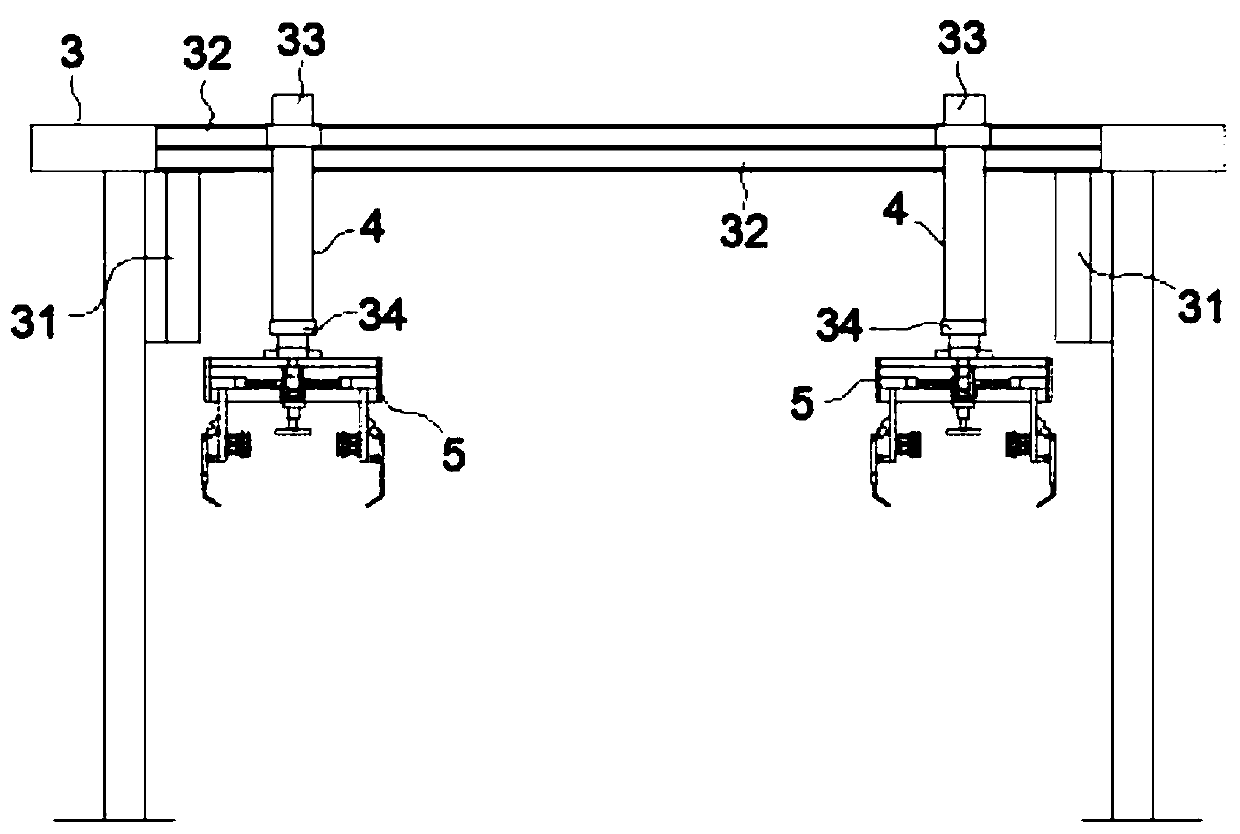

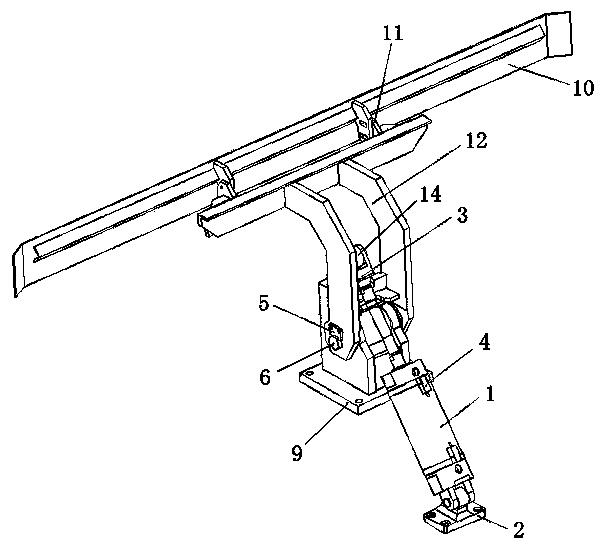

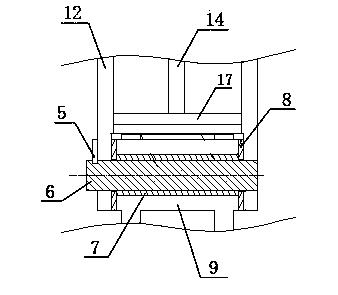

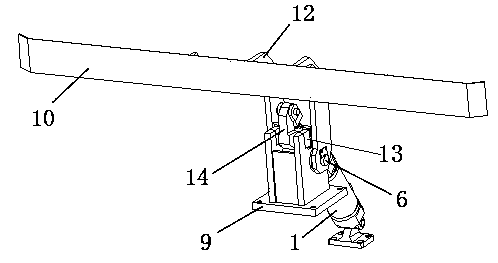

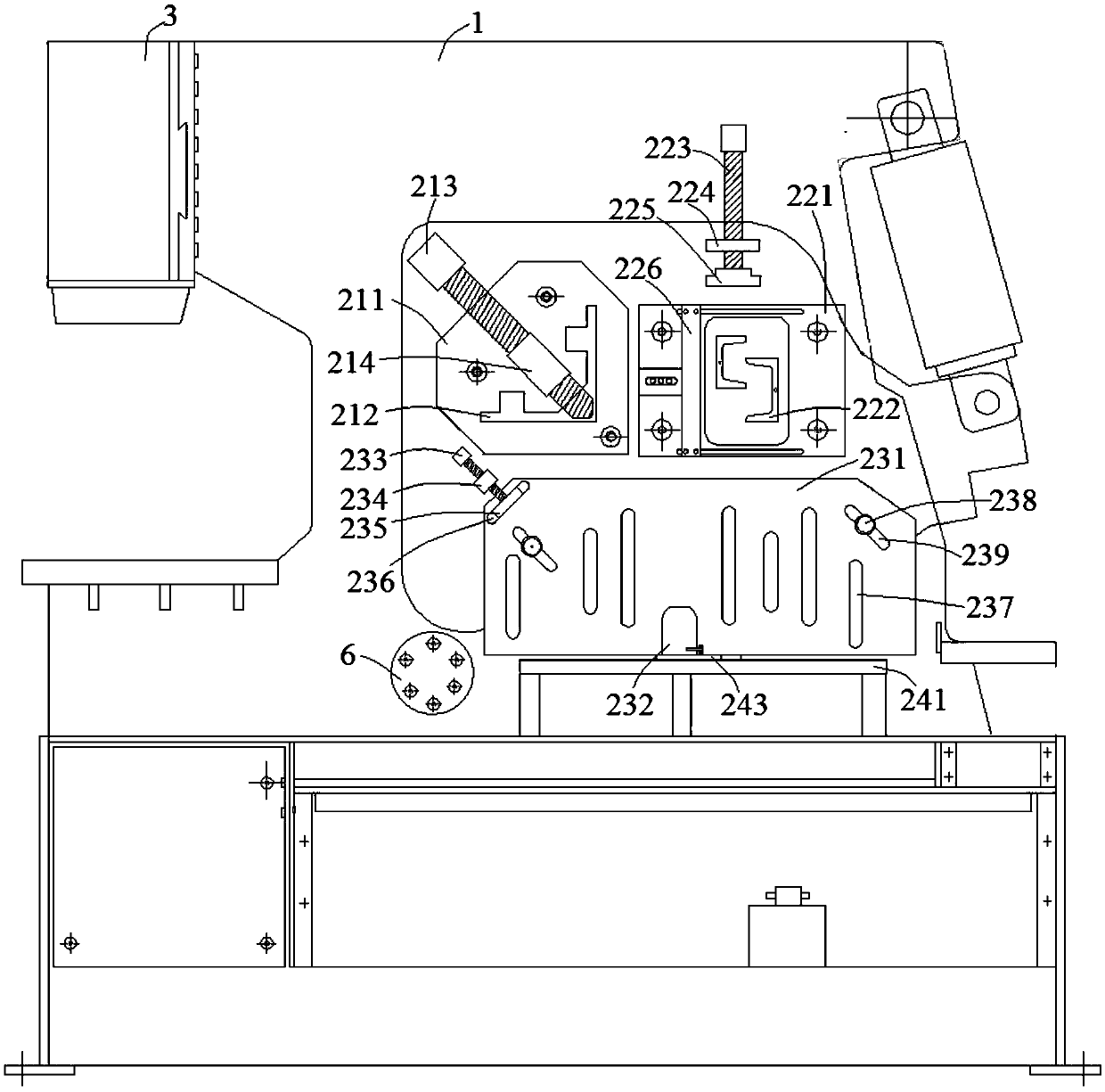

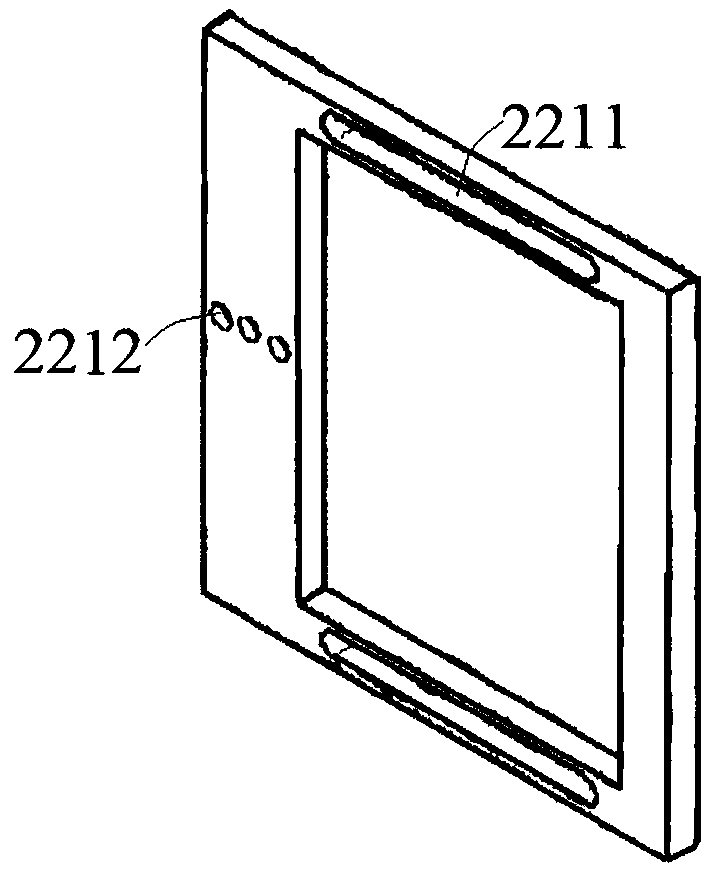

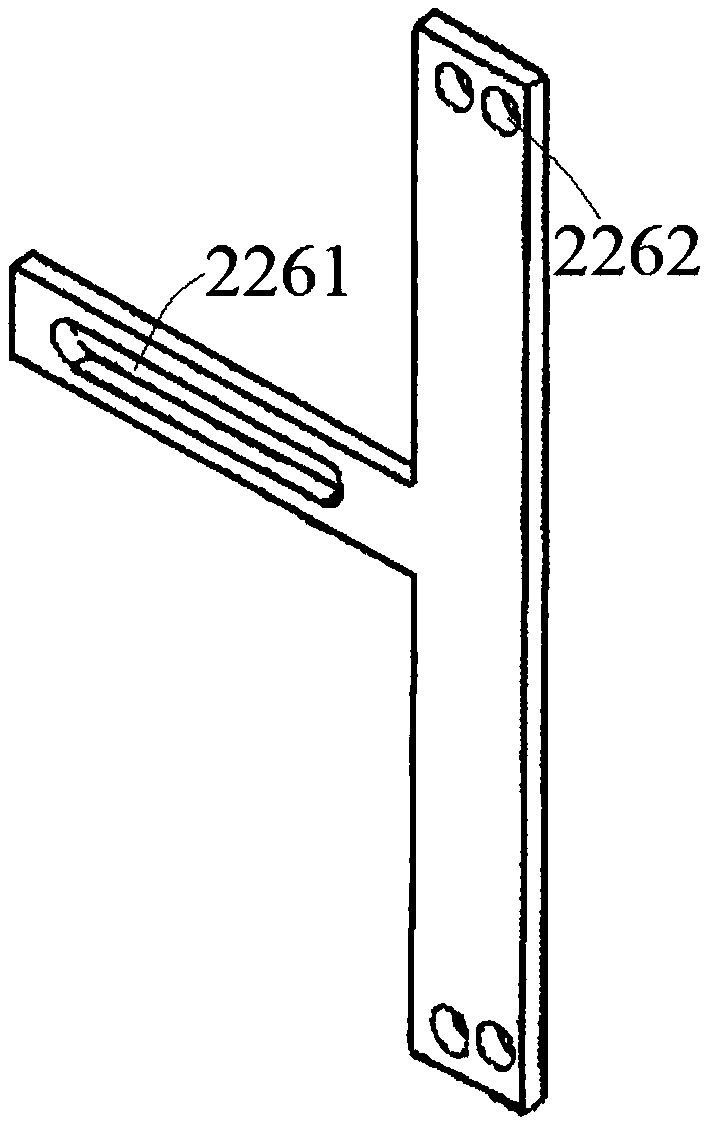

Efficient stacking machine based on double-gripper truss robot

ActiveCN110104426ASolve the problem that the cycle cannot be completed within 4sPlenty of timeConveyorsStacking articlesLinear motionControl system

The invention discloses an efficient stacking machine based on a double-gripper truss robot. The efficient stacking machine mainly comprises a truss carrying system, a material conveying system, a control system and a safety protection system. The material conveying system is composed of five conveying lines which are divided into two roller conveying lines, two right-angle turning conveying linesand one straight conveying line. The truss carrying system adopts the single double-gripper truss robot, the double-gripper truss robot is provided with eight motion axes, and the single double-gripper truss robot is arranged on the two sides of the two roller conveying lines through the two X linear motion axes; each Y linear motion axis, Z linear motion axis and R rotation axis form a group ofmotion axis assembly, each group of motion axis assembly is correspondingly provided with a robot gripper, a material blocking device is correspondingly arranged in front of the corresponding robot gripper, and the material blocking device is arranged on a truss beam. The efficient stacking machine is high in stacking efficiency and low in implementation cost.

Owner:灵谷化工集团有限公司 +2

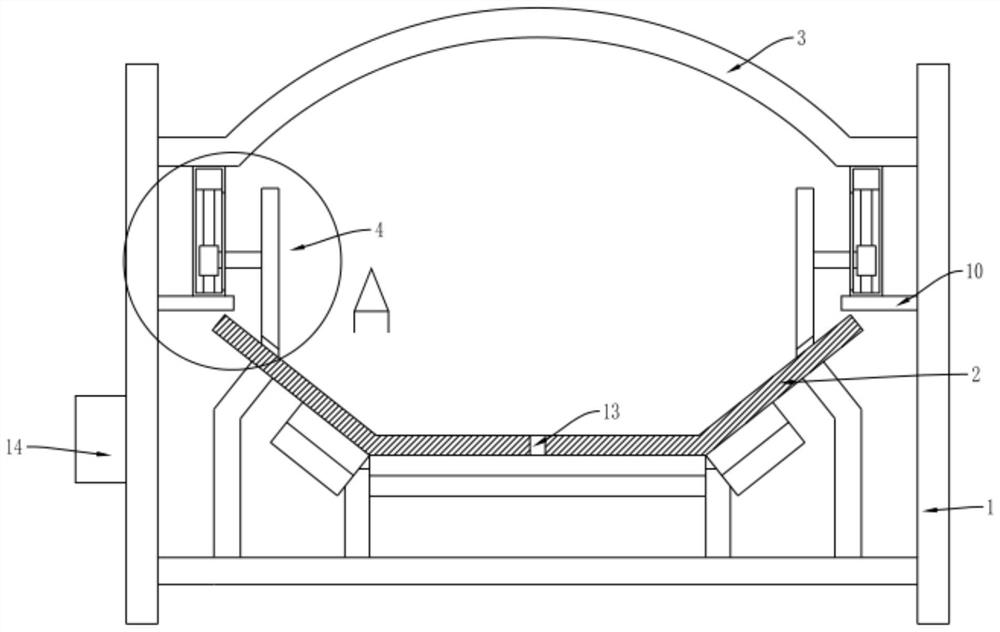

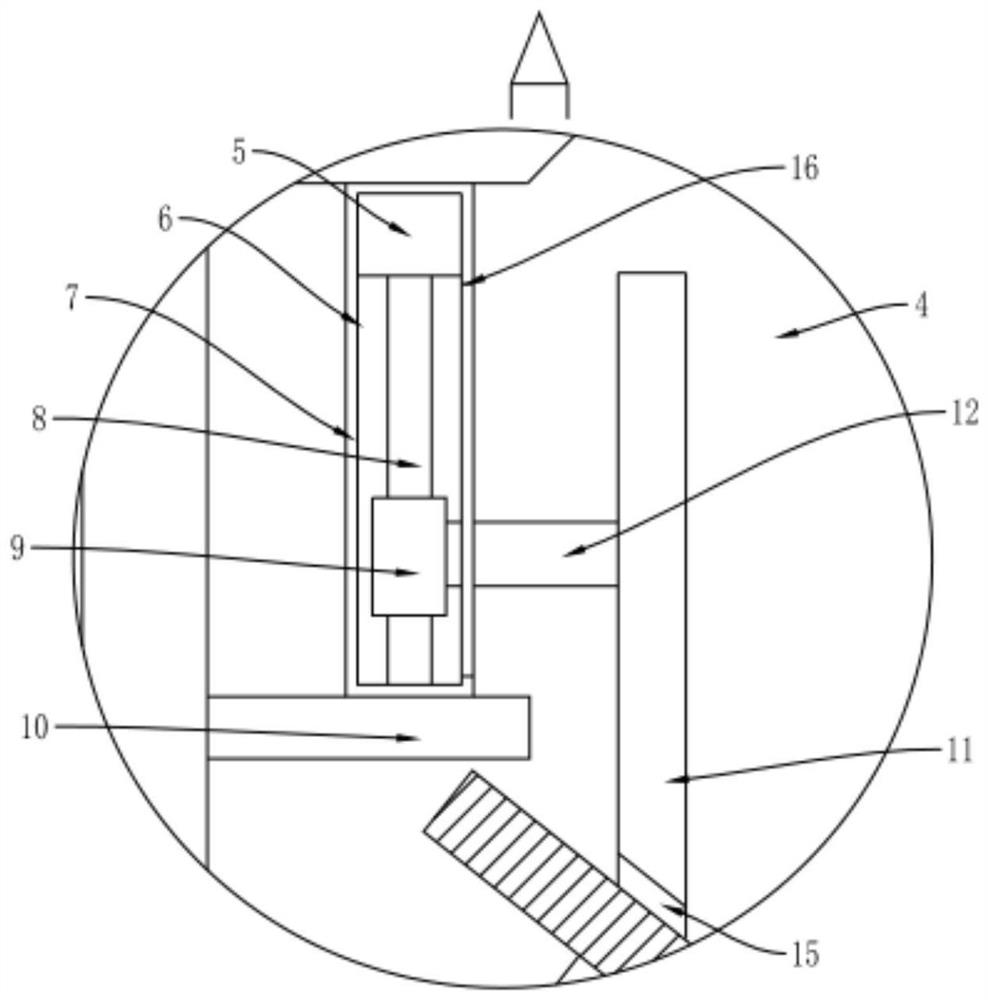

Rice huller with variable-frequency vibration feeding function

InactiveCN112774764AConvenient whereaboutsAccurate whereaboutsGrain huskingGrain polishingAnimal scienceElectric machinery

The invention relates to the technical field of rice huller design, and discloses a rice huller with a variable-frequency vibration feeding function. The rice huller comprises a machine body, a feeding hopper, a falling plate, two rubber rollers, a discharge port, an extraction pipe and an air inlet, a first guide plate is arranged at the upper end in the feeding hopper, and a second guide plate is further arranged at the position, located at one side of the first guide plate, in the feeding hopper. The lower end of the first guide plate inclines towards one side of the second guide plate, a rotating shaft is arranged at the position, located at the lower end of the second guide plate, in the machine body, feeding paddles are arranged at the peripheral side of the rotating shaft, and a driving motor used for being connected with the rotating shaft is arranged at the outer side of the feeding hopper. After rice enters the feeding hopper, the driving motor is used for driving the rotating shaft and the feeding paddles to rotate, and at the moment, the feeding paddles can turn over the rice between the first guide plate and the second guide plate and apply downward acting force to the rice, so that the possibility that the rice is blocked between the first guide plate and the second guide plate can be reduced.

Owner:浙江粮工机械科技有限公司

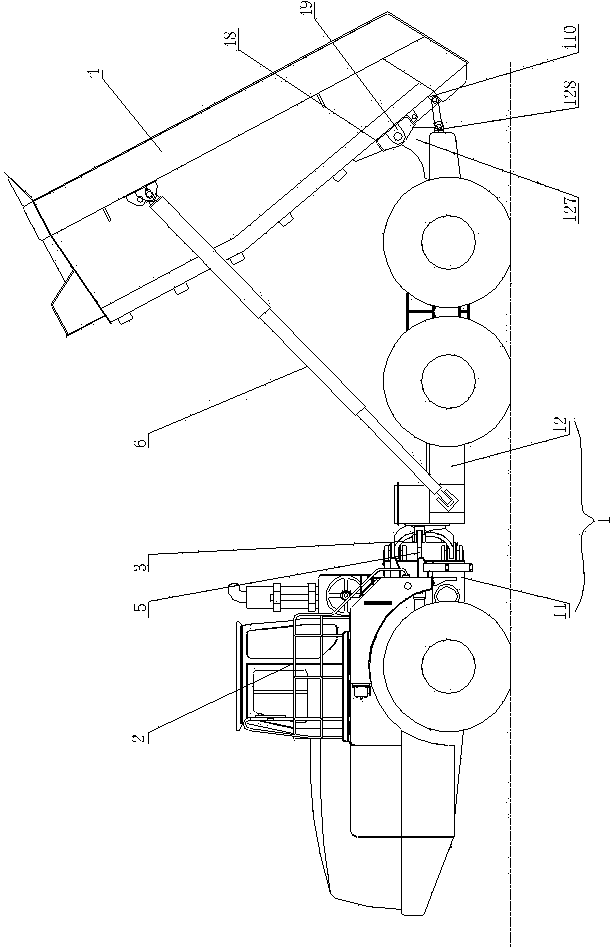

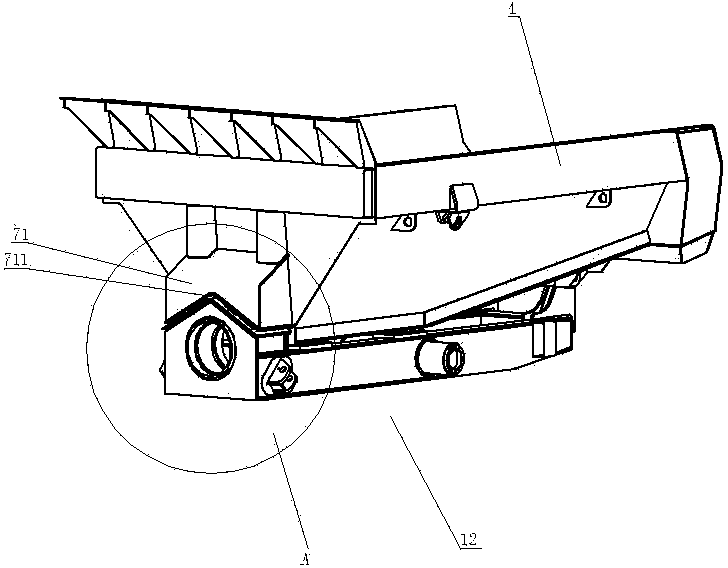

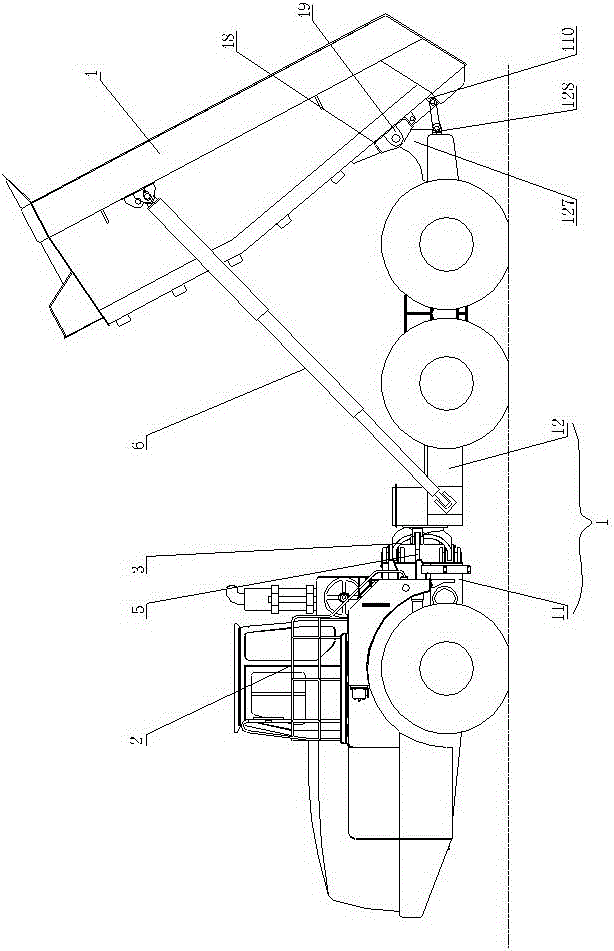

Hinged dumper container assembly, and loading and unloading methods thereof

ActiveCN104071063AHigh strengthImprove carrying capacityUnderstructuresVehicle with tipping movementVehicle frameEngineering

