A push-type lid switch locking device

A locking device and cover switch technology, applied in the direction of building fastening devices, wing leaf fastening devices, centrifuges, etc., can solve problems such as safety risks, low efficiency, cumbersome operation, etc., to reduce work intensity and improve Effects of Ease of Use and Security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

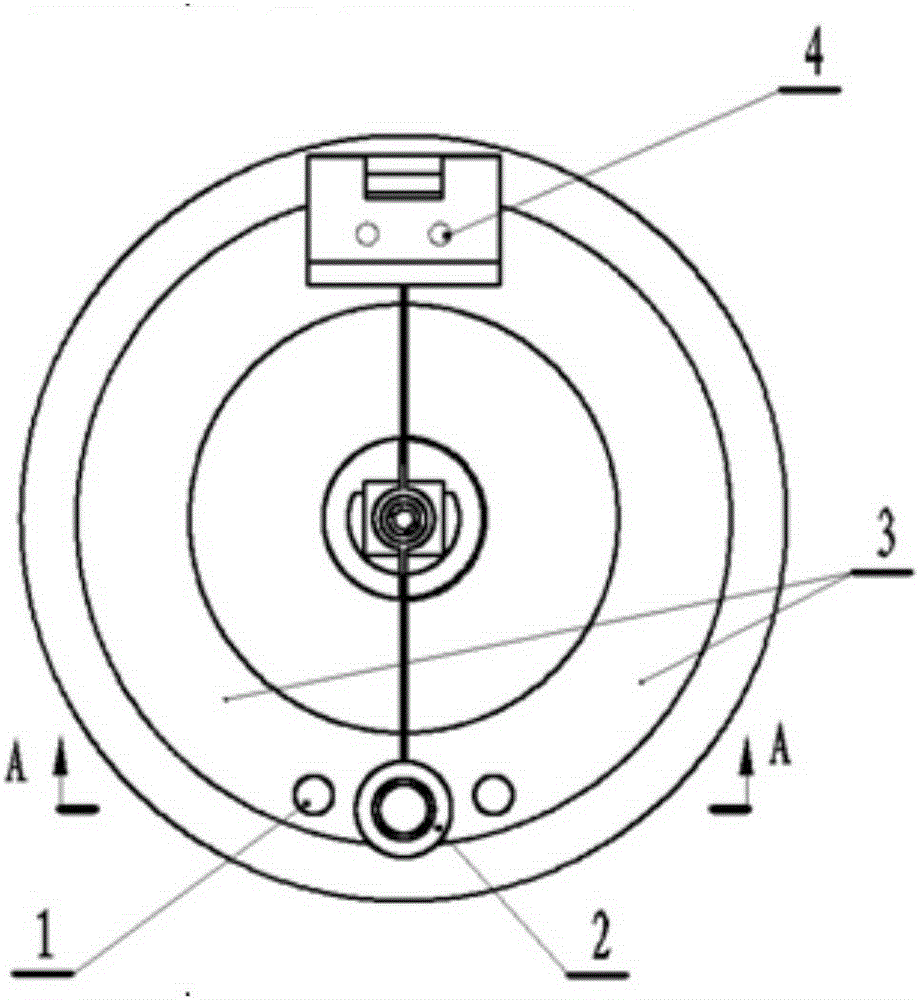

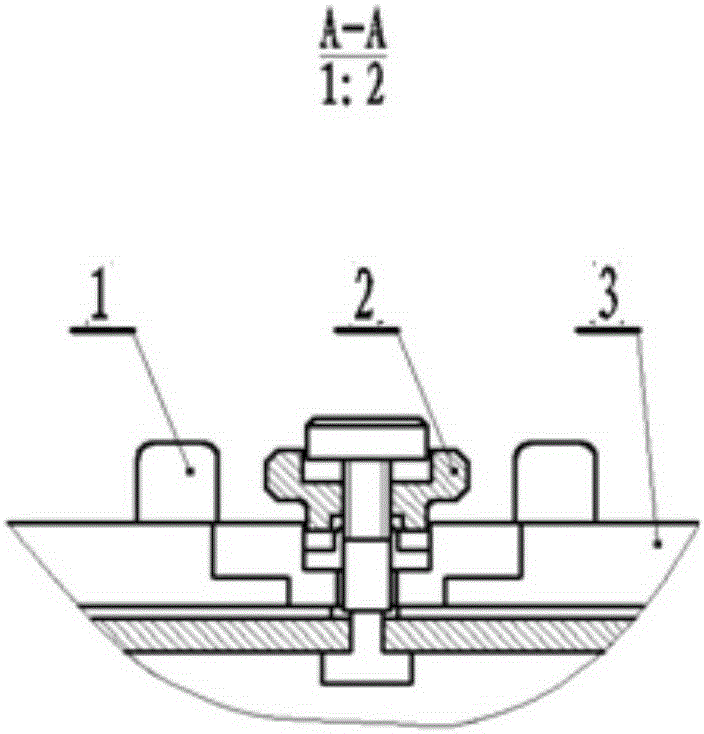

[0055] Such as Figures 1 to 3 As shown, the existing centrifuge cover switch locking device is a screw-type cover switch, such as figure 1 , The lock nut 2 has an internal thread, which can be rotated left and right. Rotate downward to compress the observation plate assembly 3, and rotate upward to loosen the observation plate assembly 3. The left and right halves of the viewing plate assembly 3 can rotate around the rotating pin shaft 4, image 3 It is a schematic diagram of the separation of the two viewing plate assemblies 3 . When the consumables are installed, close the observation plate assembly 3, rotate the lock nut 2, and the lock nut 2 moves down to press the observation plate assembly 2. When the acquisition is completed, rotate the lock nut 2, move the lock nut 2 upwards to loosen the observation plate assembly 3, pull the handle 1, and separate the observation plate assembly 3 to the left and right sides, as image 3 , take out the centrifuge cup consumables....

