Device for detecting tail end of automobile punch progressive die material strip

A detection device and progressive die technology, which is applied in the field of stamping equipment, can solve problems such as the inability of the punch to stop working in time, the detection of misfeeding is not sensitive enough, and the mold is damaged, so as to achieve good control, good feeding step distance, and reduce losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

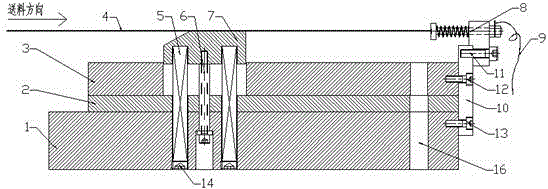

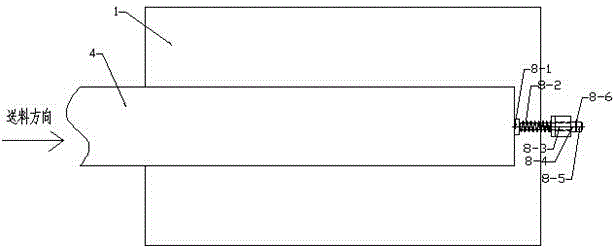

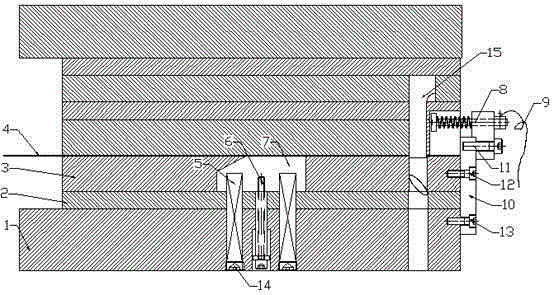

[0020] A detection device for the tail end of a material strip of a progressive die for automobile stamping can be used in the continuous production of a progressive die for automobile products. The present embodiment will be described in detail below in conjunction with the accompanying drawings. like figure 1 As shown, the detection device mainly includes a lower mold part composed of a lower mold base 1, a die backing plate 2, and a die plate 3. The detection device includes a detector fixed at the tail end of the lower die part by connecting screws 12, 13. Seat 10, detector 8 is fixedly installed on the fixed seat. like figure 2 As shown, the detector includes a detector body 8-3 installed on the detector holder 10, a detection rod 8-1 at the contact end of the material tape is installed on the detector body, a spring 8-2 is sleeved on the detection rod, and the detection rod is on the It can be freely expanded and contracted under the action of spring. Nuts 8-4 and 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com