The invention discloses a hinged dumper container assembly, and loading and unloading methods thereof. The container assembly comprises a rear frame and a container, wherein the rear frame comprises a rear frame longitudinal beam assembly, a frame anti-torsion tube, a rear frame lifting seat, a lower hinge seat, a lower bolt seat and a hinge body bearing; the container comprises a bottom plate, a rear tilted plate, a left side plate, a right side plate and a front plate, a left longitudinal beam and a right longitudinal beam are arranged on the left side plate and the right side plate respectively, a left lifting support seat and a right lifting support seat bulging out of the left longitudinal beam and the right longitudinal beam are arranged on the left longitudinal beam and the right longitudinal beam respectively, and an upper hinge seat and an upper bolt seat are arranged at the bottom of the container. The loading method is as follows: returning the container, and loading materials in the container; the unloading method is as follows: turning the container by a lifting oil cylinder, and when the container is turned to a certain position, connecting the upper bolt seat with the lower bolt seat by a bolt; during the turnover process of the container, the materials are detached from the container. The container assembly, and the loading and unloading methods thereof disclosed by the invention are capable of improving the anti-torsion capacity of the frame, improving the bearing capacity and strength of the lifting support seat realizing location for the container, and improving the safety performance of loading and unloading.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

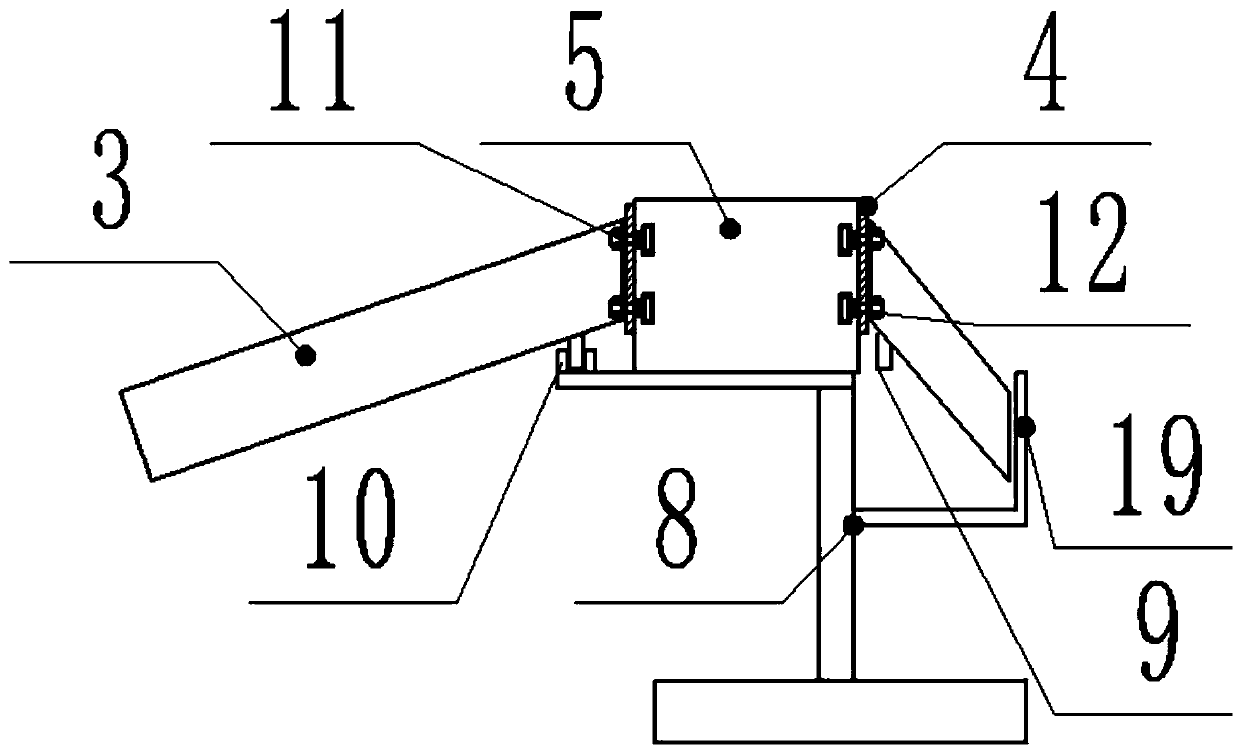

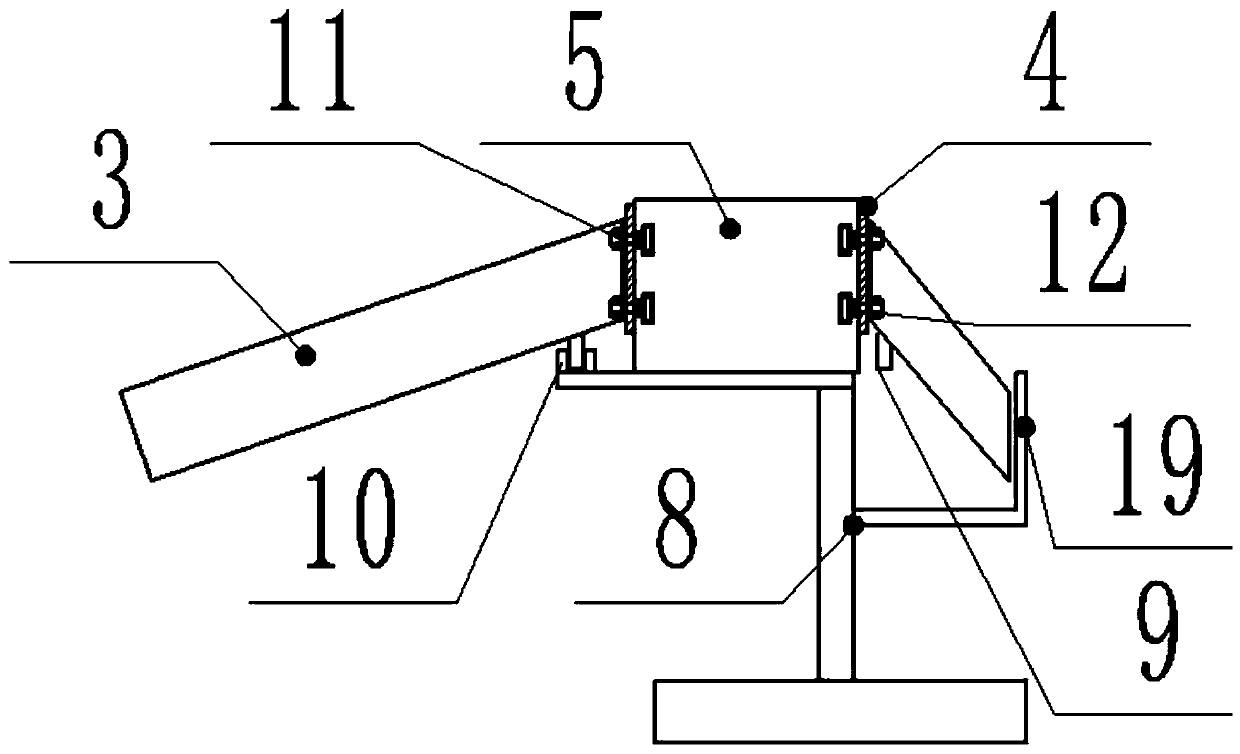

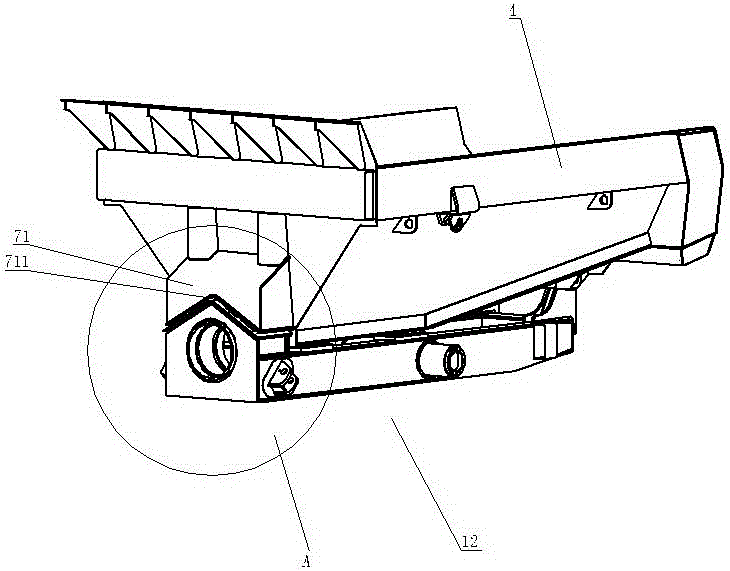

Stop mechanism of car back door fastening mould

InactiveCN103521634AControl the pace of processing and productionImprove job stabilityShaping toolsMetal-working feeding devicesEngineeringBack door

The invention relates to a stop mechanism of a car back door fastening mould. The stop mechanism comprises a base, a lug seat, 7-shaped main rotating arms, a stop plate and an auxiliary rotating arm, the base and the lug seat are arranged on a lower mould of the car back door fastening mould, the lower ends of the main rotating arms are hinged to the base through a rotating shaft, the stop plate is connected with the upper ends of the main rotating arms, one end of the auxiliary rotating arm is connected with the lower portions of the main rotating arms while the other end of the auxiliary rotating arm is hinged to a piston rod head of an air cylinder, the tail end of the air cylinder is hinged to the lug seat, and the auxiliary rotating arm can rotate around the rotating shaft together with the main rotating arms. The stop mechanism of the car back door fastening mould is large in stop length, good in stability and capable of achieving automation control.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

