Motor unidirectional control, self-spring lock with detached teeth

A unidirectional, motor technology, applied in the field of locks, can solve the problems of short life, poor tamper resistance, high noise, etc., and achieve the effects of low requirements, good stability and high fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

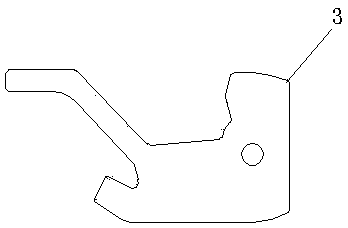

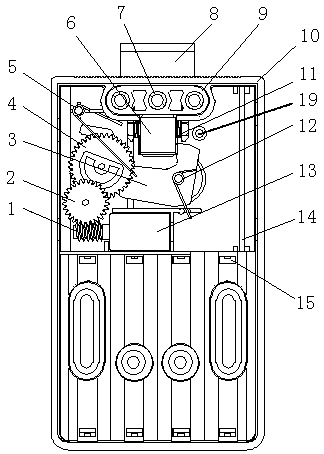

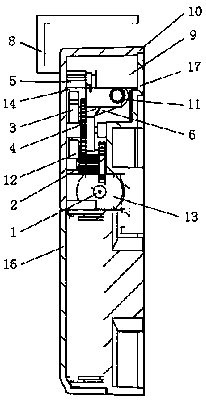

[0035] like Figure 1-10 As shown, the motor unidirectionally controls the tooth-off self-spring lock, including: a housing, a motor, a door edge, a pin-like spring, a torsion spring, a mouse trap spring, a compression spring and a circuit board, and the motor 13 is fixed in the housing 10 In the motor groove of the middle part of the frame, the helical gear 1 located on one side of the housing 10 is connected to the motor shaft, and the helical gear 1 is connected with the transmission gear 2 and the three-layer gear 4 fixed on the column on the front wall of the housing 10. three compression springs 7 are arranged in the spring case 9 fixed to the columnar pipe in the middle of the upper wall of the housing 10, and the front wall of the housing 10 corresponding to the spring case 9 is provided with a Socket 18, the L-shaped dead bolt 6 is fixed on the bracket rotating rod of the matching position of the lower end of the columnar pipe, and the mouse trap springs 11 which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com