Automatic plasticine production equipment

A technology of automatic production and plasticine, applied in the field of rubber processing equipment, can solve the problems of increasing the rotating force of the feeding cylinder, loosening of the discharging and loading board, increasing energy consumption of the equipment, etc., and achieves easy sliding up and down, convenient material storage, and improved flexibility and fluency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

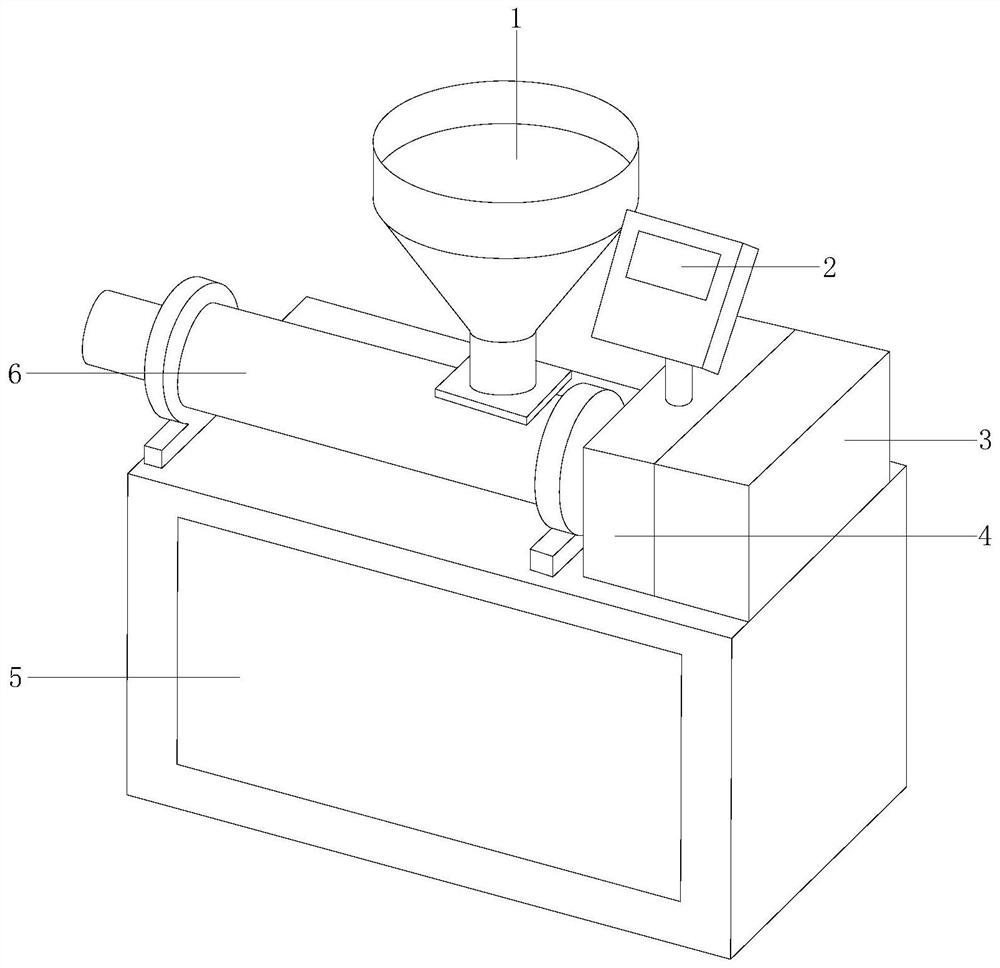

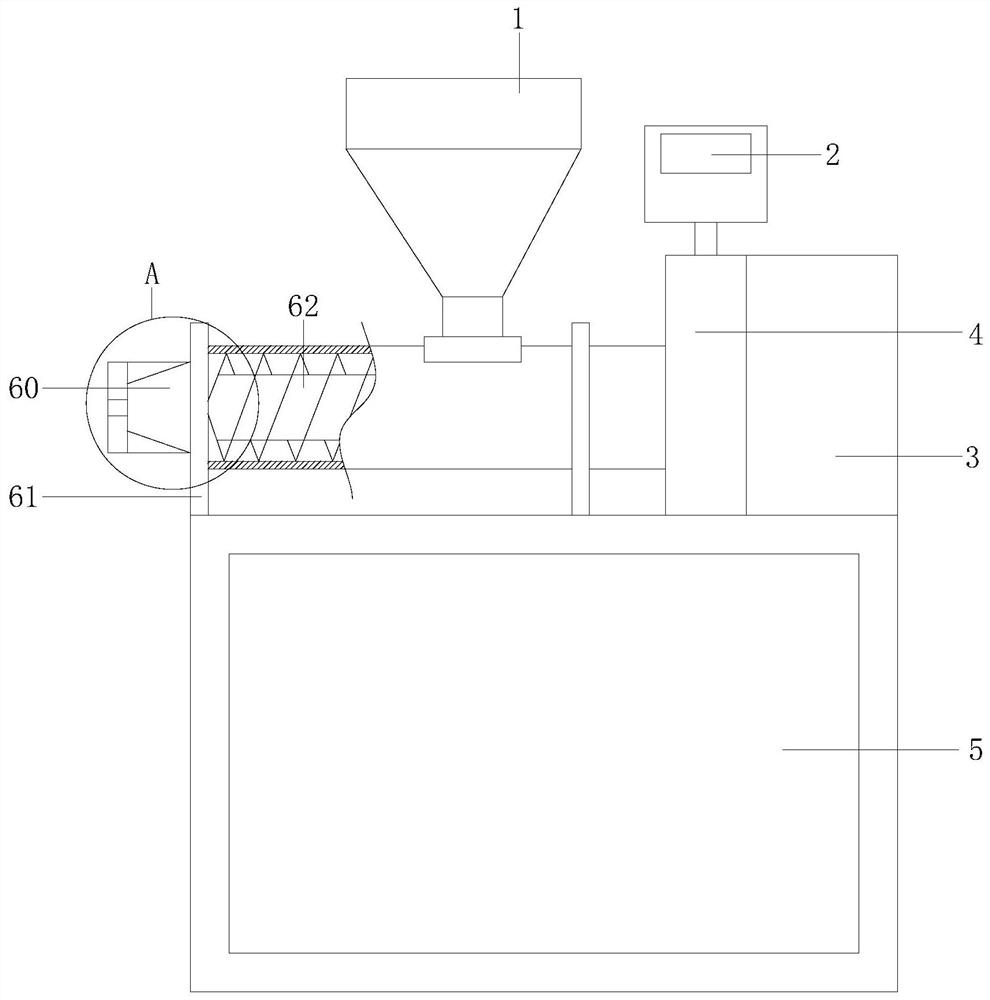

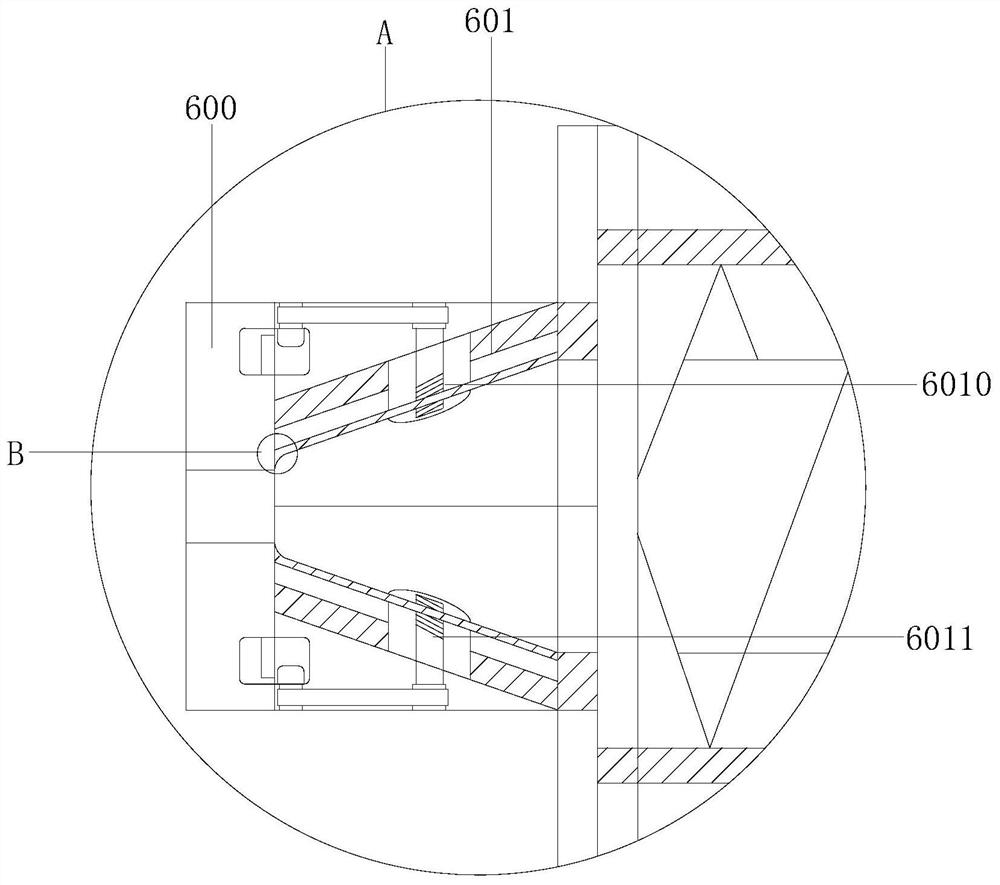

[0027] Example 1 see Figure 1-4 , the present invention provides a technical scheme of plasticine automatic production equipment: its structure includes a material inlet barrel 1, a control panel 2, a motor 3, a connecting frame 4, a frame 5, and a material outlet cylinder 6, and the material inlet barrel 1 and the outlet The barrel 6 is installed and connected and the two communicate, the control board 2 is installed on the connecting frame 4, the motor 3 and the discharging barrel 6 are installed and connected through the connecting frame 4, and the discharging barrel 6 is locked above the frame 5 , the motor 3 and the connecting frame 4 are installed above the frame 5, the discharge cylinder 6 is composed of a discharge head 60, a fixed plate 61, and a feed cylinder 62, and the discharge head 60 and the feed cylinder 62 pass through the fixed plate 61 installation and connection, the discharge head 60 includes a discharge loading plate 600, an internal device 601, the disc...

Embodiment 2

[0029] Example 2 see Figure 5-8 , the present invention provides a technical scheme of plasticine automatic production equipment: the structure of the upper structure 6010 includes a connection lock 70, a transmission structure 71, an inclined frame 72, a material partition 73, a packing frame 74, and the connection lock 70 is connected to the transmission The structure 71 is installed and connected, the transmission structure 71 and the inclined frame 72 are installed on the top of the filler frame 74, the inclined frame 72, the material spacer 73 is attached to the filler frame 74, and the right end of the material spacer 73 is connected with a rubber layer. When lifting, it plays the role of blocking material. The transmission structure 71 is connected with the material partition plate 73 through threads. The transmission structure 71 includes a motor 710, a transmission belt 711, and a threaded rod 712. The left and right ends of the transmission belt 711 surround the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com