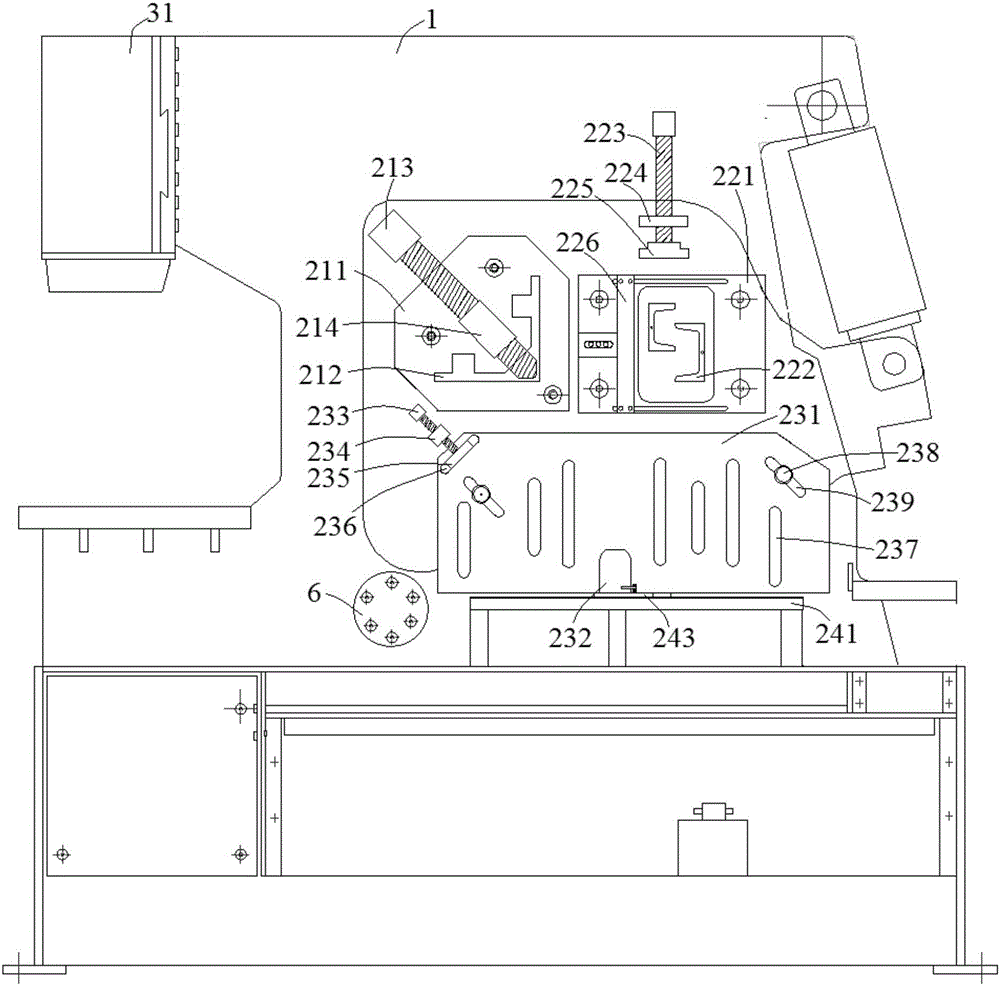

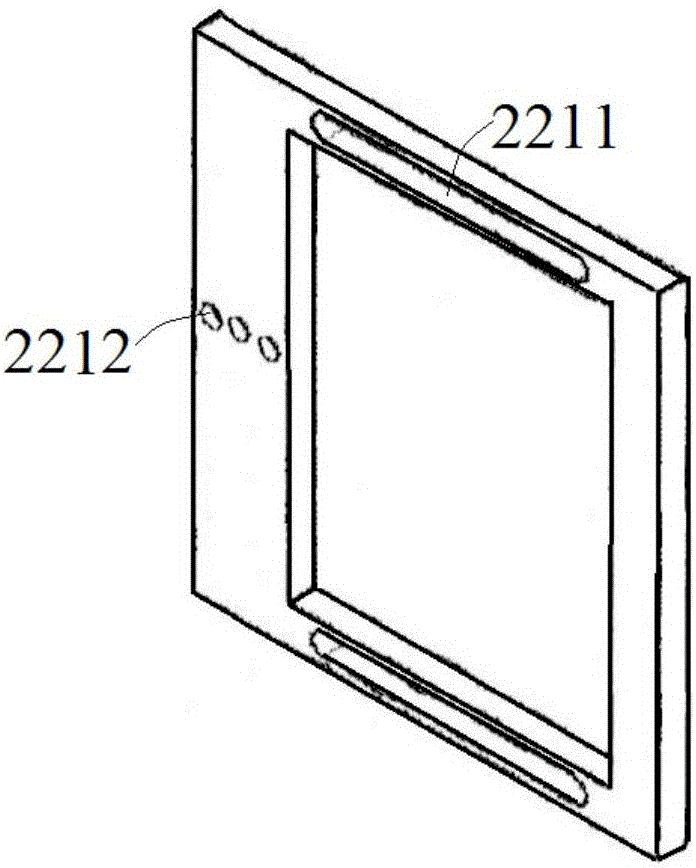

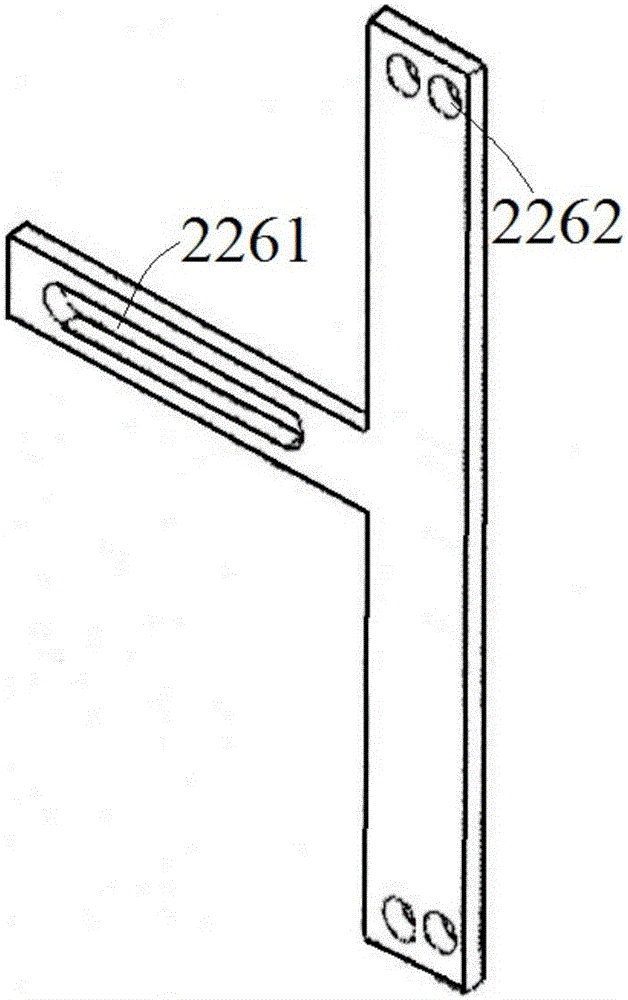

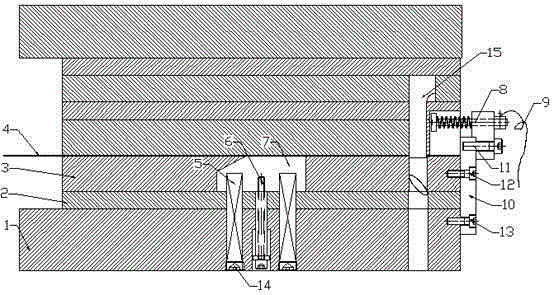

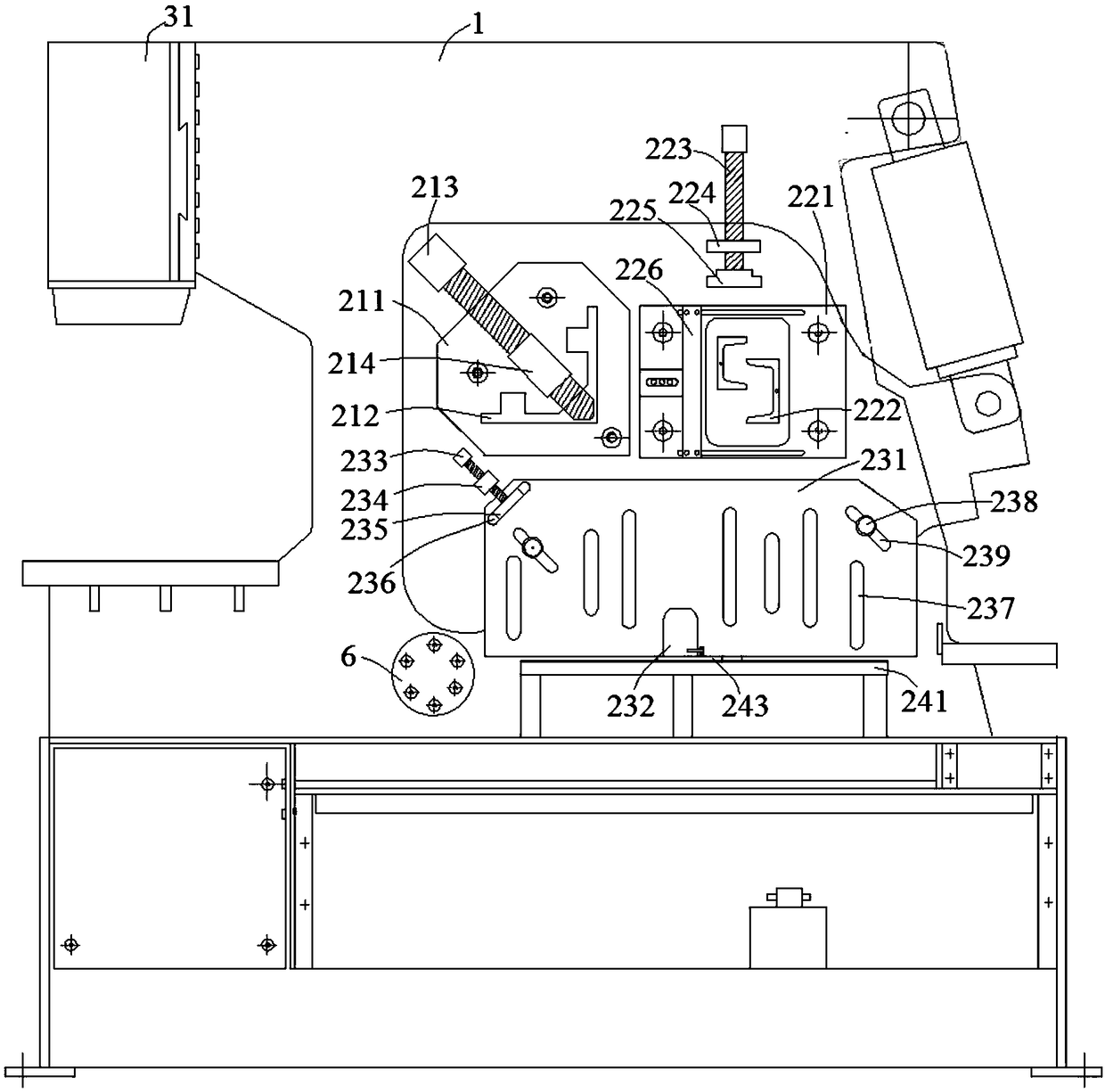

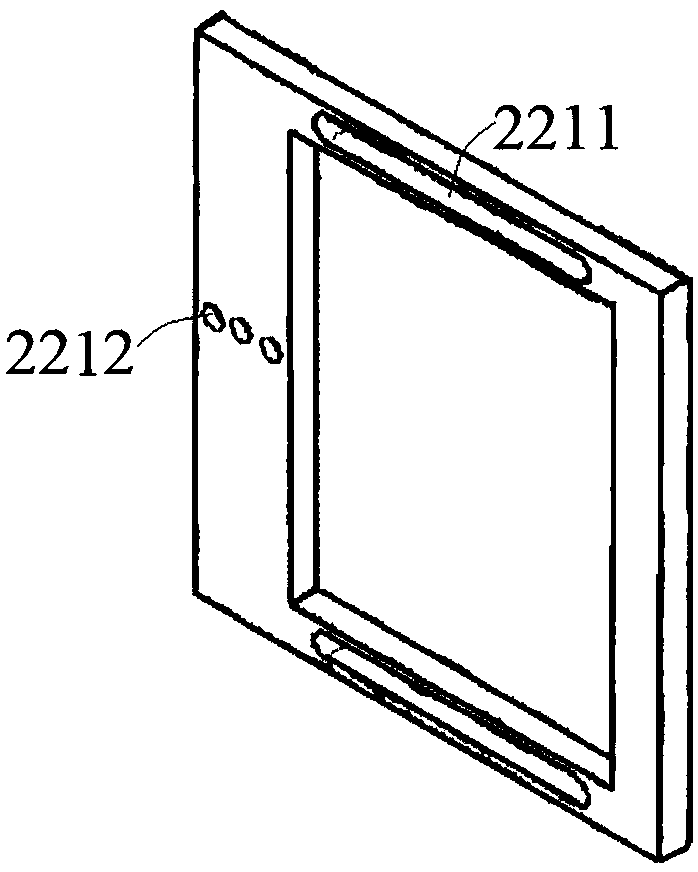

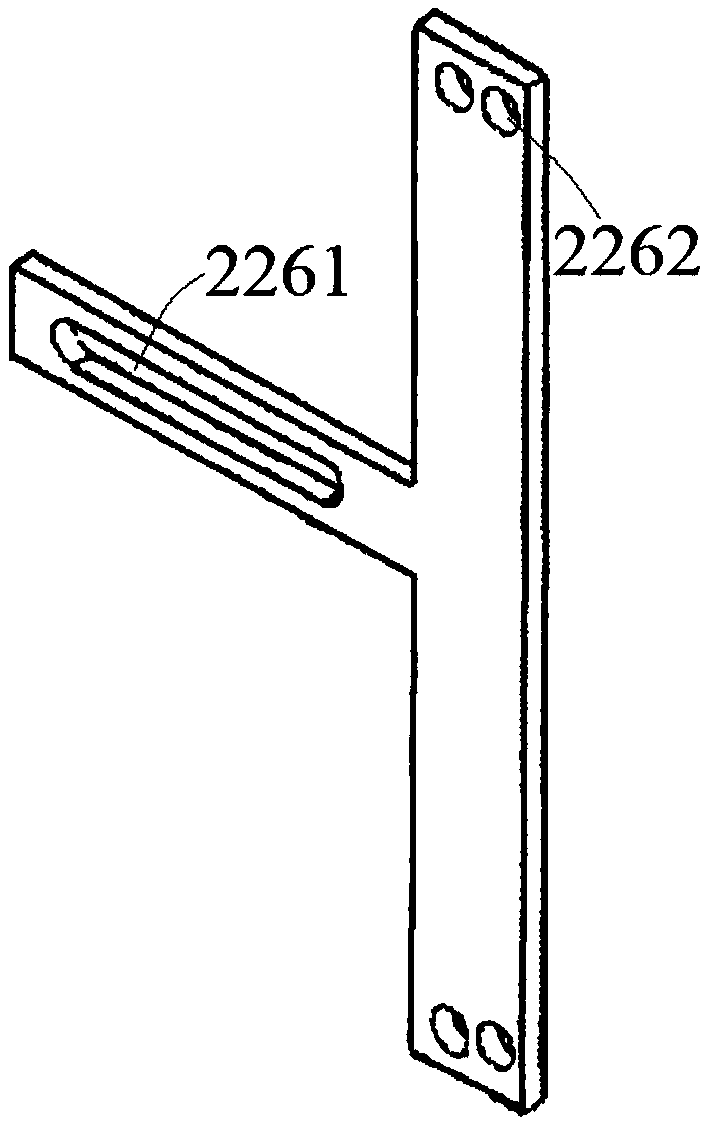

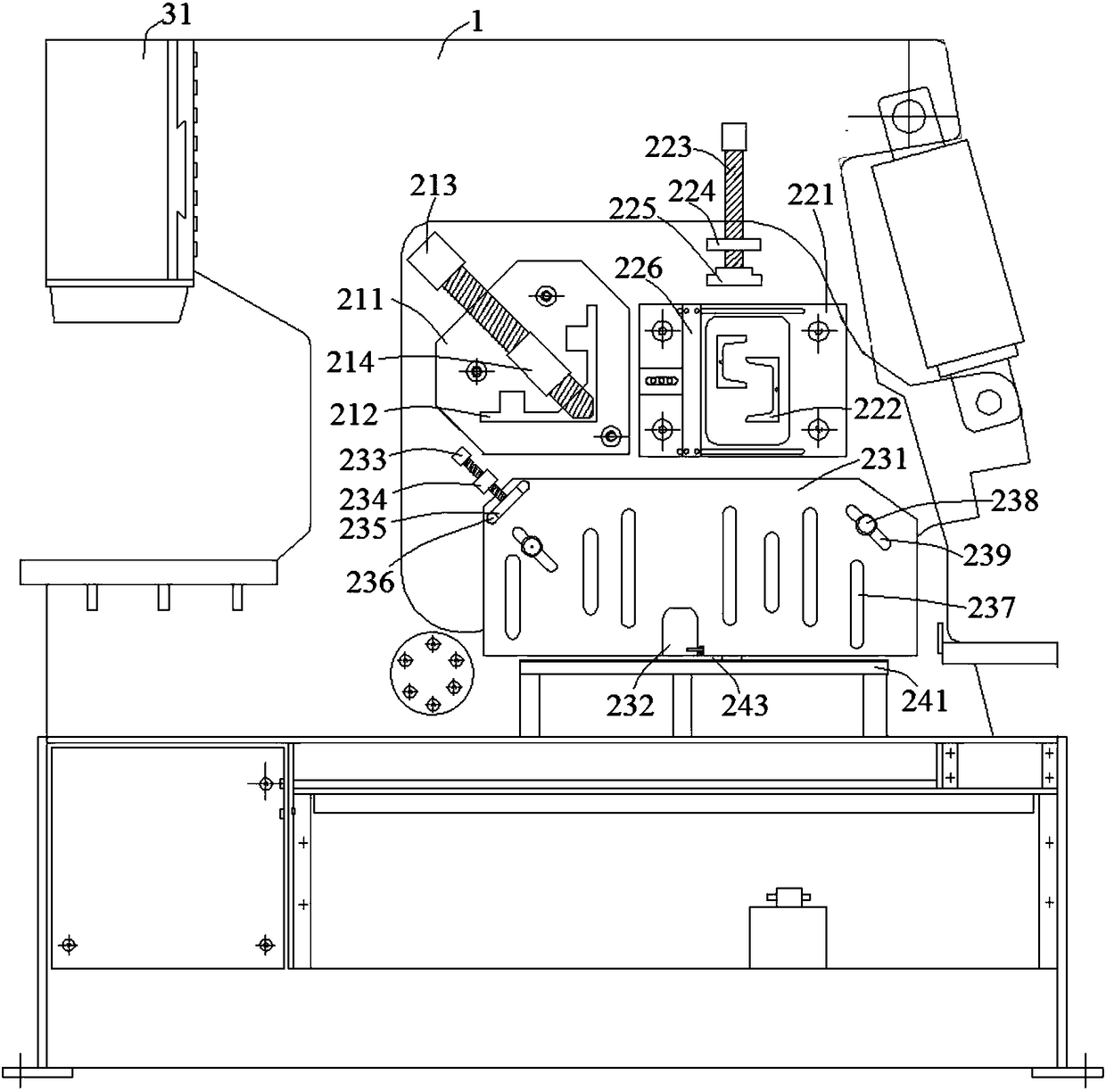

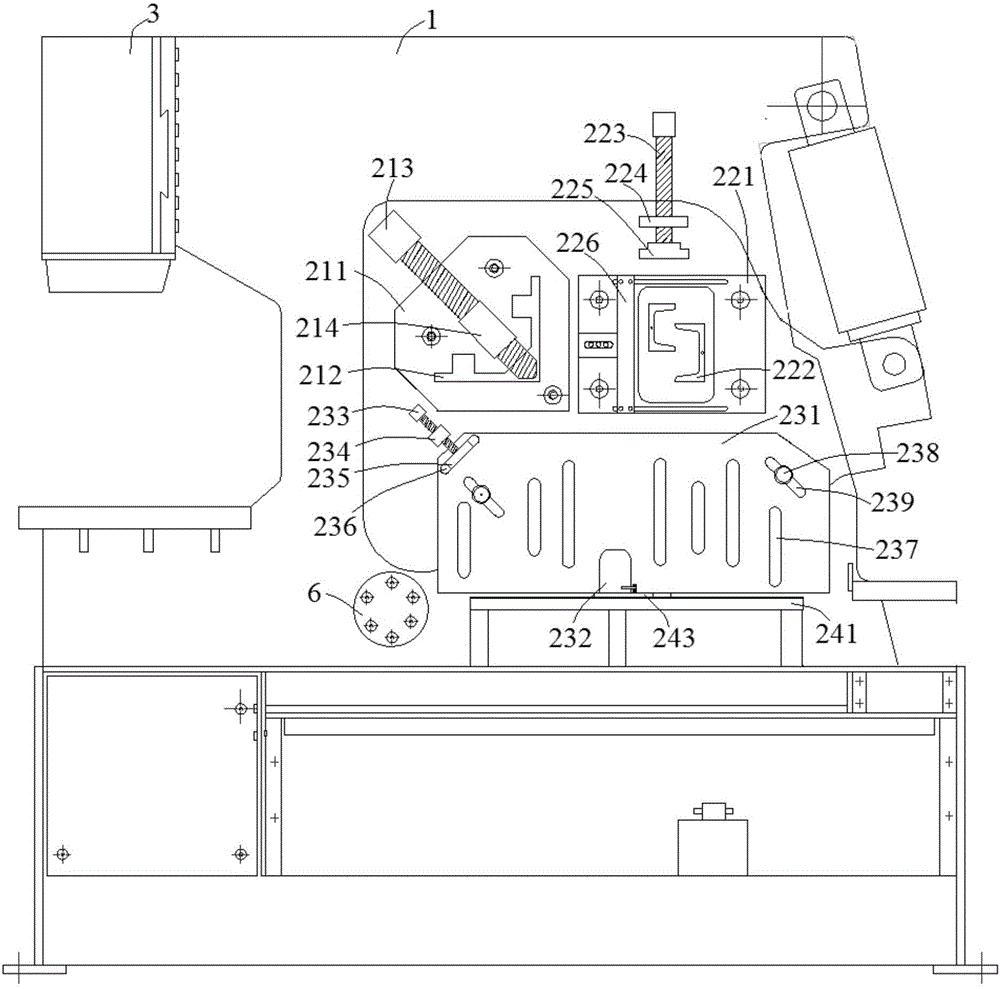

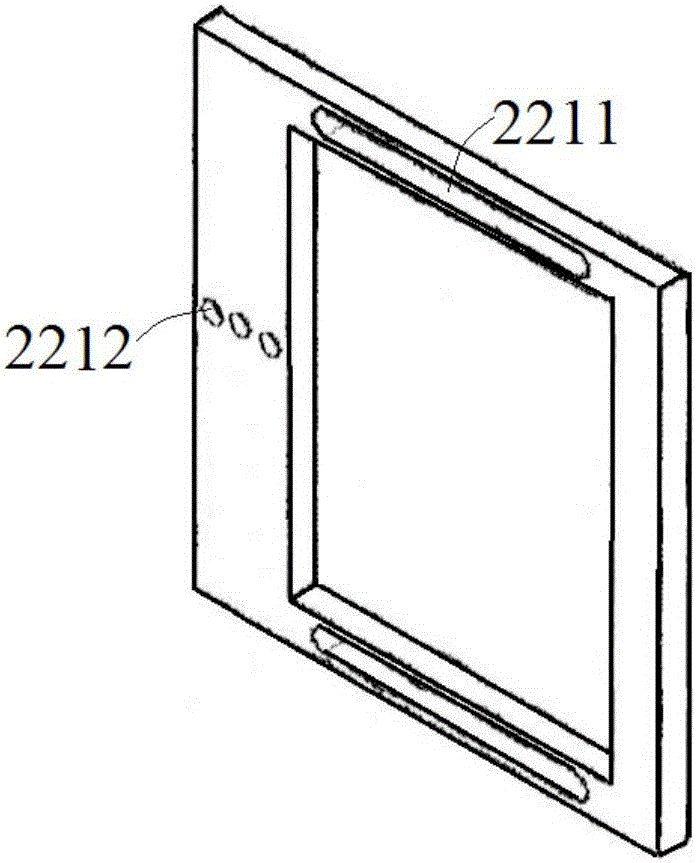

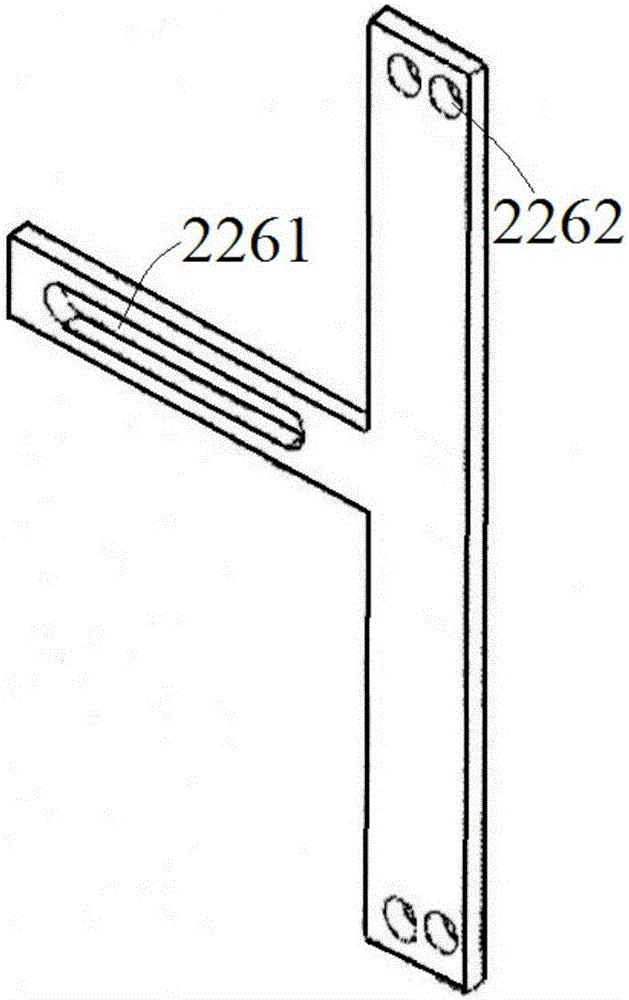

Multifunctional hydraulic combined punching and shearing machine and punching and shearing method thereof

ActiveCN106217058AAvoid deformationImprove punching accuracy and service lifeMetal-working feeding devicesShearing machinesEconomic returnEngineering

The invention discloses a multifunctional hydraulic combined punching and shearing machine and a punching and shearing method thereof, and belongs to the technical field of mechanical processing equipment. The multifunctional hydraulic combined punching and shearing machine comprises a material pressing mechanism, a lower die base pressing mechanism, a rear material blocking mechanism, an oil cylinder fixing mechanism and a cutter plate matching mechanism, wherein a hydraulic oil cylinder in the oil cylinder fixing mechanism is connected with a punching and shearing machine body through second fastening bolts; contact surfaces of the hydraulic oil cylinder and the punching and shearing machine body are oblique wedge surfaces that are matched pairwise; a cutter plate in the cutter plate matching mechanism is connected with an eccentric shaft; and by rotating the eccentric shaft, a moving cutter plate is matched with a static cutter plate. According to the multifunctional hydraulic combined punching and shearing machine and the punching and shearing method, the defects of the conventional punching and shearing machine are overcome, the use effect of the multifunctional hydraulic combined punching and shearing machine is improved, the modification cost of the conventional punching and shearing machine is low, and economic returns are good.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

Self-rotation angle tool

InactiveCN108568675ASimple structurePracticalPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to the technical field of die machining assistance tools, in particular to a self-rotation angle tool which comprises an upper tool assembly and a lower tool assembly. The uppertool assembly comprises a bearing face plate for clamping a workpiece, the lower tool assembly is fixed in the horizontal direction, the end of the upper tool assembly is hinged to the lower tool assembly, the lower tool assembly is provided with a plurality of angle pin holes, the upper tool assembly is provided with an equally-spaced pin hole aligned to one angle pin hole when the bearing face plate rotates at a certain angle, and positioning parts for fixing relative positions of the upper tool assembly and the lower tool assembly are arranged between the angle pin holes and the equally-spaced pin holes. The self-rotation angle tool is simple in structure, good in practicability and capable of saving cost and can rotate itself from 0 degree to 30 degrees.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