Embodiment 2

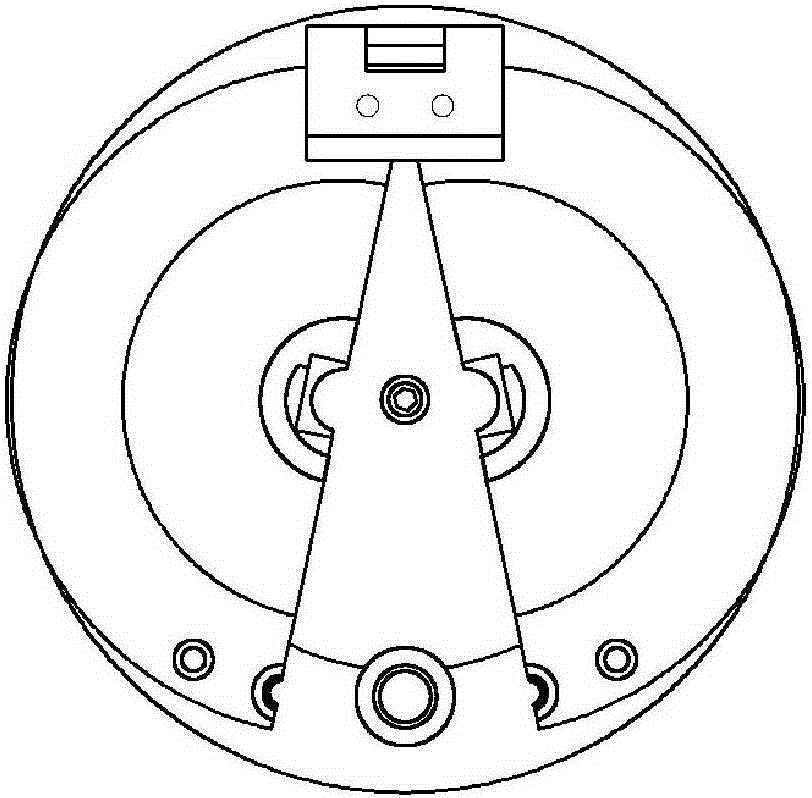

[0057] A push-type cover switch locking device, the locking device is set between the opening and closing joint surfaces of two observation plate assemblies 2, such as image 3 As shown, the observation plate assembly 2 can rotate around the rotating pin shaft 1, and the locking device includes a thrust force that is arranged between the opening and closing joint surfaces of the two observation plate assemblies 2, and always provides a thrust that makes the two have a tendency to open when the two are closed. contact 4. Such as image 3 In the partially enlarged view of , the spring and contact of the thrust contact 4 are embedded in the joint surface of the observation plate assembly 2 . Due to the action of the spring, the thrust contact always pushes the two halves of the observation board assembly 2 to the left and right sides. Two viewing plate assemblies 2 are provided with a handle 17 for pushing respectively. When used in a centrifuge, the two viewing plate assemblie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com