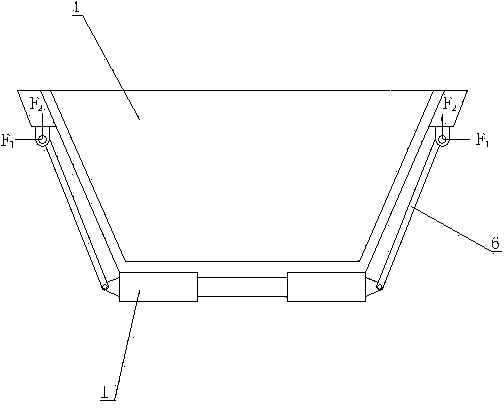

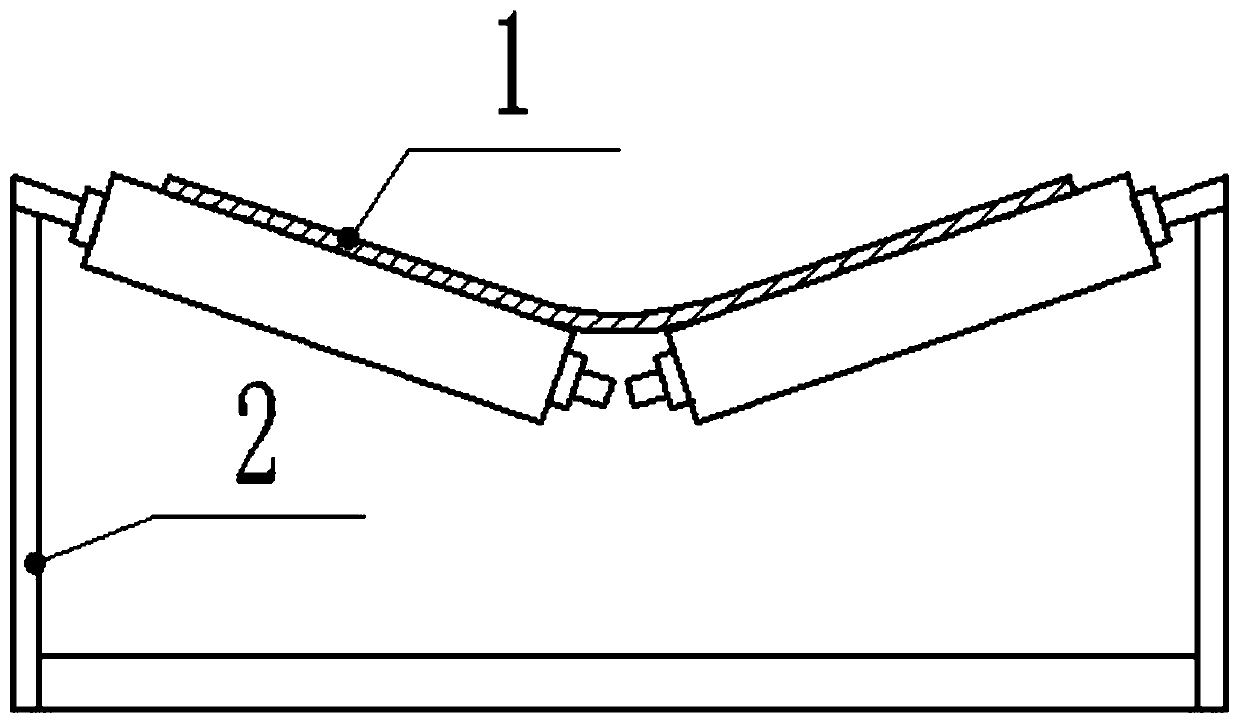

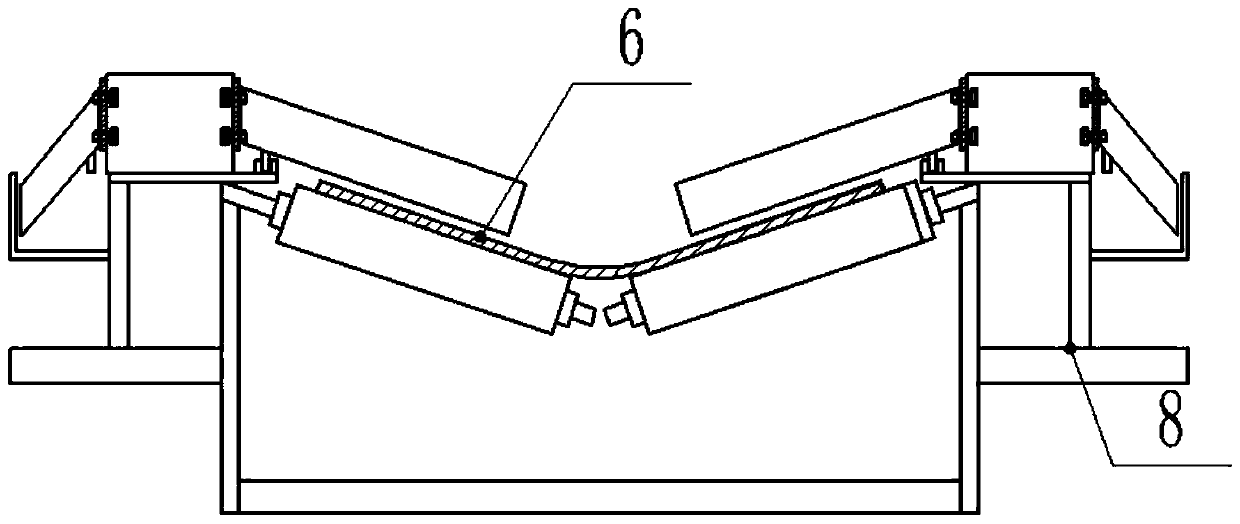

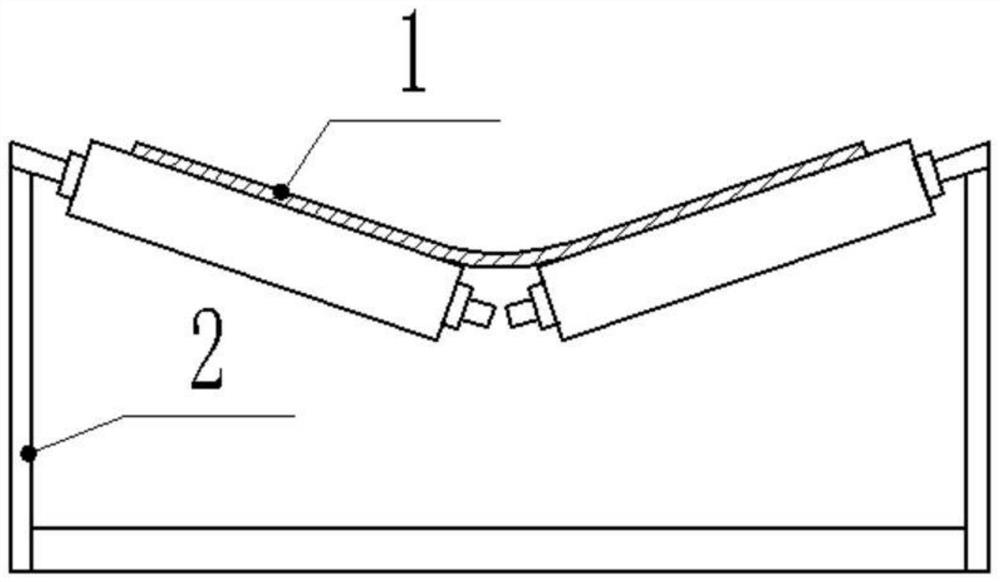

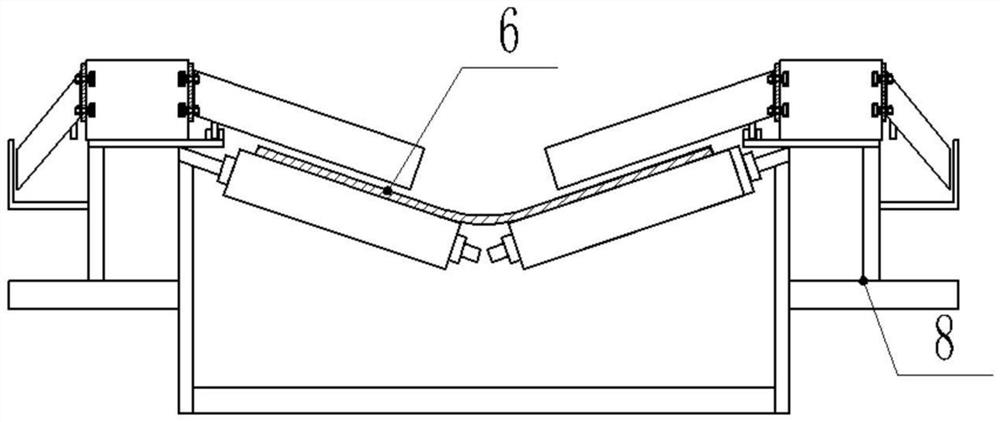

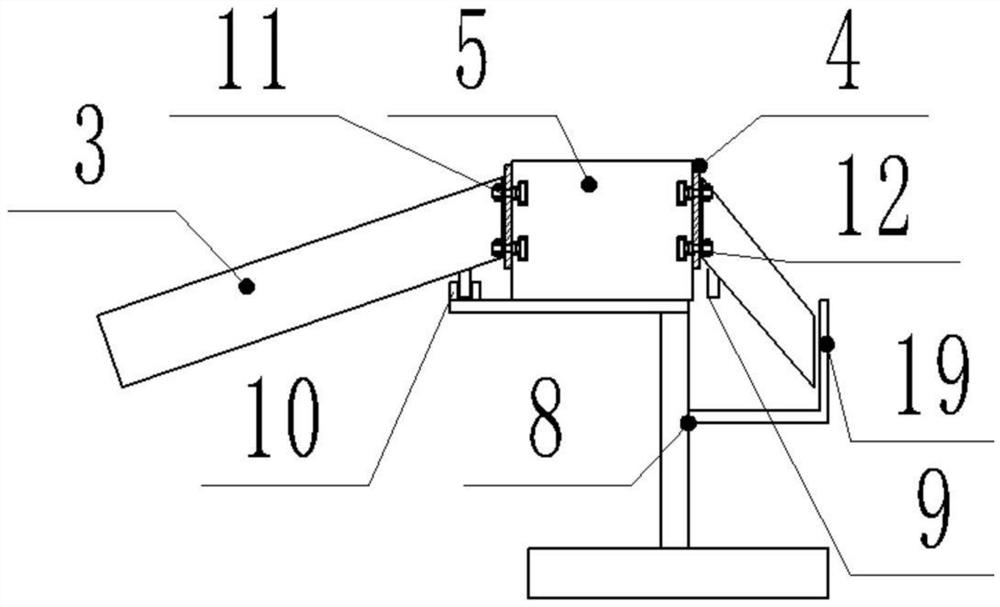

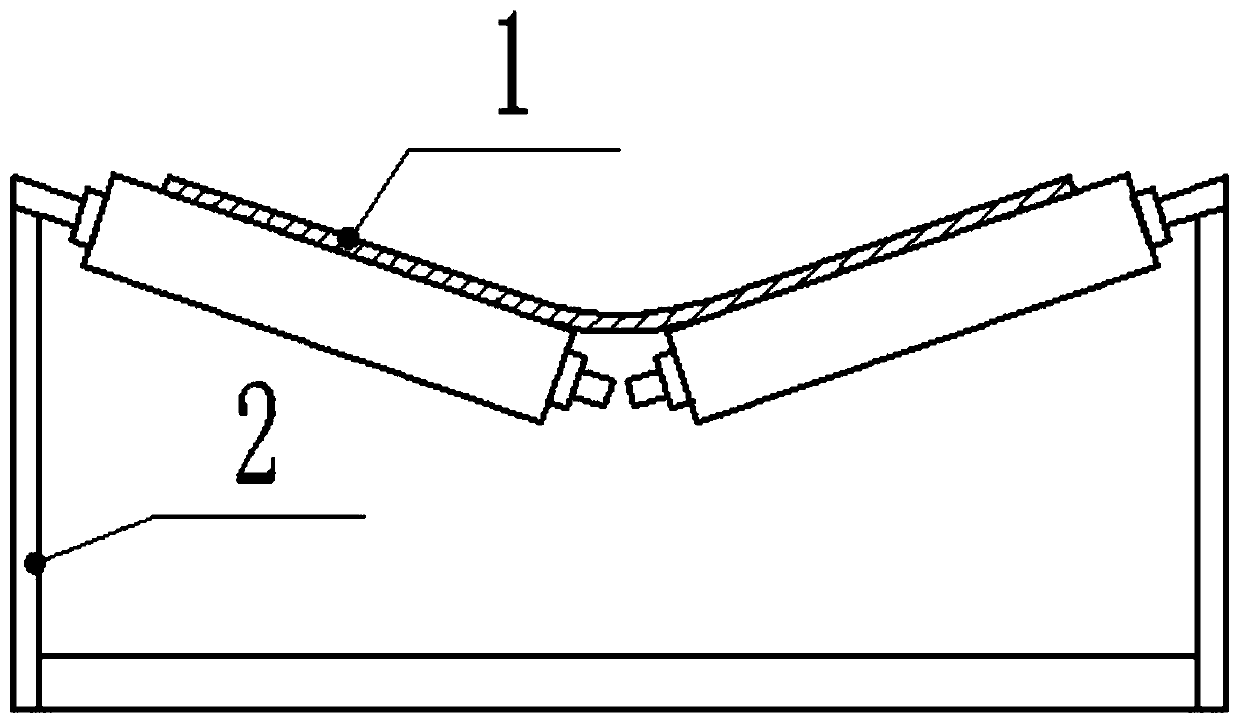

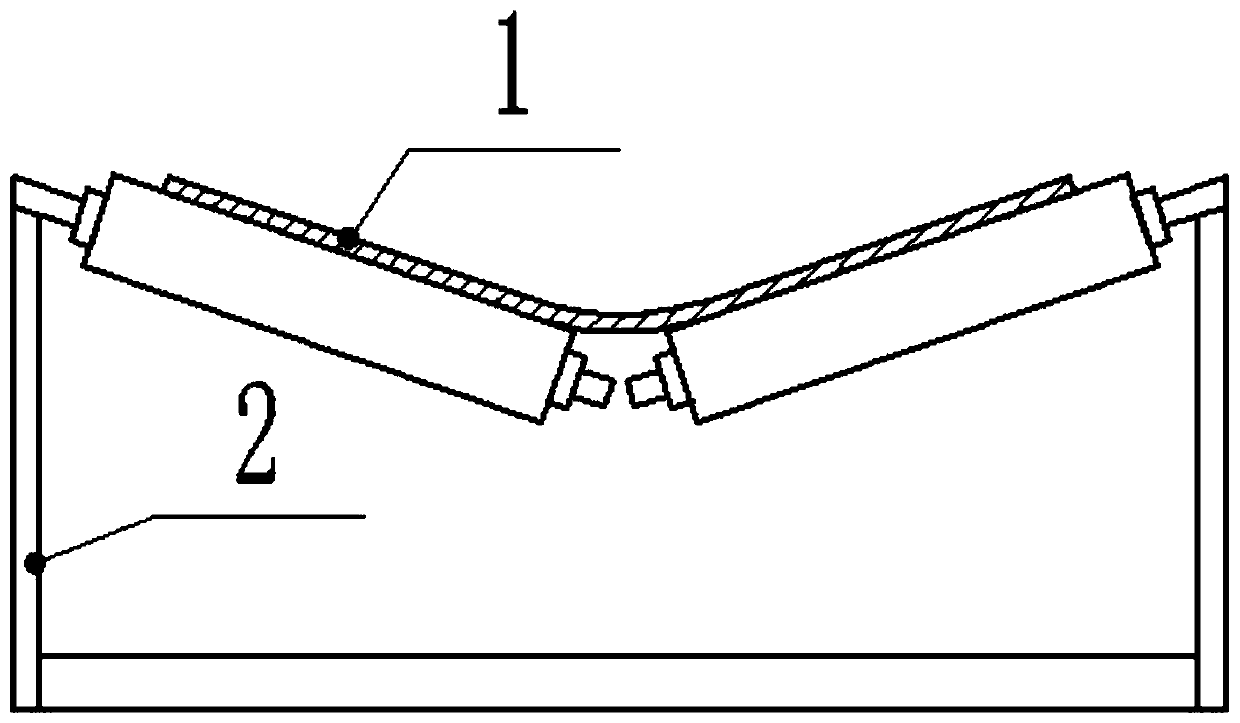

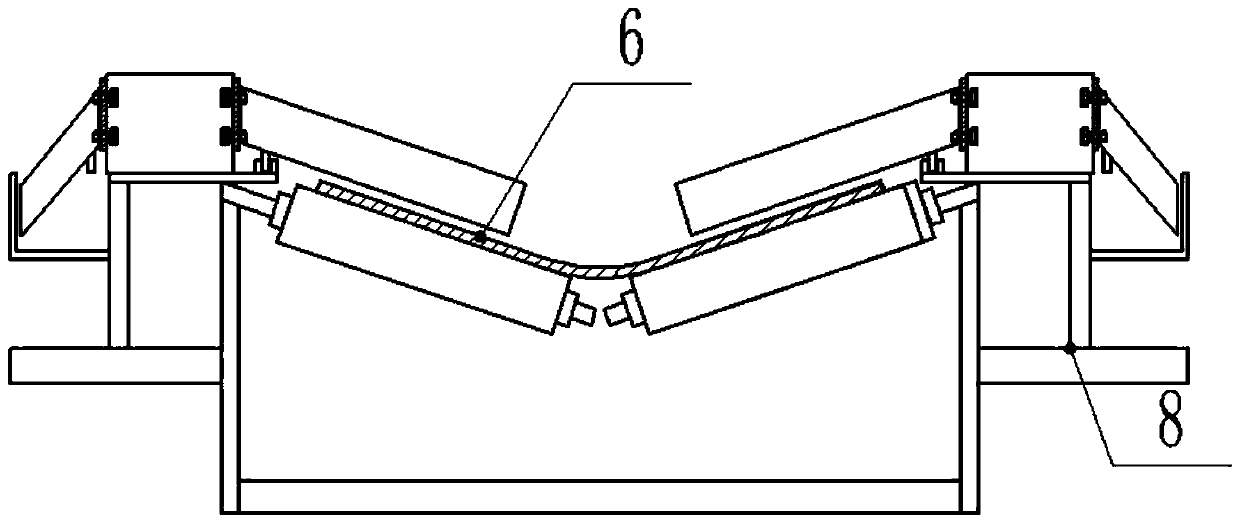

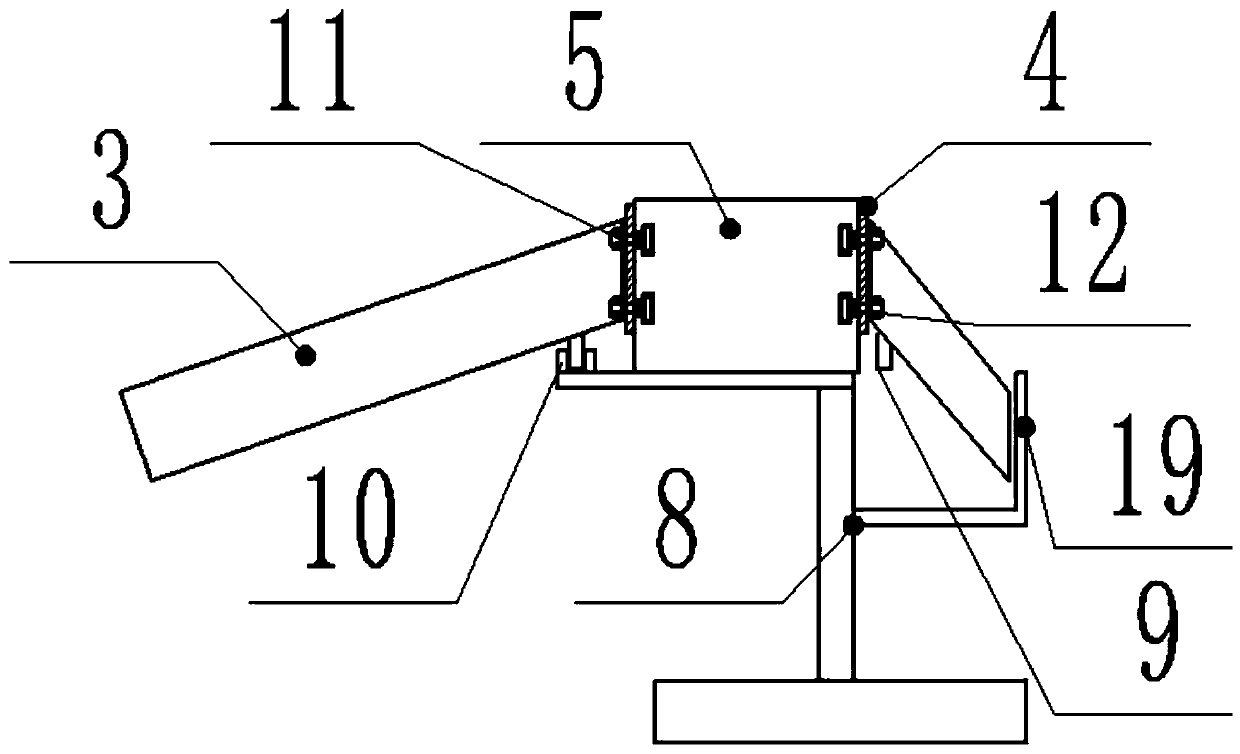

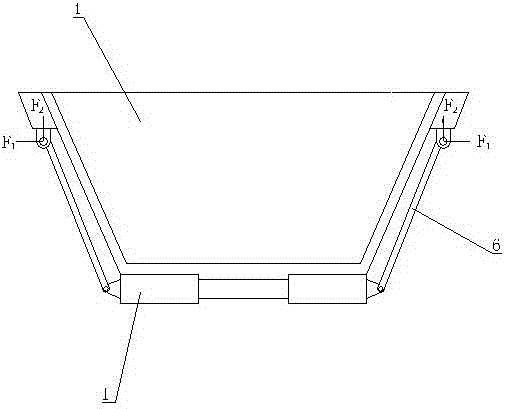

Conveying device for improving conveying efficiency of massive ore or coal

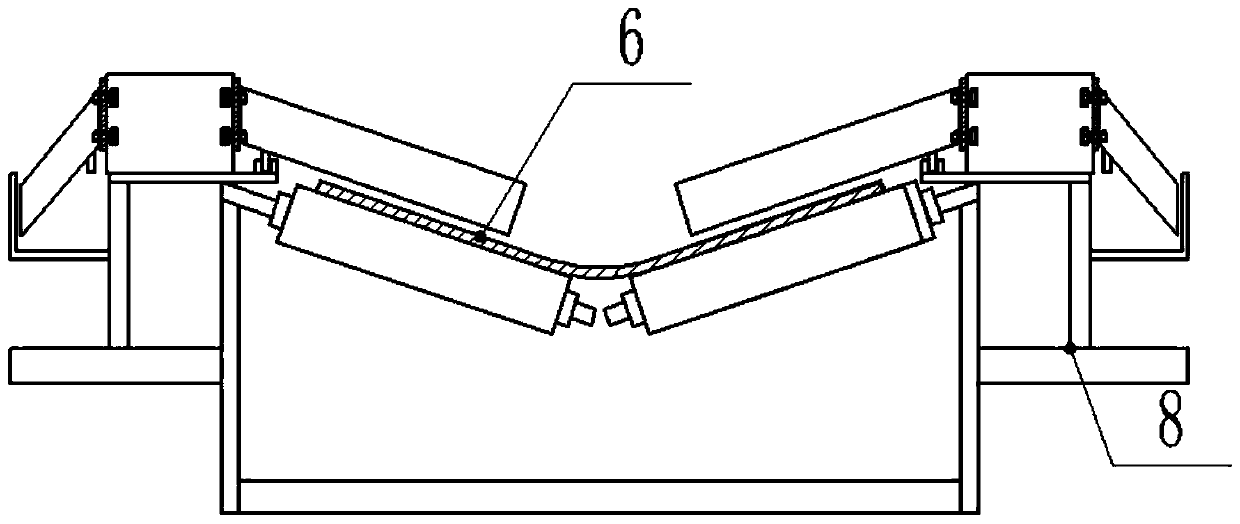

InactiveCN110589353AAvoid interferenceWill not damage the structureConveyorsEngineeringConveyor belt

The invention discloses a conveying device for improving the conveying efficiency of massive ore or coal. The conveying device comprises a conveyor belt, a conveyor belt V-shaped bracket, stop plates,a stop plate conveyor belt and a conveyor belt guide rail bracket; the conveyor belt is laid on the conveyor belt V-shaped bracket in a V shape, and the V-shaped conveyor belt is provided with two conveying sides; and when the stop plates are ready to be taken away from the upper part of the conveyor belt by the stop plate conveyor belt, limiting columns under the stop plates can slide from a limiting slot to a V-shaped limiting slot, and then can be separated from the V-shaped limiting slot, so that the stop plates can rotate around hinge pins, and at this time, the stop plates are close tothe stop plate conveyor belt to be folded through limiting by a limiting plate, thus, the stop plates basically do not occupy the arrangement space of the conveying device, and the conveying device has the practical value. The conveying device solves the problem that when the massive coal or ore is conveyed by the V-shaped conveyor belt with an included angle, stop plates cannot be arranged on theconveyor belt, so that the conveying efficiency of the conveyor belt is low and potential safety hazards exist.

Owner:丰城曲江煤炭开发有限责任公司

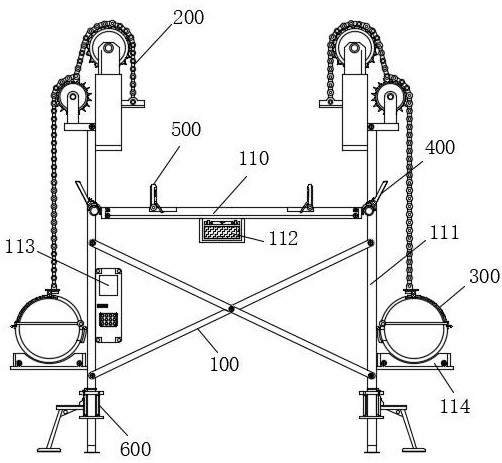

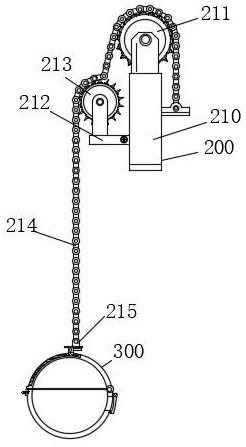

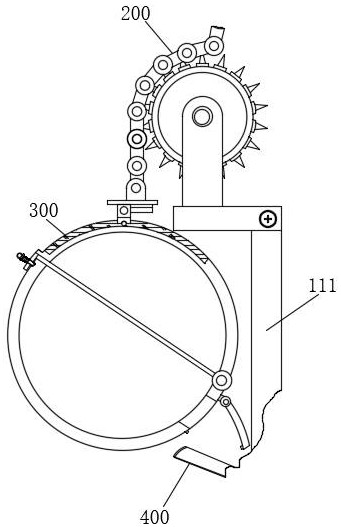

Scaffold with automatic discharging function for building construction

InactiveCN112814361AReduce laborImprove work efficiencyScaffold accessoriesArchitectural engineeringGravity center

The invention relates to the technical field of building construction, and particularly relates to a scaffold with an automatic discharging function for building construction. The scaffold comprises a device body, wherein the device body comprises a scaffold transverse plate, and scaffold supporting columns are fixedly installed on the front face and the back face of the scaffold transverse plate through installation racks. According to the scaffold, a lifting mechanism, a placing conveying mechanism and a material guiding mechanism are arranged, an electric air cylinder drives an arc-shaped placing cylinder to be lifted through a chain body, the arc-shaped placing cylinder is lifted to an installation stop block to be blocked and cannot continue to be lifted, at the moment, the chain body continues to apply upward force to the arc-shaped placing cylinder, the gravity center of the arc-shaped placing cylinder is changed through a sliding structure composed of a sliding groove and a sliding block, and therefore a discharging channel faces downwards; and at the moment, discharging work is carried out through guiding of a material guiding plate and blocking of a material blocking plate, and therefore the labor amount of workers is effectively reduced, and the working efficiency of the workers is greatly improved.

Owner:王一博

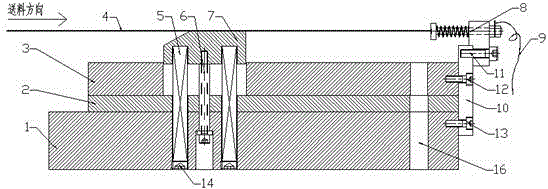

Device for detecting tail end of automobile punch progressive die material strip

InactiveCN104399810AReduce lossesImprove securityShaping toolsShaping safety devicesControl switchWasher

The invention relates to a device for detecting a tail end of an automobile punch progressive die material strip. The device comprises a lower mold holder, a concave mold liner plate and a concave mold plate, and also comprises a detector fixed seat which is fixed on the tail ends of the lower mold holder and the concave mold plate, a detector is fixedly installed on the fixed seat, the detector is provided with a detection rod which is provided with a material strip contact end, a spring, a detector body, a nut and a washer, and the detector is connected with a punch press control switch through a detector switch connecting wire. By adopting the device, the detection precision is high, since the detection rod on the material strip contact end does not contact the material strip at the moment when error in feeding is discovered, a circuit is disconnected, a punch press is stopped working, so that the mold is stopped, the production loss is reduced, and the production safety is improved. A material supporting block device is arranged in the mold, so that after the mold is locked, the problem that the material strip cannot bounce up due to the excessively high pressure of an upper mold and a lower mold can be effectively prevented. The end part of the detector also plays a role in stopping the material, so that a feeding step pitch can be better controlled, and simplicity and convenience in operation can be realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

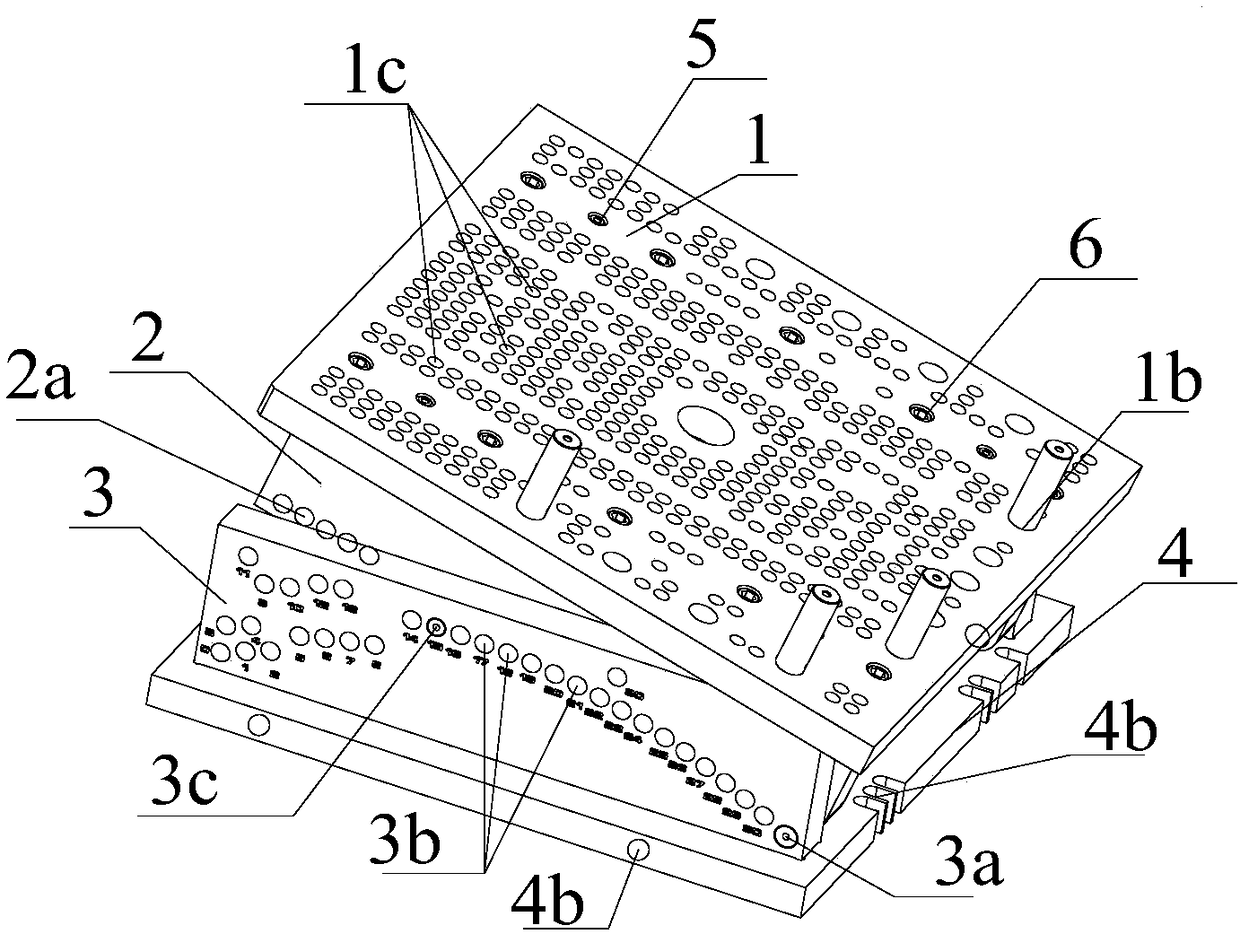

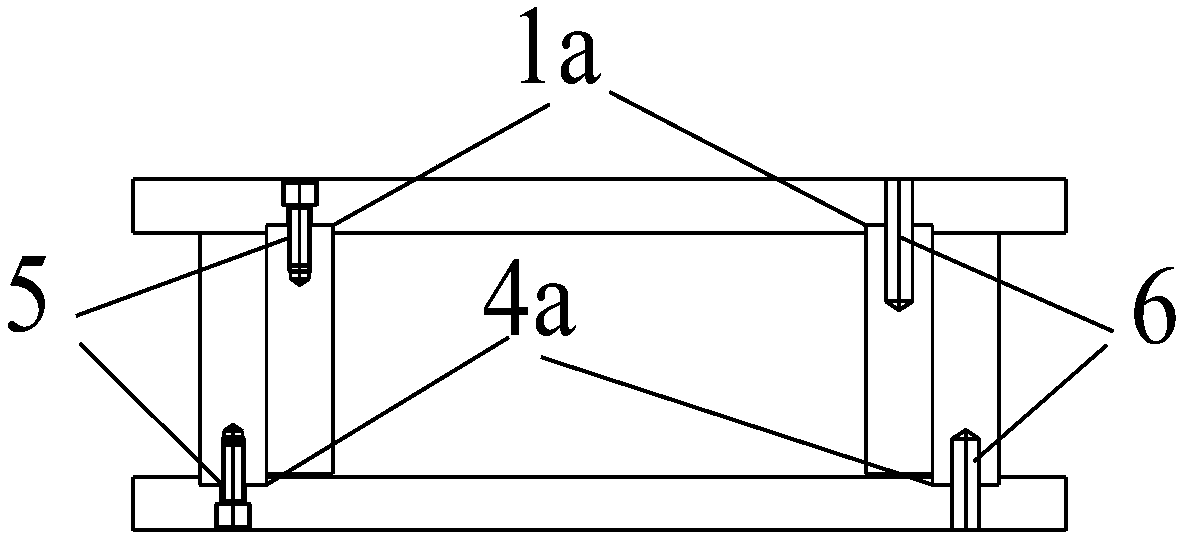

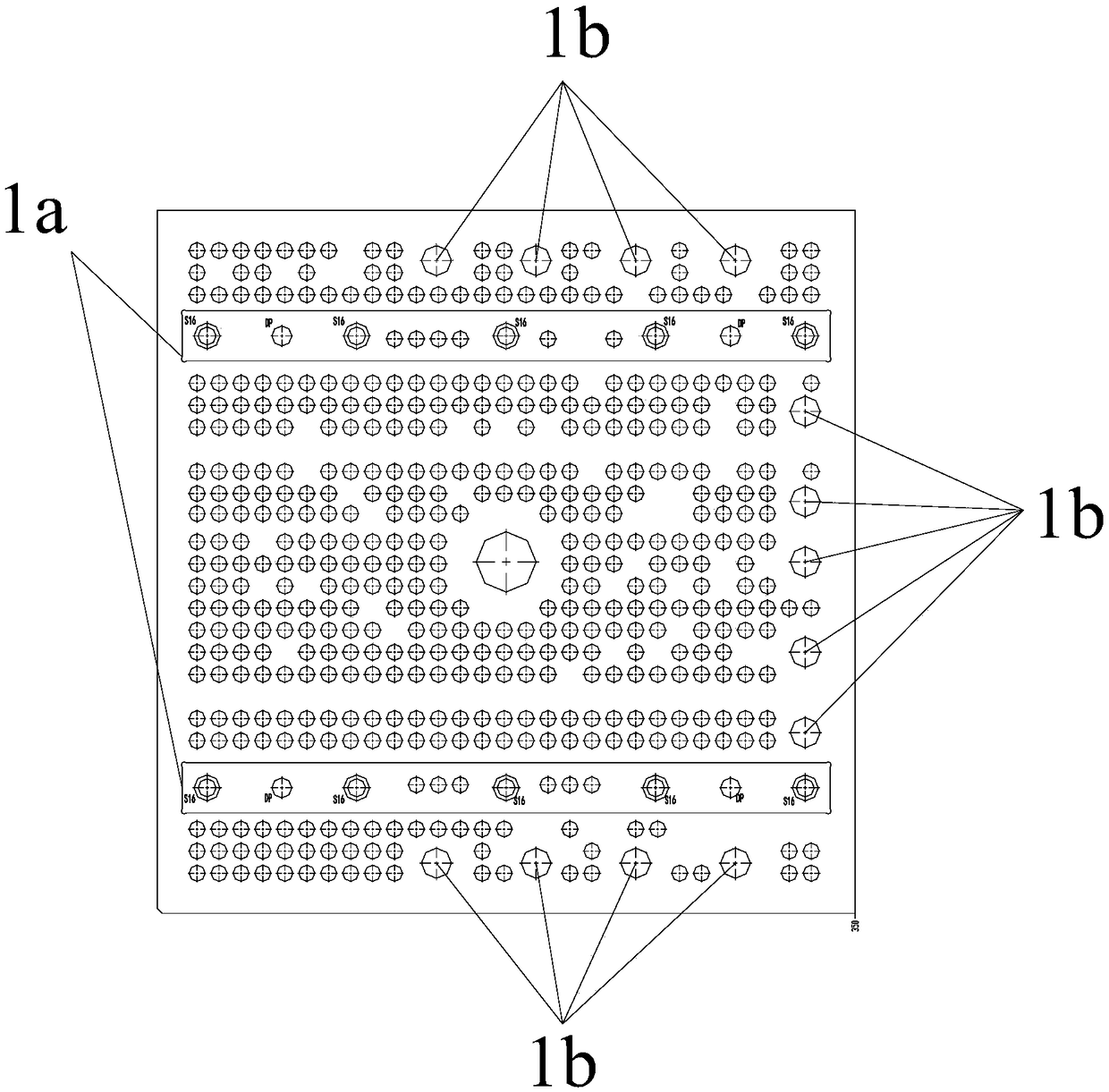

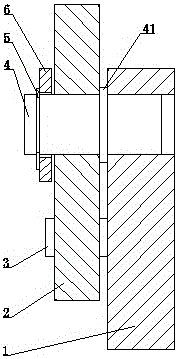

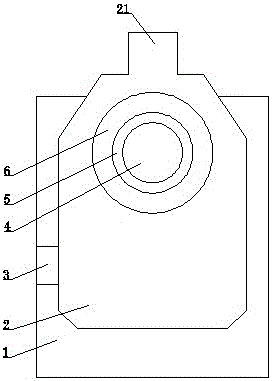

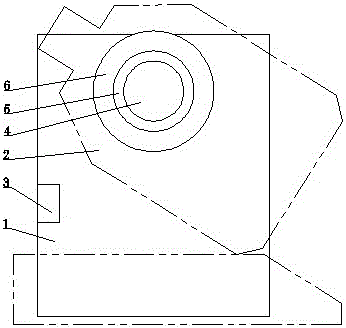

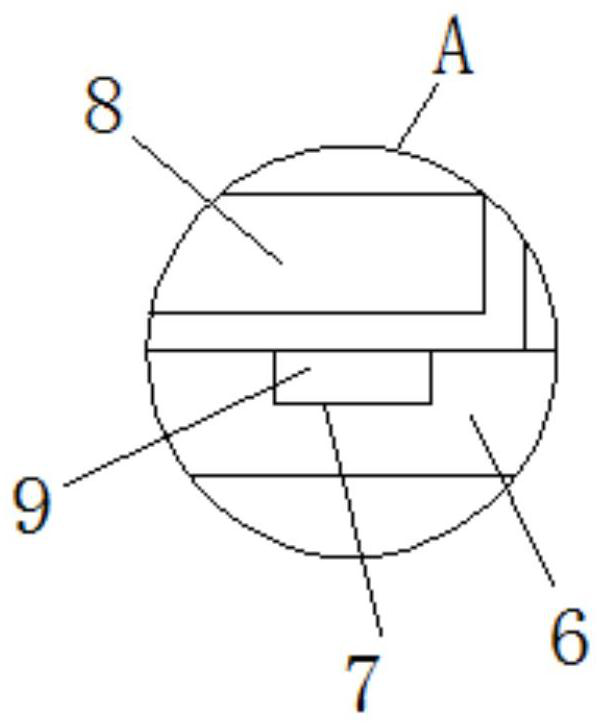

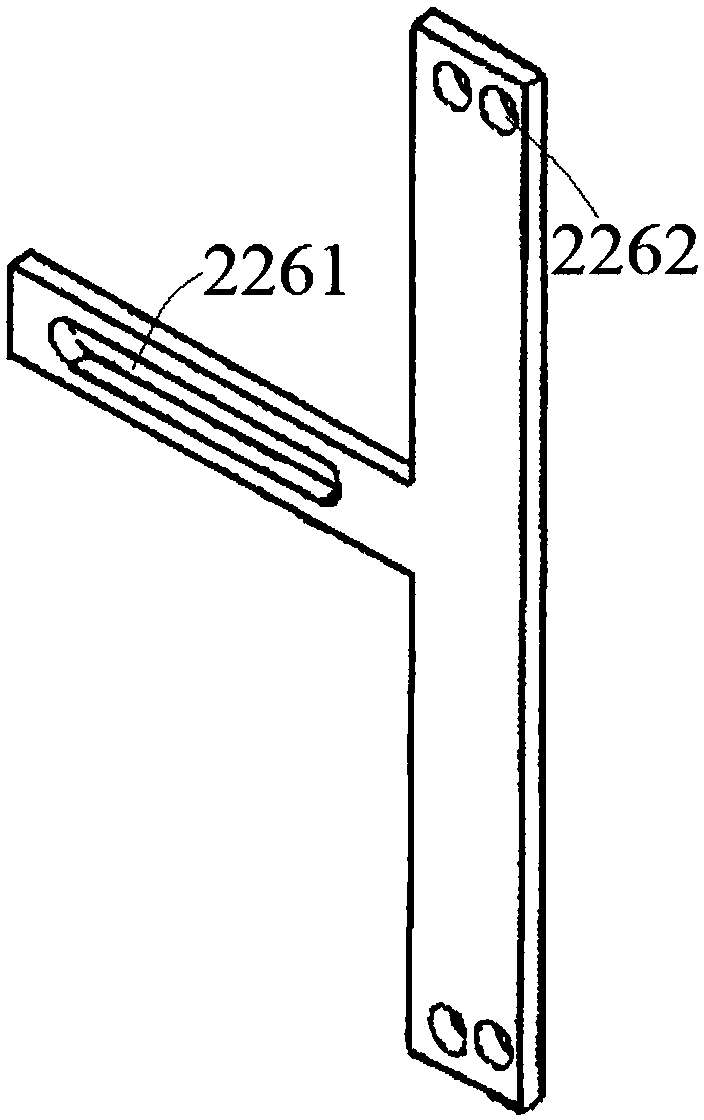

One-direction blocking mechanism of roller bed conveyor

The invention discloses a one-direction blocking mechanism of a roller bed conveyor. The one-direction blocking mechanism of the roller bed conveyor comprises a base plate (1), a blocking plate (2), a limiting block (3), a rotary shaft (4), a stop ring (5) and a gasket (6), a rectangular stopper (21) is arranged on the upper portion of the blocking plate (2); an annular boss (41) is arranged on the middle portion of the rotary shaft (4); the right portion of the rotary shaft (4) is installed into a hole of the base plate (1); the blocking plate (2) and the gasket (6) are installed on the left portion of the rotary shaft (4) sequentially from right to left; the stop ring (5) is installed in an annular slot in the left end of the rotary shaft (4); the limiting block (3) is installed in the position, close to the inner side, of the left side face of the blocking plate (2); and the weight of the portion, below the rotary shaft (4), of the blocking plate (2) is larger than that of the portion, above the rotary shaft (4), of the blocking plate (2). The one-direction blocking mechanism of the roller bed conveyor is simple in structure, safe, reliable and long in service life.

Owner:HUANGSHI HUATIAN AUTOMATION EQUIP

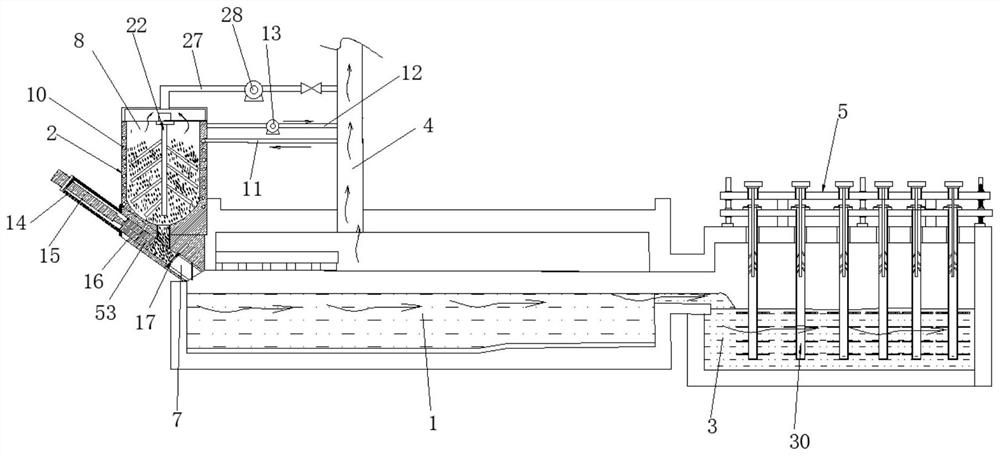

Melting device for glass fiber production

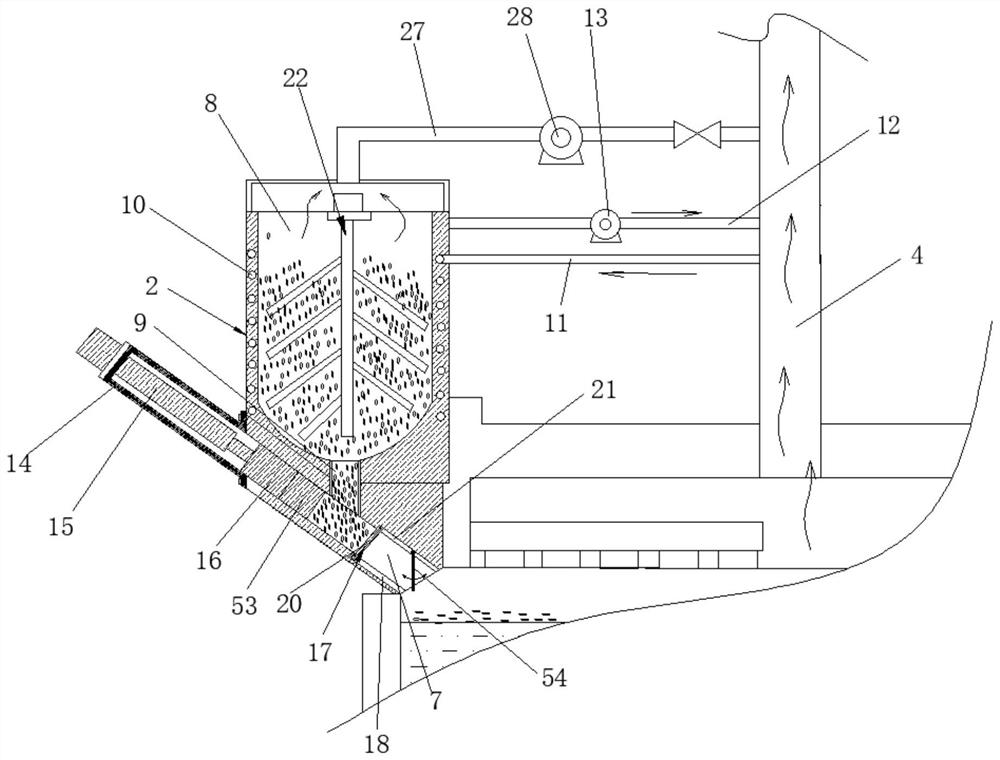

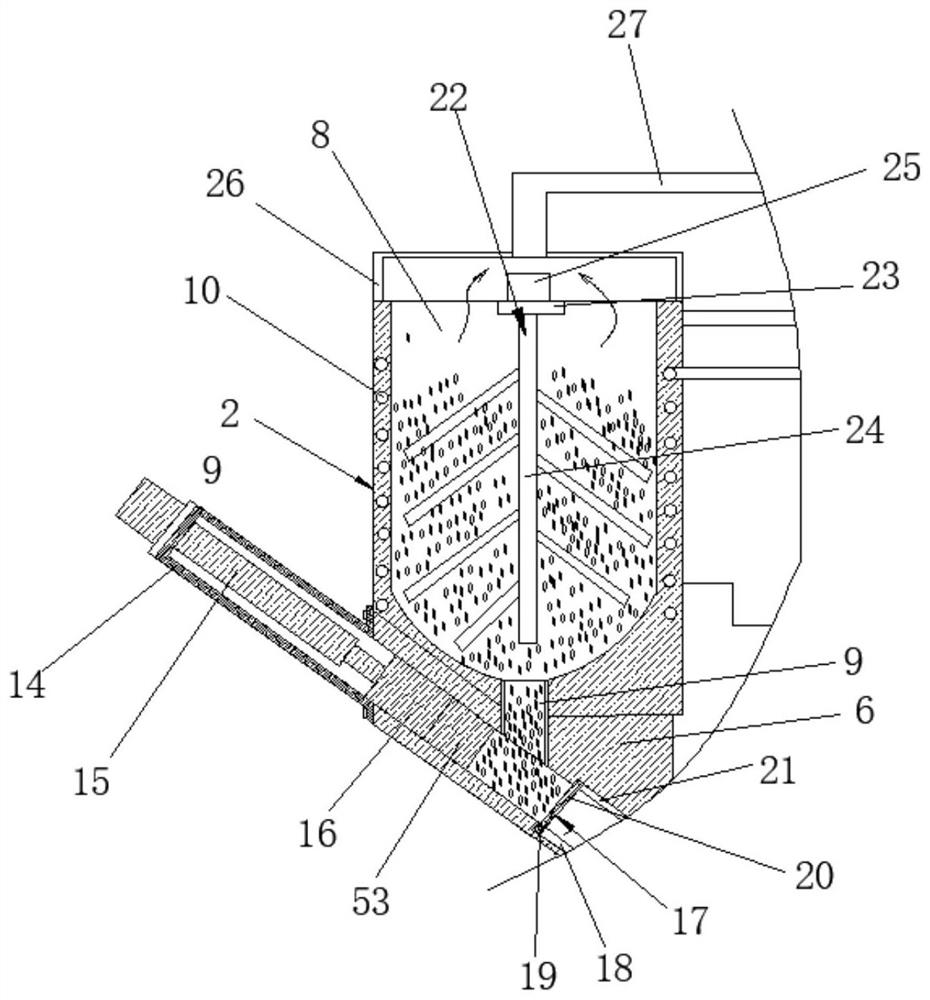

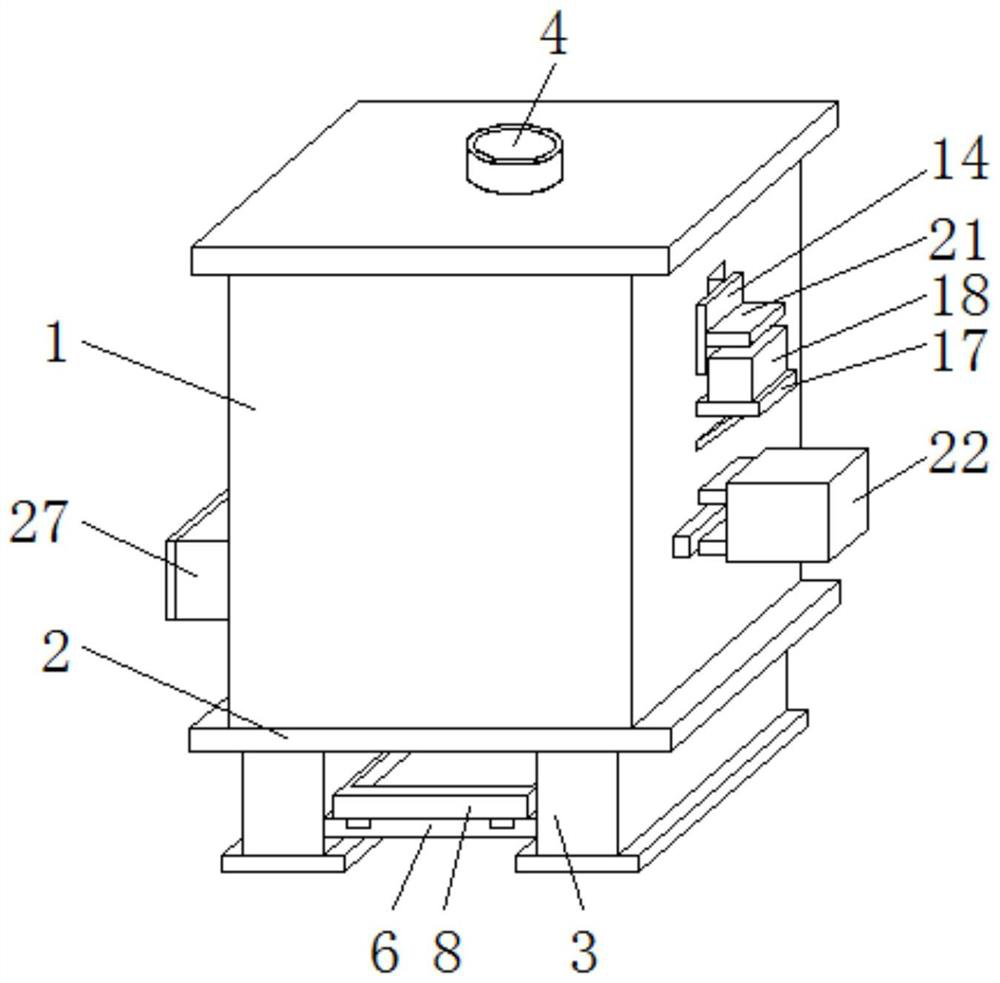

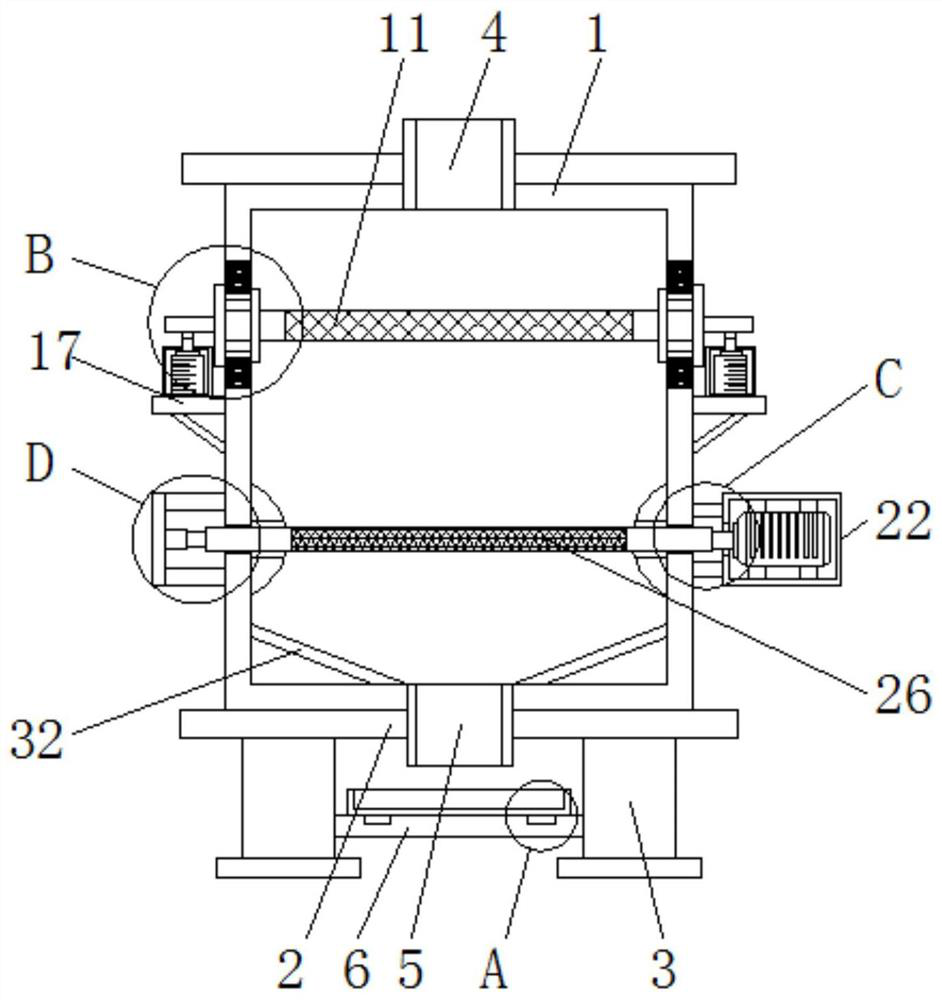

ActiveCN113371996AQuality improvementPrevent overflowCharging furnaceGlass furnace apparatusGlass fiberMelting tank

Owner:SHANDONG FIBERGLASS GRP

Screening device for machining

PendingCN114054346ALabor savingImprove efficiencySievingScreeningStructural engineeringManufacturing engineering

The invention discloses a screening device for machining, which comprises a shell. A bottom plate is fixedly connected to the bottom of the shell, welding columns are welded to the positions, close to the two sides, of the bottom of the bottom plate, a reinforcing plate is fixedly connected to the position, close to the bottom, between the two welding columns, and moving grooves are formed in the positions, close to the two sides, of the top of the reinforcing plate; a material receiving disc is arranged at the top of the reinforcing plate, moving strips are fixedly connected to the positions, close to the two sides, of the bottom of the material receiving disc, the bottoms of the moving strips penetrate into the moving grooves and make contact with the inner walls of the moving grooves, and movable grooves are formed in the positions, close to the top, of the two sides of the shell. According to the screening device for machining, through the design of the first air cylinder, the second air cylinder, the movable groove, the first piston rod, the second piston rod and the supporting plate, manual screening of the screening device is not needed, the automatic screening function is achieved, the labor force is reduced, and the working efficiency is improved.

Owner:翁斌

A punching and shearing method of a multifunctional punching and shearing machine with high cutting quality and convenient operation

ActiveCN106271656BImprove cut qualityEasy to operateMetal-working feeding devicesOther manufacturing equipments/toolsBlade plateEngineering

The invention discloses a convenient-to-operate multifunctional punching and shearing machine with high shearing quality and a punching and shearing method thereof, and belongs to the technical field of machining equipment. The multifunctional punching and shearing machine provided by the invention comprises a knife board matching mechanism, wherein the knife board matching mechanism comprises a knife board matching eccentric shaft, wherein the knife board matching eccentric shaft is provided with an outer fixing plate, a first concentric section, a second eccentric section and a third concentric section sequentially; the knife board matching eccentric shaft transversely penetrates a machine body and is fixed to a wallboard of the machine body through the outer fixing plate; and knife boards are connected with the second eccentric section of the knife board matching eccentric shaft through a connecting plate. The multifunctional punching and shearing machine enables the knife board of a moveable knife to rotate around an elliptic radian and the rotation by the method can guarantee that the knife board of the moveable knife and a knife board of a static knife achieve position matching, so that a knife edge of the moveable knife and a knife edge of the static knife can be matched; the method is implemented once for all, that is, mismatching is not liable to occur when blades are changed again after one-time adjustment, so the use of customers is greatly facilitated.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

Automatic lifting guide chute device

PendingCN114873162AReduce wearExtended service lifeConveyorsControl devices for conveyorsServoEngineering

The invention discloses an automatic lifting guide chute device which comprises a rack, a conveying belt, an upper cover plate and a lifting assembly, the conveying belt is arranged on the rack, the upper cover plate is arranged at the top of the rack, and the lifting assembly is close to the conveying belt and arranged below the upper cover plate; the lifting assembly comprises a servo motor, a movable cavity, a side plate, a threaded rod, a threaded sleeve block, an outer supporting plate, a material blocking plate and a connecting plate, the outer supporting plate is arranged on the outer side wall of the rack, one end of the side plate is arranged below the upper cover plate, the other end of the side plate is arranged on the outer supporting plate, the movable cavity is formed in the side plate, and the servo motor is arranged below the top wall of the movable cavity. The invention belongs to the technical field of conveying mechanical equipment, and particularly relates to an automatic lifting guide chute device which can automatically adjust the height of a striker plate, so that the striker plate is not in contact with a conveying belt in a no-load state, the abrasion degree of the striker plate and the conveying belt is reduced, the service life of the conveying belt is prolonged, and the production cost is reduced.

Owner:沈阳金鼎电科环境工程有限公司

A binder for perlite thermal insulation products and its preparation method

The invention discloses an adhesive for an adiabatic pearlite product and a preparation method of the adhesive. The adhesive is prepared from raw materials as follows: heavy calcium carbonate, white cement, calcium silicon powder, a thickening agent, redispersible latex powder, pregelatinized cassava starch and water. The preparation method comprises the following steps: (a), adjusting a region between a second connecting plate and a third connecting plate; (b), mixing heavy calcium carbonate with the white cement; (c), preparing glue; (d), discharging the mixture of heavy calcium carbonate and white cement into the glue for mixing; (e), collecting the adhesive; (f), cleaning a two-way preparation device. Heavy calcium carbonate and the white cement are fully mixed and guided, the water-soluble glue is prepared from the pregelatinized cassava starch and water through mixing, the whole two-way preparation device is then rotated by 180 degrees to discharge the mixture of heavy calcium carbonate and white cement into the glue for mixing and stirring, the mixing speed is high, preparation space is small, and the preparation cost can be effectively reduced; the prepared adhesive is cured more quickly and has higher strength and better temperature resistance.

Owner:ZHEJIANG ASKER TECH

A punching and shearing method of a multifunctional hydraulic combined punching and shearing machine

ActiveCN106217058BHigh precisionExtended service lifeMetal-working feeding devicesShearing machinesEngineeringMachining

The invention discloses a multifunctional hydraulic combined punching and shearing machine and a punching and shearing method thereof, and belongs to the technical field of mechanical processing equipment. The multifunctional hydraulic combined punching and shearing machine comprises a material pressing mechanism, a lower die base pressing mechanism, a rear material blocking mechanism, an oil cylinder fixing mechanism and a cutter plate matching mechanism, wherein a hydraulic oil cylinder in the oil cylinder fixing mechanism is connected with a punching and shearing machine body through second fastening bolts; contact surfaces of the hydraulic oil cylinder and the punching and shearing machine body are oblique wedge surfaces that are matched pairwise; a cutter plate in the cutter plate matching mechanism is connected with an eccentric shaft; and by rotating the eccentric shaft, a moving cutter plate is matched with a static cutter plate. According to the multifunctional hydraulic combined punching and shearing machine and the punching and shearing method, the defects of the conventional punching and shearing machine are overcome, the use effect of the multifunctional hydraulic combined punching and shearing machine is improved, the modification cost of the conventional punching and shearing machine is low, and economic returns are good.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

A method for improving the transmission efficiency of bulk ore or coal

ActiveCN110589354BImprove transmission efficiencyWill not damage the structureConveyorsMining engineeringStructural engineering

The invention discloses a method for improving the conveying efficiency of block ore or coal. The mined ore or coal is placed on the conveying surface of any position of the conveyor belt, and the initially placed ore or coal is squeezed on at least two rows of baffle plates. Until the baffle plate and the conveying surface of the conveyor belt move synchronously; then the ore or coal is continuously placed on the conveying surface at the bottom end of the conveyor belt for transmission. When the baffle plate and the conveying surface of the conveyor belt move synchronously, the baffle plate passes through The baffle conveyor belt is pulled on the conveyor belt guide frame to circulate and run. When the baffle plate runs from the outside of the conveyor belt guide frame to the conveyor belt inside the conveyor belt guide frame, the limit post under the baffle plate slides into the limit slot, and passes through the baffle plate. The hinge point of the conveyor belt of the material plate and the baffle plate, and the limit point of the limit column at the limit point of the limit slot are jointly limited, so that the baffle plate is unfolded on the conveyor belt to act as a material stopper, which can increase the transportation of ore or ore on the conveyor belt. Coal thickness, thereby improving transportation efficiency.

Owner:江门市新会区泰盛石场有限公司

A transmission device aimed at improving the transmission efficiency of lumpy ore or coal

InactiveCN110589353BAvoid interferenceWill not damage the structureConveyorsMining engineeringStructural engineering

The invention discloses a conveying device for improving the conveying efficiency of massive ore or coal. The conveying device comprises a conveyor belt, a conveyor belt V-shaped bracket, stop plates,a stop plate conveyor belt and a conveyor belt guide rail bracket; the conveyor belt is laid on the conveyor belt V-shaped bracket in a V shape, and the V-shaped conveyor belt is provided with two conveying sides; and when the stop plates are ready to be taken away from the upper part of the conveyor belt by the stop plate conveyor belt, limiting columns under the stop plates can slide from a limiting slot to a V-shaped limiting slot, and then can be separated from the V-shaped limiting slot, so that the stop plates can rotate around hinge pins, and at this time, the stop plates are close tothe stop plate conveyor belt to be folded through limiting by a limiting plate, thus, the stop plates basically do not occupy the arrangement space of the conveying device, and the conveying device has the practical value. The conveying device solves the problem that when the massive coal or ore is conveyed by the V-shaped conveyor belt with an included angle, stop plates cannot be arranged on theconveyor belt, so that the conveying efficiency of the conveyor belt is low and potential safety hazards exist.

Owner:丰城曲江煤炭开发有限责任公司

Punching and shearing method of assembly type heavy hydraulic punching and shearing machine with high punching and shearing precision

ActiveCN108057770AHigh precisionExtended service lifePerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a punching and shearing method of an assembly type heavy hydraulic punching and shearing machine with high punching and shearing precision, and belongs to the technical field of machining processing equipment. The punching and shearing machine includes a material pressing mechanism, a lower mould seat compressing mechanism, a back material blocking mechanism, and an oil cylinder fixing mechanism. Wherein a hydraulic oil cylinder in the oil cylinder fixing mechanism and a punching and shearing machine body are connected through a second fastening bolt, and the contact surfaces of the hydraulic oil cylinder and the machine body are inclined wedge surfaces matched in pairs. The side surface of the hydraulic oil cylinder is provided with a groove or a convex table, andcorrespondingly, the side surface of the machine body is provided with a convex table or a groove matched with the groove or the convex table. The convex table is a T-shaped convex table or a swallowtail shaped convex table. The groove is a T-shaped groove or a swallow tail shaped groove, wherein the size of the T-shaped groove or the swallow tail shaped groove is matched with the size of the convex table. According to the punching and shearing method, the using effect of the punching and shearing machine is improved; the improvement cost to an existing punching and shearing machine is low; and the economic efficiency is good.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

Method for improving conveying efficiency of massive ore or coal

ActiveCN110589354AWill not damage the structureAvoid interferenceConveyorsEngineeringMechanical engineering

The invention discloses a method for improving the conveying efficiency of massive ore or coal. The mined ore or coal is placed on a conveying surface at any position of a conveying belt, and the initially placed ore or coal is at least extruded on two rows of material baffles until the material baffles and the conveying surface of the conveying belt move synchronously; and then the ore or coal iscontinuously placed on the conveying surface of the bottom end part of the conveying belt to be conveyed, when the material baffles move synchronous with the conveying surface of the conveying belt,the material baffles are pulled on a conveying belt guide rail frame through a material baffle conveying belt to circularly operate, and when the material baffles move from the outer side of the conveying belt guide rail frame to the conveying belt on the inner side of the conveying belt guide rail frame, limiting columns below the material baffles slide into limiting grooves, through the joint limit of hinge points of the material baffles and the material baffle conveying belt and limit points of the limiting columns in the limiting grooves, the material baffles are unfolded on the conveyingbelt to play a material blocking role, so that the thickness of the ore or coal transported on the conveying surface of the conveying belt can be increased, and the transportation efficiency is further improved.

Owner:江门市新会区泰盛石场有限公司

An articulated dump truck container assembly and its loading and unloading method

ActiveCN104071063BHigh strengthImprove carrying capacityUnderstructuresVehicle with tipping movementEngineeringLoading unloading

The invention discloses a hinged dumper container assembly, and loading and unloading methods thereof. The container assembly comprises a rear frame and a container, wherein the rear frame comprises a rear frame longitudinal beam assembly, a frame anti-torsion tube, a rear frame lifting seat, a lower hinge seat, a lower bolt seat and a hinge body bearing; the container comprises a bottom plate, a rear tilted plate, a left side plate, a right side plate and a front plate, a left longitudinal beam and a right longitudinal beam are arranged on the left side plate and the right side plate respectively, a left lifting support seat and a right lifting support seat bulging out of the left longitudinal beam and the right longitudinal beam are arranged on the left longitudinal beam and the right longitudinal beam respectively, and an upper hinge seat and an upper bolt seat are arranged at the bottom of the container. The loading method is as follows: returning the container, and loading materials in the container; the unloading method is as follows: turning the container by a lifting oil cylinder, and when the container is turned to a certain position, connecting the upper bolt seat with the lower bolt seat by a bolt; during the turnover process of the container, the materials are detached from the container. The container assembly, and the loading and unloading methods thereof disclosed by the invention are capable of improving the anti-torsion capacity of the frame, improving the bearing capacity and strength of the lifting support seat realizing location for the container, and improving the safety performance of loading and unloading.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

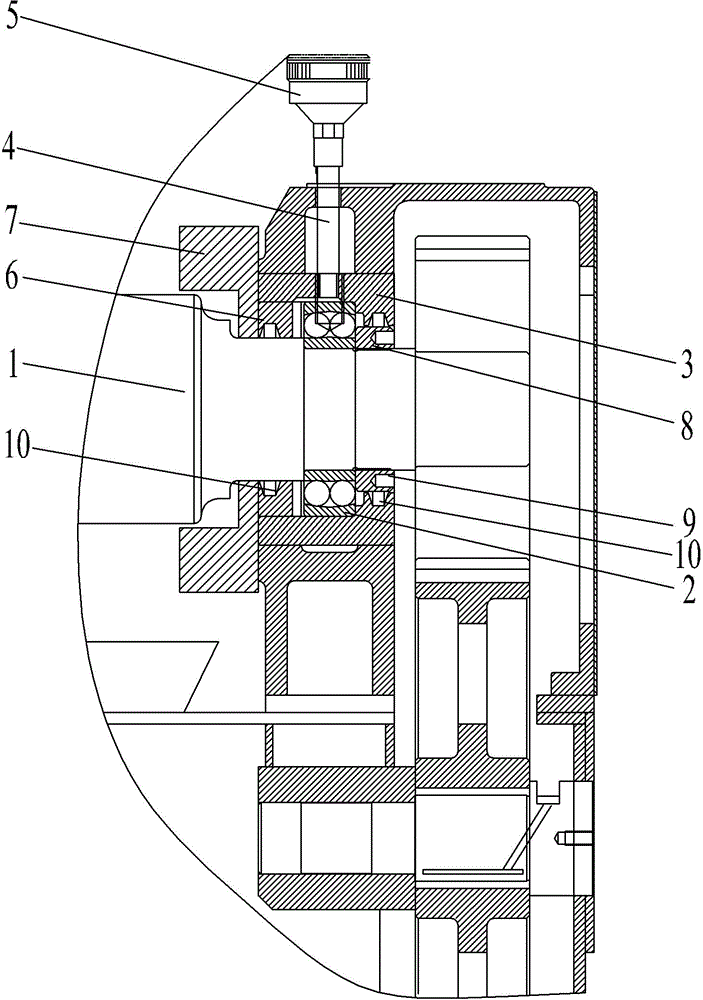

Leakage-proof structure used for roller in open mill

InactiveCN104647627ASimple structurePlay the role of retaining materialEngine sealsEngineeringScrew thread

The invention provides a leakage-proof structure used for a roller in an open mill, wherein the leakage-proof structure is simple in structure, can effectively avoid oil leakage during operation and is high in production efficiency. The leakage-proof structure includes a roller body. A bearing is fixed on one end of the roller body. A bearing base is fixed on the bearing and is provided with an oil filling pipe. The oil filling pipe is connected to an oil cup. A pressing cover is arranged at a gap at one side of the bearing and is installed onto the roller body. An external peripheral surface of the pressing cover is attached to an inner wall surface of the bearing base. An end cover is arranged on the roller body, wherein a step-shaped circular surface is formed internally on the end cover. The inner circular surface of the end cover is connected to the external periphery of a mounting end of the roller body through screw threads and is pressed against the outer side of the pressing cover. An outer circumference of the end cover is contact with a gap of the roller. A sealing cover is arranged on the roller body and is fixed to the other side of the bearing through screws. A contact end surface between the bearing base and an outer end of the sealing cover is a concavo-convex surface, wherein sealing rings are arranged in both the concavo-convex surface of the bearing base and the pressing cover combined with the roller.

Owner:WUXI HOUZHAI ZHENXIN MACHINERY

Convenient-to-operate multifunctional punching and shearing machine with high shearing quality and punching and shearing method thereof

ActiveCN106271656AImprove cut qualityEasy to operateMetal-working feeding devicesOther manufacturing equipments/toolsBlade plateEngineering

The invention discloses a convenient-to-operate multifunctional punching and shearing machine with high shearing quality and a punching and shearing method thereof, and belongs to the technical field of machining equipment. The multifunctional punching and shearing machine provided by the invention comprises a knife board matching mechanism, wherein the knife board matching mechanism comprises a knife board matching eccentric shaft, wherein the knife board matching eccentric shaft is provided with an outer fixing plate, a first concentric section, a second eccentric section and a third concentric section sequentially; the knife board matching eccentric shaft transversely penetrates a machine body and is fixed to a wallboard of the machine body through the outer fixing plate; and knife boards are connected with the second eccentric section of the knife board matching eccentric shaft through a connecting plate. The multifunctional punching and shearing machine enables the knife board of a moveable knife to rotate around an elliptic radian and the rotation by the method can guarantee that the knife board of the moveable knife and a knife board of a static knife achieve position matching, so that a knife edge of the moveable knife and a knife edge of the static knife can be matched; the method is implemented once for all, that is, mismatching is not liable to occur when blades are changed again after one-time adjustment, so the use of customers is greatly facilitated.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

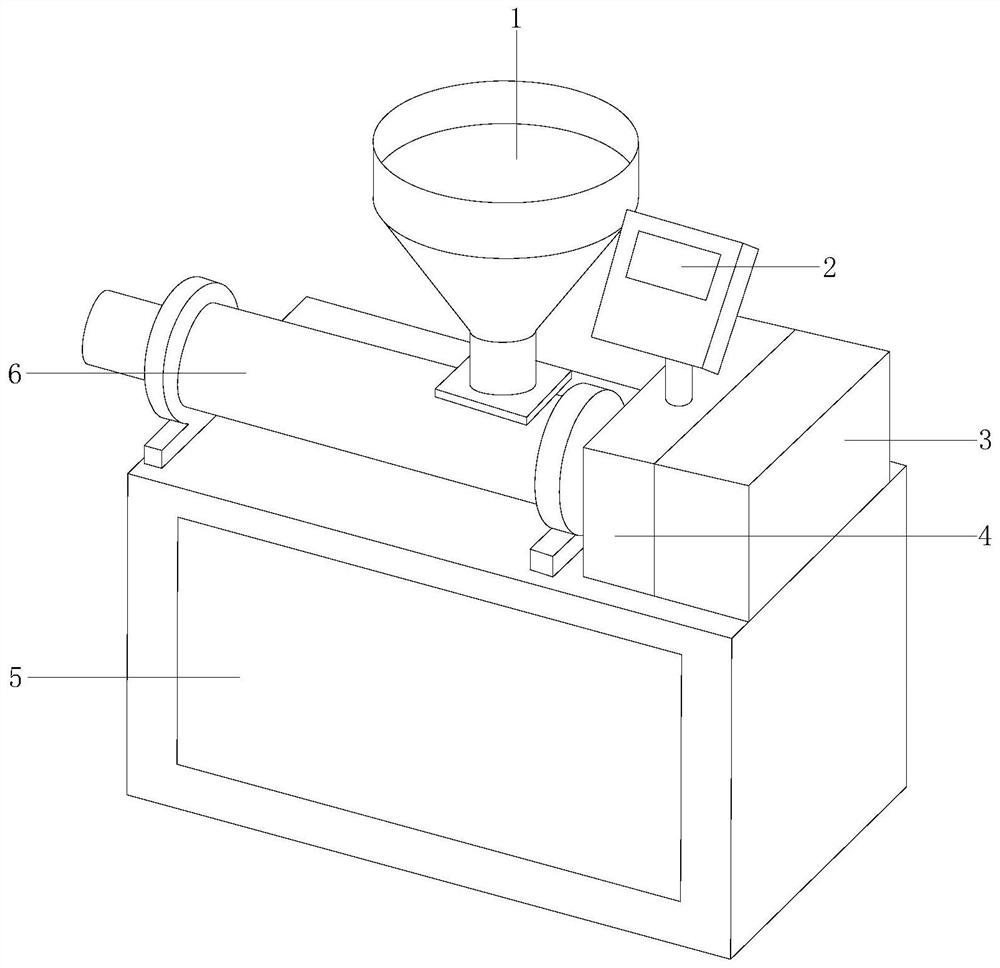

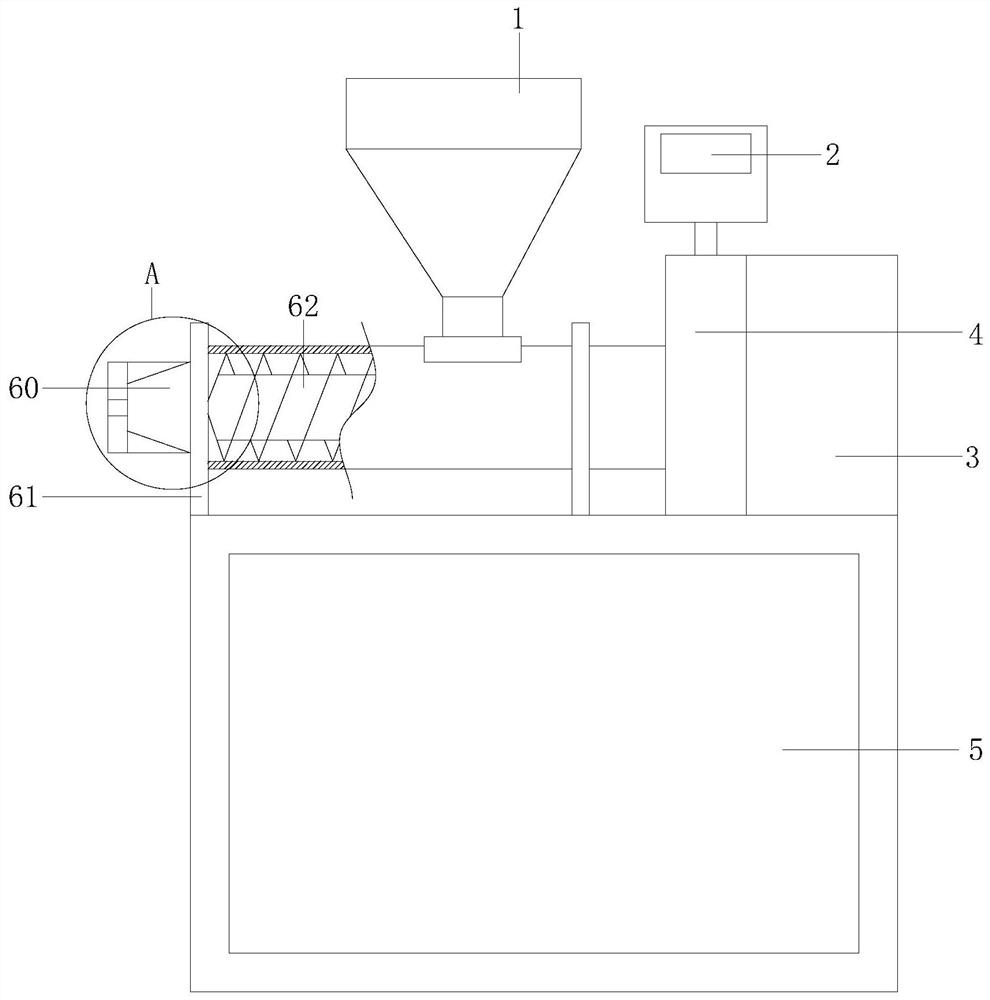

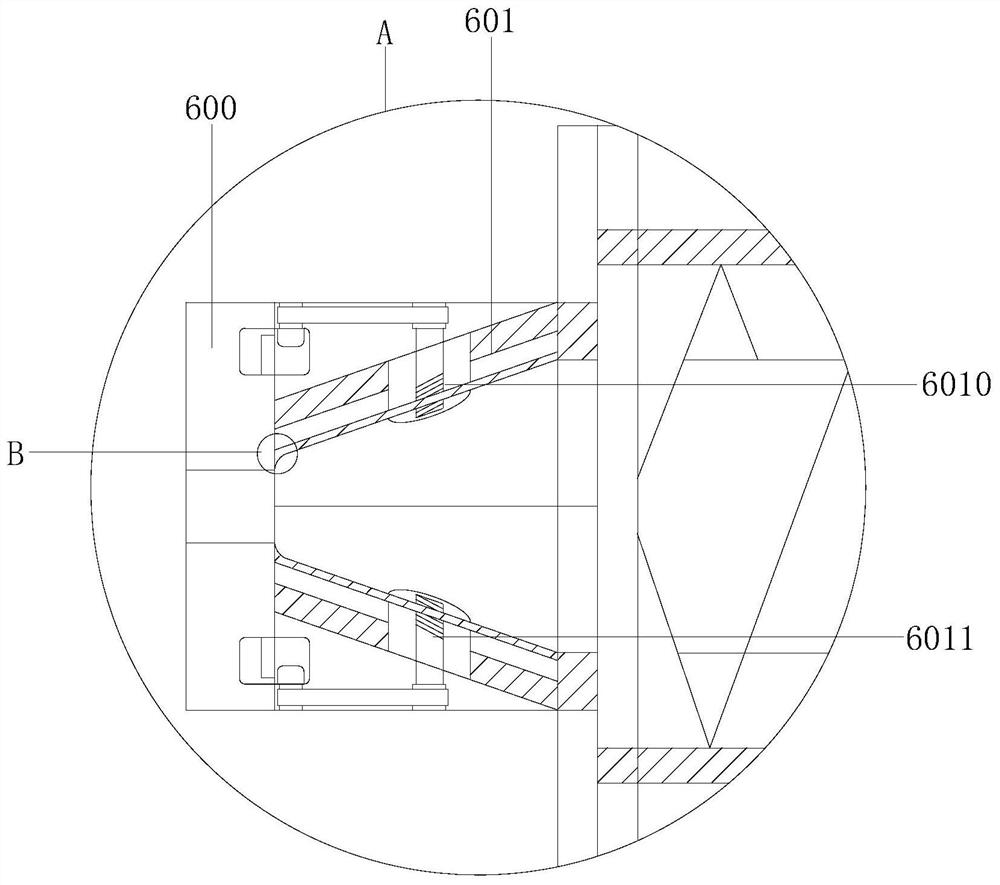

Automatic plasticine production equipment

InactiveCN112976526AConvenient storageImprove flexibility and fluencyElectric machineryStructural engineering

The invention discloses automatic plasticine production equipment which structurally comprises a feeding barrel, a control panel, a motor, a connecting frame, a working frame and a discharging barrel, wherein the feeding barrel and the discharging barrel are connected and communicate, the control panel is installed on the connecting frame, the motor and the discharging barrel are connected through the connecting frame, the discharging barrel is locked above the working frame, the motor and the connecting frame are installed above the working frame, the discharging barrel is composed of a discharging head, a fixing plate and a feeding barrel, and the discharging head and the feeding barrel are installed and connected through the fixing plate. The discharging plate is of a replaceable structure and can be rotationally replaced according to different extrusion thickness the inner space of an inner device is in an adjustable cone shape and can be adjusted according to the width of an extrusion opening, the cone shape can effectively apply force to the extrusion position, the rotating energy consumption of the feeding barrel is indirectly saved, the pushing force is extruded from the extrusion opening in a centered mode, and the looseness of the discharging plate is reduced.

Owner:李志猛

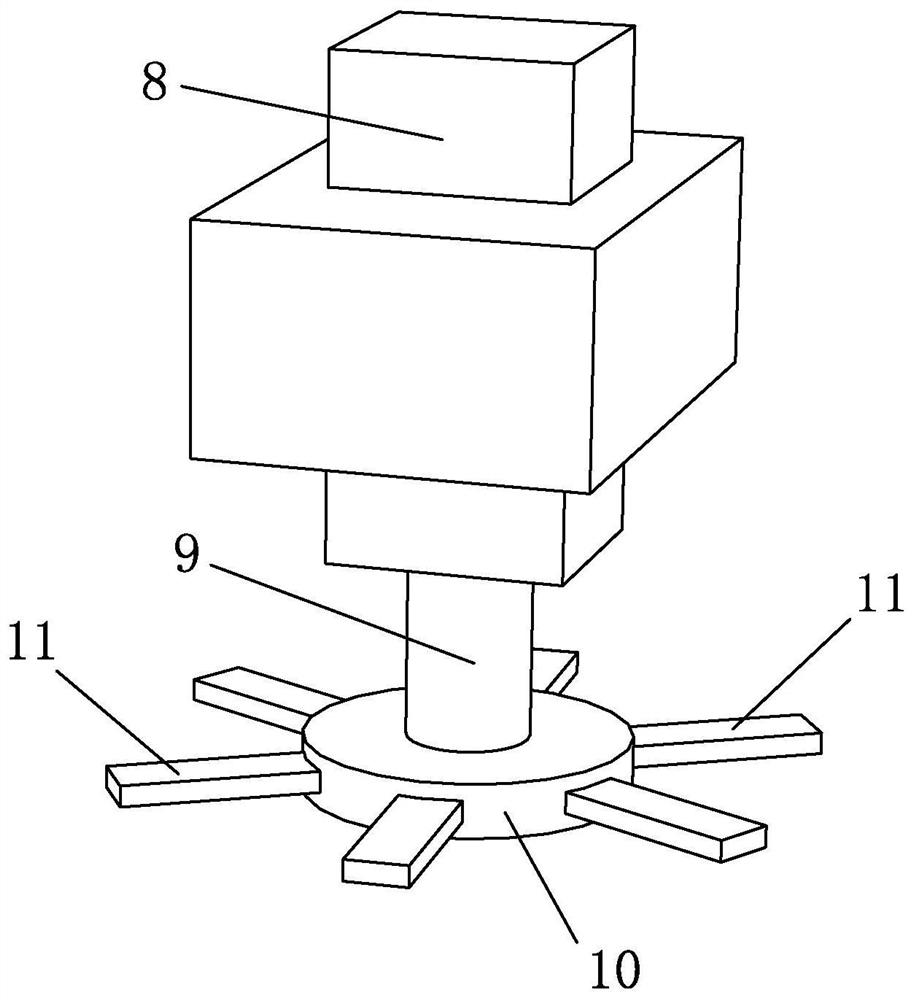

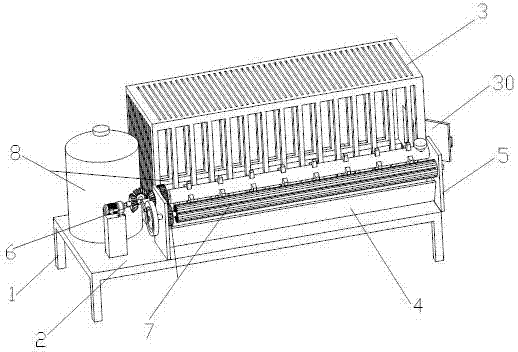

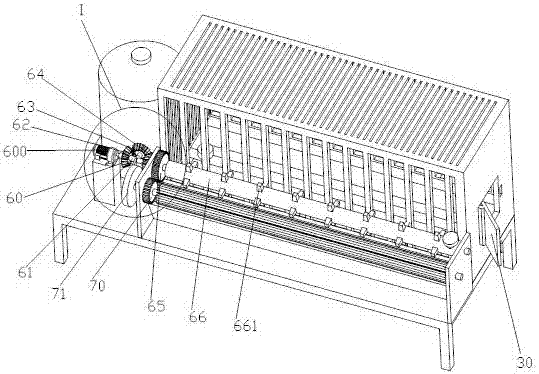

Hencoop automatic feeding and water filling device

ActiveCN107041324ADoes not affect growth and developmentUniform feedingAvicultureGear driveGear wheel

The invention provides a hencoop automatic feeding and water filling device, and belongs to the hencoop equipment technical field; the advantages are that an automatic feeding mechanism including a driving bevel gear, a driven bevel gear I, a driven bevel gear II and a rotary gear can stably blanking at an even speed; when a rotary feeding chamber of the automatic feeding mechanism rotates, a limit block of an elastic limit part of a material spreader can be released from a discharge barrel outlet under the centrifugal force, thus carrying out blanking; in addition, the rotary gear drives a drive gear to rotate, and a material stop fin can stop the material; the hencoop automatic feeding and water filling device can automatically feed and fill water through electric control, no artificial feeding is needed, thus greatly reducing people labor intensity without affecting chicken flock growth; a water level sensor is arranged in a water supply tank, and can monitor the water level in the water supply tank in real time in working; when the water level is too low, the water supply tank can be automatically filled; the hencoop automatic feeding and water filling device is convenient and fast, thus satisfying people demands.

Owner:SHANDONG NEW HOPE LIUHE GROUP

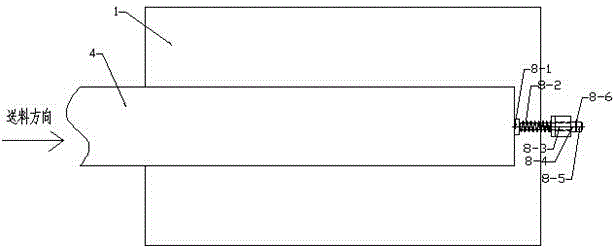

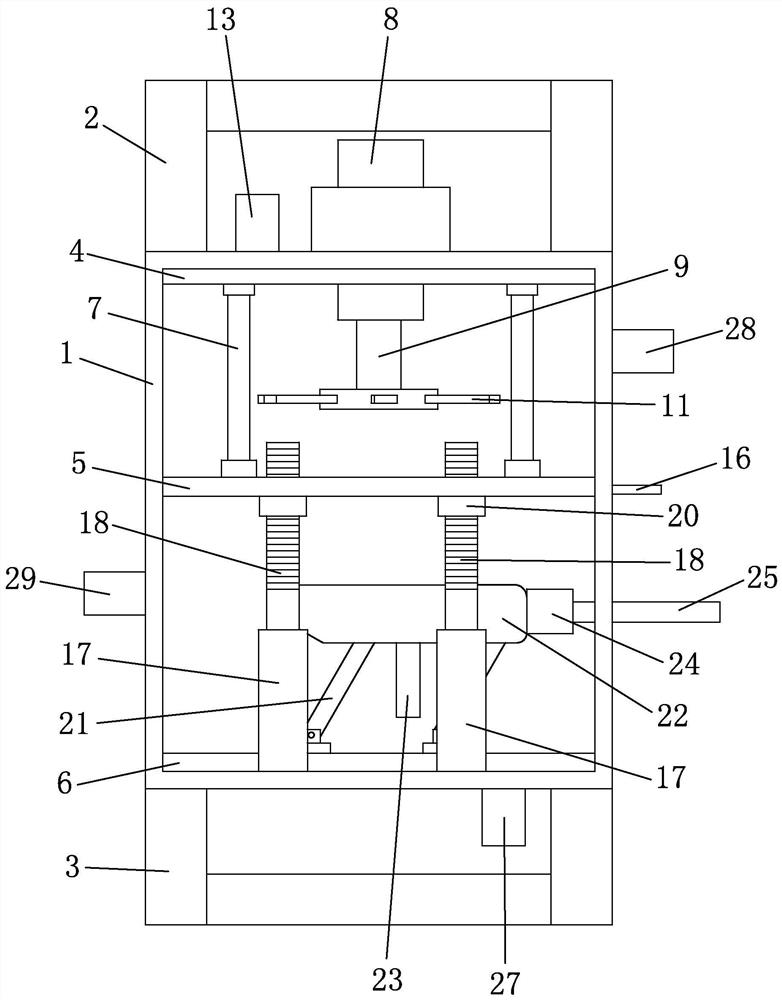

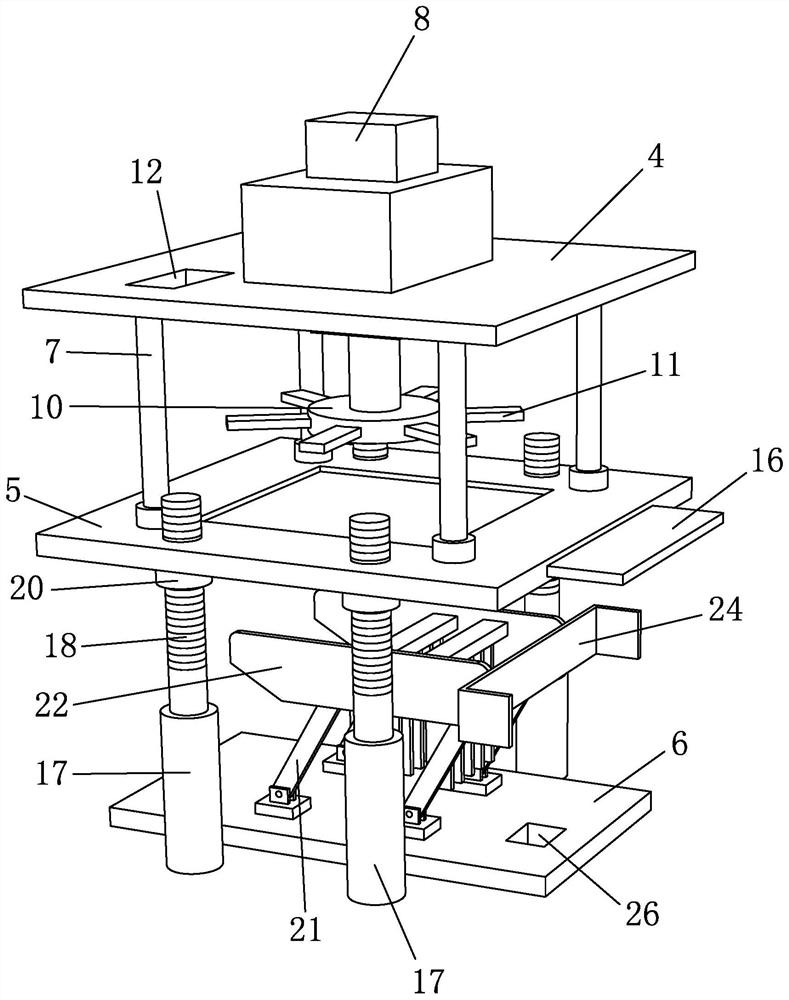

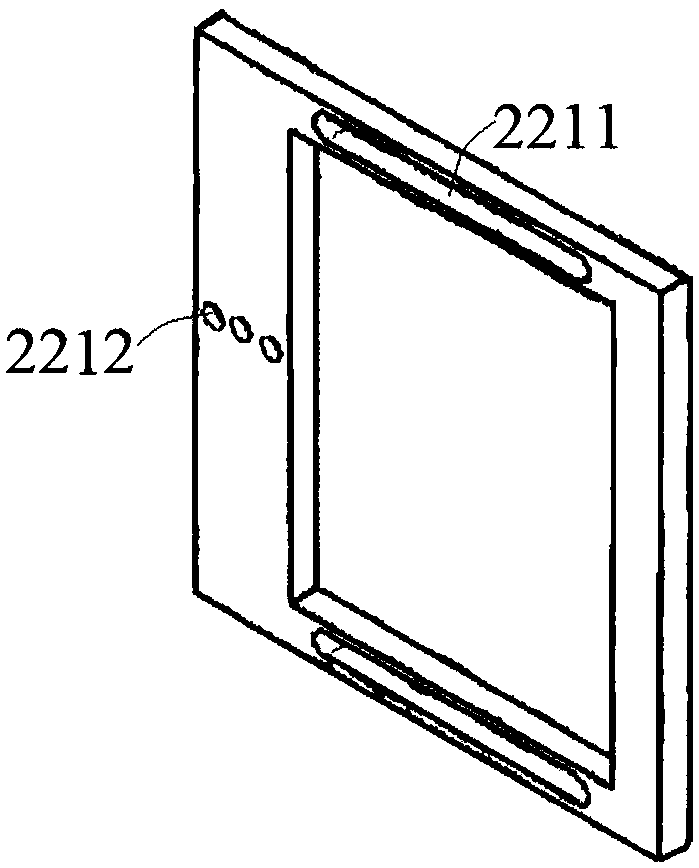

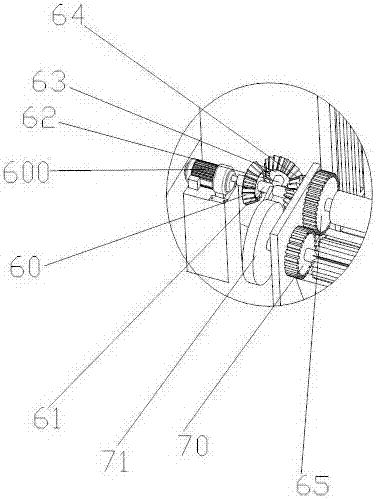

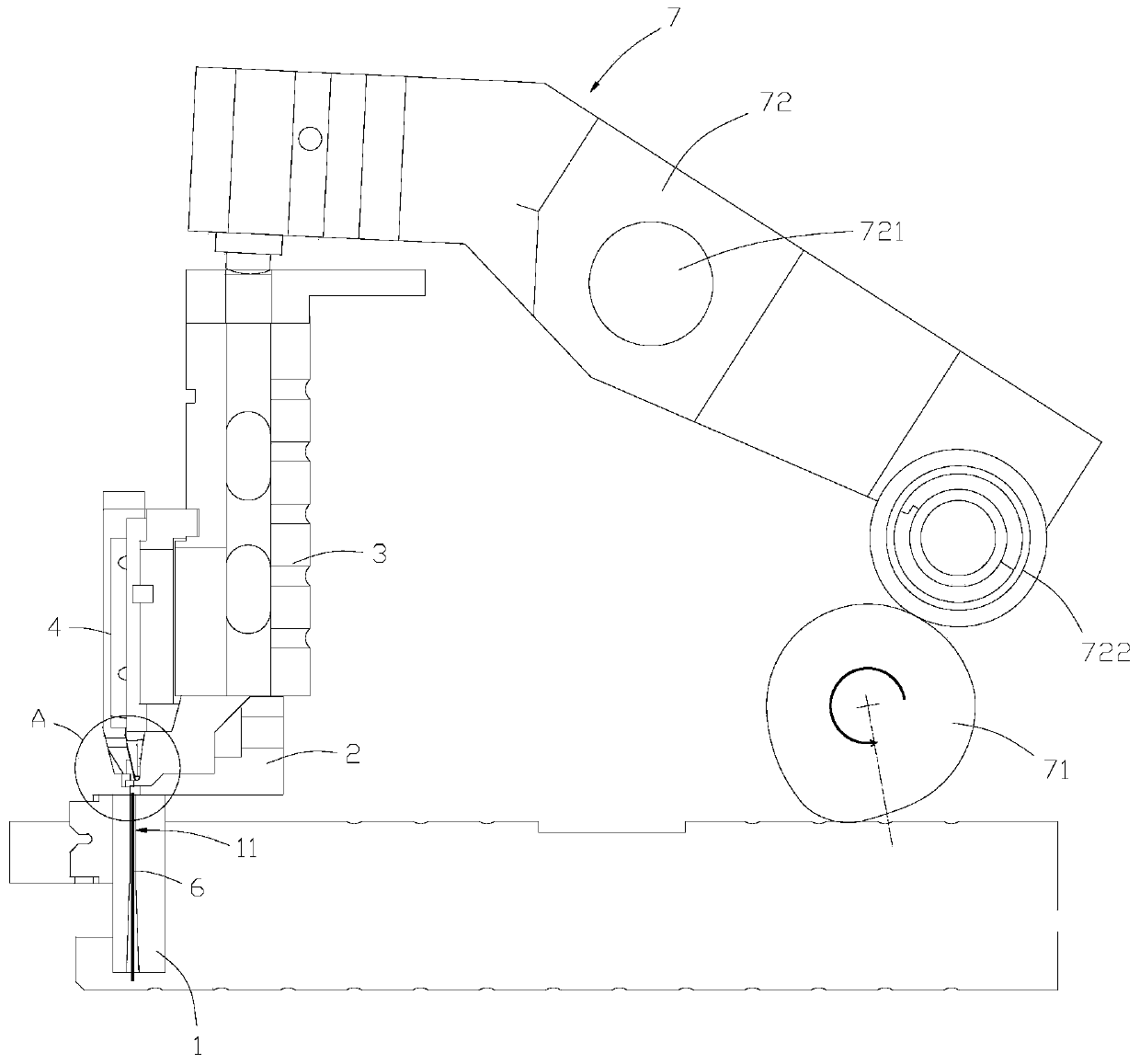

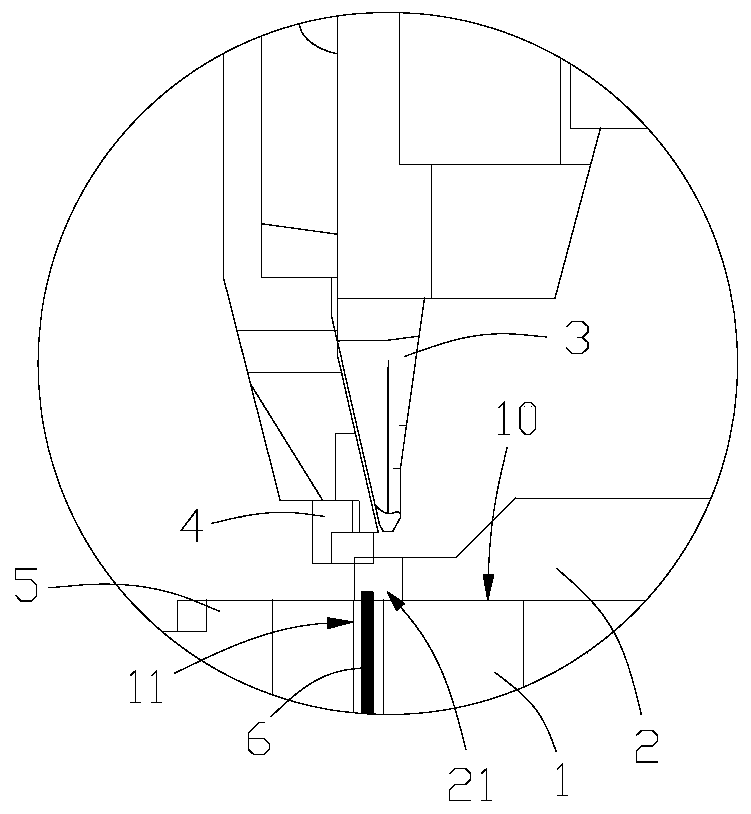

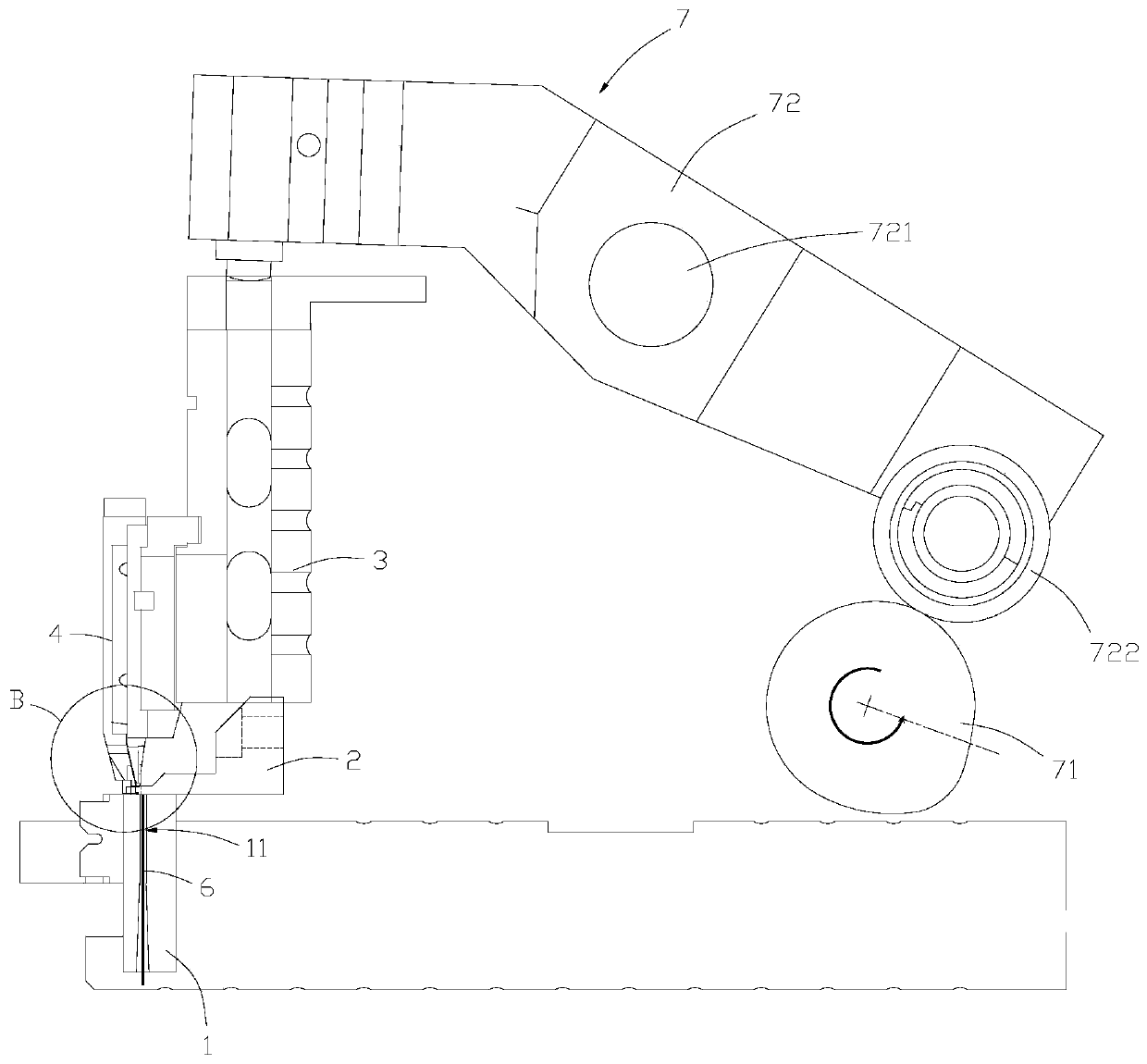

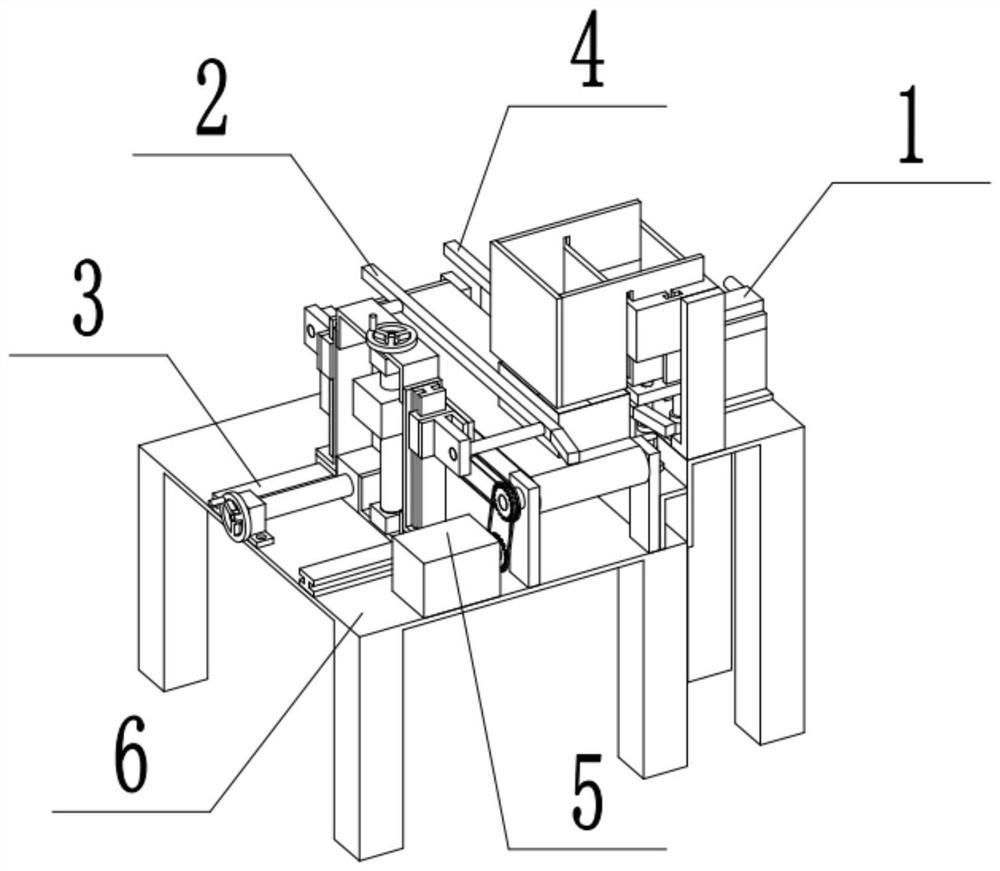

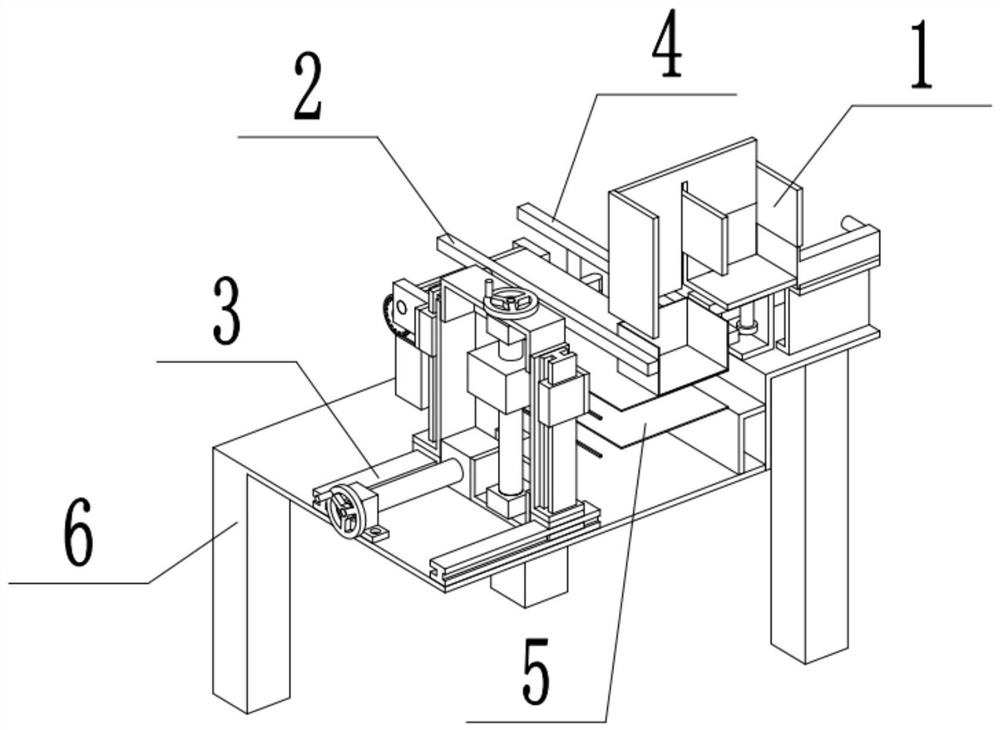

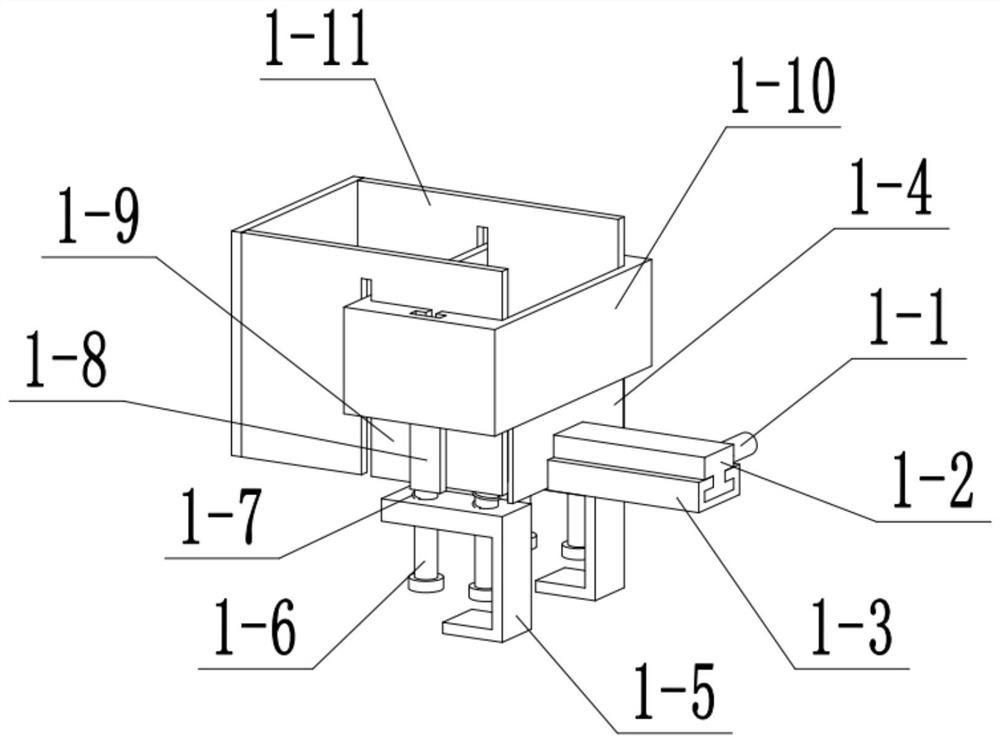

Zipper chain element manufacturing device and method, and element arrangement device

ActiveCN110193568BPrevent flying outPlay the role of retaining materialSlide fastenersWire rodPunching

The invention belongs to the technical field of zipper manufacturing, and particularly relates to a zipper tooth manufacturing device and method and a tooth arranging device. The zipper tooth manufacturing device comprises a sliding base, a cutting knife, a punching head and a stripping piece, wherein the cutting knife, the punching head and the stripping piece are arranged above the sliding base,a cutting plane is arranged on the upper side of the sliding base, the sliding base is internally provided with a wire rod channel, the front side of the sliding base is connected with a blanking die, a forming part is arranged on the blanking die, the wire rod channel is intermittently conveyed to the upper part of the cutting plane at a preset supply amount for each time, the sliding seat movesback and forth in a reciprocating mode, the cutter is in sliding contact with the cutting plane, a cutting edge is arranged at the front end of the cutting knife, the punching head is arranged abovethe cutting edge in a lifting mode, the stripping piece is arranged on the front side of the punching head in a lifting mode. According to the zipper tooth manufacturing device, when the device is used for cutting, the part of the wire rod protruding cutting plane enters the cutting edge along with the backward movement of the sliding seat, the material removing part is descended to the front sideof the wire rod in the cutting edge, the wire rod in the cutting edge is at least partially shielded, the wire rod is prevented from being thrown out instantly, the phenomenon that the wire is missing during subsequent tooth removal is avoided, the production efficiency is effectively improved, and the reworking rate is reduced.

Owner:广东顺德三扬科技股份有限公司

Food meat roll packaging equipment

The invention relates to the field of food machinery, in particular to food meat roll packaging equipment. The position of a stop lever is adjusted according to the size of a packaging box, so that the falling position is more accurate, waste is reduced, the quantitative distribution weight is accurately known manually, and the situation that the weights of all parts are different is avoided. The food meat roll packaging equipment comprises a falling device, an up-and-down adjusting device, a front-and-back adjusting device, a fixed stop lever device, a feeding device and a base. An adjusting nut is rotated, a fixed stop lever is adjusted, and a rotating handle B is rotated, so that a screw rod B drives a screw sleeve B to move, a vertical bearing seat mounting plate A and a vertical bearing seat mounting plate B are driven to move, the up-and-down adjusting device moves, a rotating handle A is rotated, a screw rod A drives a screw sleeve A to move, an adjusting stop lever mounting seat is moved, an adjusting stop lever is moved, meat rolls fall into a material bearing table, the material bearing table falls onto a support, a material pushing plate is pushed, the material pushing plate is pulled back, a material bearing spring lifts up the material bearing table, a motor drives a belt rotating shaft A and a belt rotating shaft B to rotate through a short chain and a long chain, and the belt drives a packaging box to move forwards.

Owner:董凯锋

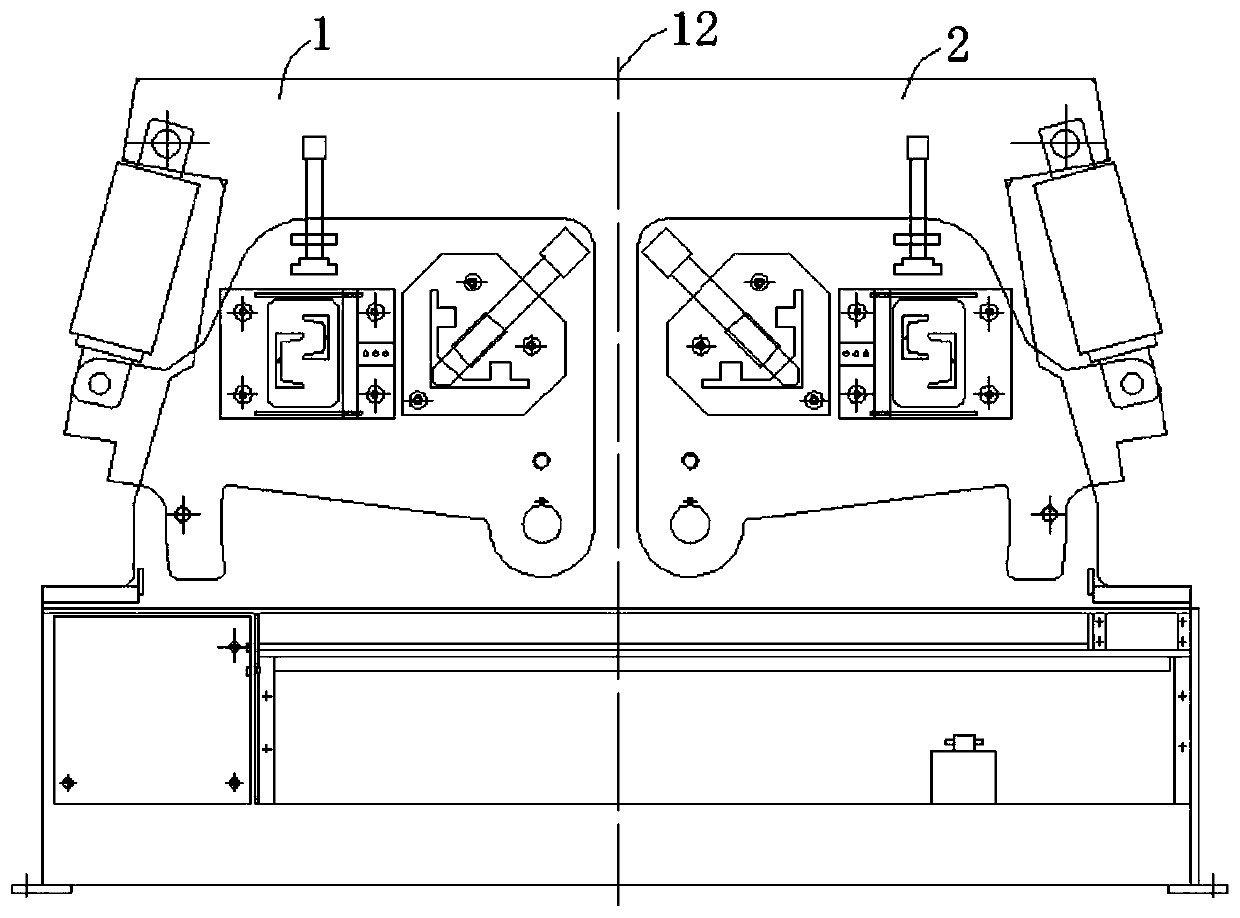

A punching and shearing method of a double-head angle iron hydraulic combined punching and shearing machine

ActiveCN106734505BEasy to useLess prone to mismatchesMetal-working feeding devicesOther manufacturing equipments/toolsEconomic benefitsEngineering

The invention discloses a double-head angle iron hydraulic combined punching and shearing machine and a punching shear method thereof, and belongs to the technical field of machining equipment. The double-head angle iron hydraulic combined punching and shearing machine comprises a first operation area and a second operation area, the first operation area and the second operation area are mirror symmetrical with the central axis as the axis, wherein the second operation area comprises a knife plate matching mechanism, a knife plate in the knife plate matching mechanism is connected with an eccentric shaft, and a moving knife plate is matched with a static knife plate by rotating the eccentric shaft. The double-head angle iron hydraulic combined punching and shearing machine is a special machine for angle iron shearing, mainly solves the problem of shearing inconvenience caused by opposite direction of an angle steel cutting angle Moreover, the double-head angle iron hydraulic combined punching and shearing machine is improved concerning other defects of existing punching and shearing machine, the use effect of the punching and shearing machine is improved, and the economic benefit is good.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

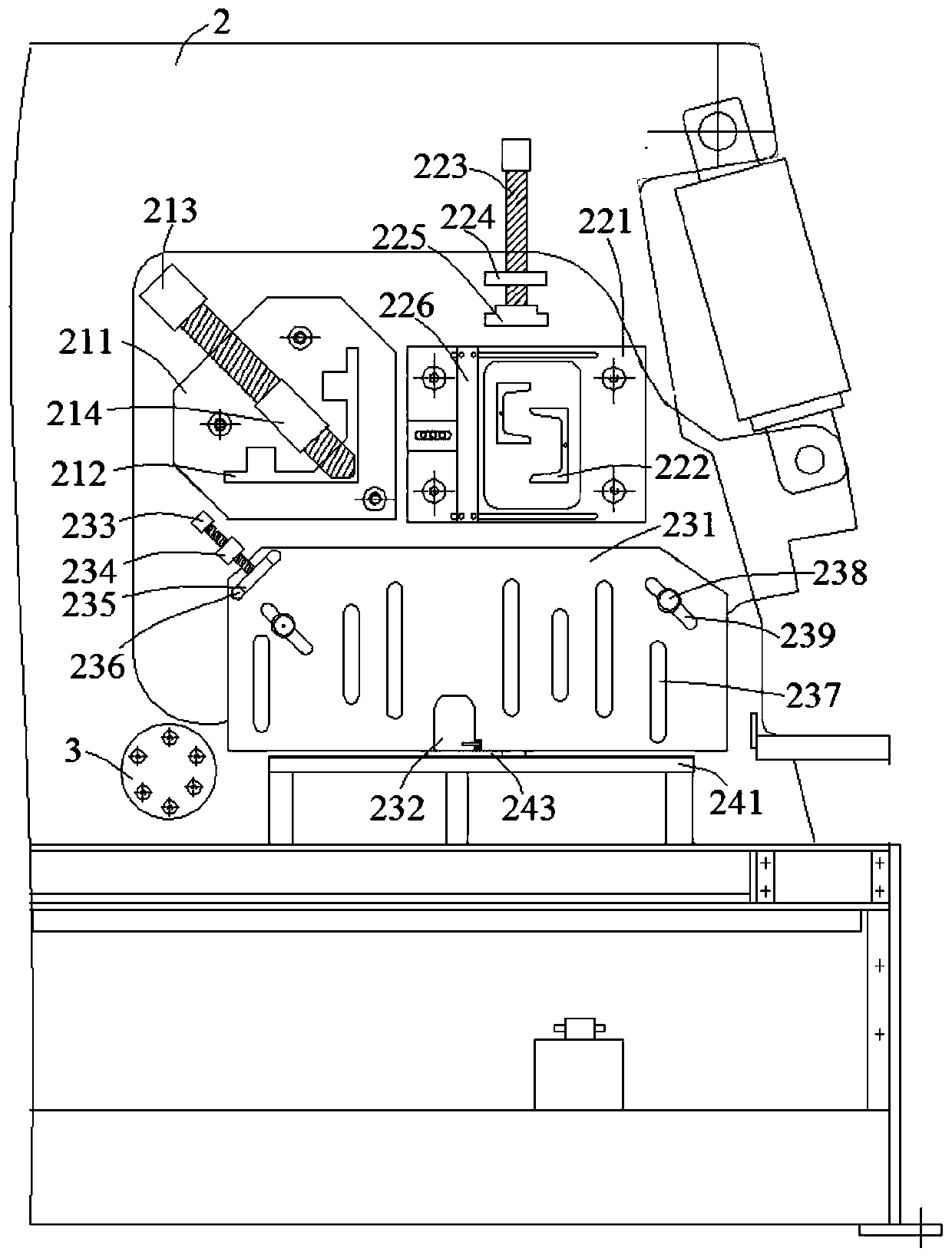

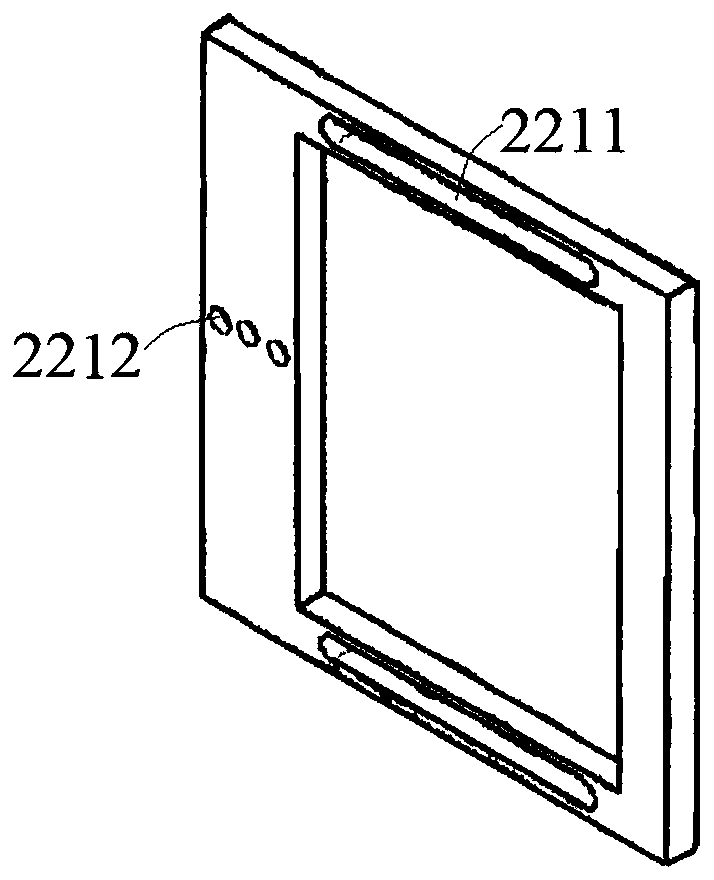

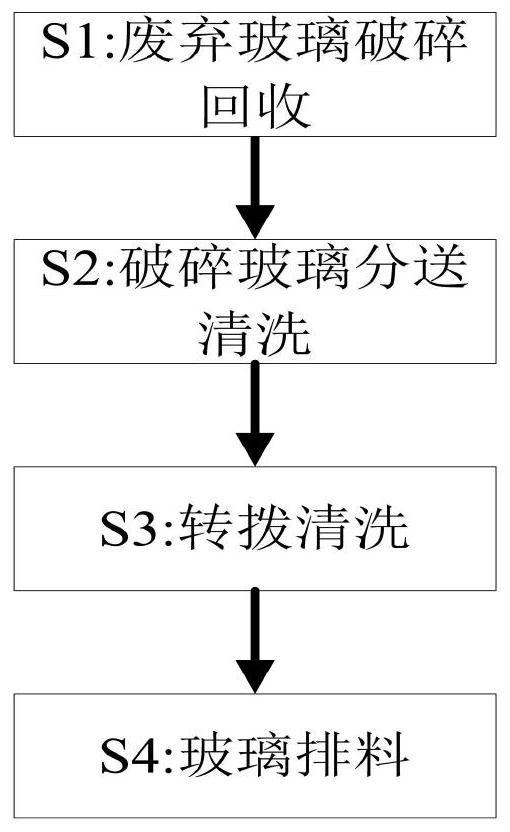

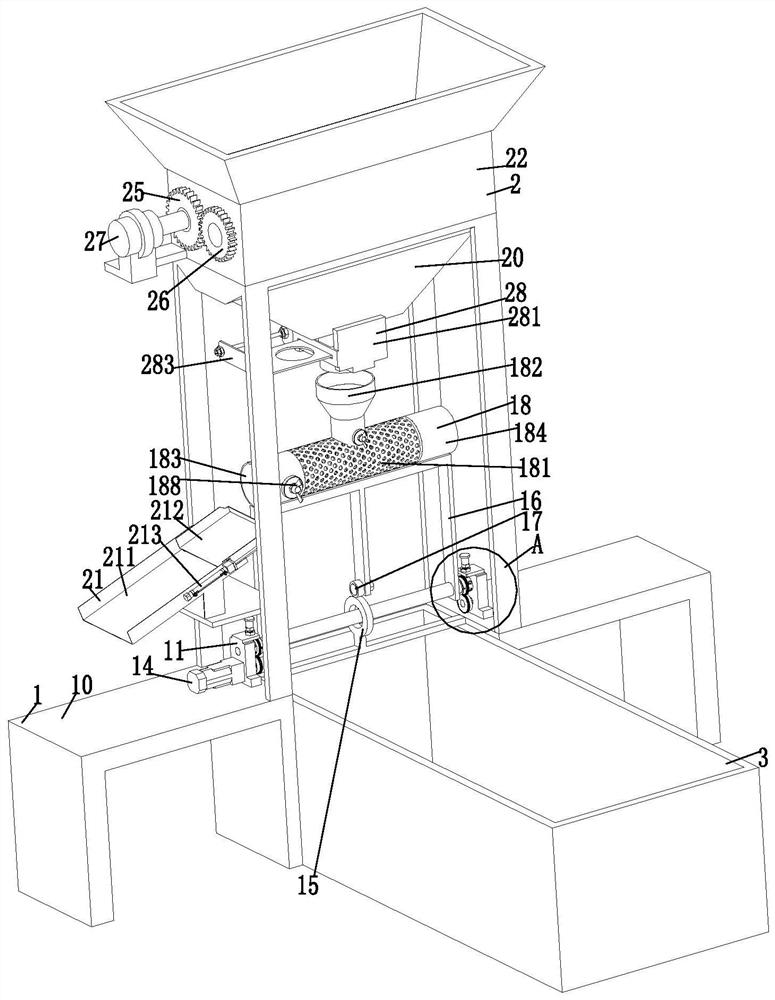

A method for secondary recycling of waste glass

ActiveCN112007934BIncrease contact rangePlay the role of retaining materialSolid waste disposalCleaning using liquidsEnvironmental engineeringMechanical engineering

The invention provides a waste glass secondary recycling method. A cleaning mechanism, a rolling mechanism and a water tank are included, the rolling mechanism is installed on the cleaning mechanism and located over the cleaning mechanism, the water tank is installed on the cleaning mechanism, and the water tank is located under the cleaning mechanism; and the problems that before broken glass serves as a raw material to be put into production, recycled waste glass needs to be broken and cleaned, the danger of hurting people exists due to glass breaking and cleaning, and cleaning work consumesmanpower are solved.

Owner:唐山金信新能源科技有限公司

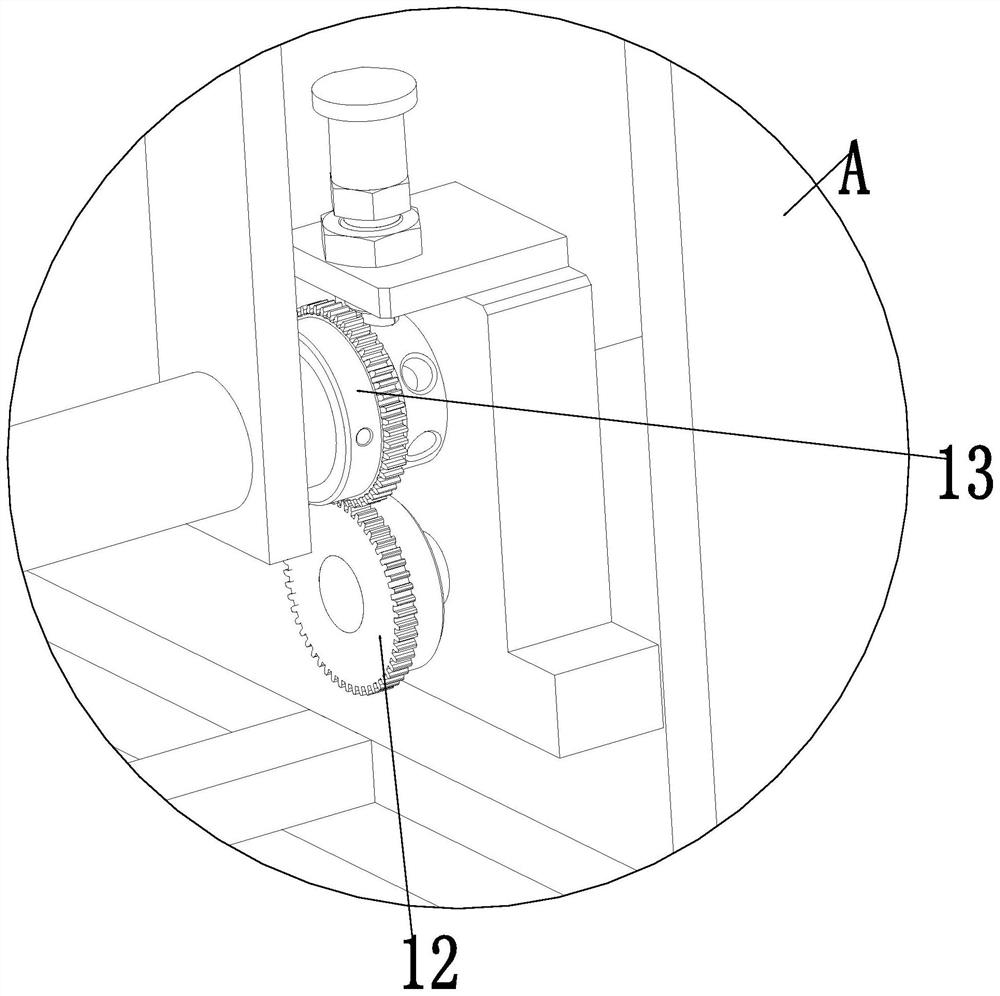

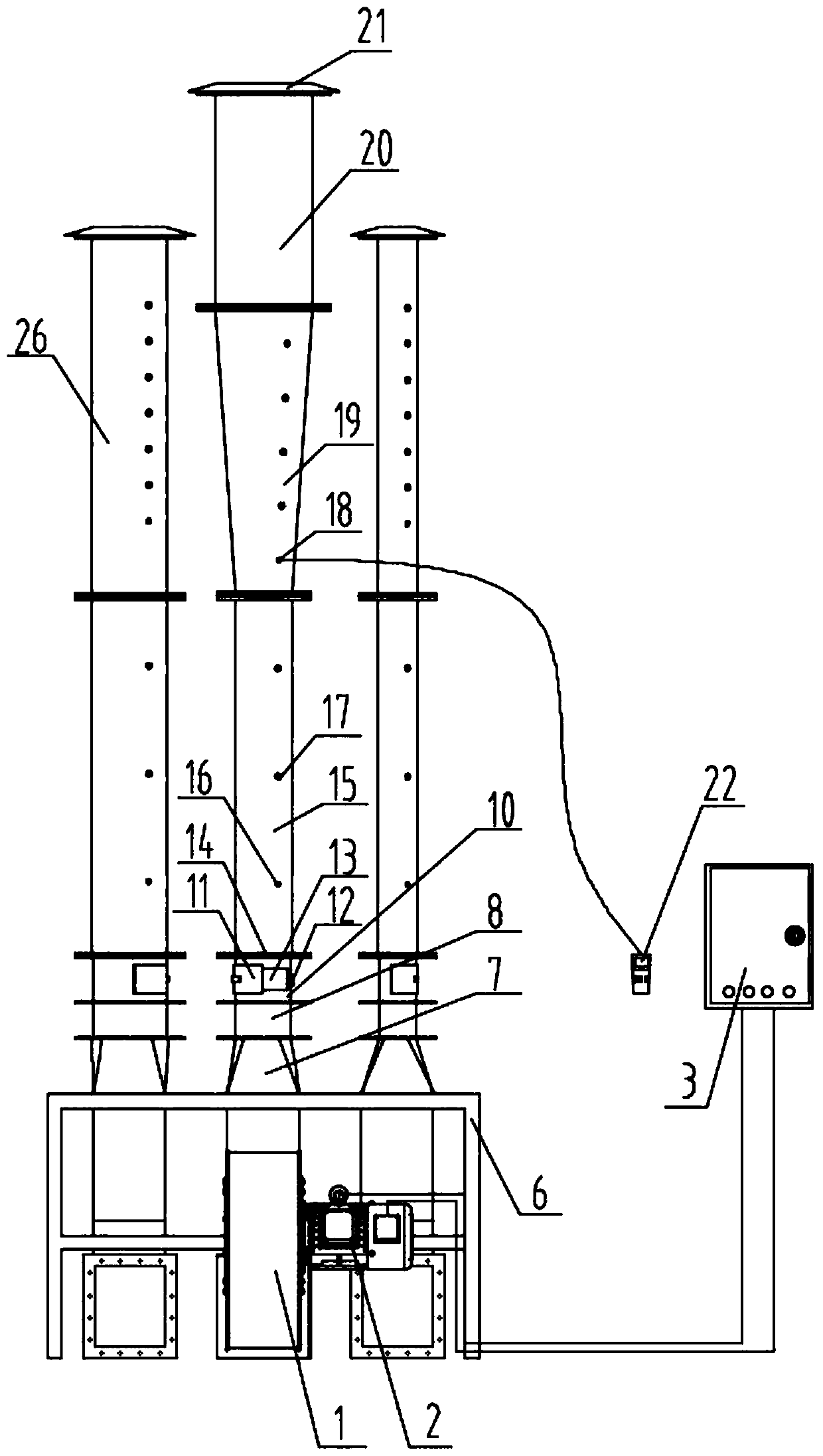

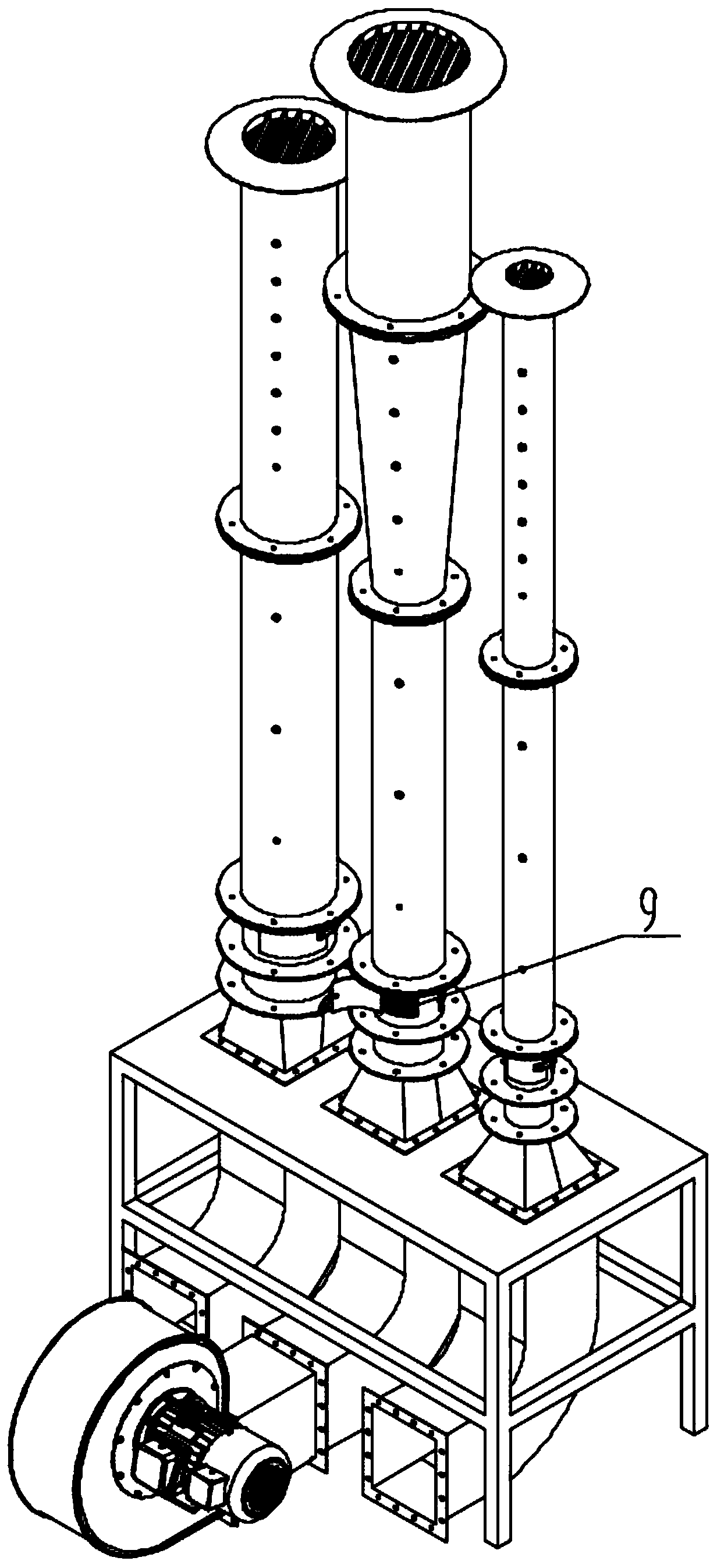

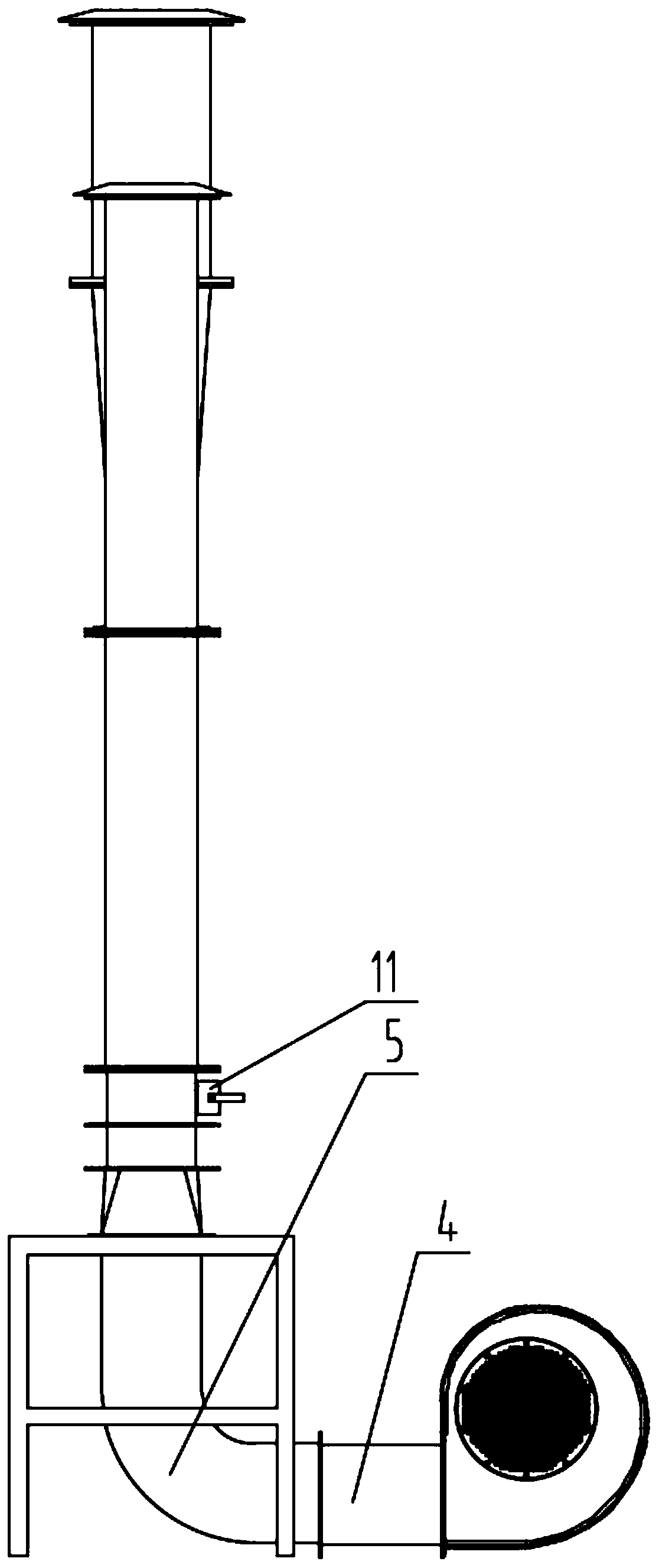

Multifunctional agricultural material suspension speed test device

PendingCN111175013AEasy to measure levitation speedEasy to observeAerodynamic testingFluid speed measurement using pressure differenceAgricultural scienceStraight tube

The invention relates to a multifunctional agricultural material suspension speed test device, which comprises at least one group of testing units. Each testing unit comprises a collecting pipe, a rectifying pipe, a feeding pipe, a first steady flow straight pipe and a conical testing pipe which are sequentially connected from bottom to top; the first steady flow pipe is vertically provided with afirst test hole along the side surface of the pipe wall; a second test hole is vertically formed in the conical test tube along the side surface of the tube wall; the number of the first test holes and the number of the second test holes are both not less than 3, and it is guaranteed that at least one test hole is correspondingly formed in the top side, the middle and the bottom side of the pipewall; the caliber of the conical test tube is small at the lower part and large at the upper part; the top of the conical test tube is connected with a second steady-flow straight tube; the top of thesecond steady flow straight pipe is connected with a diffusion cover; and the first steady flow straight pipe, the conical test pipe and the second steady flow straight pipe are all transparent pipes. According to the multifunctional agricultural material suspension speed test device disclosed by the invention, various tests on materials can be realized; the test is visual and can be observed clearly, and test data can be collected and analyzed conveniently.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com